Preparation method for hot-rolled low-density steel with strength and ductility product being greater than or equal to 40 GPa.%

A technology of low-density steel and strong plasticity, applied in the field of metal materials, can solve the problems of difficulty in meeting toughness requirements and decreased steel toughness, and achieve the effects of short production process, reduced steel plate density, and improved strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

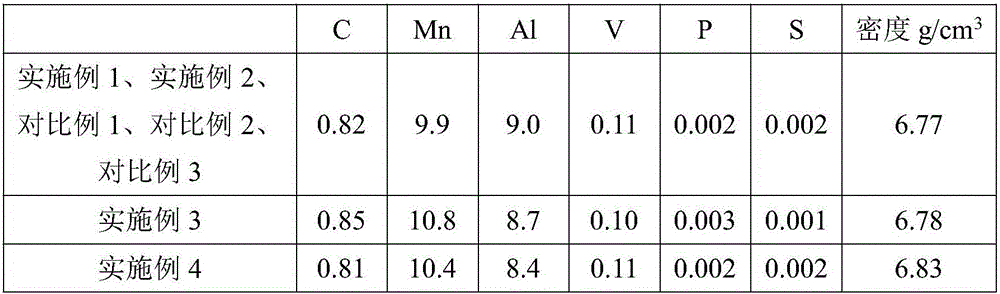

[0035] The chemical composition and density of Example 1 of the present invention are as shown in Table 1. The specific implementation process is: (1) smelting in a vacuum smelting furnace and casting into a slab, forging the slab into a slab, and eliminating the components in the slab during the forging process Segregation to remove defects such as shrinkage cavities and porosity; (2) Heating the slab to 1150°C, keeping it warm until the structure is homogenized, and then performing 6 passes of hot rolling. 87%, water-cooled to 240°C for coiling after rolling, and then air-cooled to room temperature to obtain a hot-rolled steel strip; (3) The hot-rolled steel strip is subjected to solution treatment, the solution treatment temperature is 900°C, the holding time is 60min, and then directly Water quenching to room temperature to obtain a finished low-density steel strip.

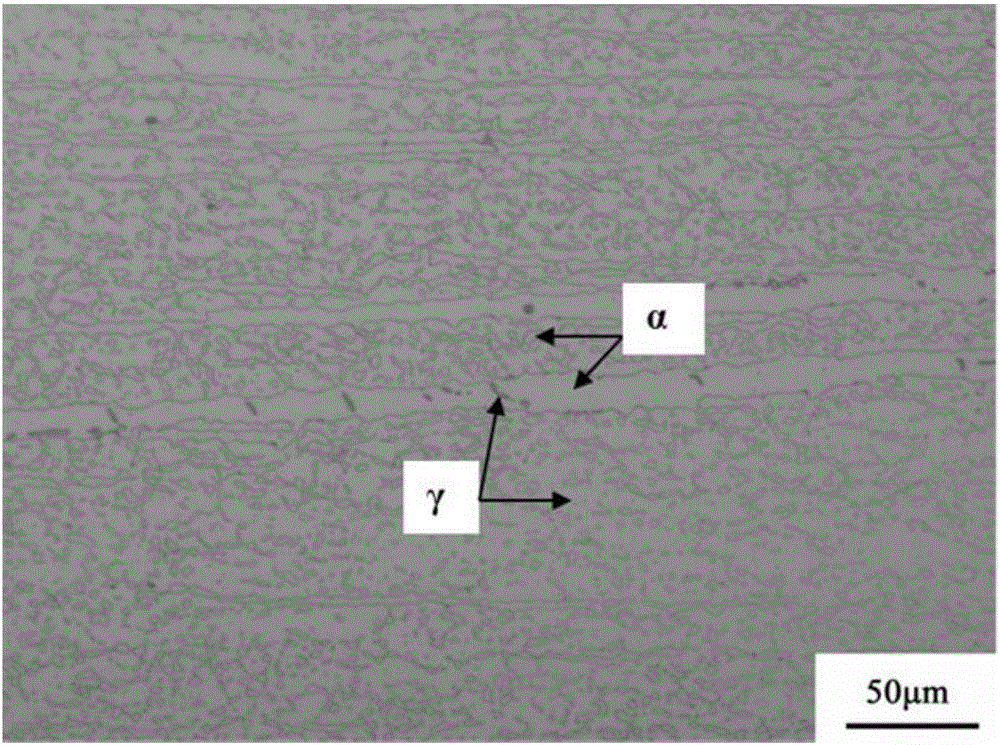

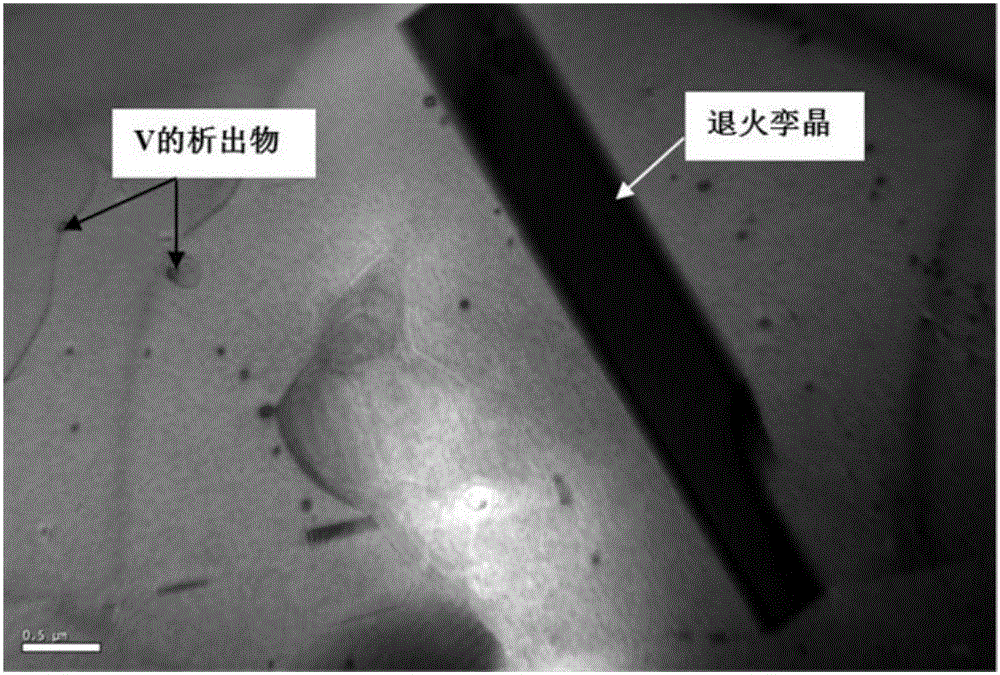

[0036] Observation and analysis of the structure of the finished steel strip shows that the structure of t...

Embodiment 2

[0038] The chemical composition and density of Example 2 of the present invention are exactly the same as those of Example 1, as shown in Table 1. The specific implementation process is: (1) smelting in a vacuum smelting furnace and casting into a billet, forging the billet into a slab, and the forging process (2) Heating the slab to 1180°C, keeping it warm until the structure is homogenized, and then performing 6 passes of hot rolling, the starting temperature of hot rolling is 1100°C, and the final rolling The temperature is 890°C, and the cumulative deformation is 92%. After rolling, it is water-cooled to 265°C for coiling, and then air-cooled to room temperature to obtain a hot-rolled steel strip; (3) The hot-rolled steel strip is subjected to solution treatment, and the solution treatment temperature is 950°C , the holding time is 60min, and then directly water quenched to room temperature to obtain the finished low-density steel strip.

[0039] Observation and analysis of ...

Embodiment 3

[0043] The chemical composition and density of Example 3 of the present invention are shown in Table 1, and the specific implementation process is the same as that of Example 1.

[0044] It is observed that the structure of the quenched steel strip is a dual-phase structure of ferrite + austenite, annealing twins exist in the austenite, and there are nanoscale vanadium precipitates in the grains. The results of the mechanical properties test are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com