Gas pre-distributor of fixed-bed reactor for preparing maleic anhydride through n-butane oxidation

A technology of fixed bed reactor and gas predistributor, which is applied in the fields of chemical instruments and methods, organic chemistry, chemical/physical process, etc. It can solve the problem of uneven gas distribution of reactants, uneven use of catalysts, and n-butane conversion Low efficiency and other problems, to achieve the effect of improving catalyst utilization, improving the influence of local impact unevenness, and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

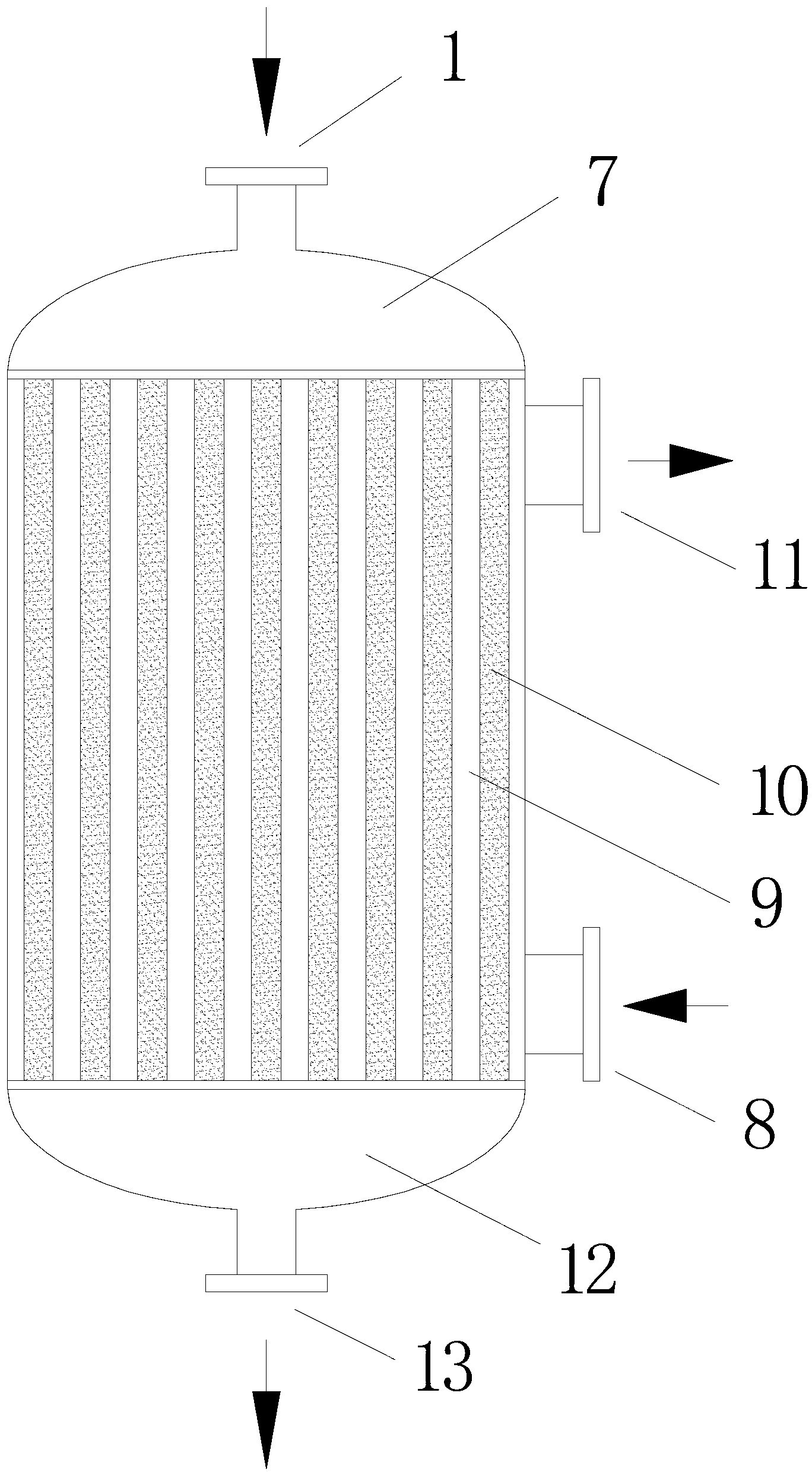

[0034] As shown in Figure 3(a), the gas predistributor for the fixed bed reactor of the present invention includes horizontal guide vanes 2, guide pipes 3 and cones arranged independently in sequence along the central axis of the gas inlet pipe 1 of the fixed bed reactor. Shaped cap 4, horizontal deflector 2, guide pipe 3 and conical cap 4 are all located in the area between the gas inlet of the fixed bed reactor and the gas distribution plate 5, and the horizontal guide vane 2 is close to the gas of the fixed bed reactor. Inlet; one end of the draft tube 3 is opposite to the mouth of the conical cap 4, and the other end is close to the horizontal deflector 2; the conical tip of the conical cap 4 is far away from the gas inlet of the fixed bed reactor.

[0035] For a reactor with an inner diameter of 3000mm, the optimized structure of the gas predistributor is selected: the horizontal deflector 2 is circular, the ratio of the outer diameter to the inner diameter is 1.05~1.7:1, ...

Embodiment 2

[0037] In a tubular gas-solid fixed-bed reactor with a diameter of 3039mm, air is used as the gas between the tubes, and the inlet gas velocity is 17.7m / s, and the Fluent fluid dynamics simulation calculation software is used for simulation. The form of the gas pre-distributor is shown in Figure 3 (a): wherein, the inner diameter of the annular horizontal deflector 2 is 700 mm, and the distance from the gas inlet is 150 mm; the diameter of the end port of the guide tube 3 close to the gas inlet pipe 1 is 400mm, the included angle between the pipe wall of the draft tube 3 and the central axis of the gas inlet pipe 1 is 45°, and the height of the draft tube 3 is 282.84mm; A conical cap 4 is arranged at 200 mm from the port at one end, and the conical angle of the conical cap 4 is 90°.

[0038] Figure 4(a) is the gas velocity cloud diagram in the gas predistributor under the operation of producing a certain chemical product, and Figure 4(b) is the low gas velocity cloud diagram i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com