Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Realize rotary motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

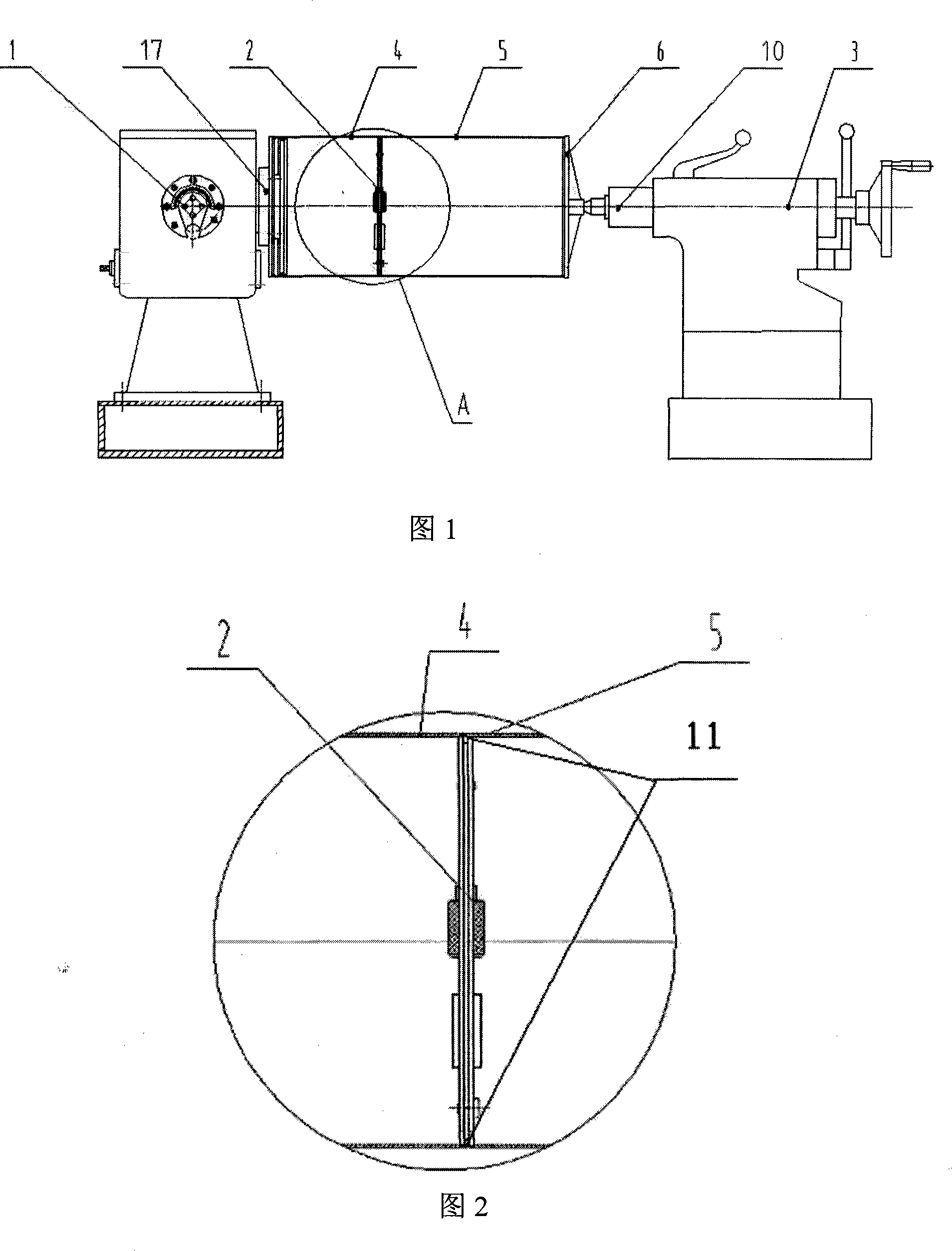

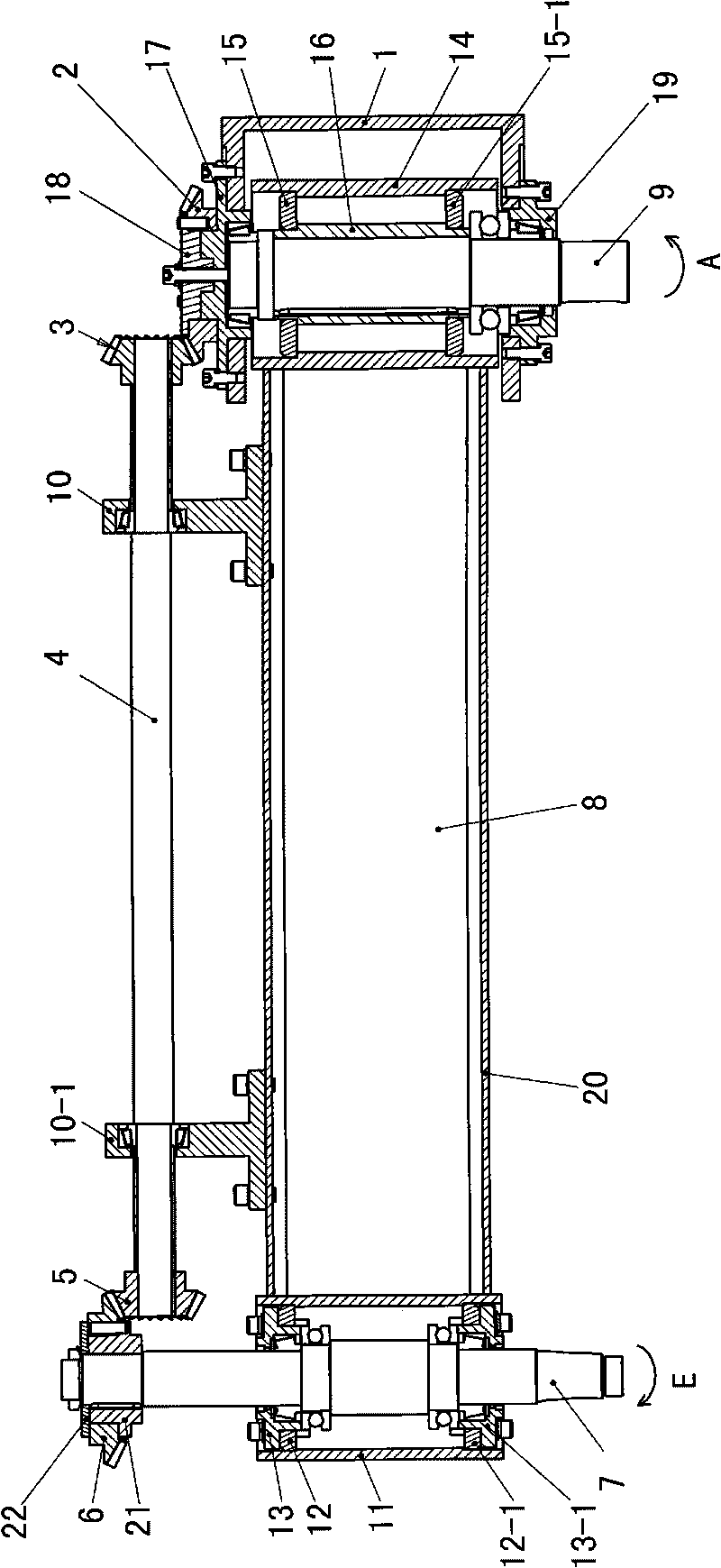

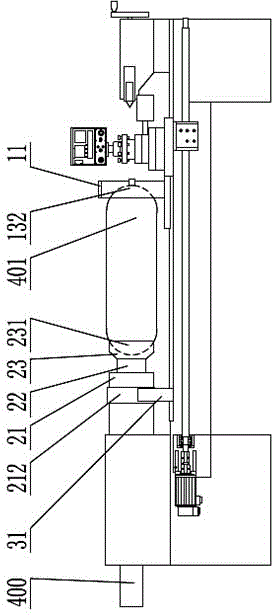

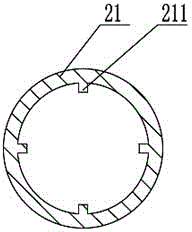

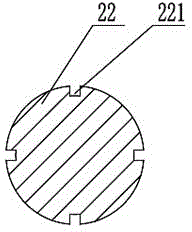

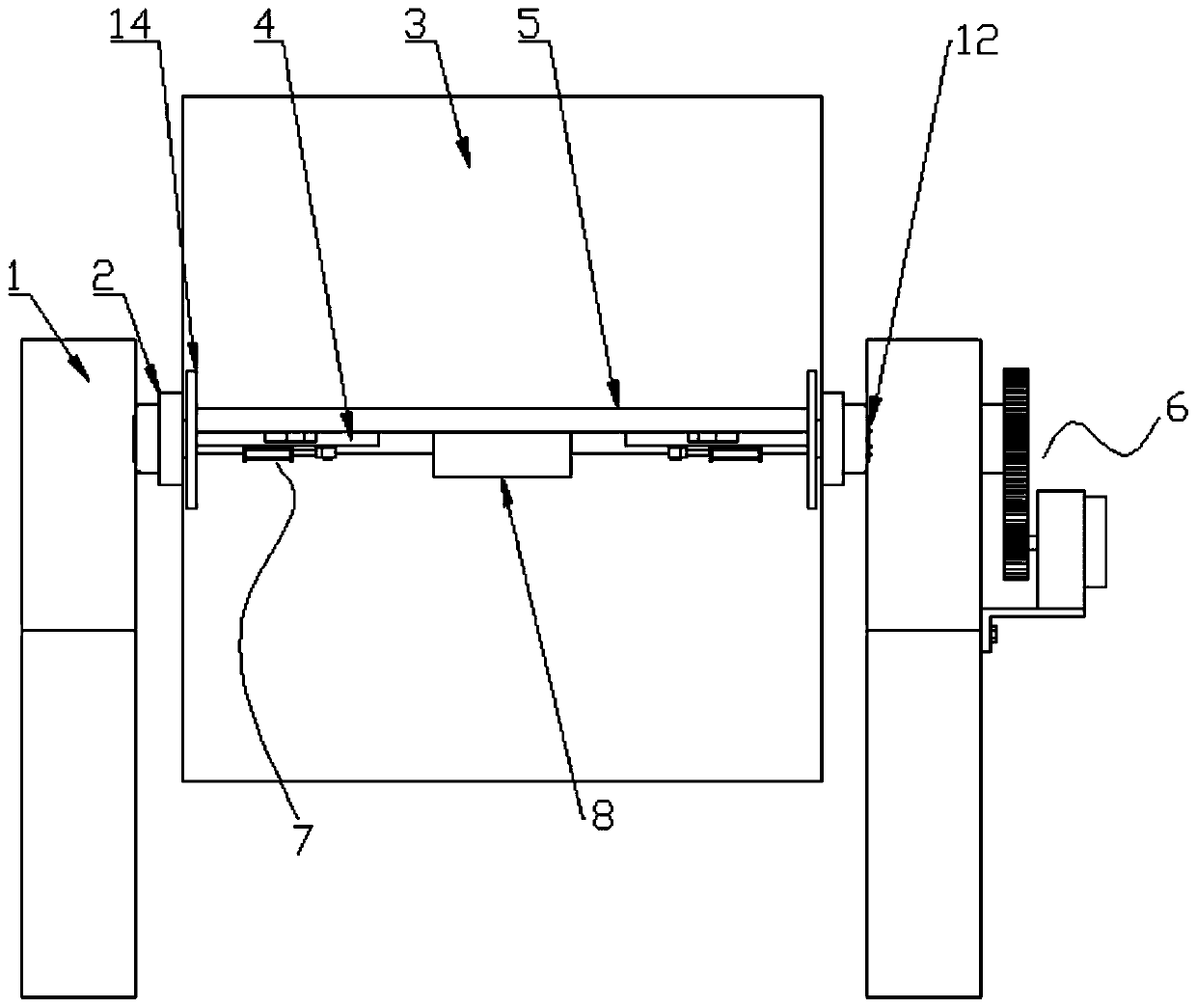

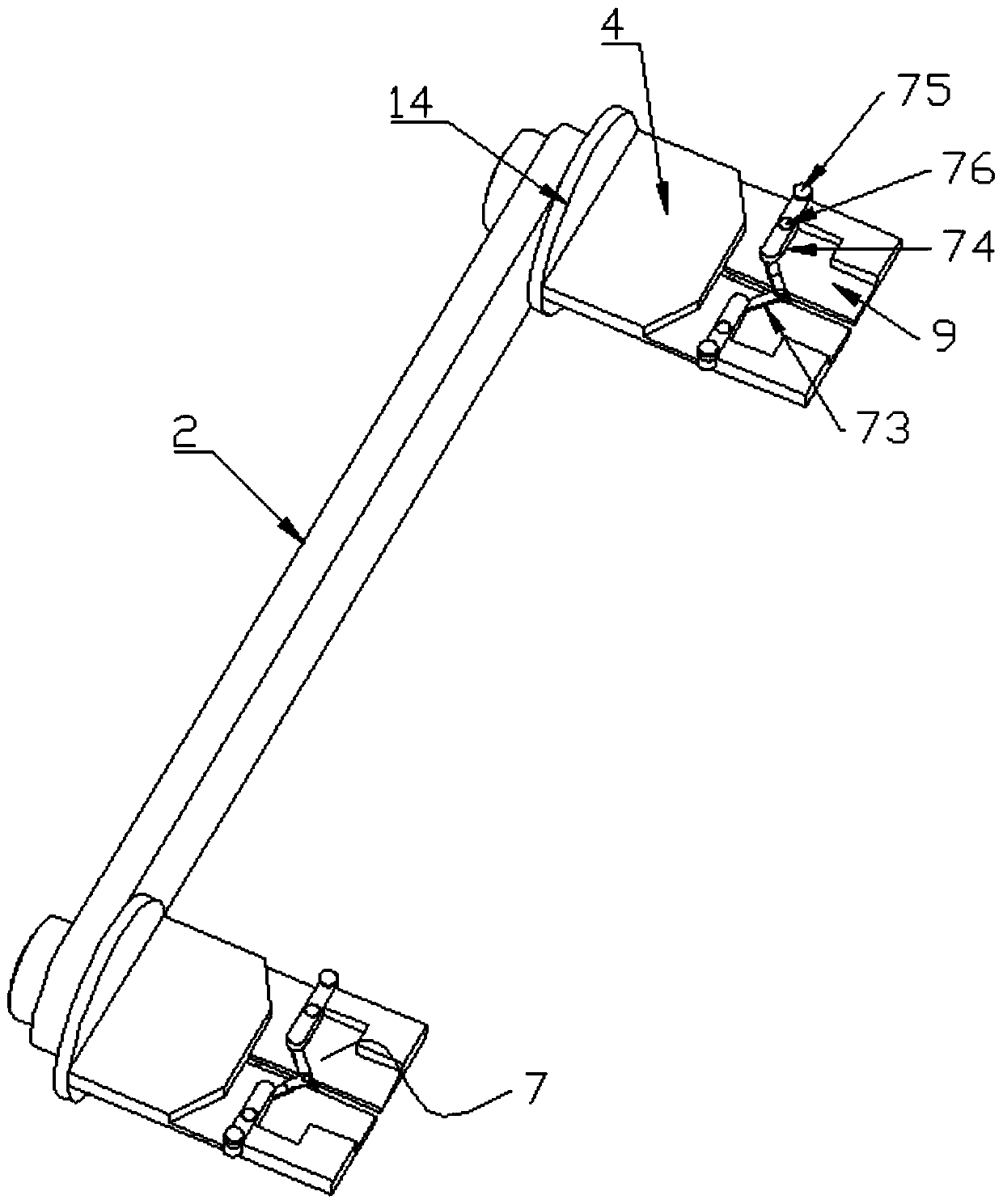

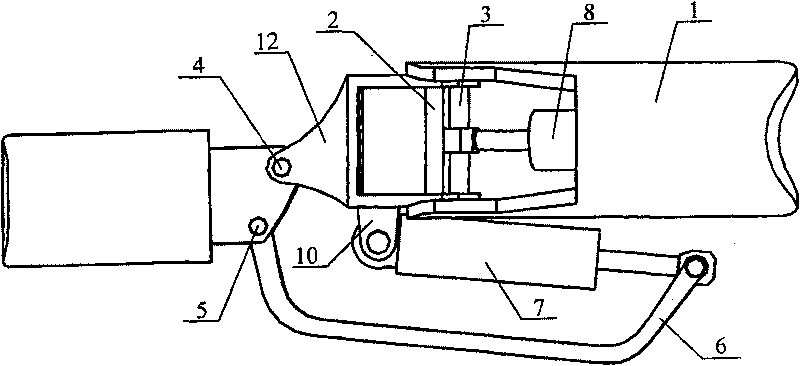

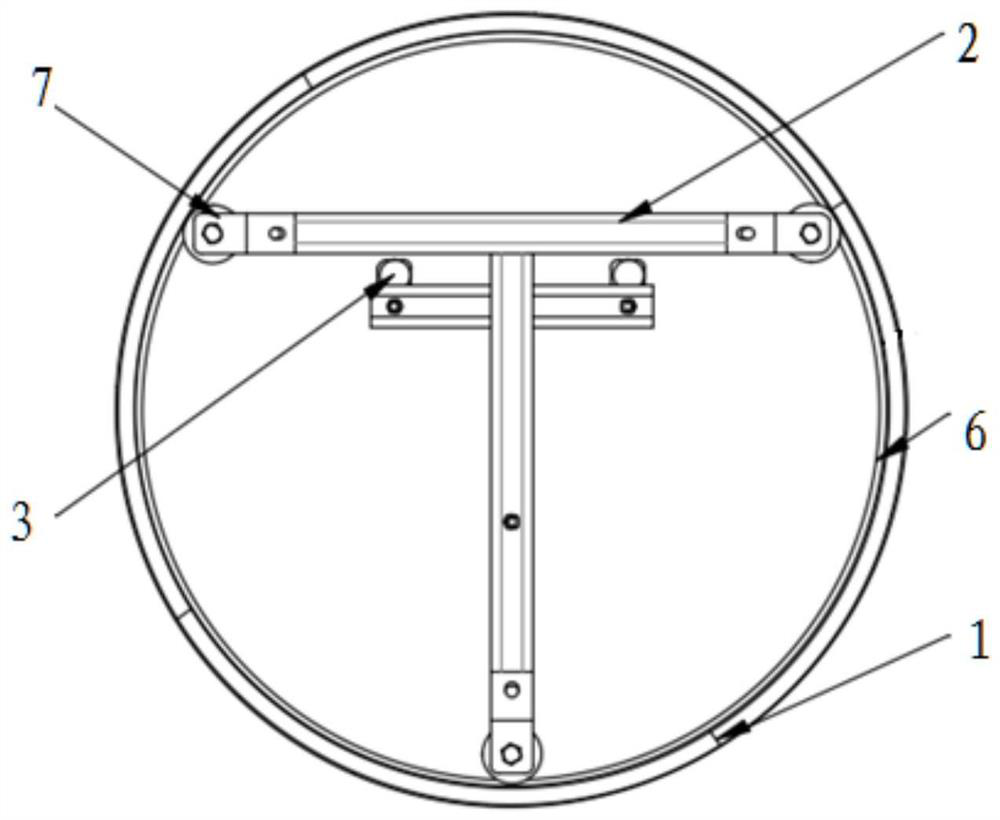

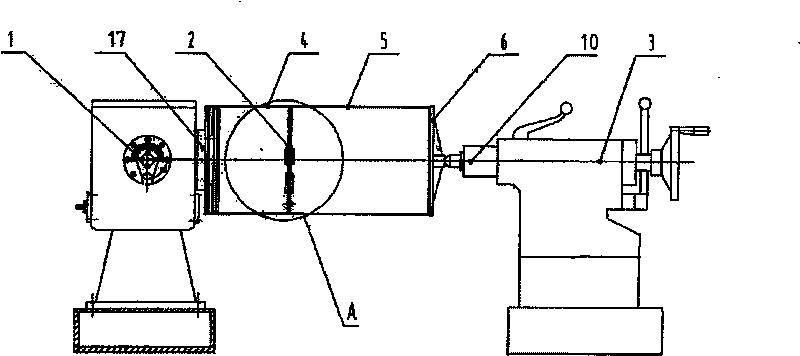

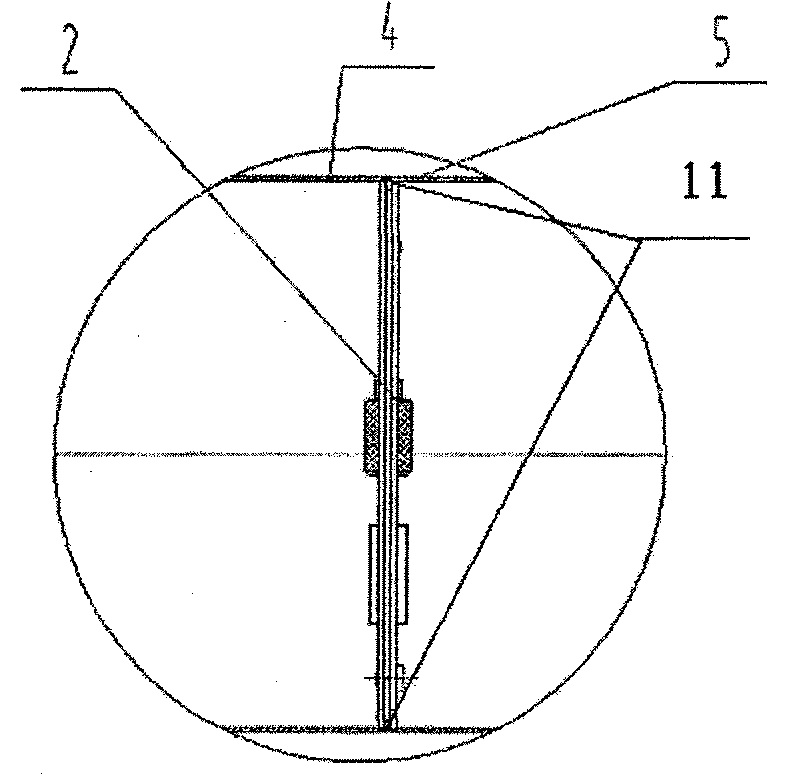

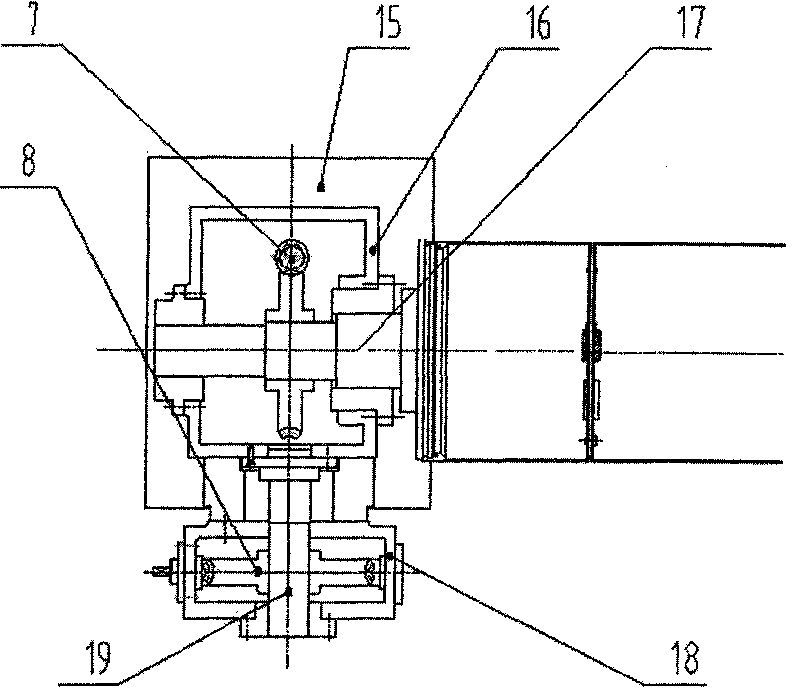

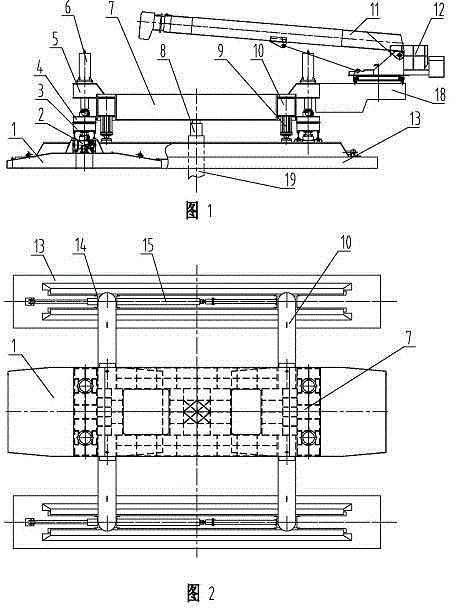

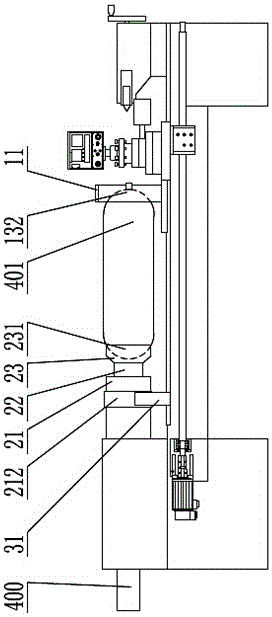

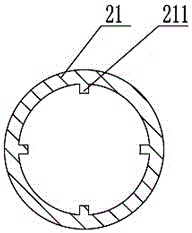

Thin walled cylinder girth laser welding tong

InactiveCN101229612ARealize rotary motionAccurate splicingWelding/cutting auxillary devicesAuxillary welding devicesGyrationEngineering

The invention discloses a circular seam laser welding fixture for a thin-wall cylinder, which comprises a head frame, an extended ring, a rear frame of a machine tool and a top plate. When in operation, the extended ring is placed between the head frame and the rear frame of the machine tool and sleeved in a place where two workpieces to be welded are spliced; one non-splicing end of the workpiece is retained and positioned on a spindle of the head frame while the other non-splicing end is attached to a positioning surface of a baffle; a top point of the rear frame of the machine tool is arranged in a top point hole of the baffle. By adopting a retractable extended ring, the invention realizes the correct splicing and retaining of the thin-wall cylinder; the gyration of the cylinder can be realized by a way that the head frame with the function of turning drives a head part of the cylinder and a tail part of the cylinder is supported by the rear frame and the top plate; meanwhile, the splicing precision also meets the requirement of the laser welding. A worm-and-gear mechanism of the spindle in the head frame can accomplish the precise gyration of the workpiece and the head frame with a turnover function is convenience for feeding and discharging of a longer workpiece. The invention has the advantages of precise positioning, reliable and convenient fixture, convenient application, high efficiency, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

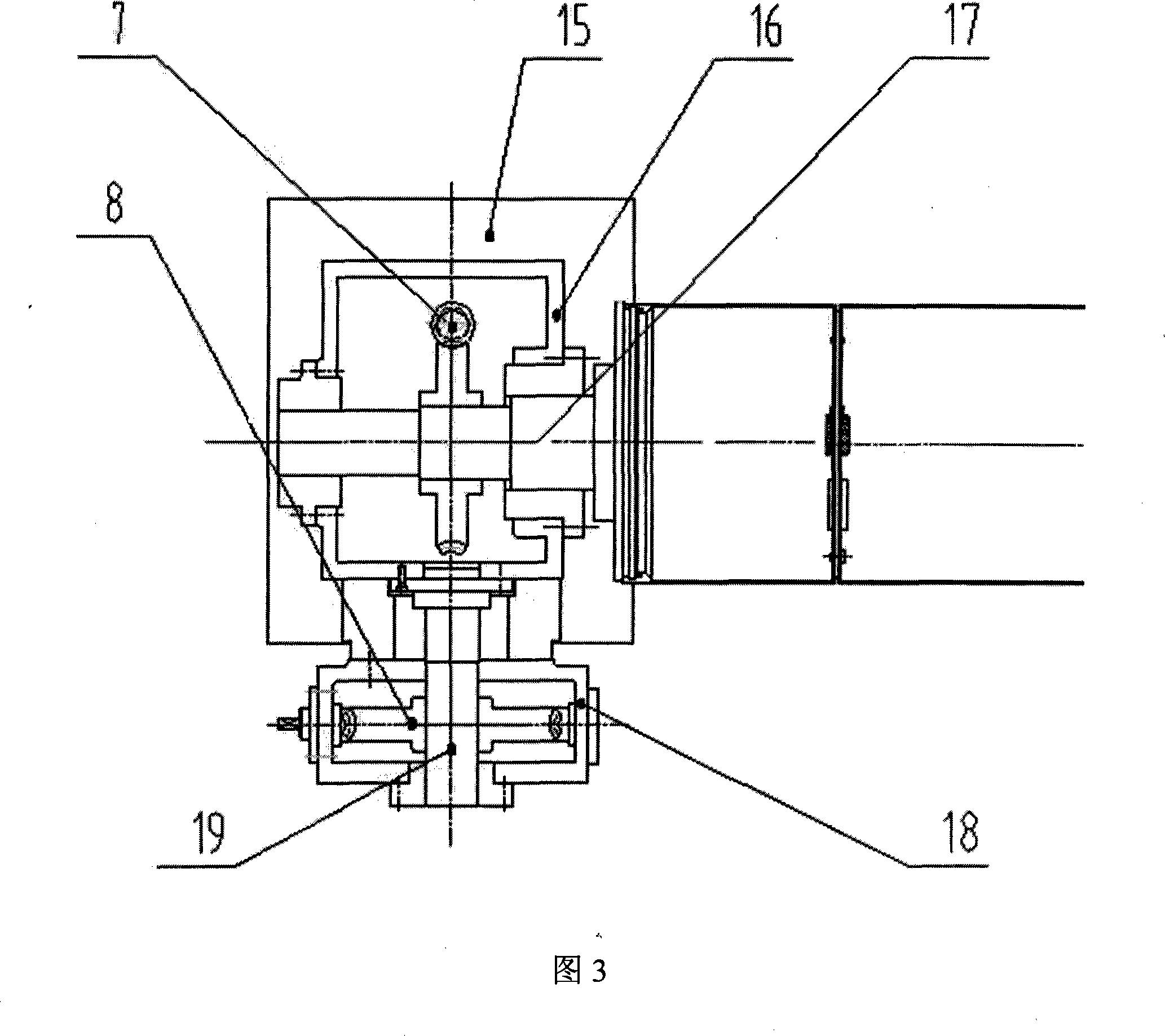

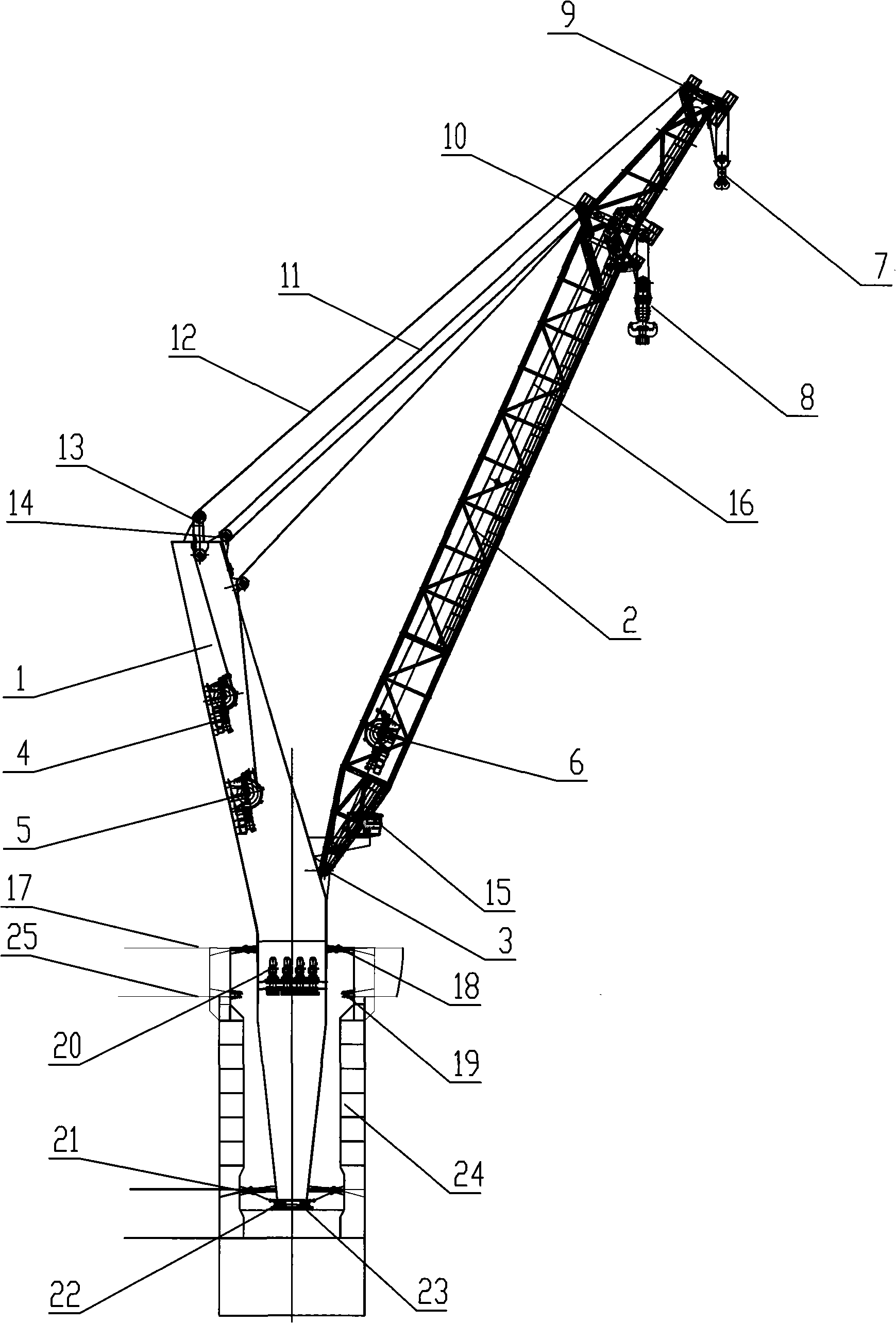

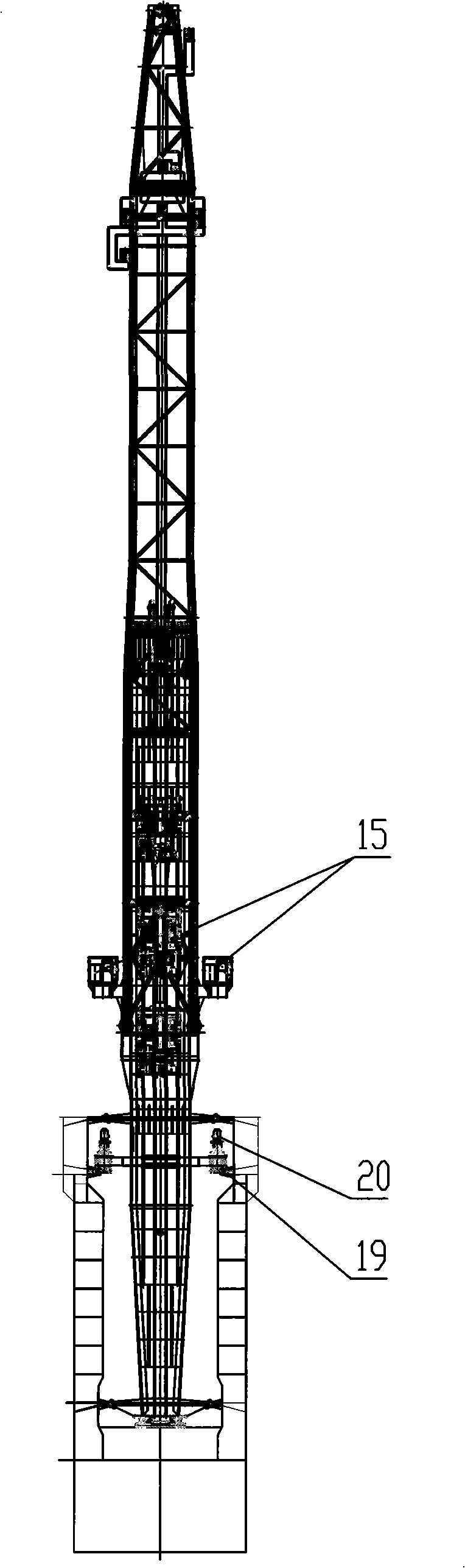

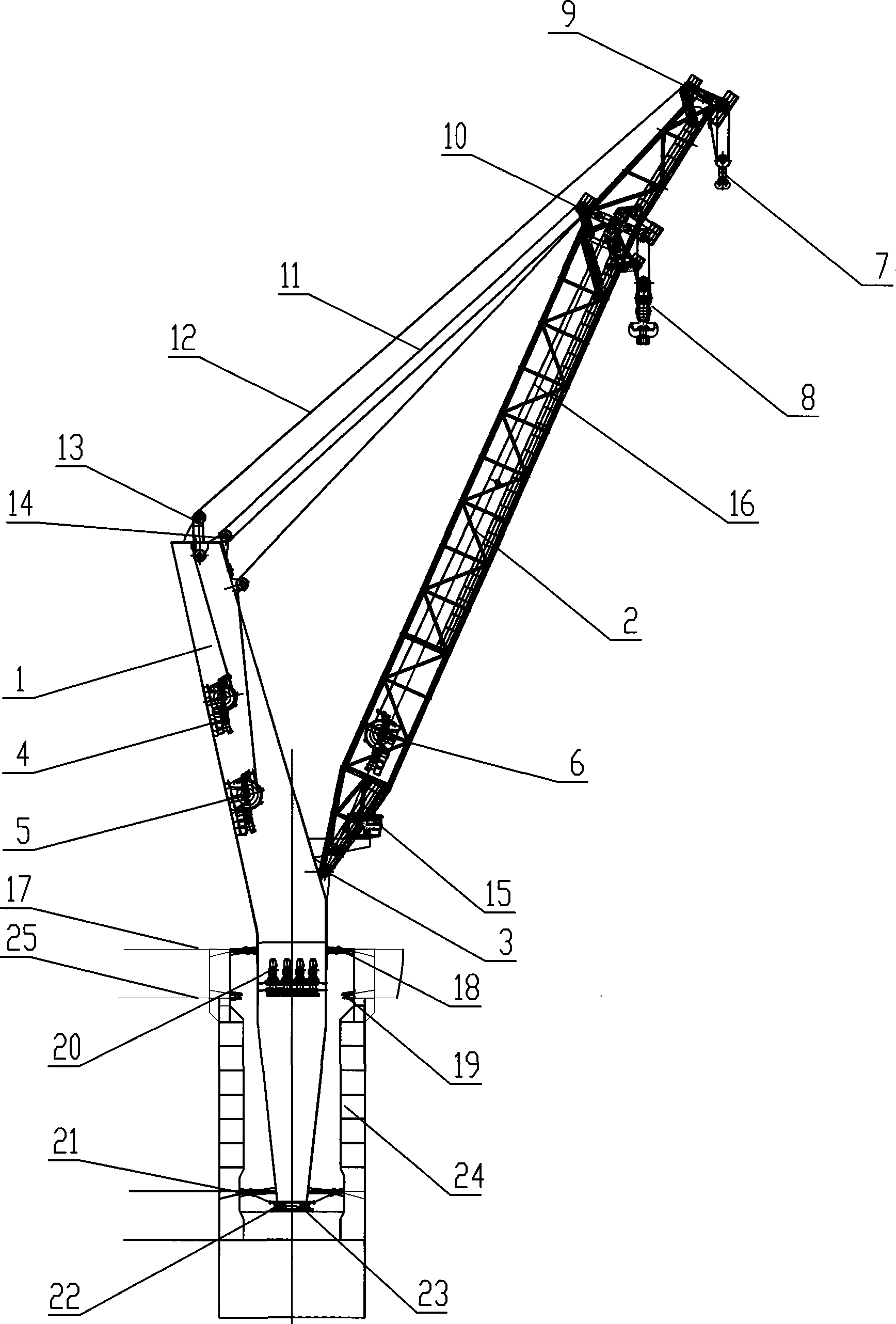

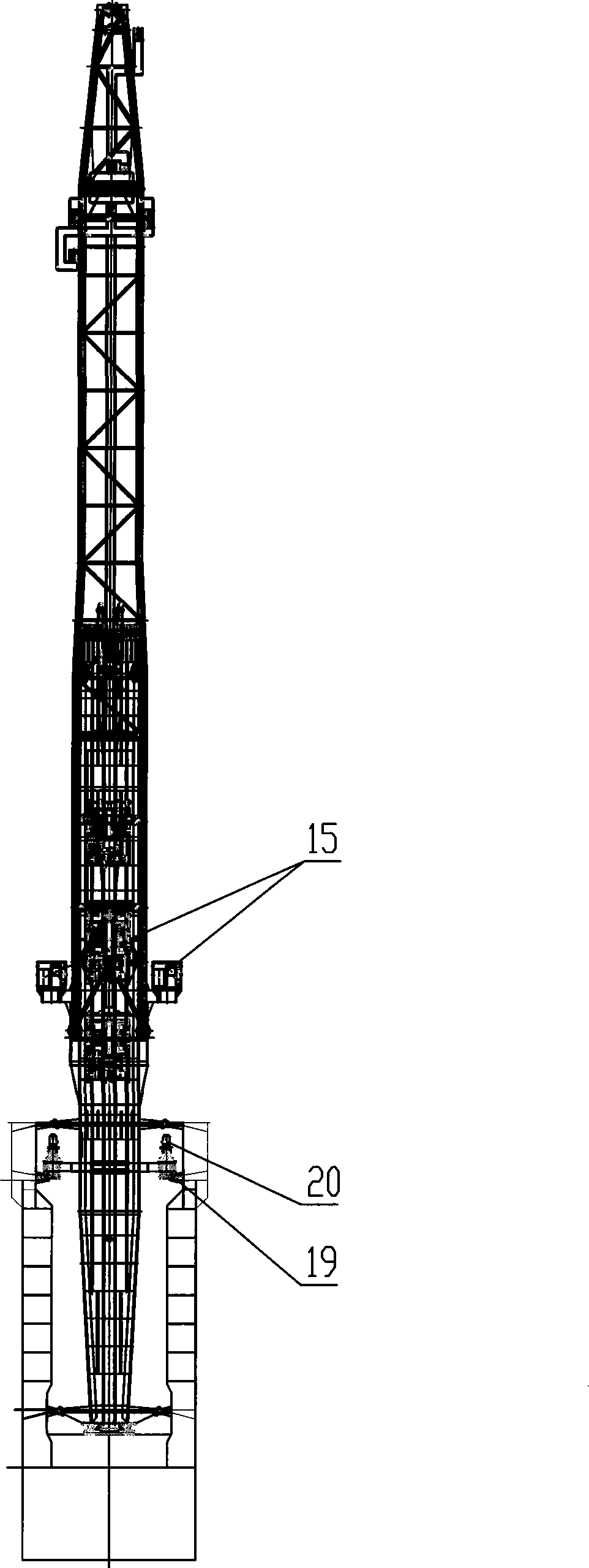

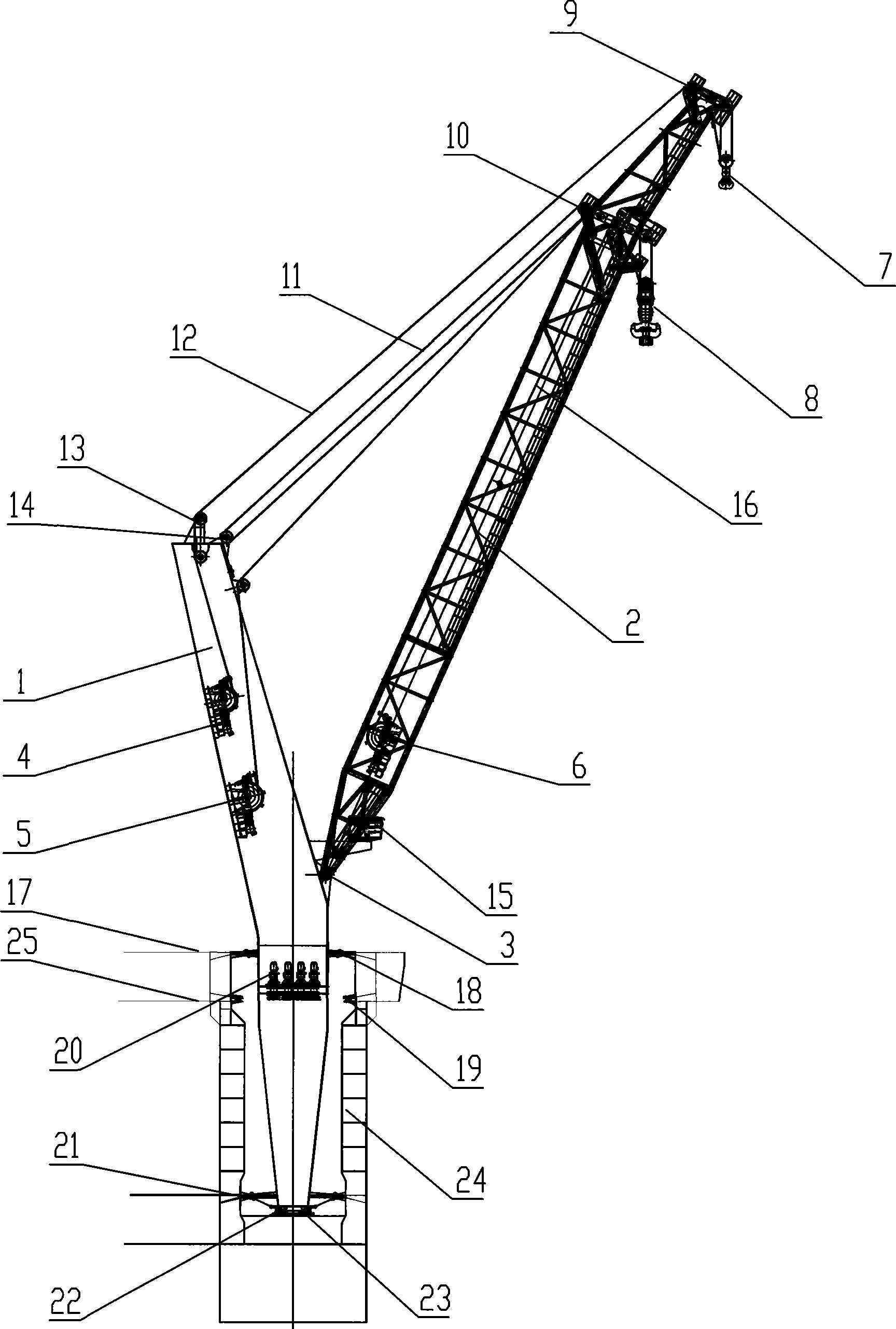

Large-scale full-turning offshore platform crane

ActiveCN101343021ASmall sizeSolve the problem of occupying a large deck areaCargo handling apparatusPassenger handling apparatusGyrationThrust bearing

The invention provides a large full-gyration offshore platform crane which relates to the lifting machinery and comprises a rotary column, an arm support, a main lifting winch, an auxiliary lifting winch, an arm support variable-breadth winch, a gyration bearing drive mechanism, a main hanger hook, an auxiliary hanger hook and a driver cab. The arm support is connected with the middle part of the rotary column through a hinge point mounted on the root of the arm support; the lower half part of the rotary column is arranged under a main deck and connected with a semi-diving platform through the gyration bearing drive mechanism. The gyration bearing mechanism is composed of an upper radial bearing, a lower radial bearing, a peg-tooth, a three-in-one decelerator, a centripetal thrust bearing and a rubber support; the upper radial bearing and the lower radial bearing are respectively mounted on the middle and the lower parts of the rotary column. The centripetal thrust bearing and the rubber bearing are sequentially mounted on the bottom part of the rotary column; the peg-tooth mounted on the lower deck is meshed with the three-in-one decelerator mounted on the corresponding position of the rotary column. The large full-gyration offshore platform crane has the advantages of novel, compact and practical structure, high efficiency and being a large full-gyration offshore platform crane with economical and practical properties.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

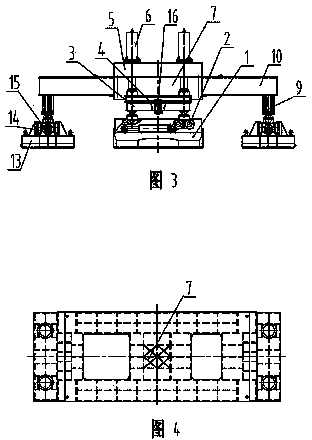

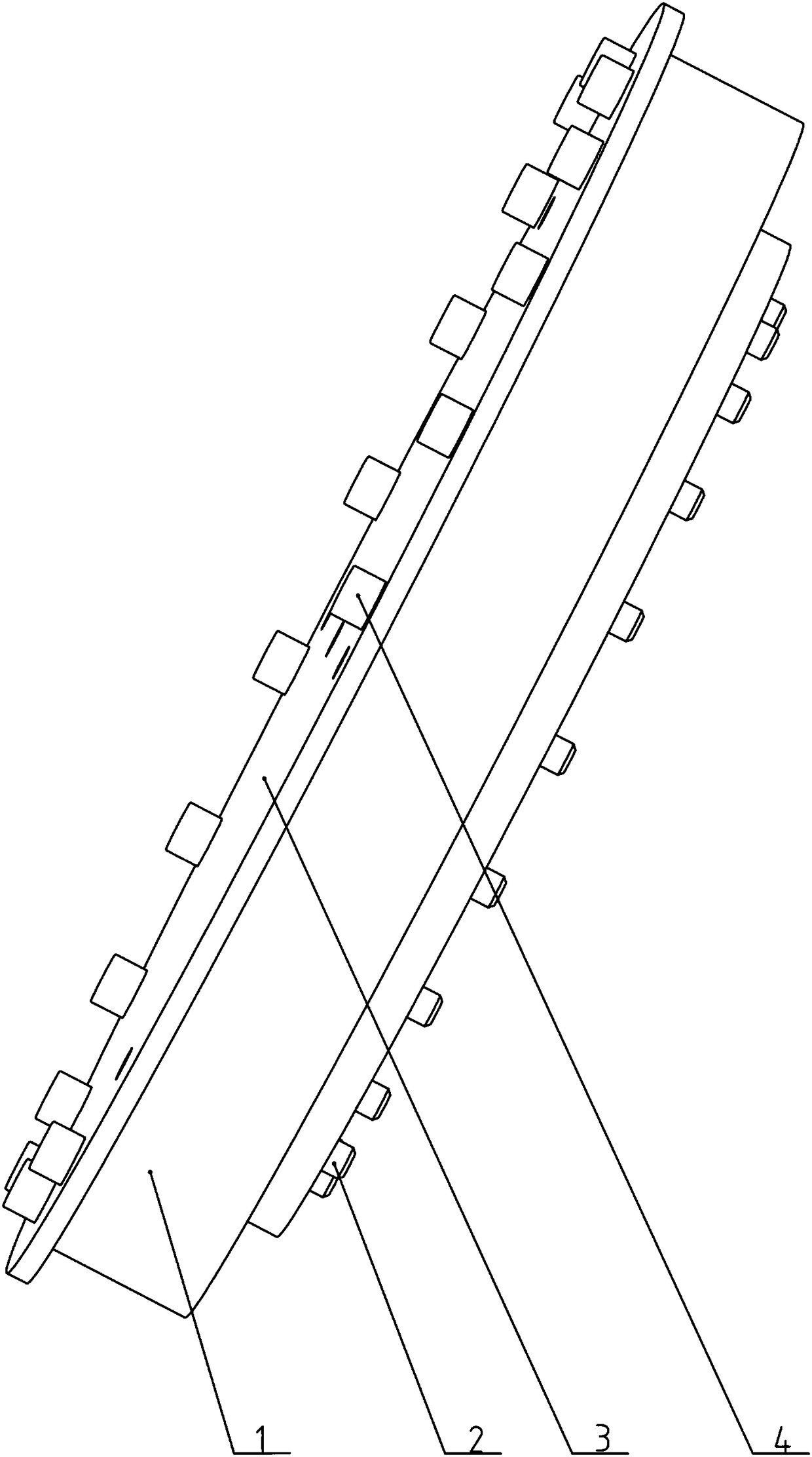

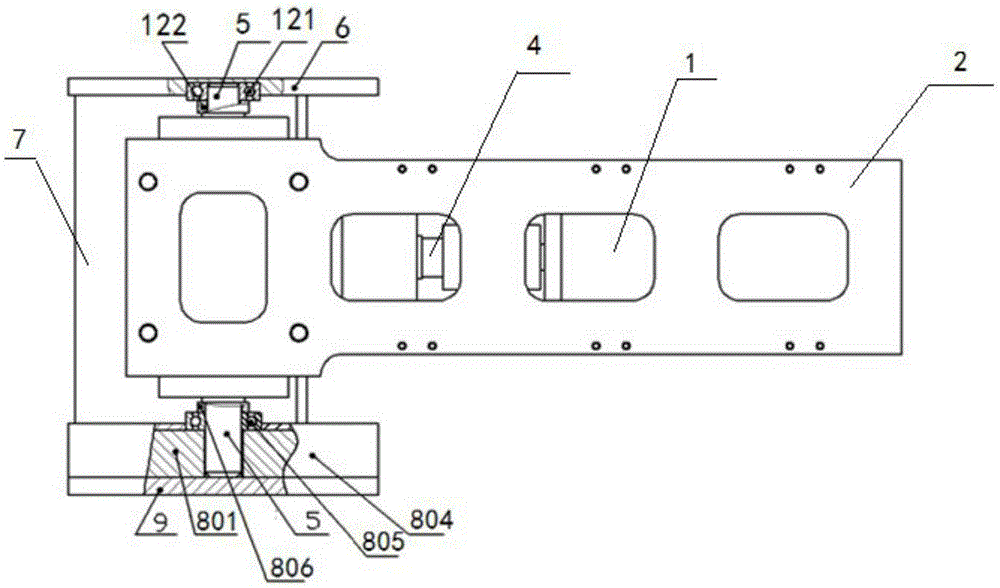

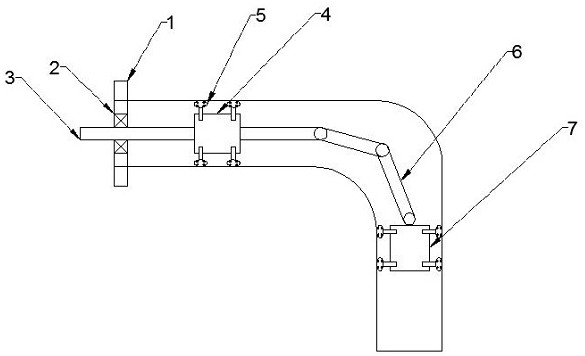

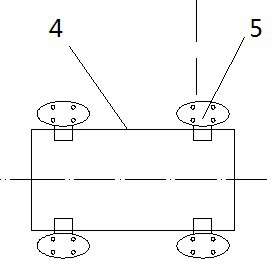

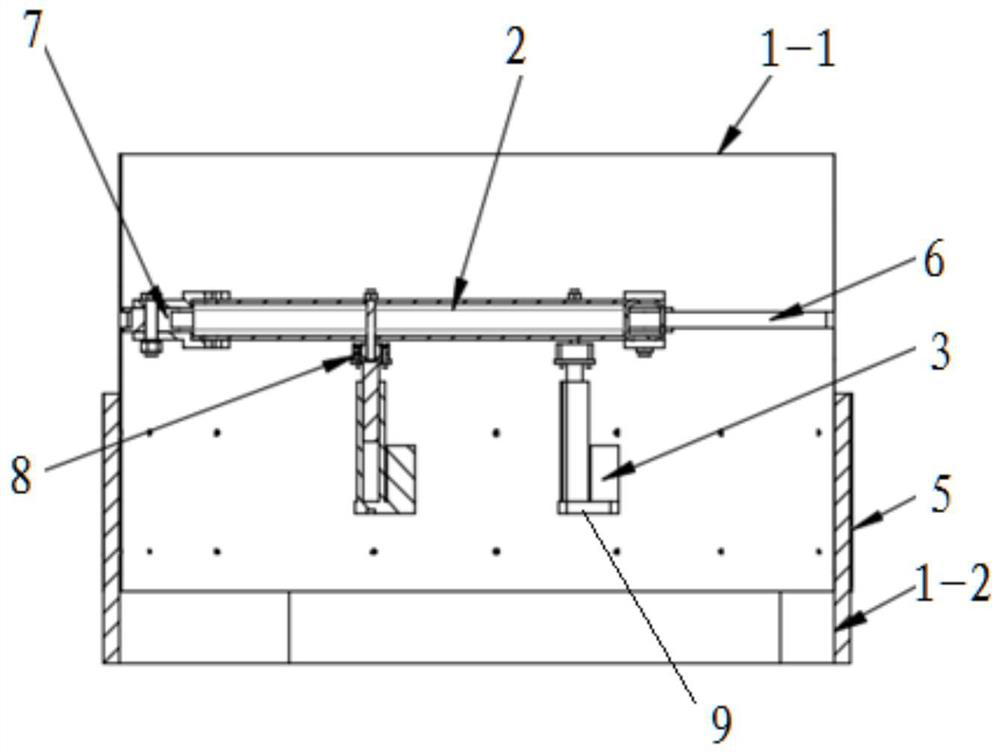

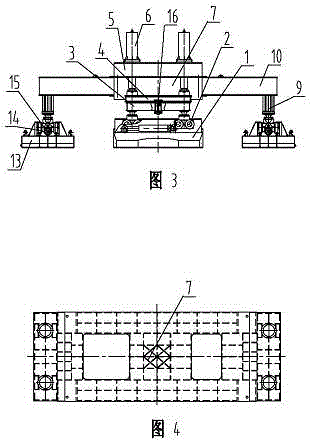

Walking type detection platform for static load of engineering foundation piles

InactiveCN103362150ARealize rotary motionFlexible and convenient to moveFoundation testingHydraulic cylinderControl engineering

The invention discloses a walking type detection platform for the static load of engineering foundation piles, which comprises a supporting platform movably supported on two long boats and two short boats, wherein the two short boats are respectively arranged at two ends of the supporting platform, and a short-boat walking vehicle is arranged on each short boat and is fixedly connected with a short-boat slewing platform; vertical lifting hydraulic cylinders mounted on the supporting platform is hinged to the short-boat supporting platforms; the short-boat slewing platforms are hinged to the short-boat supporting platforms through swing pin shafts; two long-boats are respectively arranged on two sides of the supporting platform; each long boat is provided with two movable long-boat walking vehicles which are hinged to the lower ends of the corresponding legs of the long boats; the legs of the long boats are mounted on the supporting platform through beams of legs of the long boats; long-boat walking hydraulic cylinders are arranged between the long-boat walking vehicles and the long boats; a crane is mounted on the supporting platform. The detection platform can perform self-propelled move as a whole, requires no repetitive construction and hoisting, and has the features of safety in use, reasonable structure, high operating efficiency and the like.

Owner:江苏久工重型机械股份有限公司

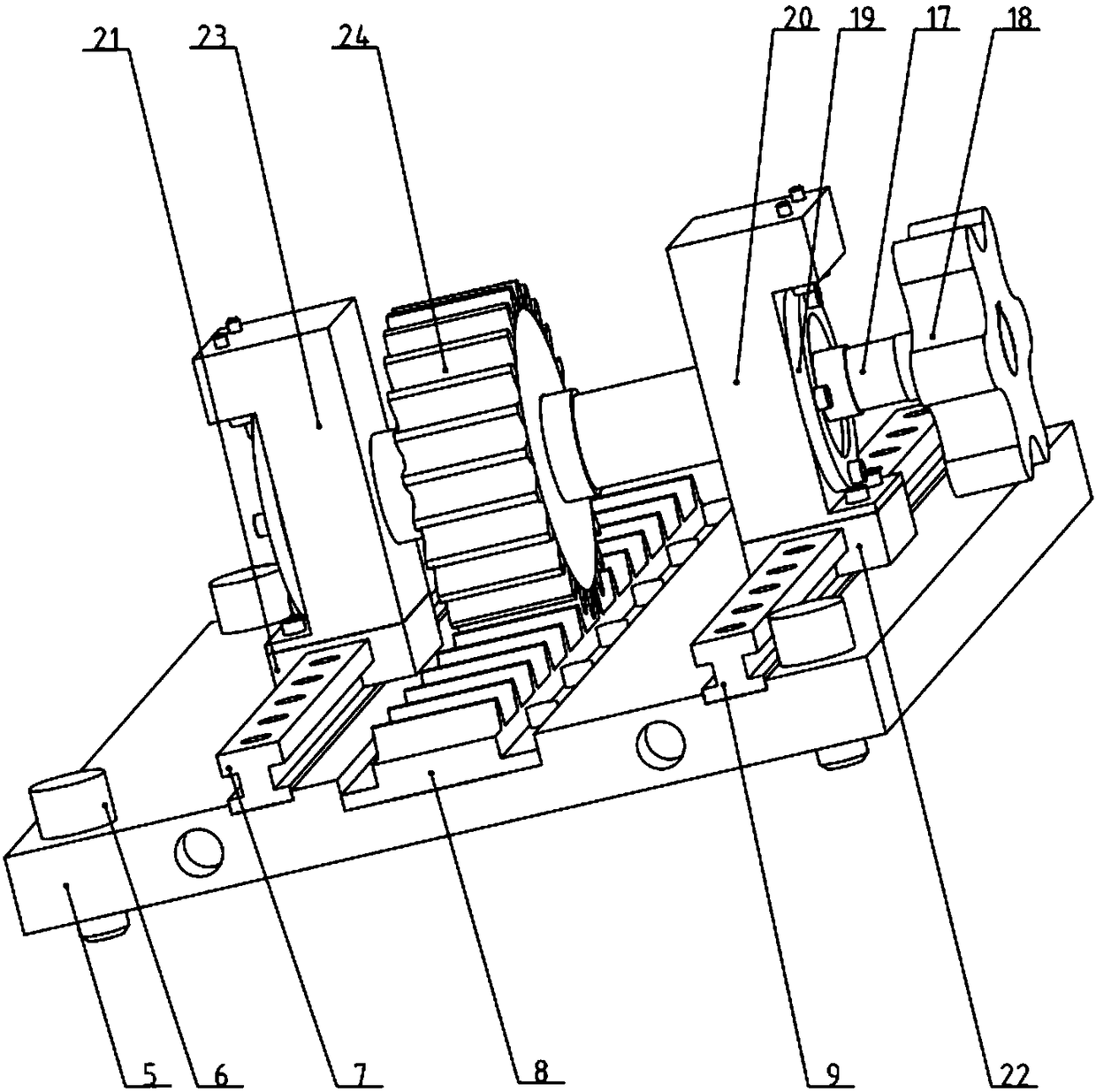

Flexible joint for joint robot

The invention discloses a flexible joint for a joint robot. The flexible joint is characterized by comprising a motor, a joint connecting plate, a motor frame, a coupling, a bevel gear commutator, a first connecting plate, a connecting frame, a flexible output end, a second connecting plate, a support plate, a joint mounting plate and a support end, wherein the joint connecting plate and the joint mounting plate are fixedly connected through the support plate; the motor is fixedly connected with the motor frame through bolts; the motor frame is fixedly connected with the joint mounting plate through bolts; the motor is connected with the bevel gear commutator through the coupling; one end of the output shaft of the bevel gear commutator is connected with the flexible output end through a flexible output end sleeve and a second support bearing sequentially from inside to outside; the other end of the output shaft of the bevel gear commutator is connected with the support end through a support end sleeve and a first support bearing sequentially from inside to outside; the support end is connected with the first connecting plate.

Owner:HEBEI UNIV OF TECH

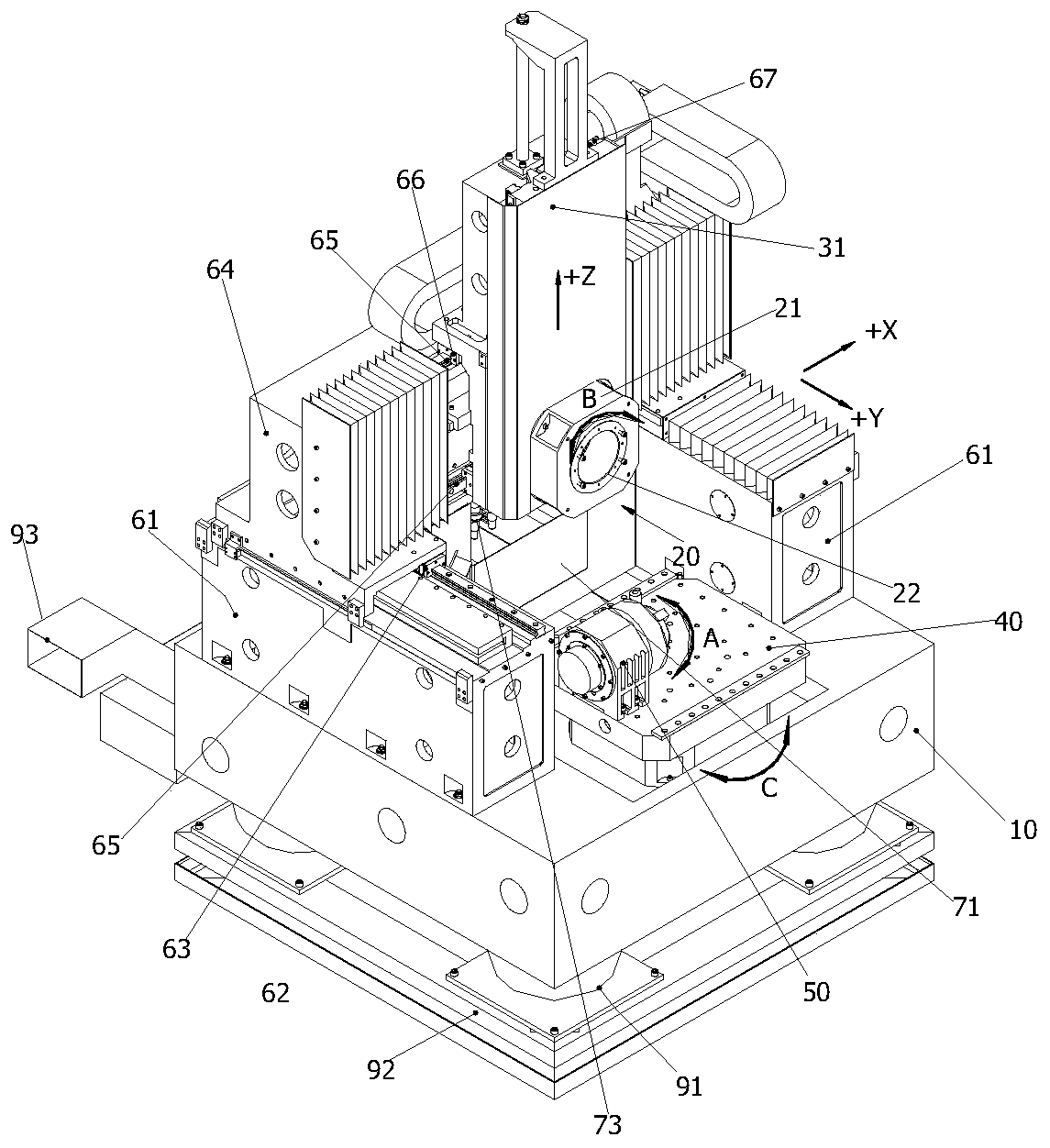

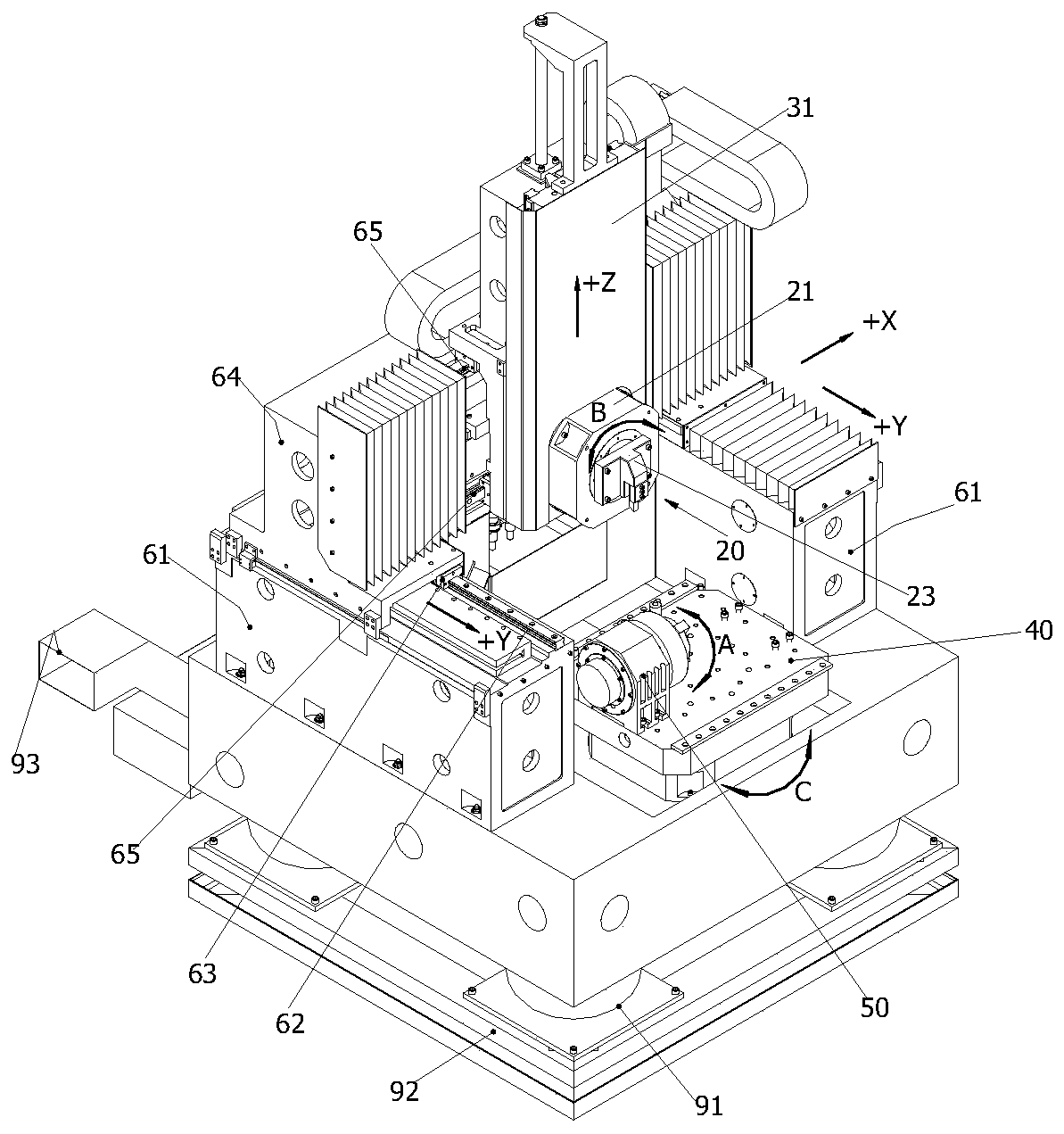

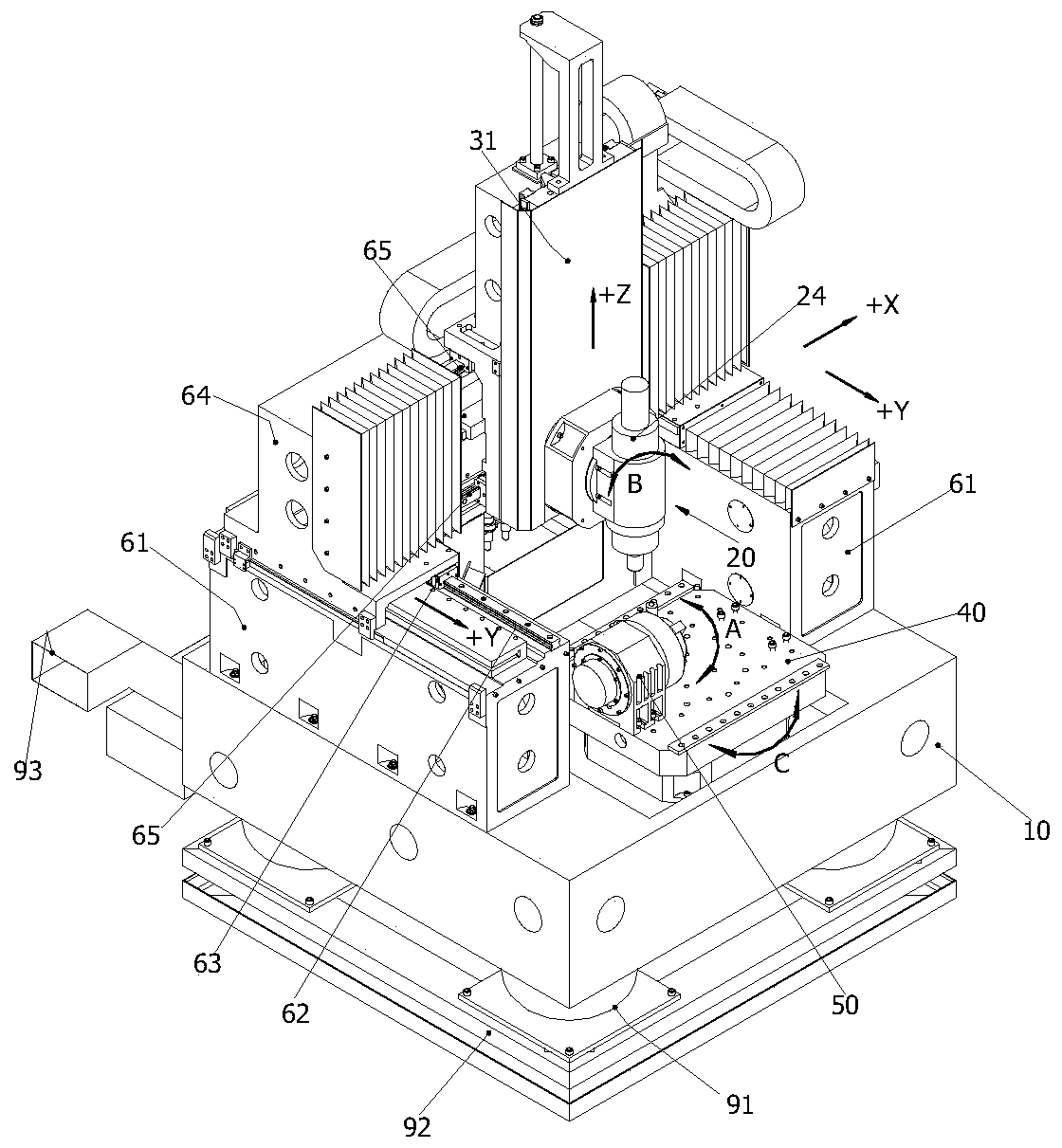

Novel precision composite six-axis linkage numerical control machine tool

PendingCN111390562ARealize rotary motionImprove machining accuracyAutomatic control devicesFeeding apparatusNumerical controlVertical plane

The invention aims to design a novel precision composite six-axis linkage numerical control machine tool. A tool apron is installed on a sliding seat and swings in a vertical plane relative to the sliding seat, a machine tool body is provided with a Z-axis driving device for driving the sliding seat to move up and down, an X-axis driving device and a Y-axis driving device, the X-axis driving device and the Y-axis driving device move in the X direction and the Y direction, a rotary machining platform is further arranged on the machine tool body, a clamping mechanism for clamping a workpiece andenabling the workpiece to rotate and be positioned is arranged on the rotary machining platform, the rotation center of the rotary machining platform is consistent with the Z direction, and the rotation center of the clamping mechanism is consistent with the X direction. According to the novel precision composite six-axis linkage numerical control machine tool, due to the arrangement of the Z-axis driving device, the X-axis driving device and the Y-axis driving device, a tool on the tool apron can move to any position of an operation area, the clamping mechanism and the rotary machining platform can rotate at will, rotary motion of a workpiece is achieved, and the tool apron can swing in the vertical plane, so that a six-axis linkage machining mode is achieved, the novel precision composite six-axis linkage numerical control machine tool can adapt to machining of parts of different complex curved surface structures, and high-precision machining of the workpiece is met.

Owner:HEFEI UNIV

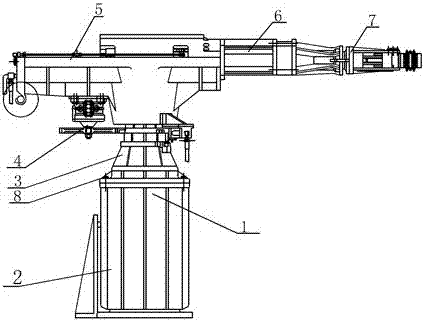

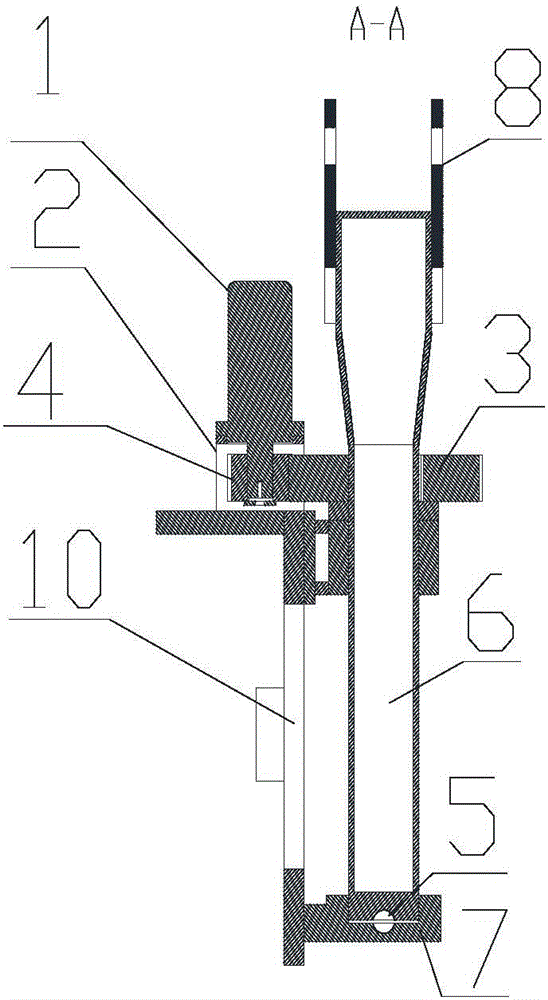

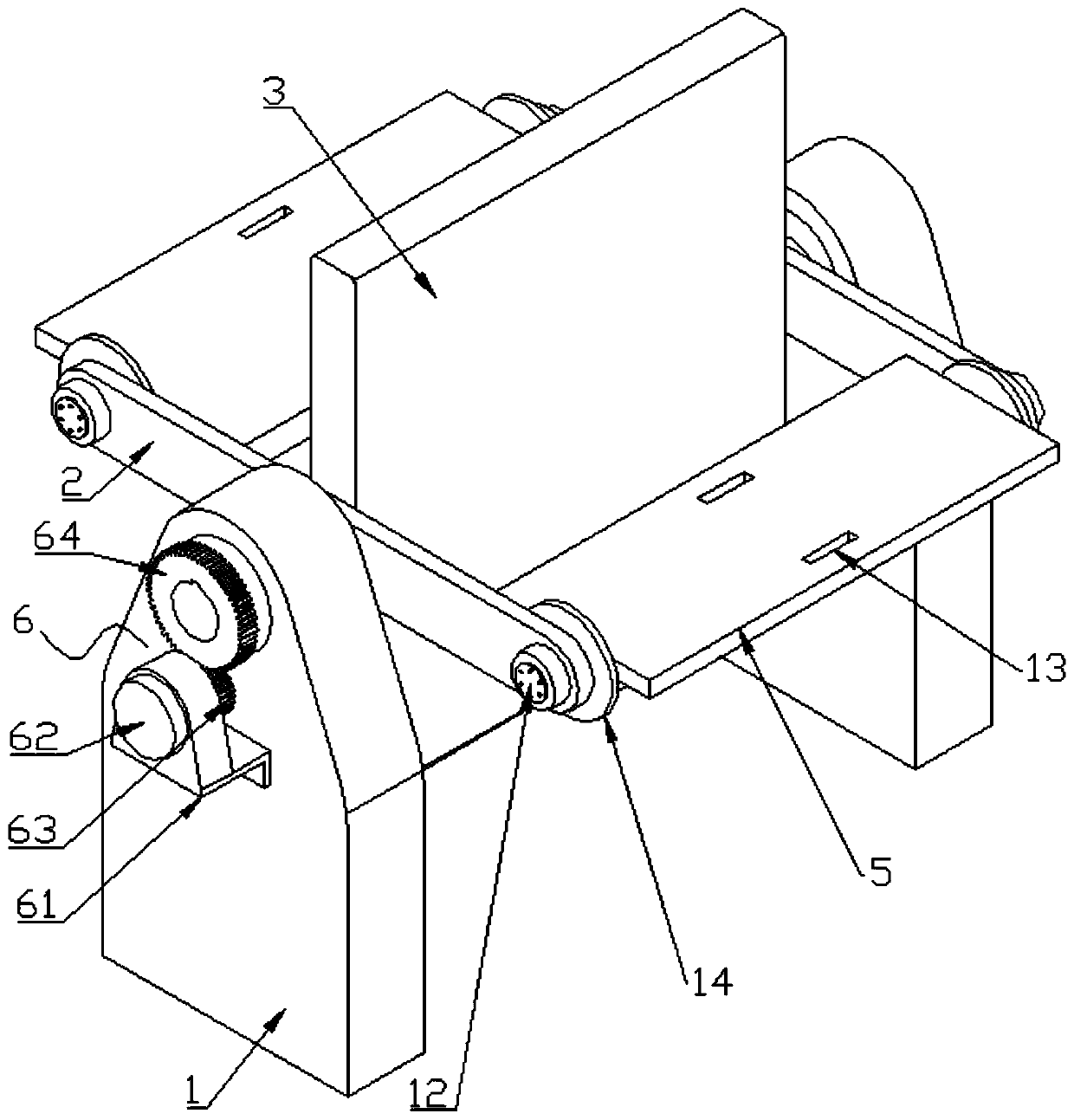

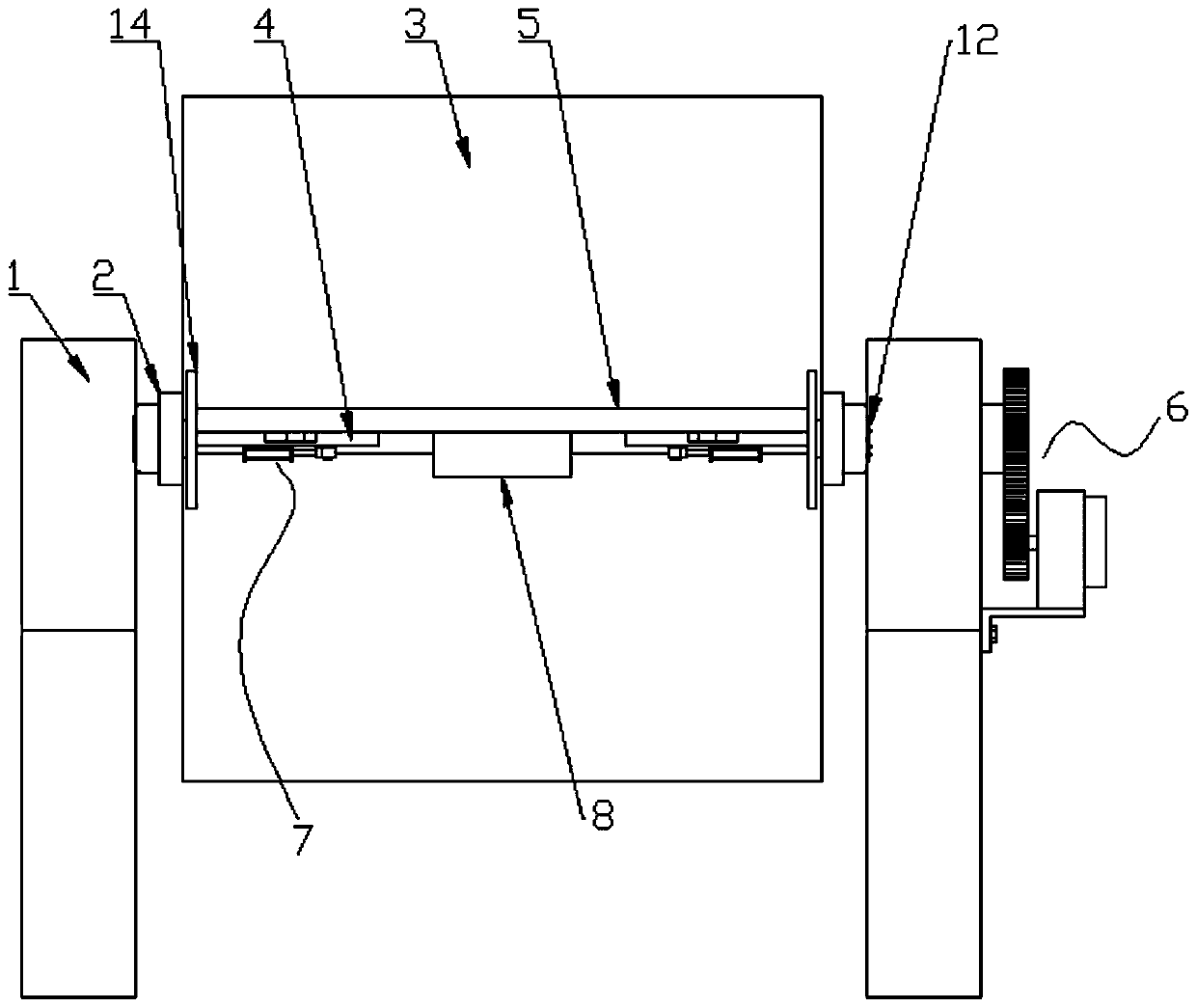

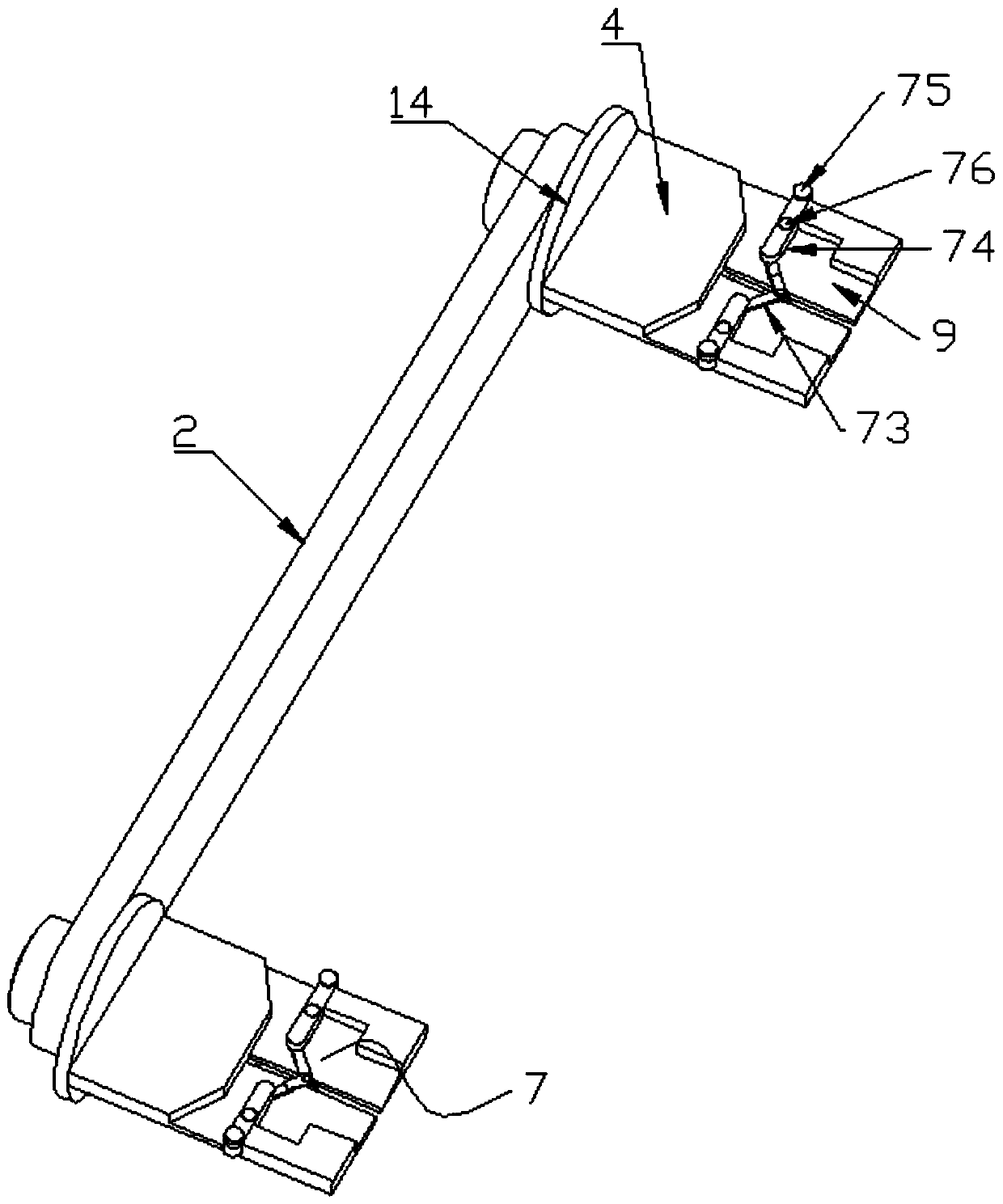

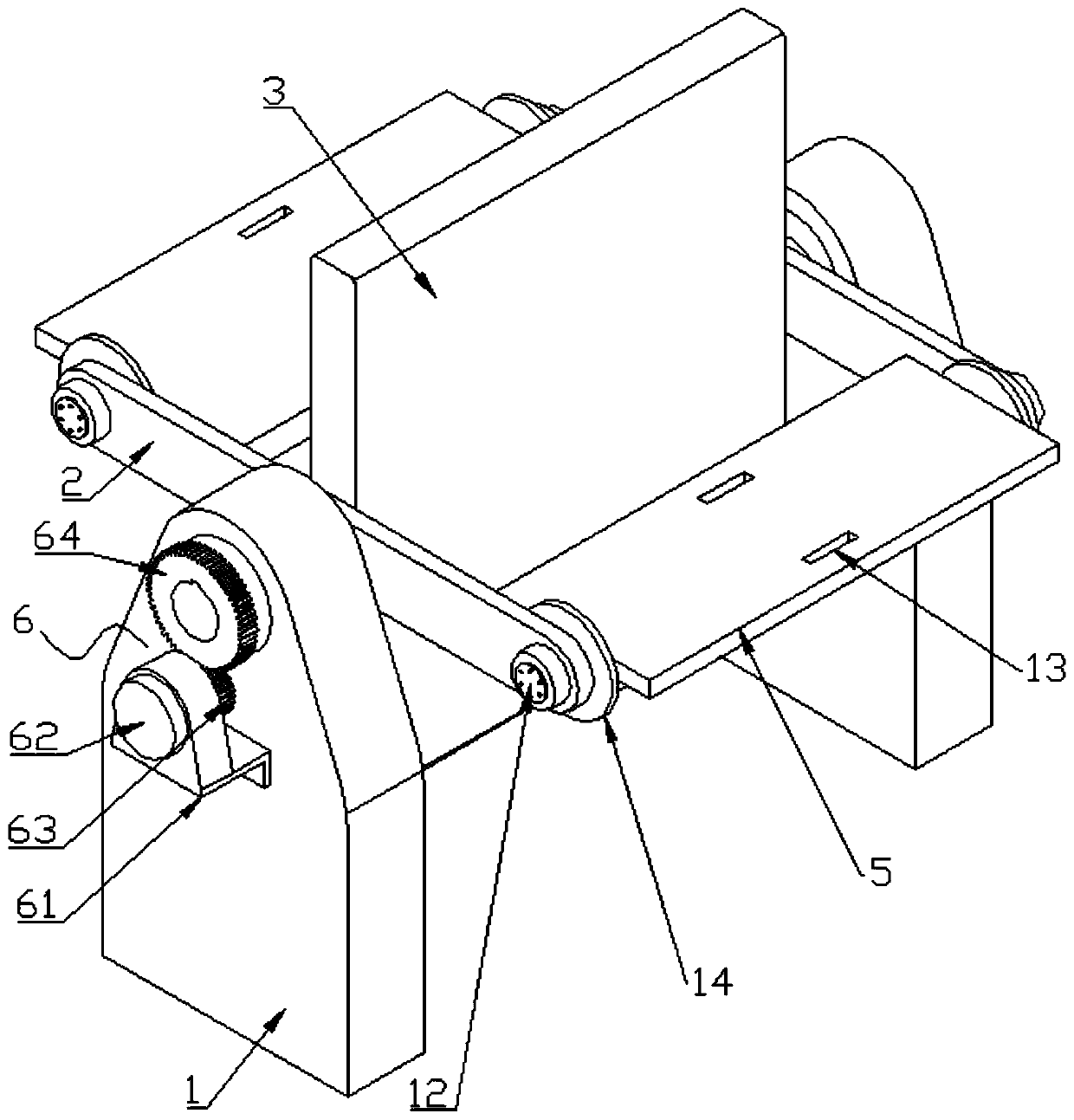

Hydraulic feeding mechanical hand

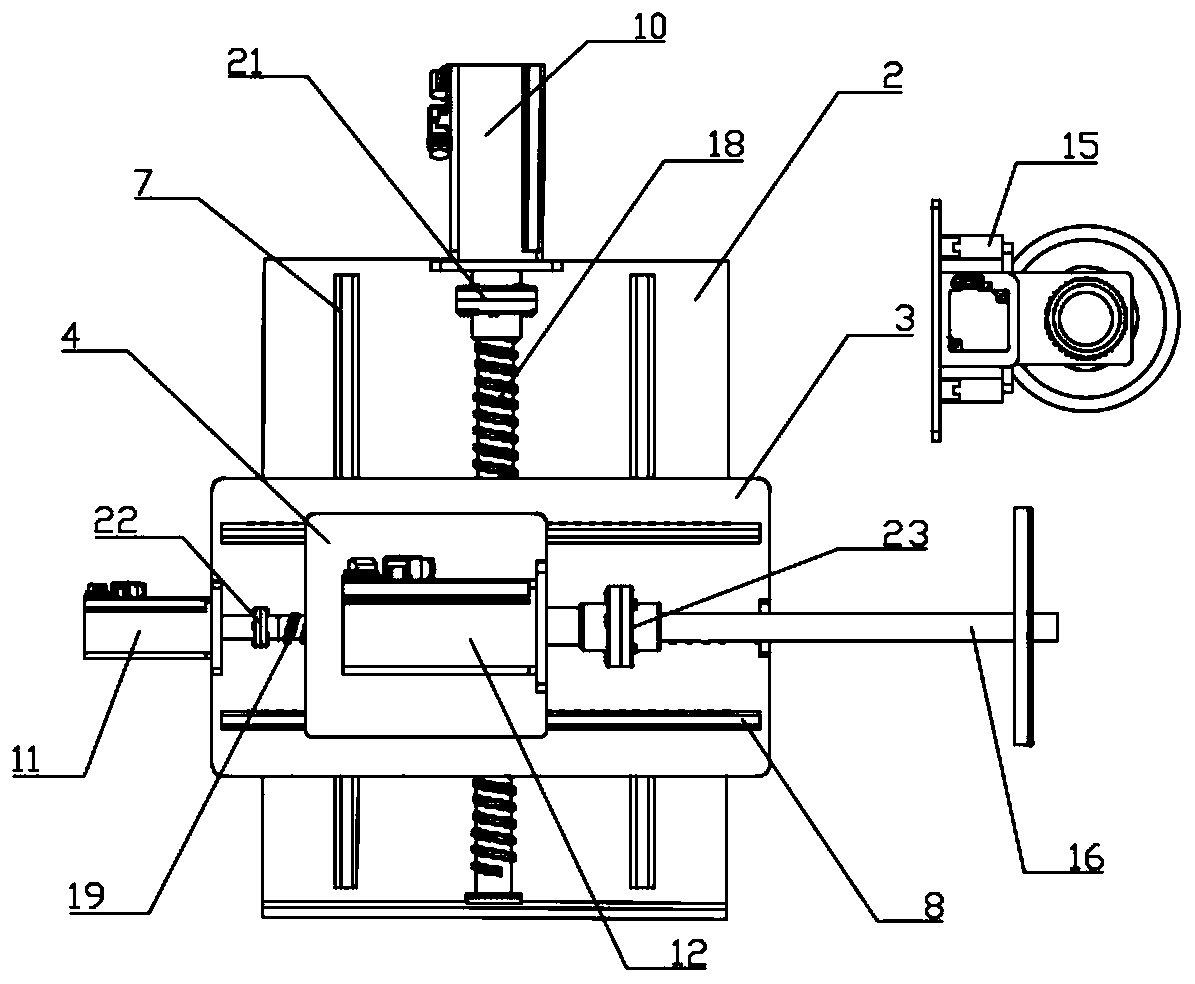

PendingCN107088782ACushion and adjust impact forcePrevent slidingProgramme-controlled manipulatorGripping headsHand partsRobot hand

The invention discloses a hydraulic feeding mechanical hand which comprises an arm assembly (1), a rotary wrist assembly (6) and a clamping type hand assembly (7). The arm assembly and the clamping type hand assembly are connected through the rotary wrist assembly (6). The arm assembly comprises an arm lifting mechanism (2), an arm bearing and positioning mechanism (3), an arm rotating mechanism (4) and an arm telescopic mechanism (5). The arm lifting mechanism is provided with the arm bearing and positioning mechanism in a fixedly connected mode through a fastening bolt (8). The arm bearing and positioning mechanism is provided with the arm rotating mechanism in a matched mode. The arm rotating mechanism is provided with the arm telescopic mechanism in a matched mode. According to the hydraulic feeding mechanical hand, structural design is simple and reasonable, applicability is quite good, a guide sleeve can be effectively prevented from sliding and tilting in the lifting process, buffer force can be provided when an arm descends, and the stroke of all the components in the device can be effectively controlled when the components are operated.

Owner:TAIZHOU POLYTECHNIC COLLEGE

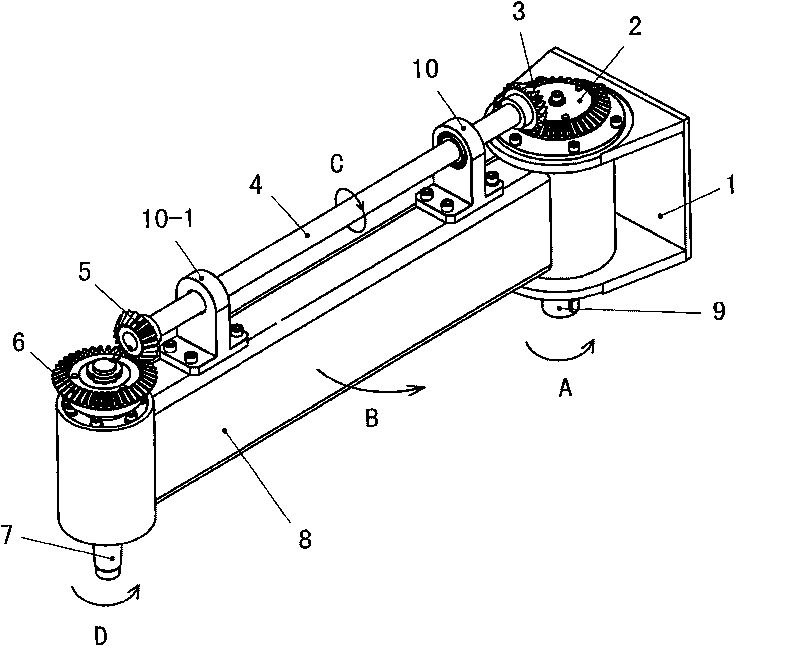

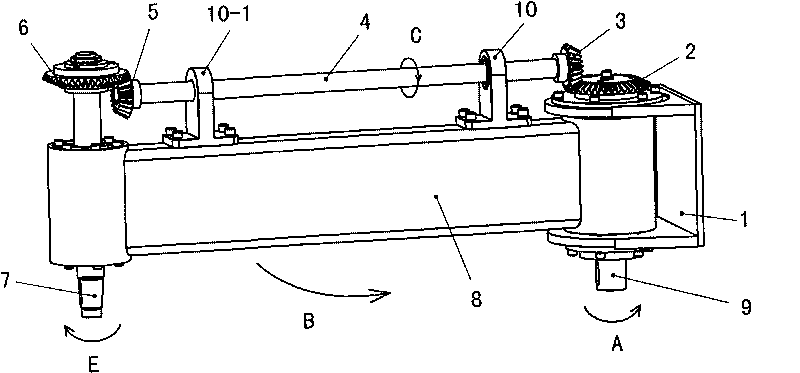

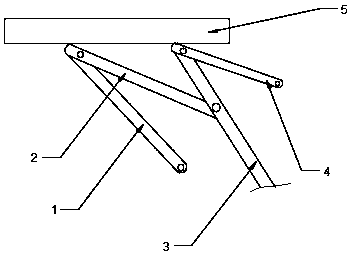

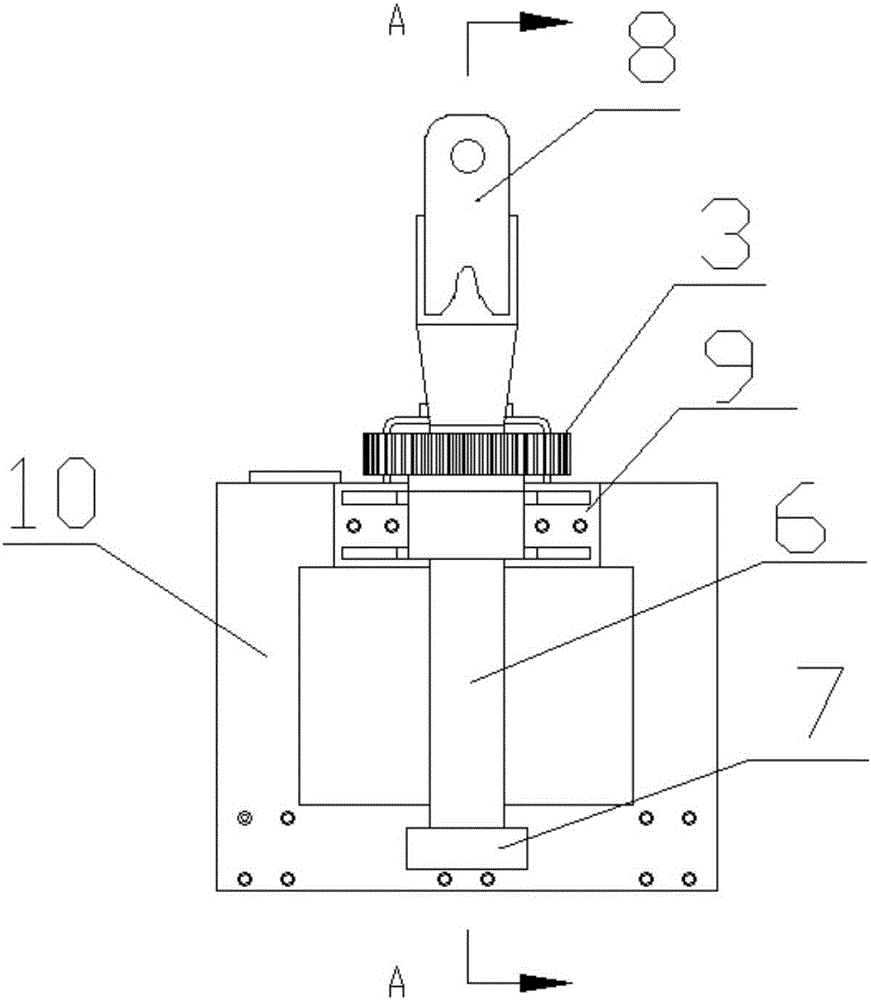

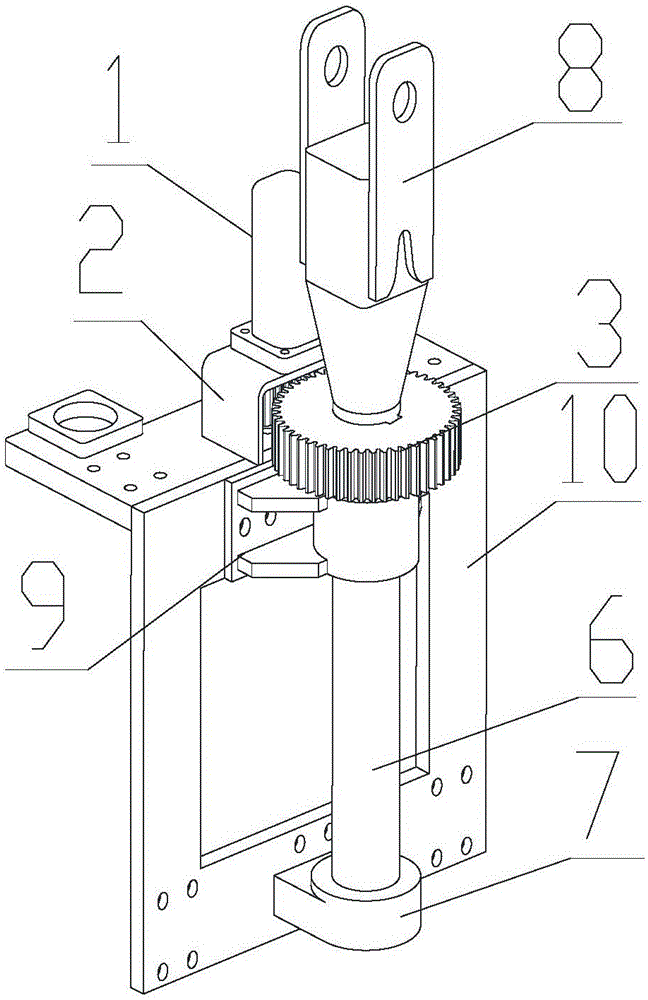

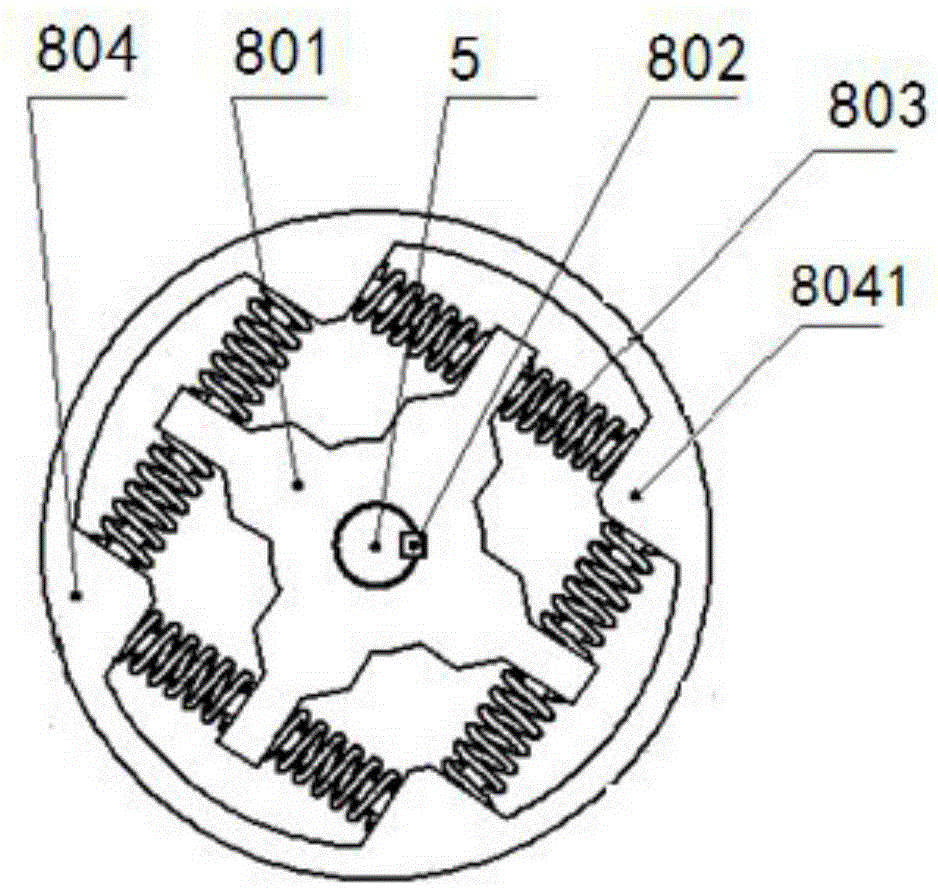

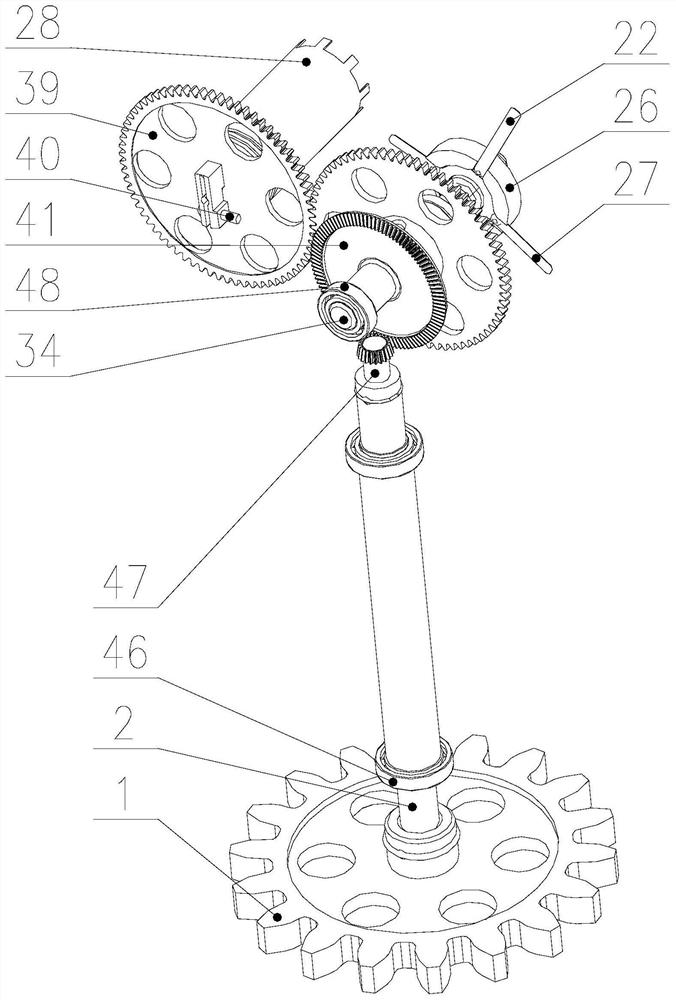

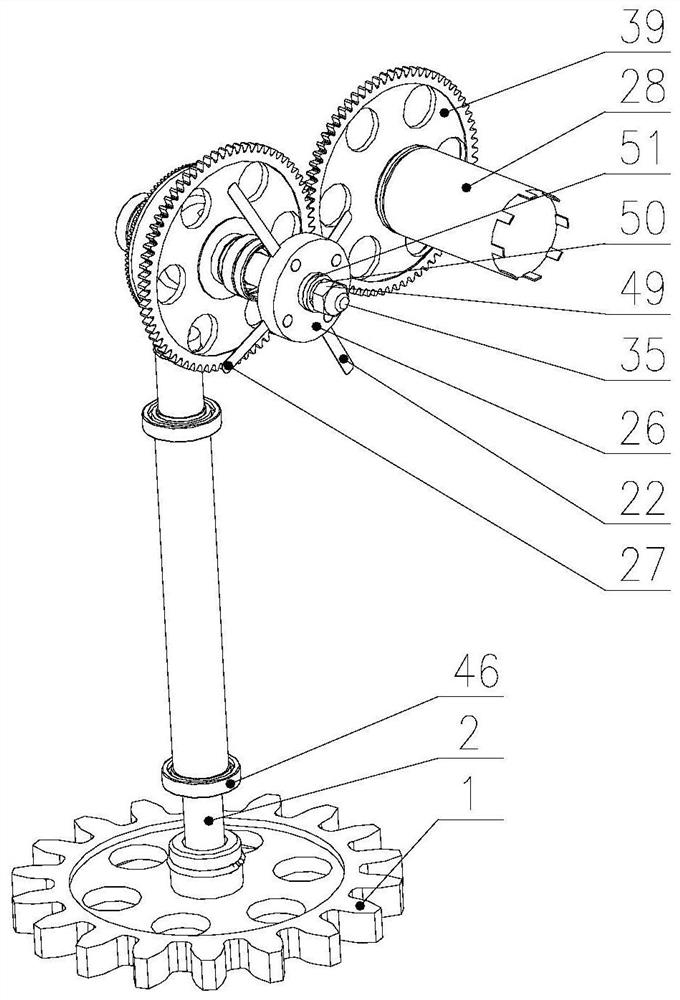

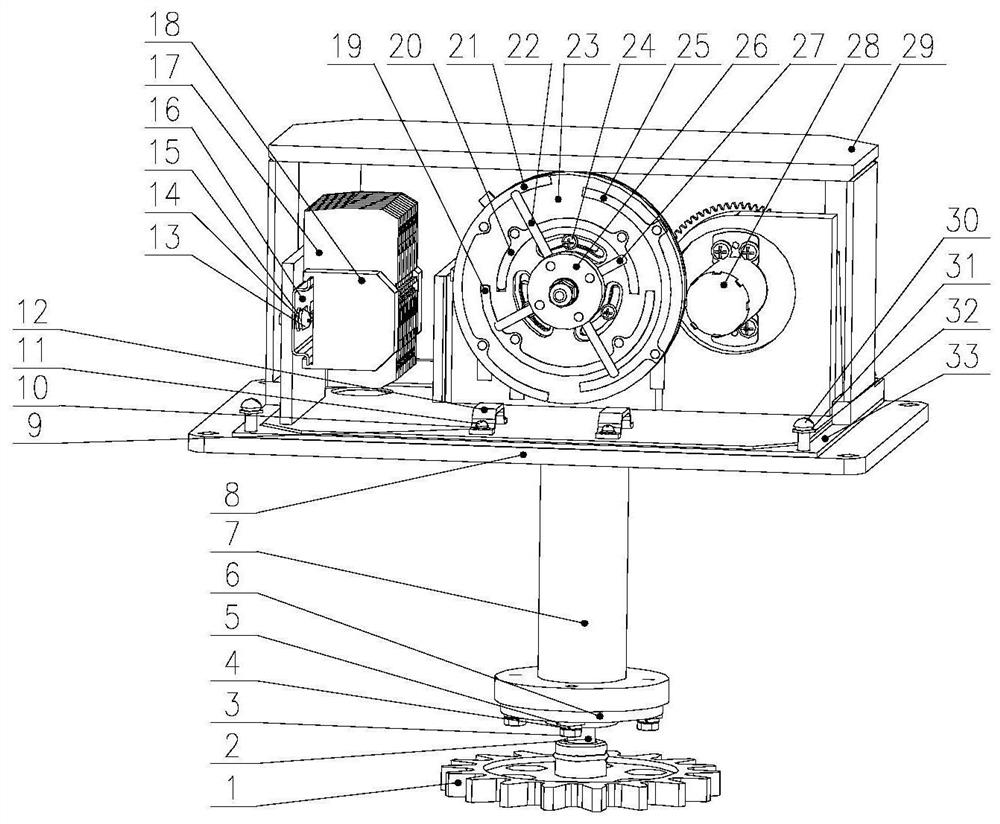

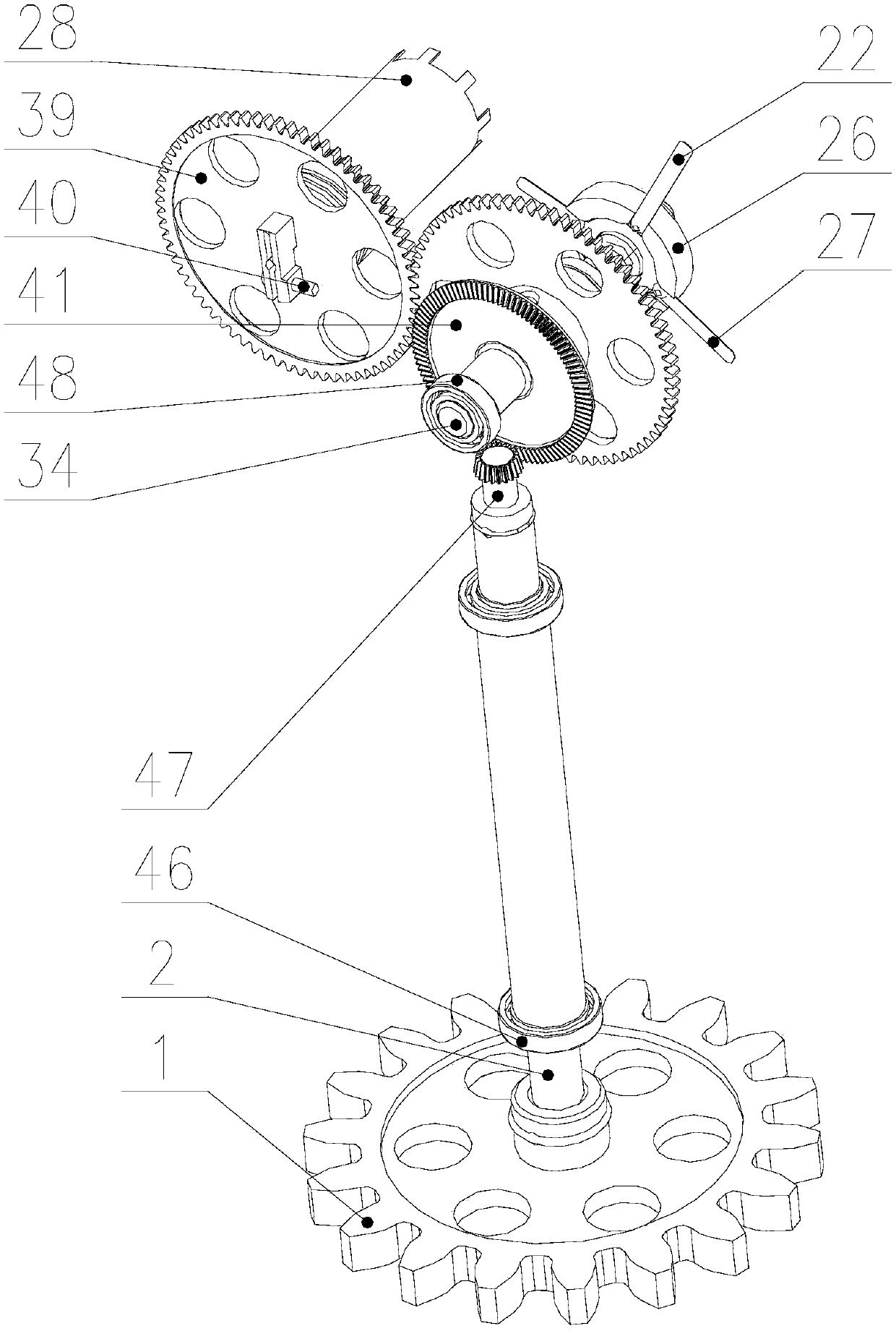

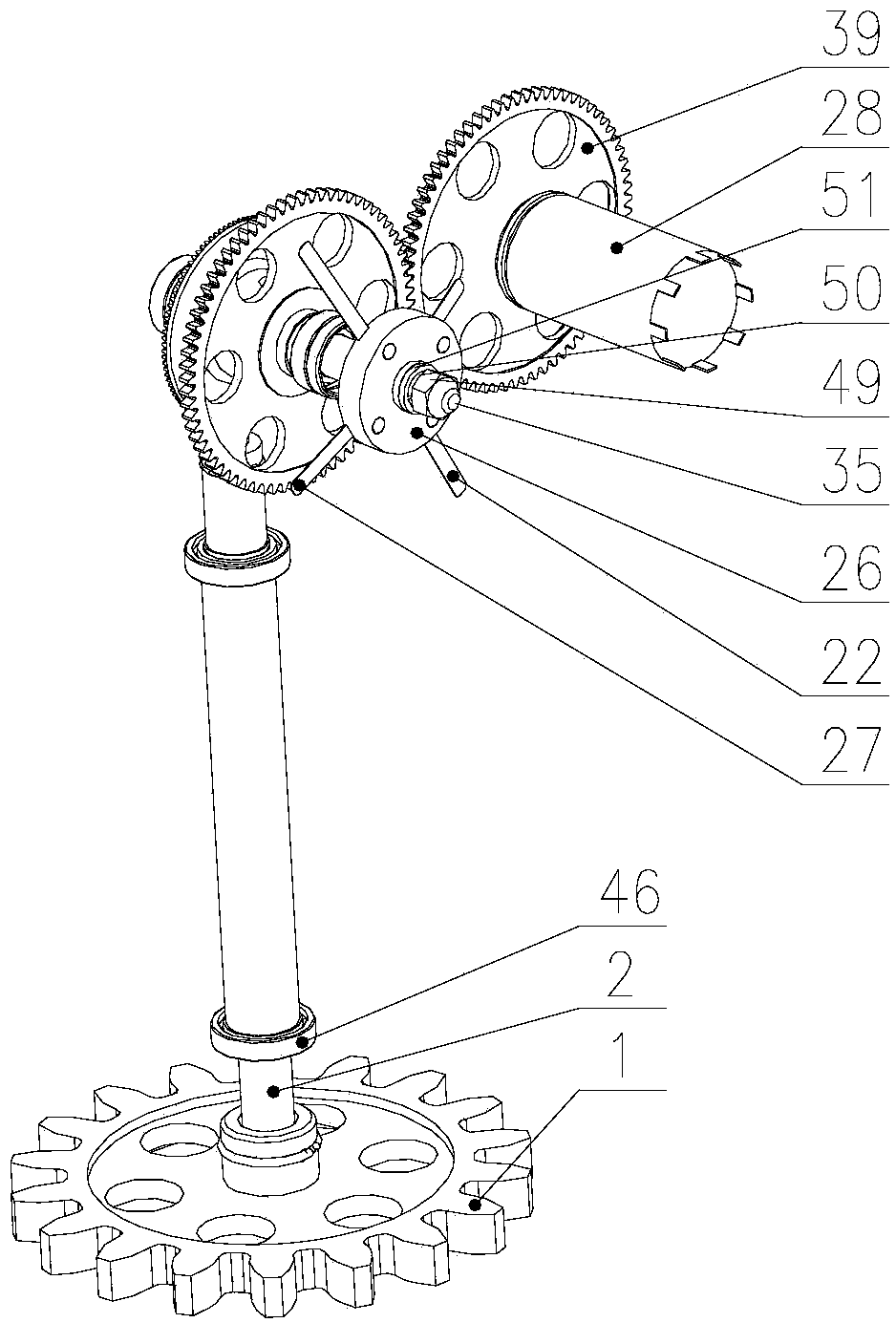

Wrist transmission mechanism of stacking robots

The invention relates to the field of mechanical transmission, and discloses a wrist transmission mechanism of stacking robots. In order to solve the problems such as complex structure, high cost and the like, the wrist transmission mechanism provides the following technical scheme which is characterized in that the right part of a swing arm (8) is in rotary connection with a bracket (1); a driving rotor (9) is fixedly connected with the right part of the swing arm (8); the right part of a transmission shaft passes through and is in rotary connection with a first bearing pedestal (10), while the left part passes through and is in rotary connection with a second bearing pedestal (10-1); the bottoms of the bearing pedestals are fixedly connected with the swing arm (8); a wrist rotor (7) is in rotary connection with the left end of the swing arm (8); the top of the wrist rotor (7) is fixedly connected with a fourth bevel gear (6), a first bevel gear (2) and the bracket (1); a second bevel gear (3) is fixedly connected with the right end of the transmission shaft (4) and is in meshed connection with the first bevel gear (2); and a third bevel gear (5) is fixedly connected with the left end of the transmission shaft (4) and is in meshed connection with the fourth bevel gear (6). The wrist transmission mechanism has the advantages of simple structure and low cost.

Owner:DONGHUA UNIV

Mechanical arm of robot

InactiveCN108527352AAchieve swingTo achieve elastic movementProgramme-controlled manipulatorGripping headsMechanical engineeringRobot

The invention discloses a mechanical arm of a robot. The mechanical arm of the robot is characterized in that a link arm is connected with a grabbing device, and drives the grabbing device to move, ajoint device is arranged inside the grabbing device, the link arm is formed by a four-link structure, the four-link structure is arranged on a machine frame in a hinged mode, and is connected with anarm plate, one end face of the arm plate is supported and fixed through the hinged position between a driving rod and a first link and the hinged position between a second link and a driven rod, the grabbing device is fixed at the other end face of the arm plate, and is provided with a first clamping block and a second clamping block, the lower end face of the first clamping block is provided witha sunken portion, the upper end face of the second clamping block is provided with a sunken portion, and the first clamping block and the second clamping block cooperate with each other to clamp an article. According to the mechanical arm of the robot, the rotational motion, the swinging motion and the loosing and tightening motion of the grabbing device are realized, and the positioning precision is high.

Owner:王潇

Continuous reciprocating stamping mechanism

InactiveCN108705856AEfficient embossing processRealize rotary motionRotary pressesPrinting press partsCircular discEngineering

The invention discloses a continuous reciprocating stamping mechanism, and belongs to the field of constructional material process machinery and equipment. A stamping mechanism and a driving mechanismof the continuous reciprocating stamping mechanism are sequentially and fixedly arranged on one side of a fixing bracket from the top down; a rotating disk is horizontally and fixedly arranged at theupper end of a transmission rotating shaft; the outer end of the upper side of the rotating disk is horizontally and rotatably connected with a transmission roller; a reciprocating guide plate is arranged at a guide plate rotating roll in the horizontal direction in a rolling manner; a reciprocating channel adapted to the transmission roller is horizontally arranged in a guide bracket on the lower side of the reciprocating guide plate; a printing stamper is horizontally and fixedly arranged at the middle part of the upper side of a substrate connecting plate; a lifting pressing plate is horizontally arranged on the upper side of the printing stamper; and the two sides of the lower part of a pressing roll bracket on the lower side of a pressing plate guide rod are horizontally and rotatably connected with stamping rotating rolls correspondingly. The continuous reciprocating stamping mechanism is reasonable in structural design, and a plate can be subjected to continuous reciprocating translational motion conveniently, quickly and stably and stamped quickly and efficiently to meet the requirements for machining and using.

Owner:徐阳

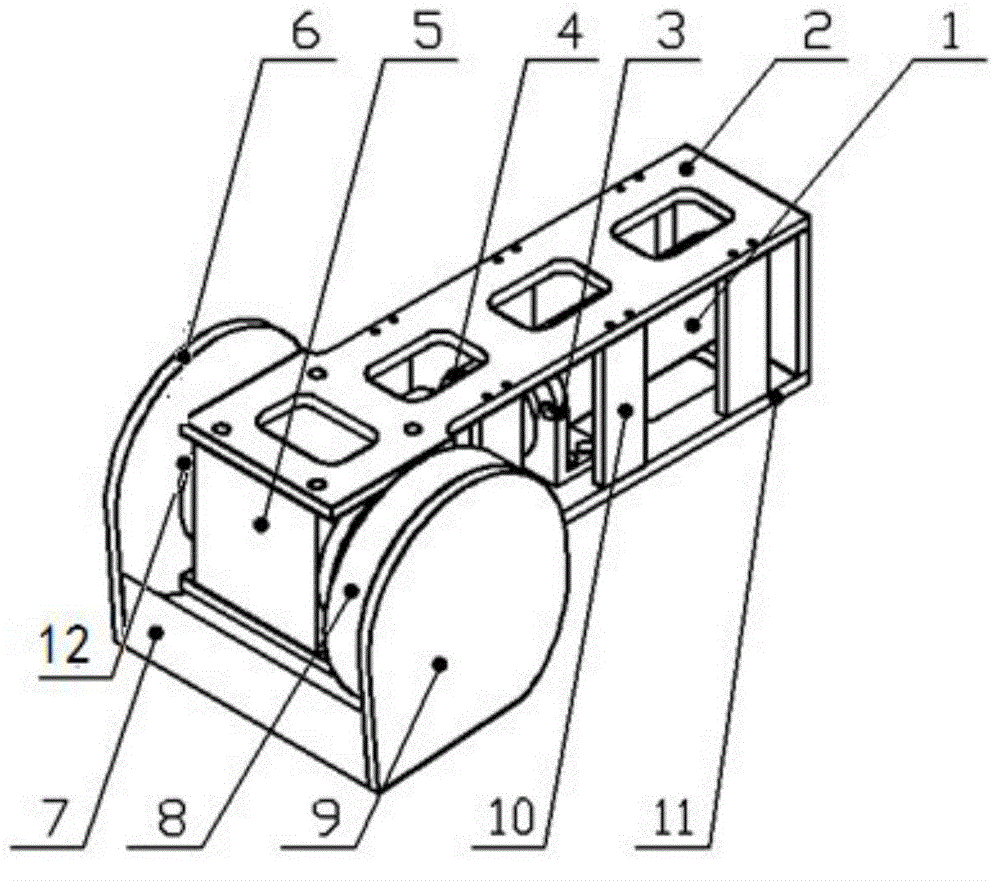

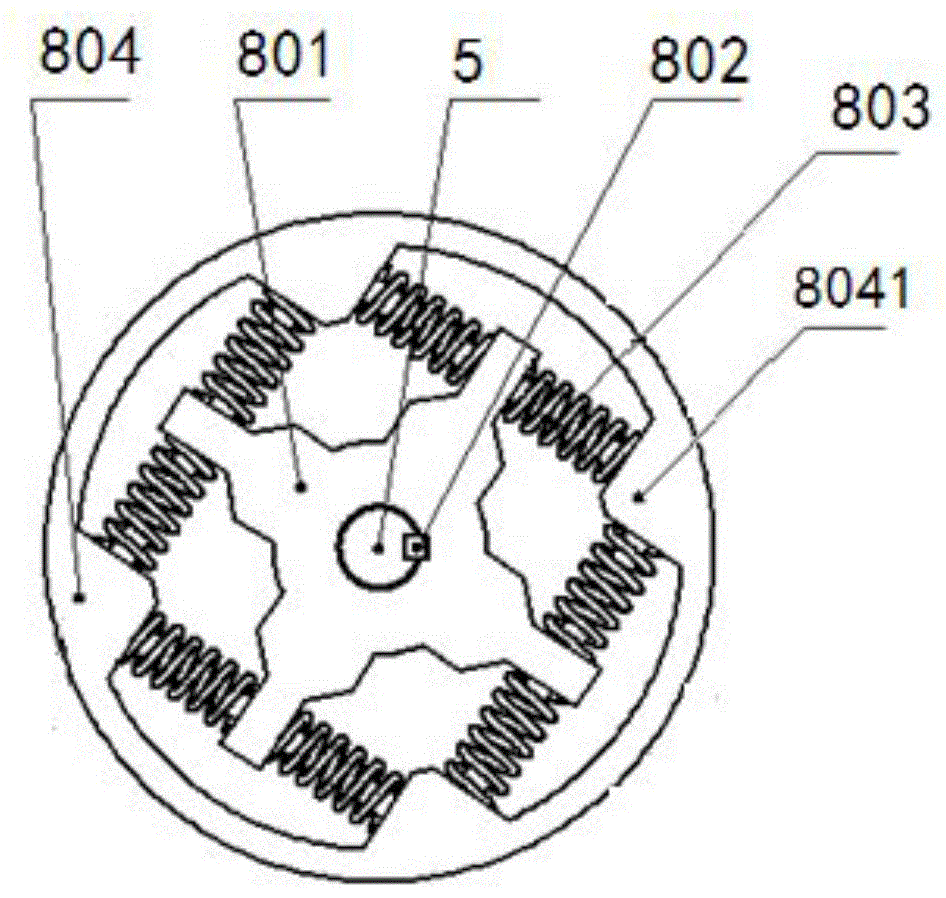

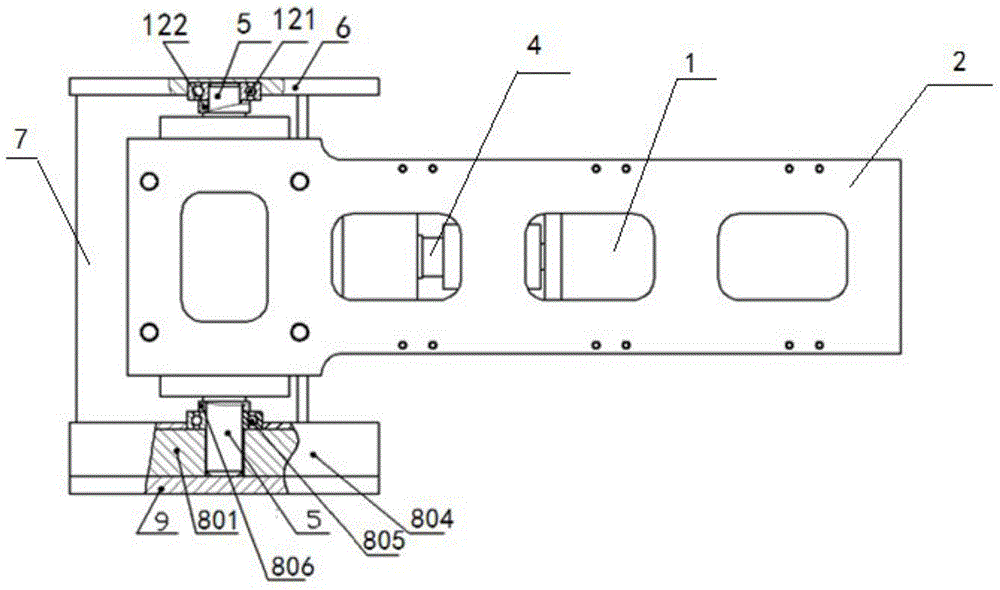

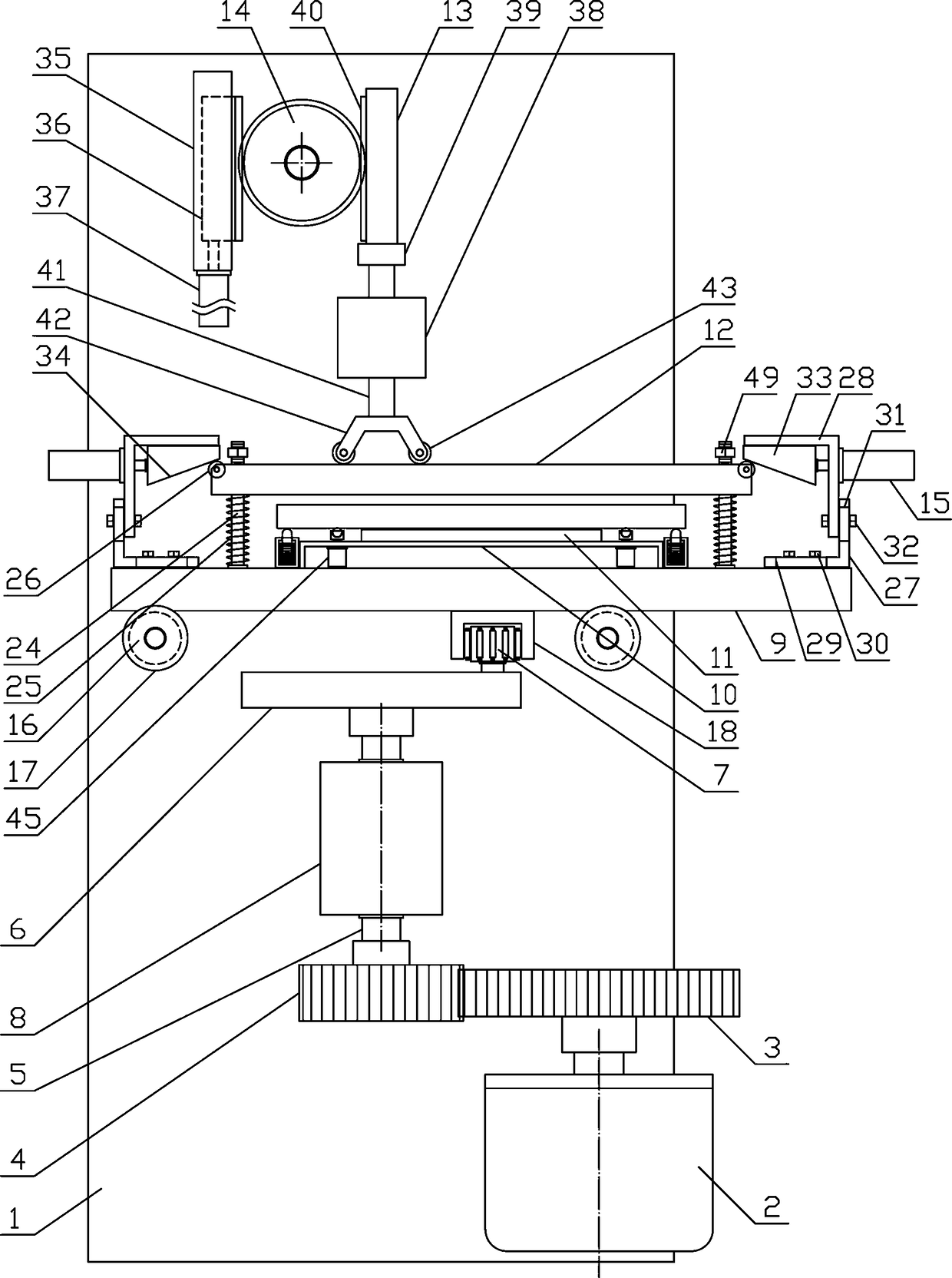

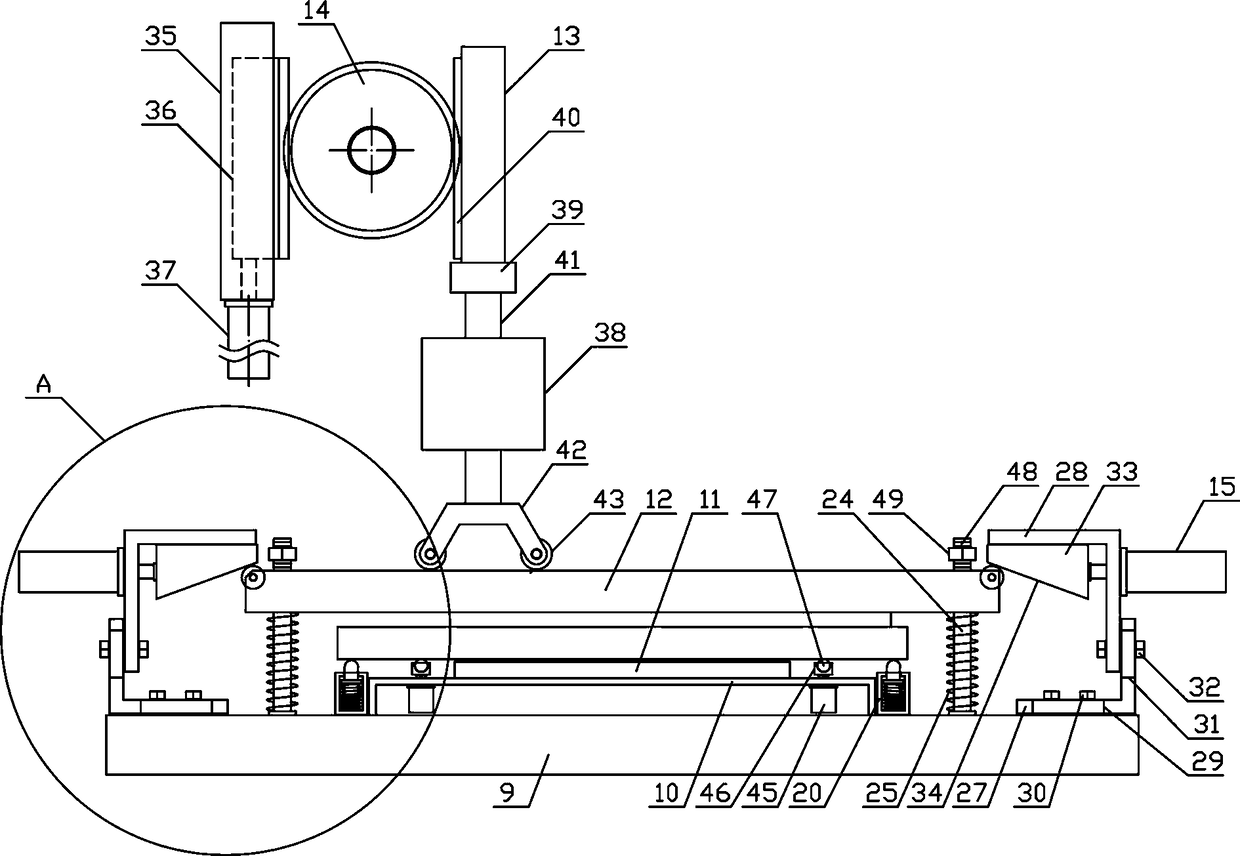

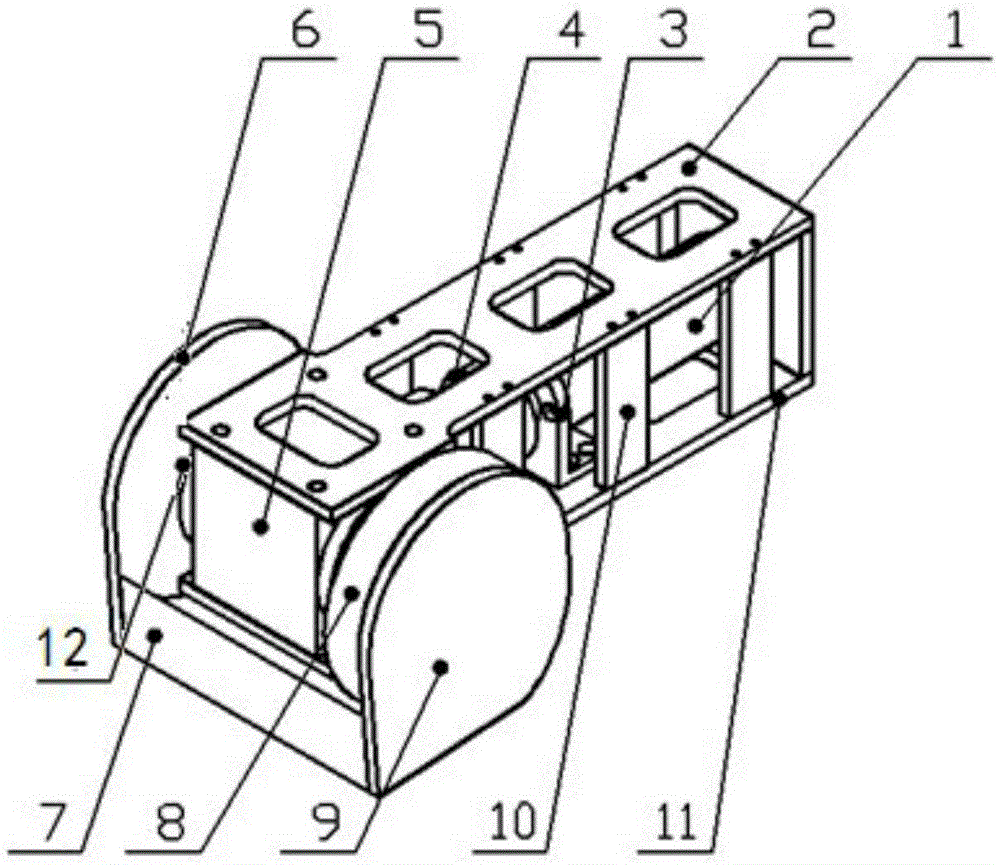

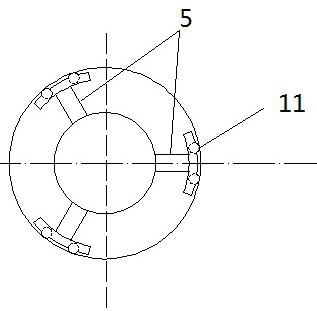

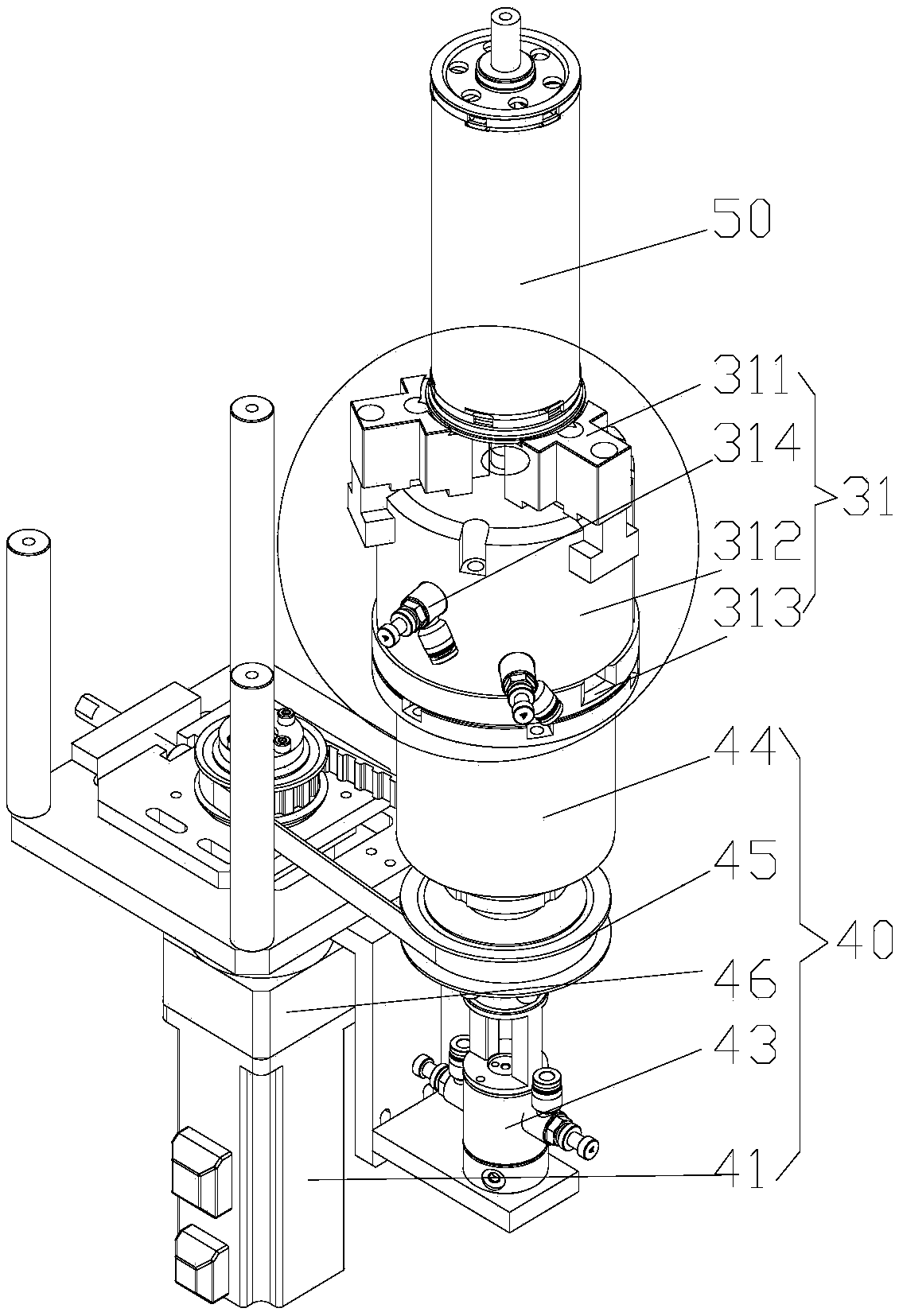

Testing device for reliability of grating encoder

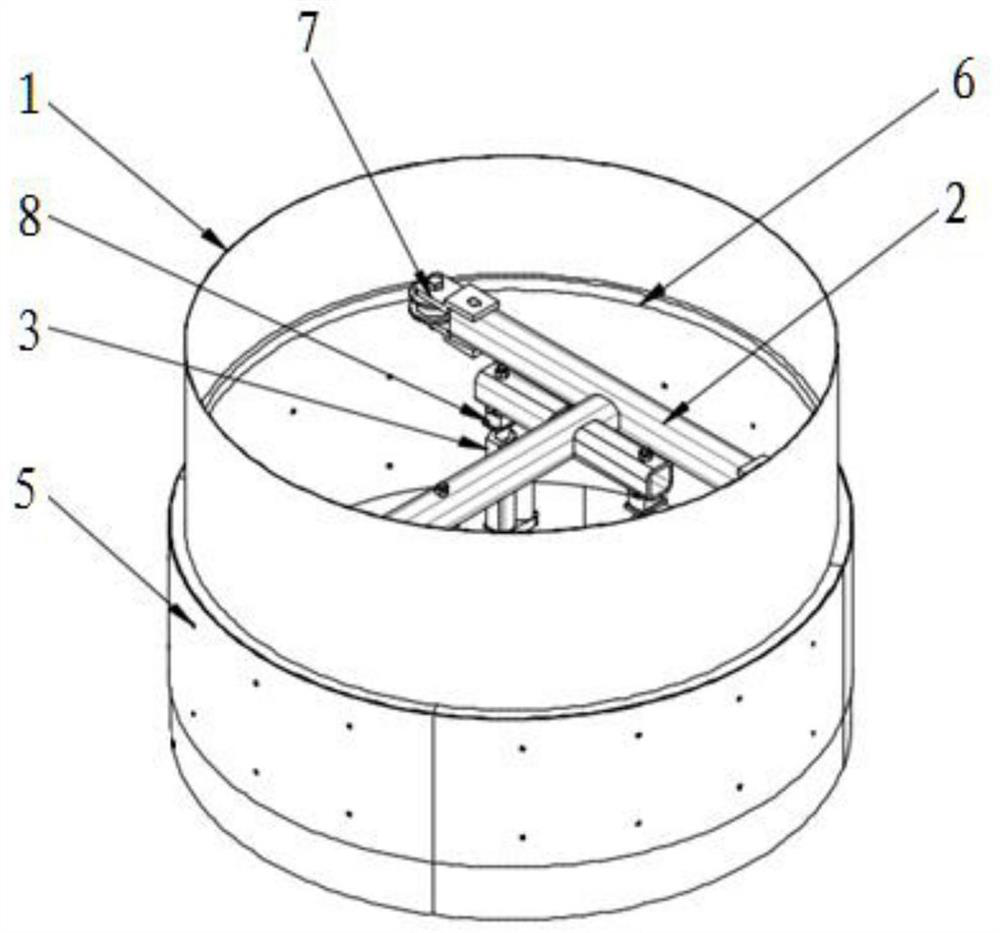

PendingCN108534817AEasy to repair and replaceImprove experimental efficiencyInstrumentsElectricityTest chamber

The invention discloses a testing device for the reliability for a grating encoder and aims at solving the problems of low reliability, high fault rate, low operation quantity and difficulty in detaching of the grating encoder. The testing device comprises a main body part, a high-low telescopic trolley, a work condition simulating device and a detection control system, wherein the main body partcomprises a rotating device (A), a handling device (B) and a mounting device; the rotating device (A) comprises a rotary supporting bearing (1); the handling device (B) comprises a boss (5); the high-low telescopic trolley comprises a docking table (150) and taper pins (155) mounted on the docking table (150); the work condition simulating device comprises a three-comprehensiveness test chamber (159); a three-comprehensiveness test chamber base plate (162) is arranged in the three-comprehensiveness test chamber (159); the main body part is mounted on the three-comprehensiveness test chamber base plate (162) through the rotary supporting bearing (1); the high-low telescopic trolley is connected with the boss (5) through the taper pin (155); the detection control system is electrically connected with the mounting device and the work condition simulating device.

Owner:JILIN UNIV

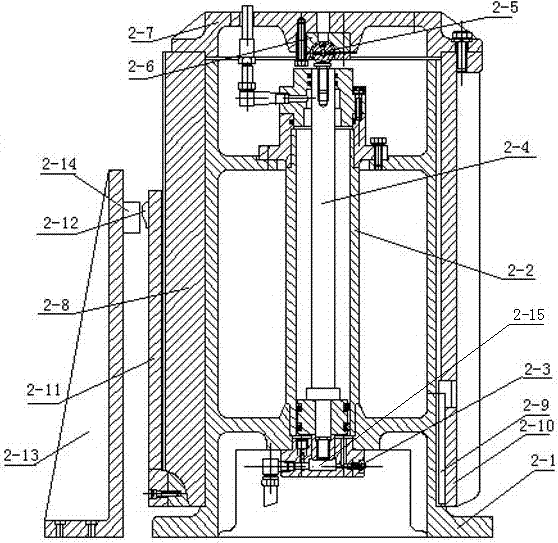

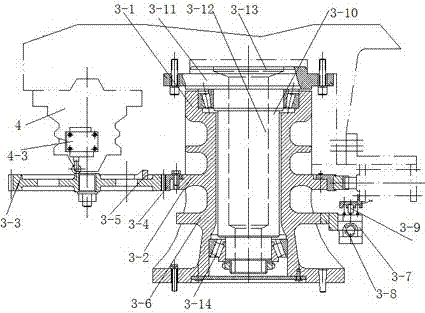

Clamp for performing turning on high pressure gas cylinder

The invention provides a clamp for performing turning on a high pressure gas cylinder, and relates to the technical field of mechanical processing tools. The clamp comprises a rotating support and a telescopic chuck, wherein the rotating support comprises a base, a supporting bearing arranged in the base and a support body, the support body is connected with an inner ring of the supporting bearing, the outer ring of the supporting bearing is connected with the base, the telescopic chuck comprises a cylinder barrel, a telescopic rod and a claw, the claw is connected with the front end of the telescopic rod, the telescopic rod is arranged in the cylinder barrel, and rotating-prevention mechanisms matched with each other are arranged on the cylinder barrel and the telescopic rod. Large-scale reformation on a lathe is not needed when the clamp is used for performing turning on the high pressure gas cylinder, only the telescopic rod and the claw need to be pushed by a pushing device of the lathe, the weight of the telescopic rod and the claw is light, and the friction force between the telescopic rod and the cylinder barrel is small, so that the pushing device of the lathe can push the telescopic rod and the claw with a smaller push force, the clamp is small in abrasion during use, and the service life is long.

Owner:衡阳金化高压容器股份有限公司

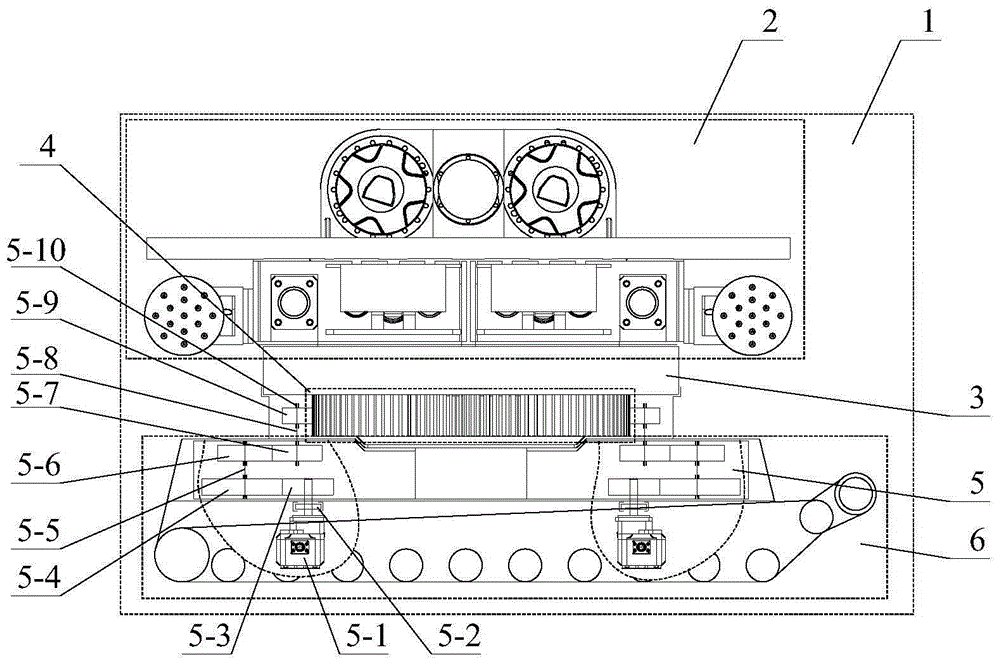

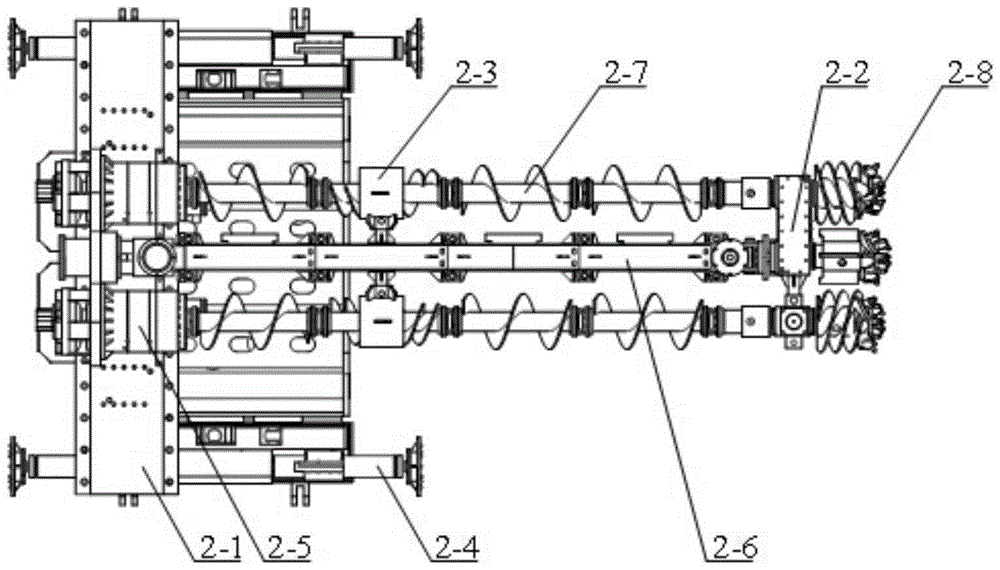

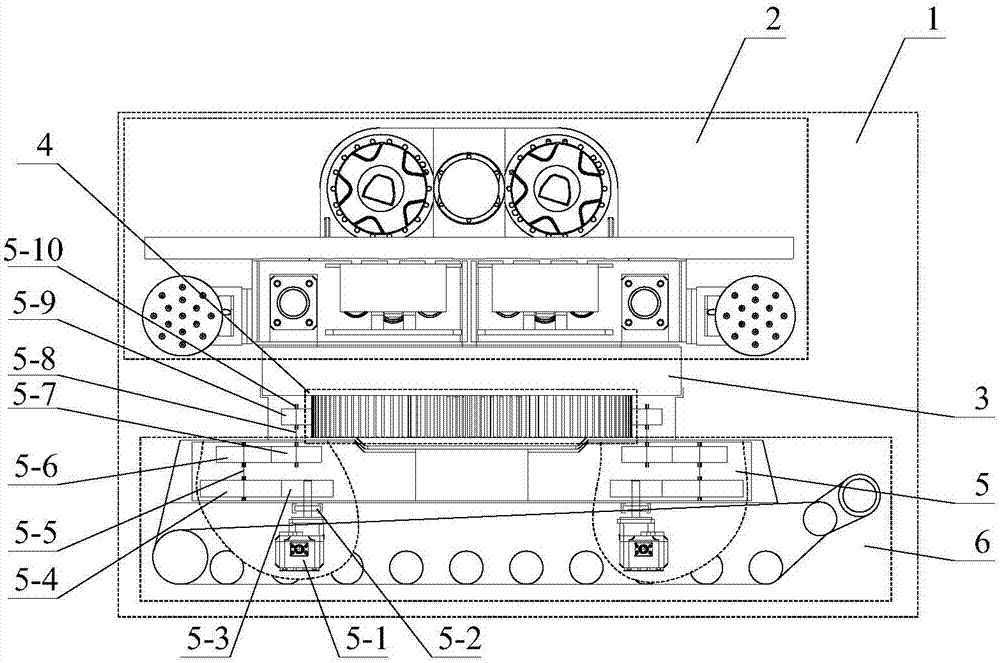

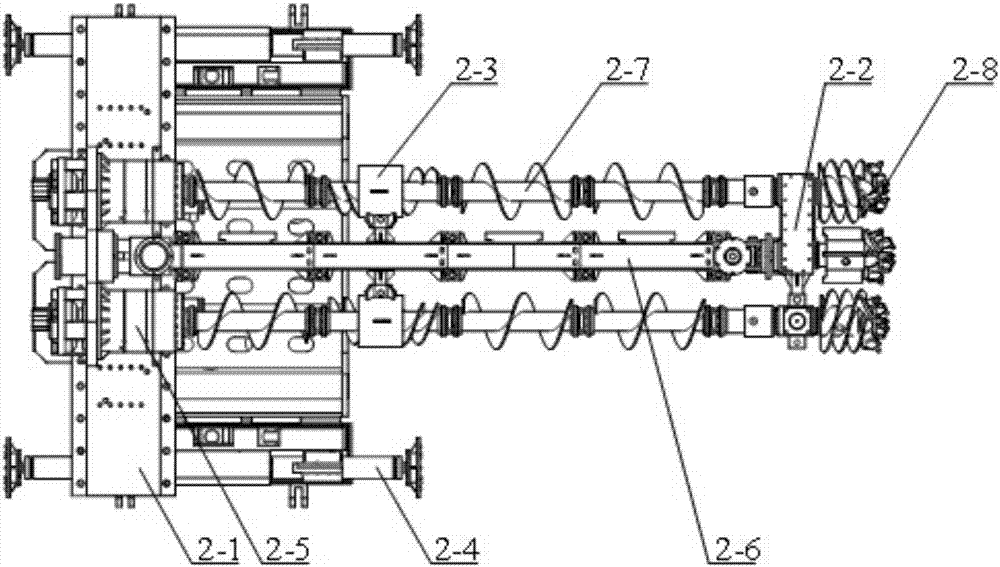

Tracked walking self-rotating bidirectional drilling coal mining machine and application method thereof

InactiveCN105178853ARealize rotary motionShorten the timeDerricks/mastsDrilling machines and methodsEngineeringMechanical engineering

The invention discloses a tracked walking self-rotating bidirectional drilling coal mining machine and an application method thereof. The coal mining machine comprises an upper frame assembly and a base arranged under the upper frame assembly. A rotary supporting device is arranged under the base. A tracked walking mechanism is arranged under the rotary supporting device. A transmission device connected with the rotary supporting device is arranged on the tracked walking mechanism. The drilling coal mining machine arranged in a roadway exploits one side of a thin seam, rotates by 360 degrees through controlling the rotary supporting device after the exploiting of the thin seam on the side, and exploits the other side after the rotary supporting device rotates to the other side of the thin seam, thereby allowing a screw drilling machine to bidirectionally mine coal at the same site without large moving equipment and greatly improving exploiting efficiency. In addition, when meeting a crossing on the way from a main roadway to a work face roadway, a screw bit can self-rotate, thus easily passing through the roadway crossing to reach a work face and saving equipment moving time.

Owner:CHINA UNIV OF MINING & TECH

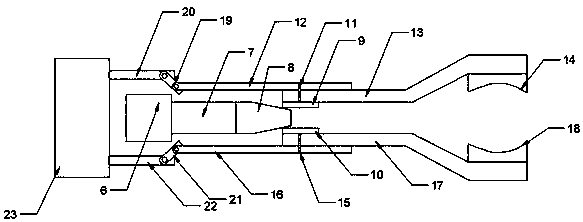

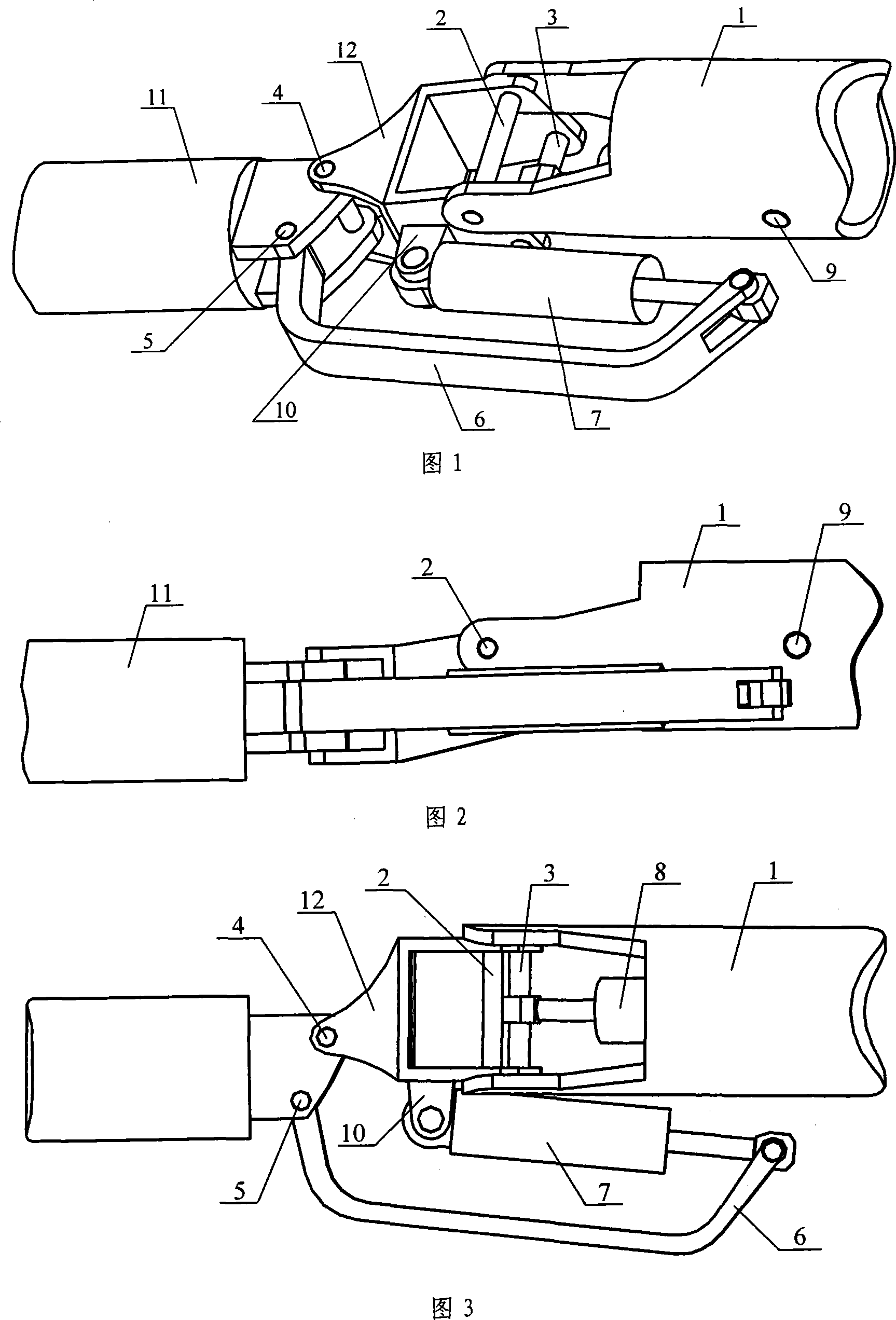

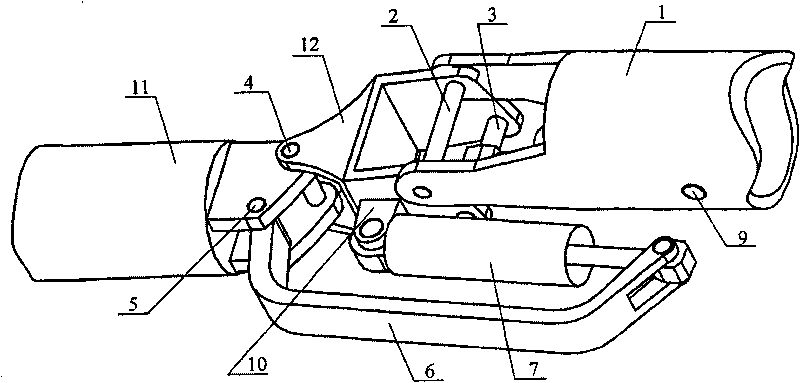

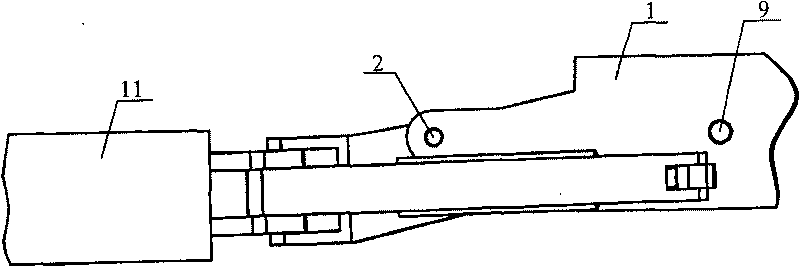

Submarine manipulator wrist joint structure with three degrees of freedom

InactiveCN101224582ACompact designRealize three degrees of freedom movementJointsUnderwater equipmentHydraulic cylinderHydraulic motor

The invention provides an underwater manipulator three degrees of freedom(DOFs) wrist structure. A connecting frame 12 is respectively connected with a front arm 1 and a wrist 11 through a wrist pitching rotating shaft 2 and a wrist yaw rotating shaft 4; the bottom end of a second hydraulic cylinder 8 in the front arm 1 is arranged on a coupling spindle 9 at the bottom of the hydraulic cylinder in a cavity of the front arm 1; the end of the piston rod of the second hydraulic cylinder 8 is connected with a piston rod coupling spindle 3 of the hydraulic cylinder on the connecting frame 12; one end of a connecting rod 6 is connected with a connecting rod coupling spindle 5 of the wrist 11; the other end of the connecting rod 6 is connected with a piston rod of a first hydraulic cylinder 7; the bottom of the hydraulic cylinder is fixed on the connecting frame 12; a hydraulic motor is arranged inside the wrist 11. The whole wrist has compact structural design, can realize the three DOFs motion of the wrist, and has the advantages of flexible operation, improving the operation space, reducing the operation dead areas of the underwater manipulator, etc.

Owner:HARBIN ENG UNIV

180-degree rotary arm

InactiveCN106069233ARealize rotary motionHedge trimming apparatusCuttersChinese charactersTransverse plane

The invention discloses a 180-degree rotary arm which comprises a moving rack, wherein the moving rack consists of a transverse plate and a longitudinal frame; the transverse plate is perpendicular to the longitudinal frame; the top surface of the transverse plate is parallel to that of the longitudinal frame; a motor fixing base is arranged at the top of the transverse plate; a motor is arranged on the motor fixing base; the motor fixing base is hollow, and the front part of the motor fixing base is lost; a small gear is arranged inside the motor fixing base; the bottom of a motor penetrates through the motor fixing base and is connected with the small gear; the small gear is exposed in front of the fixing base; the power of the motor is supplied by a hydraulic system; the longitudinal frame is in the shape of a Chinese character 'Hui'; a fixing sleeve is arranged on the front part of the longitudinal frame; a rotary arm is arranged on a rotary arm base; the fixing sleeve is used for fixing the rotary arm; the middle part of the rotary arm is sleeved by a large gear; and two moving arm connecting plates are arranged on the front side and rear side of the top of the large gear. By adopting the 180-degree rotary arm, rotary movement of 180 degrees can be achieved.

Owner:天津迈克重工有限公司

A flexible joint for articulated robots

The invention discloses a flexible joint for a joint robot. The flexible joint is characterized by comprising a motor, a joint connecting plate, a motor frame, a coupling, a bevel gear commutator, a first connecting plate, a connecting frame, a flexible output end, a second connecting plate, a support plate, a joint mounting plate and a support end, wherein the joint connecting plate and the joint mounting plate are fixedly connected through the support plate; the motor is fixedly connected with the motor frame through bolts; the motor frame is fixedly connected with the joint mounting plate through bolts; the motor is connected with the bevel gear commutator through the coupling; one end of the output shaft of the bevel gear commutator is connected with the flexible output end through a flexible output end sleeve and a second support bearing sequentially from inside to outside; the other end of the output shaft of the bevel gear commutator is connected with the support end through a support end sleeve and a first support bearing sequentially from inside to outside; the support end is connected with the first connecting plate.

Owner:HEBEI UNIV OF TECH

A crawler walking self-rotating two-way drilling coal mining machine and its use method

InactiveCN105178853BRealize rotary motionShorten the timeDerricks/mastsDrilling machines and methodsEngineeringMobile device

Provided are a tracked walking, self-rotating bidirectional drilling coal mining machine and an application method thereof. The coal mining machine comprises a coal mining machine upper frame assembly (2) and a coal mining machine base (3) provided under the coal mining machine upper frame assembly (2). A rotary supporting device (4) is provided under the coal mining machine base. A tracked walking mechanism (6) is provided under the rotary supporting device (4). A transmission device (5) connected to the rotary supporting device (4) is provided on the tracked walking mechanism (6). The drilling coal mining machine disposed in a roadway firstly mines one side of a thin seam, rotates by 360° by controlling the rotary supporting device (4) after finishing mining the thin seam on the side, and mines the other side after the rotary supporting device (4) rotates to the other side of the thin seam, thereby allowing a screw drilling machine to bidirectionally mine coal at the same site without moving the equipment greatly, thus improving mining efficiency. In addition, when a crossing appears en route from a main roadway to a working face roadway, a screw bit can self-rotate, thus easily passing through the roadway crossing to reach a working face and saving on equipment moving time.

Owner:CHINA UNIV OF MINING & TECH

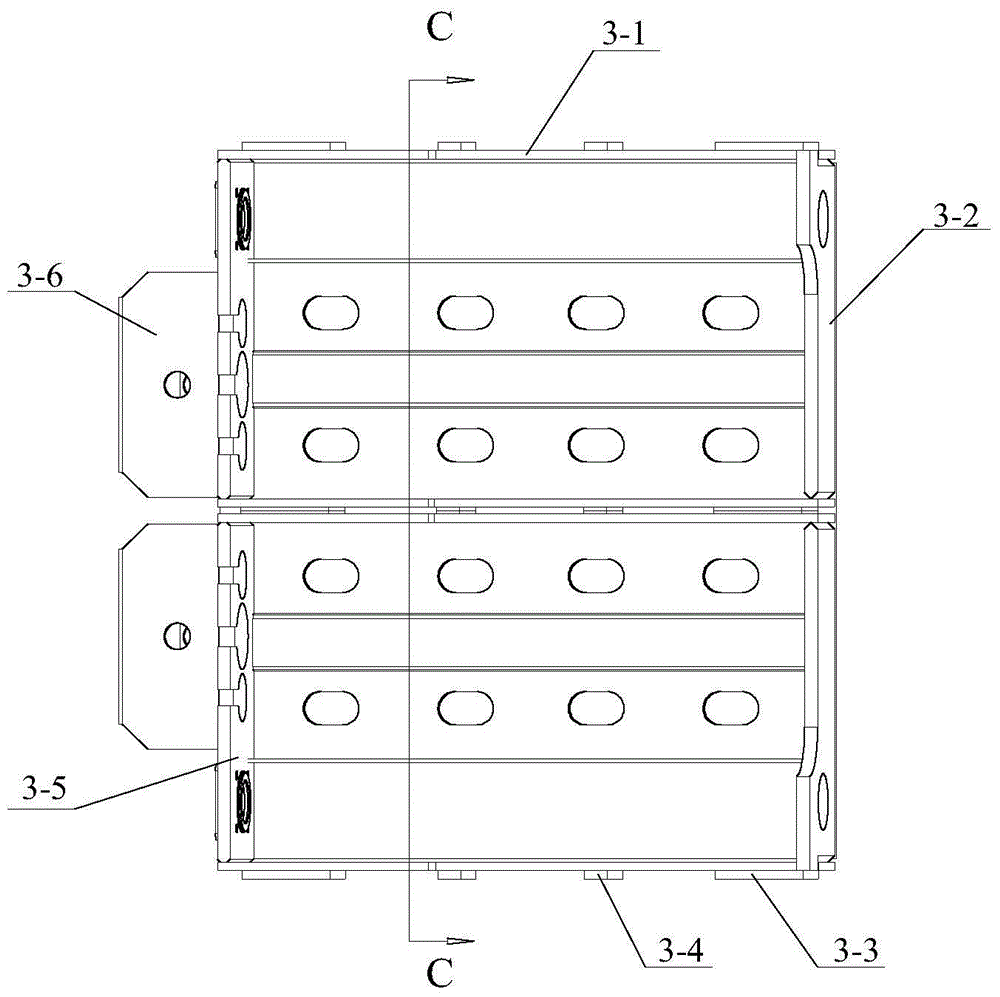

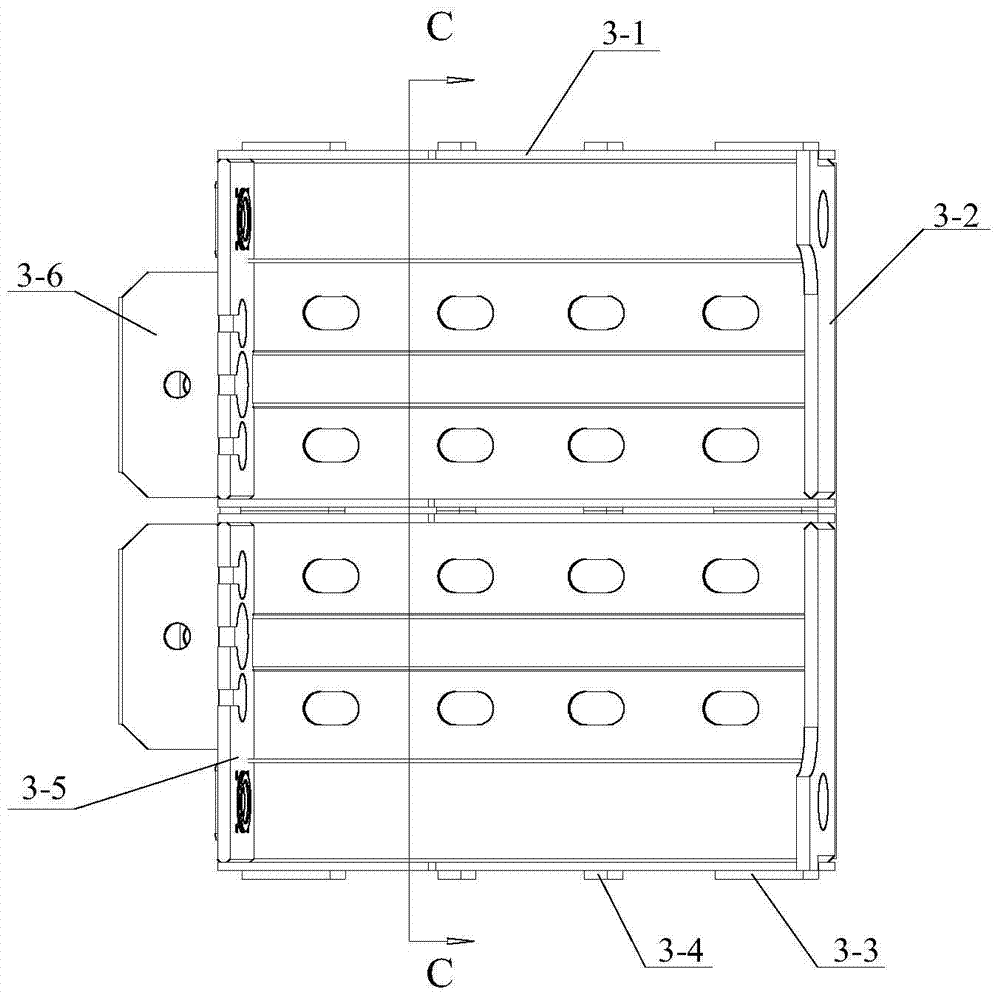

A New Automobile Chassis Quick Change Robot Welding Station

ActiveCN109940330BImprove securityImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryMachine

The invention discloses a novel automobile chassis rapid-switching robot welding station and relates to the technical field of automobile part welding. The novel automobile chassis rapid-switching robot welding station comprises machine seats, rotary supports, a clapboard, supporting platforms, fixtures and locking mechanisms, wherein the bottoms of the fixtures are provided with a battery box, and the battery box is internally provided with a storage battery. The novel automobile chassis rapid-switching robot welding station adopts a rotary type structure, when one of the fixtures performs welding operations in a welding area, the other fixture is in a rest state, at this moment, material unloading and material loading can be performed on the fixture in the rest state, and the two fixtures are separated through the clapboard, the operation safety is also improved, compared with a traditional plane type layout, more space is saved, the work efficiency is improved, the two fixtures canbe of different models, and switching of welding commands of a welding robot is just needed.

Owner:达奥(芜湖)汽车制品有限公司

Novel automobile chassis rapid-switching robot welding station

ActiveCN109940330AImprove securityImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention discloses a novel automobile chassis rapid-switching robot welding station and relates to the technical field of automobile part welding. The novel automobile chassis rapid-switching robot welding station comprises machine seats, rotary supports, a clapboard, supporting platforms, fixtures and locking mechanisms, wherein the bottoms of the fixtures are provided with a battery box, and the battery box is internally provided with a storage battery. The novel automobile chassis rapid-switching robot welding station adopts a rotary type structure, when one of the fixtures performs welding operations in a welding area, the other fixture is in a rest state, at this moment, material unloading and material loading can be performed on the fixture in the rest state, and the two fixtures are separated through the clapboard, the operation safety is also improved, compared with a traditional plane type layout, more space is saved, the work efficiency is improved, the two fixtures canbe of different models, and switching of welding commands of a welding robot is just needed.

Owner:达奥(芜湖)汽车制品有限公司

Submarine manipulator wrist joint structure with three degrees of freedom

InactiveCN101224582BSimple organizationCompact structureJointsUnderwater equipmentHydraulic motorHydraulic cylinder

The invention provides an underwater manipulator three degrees of freedom(DOFs) wrist structure. A connecting frame 12 is respectively connected with a front arm 1 and a wrist 11 through a wrist pitching rotating shaft 2 and a wrist yaw rotating shaft 4; the bottom end of a second hydraulic cylinder 8 in the front arm 1 is arranged on a coupling spindle 9 at the bottom of the hydraulic cylinder ina cavity of the front arm 1; the end of the piston rod of the second hydraulic cylinder 8 is connected with a piston rod coupling spindle 3 of the hydraulic cylinder on the connecting frame 12; one end of a connecting rod 6 is connected with a connecting rod coupling spindle 5 of the wrist 11; the other end of the connecting rod 6 is connected with a piston rod of a first hydraulic cylinder 7; thebottom of the hydraulic cylinder is fixed on the connecting frame 12; a hydraulic motor is arranged inside the wrist 11. The whole wrist has compact structural design, can realize the three DOFs moti on of the wrist, and has the advantages of flexible operation, improving the operation space, reducing the operation dead areas of the underwater manipulator, etc.

Owner:HARBIN ENG UNIV

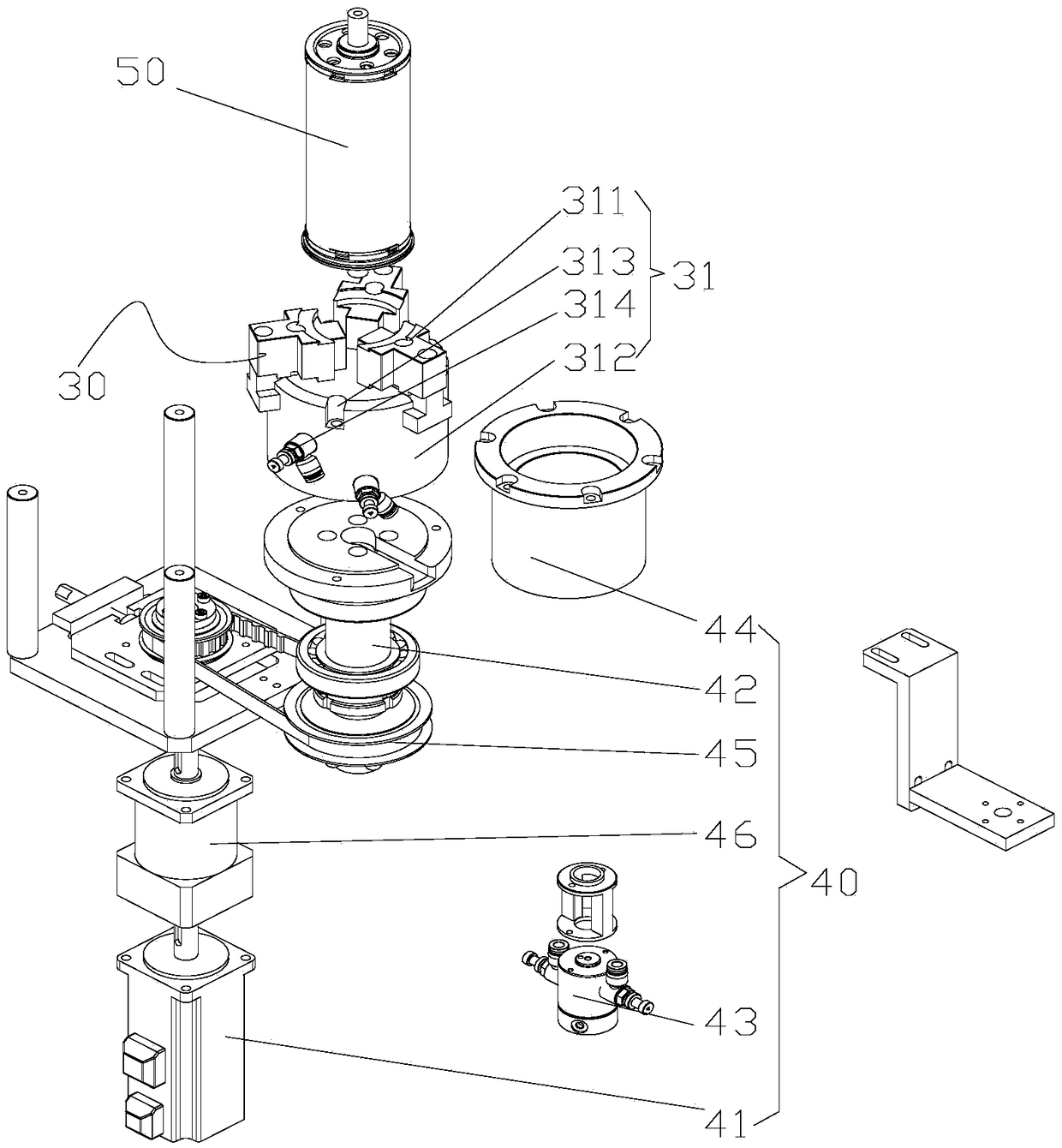

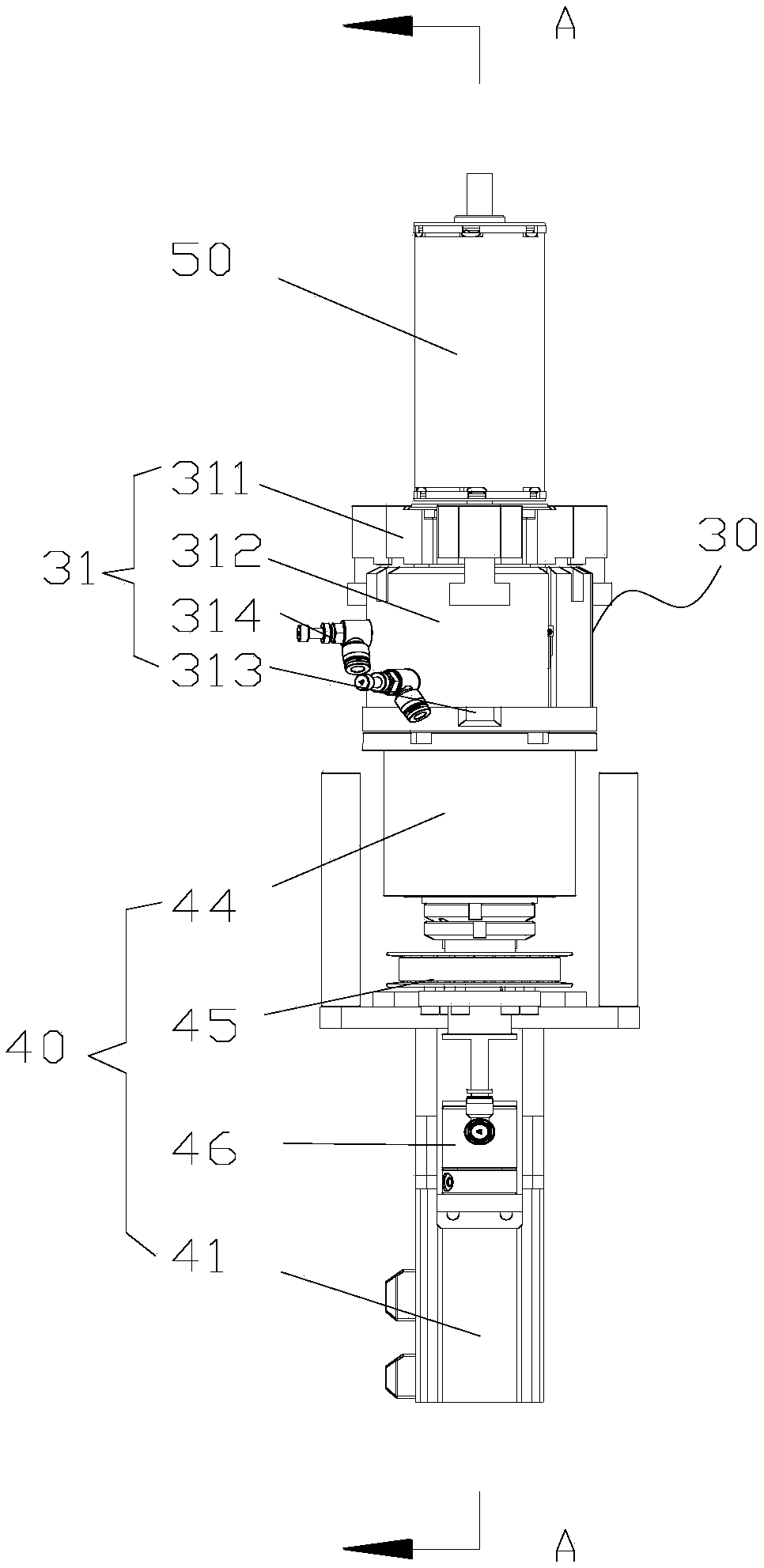

A mobile spindle machine tool with quick tool change function

ActiveCN112846883BRealize rotary motionRealize replacement workPositioning apparatusMetal-working holdersElectric machineryEngineering

The invention discloses a spindle mobile machine tool with quick tool change function, relates to the technical field of machine tool equipment, including machine tool, spindle, tool magazine, auxiliary frame, crawler belt, arc bar, support disc, arc clamping frame and tool . In the present invention, it is only necessary to turn on the motor to realize the replacement operation of the cutting tool. The operation is convenient and fast. Two adjacent arc bars are symmetrically arranged to ensure that the arc bars are paired in pairs. The outer side of the arc-shaped clamping frame further improves the stability of the arc-shaped clamping frame, thereby improving the stability of the tool and tool change operation, driving the tool to move downward, and the tool is always located in the arc-shaped clamping frame and arc-shaped during the installation and replacement process. The double clamping treatment of the bar can further improve the stability of the tool, and the track and the first support sleeve move in opposite directions, so that the track and the first support sleeve exert an inward extrusion force on the tool, which can further improve Tool stability.

Owner:JIANGSU BOSUNMAN IND EQUIP

A hand-held small pipeline operation device

Owner:SHANGHAI UNIV

A turntable angle information acquisition device

The invention provides a turntable angle information collection device. The output shaft gear and the first bevel gear are respectively sleeved at both ends of the output shaft, and the output shaft gear is engaged with an external transmission mechanism. The first bevel gear and the second bevel gear The gears are meshed and connected, the second spur gear is meshed with the first spur gear, and the output shaft of the resolver is fixedly connected to the first spur gear; it can be seen that when the output shaft gear is driven by the external transmission mechanism, it will pass through the first cone The gear, the second bevel gear, the second spur gear, and the first spur gear transmit the transmission of the external transmission mechanism to the resolver, and then, by setting the external transmission mechanism, the output shaft gear, the first bevel gear, and the second bevel gear 1. The number of teeth of the second spur gear and the first spur gear meet the set conditions, and the rotary motion of the external transmission mechanism and the 1:1 synchronous motion of the output shaft of the resolver can be realized through gear meshing transmission.

Owner:CSIC NO 710 RES & DEV INST

A forage pushing device based on frictional follow-up rotation

ActiveCN106818507BMeet job requirementsLow costAnimal feeding devicesConveyor partsAgricultural engineeringContact friction

Owner:CHINA AGRI UNIV

Thin walled cylinder girth laser welding tong

InactiveCN101229612BRealize rotary motionAccurate splicingWelding/cutting auxillary devicesAuxillary welding devicesGyrationThin walled cylinder

The invention discloses a circular seam laser welding fixture for a thin-wall cylinder, which comprises a head frame, an extended ring, a rear frame of a machine tool and a top plate. When in operation, the extended ring is placed between the head frame and the rear frame of the machine tool and sleeved in a place where two workpieces to be welded are spliced; one non-splicing end of the workpieceis retained and positioned on a spindle of the head frame while the other non-splicing end is attached to a positioning surface of a baffle; a top point of the rear frame of the machine tool is arranged in a top point hole of the baffle. By adopting a retractable extended ring, the invention realizes the correct splicing and retaining of the thin-wall cylinder; the gyration of the cylinder can berealized by a way that the head frame with the function of turning drives a head part of the cylinder and a tail part of the cylinder is supported by the rear frame and the top plate; meanwhile, thesplicing precision also meets the requirement of the laser welding. A worm-and-gear mechanism of the spindle in the head frame can accomplish the precise gyration of the workpiece and the head frame with a turnover function is convenience for feeding and discharging of a longer workpiece. The invention has the advantages of precise positioning, reliable and convenient fixture, convenient application, high efficiency, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

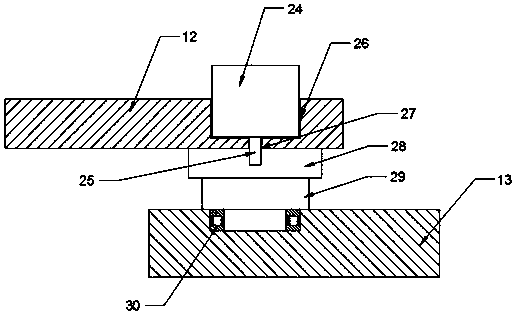

Rotating disc type angle information acquisition device

ActiveCN109631748ARealize rotary motionToothed gearingsUsing electrical meansEngineeringInformation acquisition

The invention provides a rotating disc type angle information acquisition device. An output shaft gear and a first bevel gear sleeve the two ends of an output shaft respectively, the output shaft gearis connected with an external transmission mechanism in an engaged mode, a first bevel gear is meshed with a second bevel gear, a second straight gear is in meshed connection with a first straight gear, and the output shaft of a rotary transformer is fixedly connected to the first straight gear; therefore, when the output shaft gear is in transmission with the external transmission mechanism, thetransmission of the external transmission mechanism is transmitted to the rotary transformer by the first bevel gear, the second bevel gear, the second straight gear and the first straight gear; andthe tooth number of the external transmission mechanism, the second bevel gear, the second straight gear and the first straight gear are arranged to meet the set condition, the rotation movement of the external transmission mechanism and the output shaft 1: 1 synchronous movement of the rotary transformer can be realized through gear engagement transmission.

Owner:CSIC NO 710 RES & DEV INST

Large-scale full-turning offshore platform crane

ActiveCN101343021BSmall turning radiusRealize rotary motionCargo handling apparatusPassenger handling apparatusGyrationThrust bearing

The invention provides a large full-gyration offshore platform crane which relates to the lifting machinery and comprises a rotary column, an arm support, a main lifting winch, an auxiliary lifting winch, an arm support variable-breadth winch, a gyration bearing drive mechanism, a main hanger hook, an auxiliary hanger hook and a driver cab. The arm support is connected with the middle part of therotary column through a hinge point mounted on the root of the arm support; the lower half part of the rotary column is arranged under a main deck and connected with a semi-diving platform through the gyration bearing drive mechanism. The gyration bearing mechanism is composed of an upper radial bearing, a lower radial bearing, a peg-tooth, a three-in-one decelerator, a centripetal thrust bearingand a rubber support; the upper radial bearing and the lower radial bearing are respectively mounted on the middle and the lower parts of the rotary column. The centripetal thrust bearing and the rubber bearing are sequentially mounted on the bottom part of the rotary column; the peg-tooth mounted on the lower deck is meshed with the three-in-one decelerator mounted on the corresponding position of the rotary column. The large full-gyration offshore platform crane has the advantages of novel, compact and practical structure, high efficiency and being a large full-gyration offshore platform crane with economical and practical properties.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Walking type detection platform for static load of engineering foundation piles

InactiveCN103362150BRealize rotary motionFlexible and convenient to moveFoundation testingHydraulic cylinderControl engineering

The invention discloses a walking type detection platform for the static load of engineering foundation piles, which comprises a supporting platform movably supported on two long boats and two short boats, wherein the two short boats are respectively arranged at two ends of the supporting platform, and a short-boat walking vehicle is arranged on each short boat and is fixedly connected with a short-boat slewing platform; vertical lifting hydraulic cylinders mounted on the supporting platform is hinged to the short-boat supporting platforms; the short-boat slewing platforms are hinged to the short-boat supporting platforms through swing pin shafts; two long-boats are respectively arranged on two sides of the supporting platform; each long boat is provided with two movable long-boat walking vehicles which are hinged to the lower ends of the corresponding legs of the long boats; the legs of the long boats are mounted on the supporting platform through beams of legs of the long boats; long-boat walking hydraulic cylinders are arranged between the long-boat walking vehicles and the long boats; a crane is mounted on the supporting platform. The detection platform can perform self-propelled move as a whole, requires no repetitive construction and hoisting, and has the features of safety in use, reasonable structure, high operating efficiency and the like.

Owner:江苏久工重型机械股份有限公司

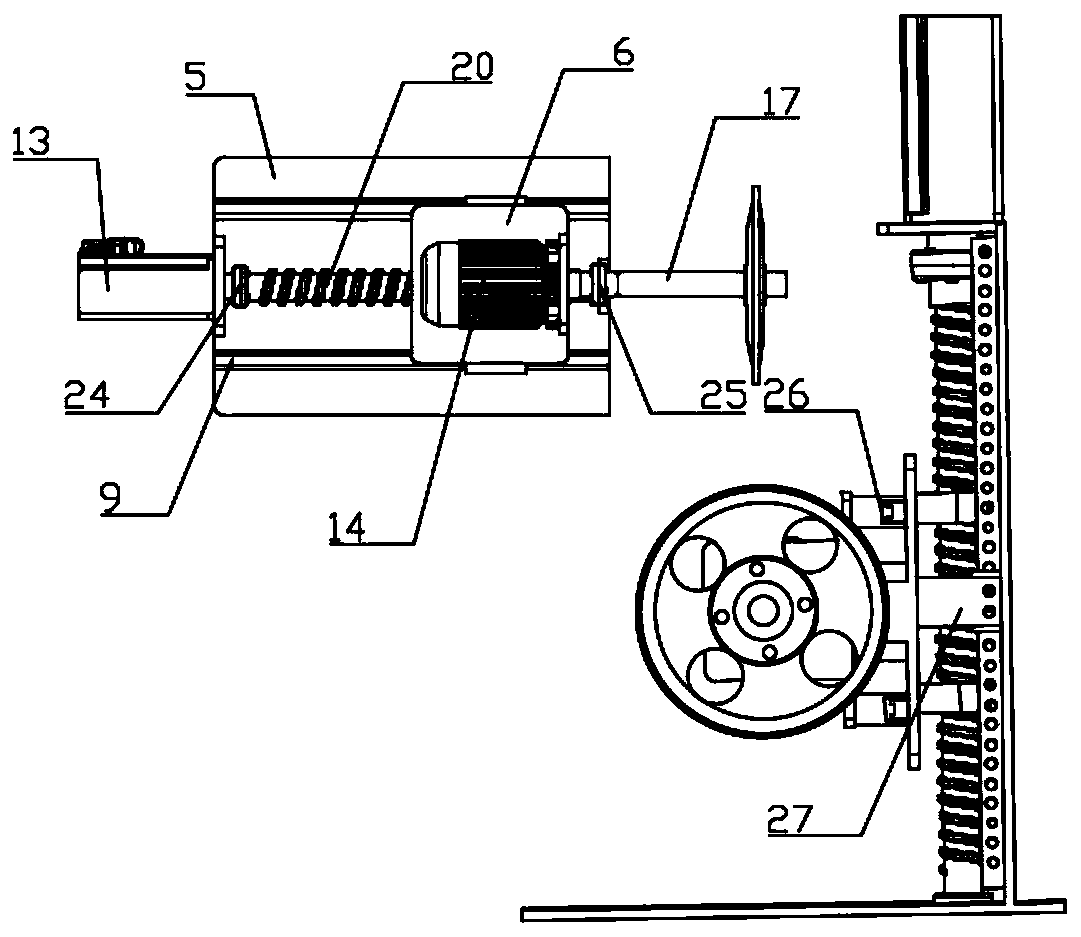

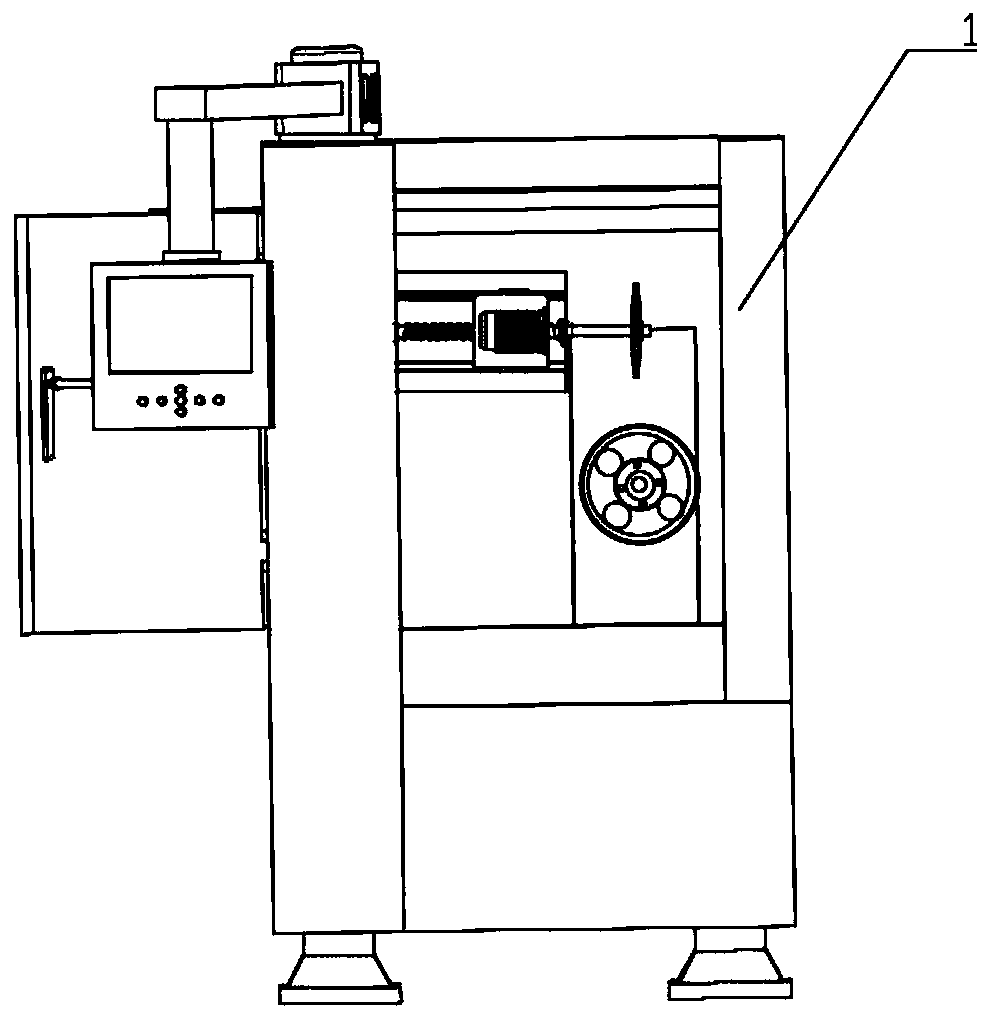

Numerical control formed grinding wheel gear grinding machine

PendingCN110814440ARealize rotary motionHigh degree of automationAbrasive surface conditioning devicesGear-cutting machinesGear grindingGear wheel

The invention discloses a numerical control formed grinding wheel gear grinding machine. The numerical control formed grinding wheel gear grinding machine comprises a box body. A main stand column anda first vertical stand column are mounted on the box body. A vertical sliding guide rail is mounted on the main stand column, a second vertical stand column is slidingly mounted on the vertical sliding guide rail in a guide manner, a transverse sliding guide rail is mounted on the second vertical stand column, and a third vertical stand column is slidingly mounted on the transverse sliding guiderail in a guide manner. According to the numerical control formed grinding wheel gear grinding machine, the problems that in the prior art, the precision of machined gears is low, and the machining efficiency of the large-specification gears is low are solved, a numerical control system, servo motors and a stepping motor are adopted for replacing a complex movement chain of a traditional mechanical transmission type gear grinding machine tool device, mounting of transmission parts and a dividing worm wheel pair is omitted, the automation degree is high, and the grinding machining precision andthe working efficiency are high.

Owner:常州固高智能装备技术研究院有限公司

Clamp component and tape laminator with same

InactiveCN109301345ARotary realizationRealize rotary motionFinal product manufactureElectrolyte accumulators manufactureEngineeringElectrical and Electronics engineering

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

A fixture for turning high-pressure gas cylinders

Owner:衡阳金化高压容器股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com