Steel pipe end rounding machine

A technology for steel pipes and pipe ends, applied in the field of longitudinal submerged arc welded pipe production line equipment, which can solve problems such as low efficiency and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

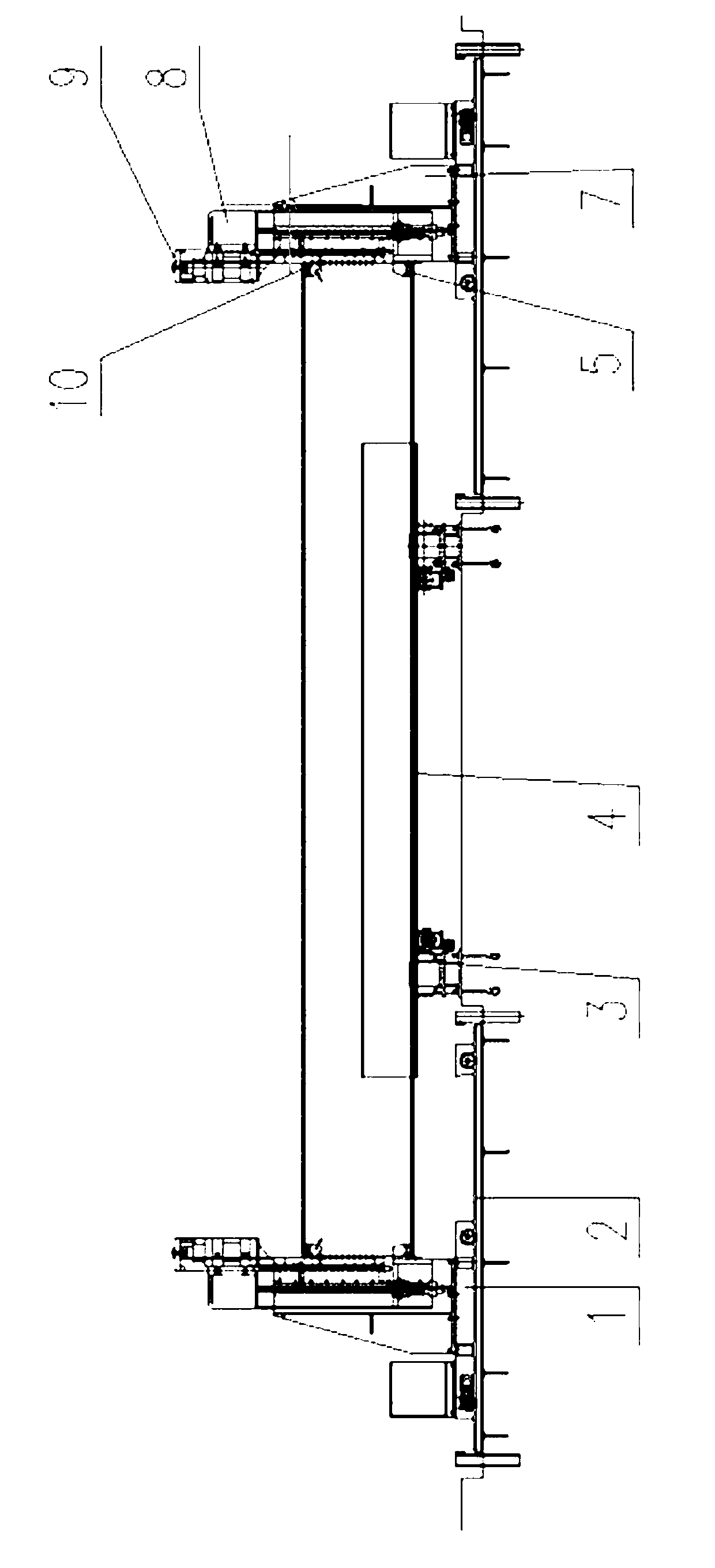

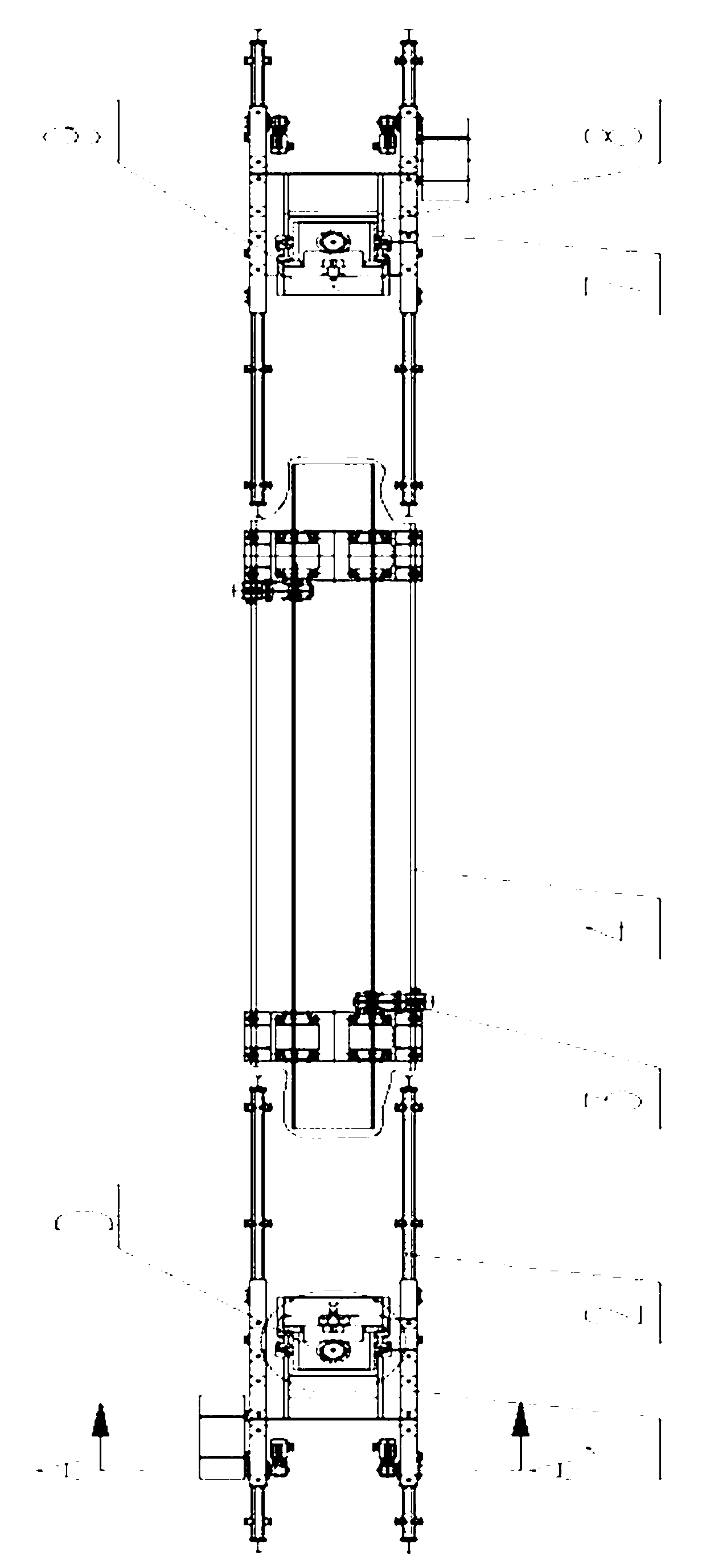

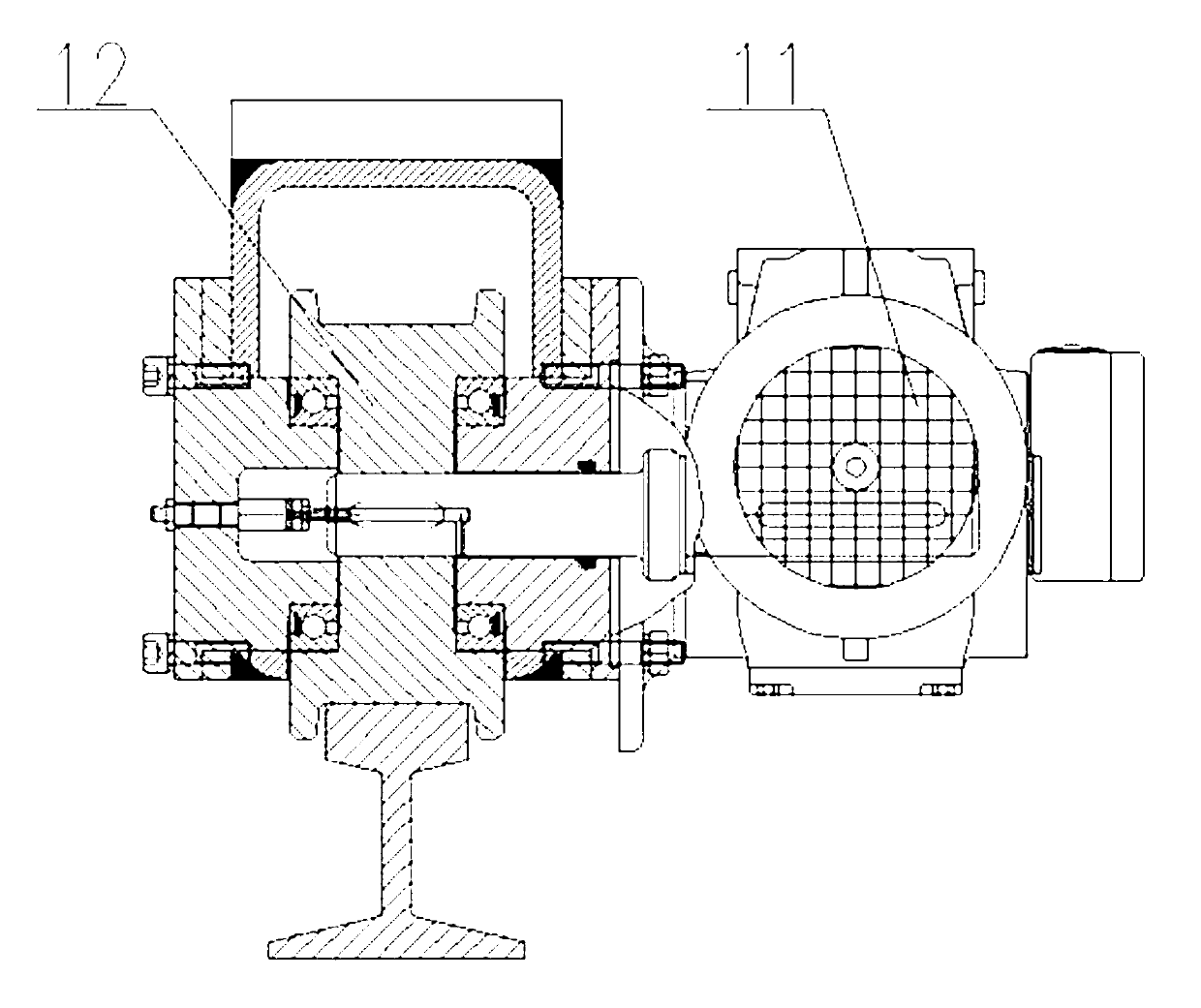

[0021] As shown in the figure, a steel pipe end rounding machine includes a car body, two sections of rails 2 are symmetrically installed on the car body, a driving car 1 is installed on the rails 2, a rotating roller 3 is installed in the middle of the two sections of rails 2, and two rotating rollers Steel pipes 4 are installed between the 3. A fixed machine base 7 is installed on the active vehicle 1, and a lower adjustment oil cylinder 16 is installed with a flange on the lower part of the mold support 8. The piston rod of the lower adjustment oil cylinder 16 is fixed on the lower end of the fixed machine base 7, and the lower adjustment oil cylinder 16 can adjust the mold support 8 as a whole. Raising or lowering to adapt to the change of the diameter and wall thickness of the steel pipe 4 causes the height change of the bus bar under the inner wall of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com