Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Improve hole reaming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel and manufacturing method thereof

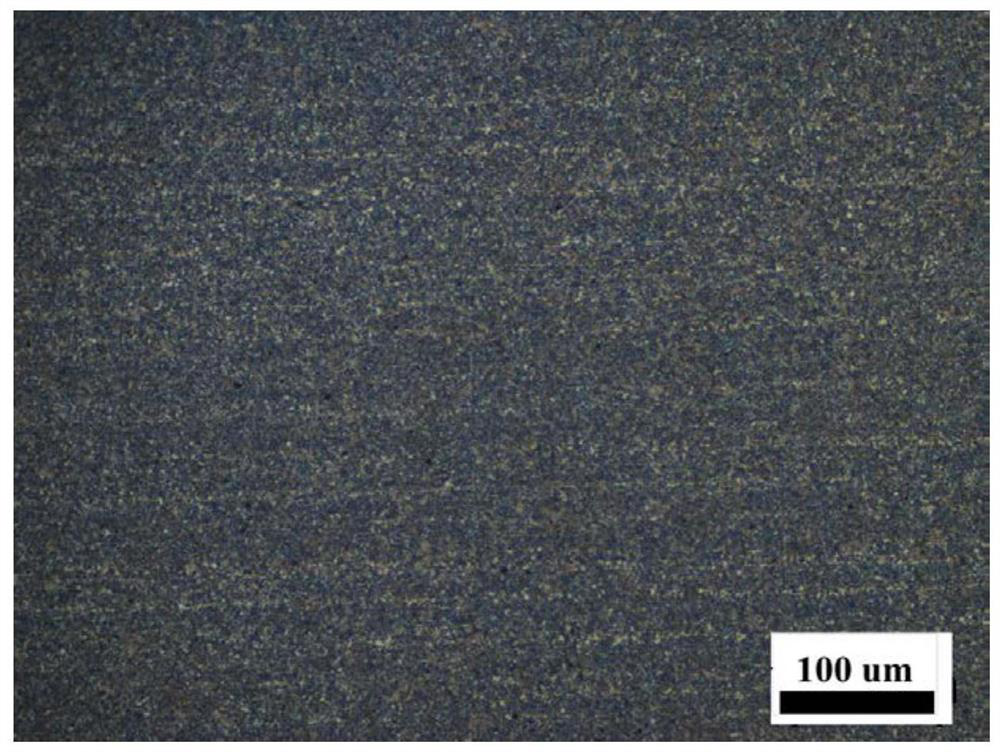

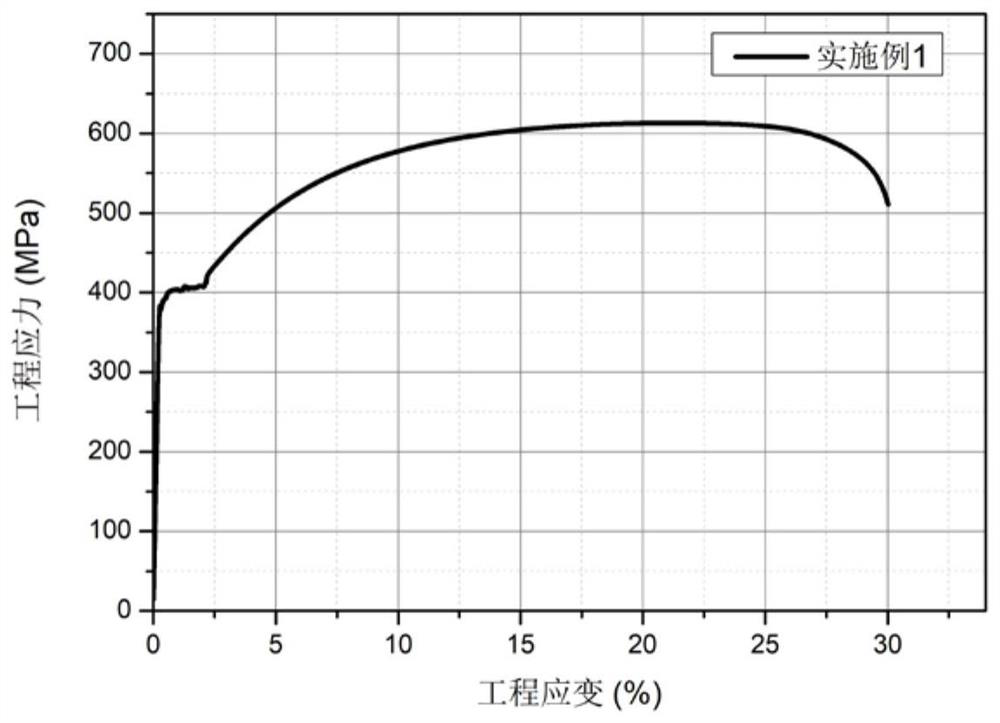

The invention provides 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel and a manufacturing method thereof. The 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel comprises, by weight, 0.05%-0.10% of C, 0.1%-0.8% of Si, 1.5% -2.5% of Mn, 0-0.015% of P, 0-0.005% of S, 0-0.003% of O, 0.02%-0.08% of Al, 0-0.005% of N, 0.05%-0.15% of Ti, 0.02%-0.06% of Nb, 0.1%-1.0% of Cr, 0.01%-0.10% of V, and the balance Fe and inevitable impurities, wherein the chemical components meet the relations that 0.15%<=Nb+Ti+V<=0.25%, and 0.01%<=(Ti-3.42N) / 4+V / 4.24<=0.06%. The microstructure of the steel is made of granular bainite and martensite; the yield strength of the steel is equal to or higher than 900 MPa, the tensile strength of the steel is equal to or higher than 980 MPa, the ductility of the steel is equal to or higher than 15%, and the hole expansion ratio of the steel is equal or higher than 50%; and the 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel has excellent strength, ductility and hole expansion matching and can be widely applied to thinned high-strength complexly-formed components such as an automobile chassis, a crossbeam and a wheel.

Owner:BAOSHAN IRON & STEEL CO LTD

780 MPa hot-rolled high-strength steel with high hole expansion ratio and manufacturing method thereof

The invention provides a 780 MPa hot-rolled high-strength steel with high hole expansion ratio and a manufacturing method thereof. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio comprises the following chemical components in percentage by mass: more than or equal to 0.03 percent and less than or equal to 0.07 percent of C, less than or equal to 0.2 percent of Si, more than or equal to 1.0 percent and less than or equal to 2.0 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.005 percent of S, more than or equal to 0.02 percent and less than or equal to 0.05 percent of Al, less than or equal to 0.005 percent of N, more than or equal to 0.08 percent and less than or equal to 0.20 percent of Ti, more than or equal to 0.15 percent and less than or equal to 0.25 percent of Mo, less than or equal to 0.003 percent of O and the balance of Fe and inevitable impurity elements, wherein Ti / Mo is more than or equal to 0.25 and less than or equal to 1.5, and (Ti-3.42N) / 4+Mo / 8 is more than or equal to 0.03 percent and less than or equal to 0.07 percent. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio is obtained through smelting, casting, high-temperature heating, hot rolling and reeling processes, and is more than or equal to 750 MPa in yield strength, more than or equal to 780 MPa in tensile strength, more than or equal to 20 percent in extensibility, more than or equal to 70 percent in hole expansion ratio when the thickness is 3-6 mm.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

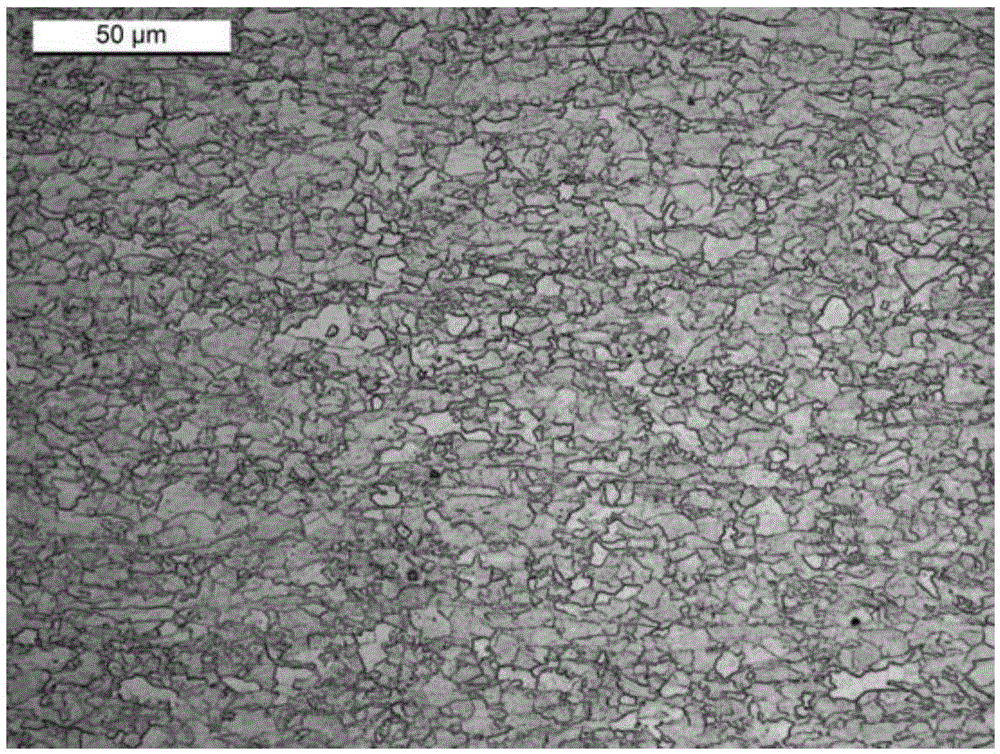

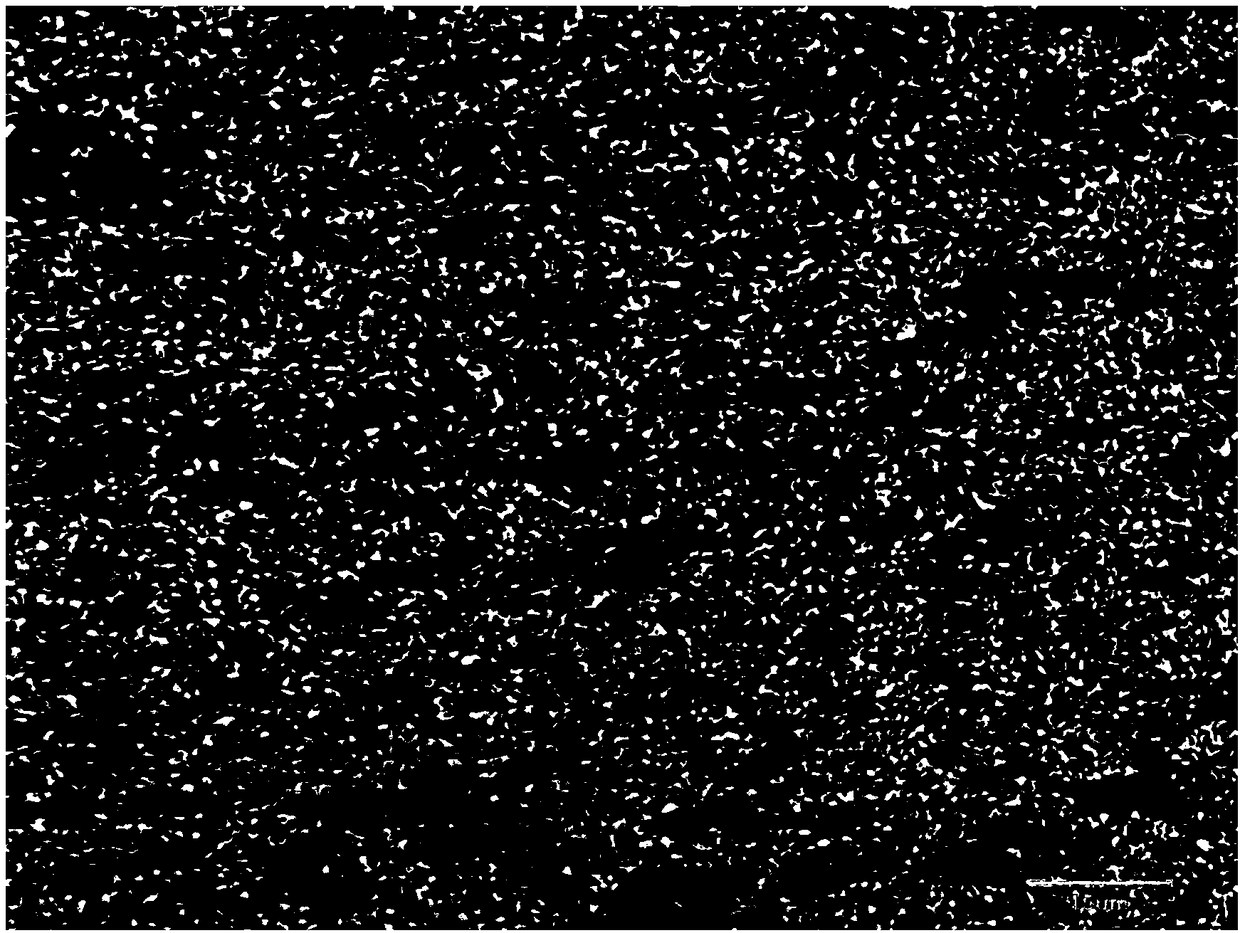

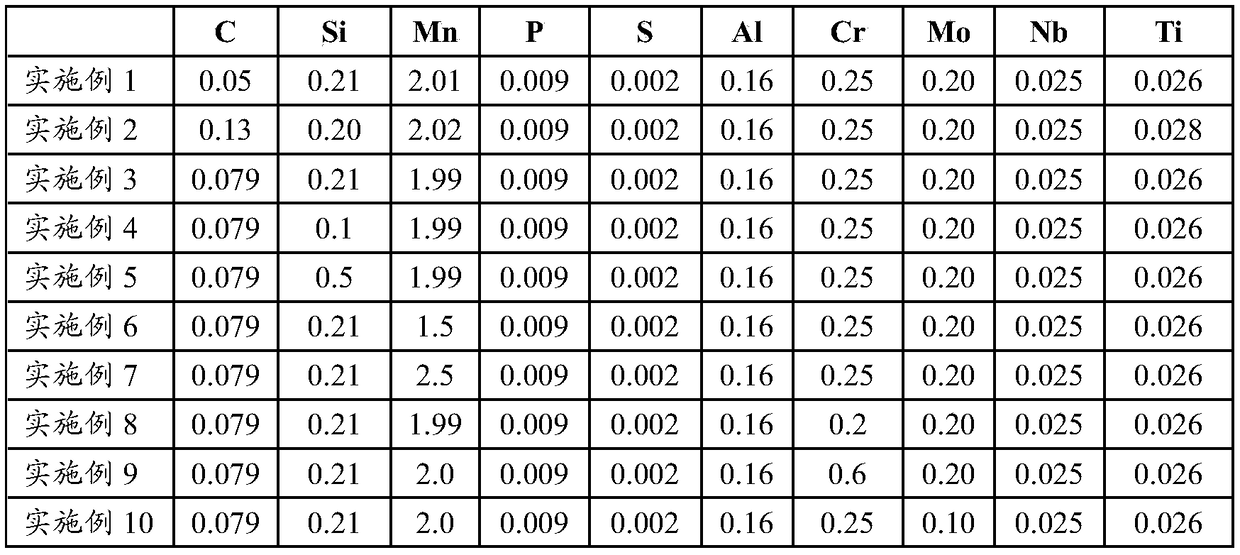

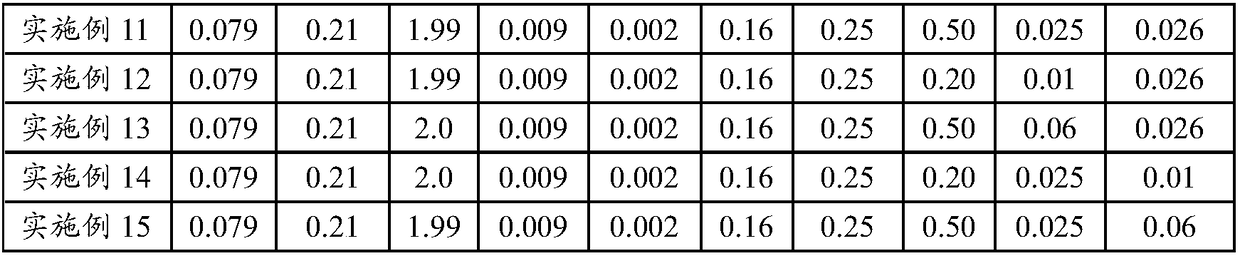

Cold-rolled hot-galvanized complex phase steel and preparation method thereof

The invention relates to a kind of cold-rolled hot-galvanized complex phase steel. Chemical components of the cold-rolled hot-galvanized complex phase steel comprise, by weight, 0.05-0.13% of C, 0.1-0.5% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.1-0.6% of Al, 0.2-0.6% of Cr, 0.1-0.5% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of Ti, and the balance Feand inevitable impurities. The invention further relates to a preparation method of the cold-rolled hot-galvanized complex phase steel. The preparation method comprises the following steps of castingmolten steel into a steel billet; conducting hot rolling on the steel billet to obtain a hot-rolled plate and conducting cold rolling on the hot-rolled plate to obtain a cold-hardened steel strip; conducting continuous galvanizing and annealing process treatment on the cold-hardened steel strip to obtain a finished cold-rolled hot-galvanized complex phase steel product. The bending performance ofthe cold-rolled hot-galvanized complex phase steel is improved on the basis of meeting the requirement for strength.

Owner:SHOUGANG CORPORATION

Radial sidetrack drilling rotating self-propelled porous jet flow drill bit

The invention relates to a radial sidetrack drilling rotating self-propelled porous jet flow drill bit, which mainly comprises a casing, a rotating drill bit body, a gear type slide ring type combined seal, an opening sealing screw, steel balls and the like, wherein a water inlet is processed at the tail end of the casing; a backward spray nozzle is processed on the casing; a forward spray nozzle and a center spray nozzle are processed on the rotating drill bit body; semicircular grooves are respectively processed in the casing and the rotating drill bit body; the steel balls are placed in the grooves formed between the casing and the rotating drill bit body; the rotating drill bit body is positioned through the steel balls and can rotate around the self axial line; the gear type slide ring type combined seal is adopted between the rotating drill bit body and the casing; through holes are formed at the lateral side of the casing; the steel balls are placed into the grooves through the through holes; and after the steel balls are placed into the grooves, the through holes are sealed through the opening sealing screws. The radial sidetrack drilling rotating self-propelled porous jet flow drill bit can effectively solve the problems of poor jet flow drill bit reaming capability, poor rock breaking hole smooth roundness, bent tracks of hydraulic jet hoses and the like of the hydraulic jet radial sidetrack drilling tiny drill hole technology, and can be widely applied to the hydraulic jet radial horizontal well technology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

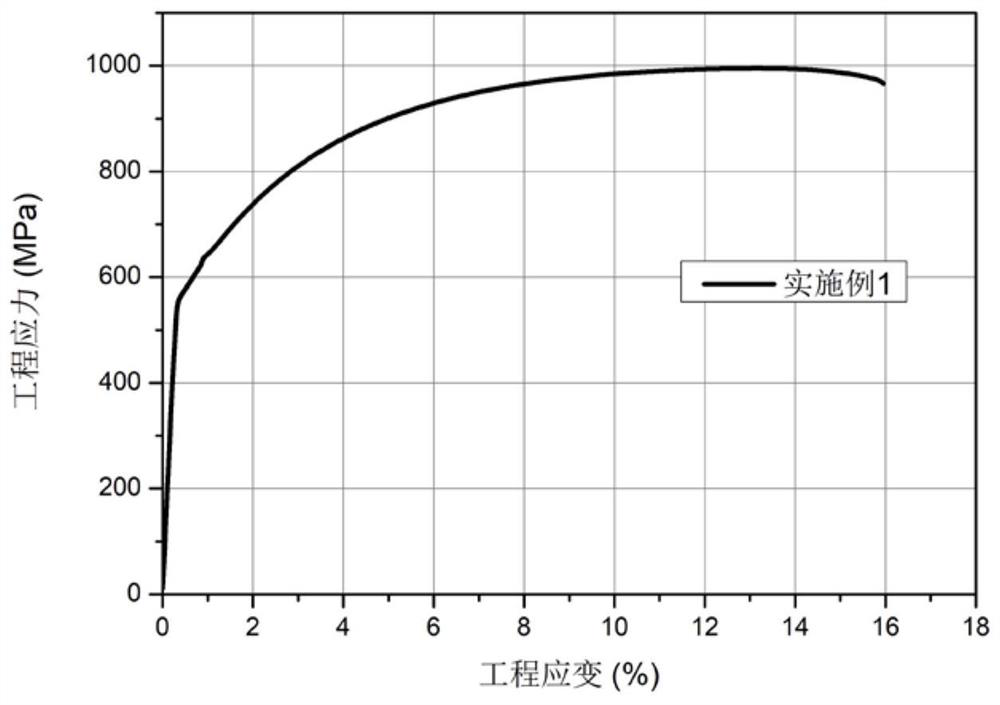

980 MPa-grade high-formability cold-rolled DH steel and preparation method thereof

The invention discloses 980 MPa-grade high-formability cold-rolled DH steel and a preparation method thereof. The steel comprises 0.16 %-0.23 % of C, 1.8 %-2.8 % of Mn, 0.3 %-1.5 % of Si, 0.02 %-1.2 %of Al, 0.02 %-0.50 % of Mo, 0.02 %-0.70 % of Cr, less than or equal to 0.01 % of P, less than or equal to 0.01 % of S, less than or equal to 0.05 % of Nb, less than or equal to 0.04 % of Ti and the balance iron and inevitable impurities. The heating temperature of a continuous casting blank is 1150-1300 DEG C, the initial rolling temperature is 1000-1150 DEG C, the final rolling temperature is greater than or equal to 880 DEG C, and the coiling temperature is 500-700 DEG C; the cold rolling reduction rate is 40 %-80 %; the annealing temperature is 760-880 DEG C, the annealing time is 10-600 s, the slow cooling outlet temperature is 660-760 DEG C, the rapid cooling rate is larger than 20 DEG C / s, the overaging temperature is 350-450 DEG C, and the overaging time is 30-3600 s; and the finishing elongation rate is 0.3 %-0.7 %. According to the steel and the method, the tensile strength of a steel sheet is 980-1100 MPa, the A <80> is 16 %-20 %, and the reaming performance is excellent.

Owner:ANGANG STEEL CO LTD

High-reaming-property hot-rolled acid-washed steel strip and production method thereof

ActiveCN104630623AImprove surface qualityImprove hole reaming effectChemical compositionAcid washing

The invention discloses a high-reaming-property hot-rolled acid-washed steel strip which comprises the following components in percentage by chemical mass: 0.05-0.1% of C, at most 0.05% of Si, 0.8-1.2% of Mn, at most 0.02% of P, at most 0.006% of S, 0.01-0.05% of Nb, and the balance of Fe and inevitable impurities. The invention also discloses a method for producing the high-reaming-property hot-rolled acid-washed steel strip. By controlling the chemical components and the technological parameters for rolling and acid washing, the microscopic metallurgical structure of the produced steel strip is ferrite+bainite, wherein the bainite structure accounts for 10-20 vol%. The tensile strength of the steel strip is greater than or equal to 540 MPa, and the reaming rate lambda is greater than or equal to 100%. The steel strip has excellent surface quality.

Owner:SHOUGANG CORPORATION +1

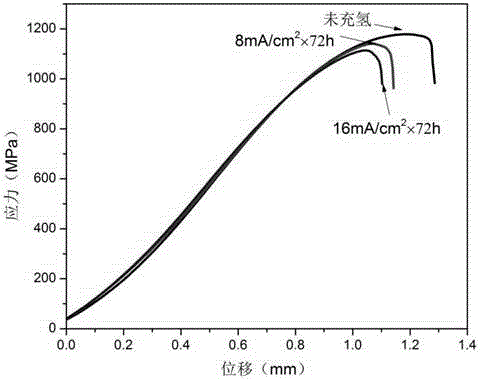

Dual phase steel with tensile strength of 1000 MPa and production method thereof

The invention discloses a dual phase steel with tensile strength of 1000 MPa and a production method thereof. The dual phase steel is composed of the following chemical components in percentage by weight: 0.08%-0.11% of C, 0.2%-0.6% of Si, 2.0%-2.5% of Mn, at most 0.01% of P, at most 0.01% of S, 0.02%-0.06% of Al, 0.4%-0.6% of Cr, 0.02%-0.05% of Ti, at most 0.003% of N, and the balance of Fe and inevitable impurities. The method solves the technical problem of how to lower the alloy cost and enhance the reaming property and delayed fracture resistance of the material on the premise of satisfying the strength requirement.

Owner:SHOUGANG CORPORATION

Hot-rolled ferrite bainite dual-phase steel strip for wheel with 590MPa class tension strength and preparation method thereof

ActiveCN109536845AStable performanceImprove fatigue performanceProcess efficiency improvementWeld seamDual-phase steel

Provided is a hot-rolled ferrite bainite dual-phase steel strip for a wheel with 590MPa class tension strength. The strip is prepared from, by weight, 0.05-0.10% of C, 0.40-0.70% of Si, 1.40-1.70% ofMn, P less than and equal to 0.020%, S less than and equal to 0.004%, 0.020-0.060% of Al, 0.015-0.035% of Nb, 0.20-0. 40% of Cr, N less than and equal to 0.0060, O less than and equal to 0.0020% and the balance of Fe and inevitable impurities. A preparation method is provided, and the method comprises the the following steps of hot metal pretreatment->converter smelting->LF+RH furnace refining->slab continuous casting->heating->rough rolling and finish rolling->control cooling->rolling->finished product inspection->factory leaving. The 590MPa class wheel steel has stable performance, effectively avoids an unsuited fatigue test which is often encountered in the use of a high-strength wheel steel, cracking of rim welding, thinning of a weld seam and cracking of a center hole of a spoke, andis a material ideal for light weight of the wheel.

Owner:BENGANG STEEL PLATES

Alloyed hot-dip galvanized DH980 steel and preparation method thereof

ActiveCN112048680AReduce original costRealize industrial productionHot-dipping/immersion processesUltimate tensile strengthFatigue limit

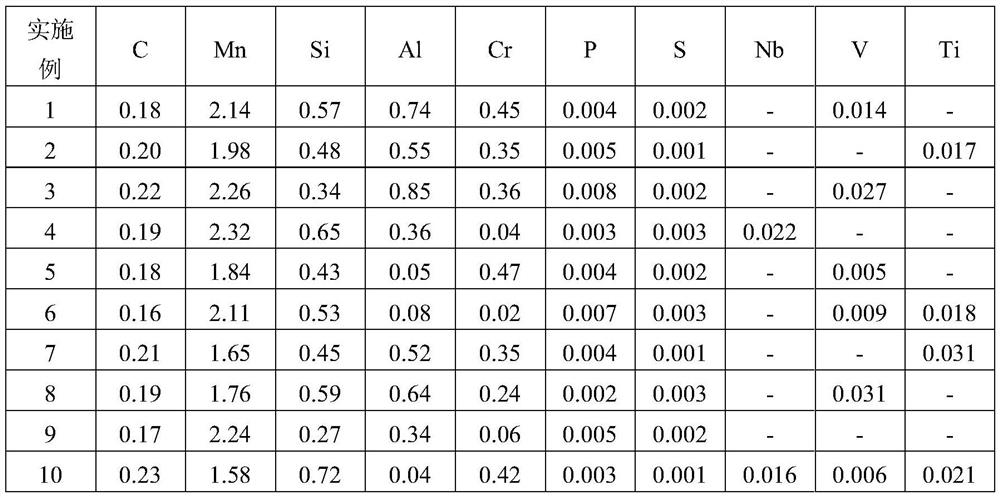

The invention discloses alloyed hot-dip galvanized DH980 steel and a preparation method thereof. The steel comprises 0.16 %-0.23 % of C, 1.5 %-2.5 % of Mn, 0.2 %-0.9 % of Si, 0.02 %-0.9 % of Al, 0.02%-0.70 % of Cr, less than or equal to 0.01 % of P, less than or equal to 0.01 % of S, less than or equal to 0.05 % of Nb, less than or equal to 0.05 % of V, less than or equal to 0.05 % of Ti, and thebalance iron and inevitable impurities, wherein the proportion of (Si+Al) is 0.6 %-1.5 %. The heating temperature of a casting blank is 1150-1300 DEG C, the initial rolling temperature is 1000-1150 DEG C, the final rolling temperature is greater than or equal to 880 DEG C, and the coiling temperature is 500-700 DEG C; the cold rolling reduction rate is 40 %-80 %; and the annealing temperature is760-880 DEG C, the annealing time is 30-300 s, the galvanizing temperature is 450-470 DEG C, the alloying temperature is 470-530 DEG C, and the alloying heat preservation time is 5-60 s. According tothe steel and the method, the tensile strength of a finished steel sheet is 980-1100 MPa, and the high-cycle fatigue ultimate strength is larger than or equal to 370 MPa; and the reaming performance is excellent.

Owner:ANGANG STEEL CO LTD

Tensile strength 700 MPa-grade high broaching hot-rolled steel plate and manufacturing method thereof

The invention relates to a tensile strength 700 MPa-grade high broaching hot-rolled steel plate and a manufacturing method thereof, and solves the technical problems of weak broaching and flanging performance of a traditional tensile strength 700 MPa-grade high broaching hot-rolled steel plate. The tensile strength 700 MPa-grade high broaching hot-rolled steel plate comprises the following chemical components in percentage by weight: 0.05-0.09% of C, 0.15-0.35% of Si, 1.20-1.80% of Mn, P not more than 0.015%, S not more than 0.008%, 0.015-0.050% of Al, 0.08-0.13% of Ti, 0.035-0.065% of V, and the balance of iron and inevitable impurities. The hot-rolled steel plate can be used for manufacturing vehicle structural parts.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

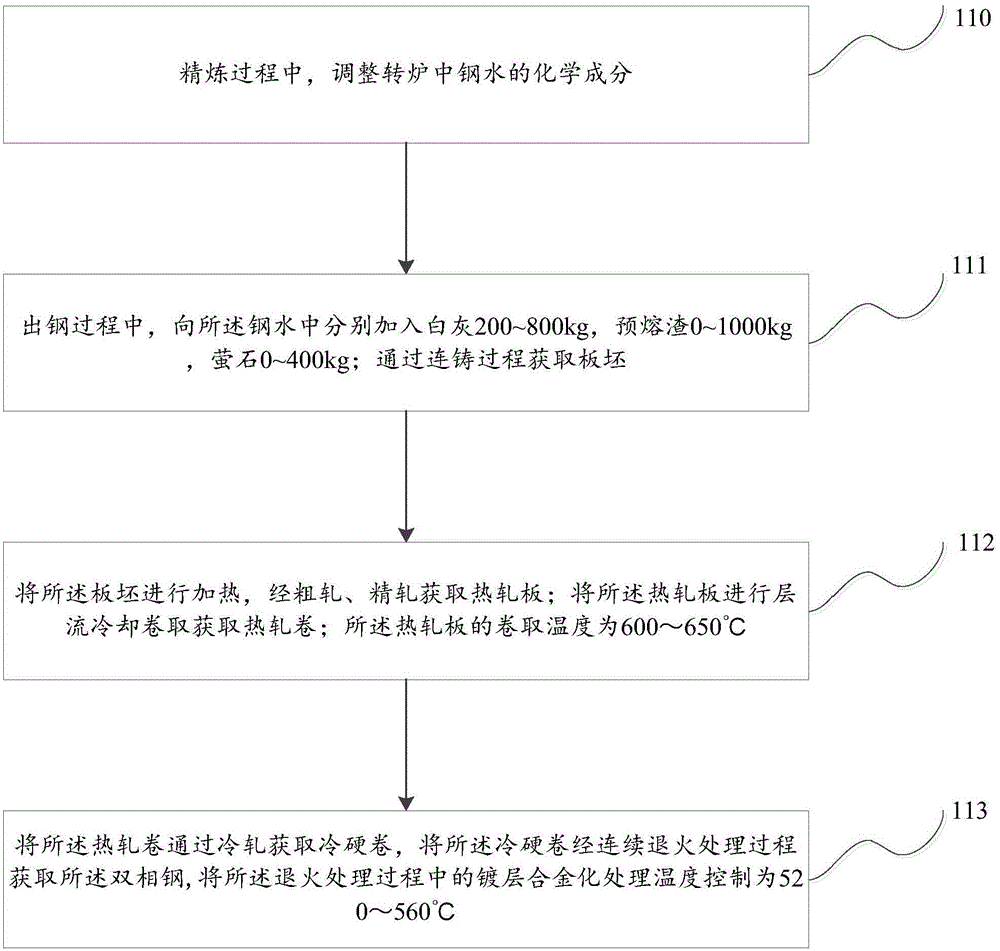

Preparation method of alloyed hot-galvanized dual-phase steel

ActiveCN104593686AReduce hardness differenceImprove hole reaming effectHot-dipping/immersion processesChemical compositionHardness

The invention provides a preparation method of alloyed hot-galvanized dual-phase steel, belonging to the technical field of high-strength cold-rolled hot-galvanized steel. Cold-rolled dual-phase DP steel comprises the following chemical components in percentage by weight: 1.3%-1.7% of Mn, less than or equal to 0.01% of P, 0.15%-0.25% of Mo, 0.15%-0.25% of Cr, 0.02%-0.04% of Nb, 0.07%-0.11% of C, 0.2%-0.5% of Si, 0.02%-0.07% of Als, less than or equal to 0.04% of N, 0.01% of S and the balance of Fe and impurities. According to the preparation method of the alloyed hot-galvanized dual-phase steel with excellent pore broadening performance, by adding a certain amount of Nb, martensite phases are refined and uniformly dispersed in a final microstructure; furthermore, by properly regulating the alloying temperature (520-560 DEG C), a proper amount of intermediate hard phase pearlite is generated, and the hardness difference between the hard martensite phases and a soft ferritic phase is reduced, so that the pore broadening performance of the dual-phase steel is improved.

Owner:SHOUGANG CORPORATION

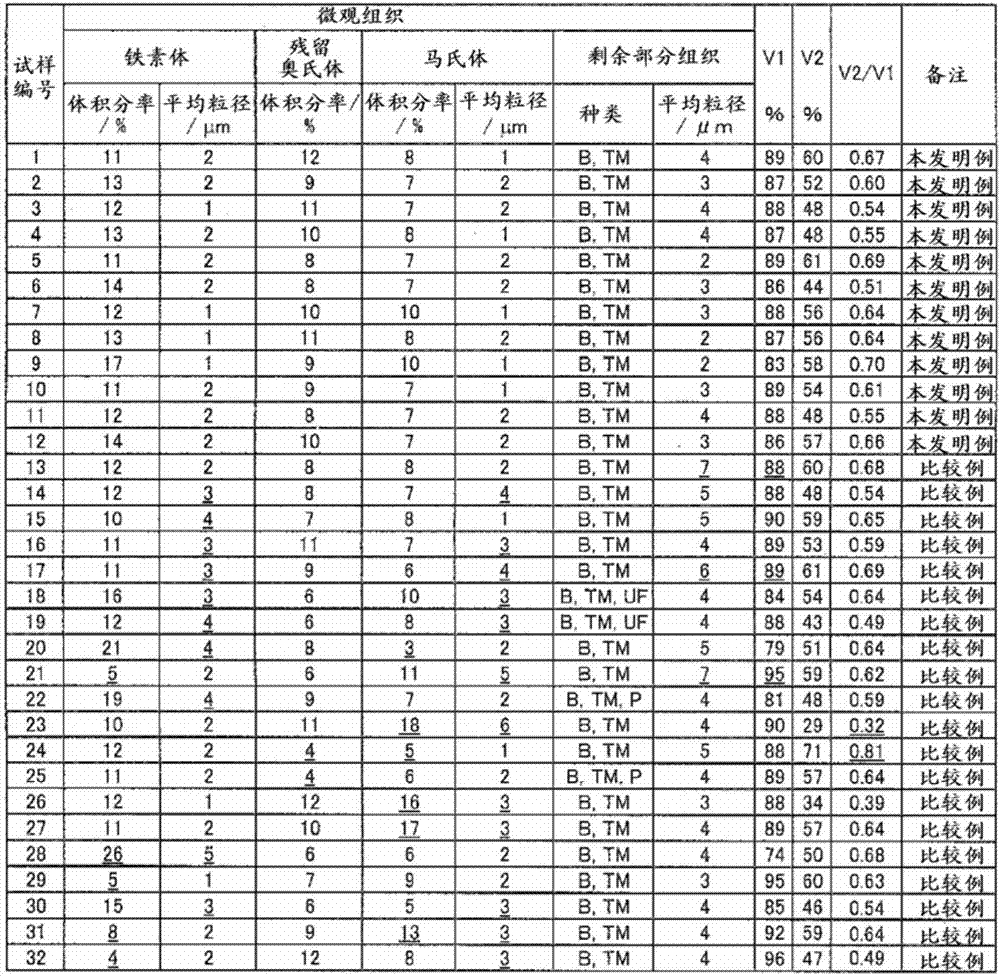

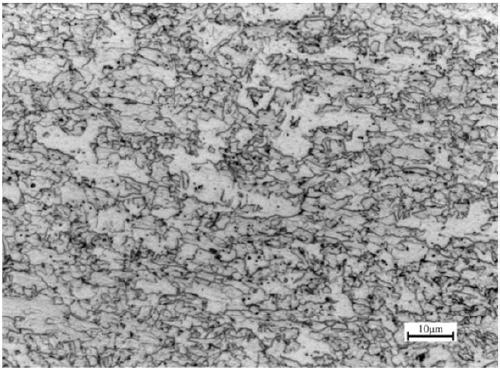

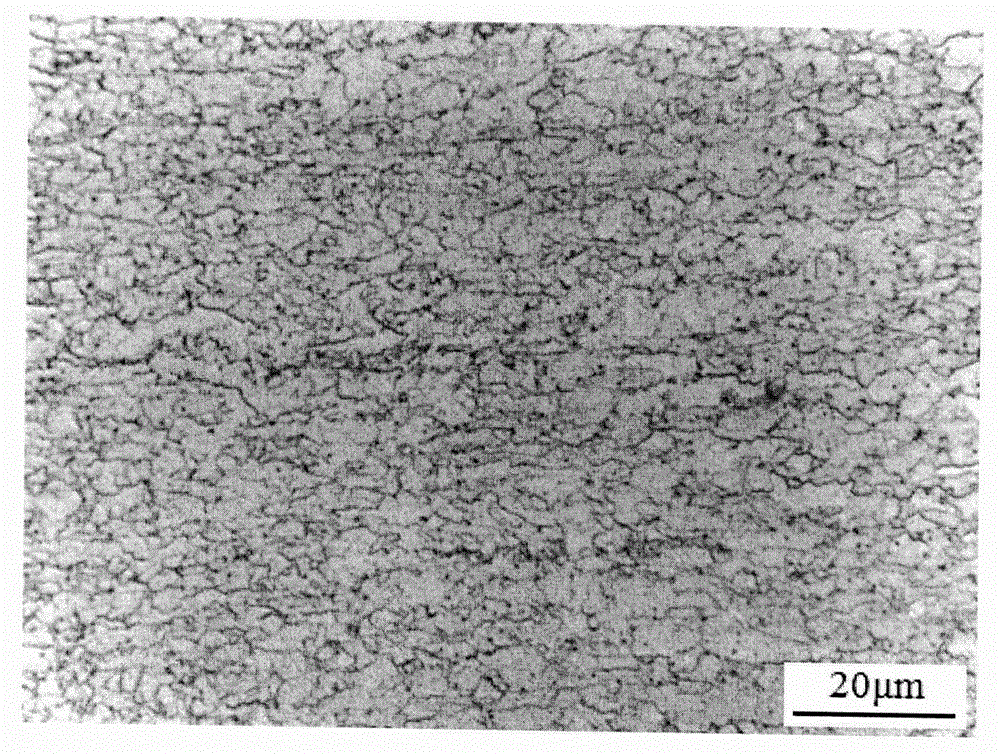

High-strength cold-rolled steel sheet and method for producing same

ActiveCN107002198AHigh tensile strengthHigh yield ratioFurnace typesHeat treatment furnacesSheet steelHigh intensity

Provided are: a high-strength cold-rolled steel sheet which solves problems of prior art and has a good balance among a plurality of characteristics (yield ratio, strength, elongation, bore expanding properties and delayed fracture resistance); and a method for producing this high-strength cold-rolled steel sheet. A high-strength cold-rolled steel sheet which is characterized by having a specific component composition and by having a microstructure that is a composite structure which contains 10-25% by volume of ferrite having an average crystal grain size of 2 [mu]m or less, 5-20% by volume of residual austenite, and 5-15% by volume of martensite having an average crystal grain size of 2 [mu]m or less, with the balance made up of tempered martensite and bainite having an average crystal grain size of 5 [mu]m or less, in said microstructure the volume fraction (V1) of hard phases other than ferrite and the volume fraction (V2) of the tempered martensite satisfying the condition of formula (1) which is 0.35<=V2 / V1<=0.75 Formula (1).

Owner:JFE STEEL CORP

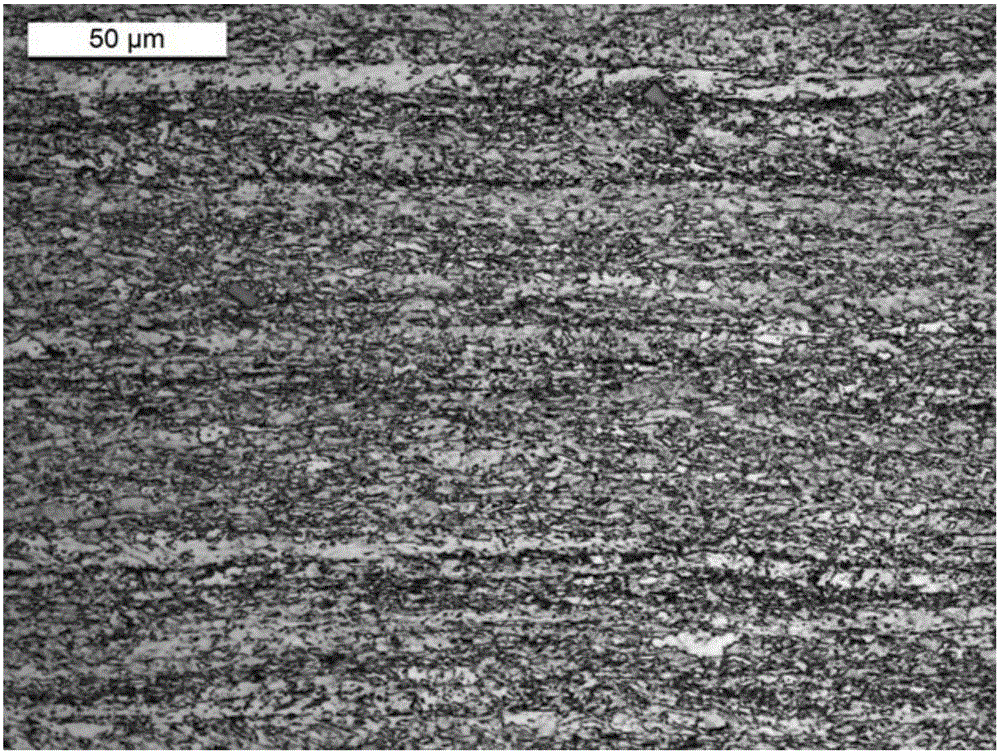

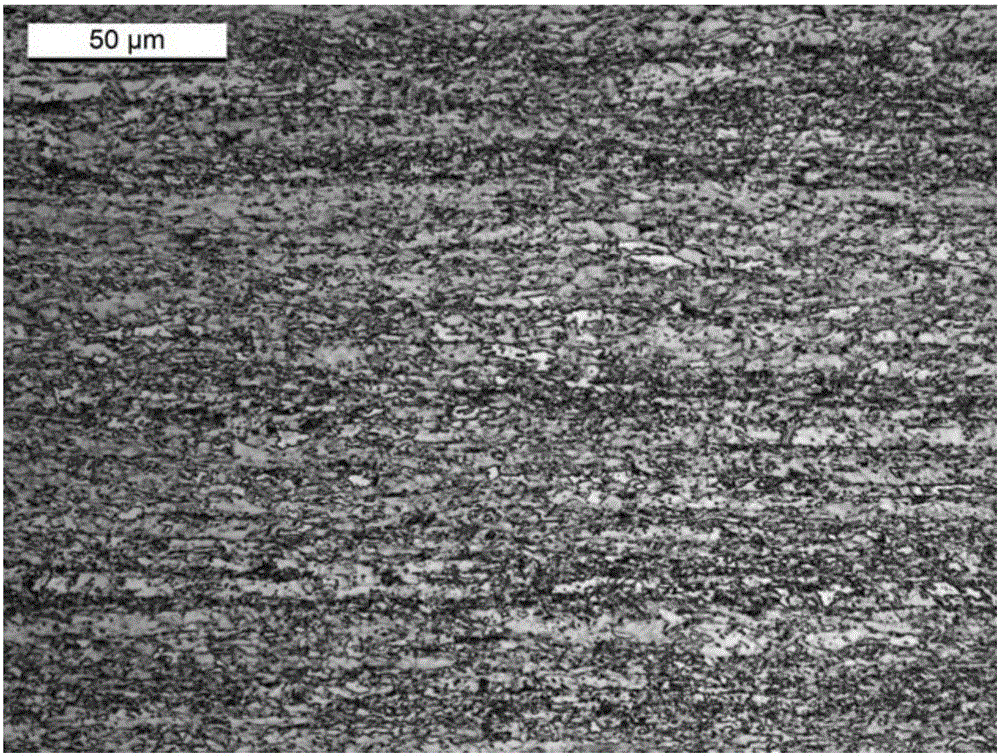

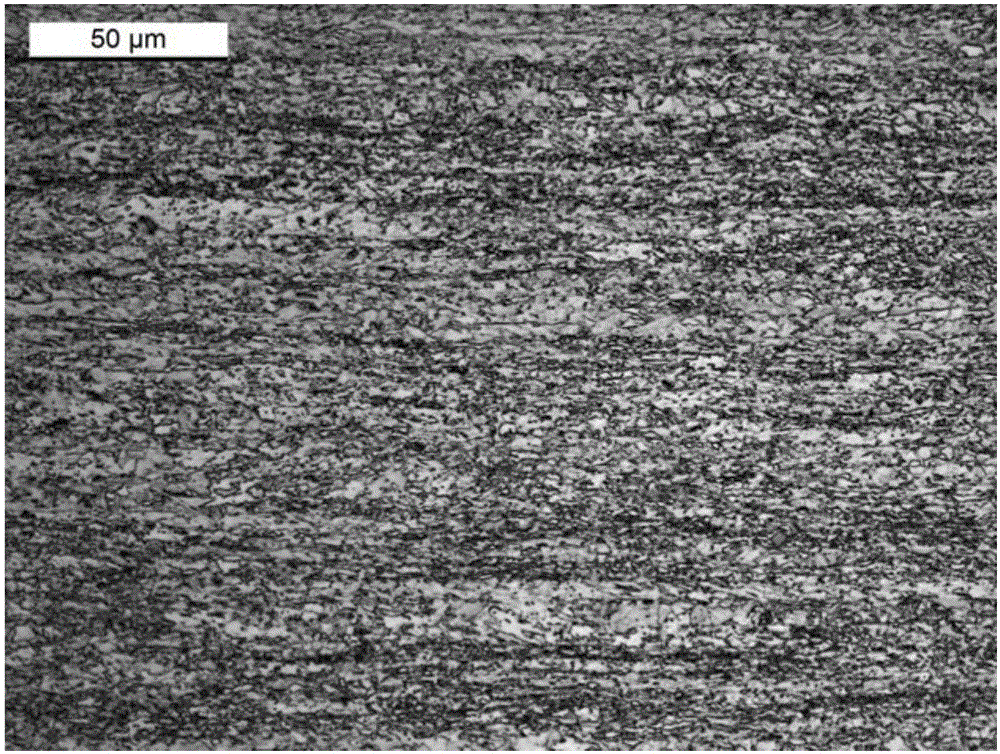

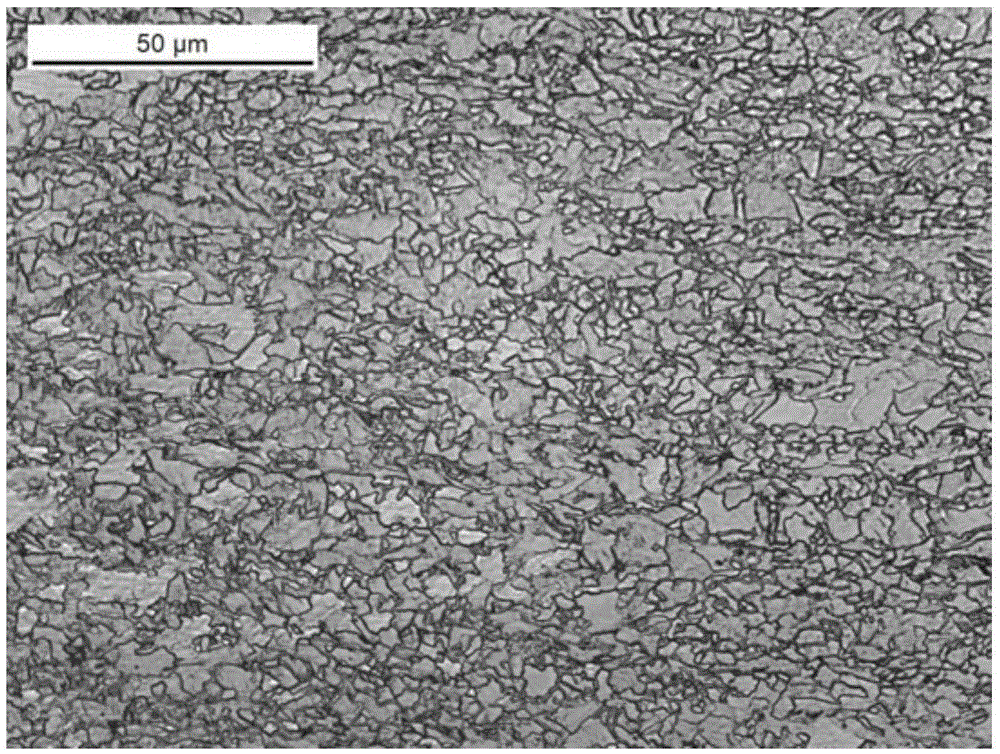

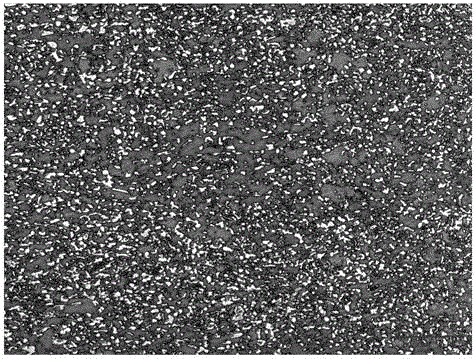

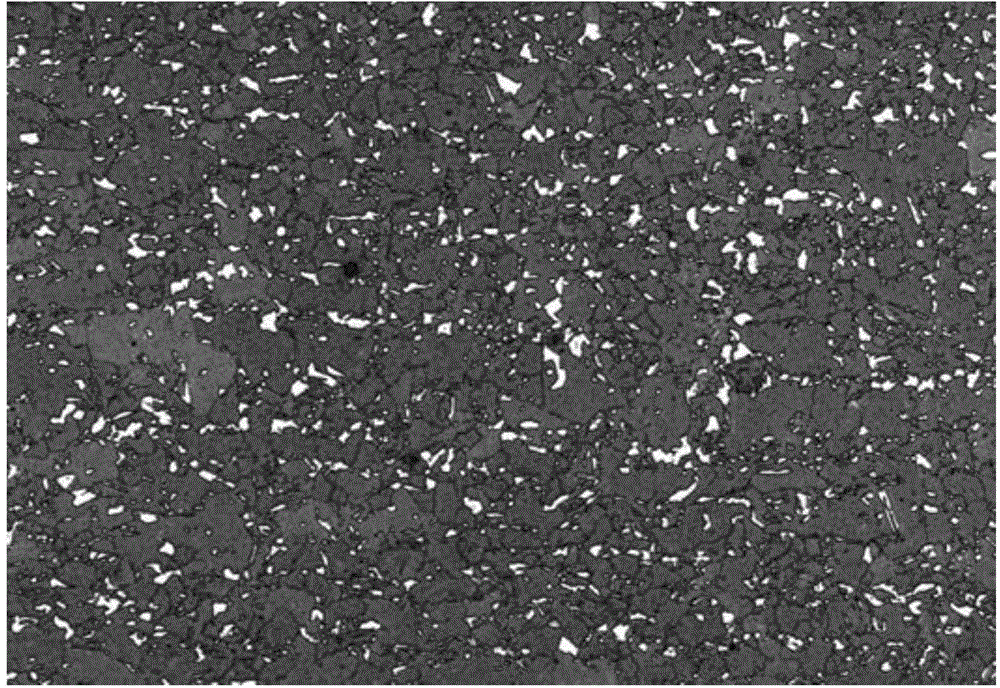

Production method for improving yield ratio and bore expansion of 1000MPa-level high-strength steel

ActiveCN103290202AHigh yield ratioImprove hole reaming effectFurnace typesHeat treatment process controlArea fractionDouble phase

The invention provides a method for improving a yield ratio and bore expansion of 1000MPa-level high-strength steel. The production method, which utilizes the existing 1000 MPa-level double-phase steel cold-rolled base material, comprises the following steps of: adopting a two-phase region heating mode and a three-stage cooling mode to obtain polygonal ferrite with the area fraction of 35-45%, lath upper bainite with the area fraction of 30-40% and martensite tissue with the area fraction of 10-25% in a metallographic figure; and using the lath upper bainite with the tissue type as a middle buffer phase of the ferrite and the martensite to buffer phase interface early-stage cracking caused by hardness difference of the ferrite and the martensite during a local flanging process. According to the production method for improving the yield ratio and bore expansion of the 1000MPa-level high-strength steel provided by the invention, the mechanical performances of the obtained 1000MPa-level high-strength steel are as follows: the tensile strength is bigger than 1000MPa, the yield ratio is 0.7-0.9, elongation at 80 scale distance is bigger than 10%, and the bore expansion rate is bigger than 50%.

Owner:SHOUGANG CORPORATION

High-strength hot-rolled steel plate and manufacturing method therefor

ActiveCN102791896AImprove hole reaming effectImprove featuresFurnace typesMetal rolling arrangementsMetallurgyEngineering

Owner:NIPPON STEEL CORP

Steel sheet and plated steel sheet, method for producing hot-rolled steel sheet, method for producing cold-rolled full-hard steel sheet, method for producing heat-treated sheet, method for producing steel sheet, and method for producing plated steel sheet

ActiveUS20190085427A1Low yield ratioHigh tensile strengthHot-dipping/immersion processesFurnace typesMicro structureSheet steel

Provided herein is a plated steel sheet having a yield ratio, strength (tensile strength), elongation, hole expansibility, and CTS. A method for producing the plated steel sheet is also provided, among others. A steel sheet of a specific composition is provided that has a micro structure containing 70 to 90% of ferrite, 5 to 20% of martensite, 5% or less of retained austenite, 10% or less of bainite, and 5% or less of perlite by volume. The ferrite has an average crystal grain diameter of 20 μm or less. The martensite has an average crystal grain diameter of 5 μm or less. The retained austenite has an average crystal grain diameter of 5 μm or less. The bainite has an average crystal grain diameter of 7 μm or less. The steel sheet has a tensile strength of 590 MPa or more.

Owner:JFE STEEL CORP

High-strength and high-plasticity 1000 Mpa grade hot rolled steel plate and preparation method thereof

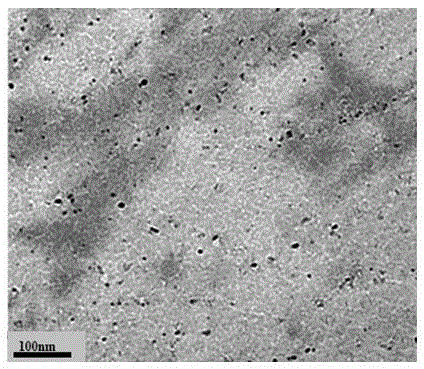

The invention discloses a high-strength and high-plasticity 1000 Mpa grade hot rolled steel plate and a preparation method thereof. The high-strength and high-plasticity 1000 Mpa grade hot rolled steel plate is prepared from the following components by weight: 0.05%-0.40% of C, 1.00%-5.00% of Mn, 0.70%-1.60% of Si, 0.1%-1.00% of Al, 0.01%-0.10% of Nb, 0.01%-0.10% of V, 0.002%-0.005% of N and the balance Fe and inevitable impurities. The steel plate has high strength and high plasticity, and Nb and V microalloy elements are added to be combined with C and N to form nanoscale cluster precipitates, so that matrix structures are strengthened. Through chemical composition design, and combined with medium temperature coiling, the nanoscale cluster precipitates with small size, uniform distribution and high density can be obtained, the strength of ferrite is obviously strengthened, the strength difference between the two matrix structures (ferrite and martensite) is reduced, the ferrite grainsize is refined at the same time, and high reaming performance is obtained.

Owner:武汉钢铁有限公司

Single-ferrite-precipitated steel plate with high strength and high pore-expansion property and preparation method for same

The invention discloses a single-ferrite-precipitated steel plate with high strength and a high pore-expansion property and a preparation method for the same. Steel comprises 0.05%-0.12% of C, 0.1%-0.7% of Si, 0.8%-2.2% of Mn, 0.05%-0.10% of Ti, less than 0.035% of P, less than 0.035% of S, 0.015%-0.060% of Als, 0.0015%-0.0050% of Ca, less than 0.0050% of Mg and less than 0.005% of N, at least oneof ingredients including 0.15%-0.3% of Cr and 0.05%-0.3% of Mo, at least one of ingredients including 0.02%-0.06% of Nb and 0.05%-0.25% of V as well as the balance being Fe and inevitable impurities.The linear speed of Si-Ca feeding is more than or equal to 3.5m / s, and a superheat degree of the molten steel is less than or equal to 30 DEG C; and the heating temperature of a casting blank is 1150-1250 DEG C, the multi-pass rolling total reduction rate is more than or equal to 80%, the final rolling temperature of hot rolling is 850-950 DEG C, the after-rolling cooling rate is 15-45 DEG C / s, and the rolling temperature is 550-650 DEG C. The finished steel plate has the good pore-expansion property.

Owner:ANGANG STEEL CO LTD

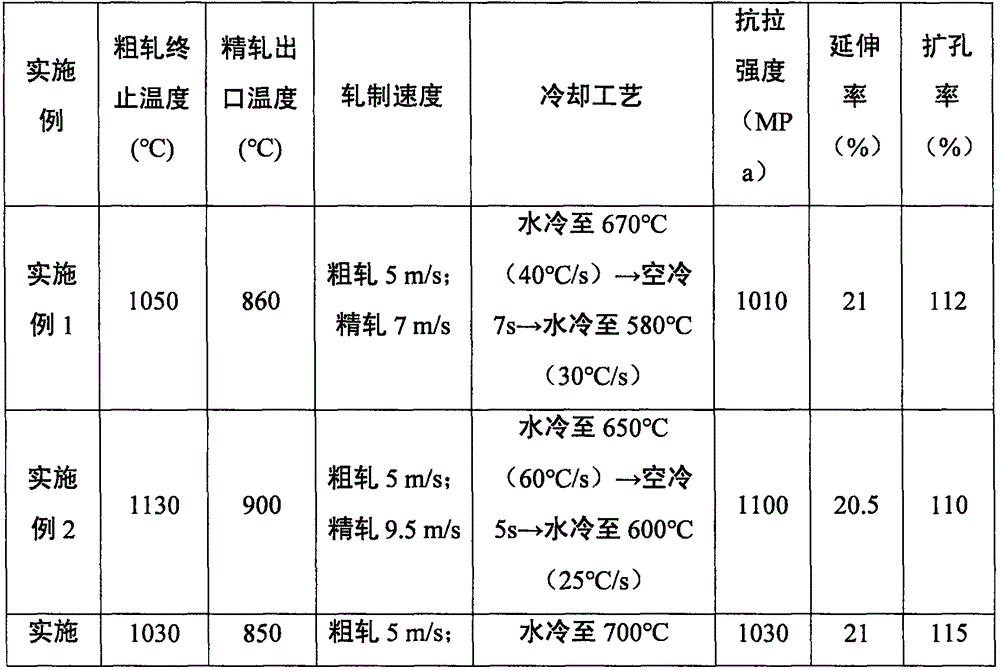

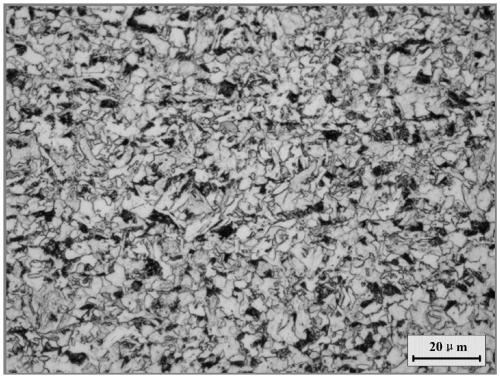

Hot-rolled pickled steel strip with high broaching performance and production method thereof

The invention discloses a hot-rolled pickled steel strip with high broaching performance and a production method thereof, and belongs to the technical field of steelmaking. The hot-rolled pickled steel strip comprises the following chemical components by mass percent: 0.03% to 0.1% of C, 0.1% or fewer of Si, 0.5% to 1.5% of Mn, 0.02% or fewer of P, 0.006% of fewer of S, 0.05% or fewer of Nb, 0.1% or fewer of Ti, 0.15% or fewer of Mo and 0.1% to 0.4% of Re, and the balance being Fe and unavoidable impurities. An internal microscopic structure of the hot-rolled pickled steel strip is ferrite. The production method comprises the steps of molten iron pretreatment, smelting, casting, hot rolling, cooling, reeling, levelling and pickling, a three-stage cooling mode of water cooling, air cooling and water cooling is adopted, and constant-speed rolling is controlled. According to the obtained hot-rolled pickled steel strip, the tensile strength is larger than or equal to 980 MPa, the broaching rate lambda is larger than or equal to 110%, the elongation is larger than or equal to 20%, and the surface quality of the steel strip is excellent.

Owner:SHOUGANG CORPORATION +1

Production method for improving yield-strength ratio and stretch-flange-formability of cold-rolled DP980 steel

The invention discloses a production method for improving the yield-strength ratio and stretch-flange-formability of cold-rolled DP980 steel. On the basis of the chemical composition design of existing cold-rolled DP980 steel, through control over the process parameters of a slab heating procedure, a hot rolling procedure and a cooling and coiling procedure, hot-rolled initial structures comprisepearlite, medium temperature bainite mixed structures and equiaxial ferrite structures, wherein all the grain sizes are no more than 5.0 [mu]m, and the average grain size is no more than 3.2 [mu]m. The volume fraction of martensite in the microstructure of the cold-rolled DP980 steel prepared with the production method provided by the invention is larger than 30.0%, and the yield-strength ratio islarger than 0.70; the hole expanding rate is no less than 55%, and meanwhile the elongation reaches 12.9% and above; and the production method is especially applicable for automobile structural members and stiffeners with the requirements for 980 MPa high tensile strength and excellent drawing characteristic as well as reaming and flanging requirements.

Owner:SD STEEL RIZHAO CO LTD

Production process of 690 MPa highly-reaming steel strip

The invention discloses a production process of a 690 MPa highly-reaming steel strip. The production process includes the steps of converter smelting, LF furnace refining, slab continuous casting, heating, roughing, fining, cooling and coiling;, according to the fining process, the inlet temperature is 1040-1090 DEG C, and the finishing temperature is 830-880 DEG C; and according to the cooling process, the steel strip is rapidly cooled to 680-720 DEG C at a cooling speed of 35-50 DEG C / s through laminar cooling at the front coarse tuning stage, subjected to air cooling for 4-8 s at the middlestage, and then quickly cooled to 450-500 DEG C at the cooling speed of 20-30 DEG C / s through laminar cooling at the last fine tuning stage. According to the production process of the 690 MPa highly-reaming steel strip, a hot rolling temperature system and a cooling strategy are reasonably designed, the strengthening effect of niobium and titanium microalloys is fully performed, by adopting meanssuch as fine grain strengthening and precipitation strengthening, the steel of the grade has the high strength, and meanwhile, high reaming performance can be still ensured; and the production process can be used for manufacturing car parts in complex shapes, the thickness of adopted steel plates can be lowered, the vehicle weight is decreased, and vehicle fuel consumption is reduced.

Owner:TANGSHAN STAINLESS STEEL +1

Tensile strength 600MPa grade low-cost high-hole-enlargement steel plate and production method thereof

The invention discloses a tensile strength 600MPa grade low-cost high-hole-enlargement steel plate and a production method thereof. The high-hole-enlargement steel plate is prepared from the following chemical components in percentage by mass: 0.15 to 0.20% of C, less than or equal to 0.30% of Si, 0.80 to 1.00% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.020 to 0.050% of Als, 0.010 to 0.030% of Ti, less than or equal to 0.0060% of N, and the balance of Fe and inevitable impurities. The production method of the steel plate comprises the processes of steelmaking, heating, rolling and cooling. The intermediate low C and conventional Mn are adopted, few amount of Si and Ti elements are added, and a cooling path is controlled, so that a hot rolled steel strip of which the tensile strength is 600 to 650MPa, the lower yield strength is 500 to 550 MPa, the elongation percentage A50 is more than or equal to 25%, and the hole enlargement rate is more than or equal to 95% is obtained, and the steel strip is low in cost, is excellent in performance and has strong market competiveness.

Owner:TANGSHAN IRON & STEEL GROUP +1

Hot rolling acid pickling strip steel with high chambering performance and production method thereof

The invention discloses hot rolling acid pickling strip steel with high chambering performance and a production method thereof. The hot rolling acid pickling strip steel is made from raw material chemical components including, by mass, 0.05%-0.1% of C, 0.1%-0.7% of Si, 0.9%-1.6% of Mn, not larger than 0.02% of P, not larger than 0.015% of S, 0.01%-0.05% of Nb, 0.01%-0.07% of Al, 0.002%-0.05% of REand the balance Fe and inescapable impurities. The production method of the hot rolling acid pickling strip steel with the high chambering performance comprises the steps of pretreatment of hot metal, converter smelting, refining, continuous casting, hot rolling, smoothening and acid pickling. The microscopic metallographic structure of the strip steel produced through the production method is ferrite+bainite, the volume ratio of the bainite structure occupies 10%-20%, the strength of extension of the strip steel is higher than or equal to 590 MPa, the chambering rate lambda is higher than orequal to 95%, and the excellent strip steel surface quality is achieved.

Owner:SHOUGANG CORPORATION +1

Highly-reamed hot-rolled pickling steel plate with 440 MPa grade tensile strength

The invention relates to a highly-reamed hot-rolled pickling steel plate with 440 MPa grade tensile strength. The technical problem of low reaming and flanging machining performance of an existing highly-reamed hot-rolled pickling steel plate with the 440 MPa grade tensile strength is mainly solved. The highly-reamed hot-rolled pickling steel plate with the 440 MPa grade tensile strength is prepared from the following chemical compositions in percentage by weight: 0.035%-0.055% of C, 0.40%-0.60% of Si, 0.95%-1.05% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.020%-0.0. 60% of Aland the balance of iron and inevitable impurities. The after-fracture elongation rate A50 mm of the hot-rolled pickling steel plate with the thickness being 1.8-6.0 mm is no less than 30%, and the reaming performance lambda is no less than 120%. The highly-reamed hot-rolled pickling steel plate has good reaming and flanging forming characteristics, and manufacturing of highly-reamed and complexly-formed automobile structural parts with the high flanging amount is met.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Steel for superhigh-strength hot rolling automobile structure and preparation method thereof

The invention relates to steel for a superhigh-strength hot rolling automobile structure and a preparation method thereof, belonging to the field of alloy steel production processes. The steel comprises the following components: 0.08 percent to 0.12 percent of carbon, 0.10 percent to 0.50 percent of silicon, 1.5 percent to 2.50 percent of manganese, less than 0.02 percent of phosphorus, less than 0.01 percent of sulfur, 0.02 percent to 0.05 percent of aluminum, 0.08 to 0.25 percent of vanadium, 0.03 percent to 0.06 percent of nitrogen and the balance of Fe and other inevitable impurities. The production process comprises the following steps of: converter smelting; external refining; continuous casting; hot rolling and reeling. The main process parameters are as follows: the heating temperature of continuous casting slabs is between 1,150 and 1,220 DEG C, the reeling temperature is between 500 and 650 DEG C, and the hot rolling total reduction ratio is more than 85 percent. According to the steel, vanadium-nitride micro alloying is adopted, vanadium precipitation is promoted by enhancing nitrogen, grains are refined, and precipitation strengthening and fine-grain strengthening are used as main strengthening measures, so that the yield strength is more than 700 MPa, the tensile strength is more than 800 MPa, the total elongation rate after fracture is more than percent, and the steel is used for high-strength automobile structures with high plasticity and good cold bending properties.

Owner:UNIV OF SCI & TECH BEIJING +1

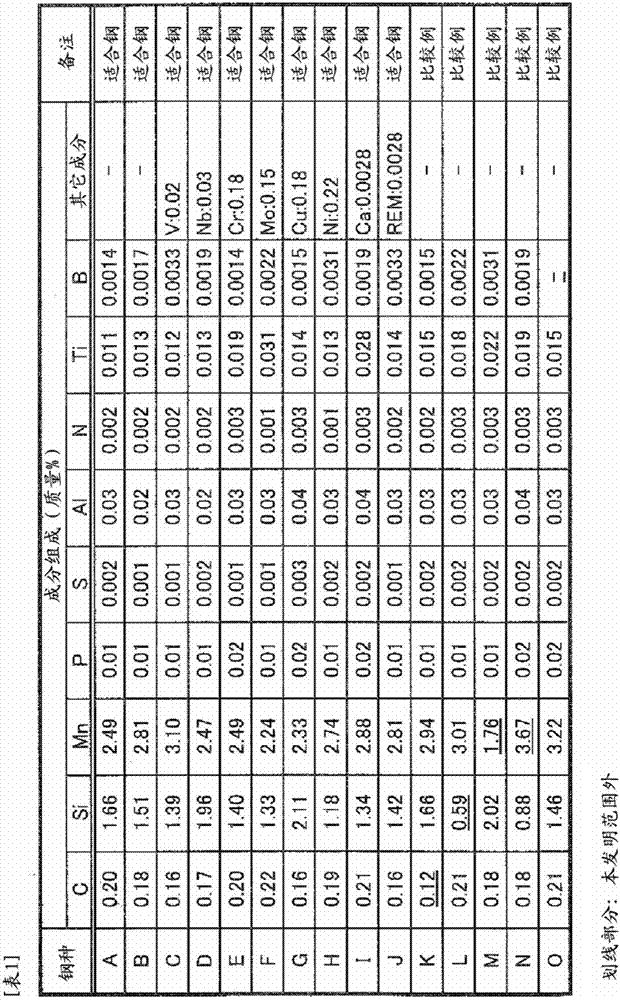

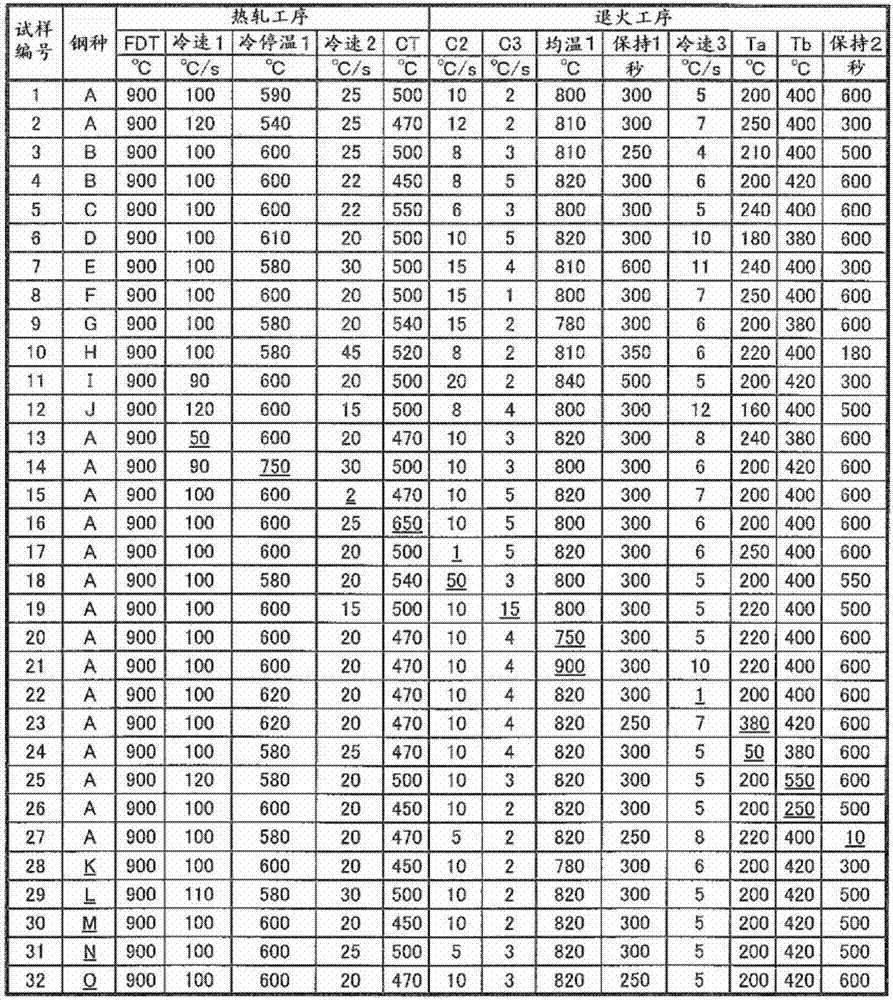

Ultra-high strength steel sheet having excellent phosphatability and hole expandability and method for manufacturing same

InactiveUS20180355453A1Excellent hole expandabilityHigh phosphatabilityHot-dipping/immersion processesFurnace typesSulfurManganese

Provided is an ultra-high-strength steel sheet having high phosphatability and hole expandability, including, by wt %, carbon (C): 0.08% to 0.2%, silicon (Si): 0.05% to 1.3%, manganese (Mn): 2.0% to 3.0%, phosphorus (P): 0.001% to 0.10%, sulfur (S): 0.010% or less, aluminum (Al): 0.01% to 0.1%, chromium (Cr): 0.3% to 1.2%, boron (B): 0.0010% to 0.0030%, titanium (Ti): 0.01% to 0.05%, nitrogen (N): 0.001% to 0.01%, and a balance of iron (Fe) and inevitable impurities, satisfying 3.4≤Ti / N≤10, 1.0≤Mn / (Si+Cr), and 0.7≤Mn* / (Si*+Cr*)≤Mn / (Si+Cr) where Ti, N, Mn, Si, and Cr refer to a weight percent (wt %), and Mn*, Si*, and Cr* refer to an average of values obtained by GDS component analysis from the surface to the 0.1 μm position in the thickness direction.

Owner:POHANG IRON & STEEL CO LTD

Alloyed hot-dip galvanized DH590 steel with high hole expansion performance and preparation method thereof

The invention discloses 590MPa-grade alloying hot-dip galvanized DH steel with high hole expansion performance and a preparation method thereof. The steel comprises the following chemical components of, in percentage by mass, 0.09%-0.15% of C, 1.0%-2.0% of Mn, 0.1%-0.5% of Si, 0.02%-0.6% of Al, 0.02%-0.4% of Mo, less than or equal to 0.03% of P, less than or equal to 0.03% of S, less than or equalto 0.003% of B, less than or equal to 0.03% of Ti and the balance iron and inevitable impurities. According to the preparation method, the heating temperature of a casting blank ranges from 1200 DEGC to 1280 DEG C, the initial rolling temperature ranges from 1080 DEG C to 1160 DEG C, the final rolling temperature is greater than or equal to 930 DEG C, and the coiling temperature ranges from 600DEG C to 700 DEG C; the cold rolling reduction rate is 50%-85%; the annealing temperature ranges from 760 DEG C to 860 DEG C, the annealing time ranges from 30 seconds to 300 seconds, the slow coolingoutlet temperature ranges from 670 DEG C to 710 DEG C, the rapid cooling rate is larger than 20 DEG C / s, the galvanizing temperature ranges from 450 DEG C to 470 DEG C, the alloying temperature ranges from 480 DEG C to 530 DEG C, and the heat preservation time ranges from 5 seconds to 60 seconds; and the finishing elongation rate is 0.2%-0.6%. The elongation percentage after fracture of a finished steel plate A50 is 30%-35%, and the hole expanding rate is larger than or equal to 60%.

Owner:ANGANG STEEL CO LTD

High-strength hot-rolled steel shaft excellent in hole expandability and ductility and production method thereof

InactiveUS7828912B2Inhibit deteriorationImprove hole reaming effectMetal rolling stand detailsSolid state diffusion coatingHigh intensityUltimate tensile strength

This invention provides a high-strength hot-rolled steel sheet having strength of at least 980 N / mm2 at a sheet thickness of from about 1.0 to about 6.0 mm and excellent in hole expandability, ductility and ability of phosphate coating, which steel sheet is directed to automotive suspension components that are subjected to pressing. The high-strength hot-rolled steel sheet contains, in terms of a mass %, C: 0.01 to 0.09%, Si: 0.05 to 1.5%, Mn: 0.5 to 3.2%, Al: 0.003 to 1.5%, P: 0.03% or below, S: 0.005% or below, Ti: 0.10 to 0.25%, Nb:0.01 to 0.05% and the balance consisting of iron and unavoidable impurities;satisfies all of the following formulas <1> to <3>:0.9≦48 / 12×C / Ti<1.7 <1>50,227×C−4,479×Mn>−9,860 <2>811×C+135×Mn+602×Ti+794×Nb>465 <3>,and has strength of at least 980 N / mm2.

Owner:NIPPON STEEL CORP

Super-high-strength hot-rolled steel plate and steel belt with good fatigue and broaching performance and manufacturing method of steel plate and steel belt

ActiveCN110643894AHigh strengthImprove hole reaming effectFurnace typesHeat treatment furnacesTensile fatigueBroaching

Owner:BAOSHAN IRON & STEEL CO LTD

Ferritomartensite hot-rolled dual phase steel with high surface quality and manufacturing method thereof

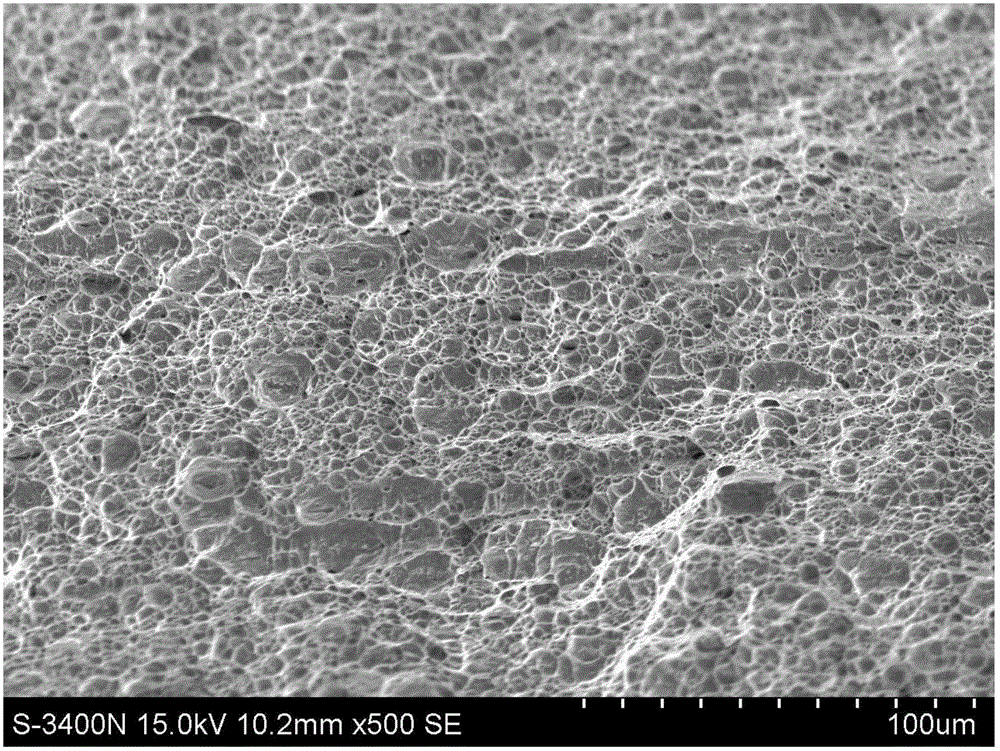

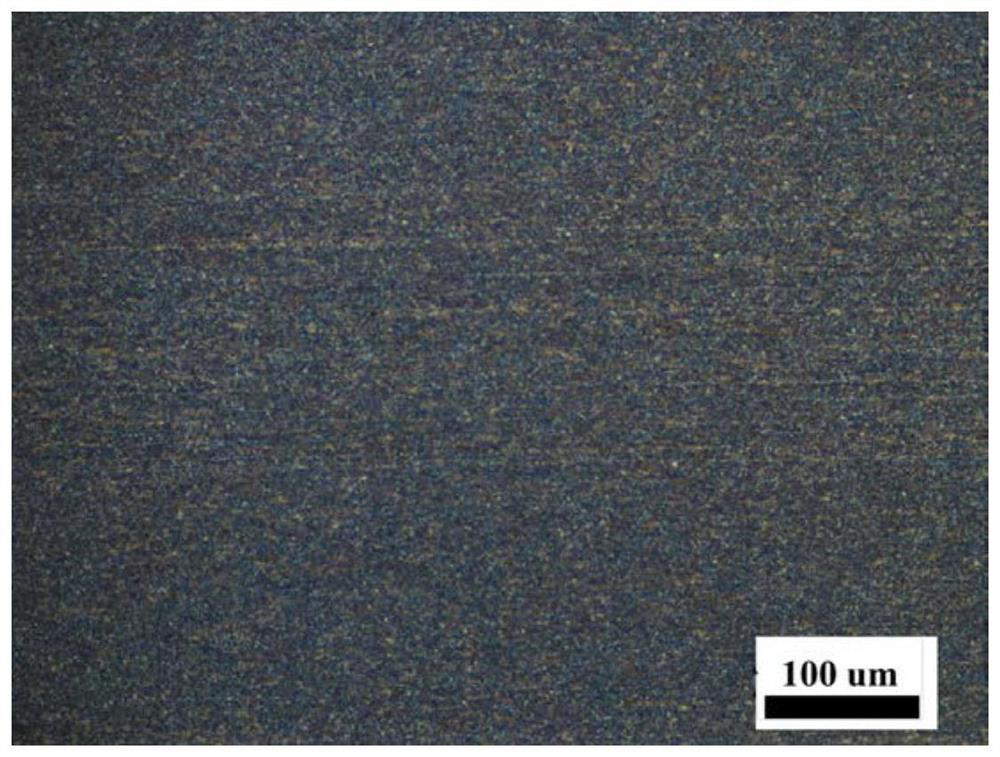

The invention discloses ferritomartensite hot-rolled dual phase steel with high surface quality and a manufacturing method thereof. The steel comprises, by weight percent, 0.04 to 0.08% of C, not larger than 0.1% of Si, 1.0 to 1.4% of Mn, 0.3 to 0.8% of Al, 0.15 to 0.60% of Cr, 0.01 to 0.03% of Nb, not larger than 0.015% of P, not larger than 0.002% of S, and not larger than 0.005% of N, one or more of not larger than 0.03% of Ti, not larger than 0.03% of V, and not larger than 0.005% of Ca and the balance Fe and inevitable impurities. The conditions that the sum of Si+2Al+Cr is larger than orequal to 1.0 and Al / Cr is smaller than or equal to 2.5 need to be met at the same time, according to the hot-rolled dual phase steel, after acid pickling, the surface is bright and clean and free offigures, the tensile strength of the steel can be up to 600 MPa or above, the yield ratio is 0.7 or below, the hole expansion rate is 50% or above, the easy forming high hole expansion property is achieved, the steel can be used for producing parts like car wheel spokes, in addition, a production process is wide in window, industrial large production is easy, and performance is stable.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for producing high-strength hot-dip galvanized steel sheet with excellent material-quality stability, processability, and deposit appearance

ActiveCN103597102AGood lookingImprove ductilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

Provided is a process for producing a high-strength hot-dip galvanized steel sheet which has a tensile strength TS of 540 MPa or higher and which is excellent in terms of material-quality stability, processability, and deposit appearance. A steel sheet that contains, in terms of mass%, 0.04-0.13% C, 0.7-2.3% Si, 0.8-2.0% Mn, up to 0.1% P, up to 0.01% S, up to 0.1% Al, and up to 0.008% N is subjected to a first heating step in which the steel sheet is heated to 400-750 DEG C in an atmosphere having an O2 concentration of 0.1-20 vol.% and an H2O concentration of 1-50 vol.% and then heated to 600-850 DEG C in an atmosphere having an O2 concentration of 0.01-0.1 vol.%, excluding 0.1 vol.%, and an H2O concentration of 1-20 vol.%. The steel sheet is subsequently subjected to a second heating step in which the steel sheet is held at 750-900 DEG C for 15-600 seconds in an atmosphere having an H2 concentration of 1-50 vol.% and a dew point of 0 DEG C or lower, cooled to a temperature in the range of 450-550 DEG C, and then held at this temperature for 10-200 seconds. Thereafter, the steel sheet is subjected to hot-dip galvanization.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com