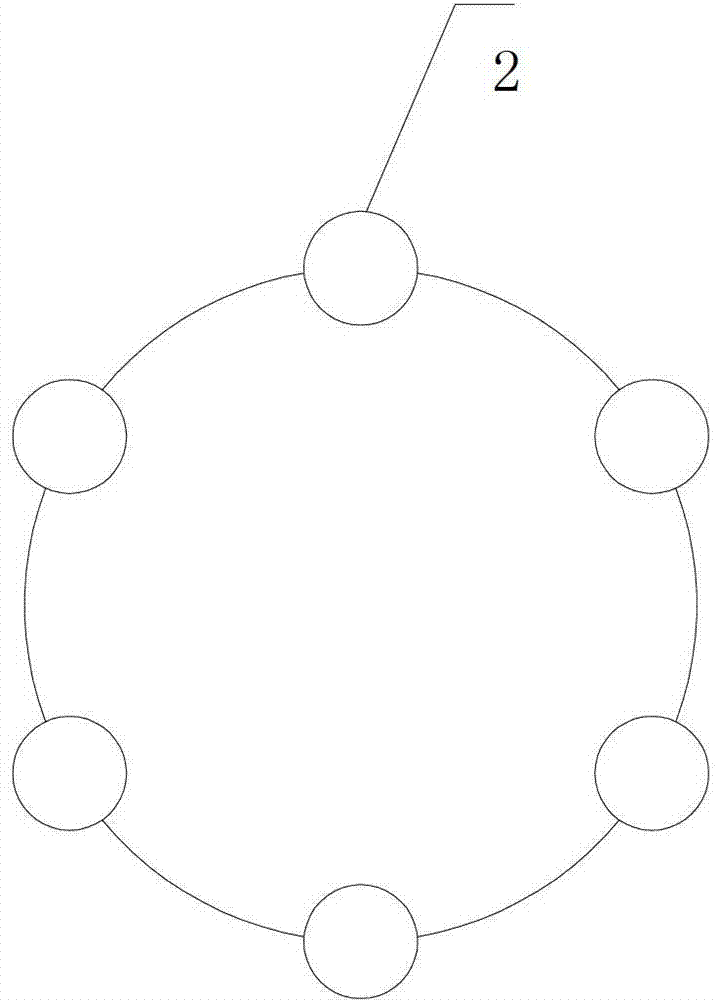

Fluidized bed reactor for the preparation of chlorosulfonated polyethylene by gas-solid method

A fluidized bed reactor, chlorosulfonated polyethylene technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult light irradiation in areas, prevent sedimentation, eliminate dead zones, and strengthen mass transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Select 100 kg of chlorinated polyethylene with a water content of less than 0.4% (mass), and feed it into the main body 1 of the fluidized bed reactor with a cylinder diameter of 500 mm through the feeding port of the fluidized bed reactor. Start the fan and use the purified air as the circulating gas. Adjust the gas flow rate, and test the particle concentration of different bed heights by the particle concentration measuring instrument; the experiment runs continuously for 2 hours; the bed height of the fluidized bed is about 1.7 meters, and the fluidization state of the particle bed is good; the particle concentration measuring instrument shows that at 0.2 For a bed height of -1 meter, the radial particle concentration distribution is 0.25-0.35, and it is in a gentle distribution state.

[0028] In the fluidized state, the material is discharged from the discharge port, weighed, and all the materials are released. No adhering material was found on the wall of the re...

example 2

[0030] Select 100 kg of chlorinated polyethylene with a water content of less than 0.4%, and feed it into the main body 1 of the fluidized bed reactor with a cylinder diameter of 500 mm through the feeding port of the fluidized bed reactor. Start the fan and use the purified air as the circulating gas. And turn on the preheater to preheat the gas to 40-45°C. Adjust the gas flow rate, and test the particle concentration of different bed heights through the particle concentration measuring instrument; the experiment runs continuously for 2 hours. The bed height of the fluidized bed is about 1.7 meters, and the fluidization state of the particle bed is good; At a bed height of 1 meter, the radial particle concentration distribution is 0.25-0.35, and it is in a gentle distribution state.

[0031] In the fluidized state, the material is discharged from the discharge port, weighed, and all the materials are released. No adhering material was found on the wall of the reactor; the o...

example 3

[0033]Select 100 kg of chlorinated polyethylene with a water content of less than 0.4%, and feed it into the main body 1 of the fluidized bed reactor with a cylinder diameter of 500 mm through the feeding port of the fluidized bed reactor. Start the blower and feed in a premixed mixture of chlorine, sulfur dioxide and nitrogen in a certain proportion. And turn on the ultraviolet lamp, the chlorinated polyethylene material and the mixed reaction gas are reacted in a fluidized state; the reaction time is about 1 hour. The bed height of the fluidized bed is about 1.5~1.7 meters, and the fluidized state of the particle bed is good; the temperature in the reactor gradually rises from room temperature to 47°C; after the reaction, exhaust and introduce air purification treatment.

[0034] In the fluidized state, discharge and weigh from the discharge port, and almost all the reaction products are discharged. No black impurities were found in the material. No adhering material was f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com