Short-process new technology for efficiently sorting micro-fine particle tin ores by applying centrifugal machine

A technology using centrifuges and fine particles, which is applied in the field of fine-grained non-ferrous metal ore and rare metal ore beneficiation, and can solve the problems of unobvious economic benefits, small processing capacity, and serious interference effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A low-grade complex polymetallic tin ore, the tin grade is 0.25%, and the embedded particle size is 0.010-0.030mm, accounting for 85.32%. The processing capacity of the traditional shaking table is too small and the floor area is large, so the fine-grained tin ore cannot be effectively recovered, and economic benefits cannot be obtained; the use of the full flotation process requires a large amount of chemicals, high production costs, and environmental pollution problems. Difficult to apply.

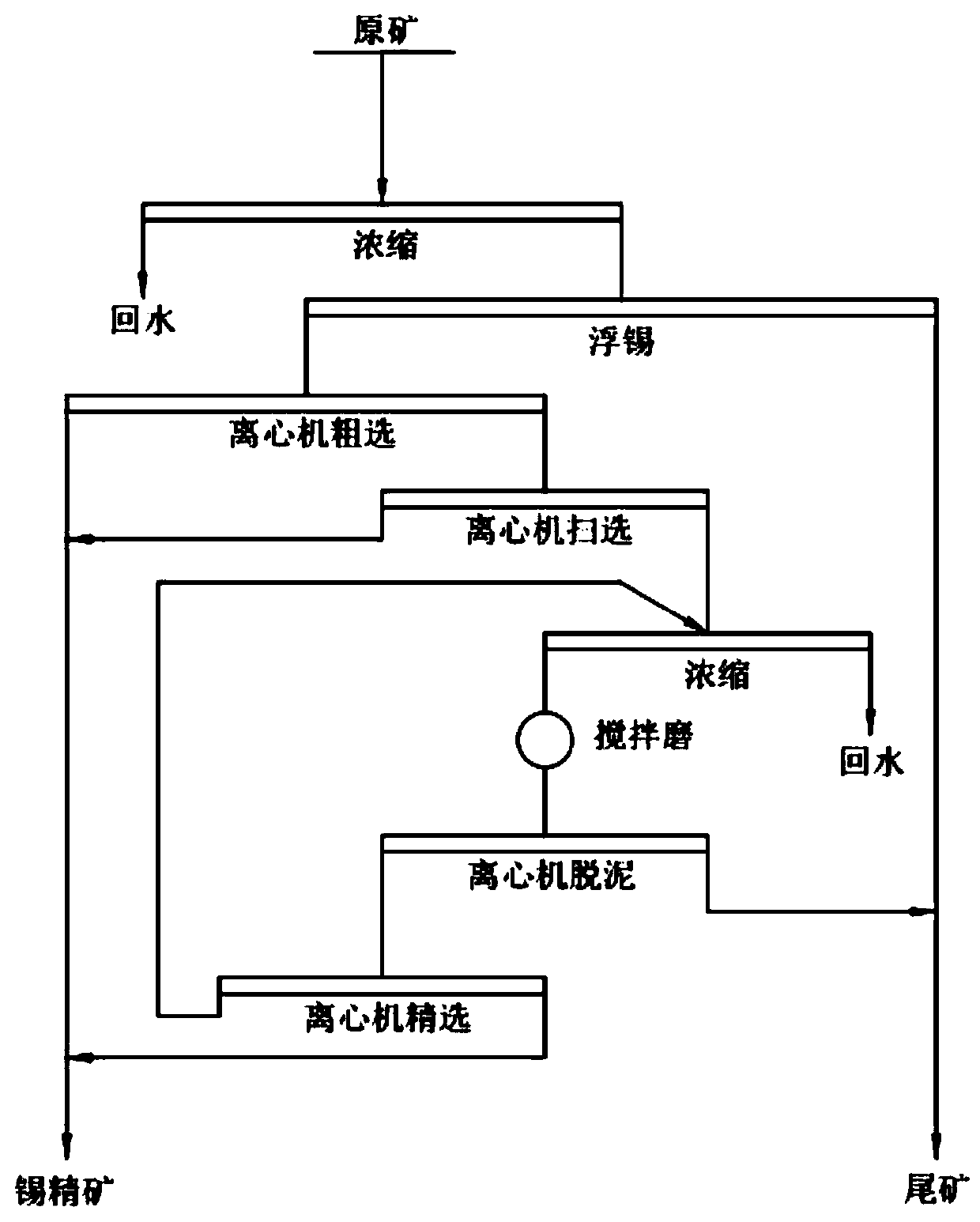

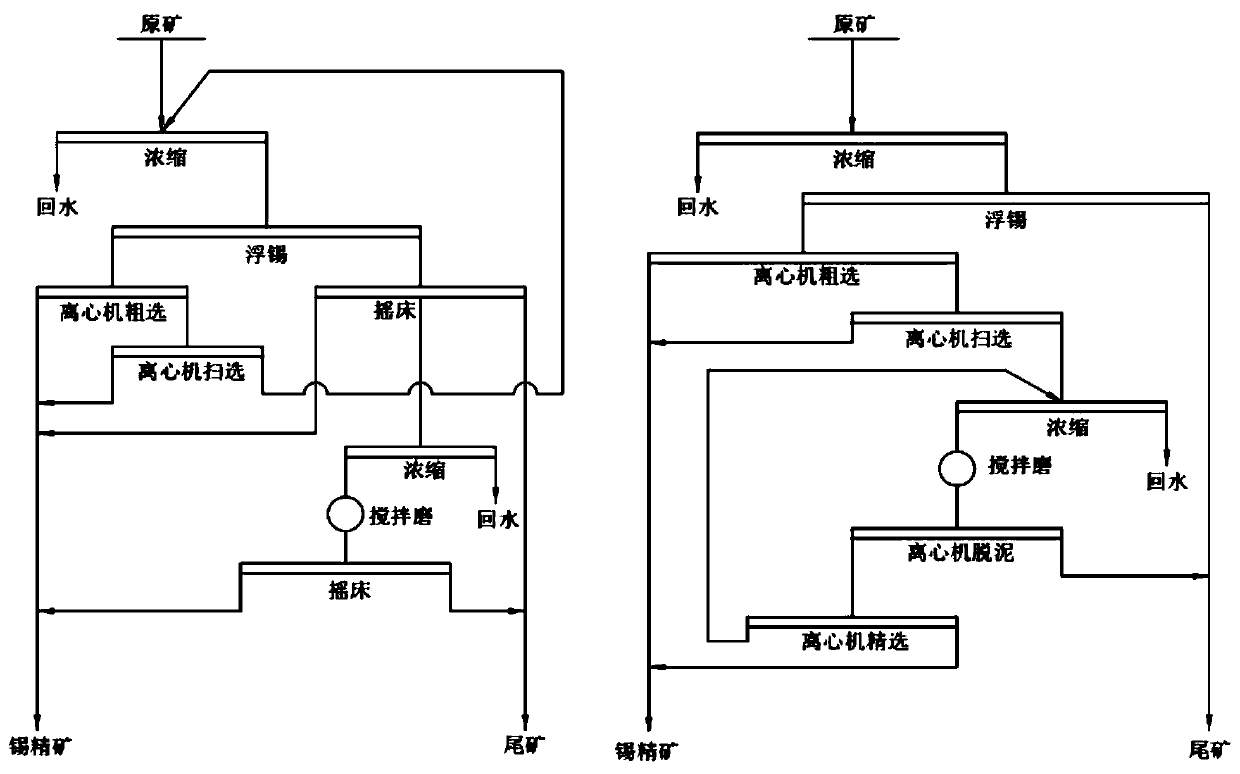

[0016] use as figure 2 The comparative results of the traditional process and the patent of the present invention are shown in Table 1 below. Both processes adopt flotation roughing, the main technical conditions: floating copper tailings particle size -0.074mm accounted for 91.75%, stirring mill classification product particle size -0.038mm accounted for 94.35%. Centrifuge roughing centrifugal strength 86.5g, ore concentration 20%, centrifuge sweeping centrifugal strength 130g...

Embodiment 2

[0022] A low-grade floating copper tailings, with a tin grade of 0.38%, are distributed in the gangue basement and are wrapped, so it is difficult to dissociate from the gangue minerals. The traditional shaking table has too little treatment capacity and poor economic benefits; flotation is not suitable; the full flotation process requires a large amount of reagents, high production costs, and environmental pollution problems, making it difficult to apply.

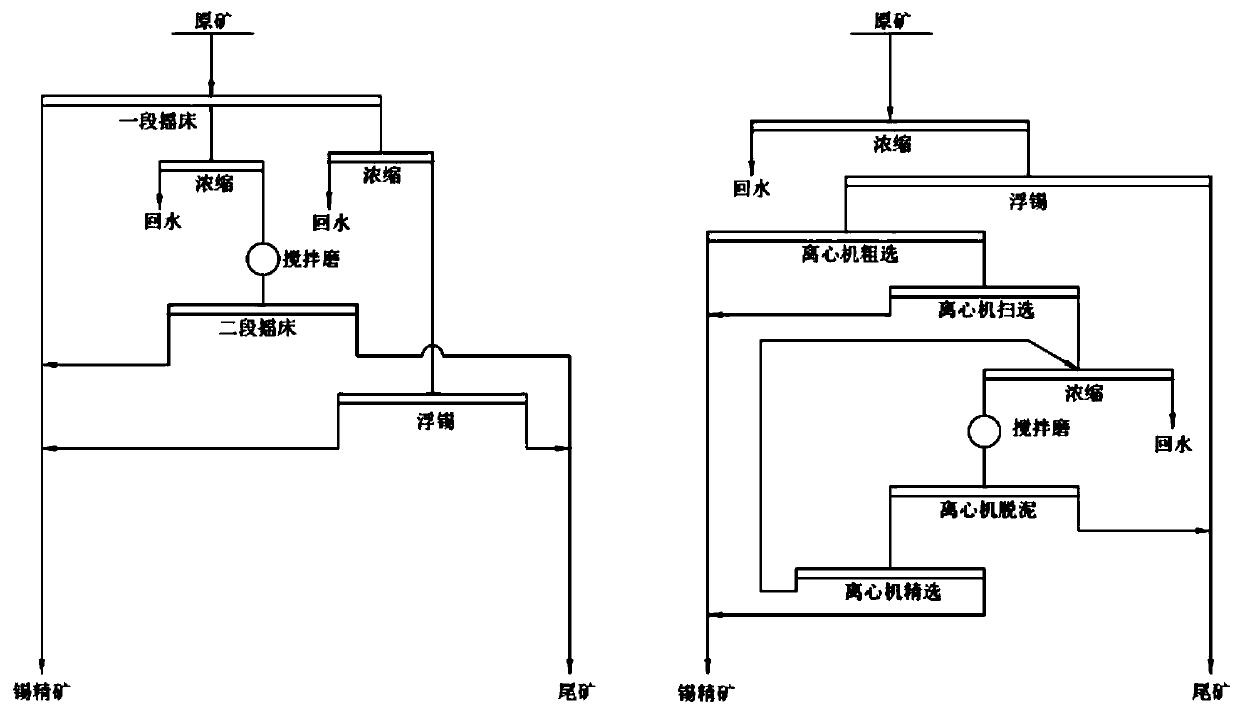

[0023] use image 3 The comparative results of the traditional process and the patent of the present invention are shown in Table 2 below. The main technical conditions of the traditional process flow: the first-stage shaker is a fine sand shaker, the ore concentration is 20%, and the stroke is 11mm; the second-stage shaker is a slime shaker, the ore concentration is 15%, and the stroke is 8mm. The main technical conditions of the patent of the present invention: floating copper tailings particle size -0.074mm accounts fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com