Flange mould system of shell branch hole of high-voltage switch

A technology of high-voltage switches and flanging molds, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the ideal fit of splines cannot be guaranteed, the damage of tie rods will be aggravated, and the shell flanging will be cracked, etc. Good edge effect, reduce processing difficulty, and improve the effect of using strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

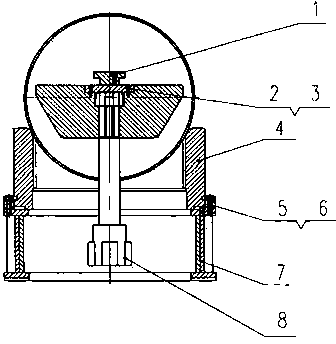

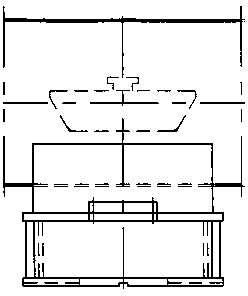

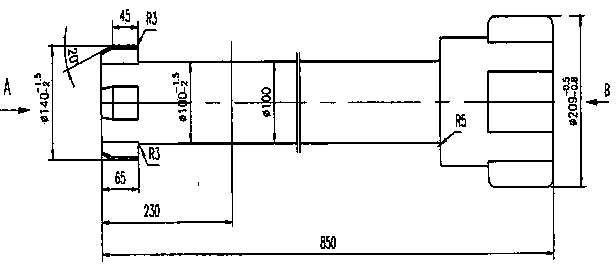

[0024] Examples are attached Figure 1 to Figure 9 As shown, it at least includes a wheel mold handle 1, a cover 2, a punch 3, a die 4, a right block 5, a left block 6, a die seat 7 and a pull rod 8. The mold handle 1 is connected with the punch 3 through a connector, and the material of the tie rod 8 is No. 45 steel, so as to improve the use strength of the tie rod from the material. The outer spline on the top end of the tie rod is changed from the original three layers to one layer. This design can ensure that the spline fit between the tie rod and the punch is always in surface contact, thereby improving the force of the tie rod during the flanging process. The top and bottom of the tie rod 8 are respectively processed with external splines. The top end is inserted into the internal spline groove of the punch 3 and then rotated 45° to engage with the punch. Connected together, the die 4 and the die base 7 are assembled together through the card slots with clearance fit, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com