A kind of manufacturing method of lead-carbon battery for pure electric vehicle

A pure electric vehicle and manufacturing method technology, which is applied in the construction of electric vehicles, lead-acid batteries, lead-acid batteries, etc., can solve the problems of high battery dead weight, low battery specific capacity, restricted application, etc., and achieves convenient solution maintenance and porosity. low, the effect of improving utilization and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

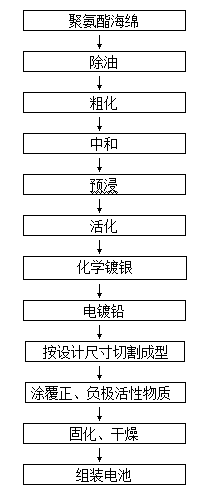

[0025] Example 1: The manufacturing steps of a lead-carbon battery for micro-hybrid vehicles are:

[0026] (1) Degreasing: Soak the polyurethane sponge of 200×200×2.5 mm and the polyurethane sponge of 200×200×4 mm in 3g / L sodium hydroxide, 10g / L sodium carbonate, and 5g / L trisodium phosphate. OP-10 emulsifier 0.5g / L, in a mixed solution, the temperature is room temperature, soaking time is 2 minutes;

[0027] (2) Coarse: soak the degreasing polyurethane sponge in a mixed solution of 100g / L sodium hydroxide and 10g / L potassium permanganate for 5 minutes;

[0028] (3) Neutralization: Soak the roughened polyurethane sponge in a solution containing 50g / L of oxalic acid and 100ml / L of hydrogen peroxide (30%) for 8 minutes;

[0029] (4) Presoaking: soak the neutralized polyurethane sponge in a prepreg solution for 30 minutes. The prepreg solution is 10g / L stannous chloride and 40ml / L hydrochloric acid;

[0030] (5) Activation: soak the pre-soaked polyurethane sponge in the activation solutio...

Embodiment 2

[0041] Example 2: The manufacturing steps of a lead-carbon battery for micro-hybrid vehicles are:

[0042] (1) Degreasing: immerse 200×200×2 mm polyurethane sponge and 200×200×3 mm polyurethane sponge together in 5g / L sodium hydroxide, 30g / L sodium carbonate, and 10g / L trisodium phosphate , OP-10 emulsifier 3g / L, in a mixed solution, the temperature is room temperature, soaking time is 10 minutes;

[0043] (2) Coarse: Soak the degreasing polyurethane sponge in a mixed solution of 200g / L sodium hydroxide and 5g / L potassium permanganate for 15 minutes;

[0044] (3) Neutralization: Soak the roughened polyurethane sponge in a solution containing 100g / L of oxalic acid and 60ml / L of hydrogen peroxide (30%) for 2 minutes;

[0045] (4) Presoaking: soak the neutralized polyurethane sponge in a prepreg solution for 15 minutes. The prepreg solution is 10g / L stannous chloride and 40ml / L hydrochloric acid;

[0046] (5) Activation: soak the pre-soaked polyurethane sponge in the activation solution f...

Embodiment 3

[0055] Example 3: The manufacturing steps of a lead-carbon battery for micro-hybrid vehicles are:

[0056] (1) Degreasing: soak the polyurethane sponge of 200×200×2 mm and the polyurethane sponge of 200×200×3 mm in 4g / L sodium hydroxide, 20g / L sodium carbonate, and 7.5g / L trisodium phosphate. , OP-10 emulsifier 2.5g / L, in a mixed solution, the temperature is room temperature, soaking time is 5 minutes;

[0057] (2) Coarse: soak the degreasing polyurethane sponge in a mixed solution of 150g / L sodium hydroxide and 7.5g / L potassium permanganate for 10 minutes;

[0058] (3) Neutralization: Soak the roughened polyurethane sponge in a solution containing 75g / L of oxalic acid and 75ml / L of hydrogen peroxide (30%) for 5 minutes;

[0059] (4) Pre-soaking: soak the neutralized polyurethane sponge in a prepreg solution for 25 minutes. The prepreg solution is 50g / L stannous chloride and 100ml / L hydrochloric acid;

[0060] (5) Activation: soak the pre-soaked polyurethane sponge in the activation so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com