Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Change flow field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

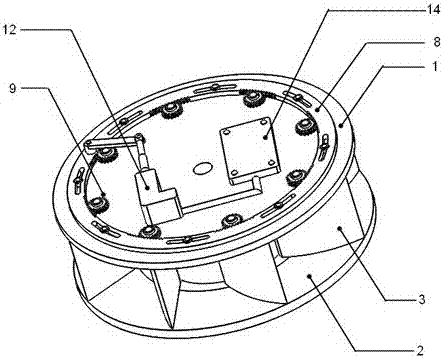

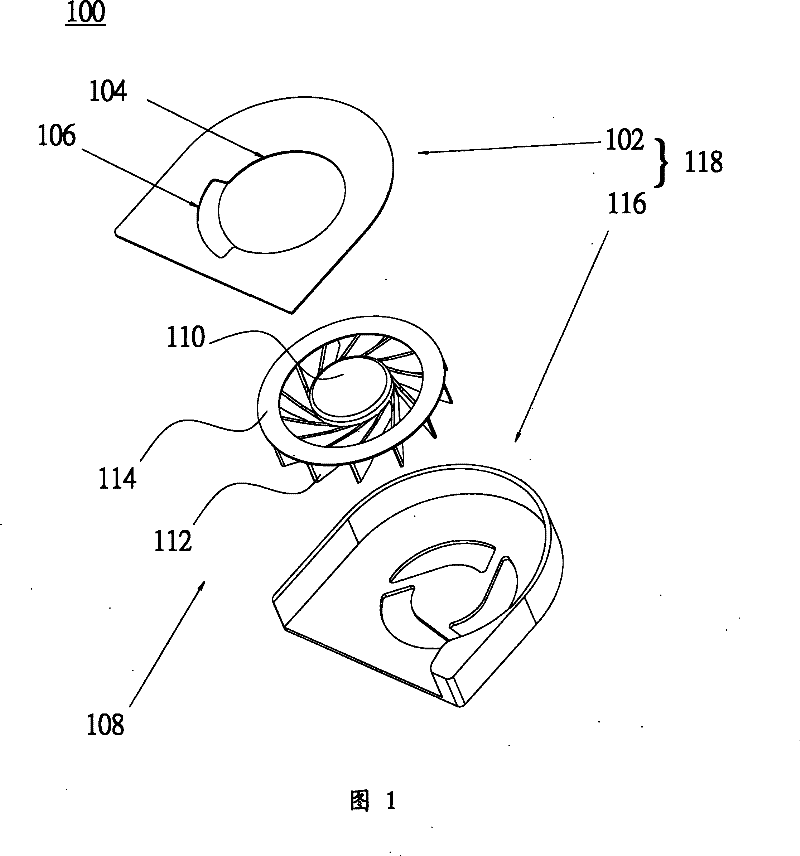

Centrifugal fan device remotely controlled with Bluetooth and with blades adjustable

ActiveCN105756987ARealize the effect of one machine with multiple functionsGood value for moneyPump componentsEngine controlImpellerAir volume

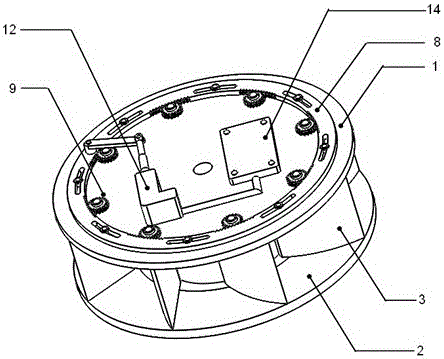

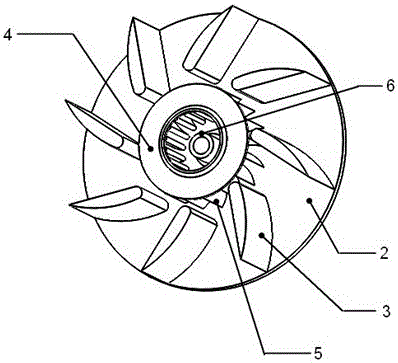

The invention discloses a centrifugal fan device remotely controlled with the Bluetooth and with blades adjustable. The centrifugal fan device comprises an outer impeller, an inner impeller, an impeller cover, impeller discs, a film type parameter sensor, a blade adjusting device, an electric push rod and a Bluetooth intelligent terminal; the outer impeller comprises an outer impeller disc and outer blades, and the inner impeller comprises the impeller cover, an inner impeller disc and inner blades; the inner impeller disc of the inner impeller is fixed to a shaft disc; the blades of the outer impeller and the inner impeller are in wing shapes respectively, through cooperation of the inner impeller and the outer impeller, the proper angle of auxiliary impeller blades can be adjusted according to the air volume under different working conditions, the effect of multiple purposes of a centrifugal fan is achieved, the purpose that the centrifugal fan device can still work stably and efficiently under the off-rating condition is achieved, remote control and automated adjustment are achieved through the Bluetooth intelligent terminal, advancement of modern technology will be undoubtedly integrated into production and life of people, and the problem of inconvenience brought by arrangement positions and space is solved through remote control with high controllability and stability.

Owner:嘉兴芸诗娇电子商务有限公司

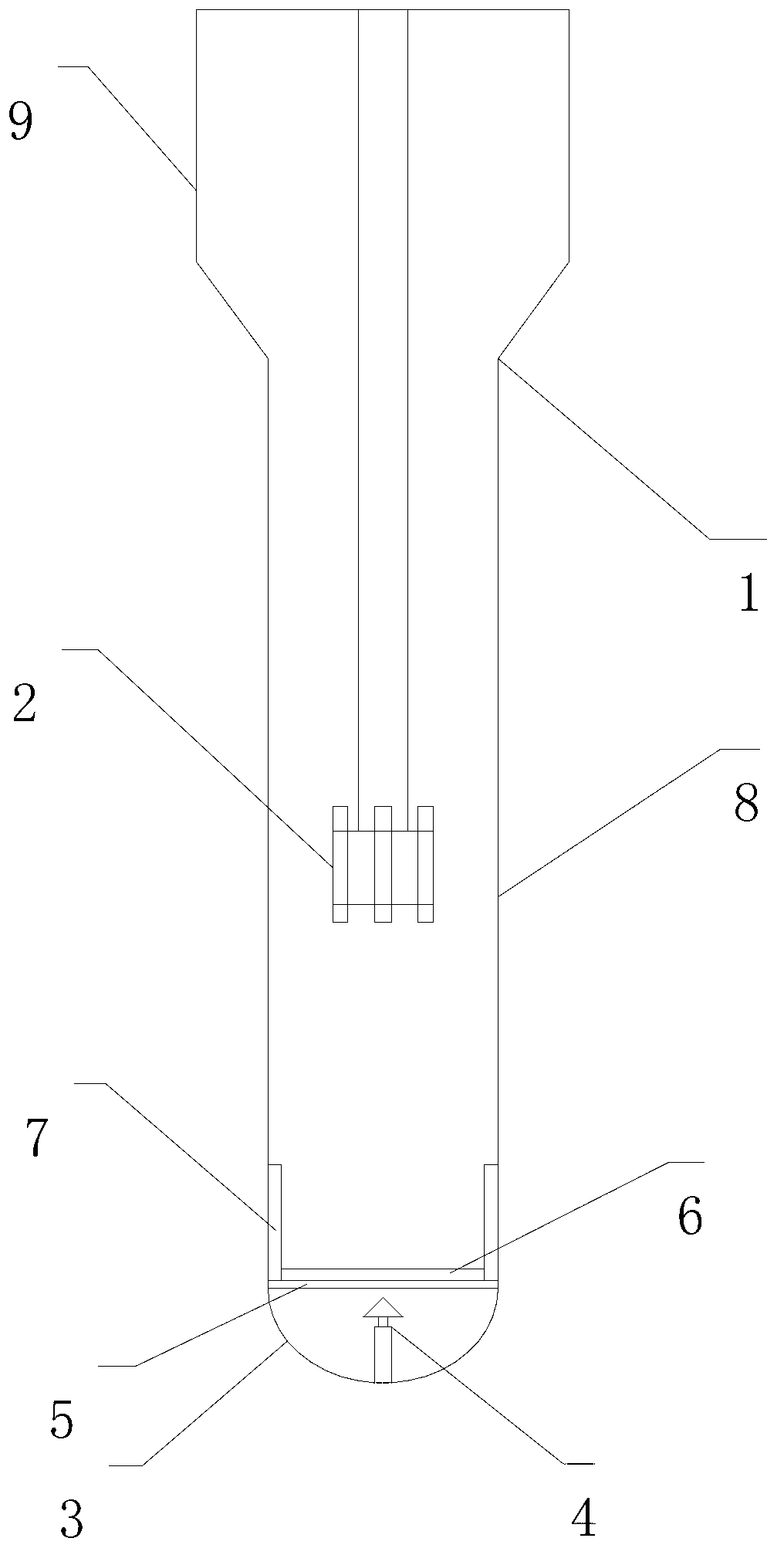

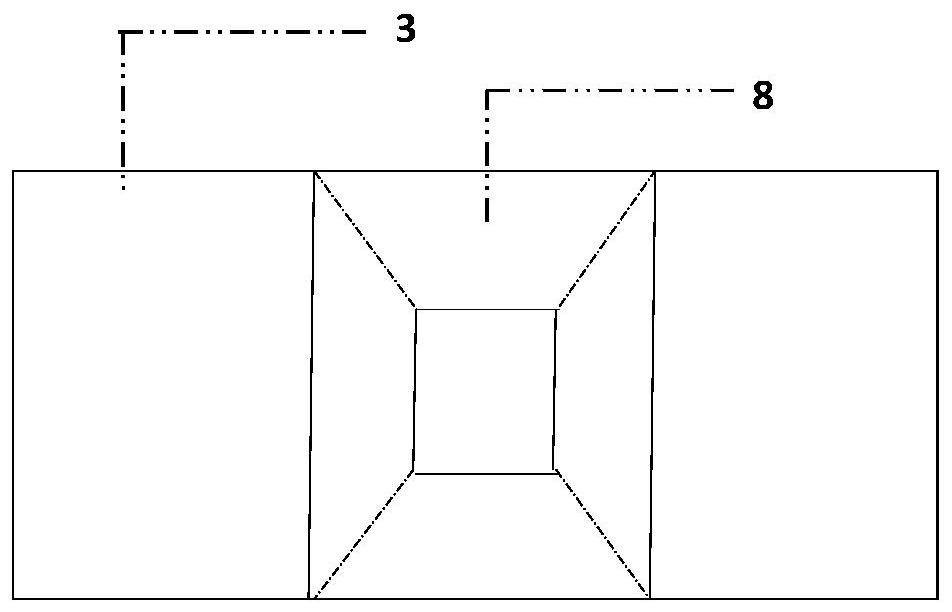

Gas pre-distributor of fixed-bed reactor for preparing maleic anhydride through n-butane oxidation

ActiveCN103071433AChange flow fieldReduce areaOrganic chemistryChemical/physical processesPtru catalystFixed bed

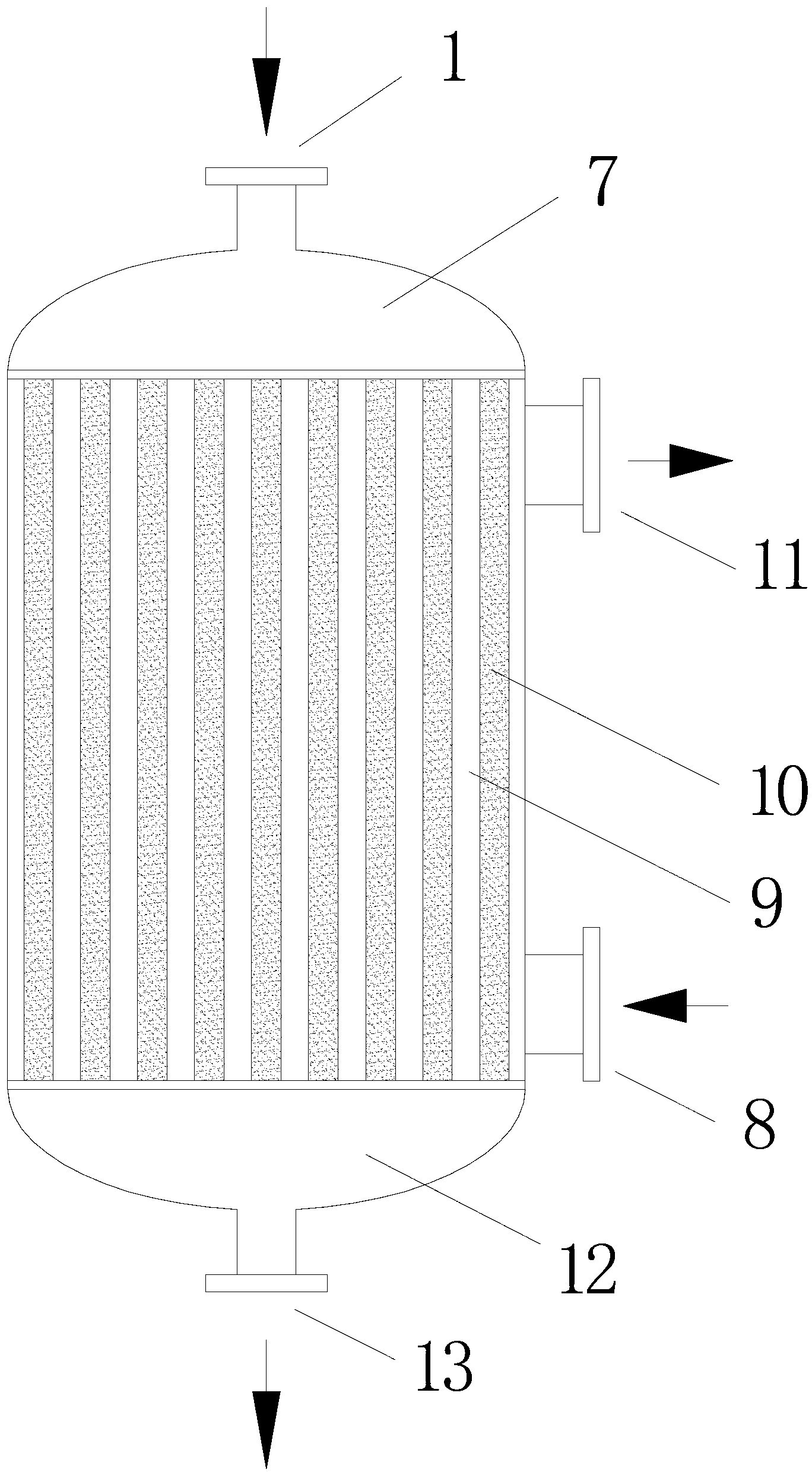

The invention discloses a fixed-bed reactor and a method for preparing maleic anhydride through n-butane oxidation. A gas inlet is formed in one end of a reactor main body; a gas pre-distributor is arranged in one end of the reactor main body and one end of the reactor main body is connected with the gas inlet; a material outlet is formed in the other end of the reactor main body; a heat exchanging medium fused salt outlet and a heat exchanging medium fused salt inlet are formed in the side wall of the reactor main body; a plurality of catalyst filling pipes are arranged in the reactor main body; gas distribution plates are respectively arranged at the two ends of the plurality of catalyst filling pipes, wherein a second homogenizing space is formed between one distribution plate and the gas inlet; a first homogenizing space is formed between the other distribution plate and the material outlet; heat exchanging medium fused salts are filled between the plurality of catalyst filling pipes; and the gas pre-distributor comprises a horizontal flow deflector, a flow guide pipe and a conical cap. According to the invention, the area of a low gas speed area can be reduced; and moreover, the influences on local impact nonuniformity of the distribution plates are improved, the stability in operation is improved and the fixed-bed reactor can be applied to industrial production of the maleic anhydride.

Owner:ZHEJIANG UNIV

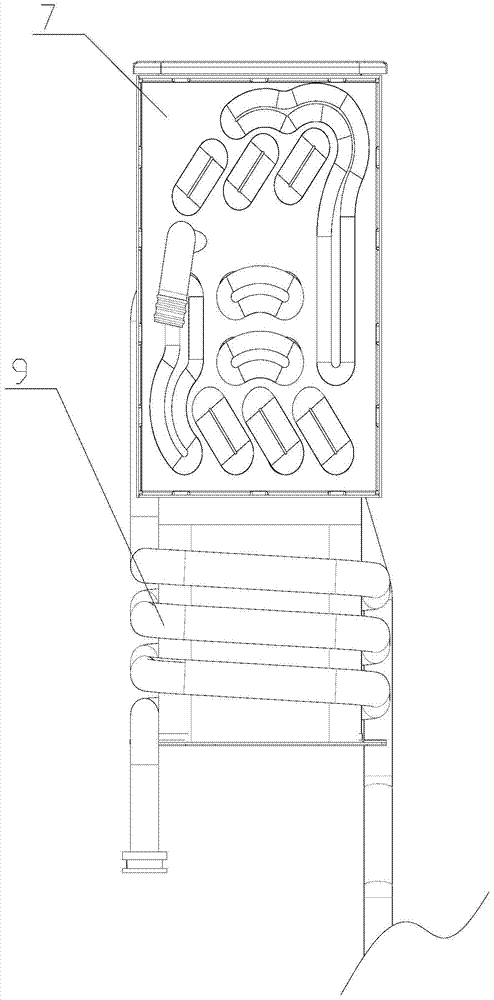

Heat exchanger

ActiveCN102954627APrevent inflowSolve the problem of drastic changes in trafficEvaporators/condensersStationary conduit assembliesPlate heat exchangerEngineering

The invention provides a heat exchanger, which comprises a collecting pipe and a distributor, wherein the distributor is arranged in the collecting pipe; and a clearance is formed between an edge in a longitudinal direction of the distributor and an inner wall of the collecting pipe. According to the distributor of the heat exchanger, refrigerating fluid can be distributed uniformly, and the process is simple.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

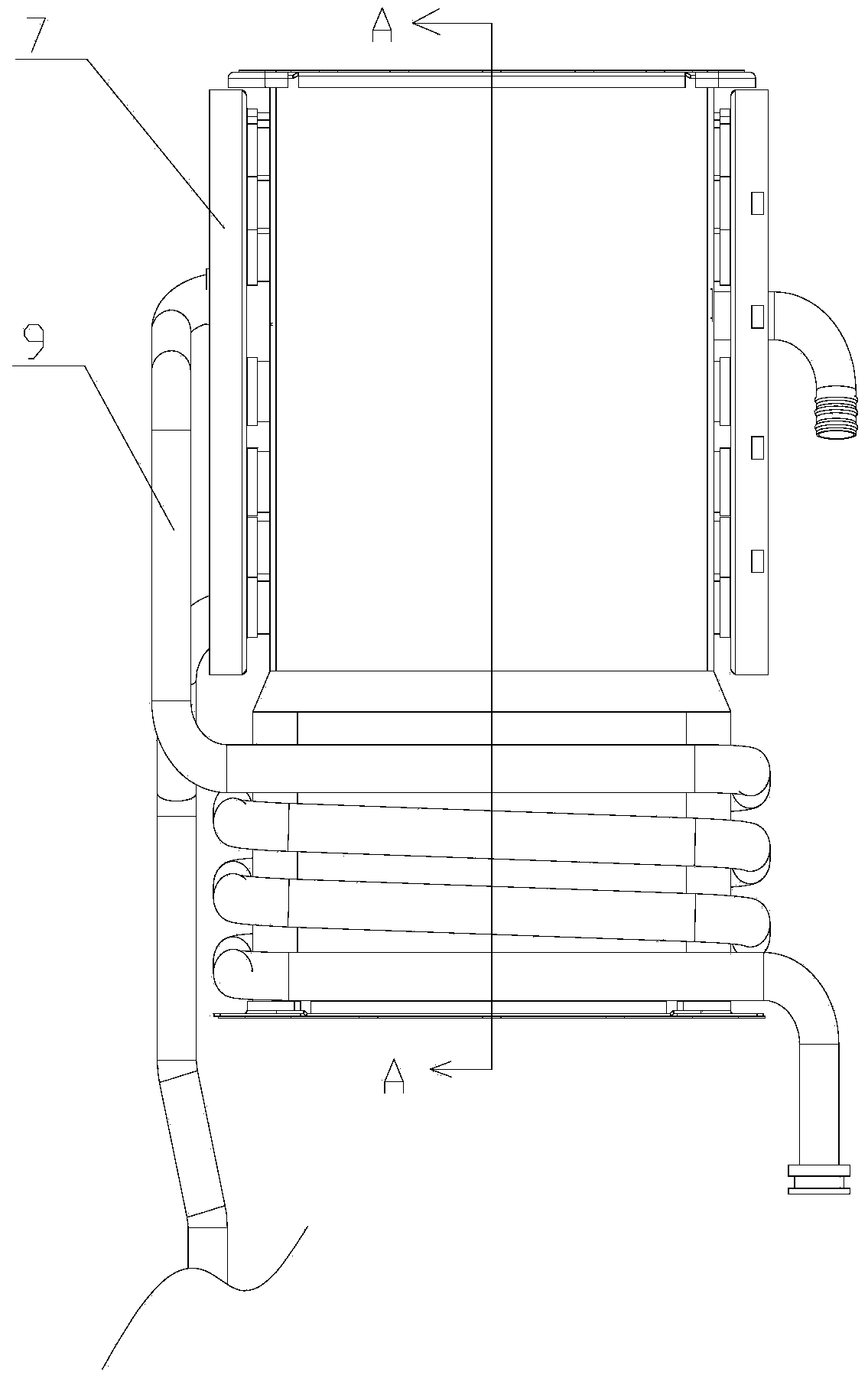

Gas water heater integrated stainless steel heat exchanger

ActiveCN103994579ASimple processingImprove welding qualityFluid heatersCorrosion preventionContinuous flowCorrosion

The invention provides a gas water heater integrated stainless steel heat exchanger which comprises a surrounding frame and multiple heat exchange tubes penetrating the surrounding frame. Water collecting boxes are arranged at the ends of the heat exchange tubes penetrating through the surrounding frame and enable the heat exchange tubes to be connected to form a continuous flowing channel. Elongated parts are arranged in at least one row of heat exchange tubes close to a high-temperature heating region. The water collecting boxes packages the elongated parts in the heat exchange tubes. The surrounding frame, the heat exchange tubes, the water collecting boxes and the elongated parts are assembled and welded to form an integral structure. The integrally-welded stainless steel heat exchanger is simple in structure and processing and small in size, the sealing performance and the corrosion resistance performance are greatly improved, a water flow field in a gas quick water heater tube is changed through the elongated parts, the situation of original uneven water temperature distribution is changed, accordingly scales are decreased, and the service life of the heat exchangers is prolonged.

Owner:A O SMITH CHINA WATER HEATER CO LTD

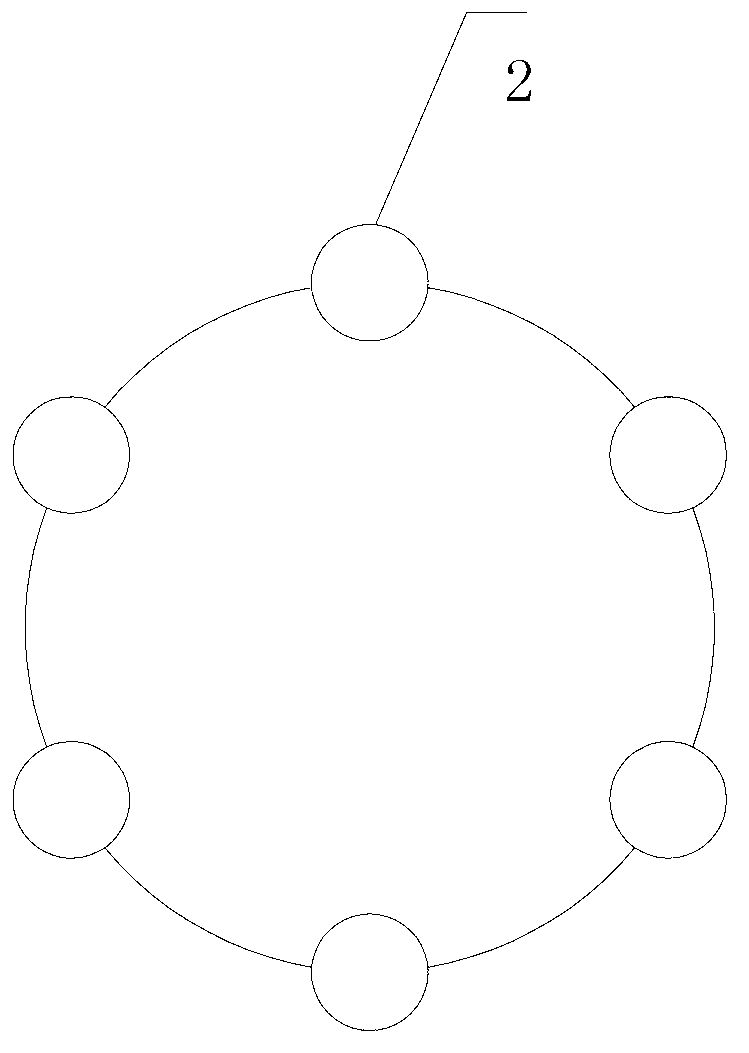

Fluidized bed reactor for preparing chlorosulfonated polyethylene by gas-solid method

InactiveCN102698663AIncrease solids concentrationPrevent subsidenceChemical/physical processesStraight tubeFluidized bed

The invention relates to a fluidized bed reactor for preparing chlorosulfonated polyethylene by a gas-solid method. The fluidized bed reactor comprises a main body of the fluidized bed reactor, wherein the main body of the fluidized bed reactor comprises a straight tube section and a reactor expansion section; the top end of the straight tube section is connected with the bottom end of the reactor expansion section; the inner diameter of the reactor expansion section is larger than that of the straight tube section; a gas premixing chamber is formed at the bottom of the main body of the fluidized bed reactor; a predistribution device is arranged at the bottom of the inner wall of the gas premixing chamber; a plurality of layers of gas distribution plates are arranged between the gas premixing chamber and the main body of the fluidized bed reactor; an ultraviolet lamp glass tube stack formed by annularly arranging a plurality of glass tubes is arranged in the center of the straight tube section, or a plurality of holes are equidistantly and radially formed in the inner wall of the straight tube section along the circumference; and the glass tubes are arranged in the holes. The fluidized bed reactor has the advantages of effectively preventing particles close to the wall surface from being adhered on the wall surface or settled; eliminating dead zones of the whole fluidized bed layer; making reactions more uniform because reaction materials in the bed layer are sufficiently irradiated by ultraviolet.

Owner:刘文潮 +1

Dead angle-free stirring sprinkling machine for pouring

InactiveCN106827240AChange flow fieldProtective envelopeMixing operation control apparatusPretreatment controlSpiral bladeEngineering

The invention discloses a stirring sprinkler with no dead angle for pouring. One end of the stirring shaft in the stirring device passes through the upper end of the stirring tank and is connected with the driving device. The upper screw and the lower screw are set; the water supply device is composed of a water nozzle, a guide pipe, a time controller, a stirring blade, a micro motor, a bevel gear transmission box, a water container and a flow control valve; The discharge port is set at the bottom of the stirring tank and connected with the screw conveyor, and the screw conveyor is connected with the spray gun through the feeding pipe. The invention changes the flow field of the vortex formed by the helical blade, protects the coating of quicklime particles, can supply water intermittently, can improve the uniformity of stirring, greatly increases the service strength and life after solidification, and reduces the eddy current contacting the bottom of the stirring tank and then upwards The energy consumption of changing the flow direction expands the influence range of the vortex and eliminates the dead angle of stirring existing on the liquid surface of the stirring tank.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

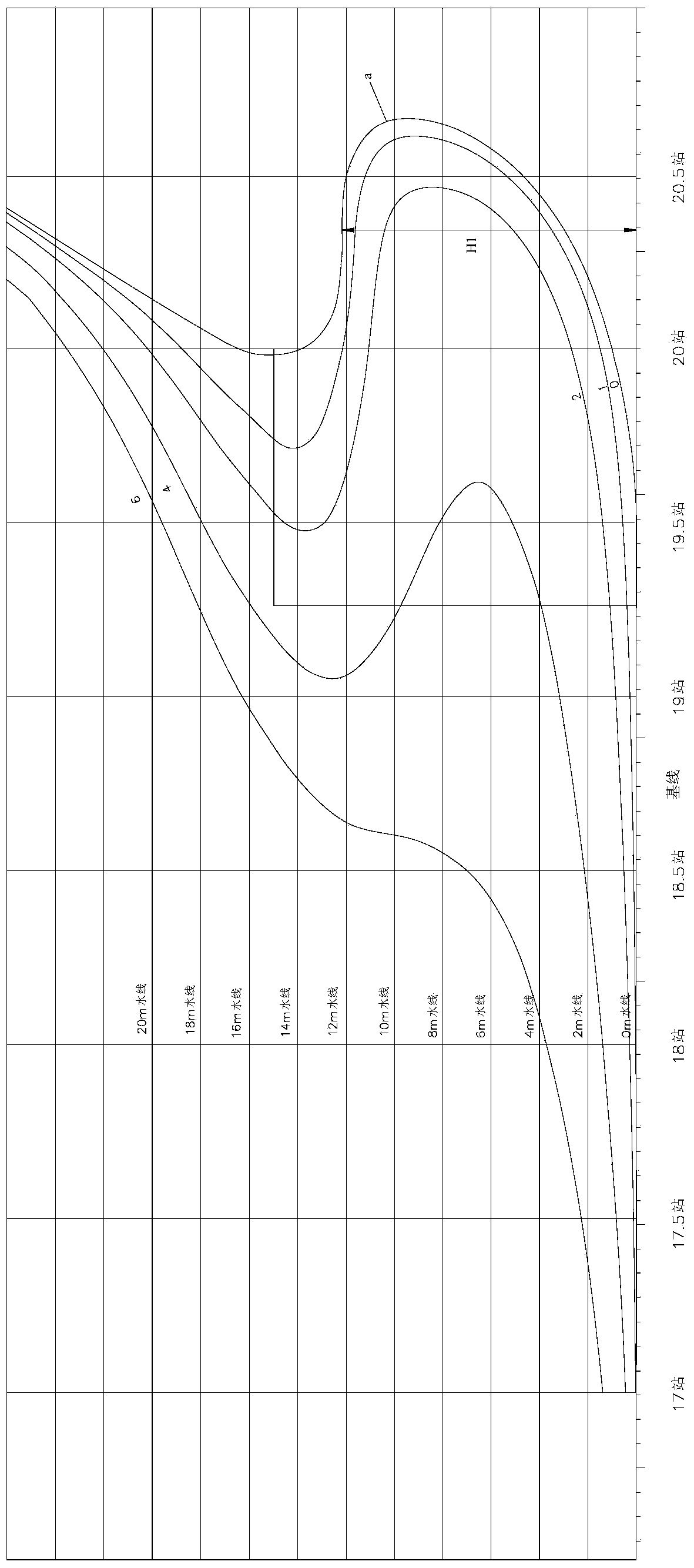

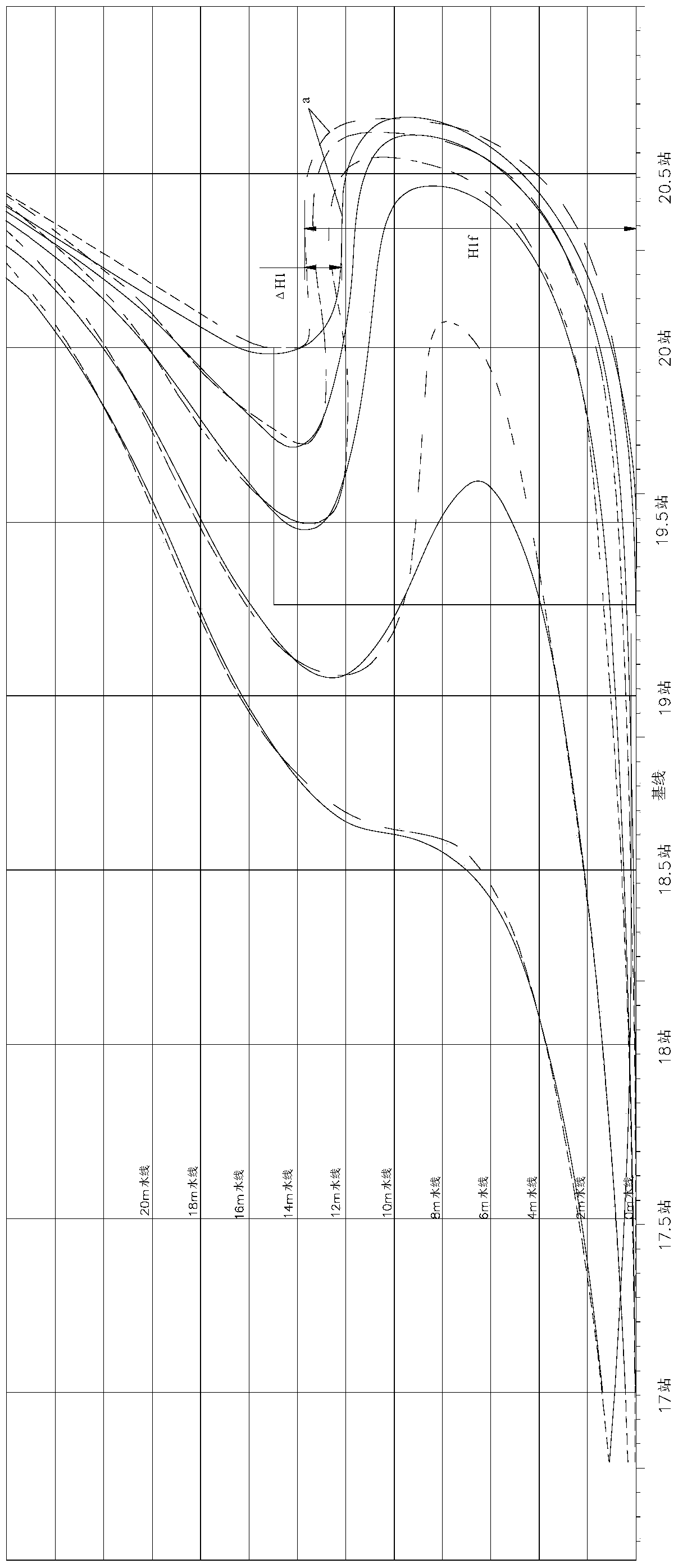

Ship

ActiveCN104890805AChange flow fieldChange pressureHydrodynamic/hydrostatic featuresEffective powerMarine engineering

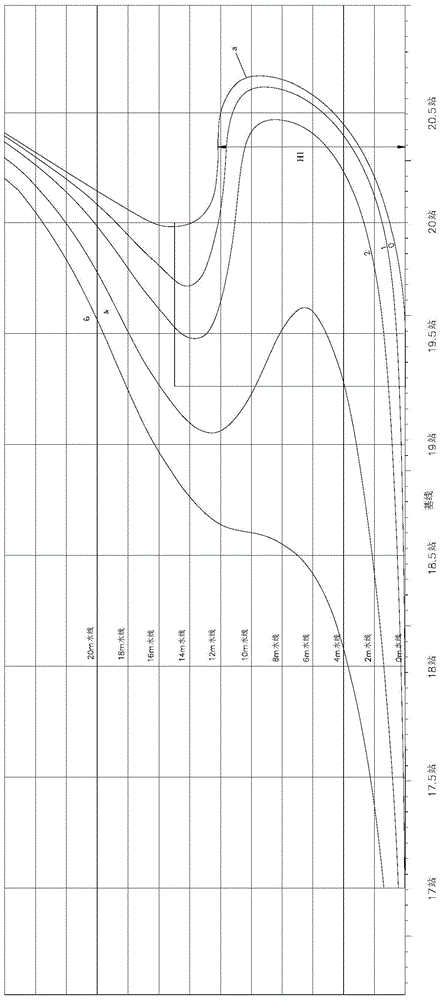

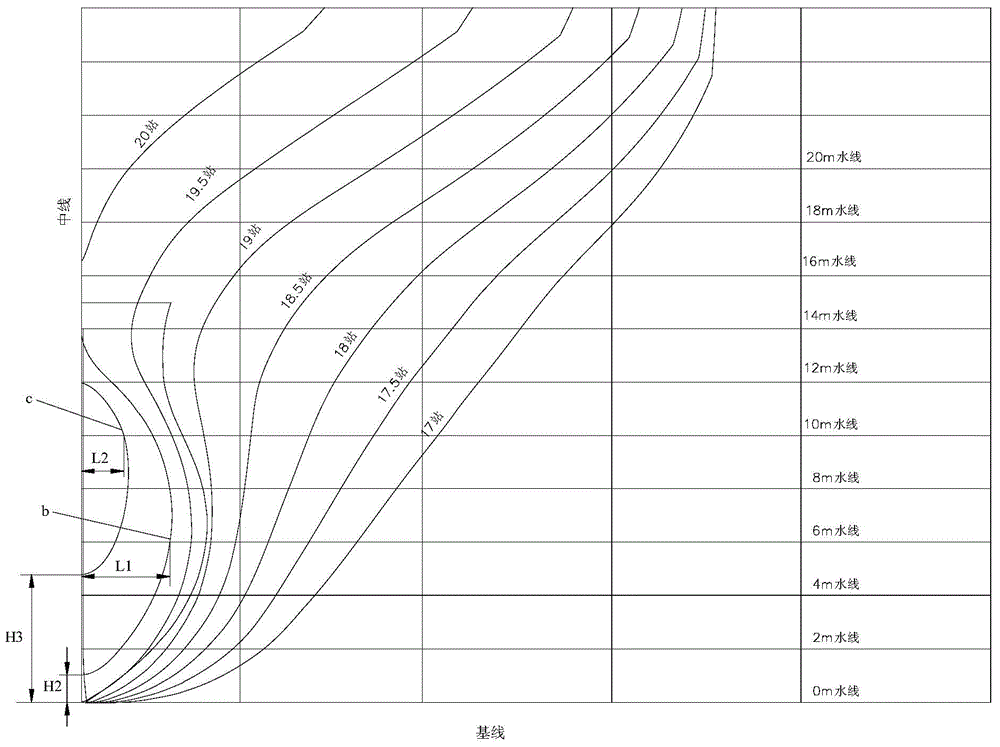

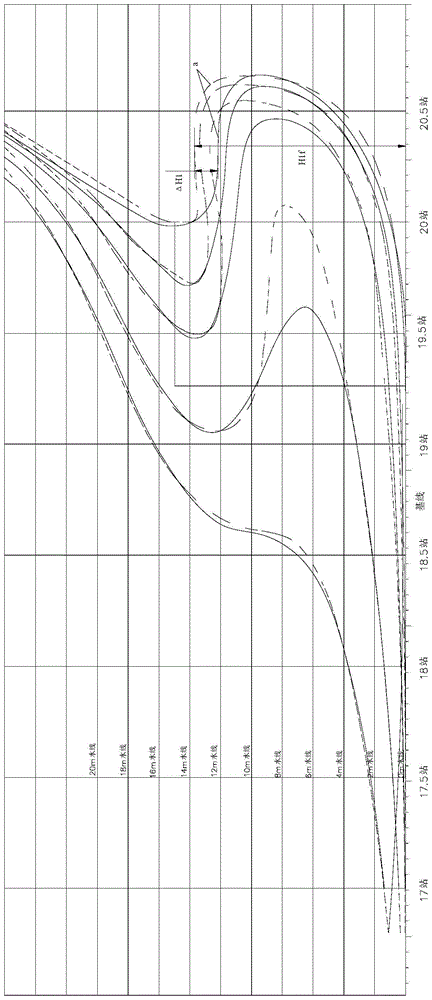

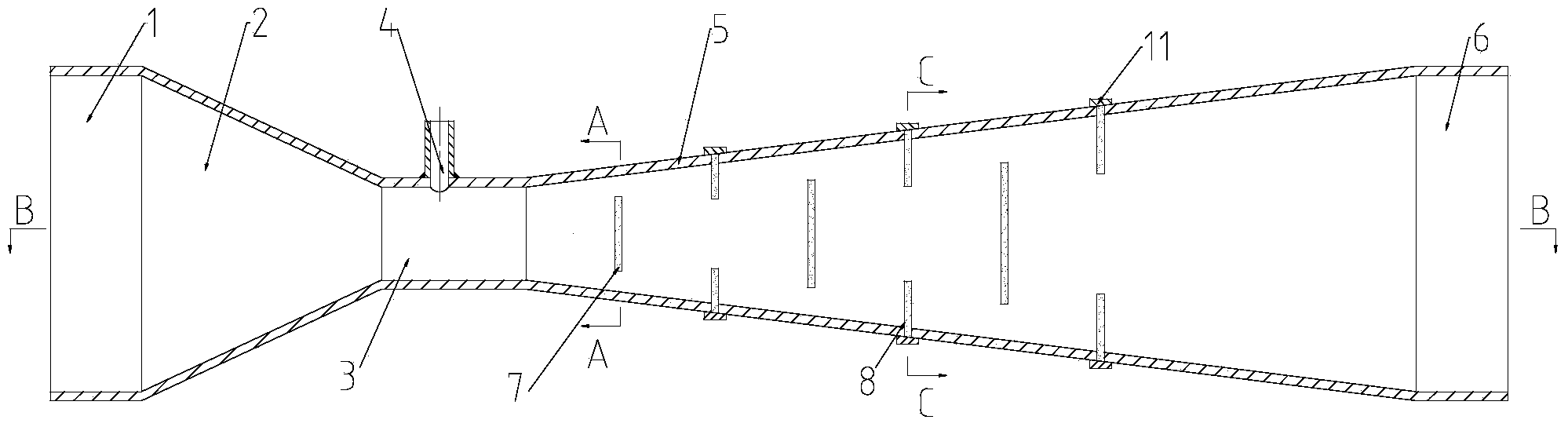

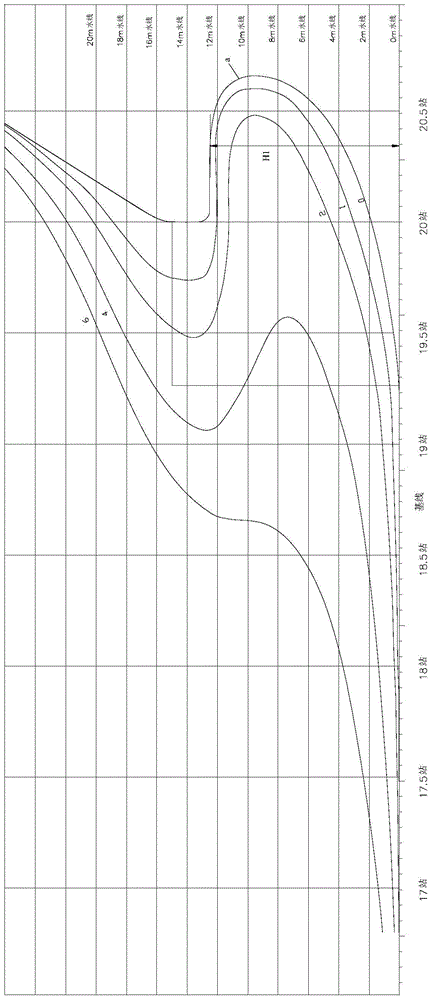

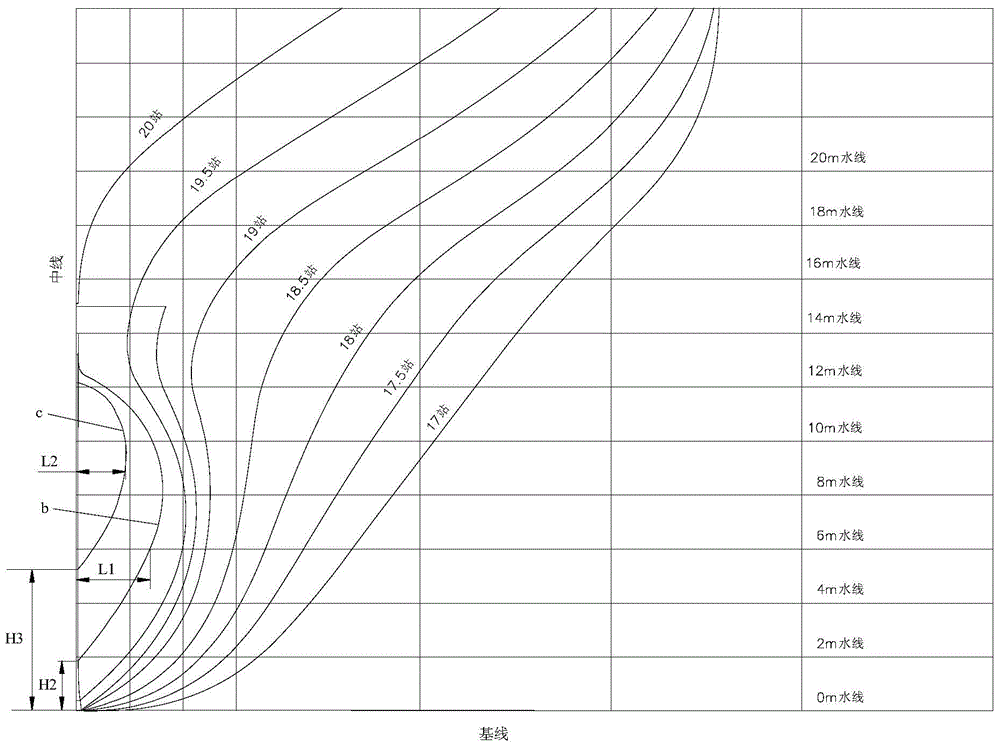

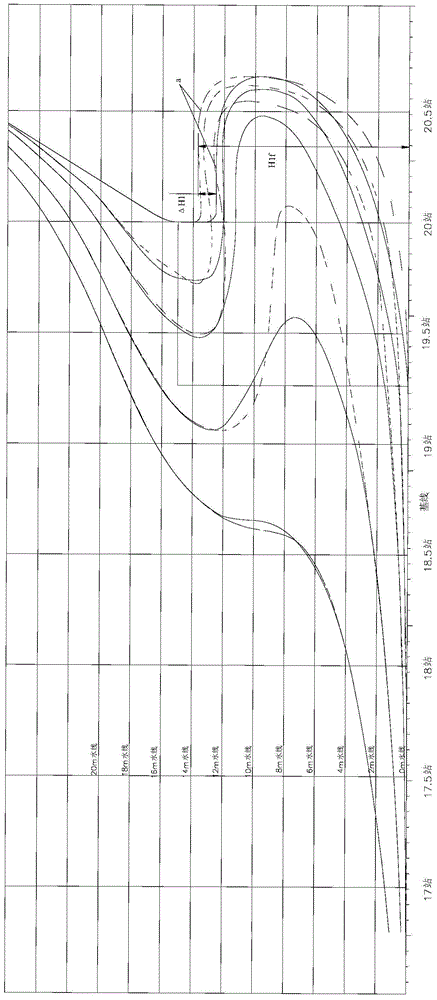

The invention discloses a ship. The ship comprises a ship body and a bulbous bow, wherein the bulbous bow is positioned under the bow part of the ship body, and the highest position of the upper part of the bulbous bow is 11.95-12.45m away from a baseline; at the 20th station of the ship body, the bottom of the bulbous bow is 750-1250mm away from the baseline; at the height of the 6m waterline at the 20th station of the ship body, the outer edge of the bulbous bow is 3100-3600mm away from a central line; at the 20.5th station of the ship body, the bottom of the bulbous bow is 4550-5050mm away from the baseline; at the height of the 10m waterline at the 20th station of the ship body, the outer edge of the bulbous bow is 1350-1850mm away from the central line. According to the ship, flow fields and pressure distribution, which is around the ship body, is changed by changing the bulbous bow, so that the ship can have lower effective power at any navigational speed, and the purpose of saving fuel oil is achieved.

Owner:CIMC SHIP OCEAN ENG DESIGN & RES INST +1

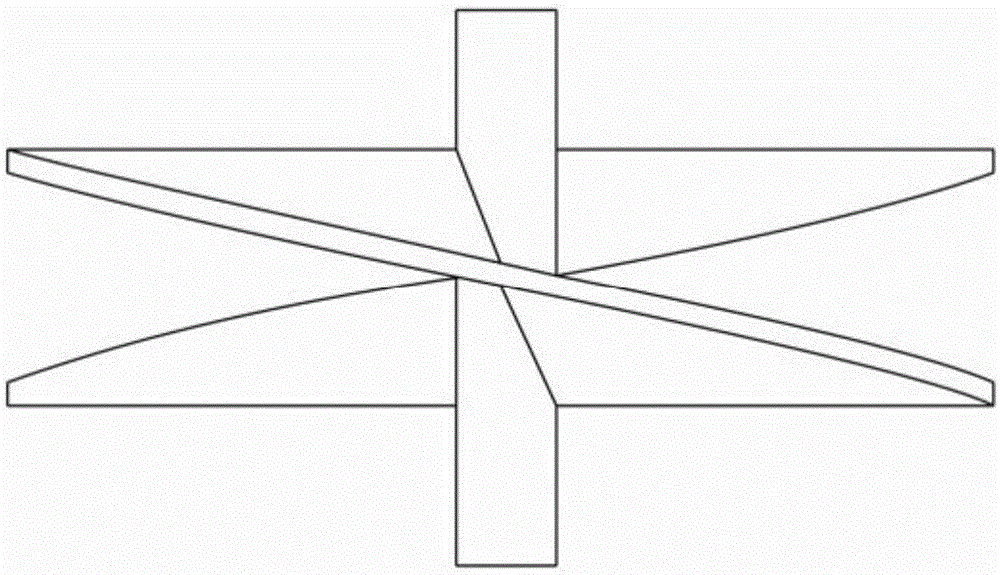

Venturi mixer with diffuser containing shrinkage cavities

ActiveCN103846027ASevere turbulenceIncrease flow rateFlow mixersMixing methodsMaterials scienceSupport plane

The invention discloses a venturi mixer with a diffuser containing a shrinkage cavity. The venturi mixer comprises a flowing pipeline, a gradual shrinking section, a throat part, the diffuser, an outflowing pipeline and an input pipe as well as the multiple groups of shrinkage cavities in the diffuser, wherein each group of shrinkage cavities comprise a fixed shrinkage cavity and an adjustable shrinkage cavity, and each adjustable shrinkage cavity is composed of two core plates; the fixed shrinkage cavities are welded on the inner wall of the diffuser through multiple support frames, and the adjustable shrinkage cavities are embedded into the diffuser; the fixed shrinkage cavities and the adjustable shrinkage cavities are alternately arranged, and a shrinkage cavity adjusting device can adjust the relative positions of the two core plates in each adjustable shrinkage cavity on line. The venturi mixer provided by the invention has the advantages that the disturbance of a mixing fluid in the diffuser of the venturi mixer is effectively strengthened, the mixing efficiency of the venturi mixer is effectively improved, and a non-uniform mixing phenomenon is avoided.

Owner:度测(上海)科技服务中心

Ship

InactiveCN104890807AChange flow fieldChange pressureHydrodynamic/hydrostatic featuresEffective powerMarine engineering

The invention relates to a ship, which comprises a ship body and a bulbous bow positioned under a bow part of the ship body, wherein the distance between the highest part of the upper part of the bulbous bow and a base line is between 12.25m and 12.75m; at the 20-th station of the ship body, the distance between the bottom of the bulbous bow and the base line is between 1600mm and 2100mm; at the height of a 6m water line of the 20-th station of the ship body, the distance between the outer edge of the bulbous bow and the center line is between 2550mm and 3050mm; at the 20.5-th station of the ship body, the distance between the bottom of the bulbous bow and the base line is between 5000mm and 5500mm; and at the height of a 10m water line of the 20.5-th station of the ship body, the distance between the outer edge of the bulbous bow and the center line is between 1600mm and 2100mm. The ship has the advantages that the flow field and pressure distribution around the ship body is changed through the change of the bulbous bow, so that the lower effective power can be realized at any navigational speed of the ship, and the goal of saving fuel is achieved.

Owner:CIMC SHIP OCEAN ENG DESIGN & RES INST +1

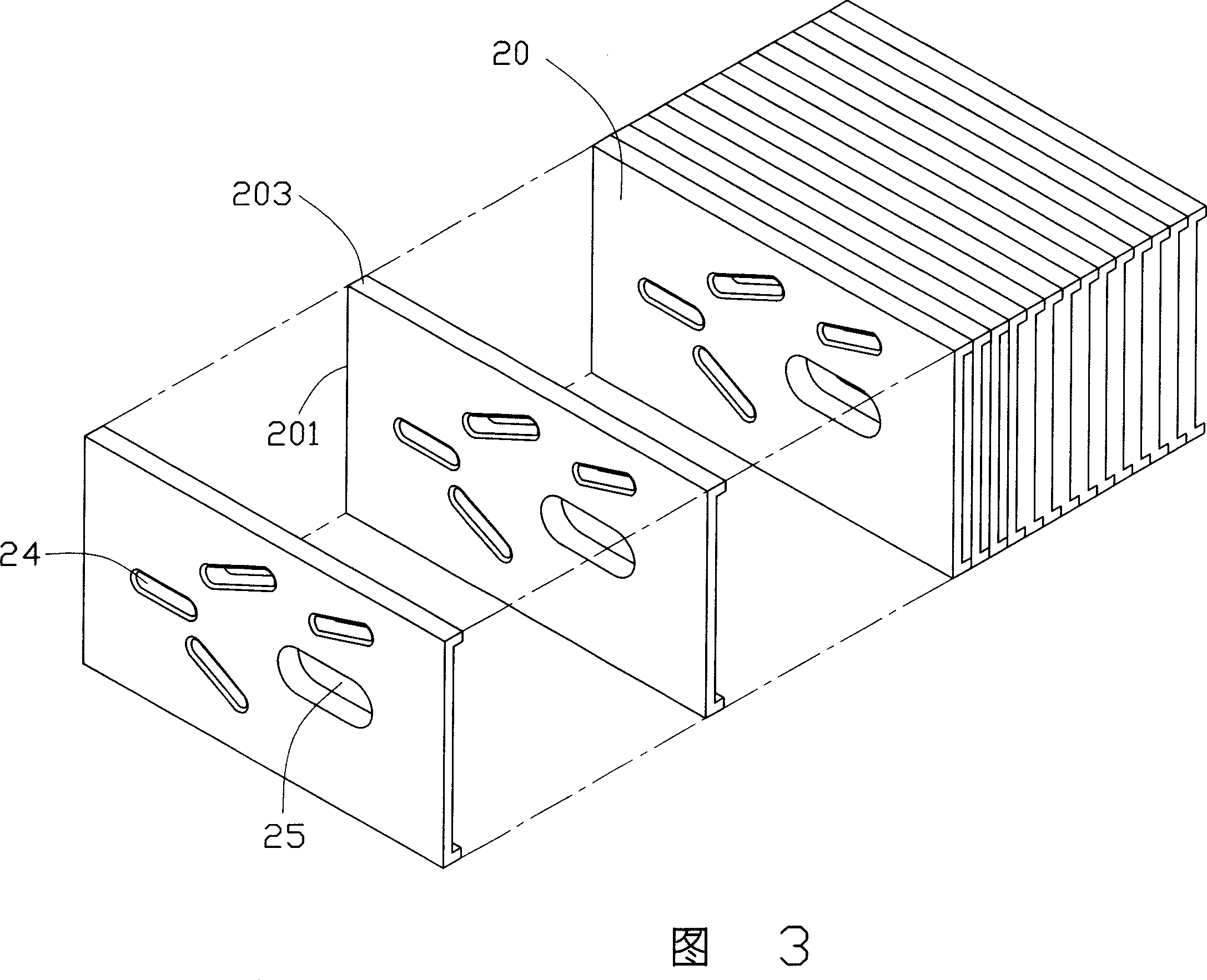

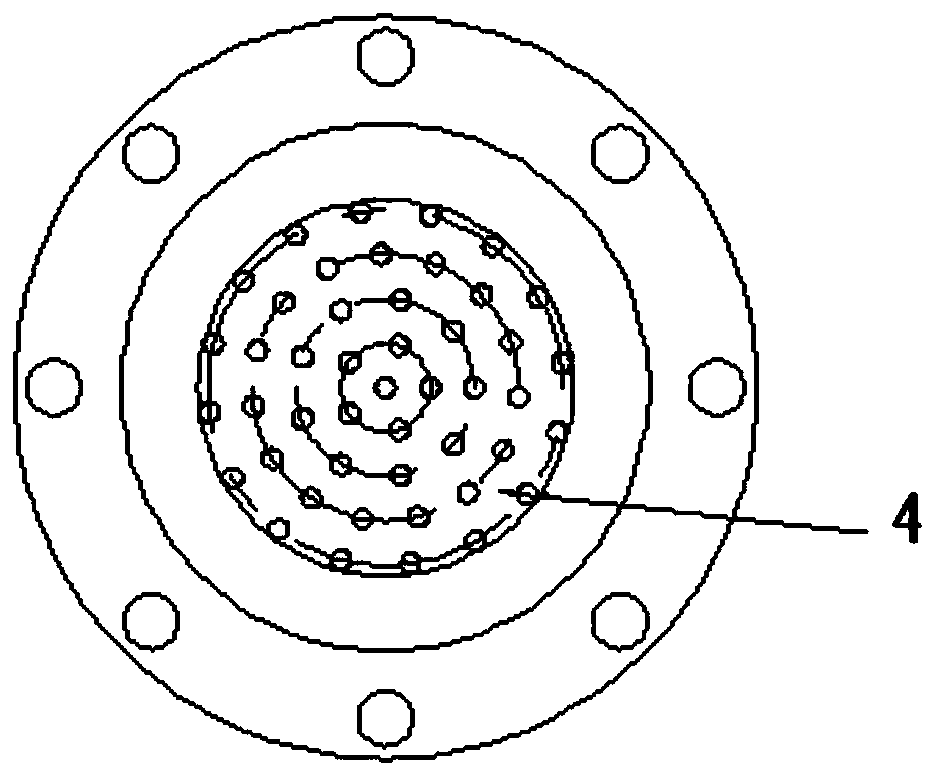

Radiator

InactiveCN101087508AIncrease cooling areaChange flow fieldDigital data processing detailsSemiconductor/solid-state device detailsHeat spreaderPhysics

A kind of radiator includes several radiating fins which are set parallel with each other and hot pipe which is set through the radiating fins, flow channel for air flow is formed between adjacent radiating fins, a through hole for the hot pipe is set on every radiating fin, several heaves are set around the through hole on the radiating fin, said several heaves are arranged to shrinkage type. Said heaves can increase radiating area of radiating fin, at the same time it can guide flow and change flow field of air flow, increase burbling effect of radiating fin, radiating efficiency can be increased.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

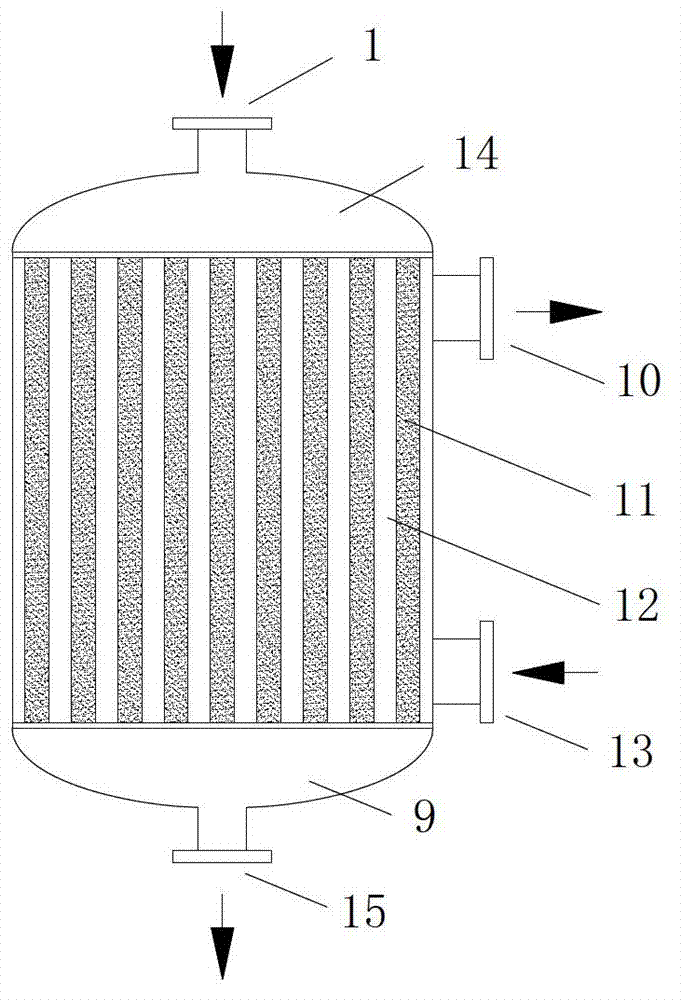

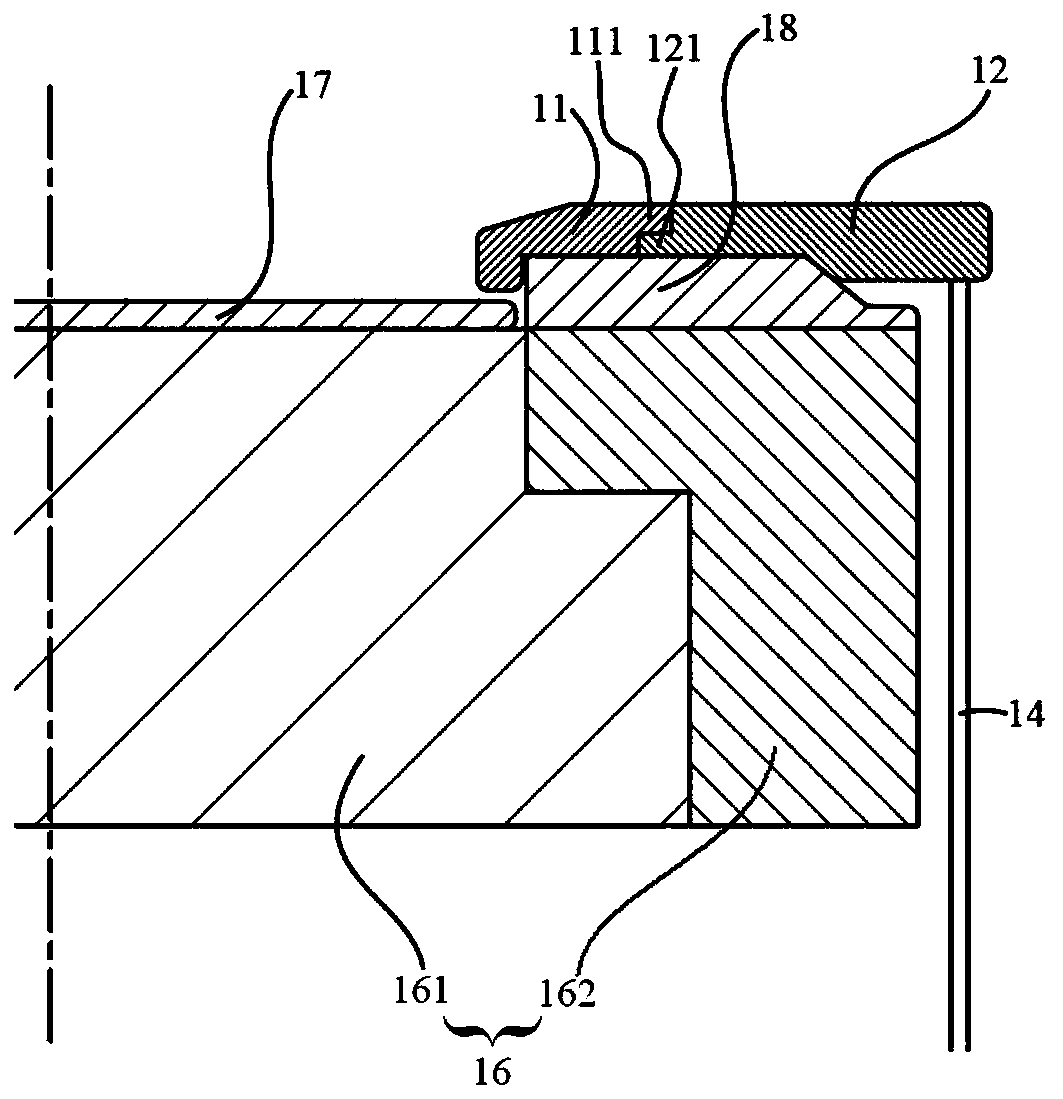

Fixed bed reactor and method for preparing maleic anhydride by virtue of normal butane oxidation

InactiveCN103028350AChange flow fieldReduce areaOrganic chemistryChemical/physical processesFixed bedMolten salt

The invention discloses a fixed bed reactor and a method for preparing maleic anhydride by virtue of normal butane oxidation. A gas inlet is formed at one end of a reactor body; a gas pre-distributer is arranged in one end of the reactor body and is connected with the gas inlet; a discharge port is arranged at the other end of the reactor body; a heat-transfer medium molten salt outlet and a heat-transfer medium molten salt inlet are formed on the side wall of the reactor body; a plurality of catalyst filling pipes are arranged in the reactor body; gas distributing plates are arranged at both ends of the plurality of catalyst filling pipes respectively, wherein a second homogenizing space is arranged between one gas distributing plate and the gas inlet while a first homogenizing space is arranged between the other gas distributing plate and the discharge port; the molten salt as a heat-transfer medium is arranged among the plurality of catalyst filling pipes; and a fluid director is connected with the inner wall of one end of the reactor body through a support rod. The fixed bed reactor provided by the invention has the advantages that the dimension of a region with a low gas velocity is reduced; and the influence of an uneven local impact on the distributing plates is decreased, so that the operation stability is improved. Therefore, the fixed bed reactor can be applied to the industrial production of maleic anhydride.

Owner:ZHEJIANG UNIV

Salinization treatment process for smoke dust of flash furnace and device thereof

InactiveCN101660058AIncrease the chance of collisionReduce the incidence of smoke and dustDispersed particle separationFlueFlue gas

The invention relates to the metallurgical field of a flash furnace, and provides a salinization treatment process for the smoke dust of the flash furnace and a device thereof. The device comprises abase, a spray gun, a mixed oxygen pipeline, a normoxic pipeline and a pure oxygen pipeline, wherein one end of the spray gun is inserted and fixed on the base, and the middle part thereof is providedwith a nozzle; the included angle between the nozzle and the central axis of a furnace body is 30-90 degrees; an air inlet of the spray gun is communicated with the mixed oxygen pipeline which is respectively communicated with the normoxic pipeline and the pure oxygen pipeline, and the normoxic pipeline and the pure oxygen pipeline are respectively provided with a pressure gage, an automatic shut-off valve, an automatic regulating value and a flow meter. By spraying pure oxygen or oxygen-enriched air into a high temperature area, sulfide in the smoke dust can be oxidized, and more smoke dust can be settled, so that the occurring rate of the smoke dust is further reduced, and oxygen required by salinization enters into a boiler through an uptake flue along with flue gas and begins to salinize contaminating metal at the medium-high temperature stage of the boiler, thus preventing the tube wall of the boiler with waste heat from being stuck with bonding substance which is not easily cleaned and avoiding the flue being corroded.

Owner:YANGGU XIANGGUANG COPPER

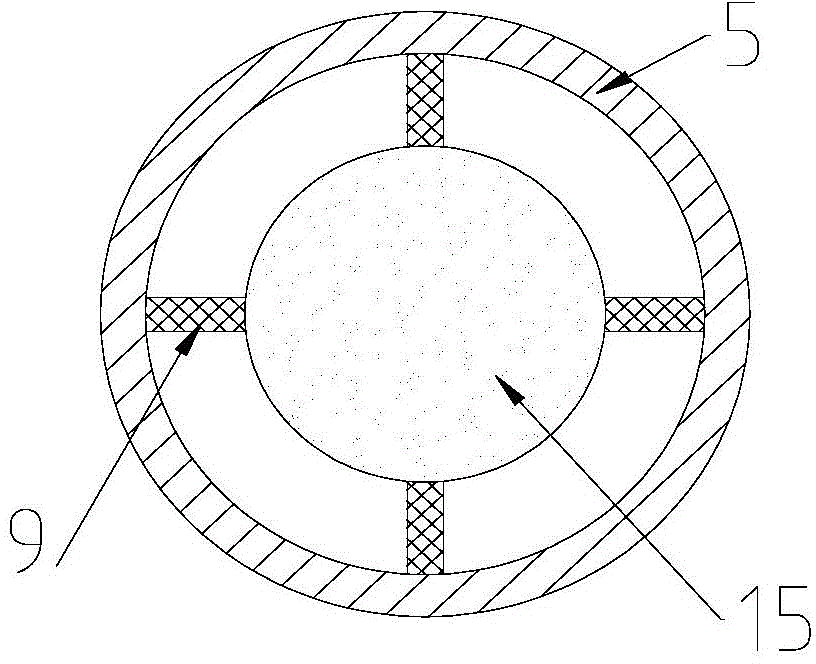

Semiconductor process chamber, wafer edge protection method and semiconductor equipment

The invention provides a semiconductor process chamber, a wafer edge protection method and semiconductor equipment. The semiconductor process chamber comprises a base and a wafer edge protection device, the wafer edge protection device is arranged on the base, and the wafer edge protection device comprises an inner protection ring and an outer protection ring, the outer protection ring is arrangedon the outer side of the inner protection ring in a surrounding mode, is in lap joint with the inner protection ring and can drive the inner protection ring to ascend and descend synchronously, the inner diameter of the inner protection ring is smaller than the diameter of the wafer, the inner protection ring is used for shielding the edge of the wafer arranged on the base, and the outer diameterof the inner protection ring is smaller than the size of a wafer transfer port of the semiconductor process chamber. According to the semiconductor process chamber, the wafer edge protection method and the semiconductor equipment provided by the invention, switching of different semiconductor processing technologies can be facilitated, the productivity is improved, the uniformity of the semiconductor processing technologies can be improved, and the problem of angle inclination of the edge of the wafer in the semiconductor processing technologies is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Sound field enhanced air flow drying and boundary layer measurement integration experiment system

InactiveCN105627964AChange flow fieldAffects the distribution of the airflow fieldWeighing by removing componentDrying gas arrangementsElectrical resistance and conductanceMeasurement device

The invention discloses a sound field enhanced air flow drying and boundary layer measurement integration experiment system comprising a dry air circulation device, a replaceable air flow distribution device, a sound wave generating device, a dried object weight measurement device, and a boundary layer measurement device. The dried object weight is measured by a precision balance disposed on a drying box, and an air circulating fan is communicated with the drying box by an inlet air circulation pipeline and an outlet air circulation pipeline to form a closed loop. The boundary layer measurement device is constituted by a thermistor thermometer C inserted in the air flow pipeline, a pitot tube, and a shifter. The outlet air circulation pipe is provided with a pore plate flowmeter. By adopting the experiment system provided by the invention, the drying rate curve of the dried object can be determined under the constant drying condition, the influences of the flow field and the sound wave on the drying process can be inspected, and the speed boundary layer and the temperature boundary layer can be measured. The experimenter can master the definition and measurement method of the object drying rate, the speed boundary layer, and the temperature boundary layer by using the experiment system.

Owner:SICHUAN UNIV

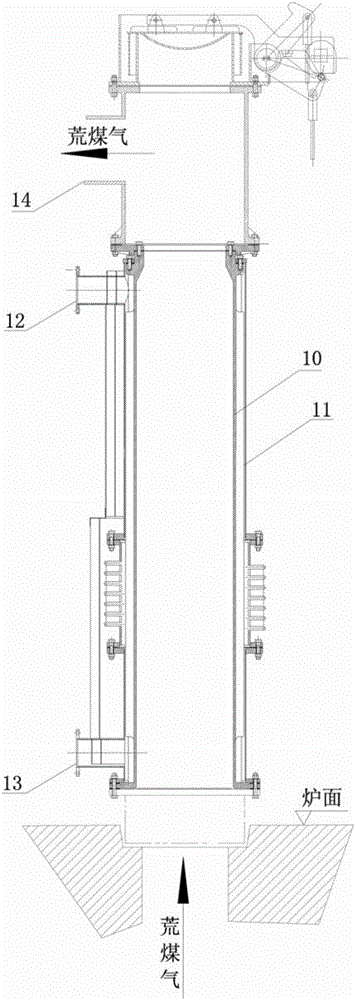

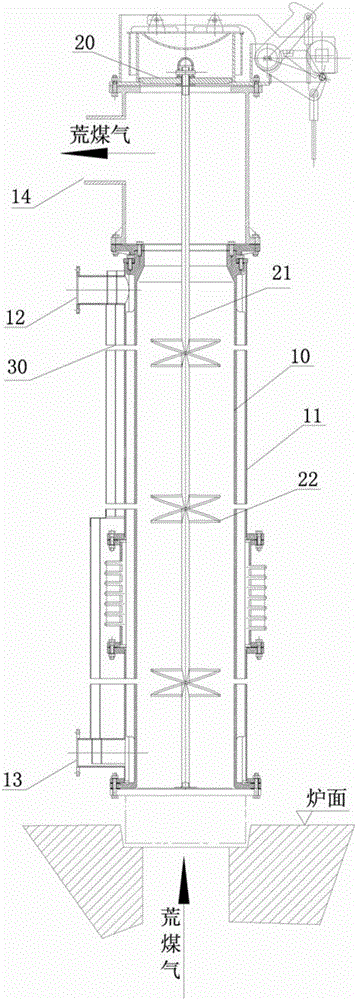

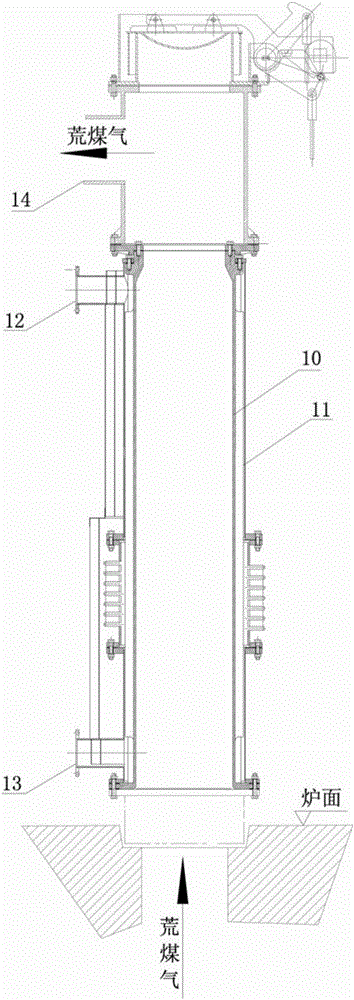

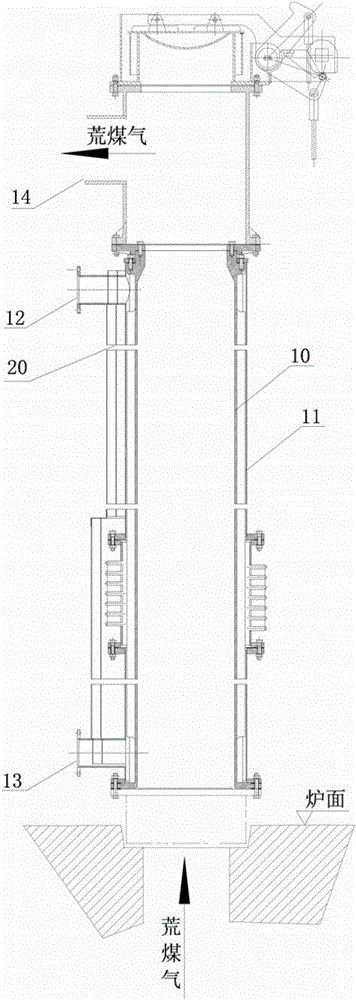

Ascension pipe of coke oven and method of applying same to recovery heat of raw coke oven gas

ActiveCN105018113AGuaranteed uptimeIncrease the Reynolds numberSteam generation using hot heat carriersDistillation gas withdrawalCoke ovenCoke oven gas

An embodiment of the invention discloses an ascension pipe of a coke oven and a method of applying the same to recovery heat of raw coke oven gas. The ascension pipe of the coke oven comprises an inner wall and an outer wall and further comprises a suspension rod fixing rack, a suspension rod and at least one spoiler which is fixedly arranged on the suspension rod; the suspension rod fixing rack is mounted in the ascension pipe of the coke oven; the suspension rod and the suspension rod fixing rack are movably connected, so that the suspension rod is overhung in the ascension pipe of the coke oven and can rotate; at least one outer fluid inlet penetrating through the inner wall and the outer wall is formed on the side wall of the ascension pipe of the coke oven, so that an outer fluid is sprayed to the ascension pipe of the coke oven through the outer fluid inlet and drives the suspension rod and the spoiler to rotate. By adopting the technical scheme provided by the invention, the flow field of raw coke oven gas can be changed, the Reynolds number of coke oven gas flowing is increased and the heat exchange efficiency of the coke oven gas in the ascension pipe is improved, so that the recovery utilization ratio of heat of the coke oven gas is improved and the operating efficiency of the coke oven is improved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

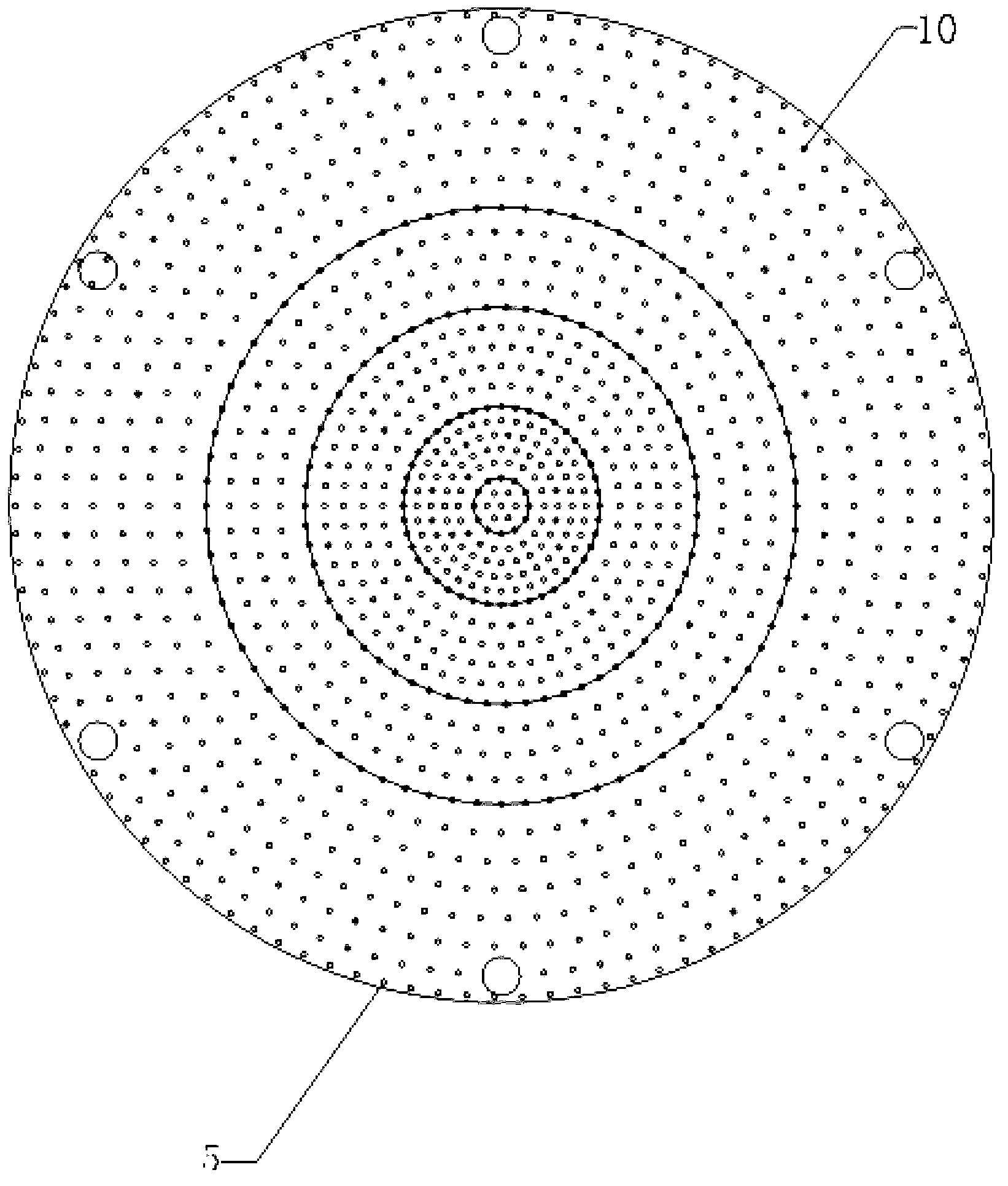

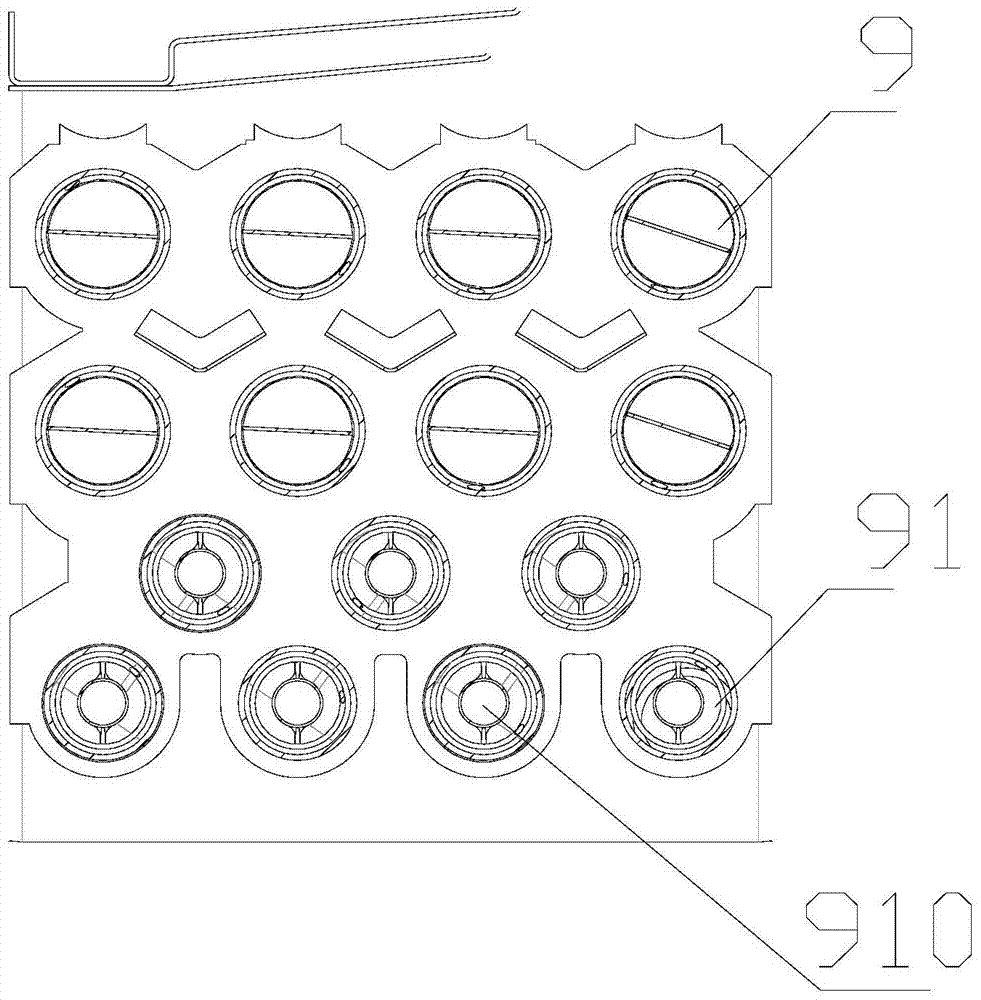

Steam noise and pressure reduction device with large pressure difference and low pressure reduction ratio

PendingCN114233901AChange flow fieldImprove uniformityValve members for absorbing fluid energyEqualizing valvesLow noiseThermodynamics

The invention discloses a steam noise reduction and pressure reduction device with large pressure difference and low pressure reduction ratio. The steam noise reduction and pressure reduction device comprises a barrel, an inlet part, an outlet part and at least two sleeve type throttling orifice plates. The barrel is provided with a first end and a second end which are opposite. The inlet portion and the outlet portion are located at the first end and the second end, respectively. The sleeve type throttling orifice plate comprises a wall part and a bottom part, the radial section of the wall part is annular, and the bottom part is connected to one end of the wall part. A plurality of through holes are formed in the wall portion of each sleeve type throttling orifice plate, and the bottom of each sleeve type throttling orifice plate is far away from the inlet portion relative to the wall portion. And the at least two sleeve type throttling orifice plates are arranged in a step-by-step sleeving mode from inside to outside and are spaced, and the total area of the through holes is gradually increased from inside to outside, so that the respective pressure reduction ratios of the at least two sleeve type throttling orifice plates are gradually increased. According to the steam noise reduction and pressure reduction device with the large pressure difference and the low pressure reduction ratio, the purposes of pressure reduction and noise reduction can be achieved at the same time, noise pollution is reduced, and the equipment use environment is safer.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

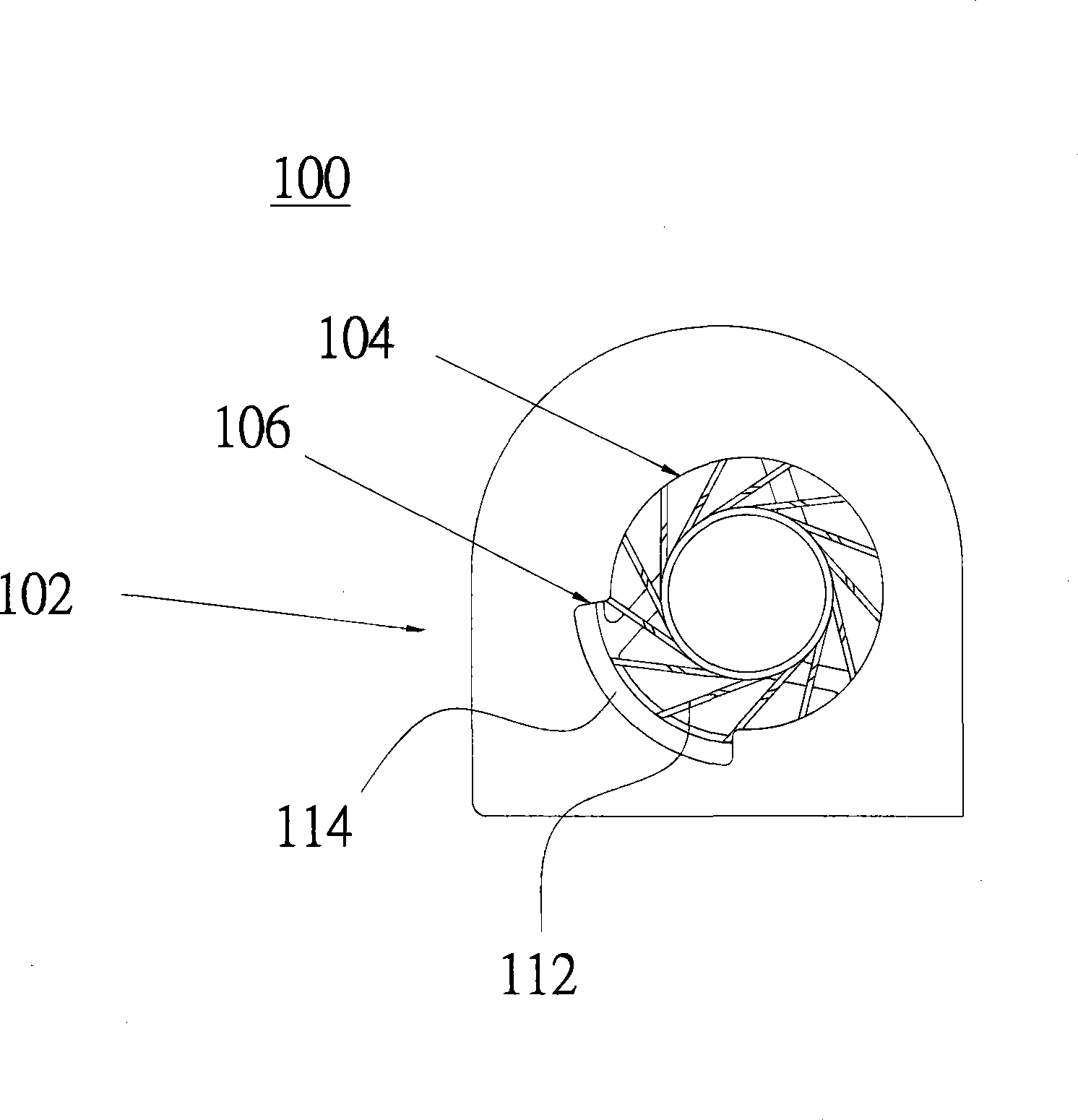

Side blowing type fan

ActiveCN101435427AIncrease air intakeChange flow fieldPump componentsRadial flow pumpsImpellerEngineering

The invention discloses a side-blow fan, which comprises a shell and an impeller, wherein the shell is provided with a master air inlet and at least one auxiliary air inlet. The impeller is arranged in the shell and comprises a hub part, a plurality of blades and at least one ring plate. The blades are arranged around the hub part. The ring plate is connected with the blades, and shields partial auxiliary air inlet. Because of the additional auxiliary air inlet, the side-blow fan can increase air input. In addition, the side-blow fan is also provided with the ring plate, and uses the ring plate to shield partial auxiliary air inlet so as to change the flow field at the auxiliary air inlet, thereby achieving an effect of great reducing operation noises.

Owner:DELTA ELECTRONICS INC

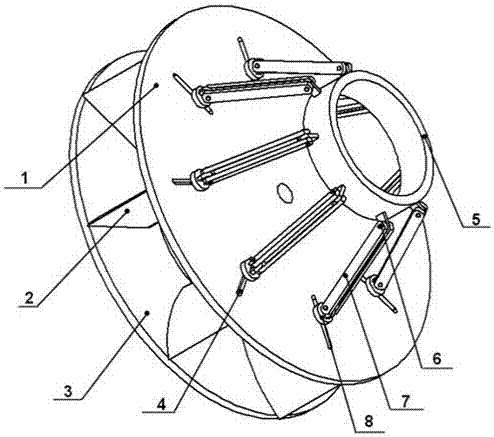

A centrifugal fan device with adjustable blades by Bluetooth remote control

ActiveCN105756987BRealize the effect of one machine with multiple functionsGood value for moneyPump componentsEngine controlImpellerAir volume

The invention discloses a centrifugal fan device with adjustable blades by Bluetooth remote control, which includes an outer impeller, an inner impeller, a wheel cover, a wheel disc, a thin-film parameter sensor, a blade adjustment device, an electric push rod and a Bluetooth intelligent terminal; The outer impeller includes an outer disc and an outer blade, and the inner impeller includes a wheel cover, an inner disc and an inner blade; the inner disc of the inner impeller is fixed on the shaft disc; the shape of the blades of the outer impeller and the inner impeller is a wing Type, by installing the cooperation of the inner impeller and the outer impeller, the appropriate angle of the blades of the auxiliary impeller can be adjusted according to the air volume under different working conditions, so as to realize the multi-purpose effect of the centrifugal fan and achieve stable and efficient work under non-rated working conditions The purpose is to realize remote control and self-regulation through the Bluetooth smart terminal. The advanced nature of modern technology will be integrated into people's production and life. The strong controllability and stable remote control solve the inconvenience caused by the placement location and space. question.

Owner:嘉兴芸诗娇电子商务有限公司

A venturi mixer with shrinkage cavity in the diffusion section

ActiveCN103846027BSevere turbulenceIncrease flow rateFlow mixersMixing methodsMaterials scienceSupport plane

The invention discloses a venturi mixer with a diffuser containing a shrinkage cavity. The venturi mixer comprises a flowing pipeline, a gradual shrinking section, a throat part, the diffuser, an outflowing pipeline and an input pipe as well as the multiple groups of shrinkage cavities in the diffuser, wherein each group of shrinkage cavities comprise a fixed shrinkage cavity and an adjustable shrinkage cavity, and each adjustable shrinkage cavity is composed of two core plates; the fixed shrinkage cavities are welded on the inner wall of the diffuser through multiple support frames, and the adjustable shrinkage cavities are embedded into the diffuser; the fixed shrinkage cavities and the adjustable shrinkage cavities are alternately arranged, and a shrinkage cavity adjusting device can adjust the relative positions of the two core plates in each adjustable shrinkage cavity on line. The venturi mixer provided by the invention has the advantages that the disturbance of a mixing fluid in the diffuser of the venturi mixer is effectively strengthened, the mixing efficiency of the venturi mixer is effectively improved, and a non-uniform mixing phenomenon is avoided.

Owner:度测(上海)科技服务中心

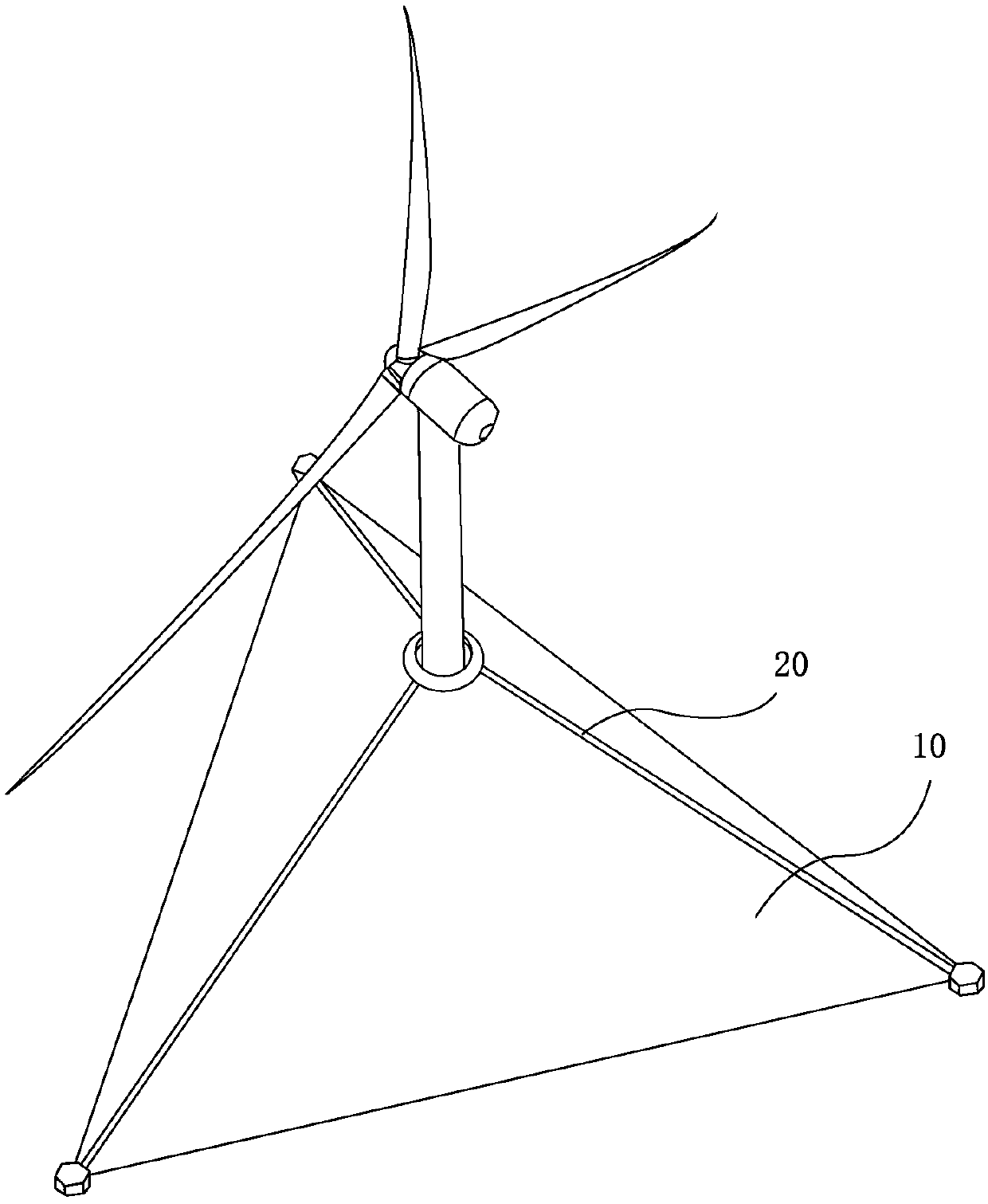

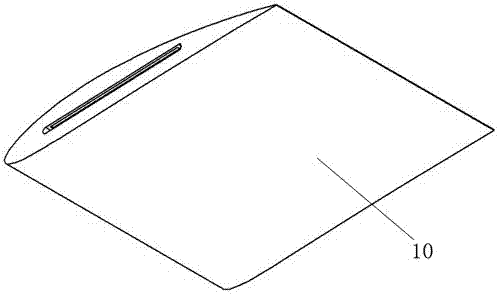

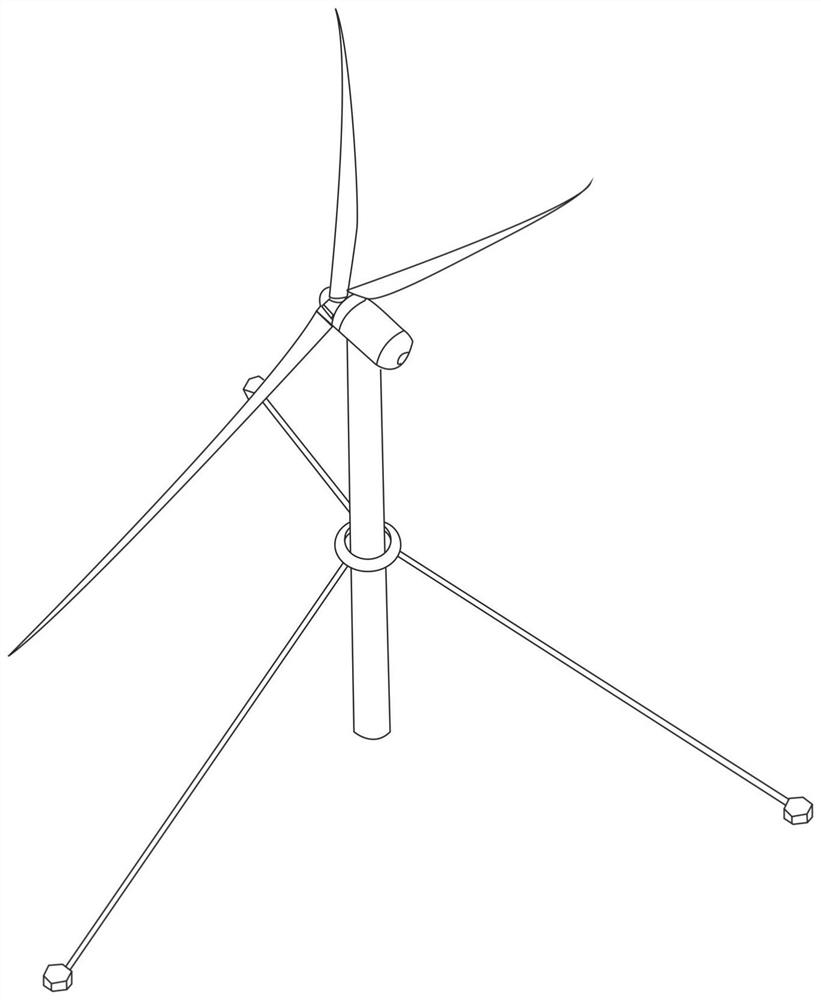

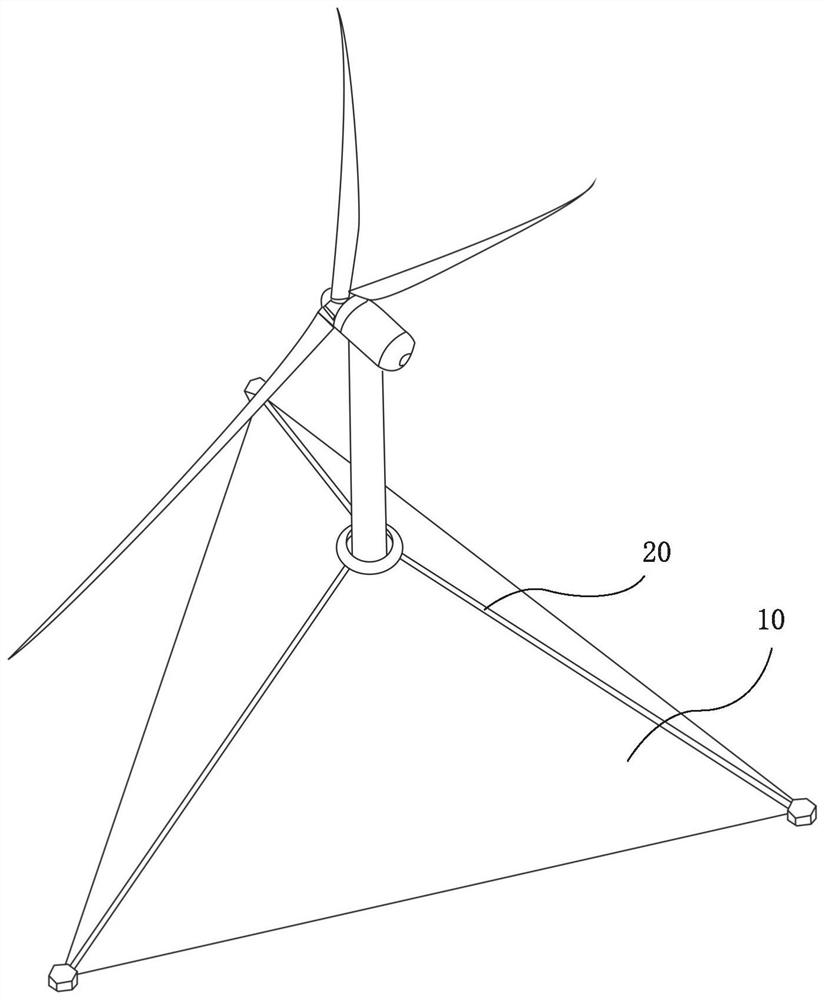

Flow guiding device of wind generating set and control method thereof as well as wind generating set

ActiveCN111089029AChange flow fieldIncrease wind speedWind motor supports/mountsMachines/enginesImpellerEngineering

The invention provides a flow guiding device of a wind generating set and a control method thereof as well as the wind generating set. The flow guiding device comprises a wind guiding screen and staycables, the first ends of the stay cables are fixed to a tower of the wind generating set, the second ends of the stay cables are fixed to the ground, and the wind guiding screen is arranged between every two adjacent stay cables to form a flow guide surface inclined relative to the vertical direction. According to the flow guiding device of the wind generating set and the control method thereof as well as the wind generating set, the flow field around the wind generating set can be changed, the actual wind speed flowing through an impeller is increased, and the generating capacity is increased.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

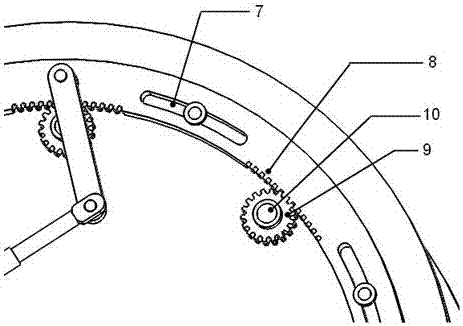

Centrifugal fan device with adjustable blades

ActiveCN106949090AImprove efficiencyLittle change in loadPump componentsPump controlImpellerAir volume

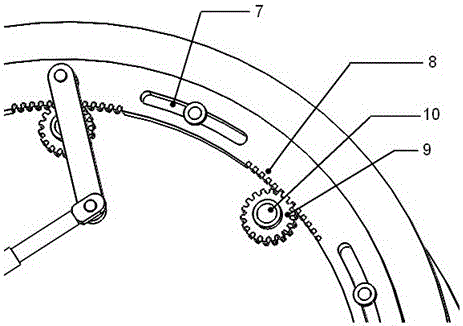

The invention discloses a centrifugal fan device with adjustable blades. The centrifugal fan device comprises an inner impeller and an outer impeller, a plurality of the inner blades are evenly distributed in the circumferential direction of an inner wheel disc, and a plurality of the outer blades are evenly distributed in the circumferential direction of an outer wheel disc; asymmetric wing shapes are adopted for both the surface of each inner blade and the surface of each outer blade, and each surface is provided with floating protrusions used for reducing near wall friction resistance. The centrifugal fan device further comprises a signal acquisition module and a blade row spacing adjustment mechanism. The blade row spacing adjustment mechanism comprises guiding slide ways and a traction device. Through matching of the inner blades and the outer blades, the outer blades can be adjusted to appropriate positions according to air volumes under different working conditions, the effect that a centrifugal fan serves several purposes is achieved, the purpose that the centrifugal fan can still work stably and efficiently under non-rated working conditions is realized, and the cost performance and efficiency of the centrifugal fan are greatly improved; the asymmetric wing-shaped blades enable flow lines to flow basically in the direction of the blades, and airflow loss is reduced.

Owner:ZHEJIANG SCI-TECH UNIV

Flow guide device and control method of wind power generating set, wind power generating set

ActiveCN111089029BChange flow fieldIncrease wind speedWind motor supports/mountsMachines/enginesImpellerAir velocity

The present invention provides a flow guiding device of a wind power generator set and its control method, and a wind power generating set. The flow guiding device includes a wind guiding screen and a stay cable. The first end of the stay cable is fixed to the tower of the wind power generator set. The second end of the stay cable is fixed to the ground, and the wind guide screen is arranged between two adjacent stay cables to form a guide surface inclined relative to the vertical direction. According to the flow guide device and control method of the wind power generator set and the wind power generator set of the present invention, the flow field around the wind power generator set can be changed, the wind speed actually flowing through the impeller can be increased, and the power generation can be increased.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Experimental device for researching migration law of pollutants under interaction of rivers and underground water

PendingCN112577854AReasonable designEasy to operateSurface/boundary effectPrecipitationshedPollutant

The invention discloses an experimental device for researching the migration law of pollutants under the interaction of a river and underground water, and relates to the technical field of research onthe migration law of pollutants. The experimental device comprises a simulation water tank used for simulating filling of an aquifer and an aeration zone; a movable water tank used for controlling aleft water head of the simulation water tank; a fixed water tank used for controlling a right water head of the simulation water tank; and a simulated riverbed arranged in the upper groove of the simulated water tank. The experimental device has the beneficial effects that the quartz sand with proper particle size after acid washing and alkali washing is used for simulating the water-containing layer, and the water head difference between the fixed water tank and the movable water tank on the two sides is adjusted by simulating the arrangement of a riverbed so as to simulate the precipitation,so that the underground water flow field is changed; different supply relations between underground water and surface water are changed by changing the water level of the simulation water tank through the water pump, so that an underground water flow field is influenced. The experimental device is reasonable in design and simple to operate, and has the characteristics of high repeatability and operability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas water heater integrated stainless steel heat exchanger

ActiveCN103994579BReduce flow fieldChange flow fieldFluid heatersCorrosion preventionWater flowEngineering

The invention provides a gas water heater integrated stainless steel heat exchanger which comprises a surrounding frame and multiple heat exchange tubes penetrating the surrounding frame. Water collecting boxes are arranged at the ends of the heat exchange tubes penetrating through the surrounding frame and enable the heat exchange tubes to be connected to form a continuous flowing channel. Elongated parts are arranged in at least one row of heat exchange tubes close to a high-temperature heating region. The water collecting boxes packages the elongated parts in the heat exchange tubes. The surrounding frame, the heat exchange tubes, the water collecting boxes and the elongated parts are assembled and welded to form an integral structure. The integrally-welded stainless steel heat exchanger is simple in structure and processing and small in size, the sealing performance and the corrosion resistance performance are greatly improved, a water flow field in a gas quick water heater tube is changed through the elongated parts, the situation of original uneven water temperature distribution is changed, accordingly scales are decreased, and the service life of the heat exchangers is prolonged.

Owner:A O SMITH (CHINA) WATER HEATER CO LTD

Coke-oven riser tube and method for recovering heat of coke-oven raw gas with application of coke-oven riser tube

InactiveCN105001883AGuaranteed uptimeChange flow fieldDistillation gas withdrawalEngineeringHeat transfer efficiency

The embodiment of the invention discloses a coke-oven riser tube and a method for recovering heat of coke-oven raw gas with the application of the coke-oven riser tube. The sidewall of the coke-oven riser tube is equipped with at least one external fluid inlet which penetrates through the inner wall and outer wall of the riser tube. Thus, an external fluid is sprayed into the coke-oven riser tube through the external fluid inlet to change the flow field of coke-oven raw gas inside the coke-oven riser tube. according to the above technical scheme, by arranging at least one external fluid inlet on the sidewall of the coke-oven riser tube so as to spray the external fluid into the coke-oven riser tube through the external fluid inlet, the flow field of the coke-oven raw gas is changed, Reynolds number of flowing of the coke-oven raw gas is increased, and heat transfer efficiency of the coke-oven raw gas in the riser tube is enhanced. Further, recovery utilization rate of heat of the coke-oven raw gas is raised, and operation efficiency of a coke oven is enhanced.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

Annular inlet blade of SDA desulfurization column

InactiveCN110124502AChanging the smoke flow fieldImprove foulingGas treatmentDispersed particle separationEngineeringFlue gas

The invention discloses an annular inlet blade of an SDA desulfurization column. The SDA desulfurizing column comprises a desulfurizing column main body. A gas inlet pipe is arranged at the top end ofthe desulfurizing column body. A plurality of air inlet blades are installed in the air inlet pipe, the bottoms of the air inlet blades are in a conical funnel shape, and the total number of the airinlet blades is 120. Each blade has a folding structure with an included angle of 135 degrees; an atomizing wheel is mounted at the bottoms of the air inlet blades; a flue gas distributor is mounted at the bottom of the atomizing wheel; a conical column is arranged at the bottom end of the desulfurizing column main body. The annular gas inlet blades change the speed and pressure of the original flue gas entering the desulfurizing column, so that the flue gas flow field is changed, and the problem of scaling of a product is improved. By arranging the baffle and the flue structure, the flue gasdistribution ratio of the upper flue and the lower flue is adjusted, and the desulfurization reaction is more sufficient.

Owner:WUHAN UNIV OF SCI & TECH

Fluidized bed reactor for the preparation of chlorosulfonated polyethylene by gas-solid method

InactiveCN102698663BIncrease solids concentrationPrevent subsidenceChemical/physical processesStraight tubeFluidized bed

The invention relates to a fluidized bed reactor for preparing chlorosulfonated polyethylene by a gas-solid method. The fluidized bed reactor comprises a main body of the fluidized bed reactor, wherein the main body of the fluidized bed reactor comprises a straight tube section and a reactor expansion section; the top end of the straight tube section is connected with the bottom end of the reactor expansion section; the inner diameter of the reactor expansion section is larger than that of the straight tube section; a gas premixing chamber is formed at the bottom of the main body of the fluidized bed reactor; a predistribution device is arranged at the bottom of the inner wall of the gas premixing chamber; a plurality of layers of gas distribution plates are arranged between the gas premixing chamber and the main body of the fluidized bed reactor; an ultraviolet lamp glass tube stack formed by annularly arranging a plurality of glass tubes is arranged in the center of the straight tube section, or a plurality of holes are equidistantly and radially formed in the inner wall of the straight tube section along the circumference; and the glass tubes are arranged in the holes. The fluidized bed reactor has the advantages of effectively preventing particles close to the wall surface from being adhered on the wall surface or settled; eliminating dead zones of the whole fluidized bed layer; making reactions more uniform because reaction materials in the bed layer are sufficiently irradiated by ultraviolet.

Owner:刘文潮 +1

Side blowing type fan

ActiveCN101435427BIncrease air intakeChange flow fieldPump componentsRadial flow pumpsImpellerEngineering

The invention discloses a side-blow fan, which comprises a shell and an impeller, wherein the shell is provided with a master air inlet and at least one auxiliary air inlet. The impeller is arranged in the shell and comprises a hub part, a plurality of blades and at least one ring plate. The blades are arranged around the hub part. The ring plate is connected with the blades, and shields partial auxiliary air inlet. Because of the additional auxiliary air inlet, the side-blow fan can increase air input. In addition, the side-blow fan is also provided with the ring plate, and uses the ring plate to shield partial auxiliary air inlet so as to change the flow field at the auxiliary air inlet, thereby achieving an effect of great reducing operation noises.

Owner:DELTA ELECTRONICS INC

ship

ActiveCN104890805BChange flow fieldChange pressureHydrodynamic/hydrostatic featuresEffective powerMarine engineering

A ship, comprising: a hull and a bulbous bow located below the bow of the hull, the distance between the highest point of the upper part of the bulbous bow and the baseline is between 11.95m and 12.45m, and at the 20th station of the hull, the bulbous bow The distance from the bottom of the bow to the baseline is between 750mm and 1250mm; at the 6m waterline height of the 20th station of the hull, the distance from the outer edge of the bulbous bow to the center line is between 3100mm and 3600mm; at the 20.5th station of the hull, the bulbous bow The distance from the bottom of the nose bow to the baseline is between 4550mm and 5050mm, and at the 10m waterline height of the 20.5th station of the hull, the distance from the outer edge of the bulbous bow to the center line is between 1350mm and 1850mm. The ship changes the flow field and pressure distribution around the hull by changing the bulbous bow, so that the ship can have lower effective power at various speeds, thereby achieving the purpose of saving fuel.

Owner:中集鑫德租赁(深圳)有限公司

A Boundary Condition Simulation Device for Acoustic Closed-End Inlet of Liquid Flow System

ActiveCN108225726BIncrease flow rateMeet high impedance requirementsHydrodynamic testingEngineeringPoint of entry

The invention discloses a simulating device for acoustic closed end inlet boundary conditions of a fluid flow system and relates to the field of simulating devices for acoustic closed end inlet boundary conditions. The simulating device comprises a recession cone, a throttle pipe, a diverging cone and a porous diffuser grid, wherein the throttle pipe is of a hollow cylindrical structure; the recession cone and the diverging cone are both in hollow conical structures; the recession cone is fixedly arranged at one axial end of the throttle pipe along the axial direction; in addition, the axialminor-diameter end of the recession cone is fixedly connected with the throttle pipe; the diverging cone is fixedly arranged at the other axial end of the throttle pipe along the axial direction; theaxial minor-diameter end of the diverging cone is fixedly connected with the throttle pipe; the porous diffuser grid is horizontally and fixedly arranged on the major-diameter end face of the diverging cone; besides, the porous diverging cone covers a through hole opening of the diverging cone; the major-diameter end of the recession cone is an inlet section; and the major-diameter end of the diverging cone is an outlet end. According to the simulating device disclosed by the invention, the problems that a traditional structure for simulating the acoustic closed end has over-great flow resistance and is seriously corroded are solved.

Owner:XIAN AEROSPACE PROPULSION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com