Low temperature glass phase enhanced SiCp/Cu composite material and preparation method thereof

A low-temperature glass and composite material technology, applied in the field of ceramic reinforced metal matrix composite materials, can solve the problems of affecting the comprehensive performance of Cu composite materials, prone to interfacial reaction, limited comprehensive performance, etc., to achieve improved interface bonding characteristics, good comprehensive mechanics performance, combined with good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

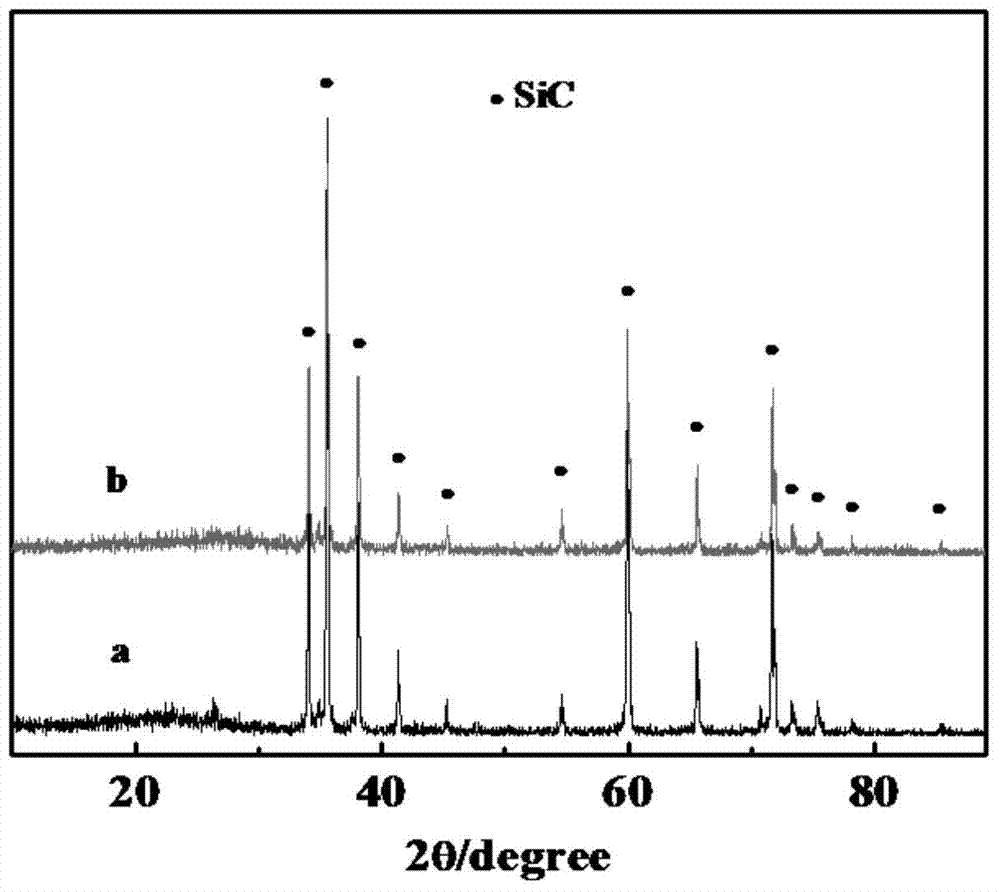

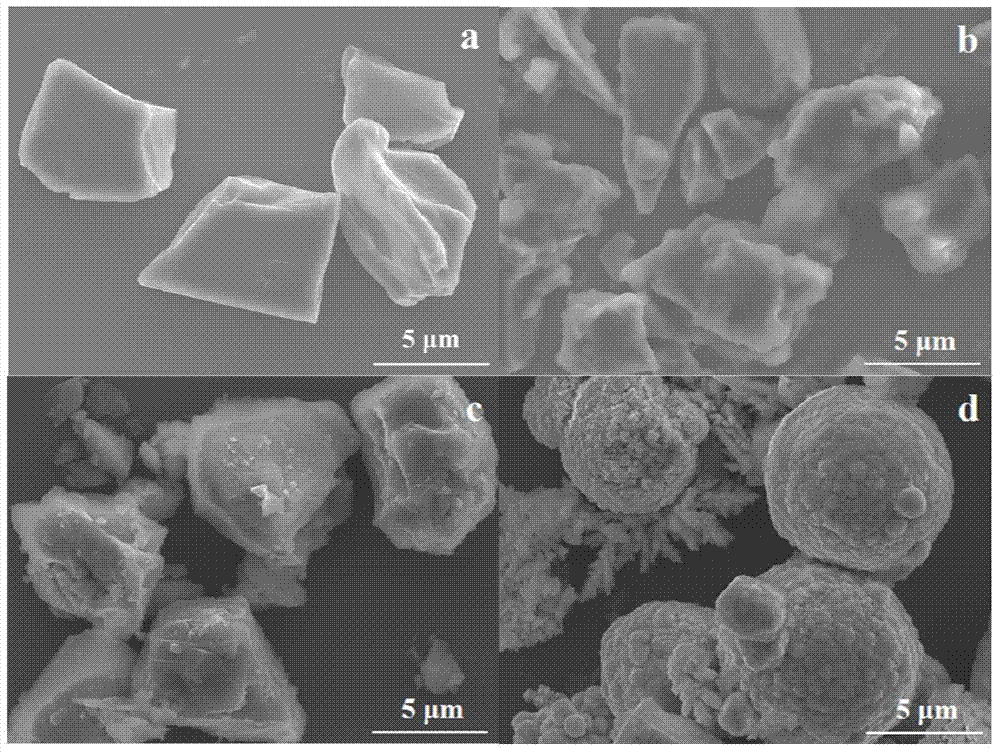

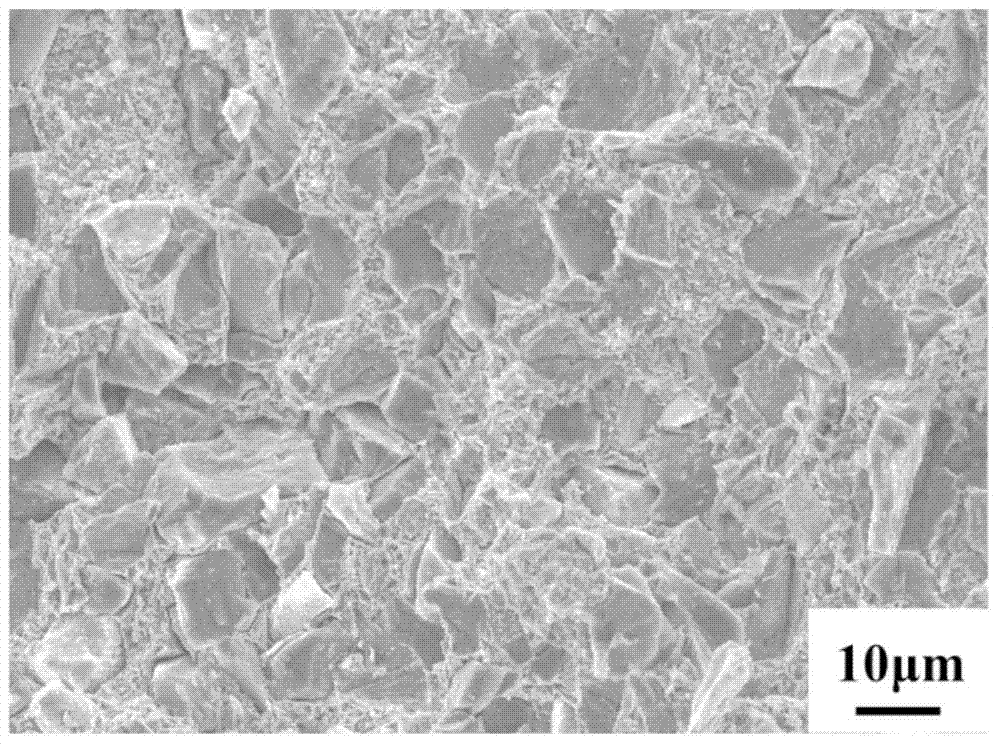

[0034] In this embodiment, SiC reinforced by low temperature glass phase p / Cu composite material, in which SiC particles wrapped by glass phase are dispersed in Cu matrix, among which SiC, SiO 2 The volume ratio of Cu and Cu is 1:0.6:3, SiO in the glass phase 2 with K 2 The molar ratio of O is 3 and the size of SiC particles is 10 μm.

[0035] In this embodiment, SiC reinforced by low temperature glass phase p The preparation method of / Cu composite material, comprises the following steps:

[0036] (1) According to the volume ratio of ester, alcohol and water as 23:35:3, disperse tetraethyl orthosilicate (TEOS) and α-SiC in ethanol solution, adjust the pH of the solution to 2 with citric acid, Stir magnetically at 45°C for 3 hours to completely hydrolyze tetraethyl orthosilicate to SiO 2 Form a sol, then use ammonia water to adjust the pH of the solution to 8, continue magnetic stirring for 0.1 hour to obtain a composite gel, vacuum filter, blow dry at 80°C for 2 hours, ...

Embodiment 2

[0043] In this embodiment, SiC reinforced by low temperature glass phase p / Cu composite material, in which SiC particles wrapped by glass phase are dispersed in Cu matrix, among which SiC, SiO 2 The volume ratio of Cu and Cu is 1:0.2:2, SiO in the glass phase 2 with K 2 The molar ratio of O is 2 and the size of SiC particles is 10 μm.

[0044] In this embodiment, SiC reinforced by low temperature glass phase p The preparation method of / Cu composite material, comprises the following steps:

[0045] (1) According to the volume ratio of ester, alcohol and water as 23:35:3, disperse tetraethyl orthosilicate (TEOS) and α-SiC in ethanol solution, adjust the pH of the solution to 2 with citric acid, Stir magnetically at 30°C for 6 hours to completely hydrolyze tetraethyl orthosilicate to SiO 2 Form a sol, then use ammonia water to adjust the pH of the solution to 9, continue magnetic stirring for 1 hour to obtain a composite gel, vacuum filter, blow dry at 75°C for 2.5 hours, ...

Embodiment 3

[0051] In this embodiment, SiC reinforced by low temperature glass phase p / Cu composite material, in which SiC particles wrapped by glass phase are dispersed in Cu matrix, among which SiC, SiO 2 The volume ratio of Cu and Cu is 1:1.2:4, SiO in the glass phase 2 with K 2 The molar ratio of O is 6, and the size of SiC particles is 10 μm.

[0052] In this embodiment, SiC reinforced by low temperature glass phase p The preparation method of / Cu composite material, comprises the following steps:

[0053] (1) According to the volume ratio of ester, alcohol and water as 23:35:3, disperse tetraethyl orthosilicate (TEOS) and α-SiC in ethanol solution, adjust the pH of the solution to 3 with citric acid, Stir magnetically at 60°C for 2 hours to completely hydrolyze tetraethyl orthosilicate to SiO 2 Form a sol, then use ammonia water to adjust the pH value of the solution to 11, continue magnetic stirring for 2 hours to obtain a composite gel, vacuum filter, blow dry at 85°C for 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com