Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve flanging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

780 MPa hot-rolled high-strength steel with high hole expansion ratio and manufacturing method thereof

The invention provides a 780 MPa hot-rolled high-strength steel with high hole expansion ratio and a manufacturing method thereof. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio comprises the following chemical components in percentage by mass: more than or equal to 0.03 percent and less than or equal to 0.07 percent of C, less than or equal to 0.2 percent of Si, more than or equal to 1.0 percent and less than or equal to 2.0 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.005 percent of S, more than or equal to 0.02 percent and less than or equal to 0.05 percent of Al, less than or equal to 0.005 percent of N, more than or equal to 0.08 percent and less than or equal to 0.20 percent of Ti, more than or equal to 0.15 percent and less than or equal to 0.25 percent of Mo, less than or equal to 0.003 percent of O and the balance of Fe and inevitable impurity elements, wherein Ti / Mo is more than or equal to 0.25 and less than or equal to 1.5, and (Ti-3.42N) / 4+Mo / 8 is more than or equal to 0.03 percent and less than or equal to 0.07 percent. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio is obtained through smelting, casting, high-temperature heating, hot rolling and reeling processes, and is more than or equal to 750 MPa in yield strength, more than or equal to 780 MPa in tensile strength, more than or equal to 20 percent in extensibility, more than or equal to 70 percent in hole expansion ratio when the thickness is 3-6 mm.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

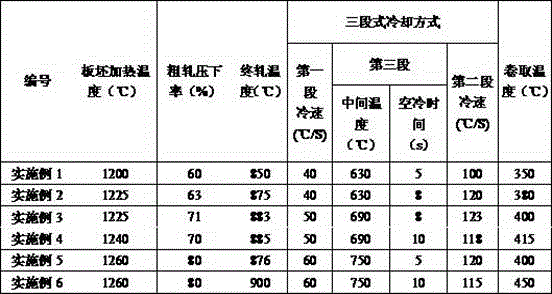

800MPa-level hot-rolled high strength chambering steel and production method thereof

The invention discloses 800MPa-level hot-rolled high strength bainite chambering steel and a production method thereof. The 800MPa-level hot-rolled high strength bainite chambering steel consists of the following chemical components in percentage by mass: greater than or equal to 4 percent and less than or equal to 0.08 percent of C, greater than or equal to 0.5 percent and less than or equal to 0.8 percent of Si, greater than or equal to 0.5 percent and less than or equal to 1.6 percent of Mn, less than or equal to 0.005 percent of P, less than or equal to 0.004 percent of S, less than or equal to 0.004 percent of N, greater than or equal to 0.15 percent and less than or equal to 0.18 percent of Ti, greater than or equal to 0.15 percent and less than or equal to 0.25 percent of Cr, greater than or equal to 0.03 percent and less than or equal to 0.05 percent of Nb, and the balance of Fe and inevitable impurity elements. The high strength bainite chambering steel with yield strength greater than or equal to 680 MPa, tensile strength greater than or equal to 800 MPa and ductility greater than or equal to 17 percent is obtained by processes of smelting, refining, slab continuous casting, slab heating, hot rolling, three-section type laminar cooling and rolling; a steel plate with the thickness of 2.8 to 6 mm has the chambering rate over 85 percent.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

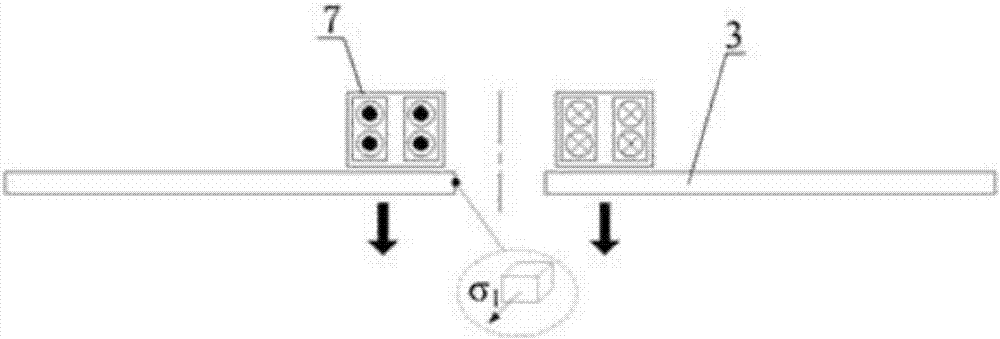

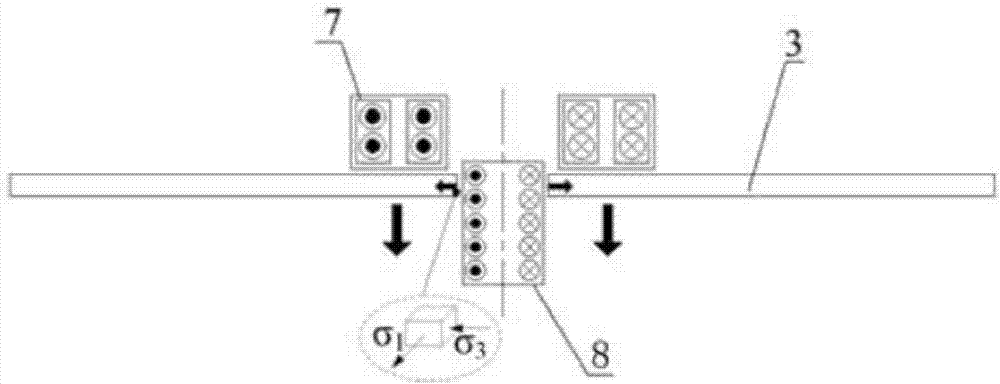

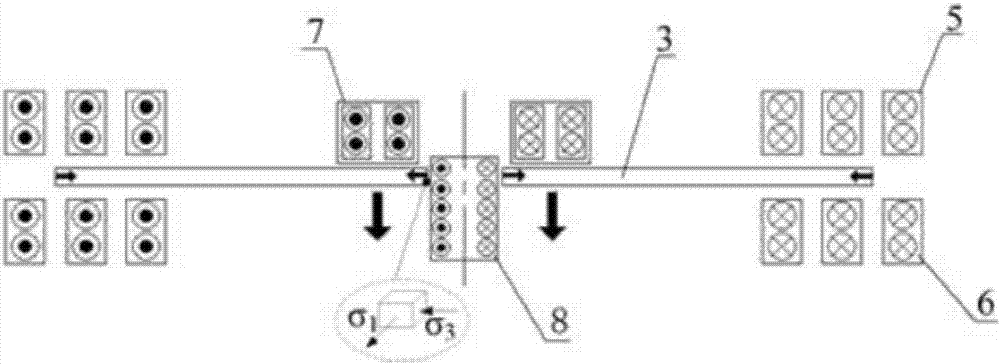

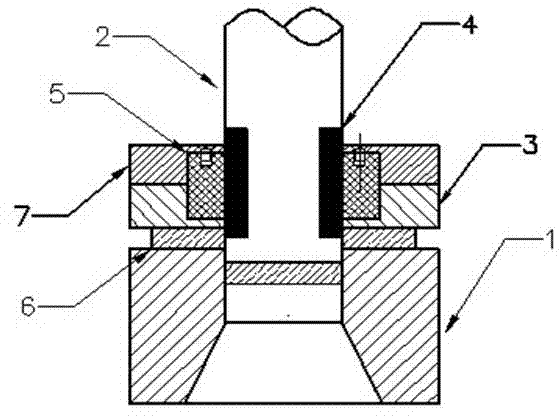

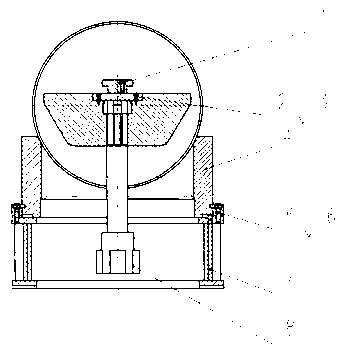

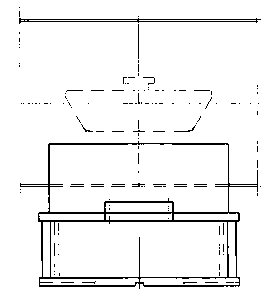

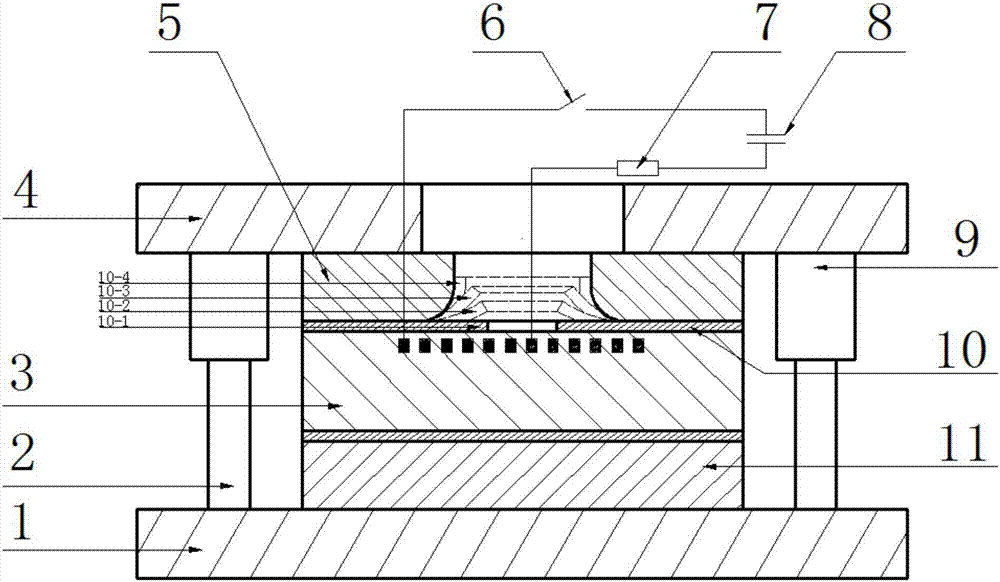

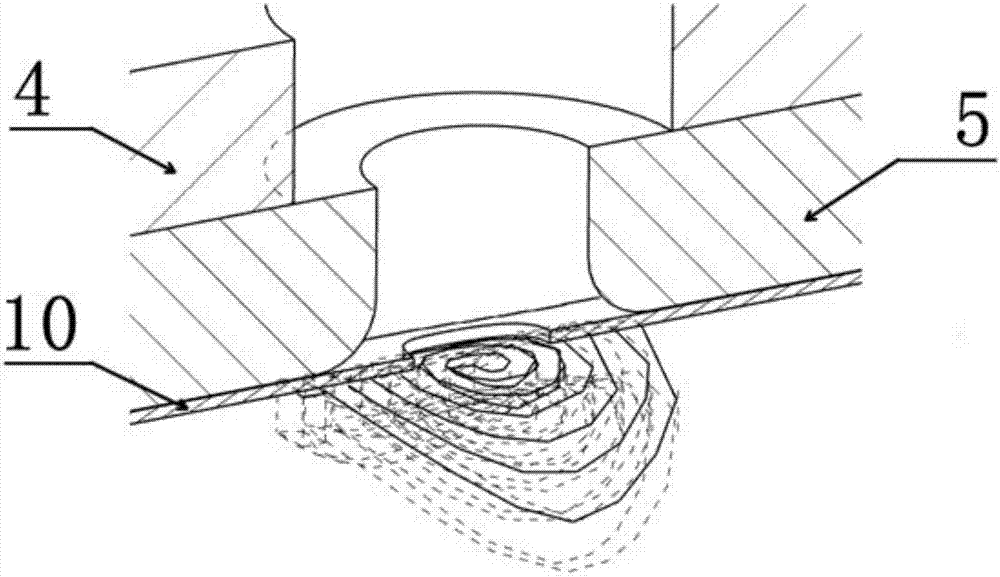

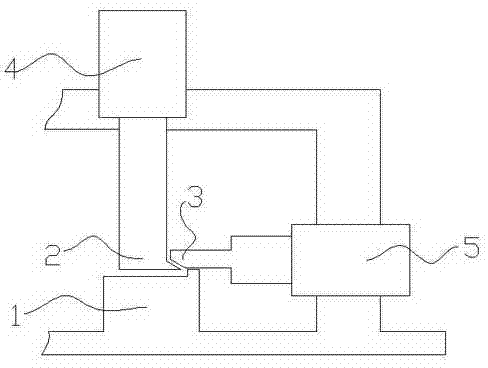

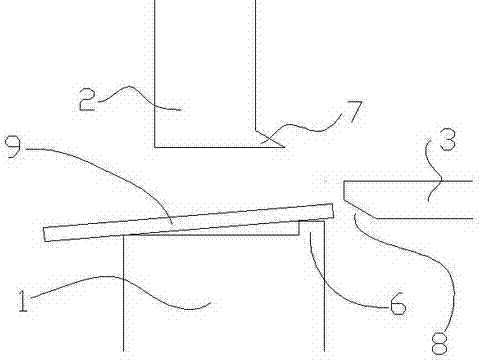

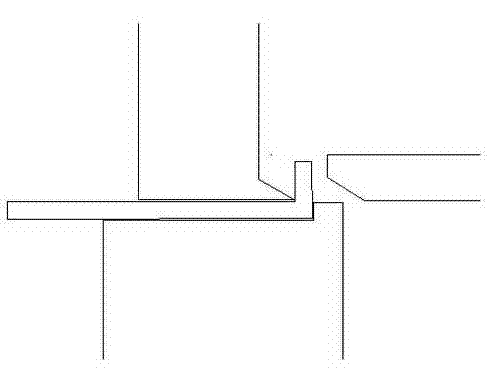

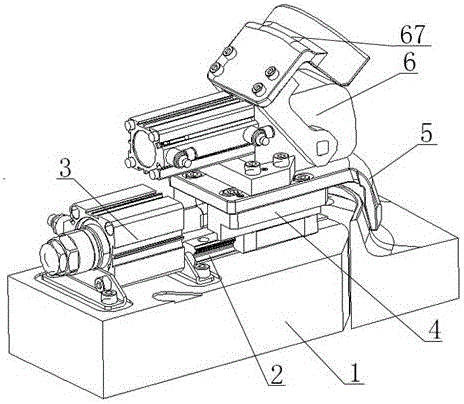

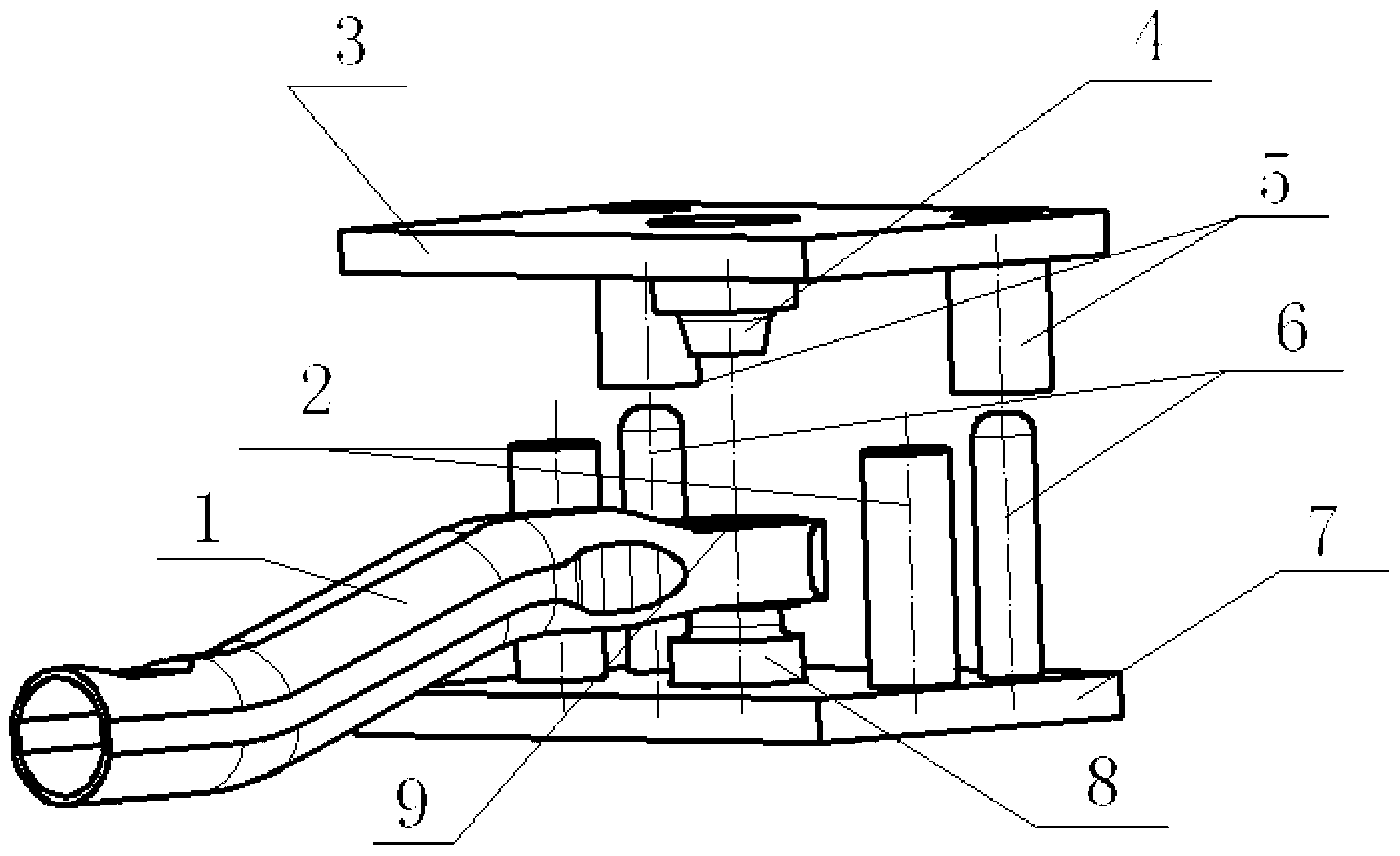

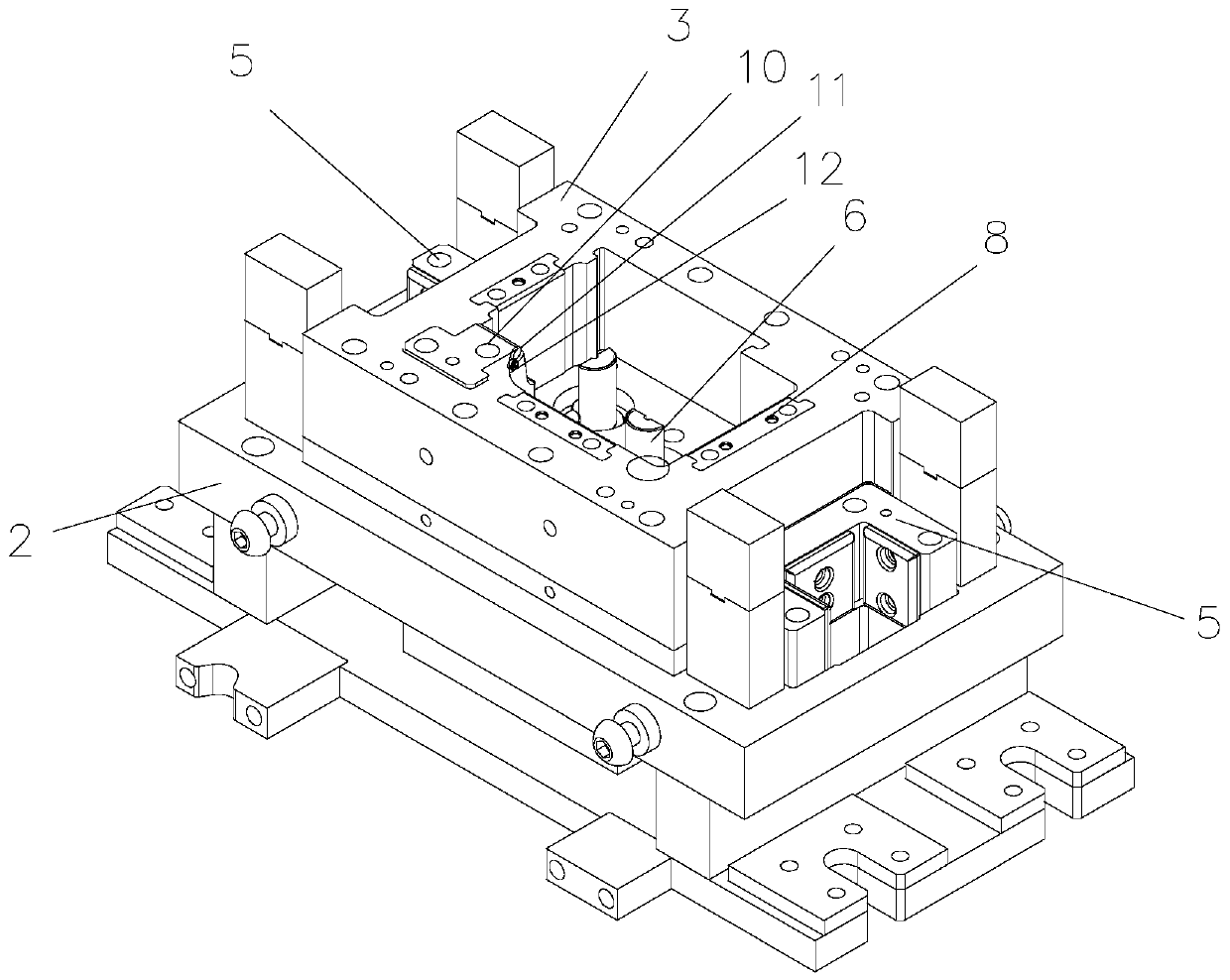

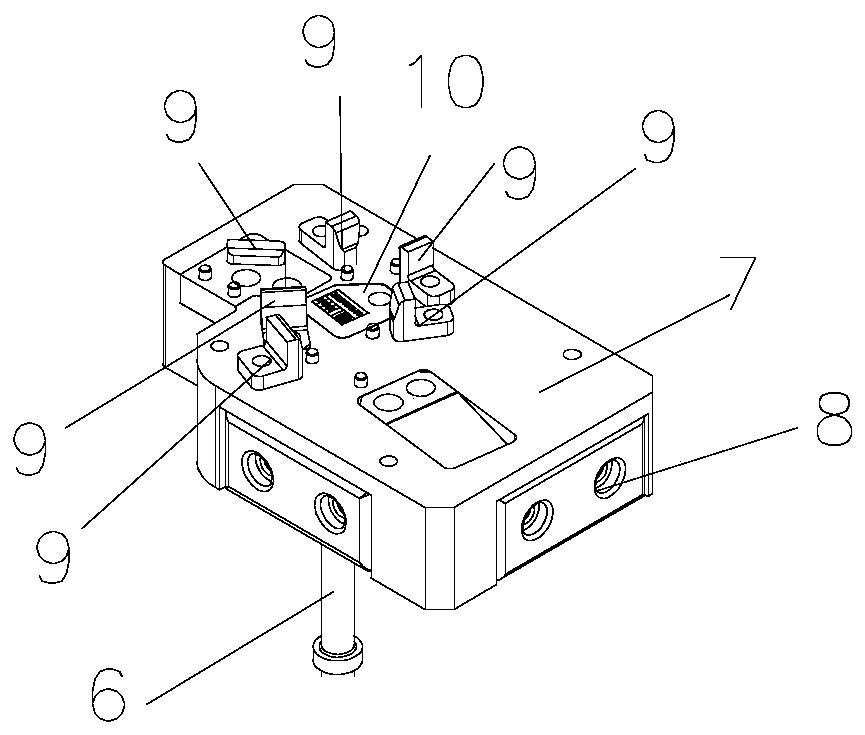

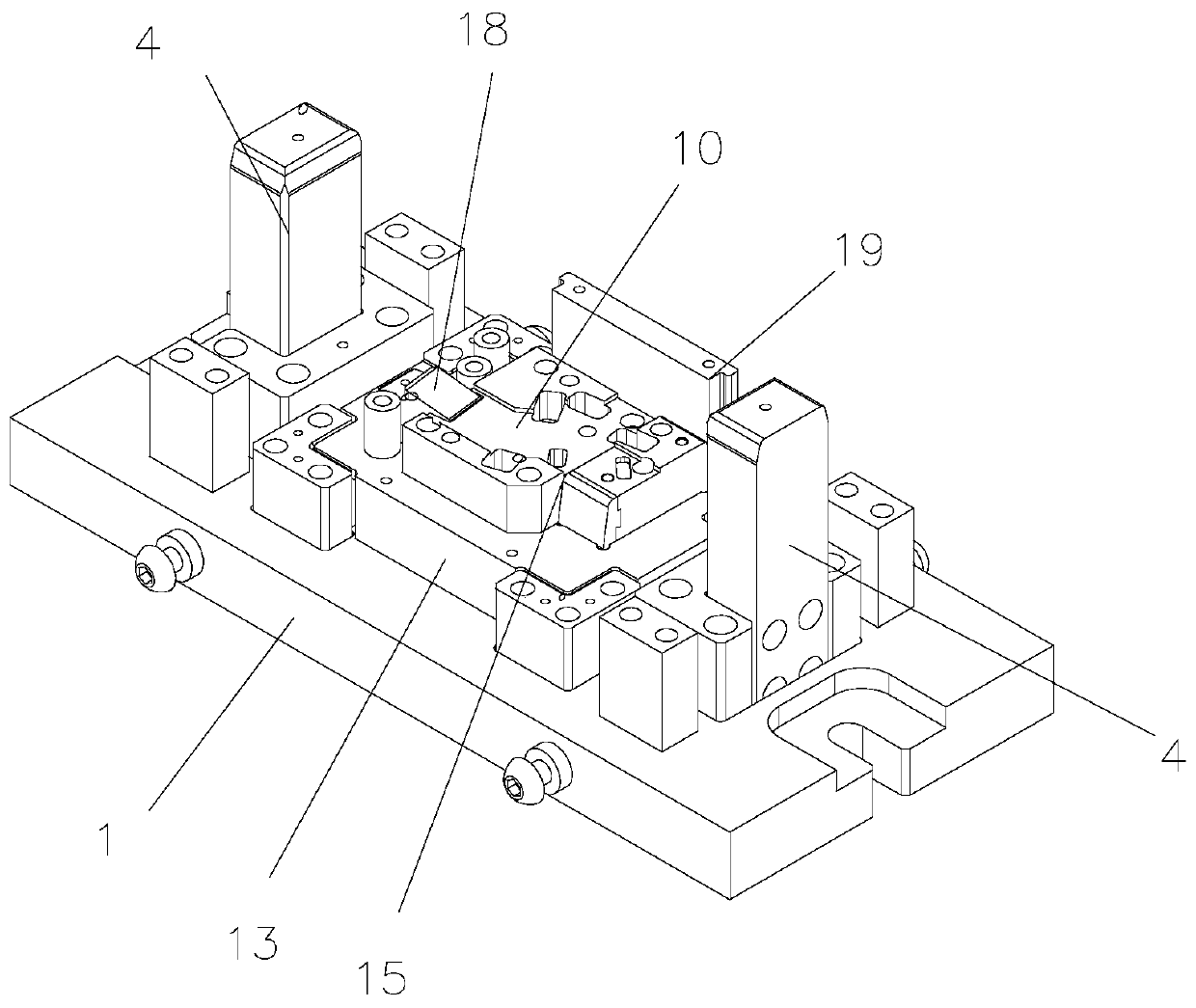

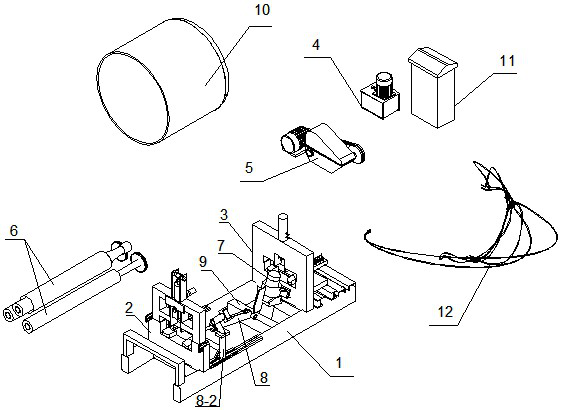

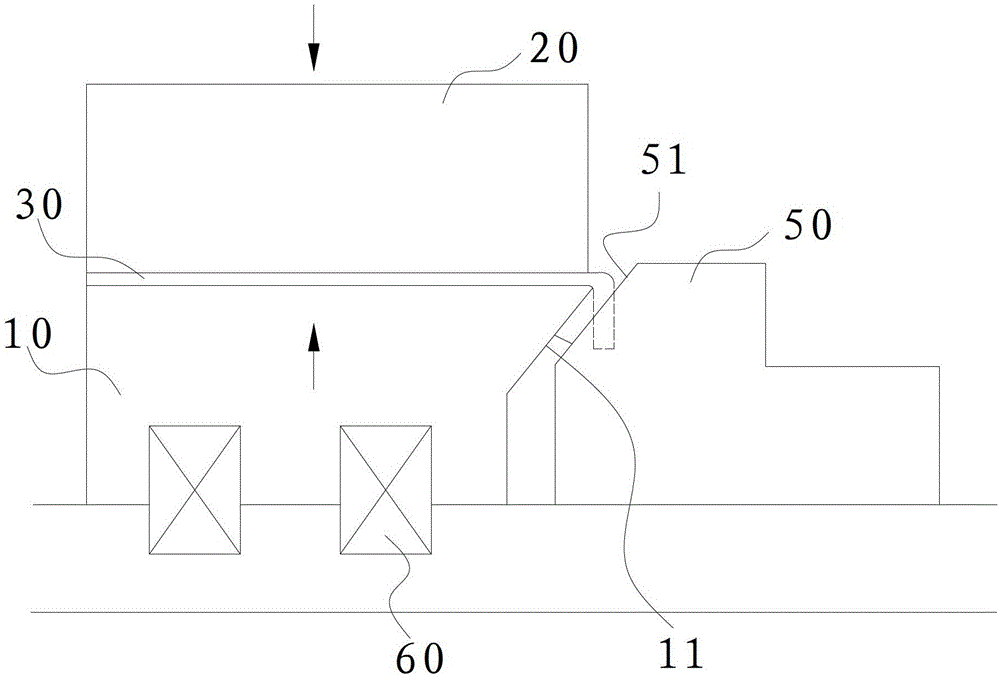

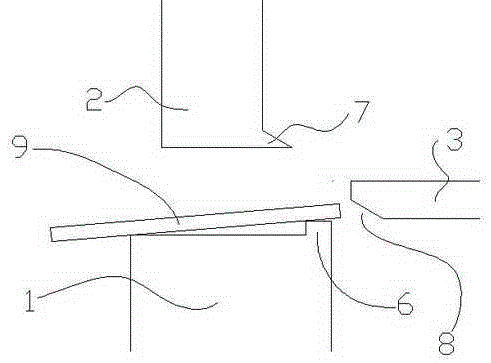

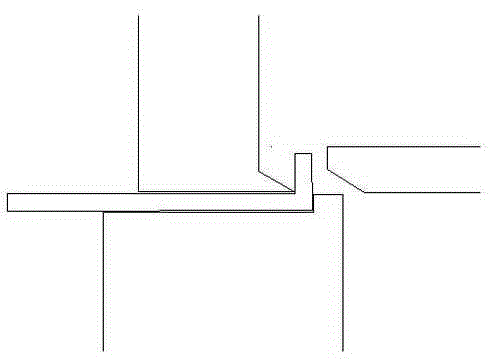

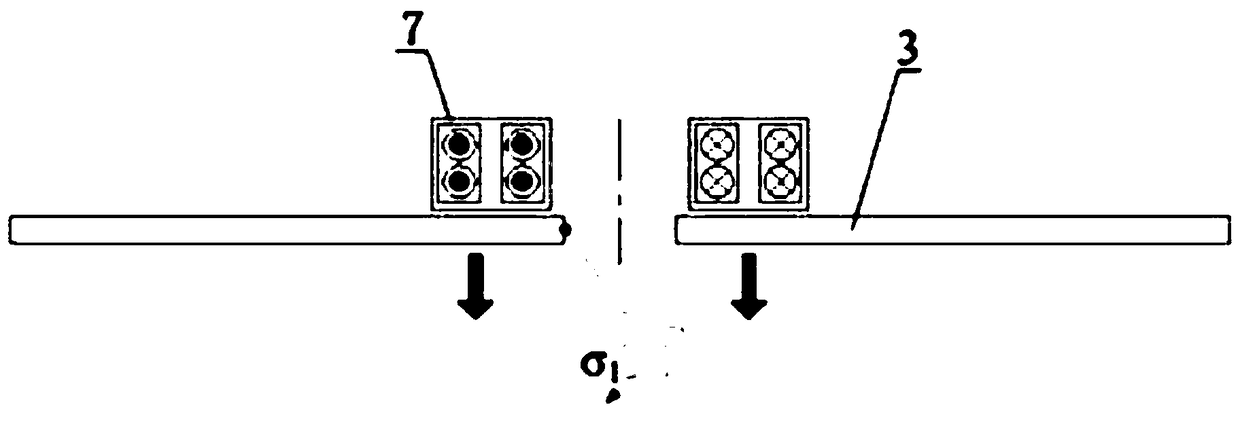

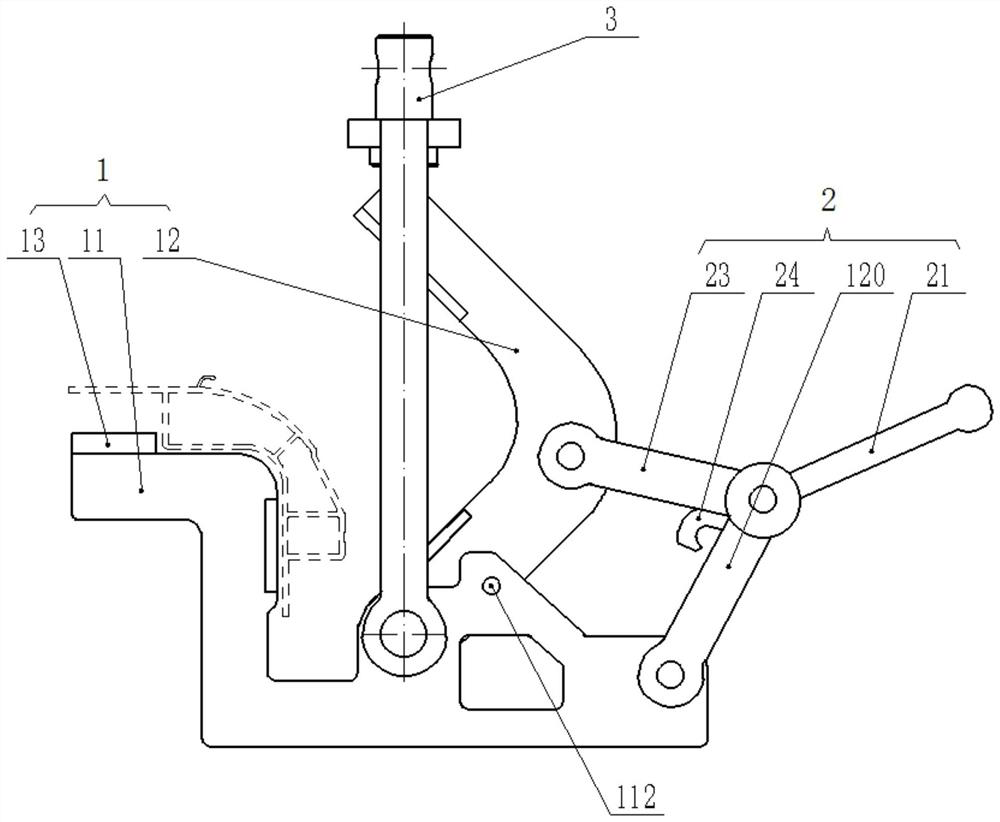

Device and method for driving plate hole flanging forming through multidirectional magnetic field force

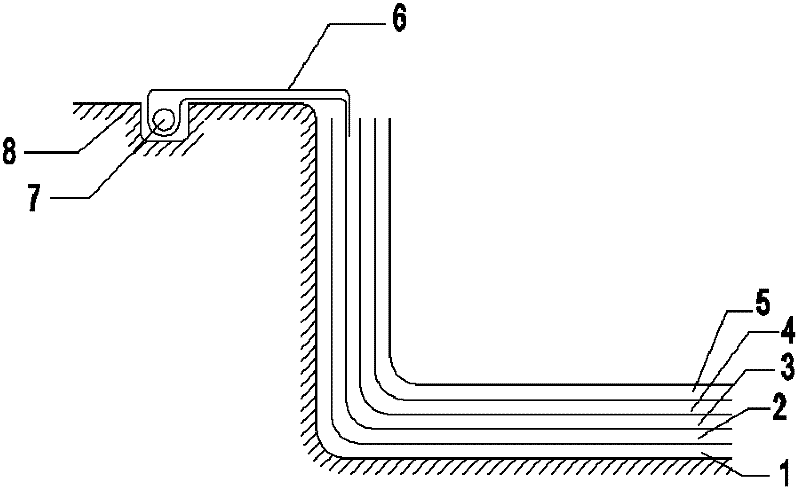

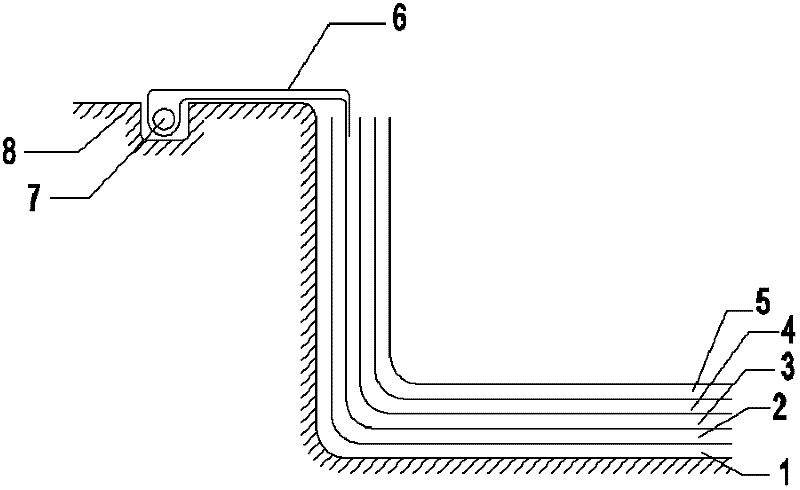

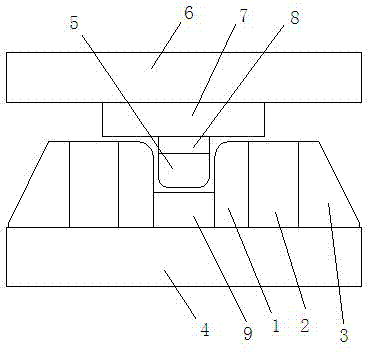

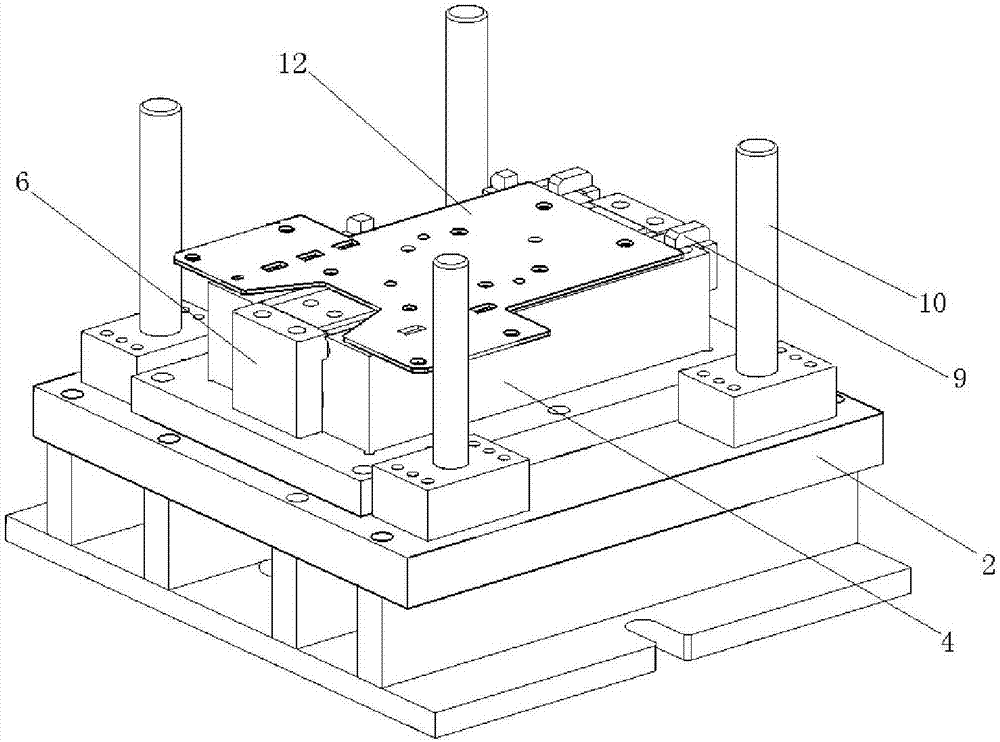

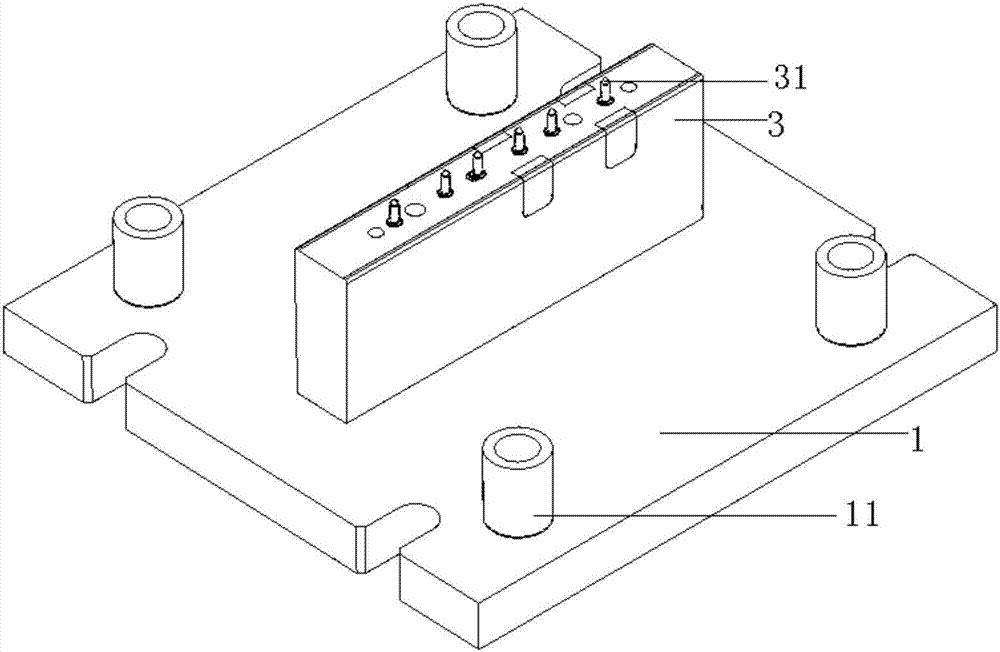

The invention discloses a device and method for driving plate hole flanging forming through multidirectional magnetic field force. The device comprises a blank holder (1) and a concave die (2). The blank holder (1) is arranged above the concave die (2) and used for pressing a plate (3) to be subjected to hole flanging forming between the blank holder (1) and the concave die (2). A concave die cavity (4) is formed in the concave die (2). An upper coil groove and a lower coil groove are correspondingly formed in the blank holder (1) and the concave die (2). Upper end hole shrinkage coils (5) are embedded in the upper coil groove. Lower end hole shrinkage coils (6) are embedded in the lower coil groove. Axial deep drawing coils (7) are arranged above the edge of a pre-formed hole of the plate (3). An inner bulging coil (8) is arranged in the pre-formed hole of the plate (3). According to the device and method, cracks can be prevented from being generated to a round hole flanging deformation area during hole flanging forming, the product quality is good, and the forming process is simple.

Owner:CENT SOUTH UNIV

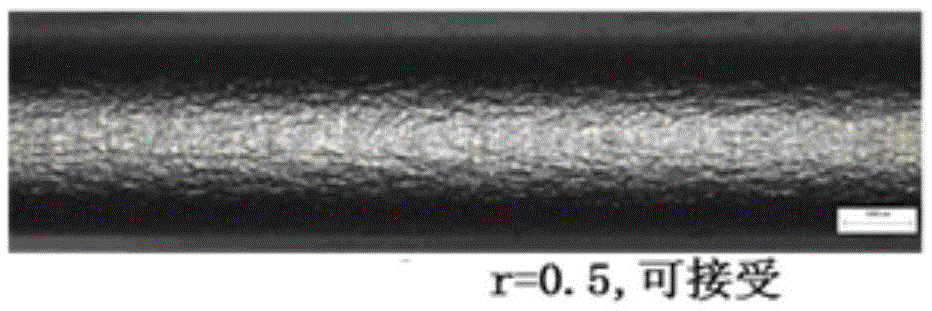

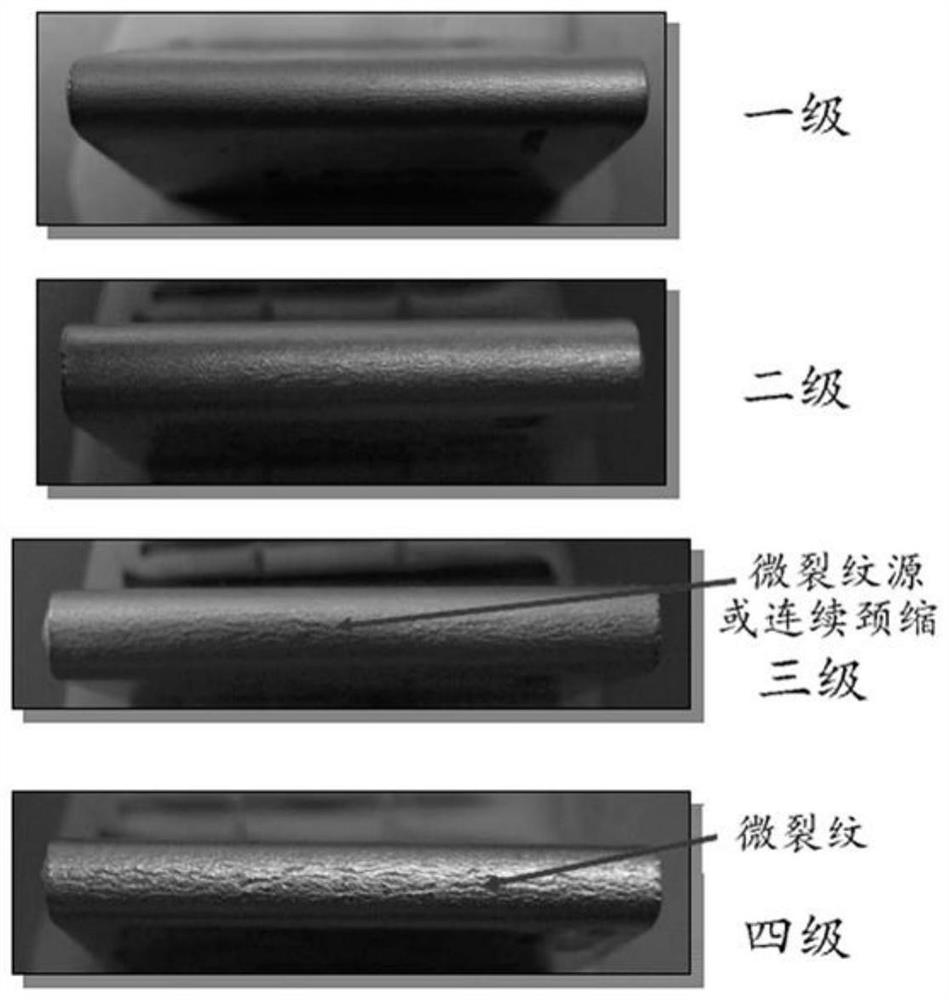

Punching method for improving flanging capability of sheet

InactiveCN102886422AImprove flanging effectHigh strengthShaping toolsPerforating toolsPunchingEngineering

The invention provides a punching method for improving the flanging capability of a sheet, belonging to the technical field of metal plastic processing formation. The method disclosed by the invention comprises the steps that: a high-frequency heating device is connected to the blank holder ring of a common punching die, a male die insulating layer is arranged in the middle of a male die; the high frequency heating device is started up after a sheet is put in the common punching die, and the high frequency heating device is shut down after the temperature of the punching edge area of the sheet reaches 500 to 700 DEG C, afterwards, the male die moves downwards and sheet blanking begins, the temperature of the blanked edge is maintained for 1 to 30 seconds at the end of the blanking, then the male die returns and the sheet is taken out to finish punching for the flanged sheet. With the adoption of the method disclosed by the invention, the flanging capability of the sheet is improved while the strength and surface quality of material are not degraded, and the method disclosed by the invention can be popularized and applied to sheet preparation in other punching processes.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

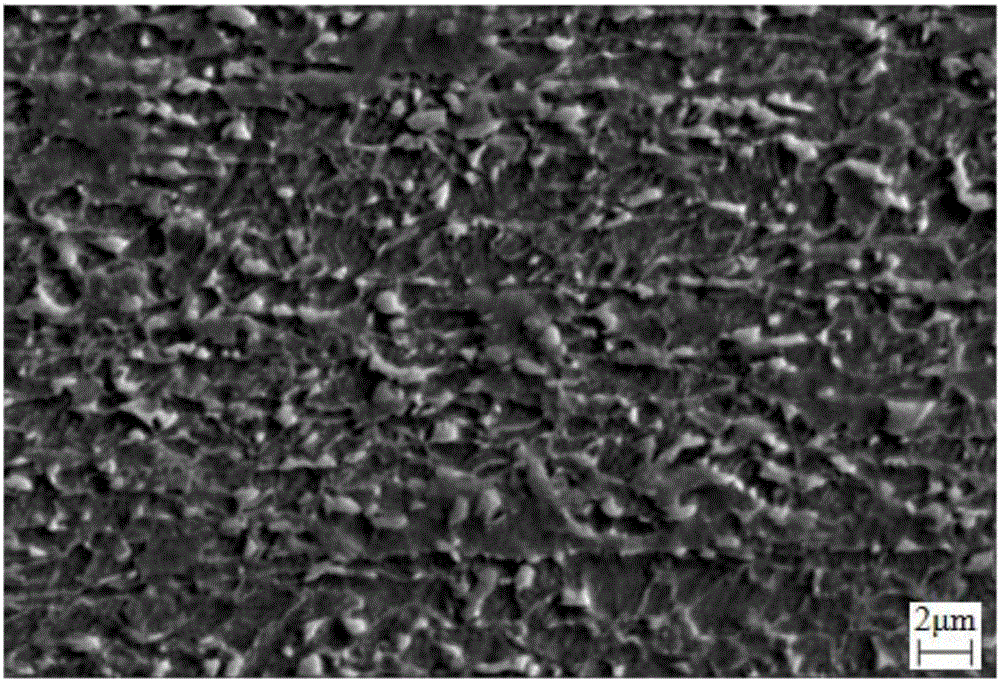

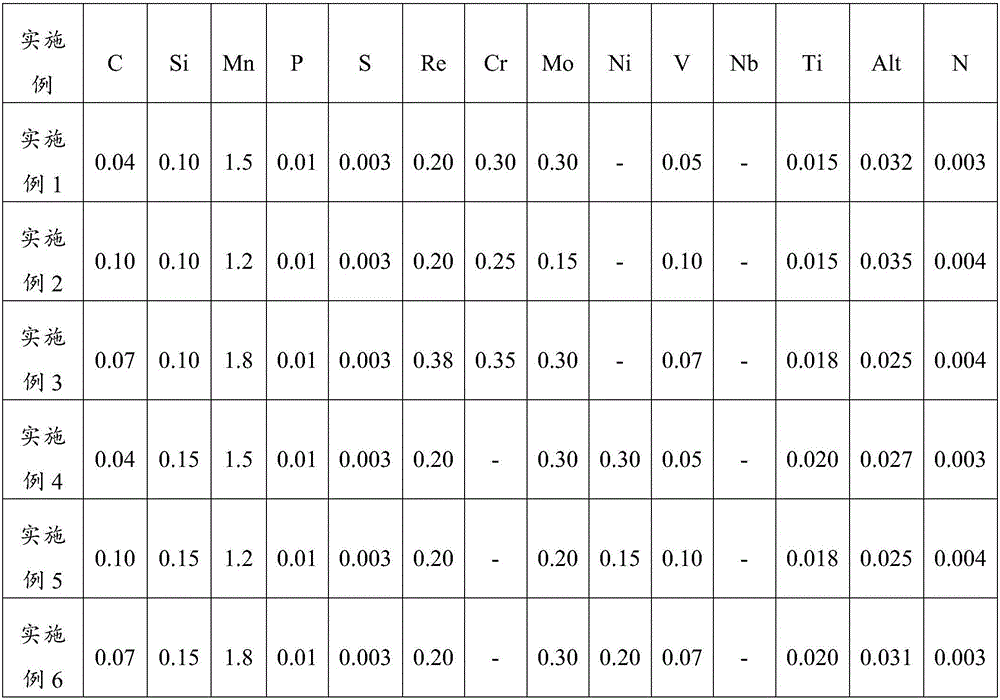

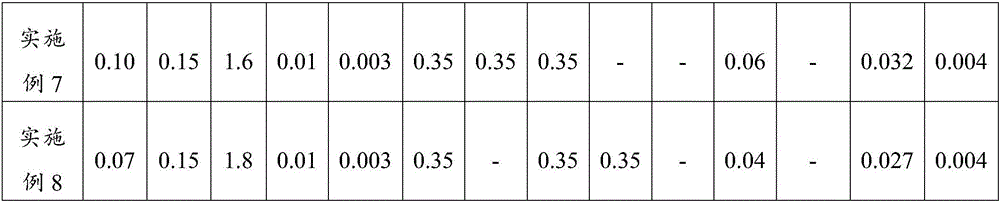

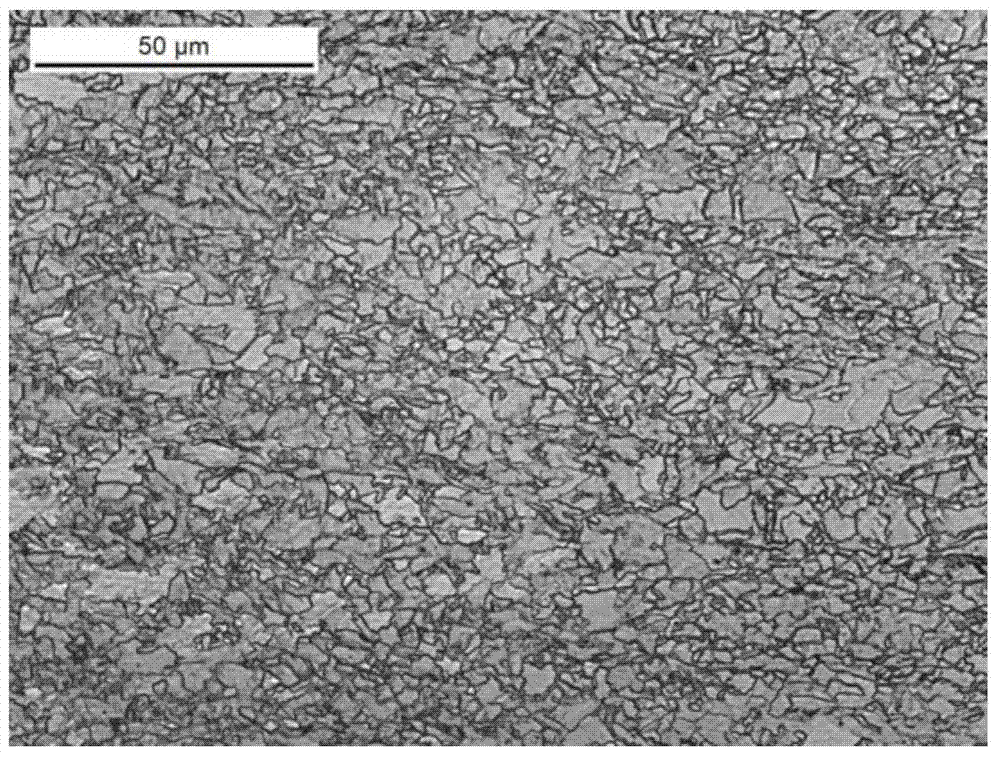

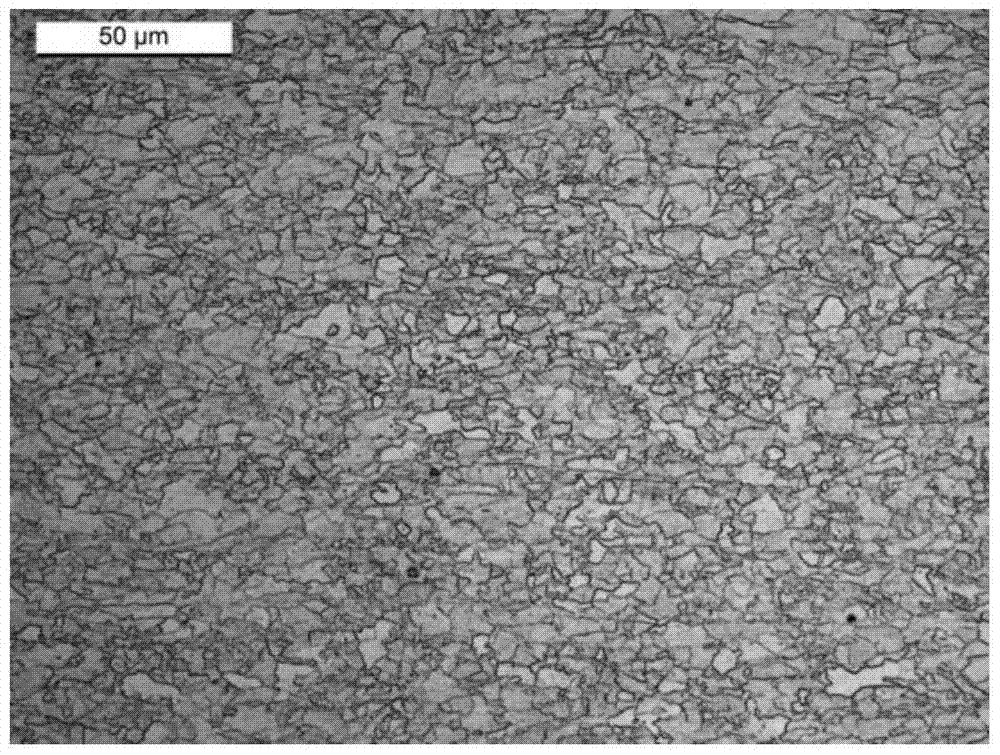

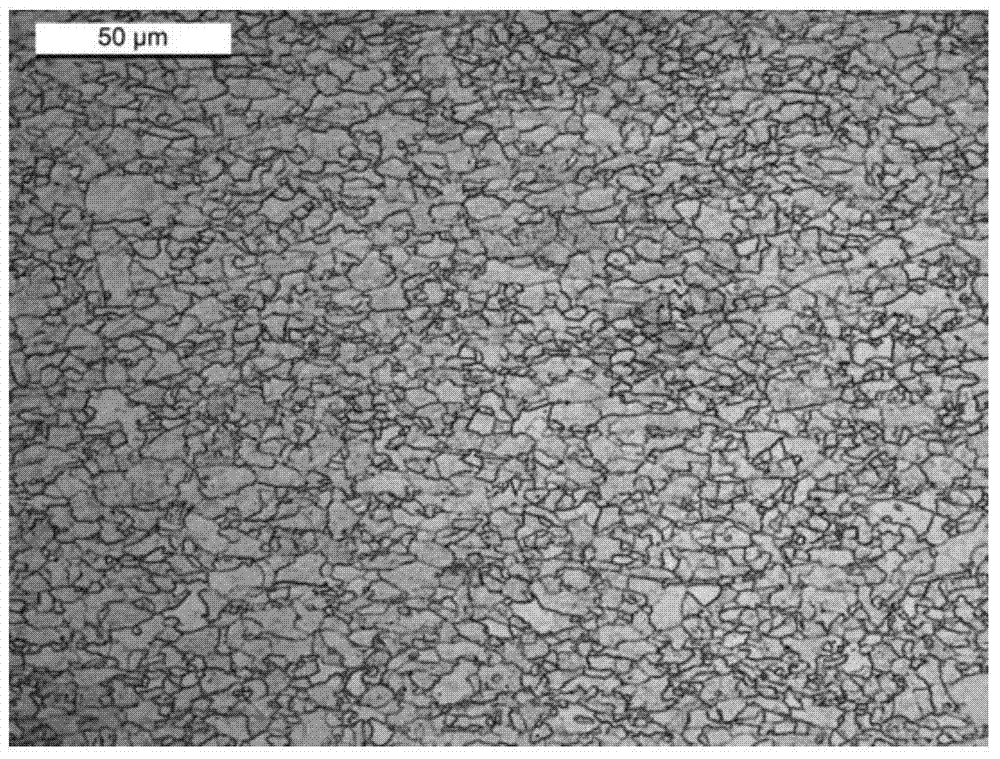

Hot-rolled multi-phase steel with excellent flangability and production method thereof

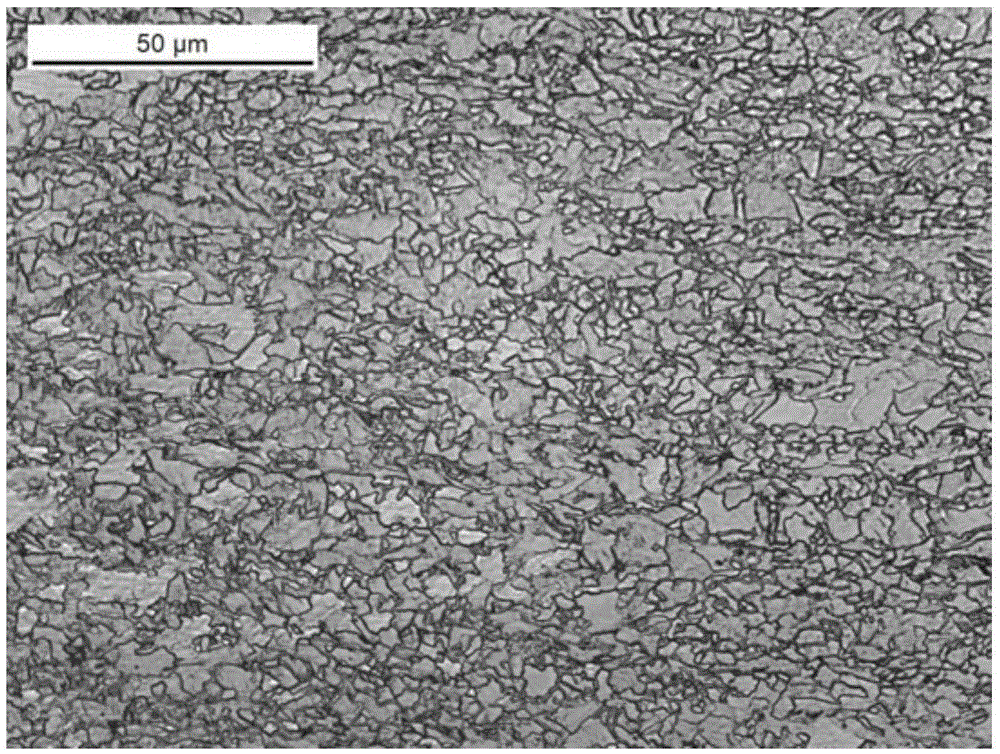

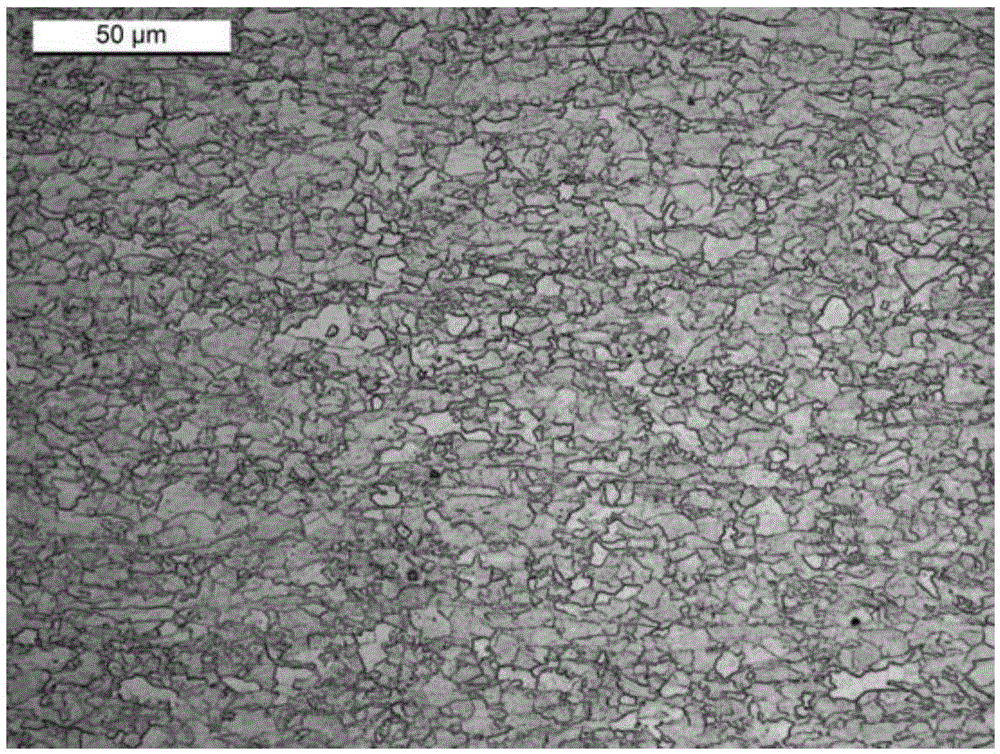

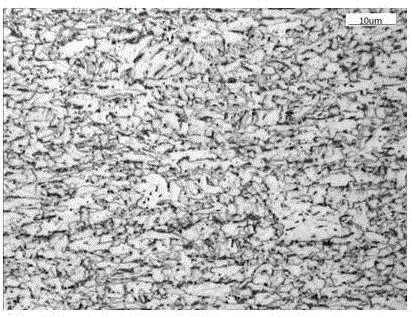

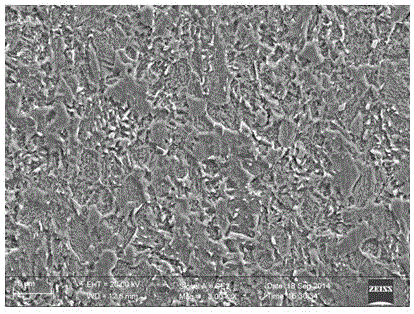

The invention discloses a hot-rolled multi-phase steel with excellent flangability and production method thereof, belonging to technical field of steelmaking. The hot-rolled multi-phase steel comprises the following chemical components by mass: 0.04 to 0.10% of C, 0.1 to 0.2% of Si, 1.0 to 2.0% of Mn, no more than 0.015% of P, no more than 0.004% of S, no more than 0.04% of Al, no more than 0.0050% of N, 0.1 to 0.4% of Re, any two selected from a group consisting of 0.25 to 0.45% of Cr, 0.1 to 0.4% of Mo and 0.1 to 0.4% of Ni, and any one selected from a group consisting of 0.04 to 0.06% of Nb and a mixture of 0.05 to 0.10% of V and 0.010 to 0.03% of Ti, with the balance being Fe and unavoidable impurities. The interior microscopic structure of the hot-rolled multi-phase steel is granular bainite. The hot-rolled multi-phase steel in the invention has good flangability, surface quality and comprehensive mechanical properties.

Owner:SHOUGANG CORPORATION

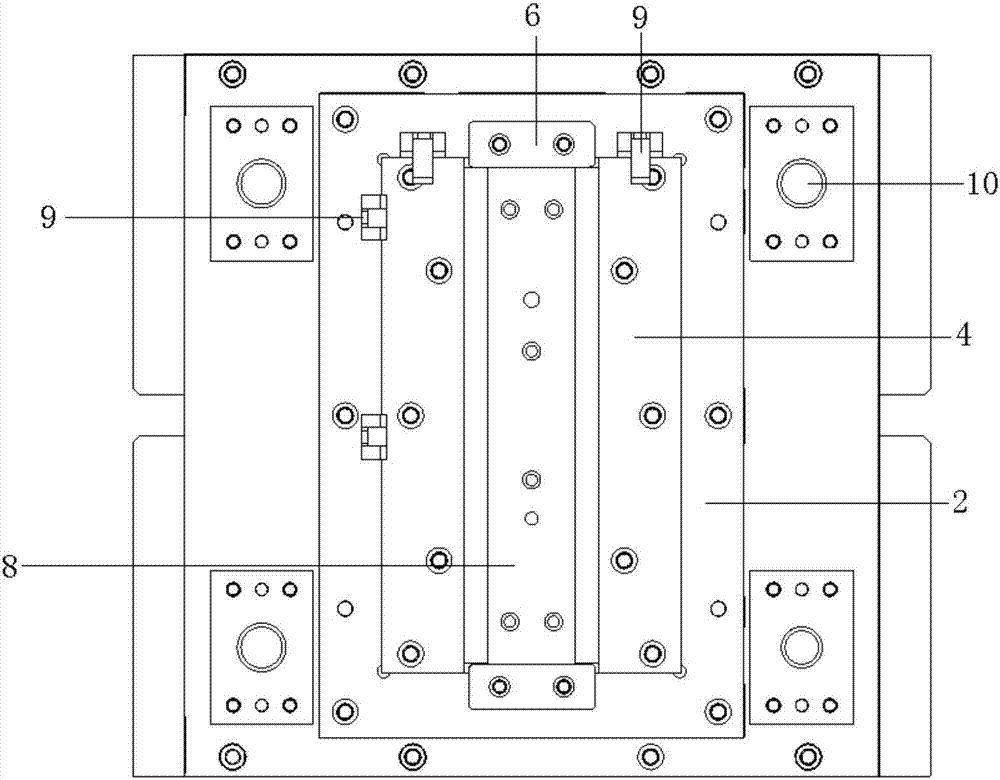

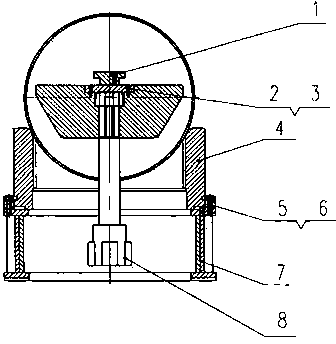

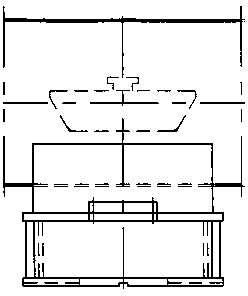

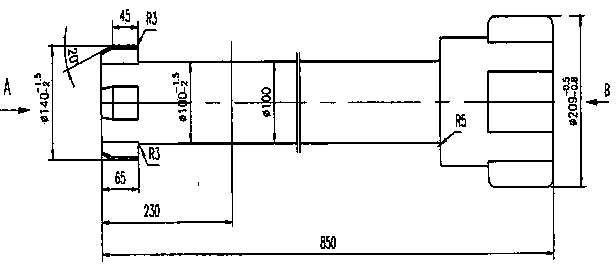

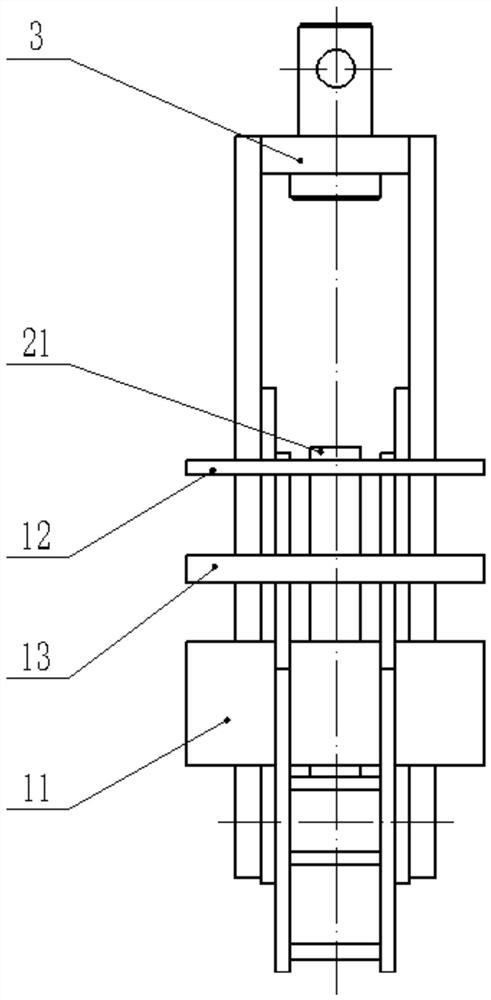

Flange mould system of shell branch hole of high-voltage switch

InactiveCN102699190ASolve problems such as easy cracking and uneven vertical edgesIncrease usage intensityShaping toolsVertical edgeEngineering

The invention belongs to a device of a flange production process of a cylindrical (shell) branch hole of aluminum and steel materials and particularly relates to a flange mould system of a shell branch hole of a high-voltage switch. The flange mould system is characterized in that: a mould handle is connected with a convex mould through a connecting piece; external splines are respectively machined at the top end and the bottom end of a pull rod; the top end of the pull rod is inserted into a spline groove in the convex mould and then rotates for 45 degrees to be clamped with the convex mould; the bottom part of the pull rod is inserted into a spline groove in an oil cylinder piston and then rotates for 45 degrees to be clamped with a main oil cylinder; a concave mould is clamped with a concave mould seat through clamping grooves which are in a clearance fit and two ends of the concave mould are fixed by a right baffling block and a right baffling block; the concave mould seat is fixed on a cross-shaped positioning key on a main worktable; a shell is placed on the concave mould to be subjected to alignment; and the convex mould is placed on an inserting head at the front end of a mechanical movable arm. The flange mould system has the advantages of reasonable and standard design, simplicity in machining and reliability in use; and the undesirable effects that a shell flange is easy to crack, a vertical edge is not straight, and the like are solved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Base material flanging machine

The invention discloses a base material flanging machine which mainly comprises a frame, a positioning pin support, a protecting grating, a suspension button station, an electric cabinet, a lifting mechanism, a heating system, an edge covering mechanism and a positioning die set. The positioning pin support is fixed on the frame. The protecting grating is disposed on the lateral side of the frame. The suspension button station is disposed on the frame. The electric cabinet is disposed on the inner side of the frame. The lifting mechanism is disposed on the inner side of the frame. The heating system is disposed on the lifting mechanism. The edge covering mechanism is disposed on the frame. The positioning die set is disposed on the edge covering mechanism. The base material flanging machine has the advantages that electric PLC control is adopted, touch-screen control buttons are used, and an automatic circulation function is provided; the base material flanging machine is compact in overall structure, simple to mount and operate, visual in touch screen display, convenient in parameter adjustment, and the like.

Owner:天津市精大稀机械设备制造公司

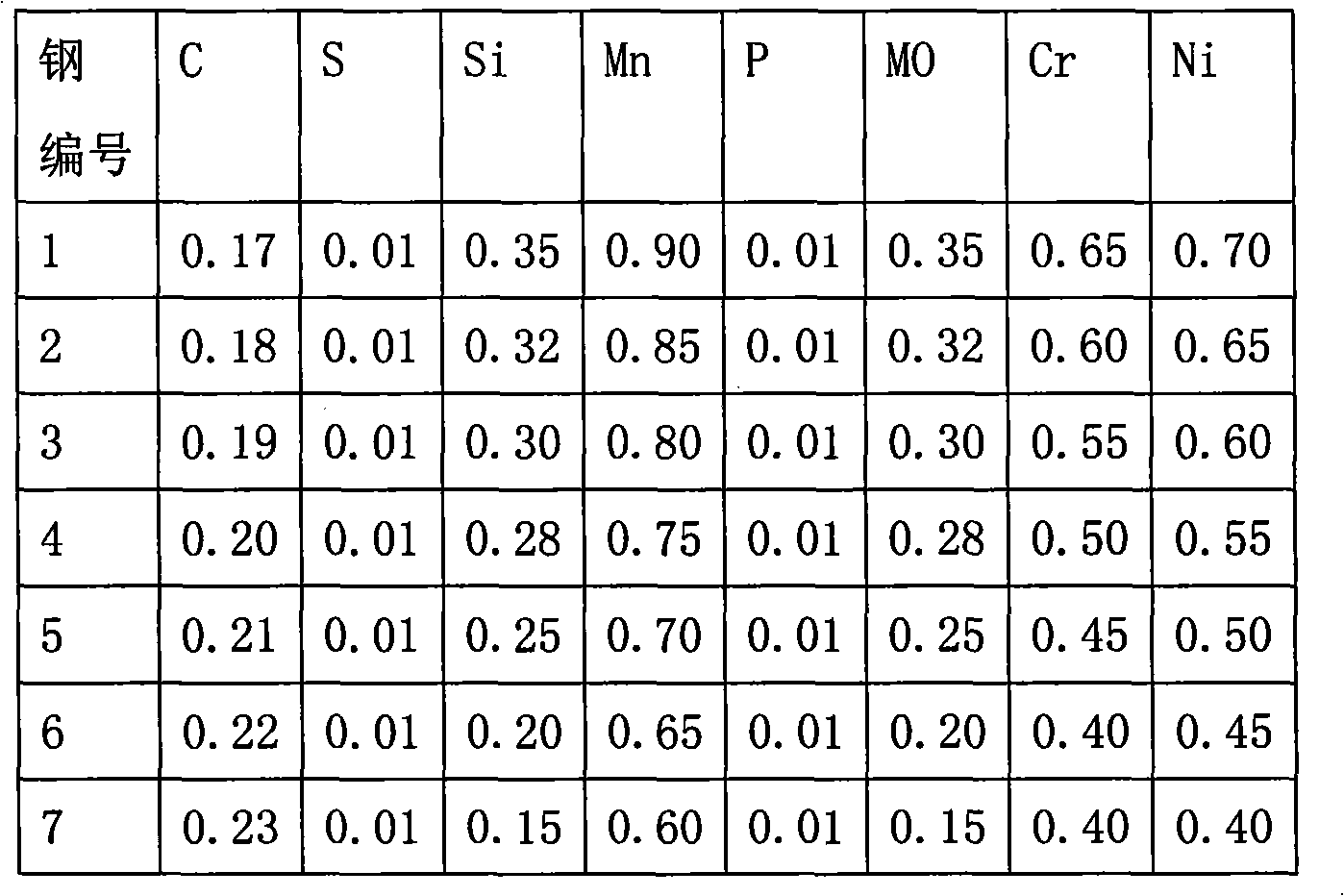

Ultrahigh strength cold rolled steel strip for automobile seat

The invention relates to an ultrahigh strength cold rolled steel strip for an automobile seat, which comprises the following components in percentage by mass: 0.17 to 0.23 percent of C, below 0.01 percent of P, below 0.01 percent of S, 0.15 to 0.35 percent of Si, 0.60 to 0.90 percent of Mn, 0.15 to 0.35 percent of Mo, 0.40 to 0.65 percent of Cr, 0.40 to 0.70 percent of Ni, and the balance of Fe. The yield strength 6s of the ultrahigh strength cold rolled steel strip is 300 to 400MPa, the tensile strength 6b is 350 to 550MPa, the elongation rate delta is more than or equal to 30 percent, and the hardness is 75 to 85; and the ultrahigh strength cold rolled steel strip has high flanging performance.

Owner:祝桥金属材料启东有限公司

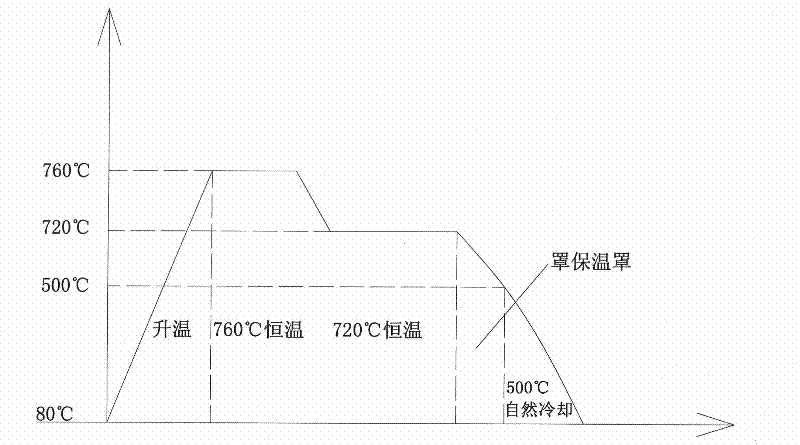

Intermediate annealing process of aluminum alloy and aluminum alloy for automobile covering part

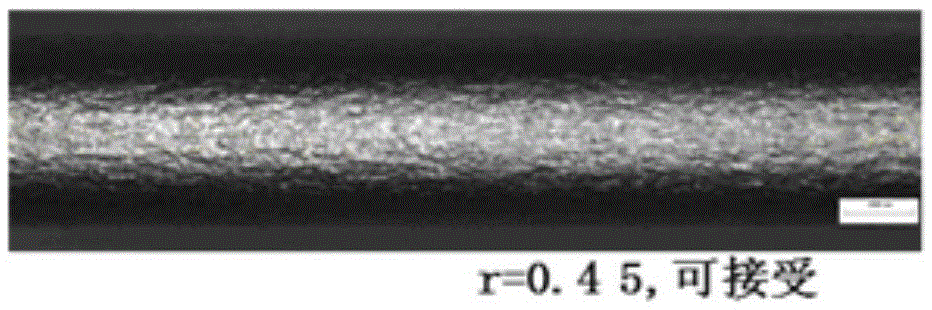

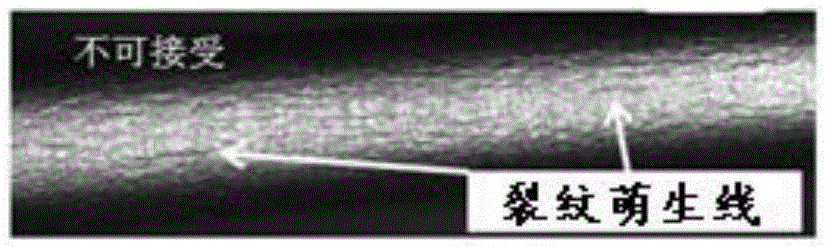

The invention provides an intermediate annealing process of an aluminum alloy. The intermediate annealing process comprises the step of carrying out intermediate annealing on a cold-rolled aluminum alloy to obtain the aluminum alloy subjected to intermediate annealing, wherein the temperature of intermediate annealing is 450-550 DEG C, and the time of intermediate annealing is 2-20 minutes. A continuous annealing mode is adopted, annealing temperature of an intermediate annealing process is increased, and morphology of the annealed aluminum alloy is improved, so that the effect of improving flangability of products is achieved. Experiment results show that the aluminum alloy which is prepared by the intermediate annealing process has smooth surfaces after being subjected to flanging, does not have crack initiation lines or cracks, and can be applied to the automobile industry. The invention further provides an aluminum alloy for an automobile covering part.

Owner:SOUTHWEST ALUMINUM GRP

Process for producing glass reinforced plastic through strong core mat vacuum infusion

The invention provides a process for producing glass reinforced plastic through strong core mat vacuum infusion, which comprises the following steps of: stacking and putting a first composite mat, a second composite mat, a third filament mat, a fourth composite mat and a fifth composite mat in a mold, enabling glass fiber fabrics at all layers to be fully soaked by resin through a vacuum resin infusion method, and conducting solidification; and adding a strong core mat which is cut according to a fixed size between the second composite mat and the third filament mat, and connecting the strong core mat with laid spiral air extraction tubes to take an effect of auxiliary air extraction. The strong core mat has the characteristic of absorbing less resin, unsaturated polyester resin flows slowly in the strong core mat and the problem that the unsaturated polyester resin enters vacuum equipment, is solidified and affects the use of the equipment because the flow rate is too high can be solved. By using the method to produce glass reinforced plastic products, the problems that the flanges of the filament mat and the composite mats are not bonded firmly and are apt to be layered are solved, and the effects of enhancing the vacuum pumping strength of a glass reinforced plastic vacuum infusion process and strengthening the flanging performance of the glass reinforced plastic are taken.

Owner:TIANJIN DEFENG TECH

Flanging die

InactiveCN103028665AReasonable structural designImprove processing efficiencyShaping toolsMechanical engineeringEngineering

The invention relates to an automobile part machining die, in particular to a flanging die, which is provided with an upper die and a lower die which are respectively arranged from the upper part to the lower part. An upper die plate is arranged at the bottom of the upper die. A cushion plate is arranged at the bottom of the upper die plate. A male die is arranged at the bottom of the cushion plate. A first annular lower die plate is arranged at the upper part of the lower die. A second annular lower die plate is arranged on the internal side of the first lower die plate. A third annular lower die plate is arranged on the internal side of the second lower die plate. A female die is arranged on the internal side of the third lower die plate. When the upper die and the lower die get close to each other, the male die is inserted into the female die and the two sides of the male die press against the internal side of the third lower die plate. The upper die and the lower die are made of A3 steel. The upper die plate, the cushion plate, the first lower die plate, the second lower die plate and the third lower die plate are made of No.45 steel. The flanging die provided by the invention has the advantages that the structural design is reasonable, the machining efficiency is high, the flanging effect is good and the application scope is wider.

Owner:芜湖中山科技有限公司

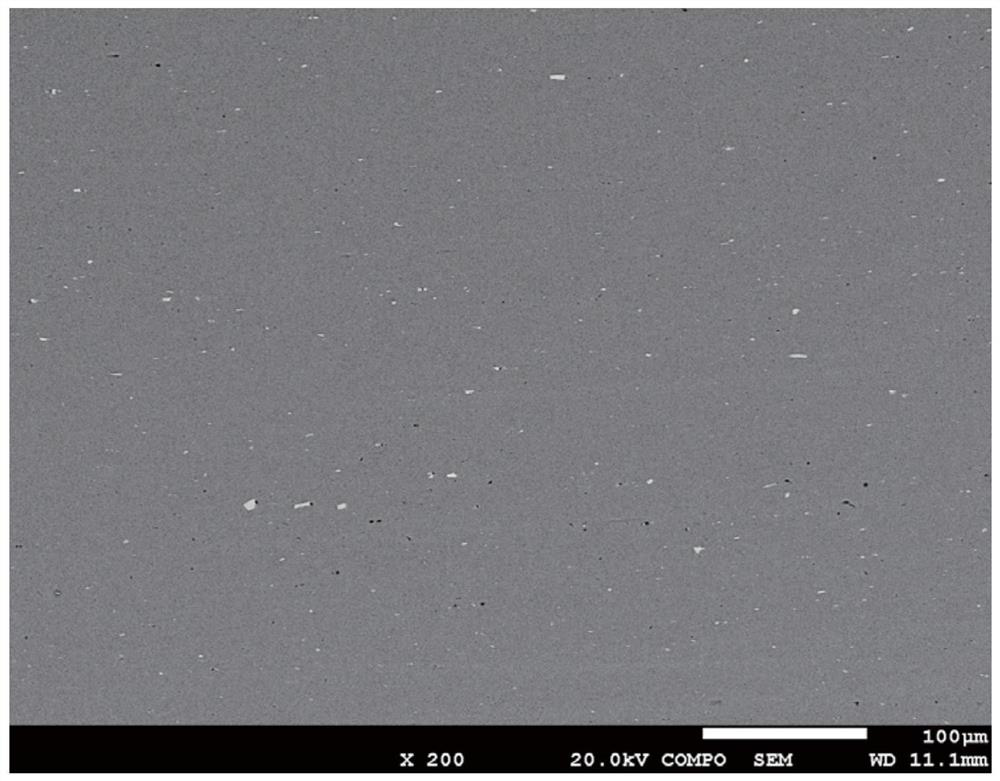

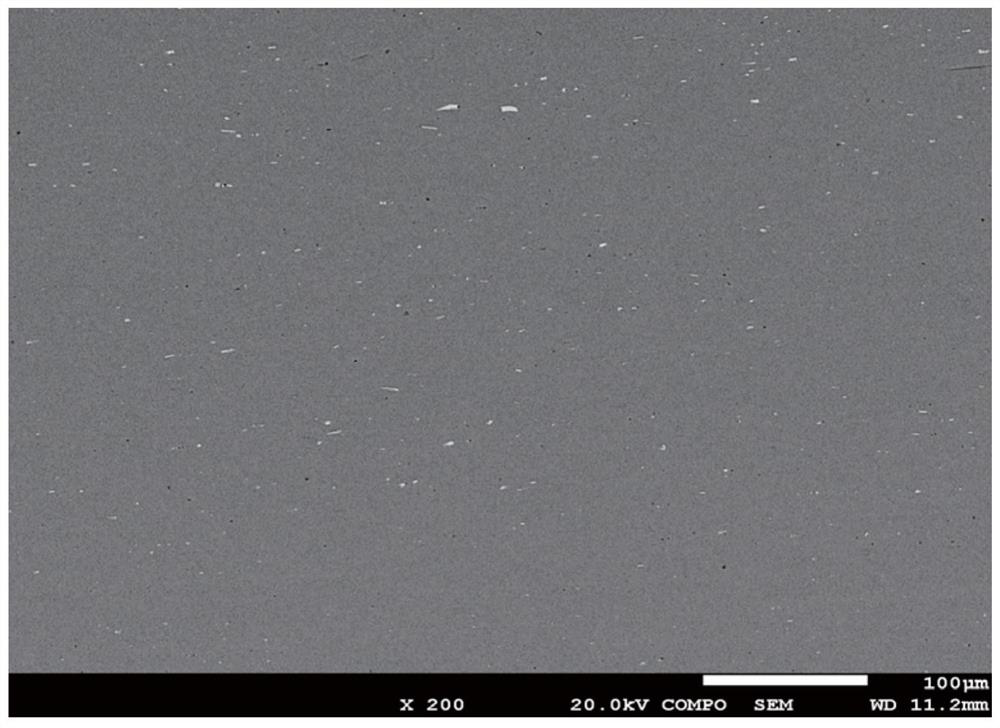

A kind of 6xxx series aluminum alloy plate with high flanging performance and preparation method thereof

ActiveCN109868398BRefine the grain sizeMeet actual needsRoll mill control devicesFurnace typesMaterials scienceAluminium alloy

The present invention provides a 6xxx series aluminum alloy sheet with high flanging performance. The aluminum alloy sheet includes the following components in terms of mass percentage: Mg: 0.1% to 1.4%; Cu: ≤ 0.35%; Mn: ≤ 0.3 %; Cr: ≤ 0.3%; Si: 0.3% to 1.8%; Fe: ≤ 0.45%, and the balance of Al, the average grain size of the finished aluminum alloy sheet along the rolling direction is less than 30 μm, and the diameter is greater than or equal to 2 μm The proportion of the number of equivalent circles of the second phase is less than 10%. The technical solution provided by the present invention effectively regulates the distribution of the second phase and the grain size in the aluminum alloy, greatly improves the flanging performance of the plate, and the obtained plate can be widely used in automobiles. 6xxx Aluminium Alloy Covers Outer Panels.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

Flanging die

InactiveCN106984710AAvoid contact formingEasy to disassembleShaping toolsVehicle componentsEngineeringFlanging

The invention discloses a flanging die. The flanging die comprises an upper die base, a lower die base, a flanging male die mounted at the bottom of the upper die base and flanging female dies mounted on the lower die base. The inner side faces of the flanging female dies are molding surfaces. The top end of each molding surface is provided with a molding rod. The molding rods are transversely inlaid in the molding surfaces correspondingly and can rotate on the corresponding molding surfaces. The opposite sides of the two molding rods are provided with rolling surfaces protruding out of the respective molding surfaces. The rolling surfaces are matched with the flanging male die to conduct flanging on blanks. According to the scheme, the rolling surfaces are used for replacing flanging female dies and are matched with the flanging male die to conduct flanging on parts. Linear contact molding (common surface contact) is avoided by adopting the rolling surfaces in the flanging process, so that flanged surfaces are more smooth, and the flanging molding effect is good.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

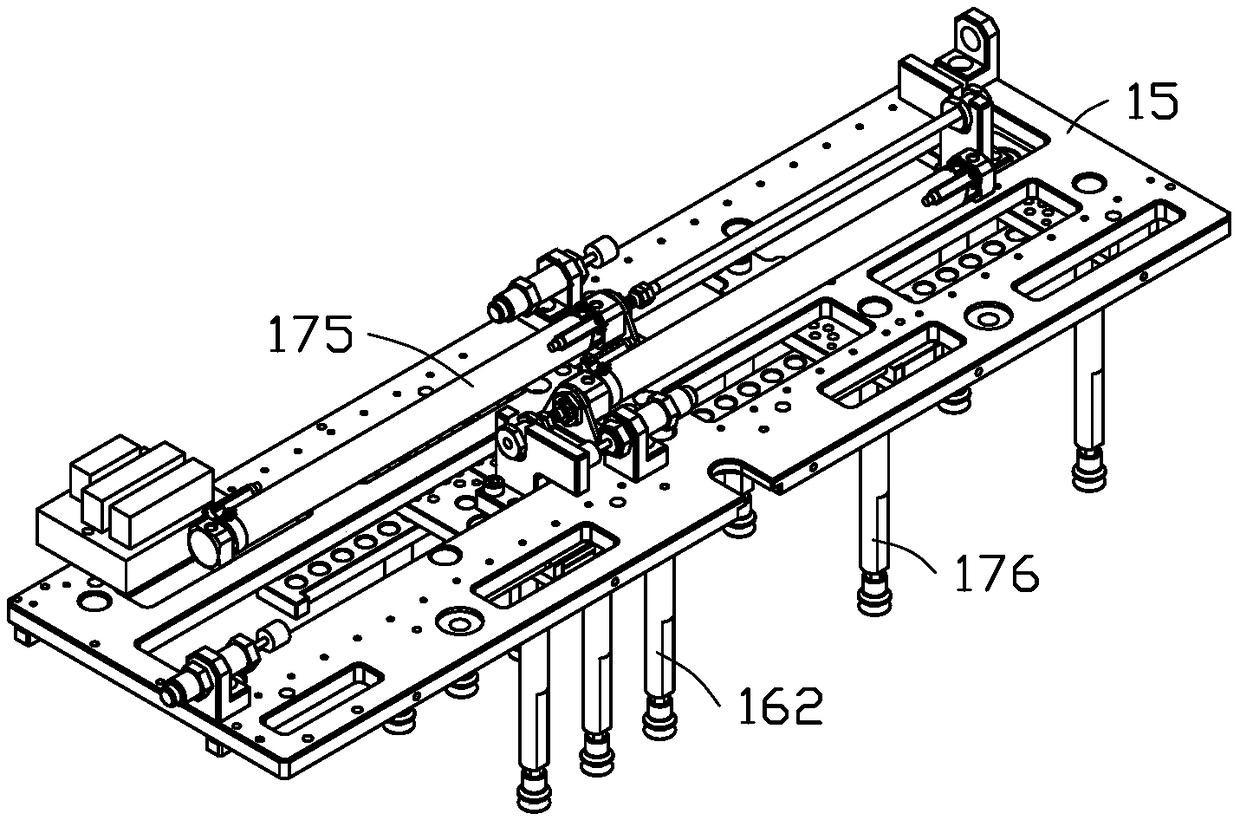

Flanging device and flanging method

PendingCN108655234AHigh degree of automationIncrease productivityMetal-working feeding devicesStripping-off devicesPunchingFlanging

The invention provides a flanging device for flanging pipe workpieces. The flanging device comprises a loading mechanism, a transportation mechanism, a first punching die, a second punching die and anunloading mechanism arranged in sequence. The first punching die comprises a first die base and a second die base, a fork knife arranged on the first die base, and a flanging module arranged on the second die base. A first inclined surface is arranged on the fork knife; the flanging module comprises a limiting block, a slide block and a first punch; the slide block is connected between the firstpunch and the limiting block; the slide block is provided with a second inclined surface matched with the first inclined surface; and when the first die base moves towards the second die base, the first inclined surface pushes the second inclined surface, so that the first punch moves towards the workpieces for pre-flanging of the workpieces, and included angles are formed between the end parts ofthe workpieces and main bodies of the workpieces. Meanwhile, the invention provides a flanging method using the flanging device.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

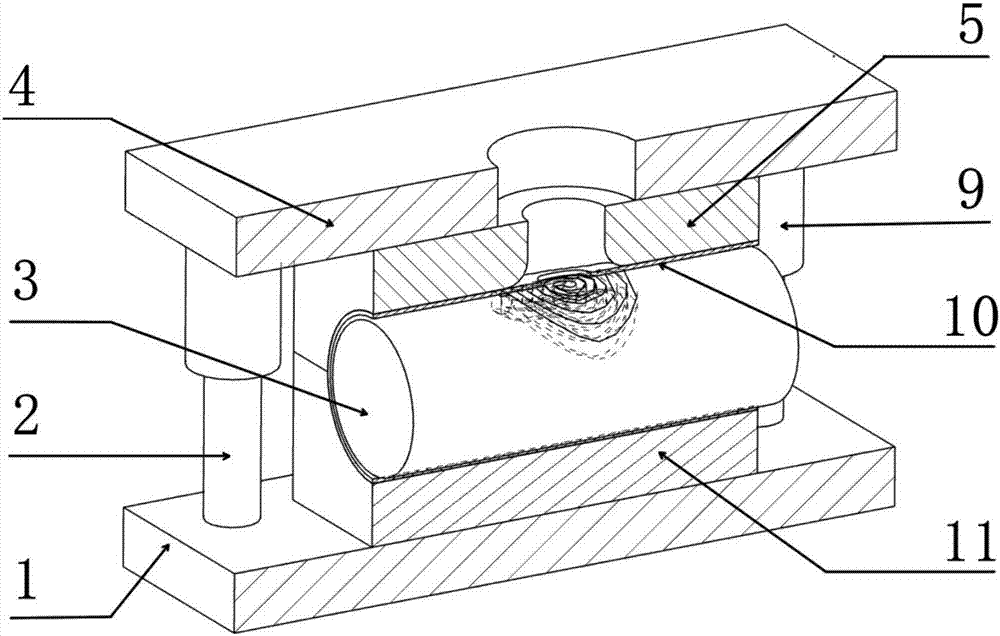

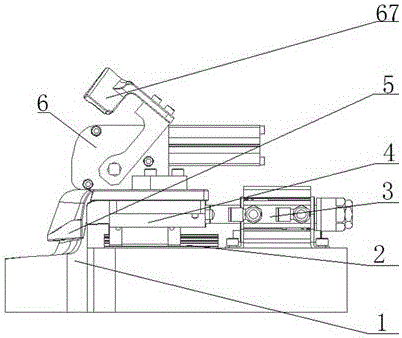

Electromagnetic lateral edge turning device and method for pipe with preformed hole

ActiveCN107138588AReasonable eddy current distributionIncrease electromagnetic forceMetallic materialsEngineering

The invention belongs to the field of metal material plastic processing and discloses an electromagnetic lateral edge turning device for a pipe with a preformed hole. The device comprises an upper die frame, an upper die, a lower die, a lower die frame, a columnar supporting body, a space spiral coil and a pulse discharge circuit. The upper die is arranged on the upper die frame, the lower die is arranged on the lower die frame, a containing hole is formed by the upper die and the lower die jointly, and the pipe with the preformed hole is sleeved with the columnar supporting body. An edge turning hole is formed in the upper die, the pulse discharge circuit and the space spiral coil are connected to form a pulse magnetic field, the top view of the space spiral coil is spiral, and the side view of the space spiral coil is arc. The space spiral coil is arranged on the top of the columnar supporting body, and a groove for containing the space spiral coil is formed in the top of the columnar supporting body. Radial electromagnetic force generated by the space spiral coil is distributed more intensively in an edge turning hole region, the electromagnetic force is higher, the energy utilization rate is higher, the service life of the coil is longer, and good economic benefits are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

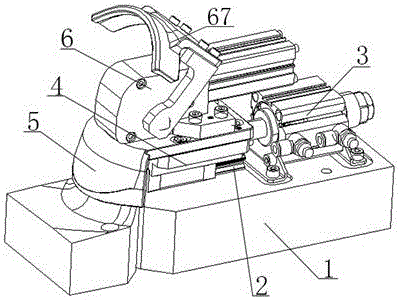

Flanging device for automobile aluminum heat protection shield

The invention discloses a flanging device for an automobile aluminum heat protection shield. The flanging device for the automobile aluminum heat protection shield comprises a base, a vertical stamping head, a first steam cylinder, a horizontal stamping head, and a second steam cylinder, wherein the vertical stamping head is arranged on the base and can move vertically, the first steam cylinder is connected with the vertical stamping head, the horizontal stamping head is arranged on the upper right of the base and can move horizontally, the second steam cylinder is connected with the horizontal stamping head, a step is arranged on the base, and a wedged protrusion is arranged at the lower right end of the vertical stamping head. Aluminum sheet material to be flanged is placed on the base, the portion, to be flanged, of the aluminum sheet material is placed on the step of the base, the horizontal distance between the right end of the bottom of the vertical stamping head and the left end of the top of the step is equal to the thickness of the aluminum sheet material, and the height of the bottom of the horizontal stamping head is accordant with the top of the step. Compared with existing steel mould stamping flanging technology, the flanging device is simple to operate, short in consumed time and few in processes, is self-powered without using pressure machine tools, and is capable of reducing producing cost for the flanging cost of the aluminum sheet material and improving producing efficiency.

Owner:安徽振华汽车部件有限责任公司

Ultrahigh strength cold rolled steel strip for automobile seat

The present invention relates to a cold rolled steel strip for an automobile seat, which comprises the following components in percentage by mass: 0.17 to 0.23 percent of C, below 0.01 percent of P, below 0.01 percent of S, 0.15 to 0.35 percent of Si, 0.60 to 0.90 percent of Mn, 0.15 to 0.35 percent of Mo, 0.40 to 0.65 percent of Cr, 0.40 to 0.70 percent of Ni, and the balance of Fe. The yield strength 6s of the ultrahigh strength cold rolled steel strip is 300 to 400MPa, the tensile strength 6b is 350 to 550MPa, the elongation rate delta is more than or equal to 30 percent, and the hardness is 75 to 85; and the ultrahigh strength cold rolled steel strip has high flanging performance.

Owner:祝桥金属材料启东有限公司

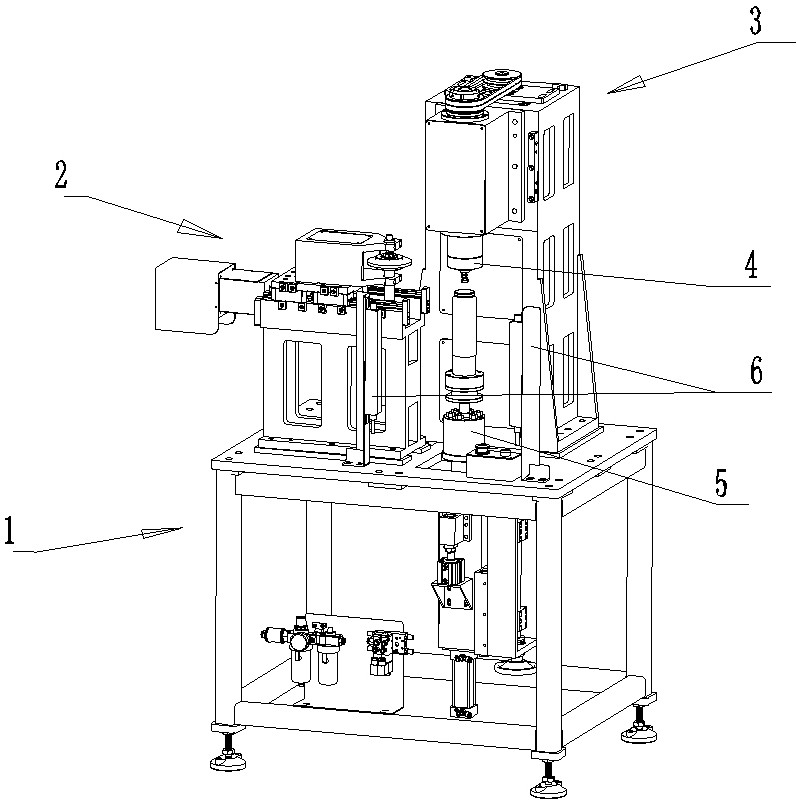

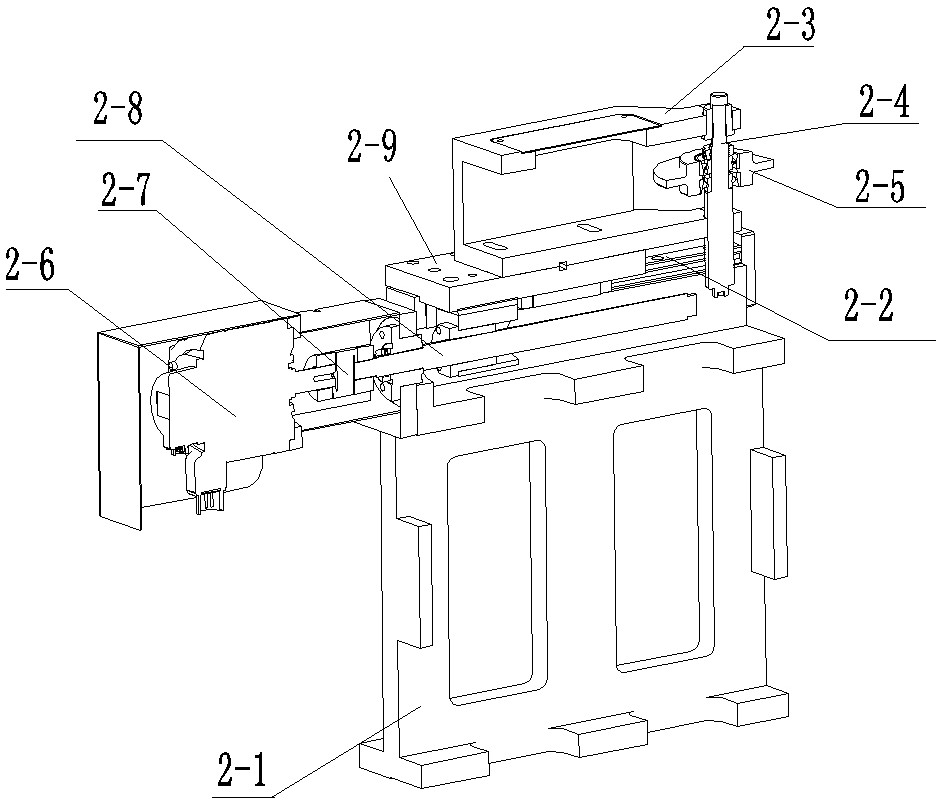

Automatic flanging mechanism

ActiveCN105965862AIngenious designCompact and reasonable structureDomestic articlesFlangingEngineering

The present invention relates to the automobile face material flanging field, and concretely relates to an automatic flanging mechanism. The automatic flanging mechanism comprises a fixed bottom die, a linear guideway, a block pushing cylinder, a sliding seat, a flange pushing block and a face material clamping mechanism, wherein the linear guideway is mounted on the fixed bottom die, the sliding seat is mounted on the linear guideway, the block pushing cylinder is mounted at the rear end of the sliding seat while the flange pushing block is mounted at the front end of the sliding seat, and the face material clamping mechanism is mounted on the sliding seat. The automatic flanging mechanism is advantageous in that the design is smart, the structure is reasonable and compact, the flanging effect is excellent, no subsequent processing is required, space is saved, cost is lowered and production requirements are met.

Owner:JIANGSU HAN GAO MACHINERY CO LTD

Quick flanging method of casing

The invention discloses a quick flanging method of a casing, which comprises the following step of: a, manufacturing a flanging mold, wherein the flanging mold comprises an upper mold plate, and a lower mold plate; an upper flanging convex mold and a lower flanging convex mold corresponding to the lower flanging convex mold are mounted on the upper mold plate and the lower mold plate respectively, guide sleeves are fixedly mounted on the upper mold plate, guide columns matched with the guide sleeves are fixedly mounted on the lower mold plate, the upper flanging convex mold and the lower flanging convex mold are sleeved with the internal apertures of the two ends of the casing respectively, and provided with arc transitional surfaces, and limiting columns are fixed on the lower mold plate. With the adoption of the method, the flanging molding of the casing is quick, the flanging effect is good, the assembling rejection rate is decreased, and the quick flanging method is suitable for mass assembling; and with the adoption of the structure, the work efficiency is improved, the product quality is ensured, and the scrap rate is decreased.

Owner:WUHU ZHONGLI CHASSIS SYST

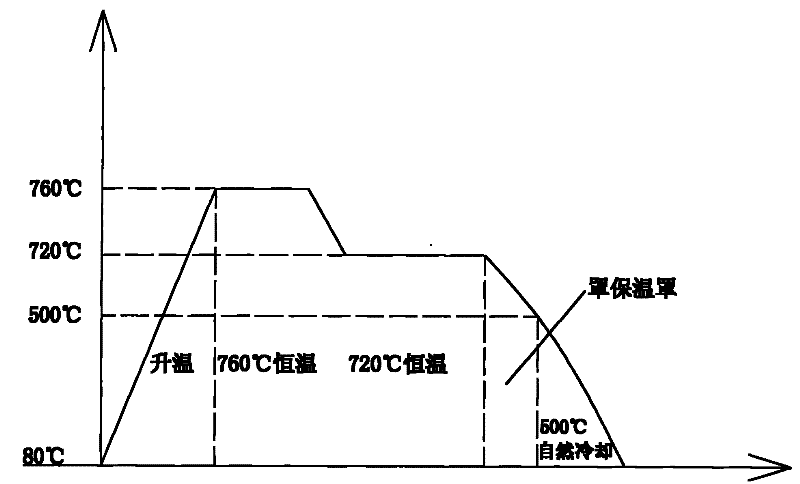

A method for improving flanging performance of aluminum alloy sheet

The invention discloses a method for improving the flanging performance of an aluminum alloy plate. The method comprises the following steps: (1) performing homogenization heat treatment on an aluminum alloy ingot, and performing air cooling and / or furnace cooling on the billet after the homogenization treatment; (2) performing heat treatment on the billet before hot rolling: the holding temperature is 520℃~560℃, the heating rate is 40℃ / h~120℃ / h, and the holding time is 1.5h~5h; (3) Then hot-roll and / or cold-roll the heated billet to obtain cold-rolled coil ; (4) On-line solution treatment and pre-aging treatment of the coil to obtain the strip in the T4P state. The present invention regulates the Mg in the structure through the reasonable matching of the uniform cooling process and the heating process before hot rolling. 2 The morphology, quantity and size of the Si phase improve the flanging performance of the T4P state plate, and the flanging performance of the alloy plate prepared by this method meets the requirements of the automobile factory.

Owner:GRIMAT ENG INST CO LTD

Stamping die for flanging processing of plate-shaped parts

InactiveCN111014465AWon't pull hairReduce frictionShaping toolsStructural engineeringManufacturing engineering

The invention discloses a stamping die for flanging processing of plate-shaped parts, wherein when the stamping die is used for flanging of aluminum parts and stainless iron or stainless steel workpieces, the workpieces cannot be galled. The stamping die comprises an upper die base and a lower die base; a lower die plate is arranged on the lower die base; a mounting groove is formed in the lower die plate; a lower forming block which moves up and down is movably arranged on the part, corresponding to the interior of the mounting groove in the lower die plate, of the lower die base through a jacking spring; a plurality of positioning pieces for limiting the position of a workpiece are arranged on the lower forming block; a flanging cutter block is arranged on the lower die plate and at theto-be-flanged part of the workpiece; a flanging rolling shaft parallel to a bending line at the flanging position of the workpiece is rotationally arranged in the flanging cutter block; a mounting notch is formed in the cutting edge of the flanging cutter block; the periphery of the flanging rolling shaft is exposed out of the mounting notch, the side face, used for forming a workpiece, of the flanging cutter block is tangent to the periphery of the flanging rolling shaft, a mounting plate is arranged on the upper die base, an upper forming block matched with the lower forming block in shape is arranged on the mounting plate, and an upper cutter block matched with the flanging cutter block is detachably arranged on the upper forming block.

Owner:长沙金鸿顺汽车部件有限公司

Flange mould system of shell branch hole of high-voltage switch

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

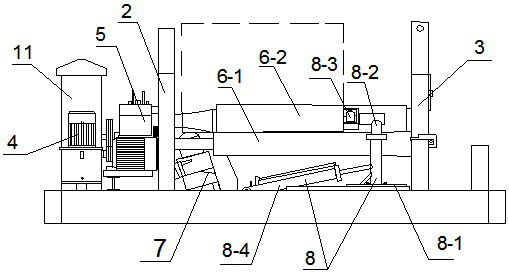

Flanging device for container manufacturing

PendingCN112676477AGuaranteed stabilityReduce consumptionHollow articlesSupporting systemControl system

The invention relates to a flanging device for container manufacturing. At present, flanging operation is needed when some super-large container workpieces are manufactured, and the workpieces are special in structure, large in appearance size and difficult to machine. The flanging device for container manufacturing comprises a supporting system, a rolling system, a pushing system and a control system, wherein the supporting system is composed of a supporting base (1), a head supporting machine frame (2) and a tail supporting machine frame (3), and three working rollers on the rolling system are connected between the head supporting machine frame and the tail supporting machine frame; and a speed reduction motor (5) is installed on one side of the head supporting machine frame, the speed reduction motor is connected with a motor, the motor (4) and the speed reduction motor are correspondingly installed above a supporting base, and an electric appliance control cabinet (11) in the control system is further installed above the supporting base. The device is applied to the field of machine manufacturing.

Owner:黑龙江省建筑安装集团有限公司

Continuous die using flanging knife flanging and sheet metal flanging processing method

The invention discloses a progressive die flanged by a flanging knife and a metal sheet flanging processing method and aims to solve the problems of complex structure and large volume of an existing device. A flanging station is formed on the progressive die flanged by the flanging knife; a lower die, an upper die and the flanging knife are arranged on the flanging station; and an angle of a processing surface of the flanging knife is fitted with the shape of a workpiece. According to the metal sheet flanging processing method, a flanging part of the workpiece is fixed by the flanging knife and the lower die and then is flanged under the action of the pressure of the upper die. According to the progressive die flanged by the flanging knife, the structure and the using method are simplified, and the occupied area is reduced. According to the metal sheet flanging processing method, the flanging effect is better, the quality of a product is higher, and the technical flow is simplified. Furthermore, the efficiency is improved, the cost is reduced, and the metal sheet flanging processing method is suitable for the flanging technologies for various metal sheets.

Owner:KUNSHAN DAYA AUTO PARTS

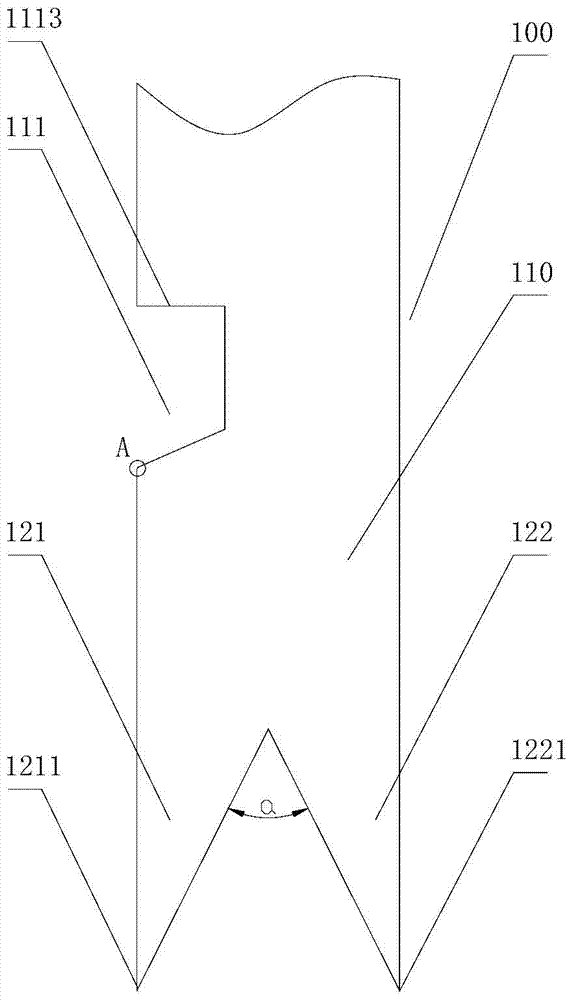

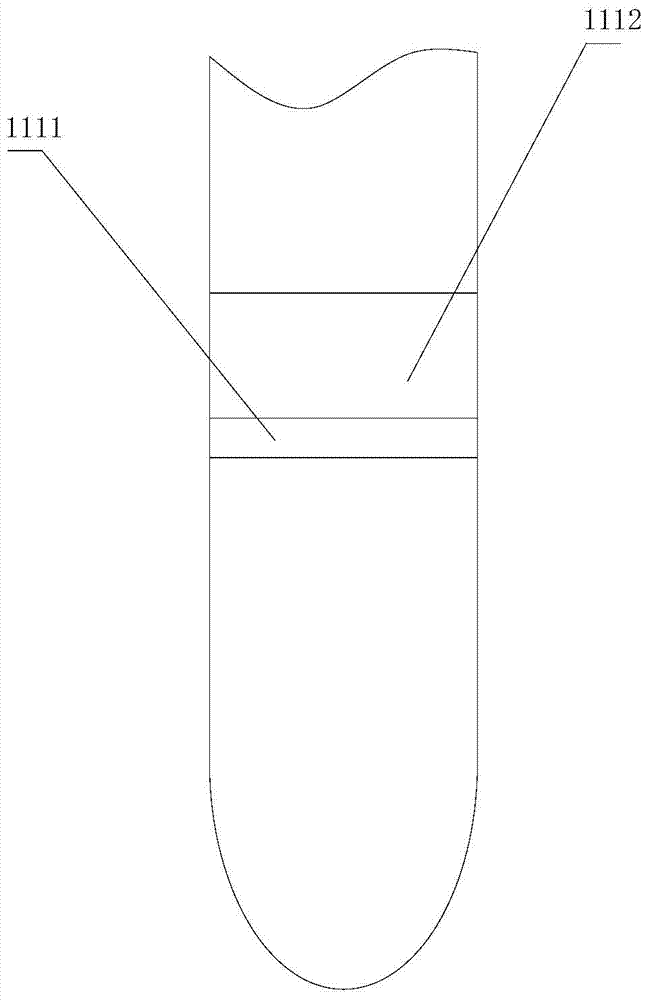

Tool bit and hole drilling and flanging tool and method

InactiveCN104741928AEfficient drilling and flanging production methodGood versatilityOther manufacturing equipments/toolsFlangingDrill hole

The invention provides a tool bit and a hole drilling and flanging tool and method. The tool bit comprises a tool bit body and a working end, and the working end is of a tip structure. A groove is formed in the middle of the outer surface of the tool bit body. The tool bit can complete the process of hole drilling and the process of flanging at the same time, and the hole drilling and flanging tool with the tool bit is used for achieving the combining of the hole drilling and flanging process of a pipeline and automatic production. An efficient hole drilling and flanging production mode is provided; better universality is achieved, and pipelines with complex shape changes can be machined; the machined flanging has a good flanging effect and excellent stability.

Owner:GREE ELECTRIC APPLIANCES INC

A 780mpa hot-rolled high-strength high-hole expansion steel and its manufacturing method

The invention provides a 780 MPa hot-rolled high-strength steel with high hole expansion ratio and a manufacturing method thereof. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio comprises the following chemical components in percentage by mass: more than or equal to 0.03 percent and less than or equal to 0.07 percent of C, less than or equal to 0.2 percent of Si, more than or equal to 1.0 percent and less than or equal to 2.0 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.005 percent of S, more than or equal to 0.02 percent and less than or equal to 0.05 percent of Al, less than or equal to 0.005 percent of N, more than or equal to 0.08 percent and less than or equal to 0.20 percent of Ti, more than or equal to 0.15 percent and less than or equal to 0.25 percent of Mo, less than or equal to 0.003 percent of O and the balance of Fe and inevitable impurity elements, wherein Ti / Mo is more than or equal to 0.25 and less than or equal to 1.5, and (Ti-3.42N) / 4+Mo / 8 is more than or equal to 0.03 percent and less than or equal to 0.07 percent. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio is obtained through smelting, casting, high-temperature heating, hot rolling and reeling processes, and is more than or equal to 750 MPa in yield strength, more than or equal to 780 MPa in tensile strength, more than or equal to 20 percent in extensibility, more than or equal to 70 percent in hole expansion ratio when the thickness is 3-6 mm.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

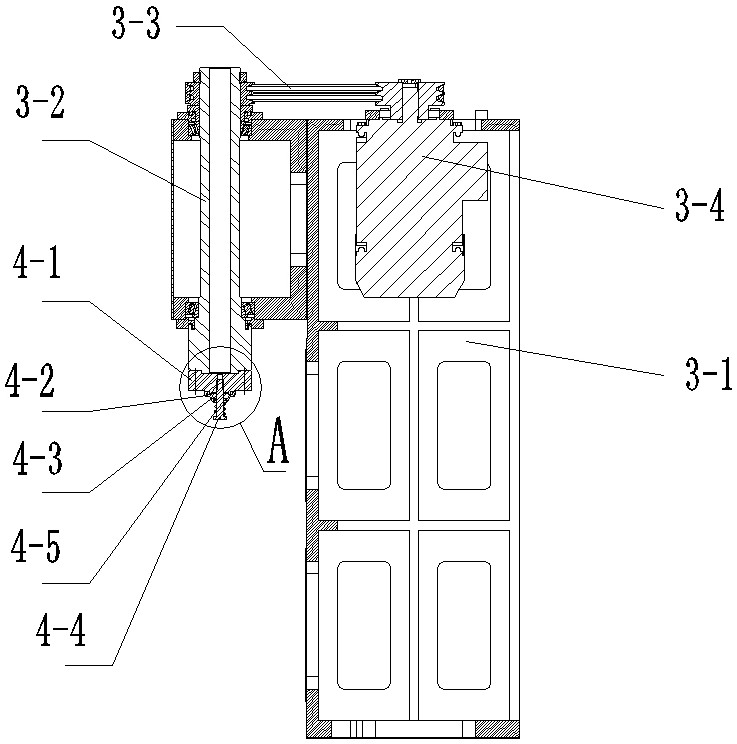

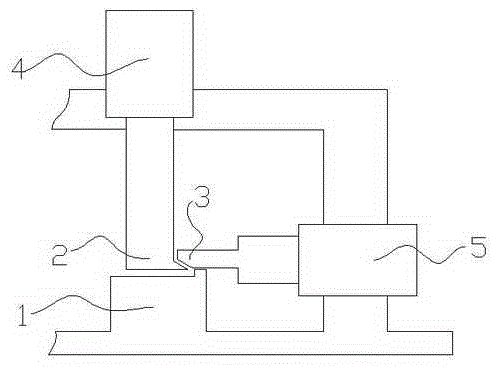

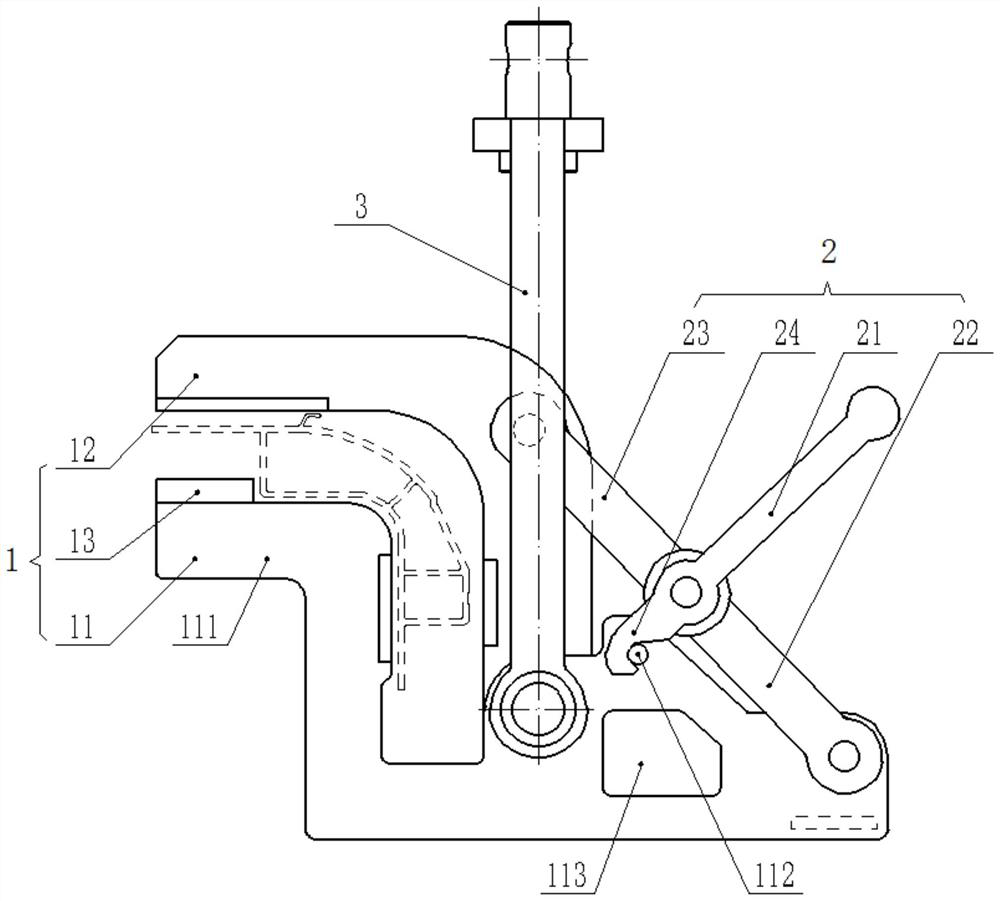

Vertical flanging machine

ActiveCN113953363AVerticality is easy to guaranteeImprove verticalityShaping toolsShaping safety devicesMachineEngineering

The invention discloses a vertical flanging machine. The vertical flanging machine comprises a base, a pressing wheel device, a stand column device, an upper mold device and a lower mold device, wherein the stand column device comprises a main shaft; the upper mold device is detachably arranged at the lower end of the main shaft; a main shaft driving mechanism drives the main shaft to rotate, so as to drive the upper mold device to rotate; the upper mold device comprises an upper mold detachably arranged at the lower end of the main shaft, a flanging sleeve and a double-taper sleeve are arranged below the upper mold, and the upper end part of a guide rod sleeved with an upper mold reset spring penetrates through a middle hole of the double-taper sleeve to be in threaded connection with the middle of the lower end of the upper mold; and the lower mold device comprises a lower mold assembly, the lower mold assembly comprises a lower mold and a lower mold shaft, and the lower end of the lower mold shaft is connected with a driving mechanism to complete mold assembly or separation of the lower mold shaft and the upper mold device. According to the vertical flanging machine, the flanging perpendicularity of an inner container is better, the production efficiency is higher, and the rejection rate is lower, so that the outer diameter of a housing corresponding to the vertical flanging machine can be reduced, the materials are saved, the cost is reduced, and a vacuum cup is smaller and more exquisite on the premise of the same capacity.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

Flanging device for aluminum heat shield for automobile

The invention discloses a flanging device for an automobile aluminum heat protection shield. The flanging device for the automobile aluminum heat protection shield comprises a base, a vertical stamping head, a first steam cylinder, a horizontal stamping head, and a second steam cylinder, wherein the vertical stamping head is arranged on the base and can move vertically, the first steam cylinder is connected with the vertical stamping head, the horizontal stamping head is arranged on the upper right of the base and can move horizontally, the second steam cylinder is connected with the horizontal stamping head, a step is arranged on the base, and a wedged protrusion is arranged at the lower right end of the vertical stamping head. Aluminum sheet material to be flanged is placed on the base, the portion, to be flanged, of the aluminum sheet material is placed on the step of the base, the horizontal distance between the right end of the bottom of the vertical stamping head and the left end of the top of the step is equal to the thickness of the aluminum sheet material, and the height of the bottom of the horizontal stamping head is accordant with the top of the step. Compared with existing steel mould stamping flanging technology, the flanging device is simple to operate, short in consumed time and few in processes, is self-powered without using pressure machine tools, and is capable of reducing producing cost for the flanging cost of the aluminum sheet material and improving producing efficiency.

Owner:安徽振华汽车部件有限责任公司

A device and method for driving plate hole turning and forming by using multi-directional magnetic field force

The invention discloses a device and method for driving plate hole flanging forming through multidirectional magnetic field force. The device comprises a blank holder (1) and a concave die (2). The blank holder (1) is arranged above the concave die (2) and used for pressing a plate (3) to be subjected to hole flanging forming between the blank holder (1) and the concave die (2). A concave die cavity (4) is formed in the concave die (2). An upper coil groove and a lower coil groove are correspondingly formed in the blank holder (1) and the concave die (2). Upper end hole shrinkage coils (5) are embedded in the upper coil groove. Lower end hole shrinkage coils (6) are embedded in the lower coil groove. Axial deep drawing coils (7) are arranged above the edge of a pre-formed hole of the plate (3). An inner bulging coil (8) is arranged in the pre-formed hole of the plate (3). According to the device and method, cracks can be prevented from being generated to a round hole flanging deformation area during hole flanging forming, the product quality is good, and the forming process is simple.

Owner:CENT SOUTH UNIV

Side plate overturning lifting appliance

PendingCN112573359AEliminate safety hazards such as falling offFlangingLoad-engaging elementsEngineeringStructural engineering

The invention belongs to the field of lifting appliance instruments, and discloses a side plate overturning lifting appliance which comprises a clamping unit. The clamping unit comprises a fixed clamping jaw and a movable clamping jaw, wherein one end of the movable clamping jaw is hinged to one end of the fixed clamping jaw. The side plate overturning lifting appliance further comprises a controlunit, wherein the control unit is used for controlling the movable clamping jaw to rotate around the hinged position of the movable clamping jaw and the fixed clamping jaw in the direction close to or away from the fixed clamping jaw. The movable clamping jaw is in the shape of a right-angle plate with a rounded corner as a whole. The fixed clamping jaw comprises a fixed clamping end, and the clamping end is integrally in the shape of a right-angle plate with a rounded corner and matched with the movable clamping jaw. Compared with the prior art, the novel side plate overturning lifting appliance has the advantages that various arc-shaped edge beam profiles can be lifted, overturning is achieved, clamping is convenient, a limiting locking device is arranged, potential safety hazards suchas falling of a side plate are eliminated, the overturning effect is ideal, the labor intensity is relieved, and the overturning efficiency is high.

Owner:SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com