A light-weight design aluminum-clad substrate and its production method

A lightweight design and production method technology, applied in the field of low-alloy steel manufacturing, can solve the problems of poor heat dissipation and high composition of wheels, achieve good interface bonding characteristics, solve heat dissipation problems, and reduce material thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

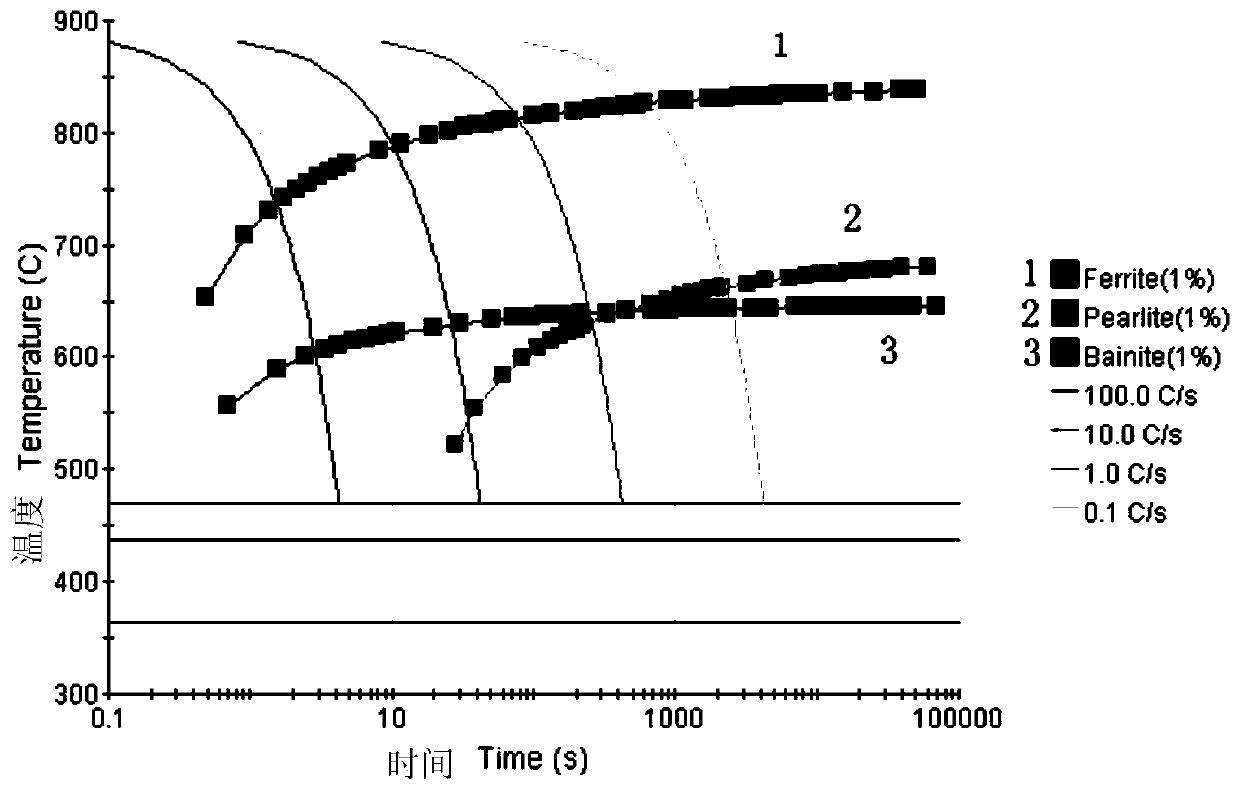

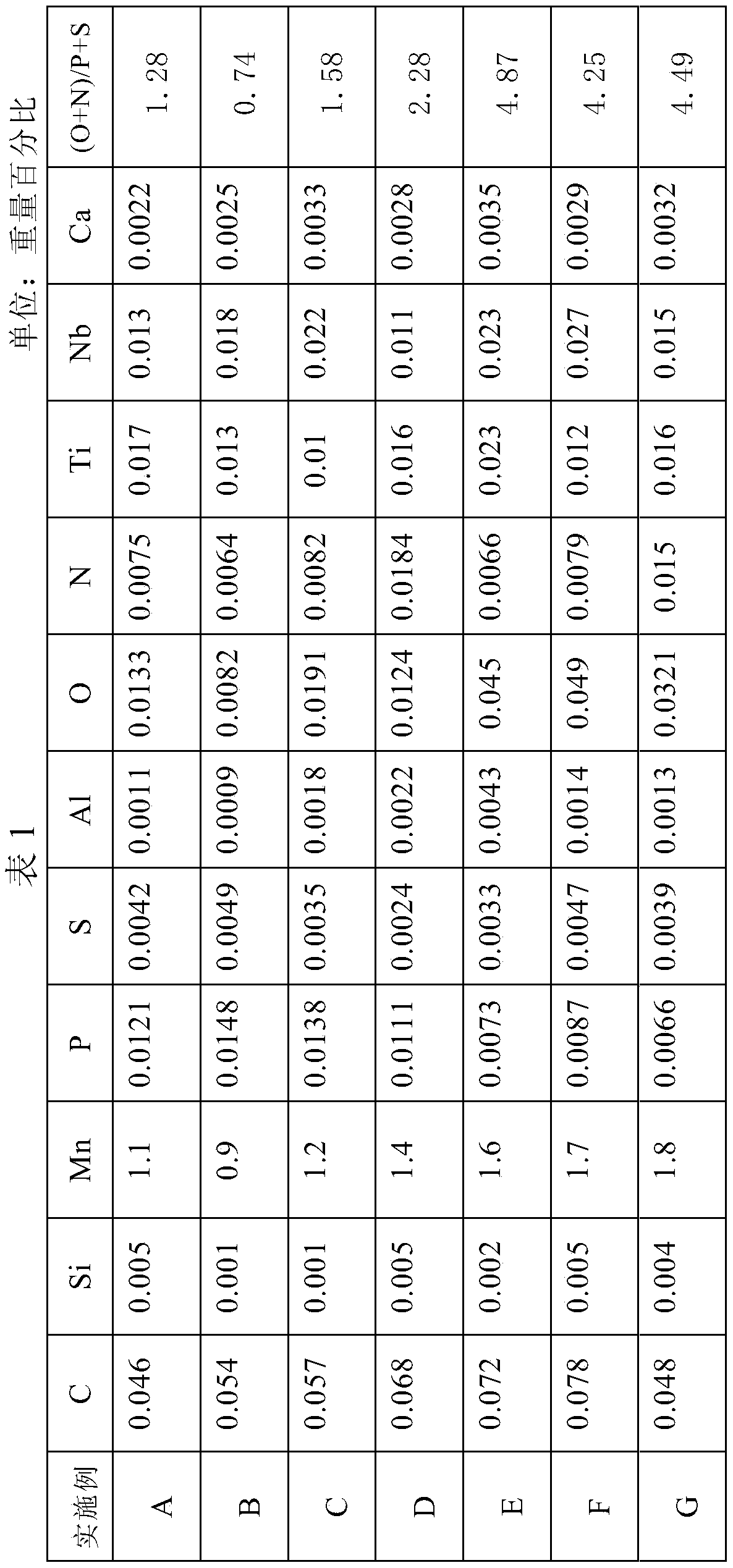

[0046] According to the steel chemical composition requirements of the present invention, steelmaking is carried out in a 500kg vacuum induction furnace, the obtained chemical composition is shown in Table 1, and cast into a 100kg steel ingot, the heating temperature is 1180°C, the finishing temperature is 860-900°C, and the coiling temperature is 520-620°C ℃.

[0047] The mechanical properties of the steel examples of the present invention are shown in Table 1. Comparing the composition and performance with similar steel types. Wherein comparative example 1 is Chinese patent publication number CN101736194A "a kind of wheel steel and its preparation method and wheel", comparative example 2 is Chinese patent publication number CN101812637A "a kind of high-strength and high-toughness automobile wheel steel and its production method", for Proportion 3 is Chinese Patent Publication No. CN103243262A "A High-strength Hot-Rolled Steel Sheet Coil for Automobile Wheels and Its Manufac...

Embodiment 2

[0052] According to the composition requirements of the present invention, the steel of the present invention is smelted on a 500kg vacuum induction furnace in a laboratory. The chemical composition is shown in Table 1. The billet heating temperature is above 1150-1200°C, the finishing temperature is 860-900°C, the coiling temperature is 520-620°C, and then air-cooled to room temperature. The mechanical properties are shown in Table 2.

[0053] According to the design scope of the steel composition and the rolling process control technology of the present invention, the yield strength of the steel in the example is ≥400MPa, the tensile strength is 500-800MPa, the elongation is above 18%, and it has good interface bonding performance with Al. It can be applied to the manufacture of heat dissipation requirements such as wheels, radiator parts and corrosion resistance requirements.

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com