Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Uniform fluidization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

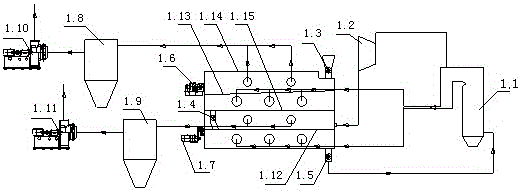

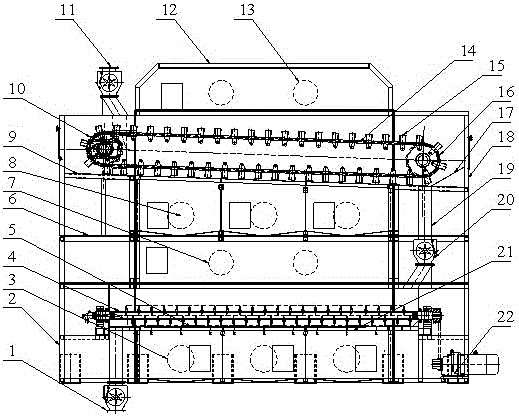

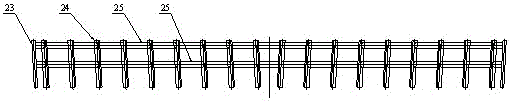

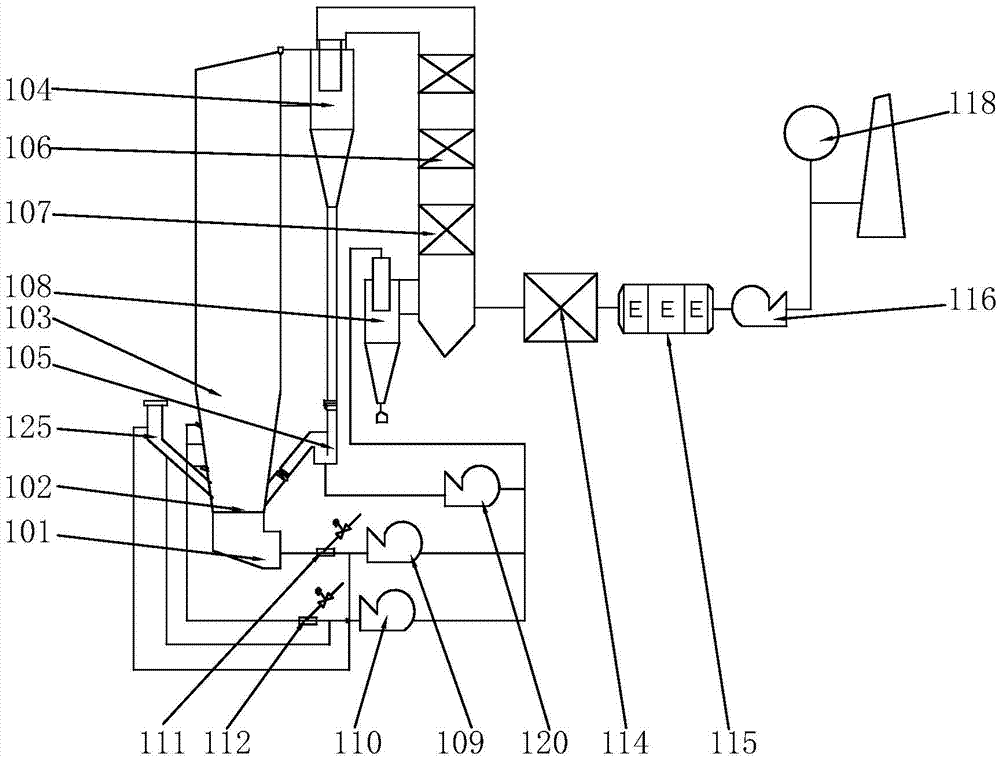

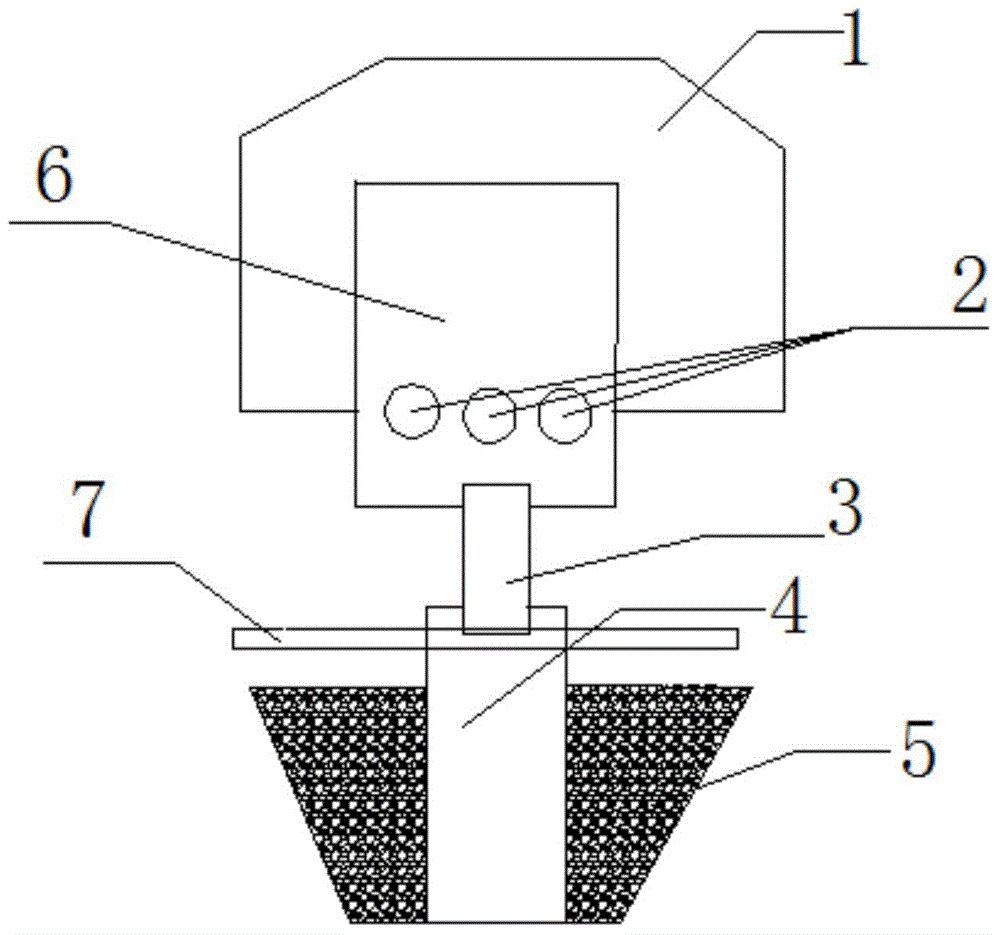

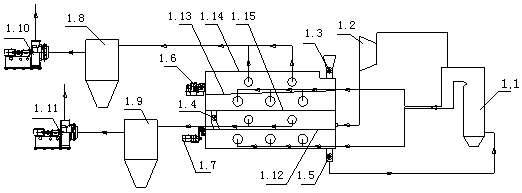

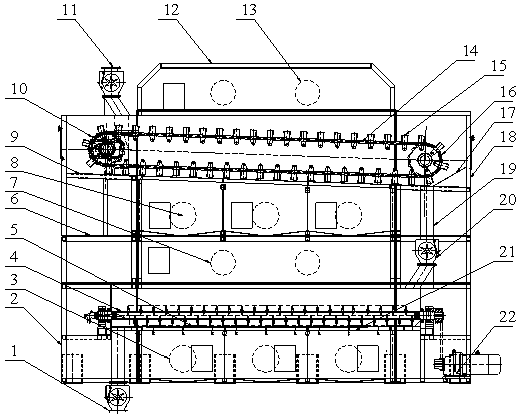

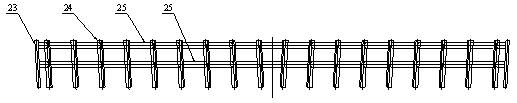

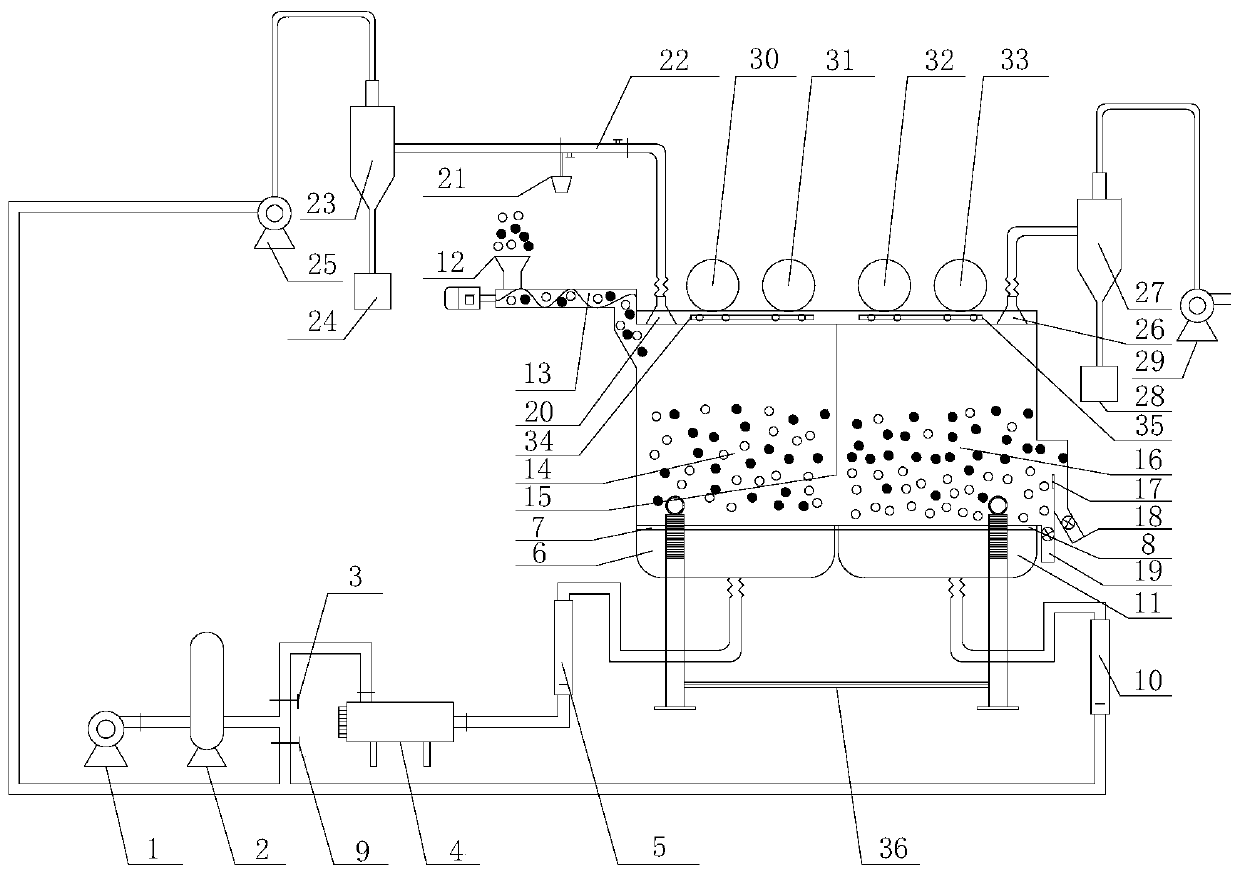

Brown coal drying method and device utilizing waste heat of smoke and steam of power plant

ActiveCN106382790AImprove economyImprove operational efficiencyDrying solid materials with heatDrying gas arrangementsBrown coalProcess engineering

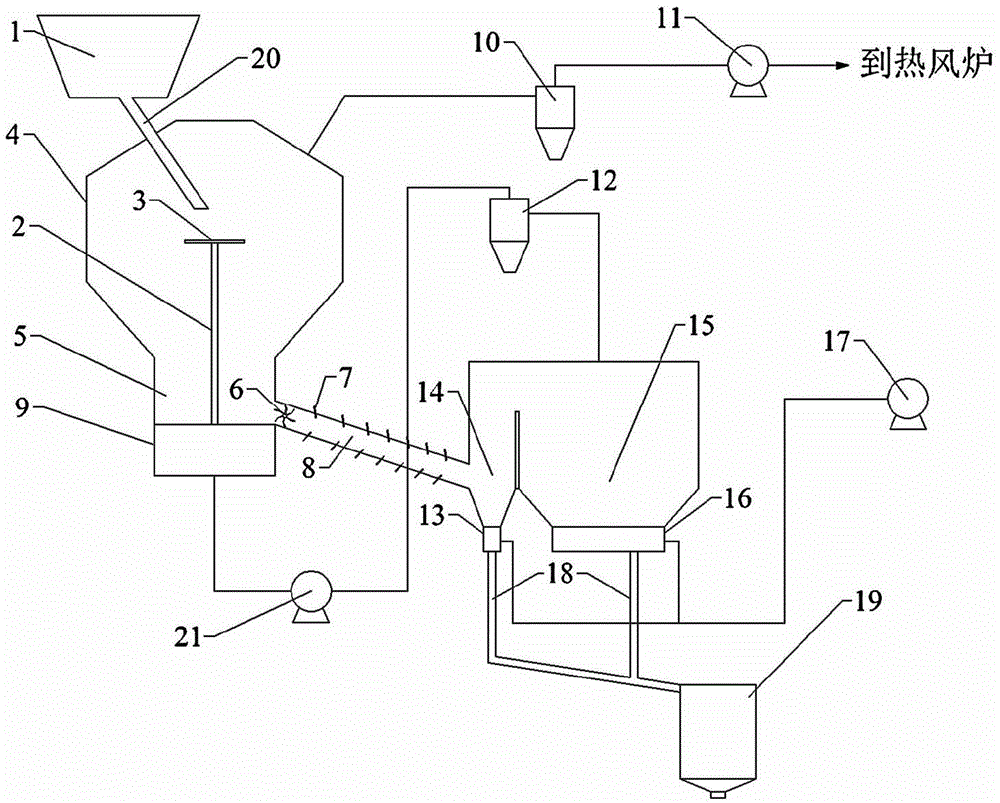

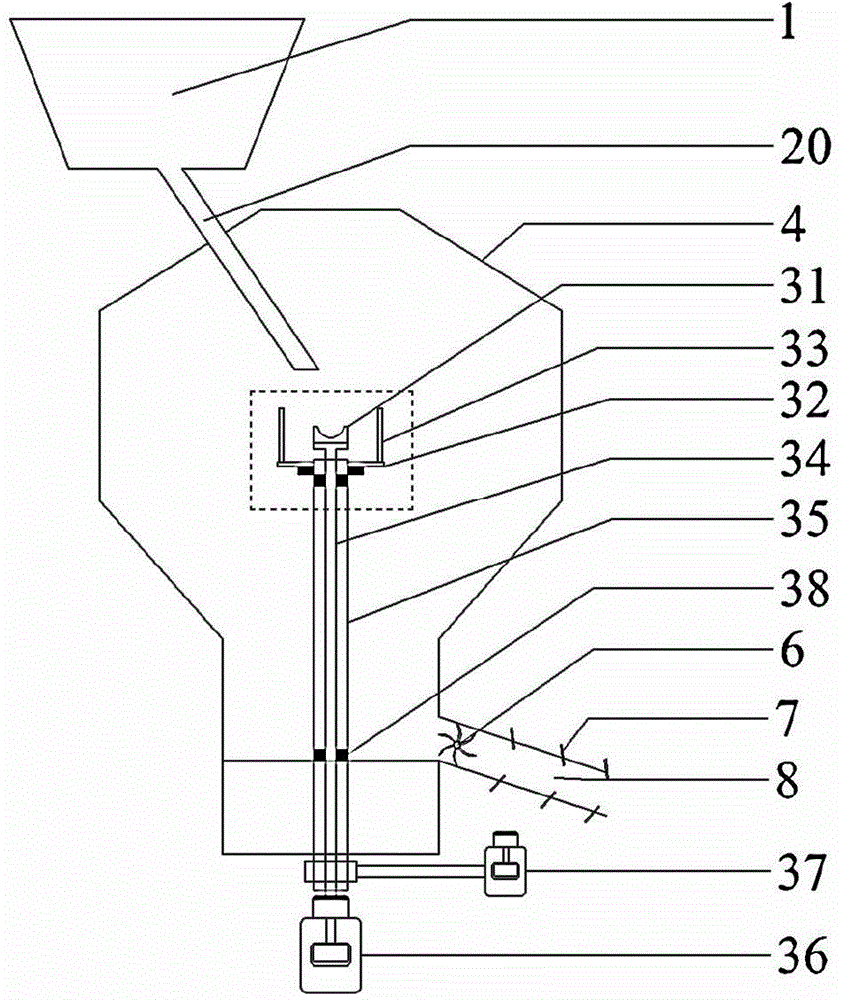

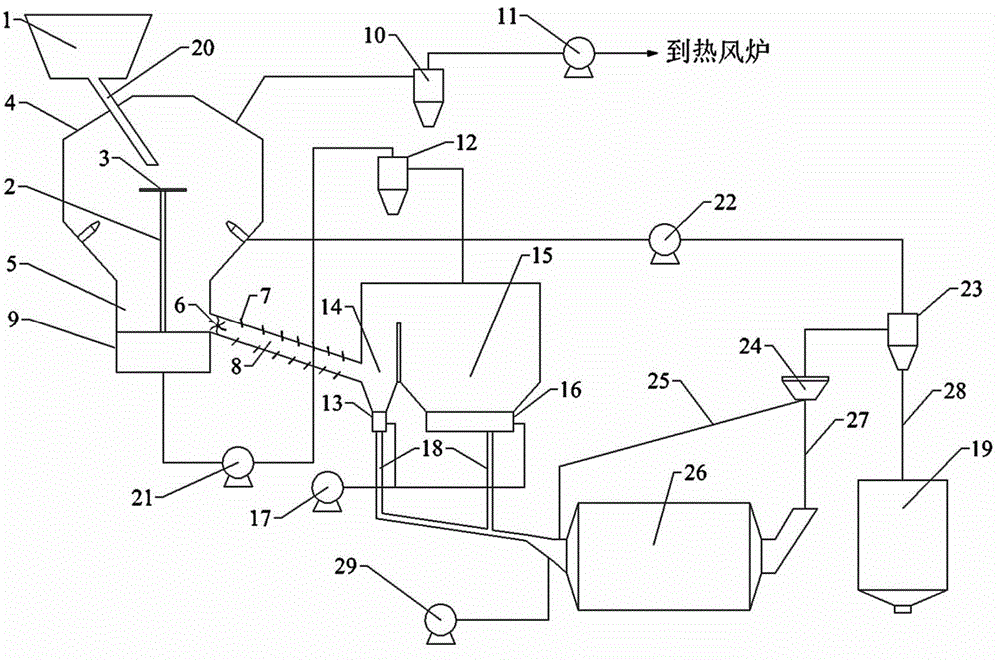

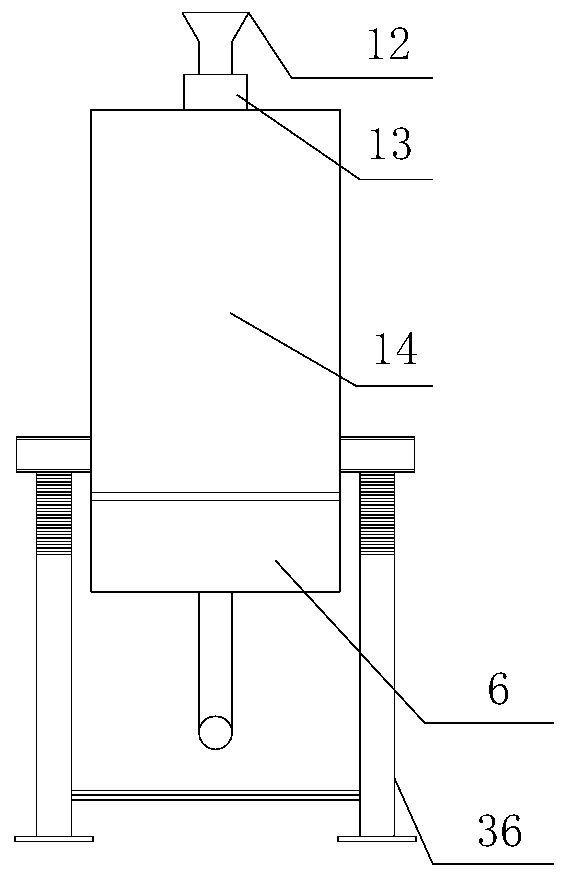

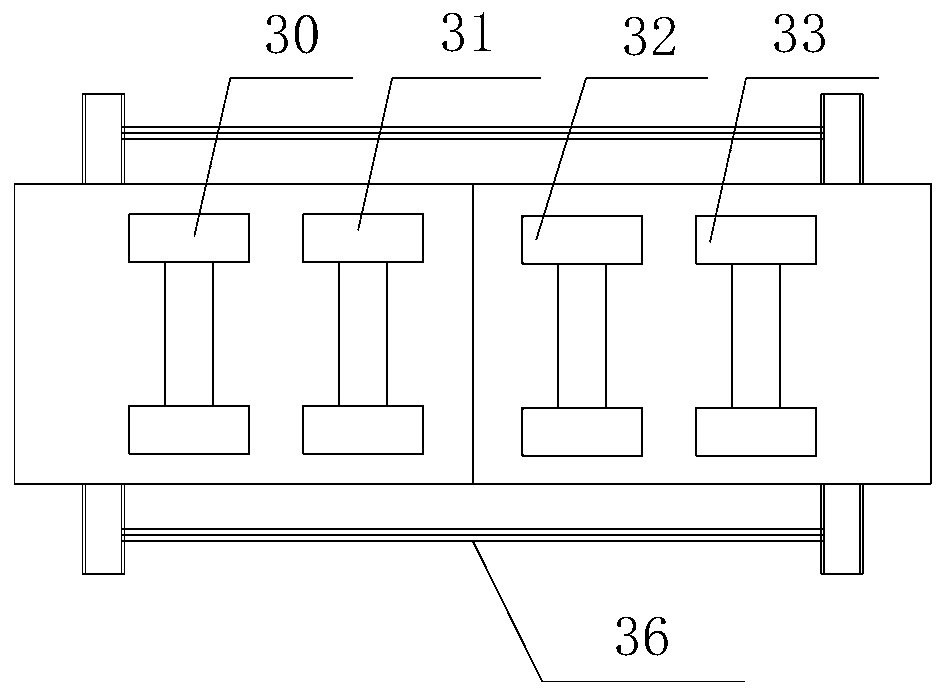

The invention discloses a brown coal drying method and device utilizing waste heat of smoke and steam of a power plant. The drying method comprises two-time drying treatment, wherein the two-time drying treatment comprises the steps that firstly, the high-temperature smoke directly discharged by a power plant coal fired boiler is utilized for conducting first-time drying treatment on damp materials, the high-temperature smoke directly makes uniform contact with the damp materials, and intermediate materials are obtained; and secondly, the high-temperature smoke and the high-temperature steam directly discharged by the power plant coal fired boiler are utilized for conducting second-time drying treatment on the intermediate materials at the same time, the high-temperature smoke directly makes uniform contact with the intermediate materials, meanwhile, the intermediate materials make uniform contact with a heat exchange pipe inflated with the steam for heat exchange, dried materials are obtained, and second-time drying treatment is achieved. The brown coal drying method and device have the beneficial effects that the power plant waste heat serves as a heat source for brown coal drying, the running economical efficiency of a power plant generator set is improved, a system for drying the brown coal and a brown coal power generation system are integrated, efficient utilization of power plant energy and optimization of a technology system are achieved, and the brown coal drying method and device belong to the poly-generation technology of the power plant.

Owner:邹平双飞成套设备有限公司

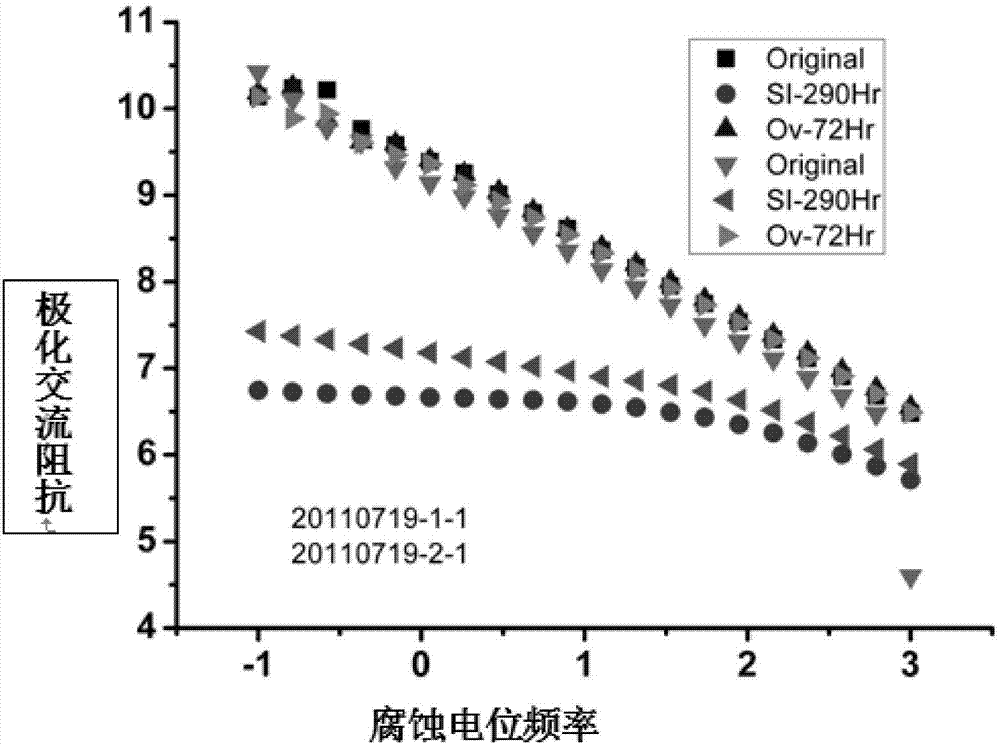

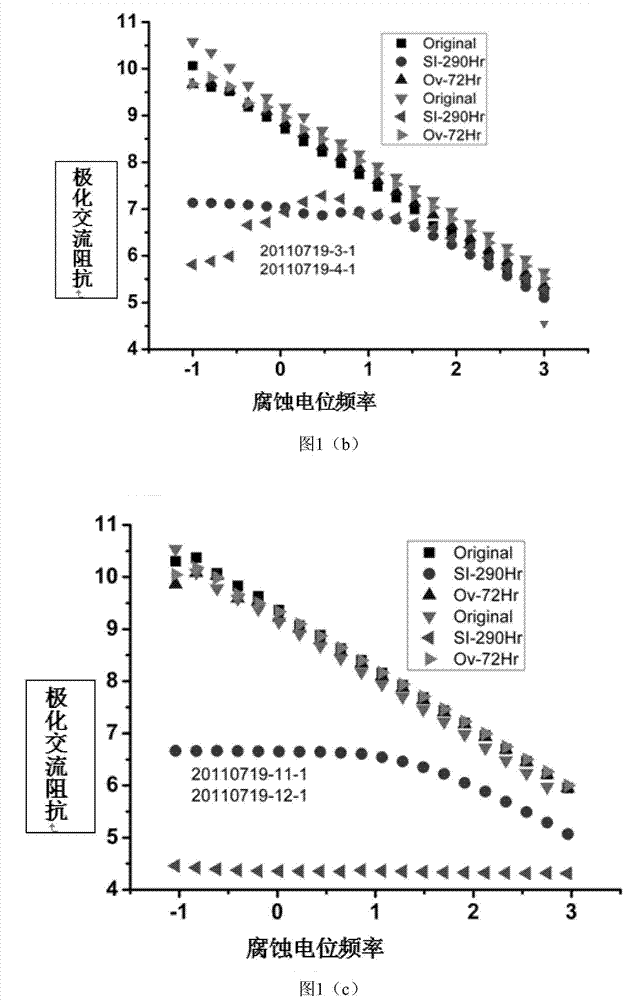

Special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating as well as preparation method and application of coating

ActiveCN104710908AHigh glass transition temperatureLight weightAnti-corrosive paintsPolyurea/polyurethane coatingsNano al2o3Conductive materials

The invention relates to a special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating. The special anticorrosion conductive powder coating is prepared from the following raw materials in parts by weight: 500-900 parts of film-forming resin and curing agent, 0-200 parts of glass flakes, 0-350 parts of filler, 15-50 parts of auxiliaries, 5-100 parts of conductive material and 1-5 parts of nanometer aluminum oxide or nano fumed silica. The powder coating has the characteristics of a high glass transition temperature, low specific gravity which is generally less than or equal to 1.1g / cm<3>, and easiness for fluidization; even though hundreds of tons of powder is added to a 20m deep well, the powder can be fluidized easily and uniformly; in case of too high specific gravity and difficult fluidization, the vertical shaft dip-coating method can not be utilized; the powder aims at a hot-dip coating construction process, and the film formed by the coating has surface conduction characteristics and high temperature water boiling resistance, and therefore, the coating is suitable for anti-corrosion coating of long linear workpieces such as mine mining anti-explosion gas pipelines, natural gas pipelines and liquefied gas pipelines; the coating is adaptive to the vertical shaft fluidized beds as deep as 20m, and still has good fluidity, which cannot be realized by common powders easily.

Owner:阜阳市诗雅涤新材料科技有限公司

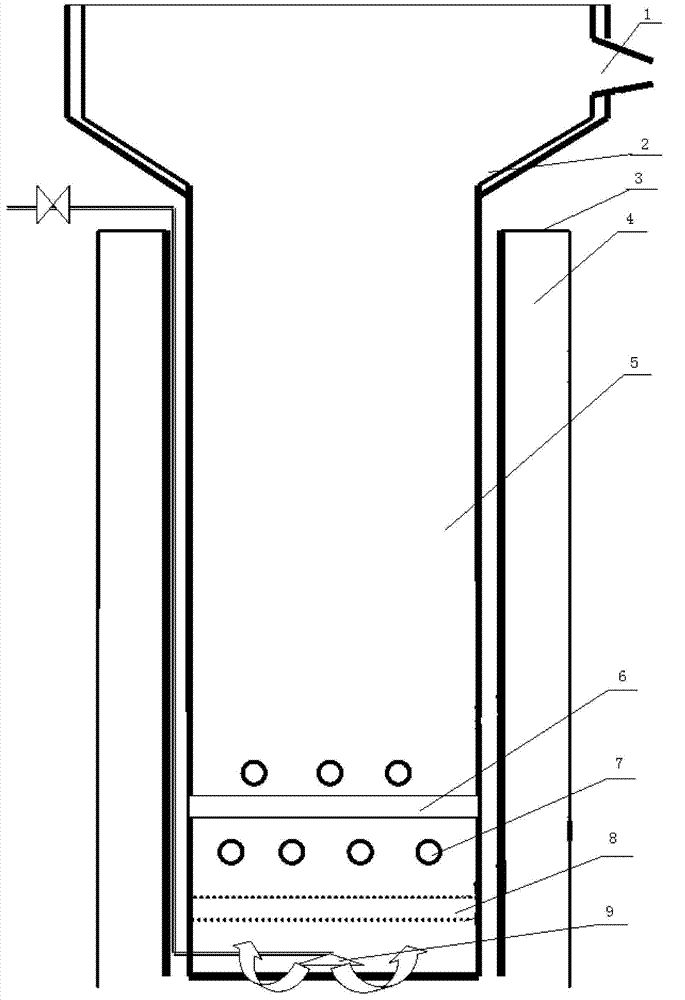

Recirculating fluidized bed oxygen-enriched combustion apparatus and operation method thereof

ActiveCN104848213AUniform fluidizationAvoid depositionFluidized bed combustionIndirect carbon-dioxide mitigationCycloneCombustion

The invention discloses a recirculating fluidized bed oxygen-enriched combustion apparatus, which comprises an air compartment, an air distribution device arranged above the air compartment and a hearth arranged above the air distribution device; the upper part of the hearth is connected with a high-temperature cyclone separator; the upper part of the high-temperature cyclone separator is connected with a heating surface; the lower part of the heating surface is connected with an economizer. The invention further discloses an operation method of the recirculating fluidized bed oxygen-enriched combustion apparatus. The recirculating fluidized bed oxygen-enriched combustion apparatus and the operation method thereof, disclosed by the invention, overcome the defects in the prior art, and intermediate temperature flue gas is used as primary air and secondary air which respectively enter the hearth to serve as recirculating air, in addition, oxygen is injected into the primary air and the secondary air, and the oxygen injection amount can be adjusted, meanwhile, an oxidizing agent is provided for combustion in the hearth, the concentration of CO2 discharged from a boiler of a recirculating fluidized bed can be enriched to more than 80%, and the capture of the CO2 in the flue gas after combustion of coal is facilitated.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

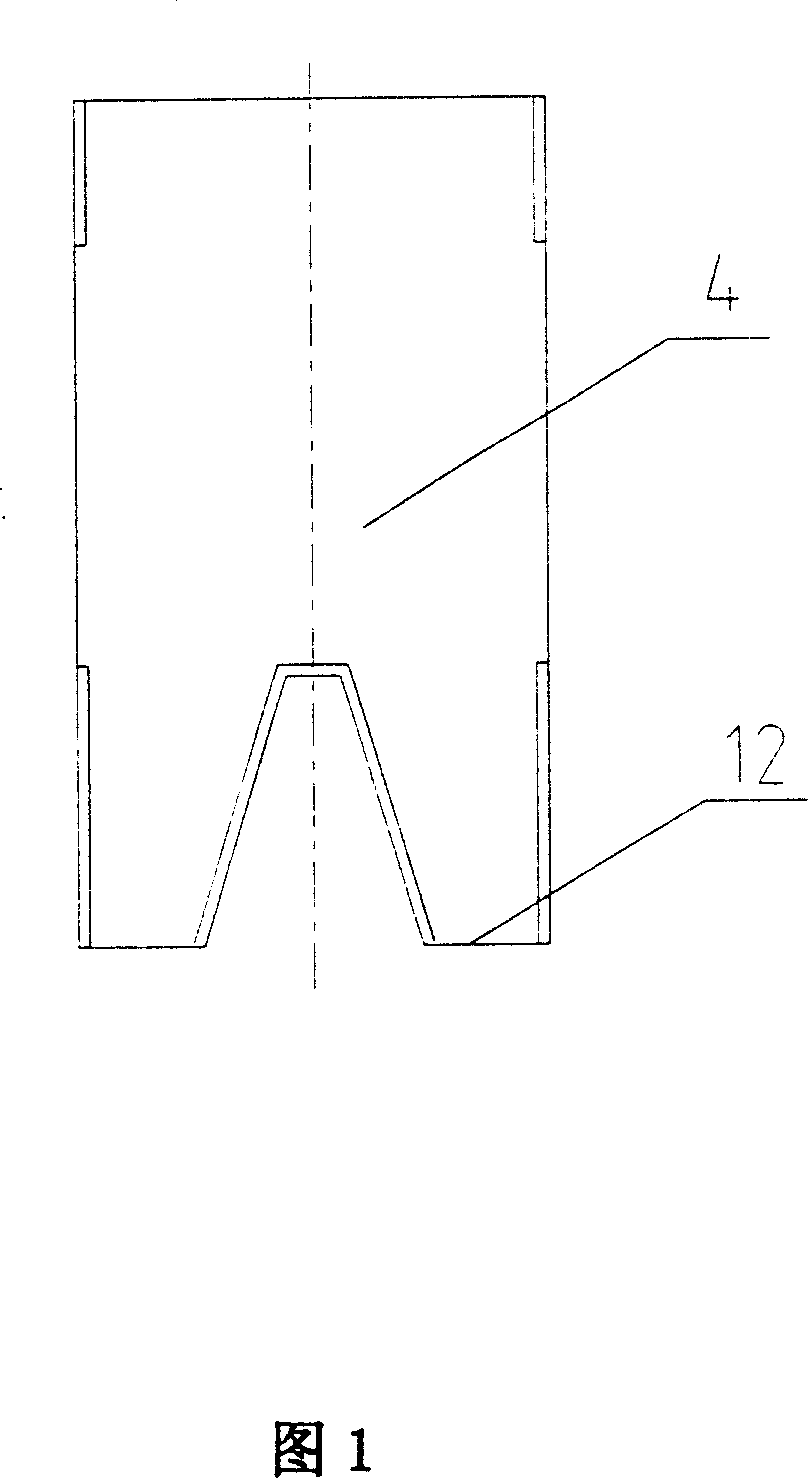

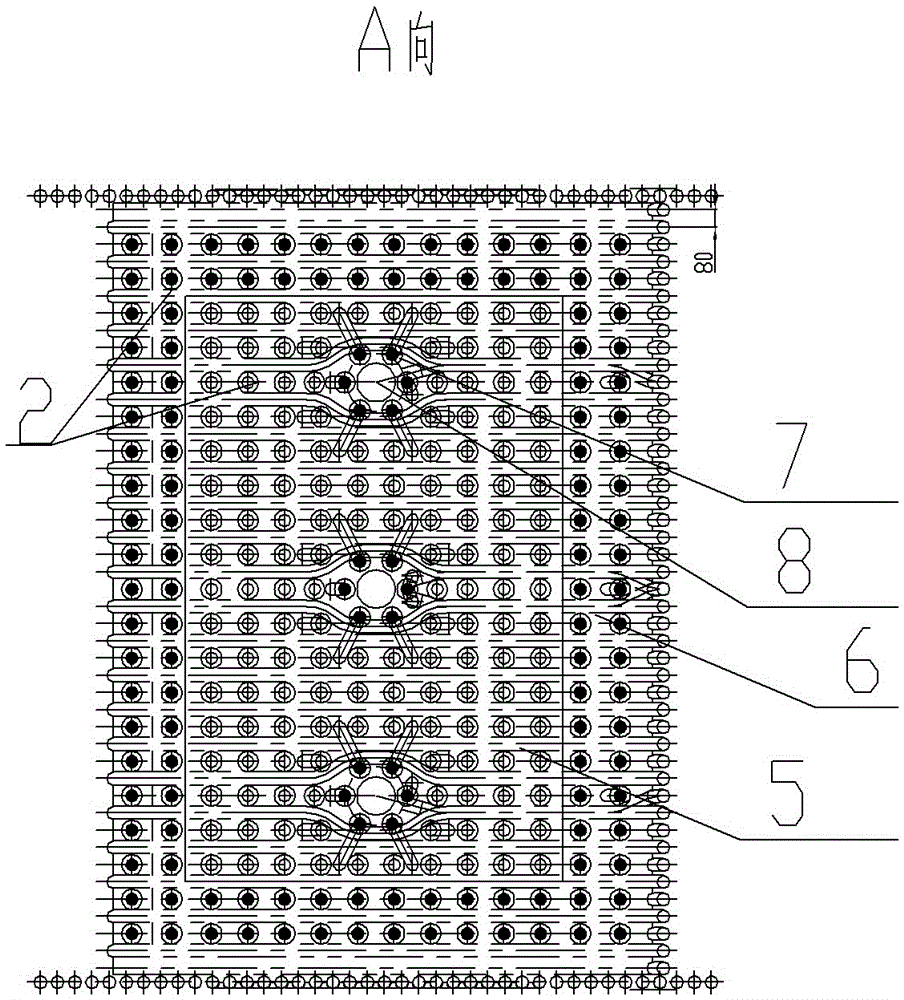

Arranging method of layered fluidization air distribution plate of fluidized bed boiler

ActiveCN1948831AImprove mixing conditionsRealize large-scaleFluidized bed combustionApparatus for fluidised bed combustionAir volumeCombustion

The invention adopts a multi-layer arrangement method of a fluidized-bed boiler bottom air-feeding plates and the integral hearth bottom consists of three independent air-feeding plates. One air-feeding plate is disposed in the lowerest part of the hearth and on the above air-feeding plate are overlaid the other air-feeding plates, so as to realize the step charging, the step air-supply and the fractional combustion of the recirculating fluidized-bed boiler. By regulating the blast volume and the fuel flow of each air-feeding plate, the uniform combustion and air-supply of the boiler can be realizer.

Owner:SHANGHAI BOILER WORKS

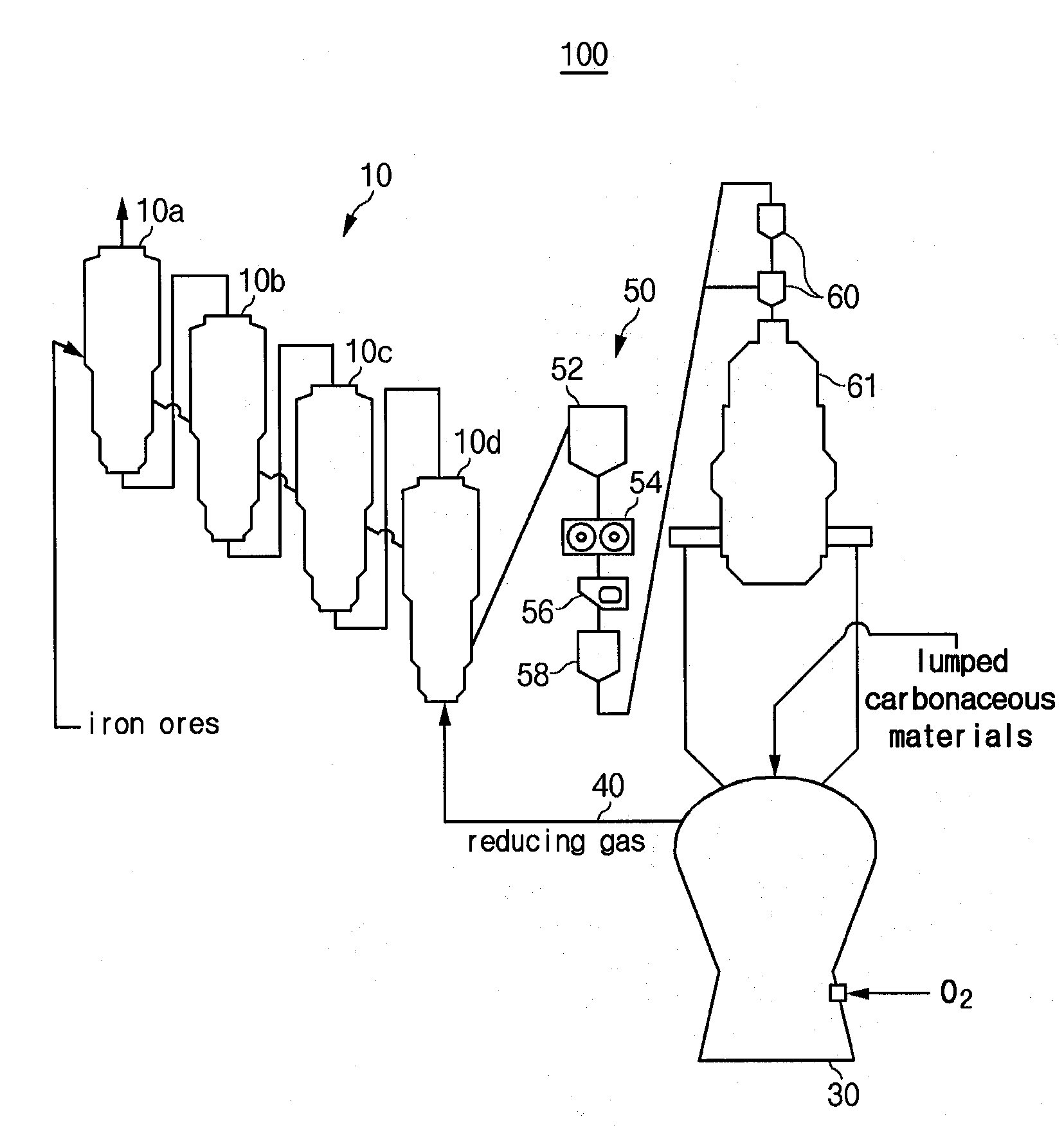

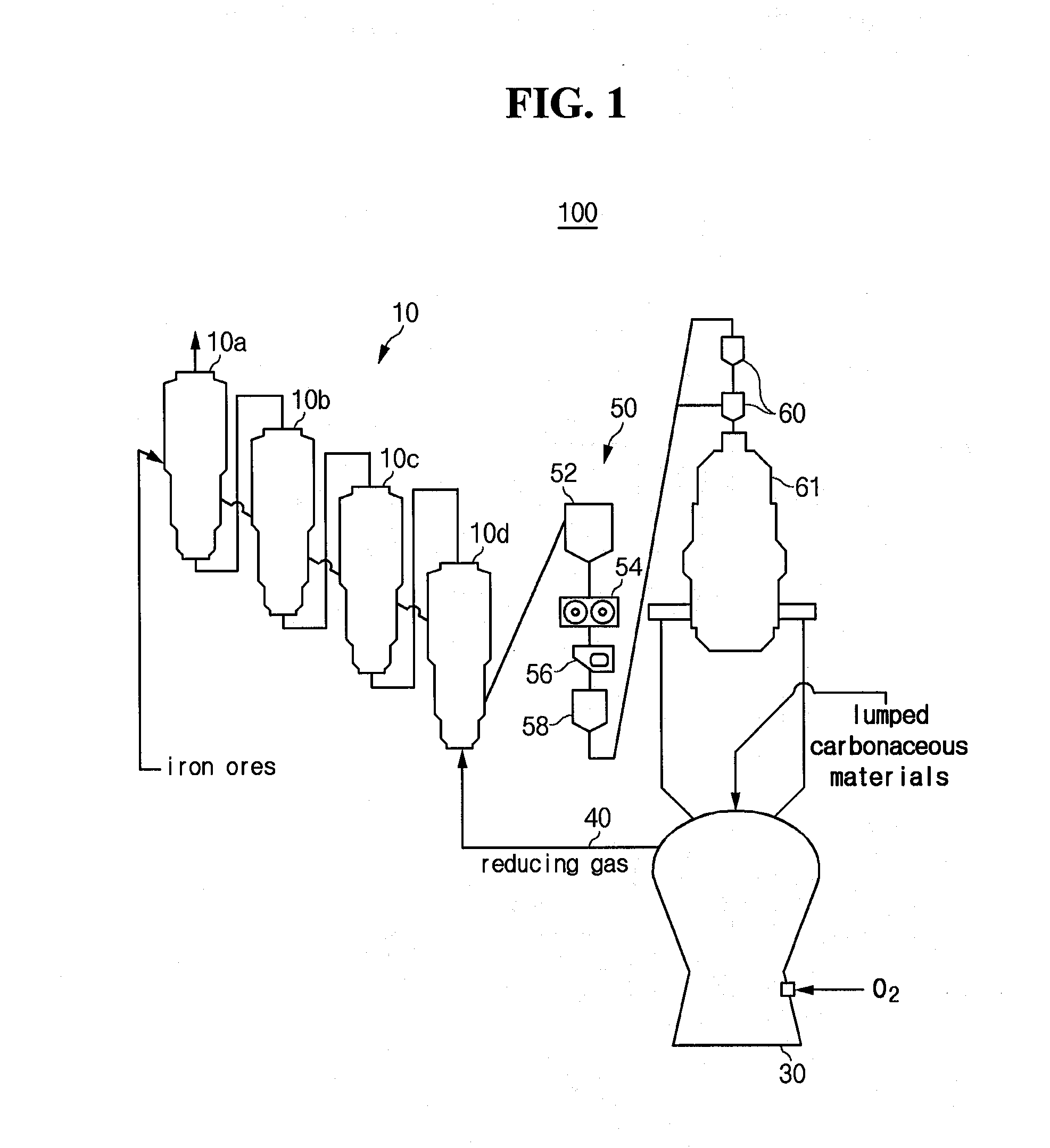

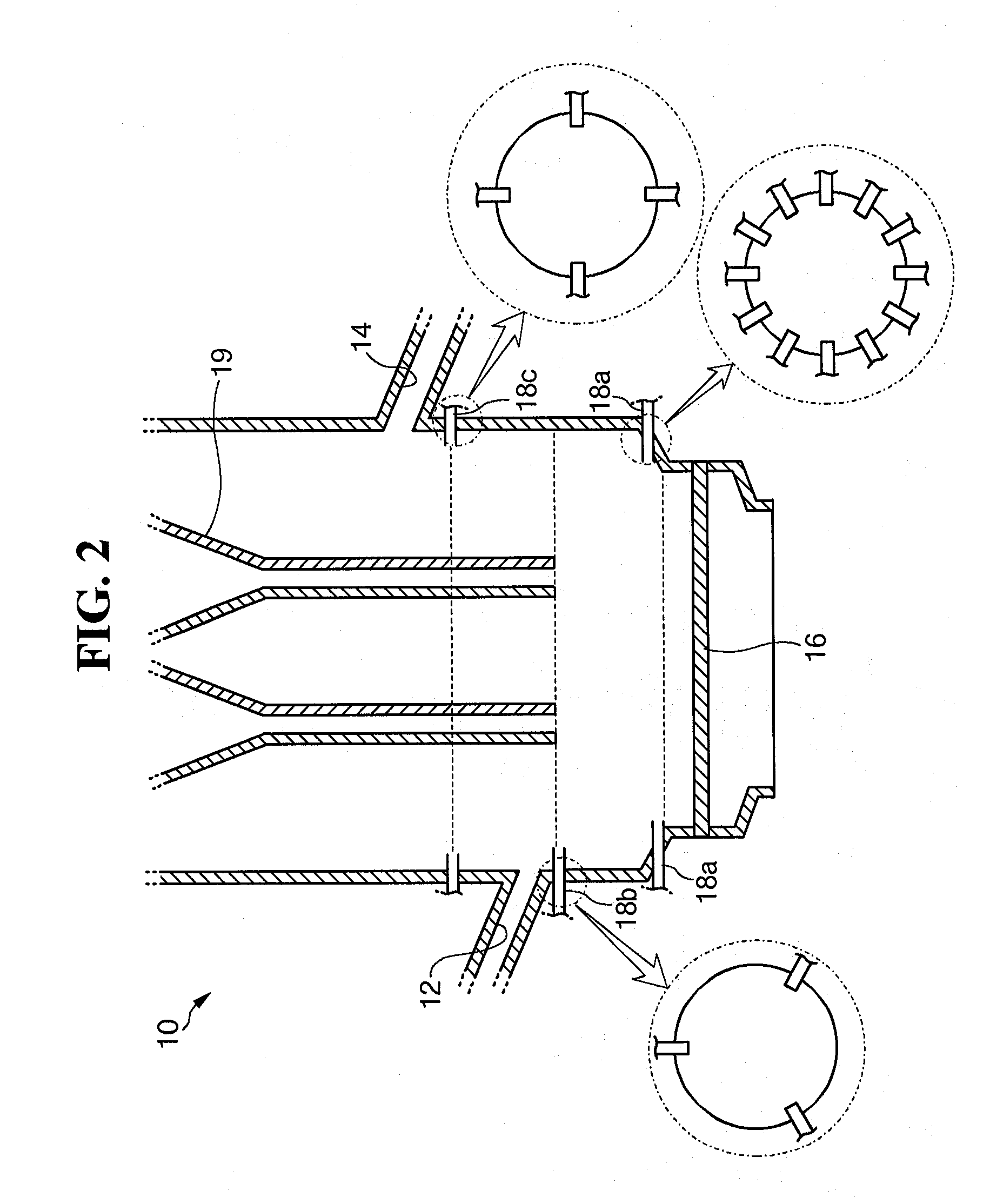

Apparatus for Manufacturing Molten Irons

InactiveUS20090008841A1Effectively distributeInhibition formationDispersed particle separationBlast furnace detailsInjectorFluidized bed

An apparatus for manufacturing molten iron includes i) at least one fluidized-bed reduction reactor that converts iron ore into reduced materials by reducing and plasticizing the iron ore, ii) a melter-gasifier into which the reduced materials are charged and oxygen is injected such that the melter-gasifier manufactures molten iron, and iii) a reducing gas supply line that supplies a reducing gas discharged from the melter-gasifier into the fluidized-bed reduction reactor. The fluidized-bed reduction reactor includes a gas injector that injects a gas into the fluidized-bed reduction reactor to remove stagnating layers.

Owner:POSCO +1

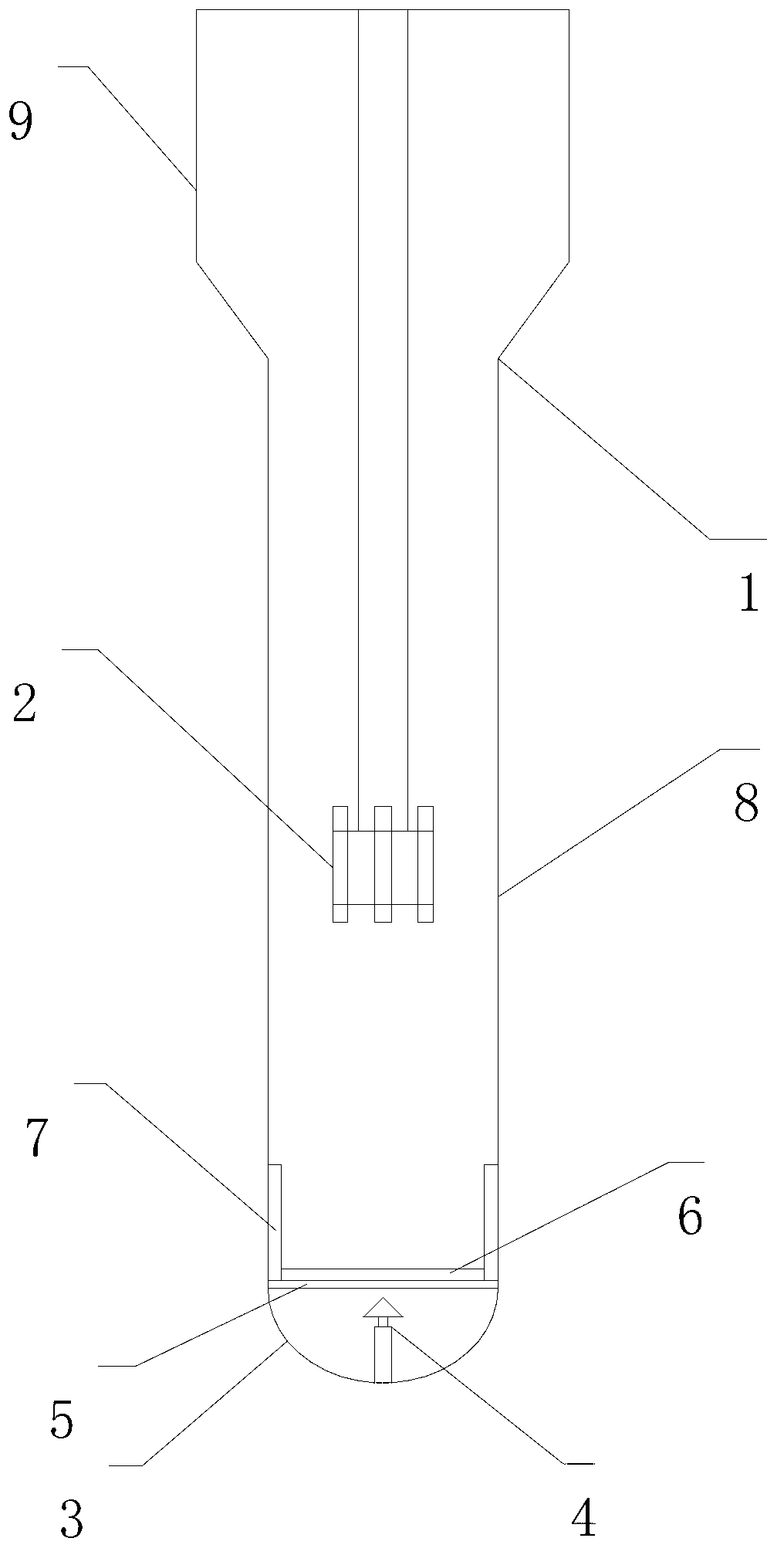

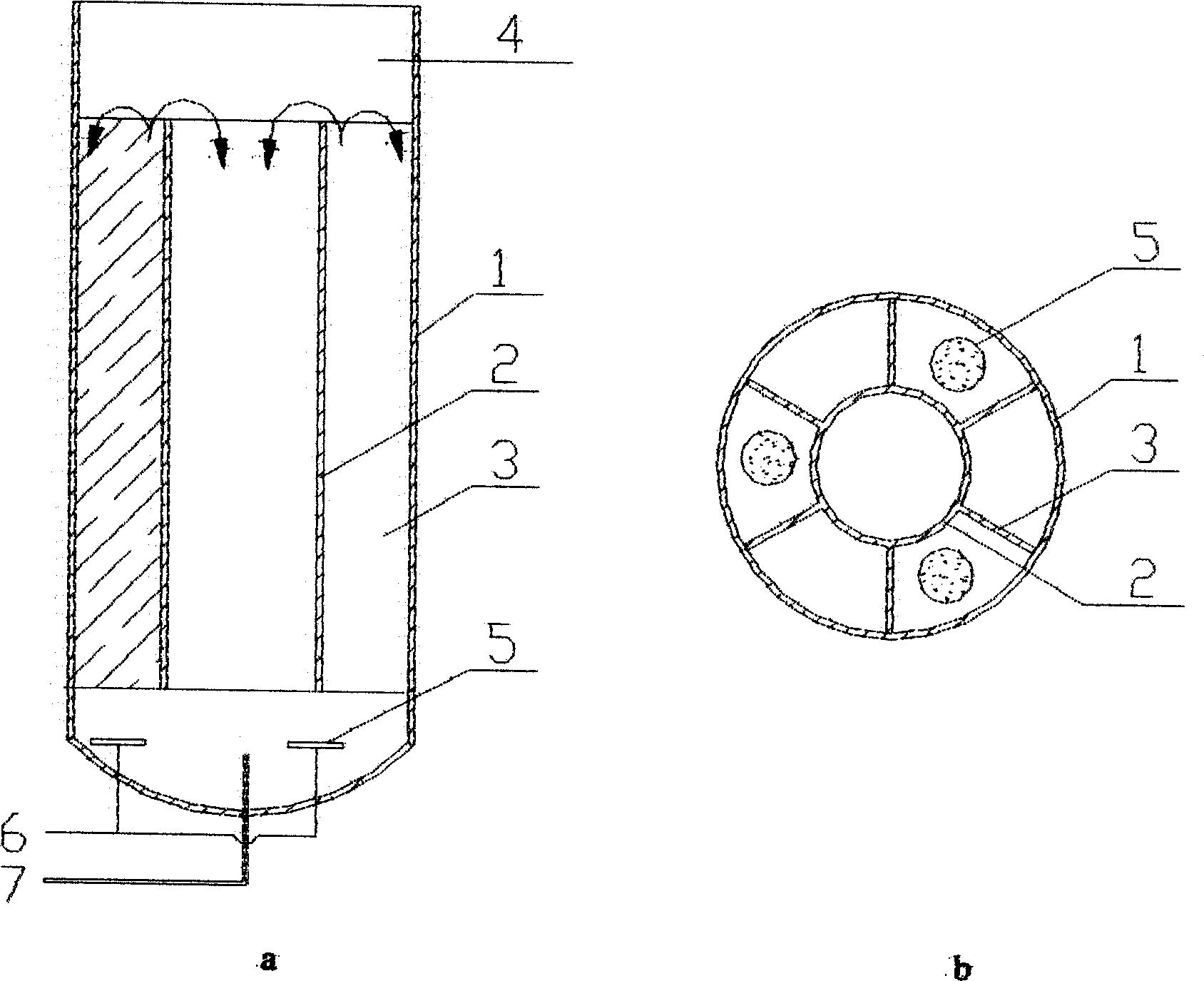

Fluidized bed reactor for preparing chlorosulfonated polyethylene by gas-solid method

InactiveCN102698663AIncrease solids concentrationPrevent subsidenceChemical/physical processesStraight tubeFluidized bed

The invention relates to a fluidized bed reactor for preparing chlorosulfonated polyethylene by a gas-solid method. The fluidized bed reactor comprises a main body of the fluidized bed reactor, wherein the main body of the fluidized bed reactor comprises a straight tube section and a reactor expansion section; the top end of the straight tube section is connected with the bottom end of the reactor expansion section; the inner diameter of the reactor expansion section is larger than that of the straight tube section; a gas premixing chamber is formed at the bottom of the main body of the fluidized bed reactor; a predistribution device is arranged at the bottom of the inner wall of the gas premixing chamber; a plurality of layers of gas distribution plates are arranged between the gas premixing chamber and the main body of the fluidized bed reactor; an ultraviolet lamp glass tube stack formed by annularly arranging a plurality of glass tubes is arranged in the center of the straight tube section, or a plurality of holes are equidistantly and radially formed in the inner wall of the straight tube section along the circumference; and the glass tubes are arranged in the holes. The fluidized bed reactor has the advantages of effectively preventing particles close to the wall surface from being adhered on the wall surface or settled; eliminating dead zones of the whole fluidized bed layer; making reactions more uniform because reaction materials in the bed layer are sufficiently irradiated by ultraviolet.

Owner:刘文潮 +1

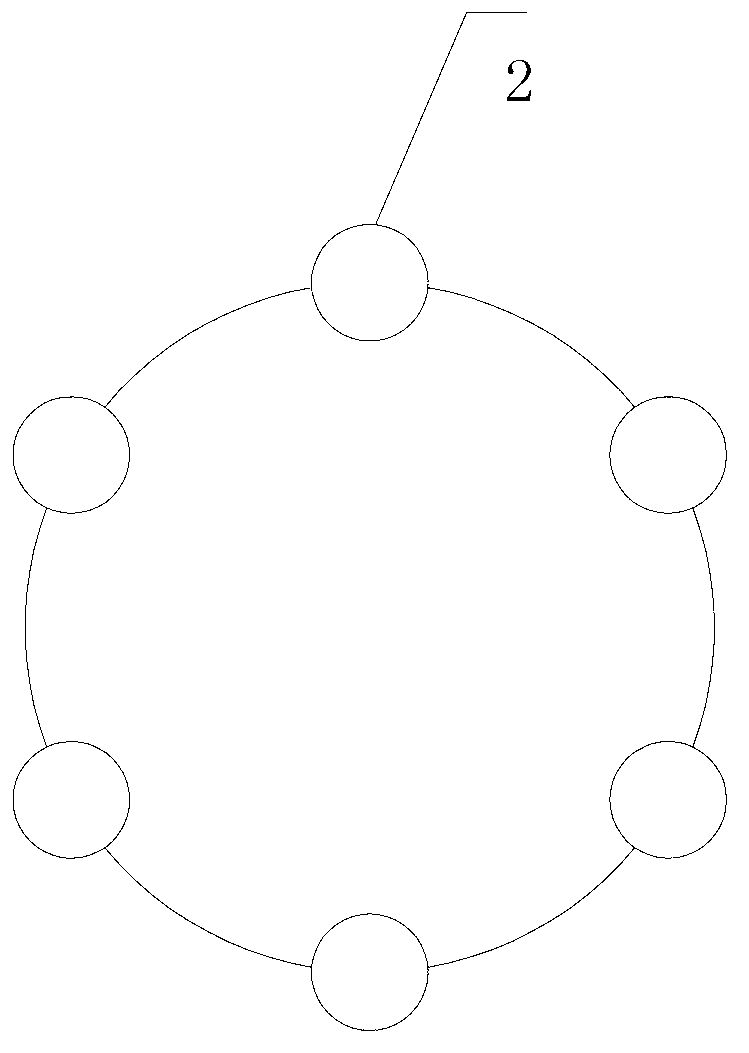

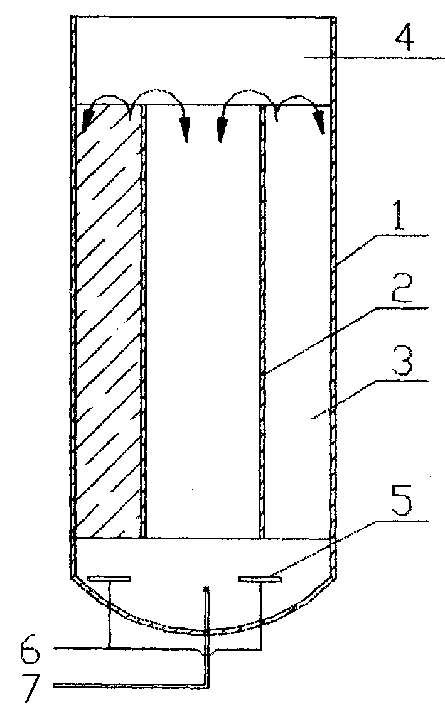

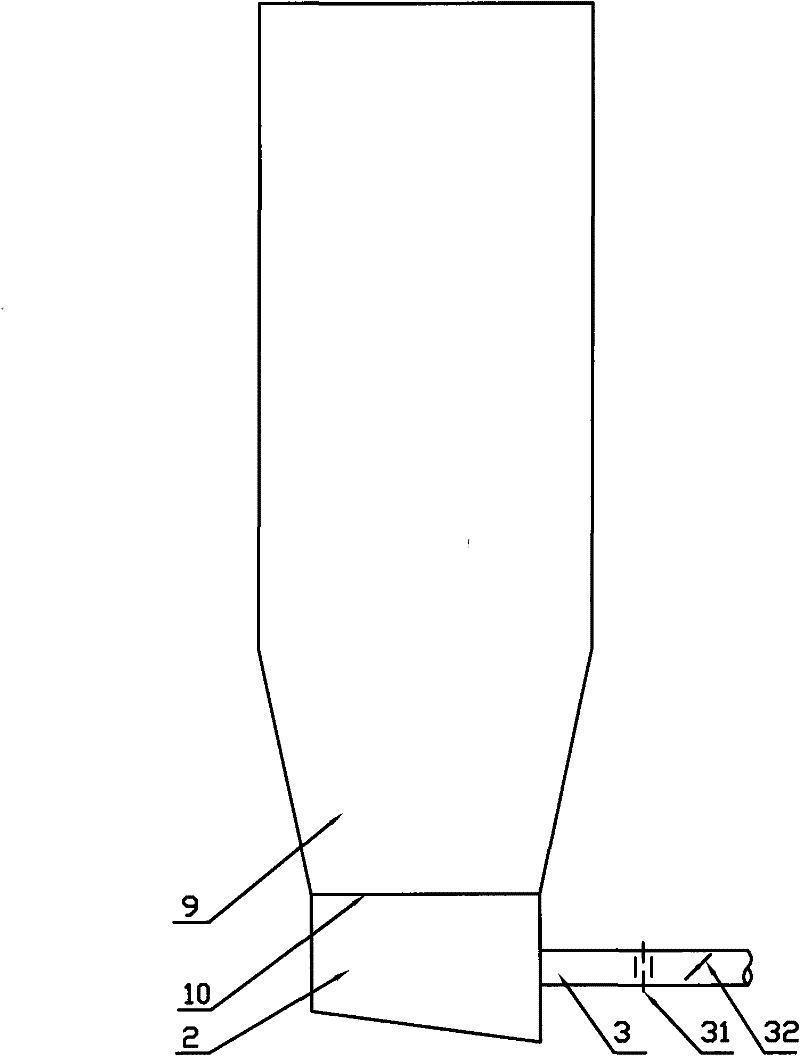

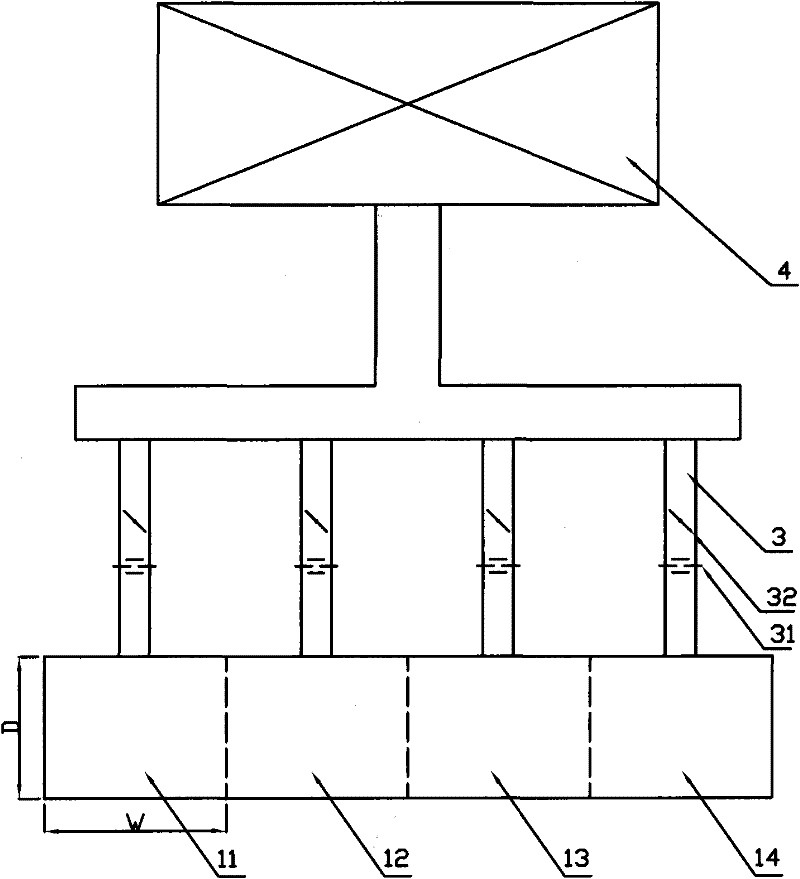

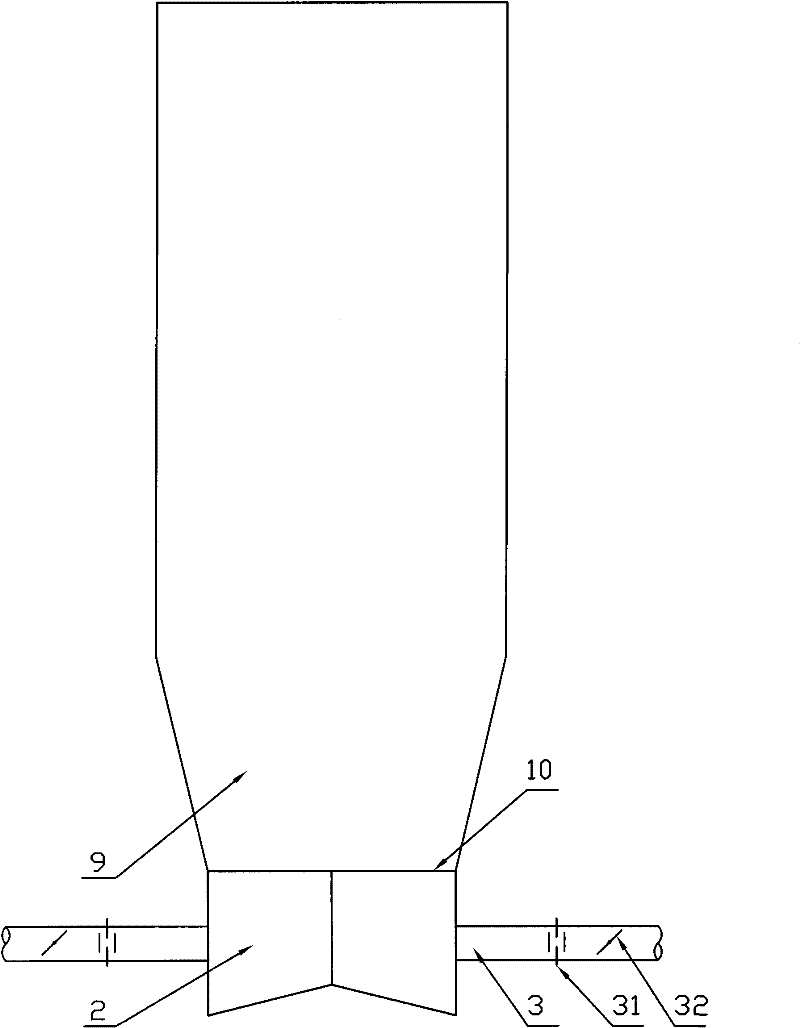

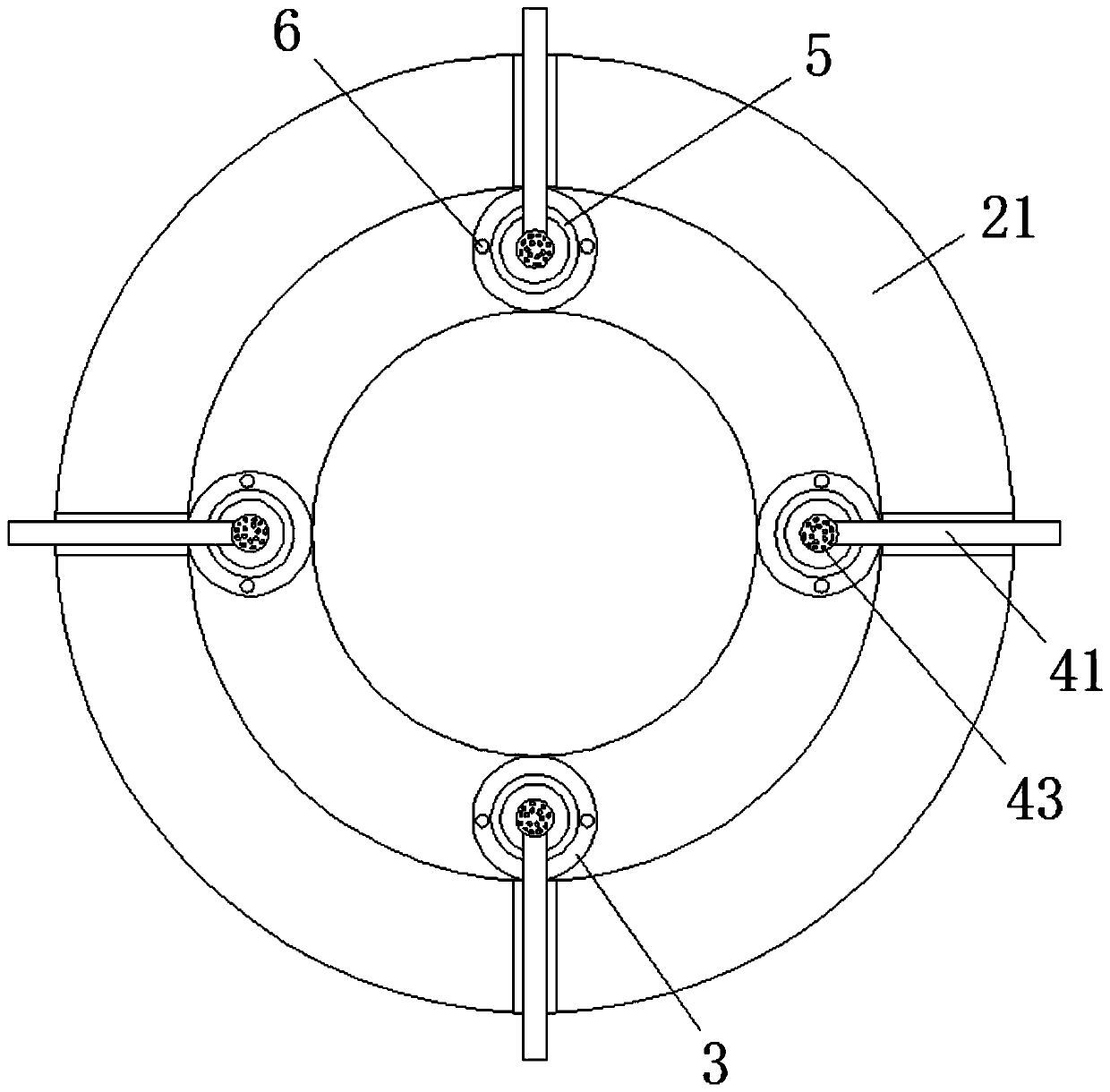

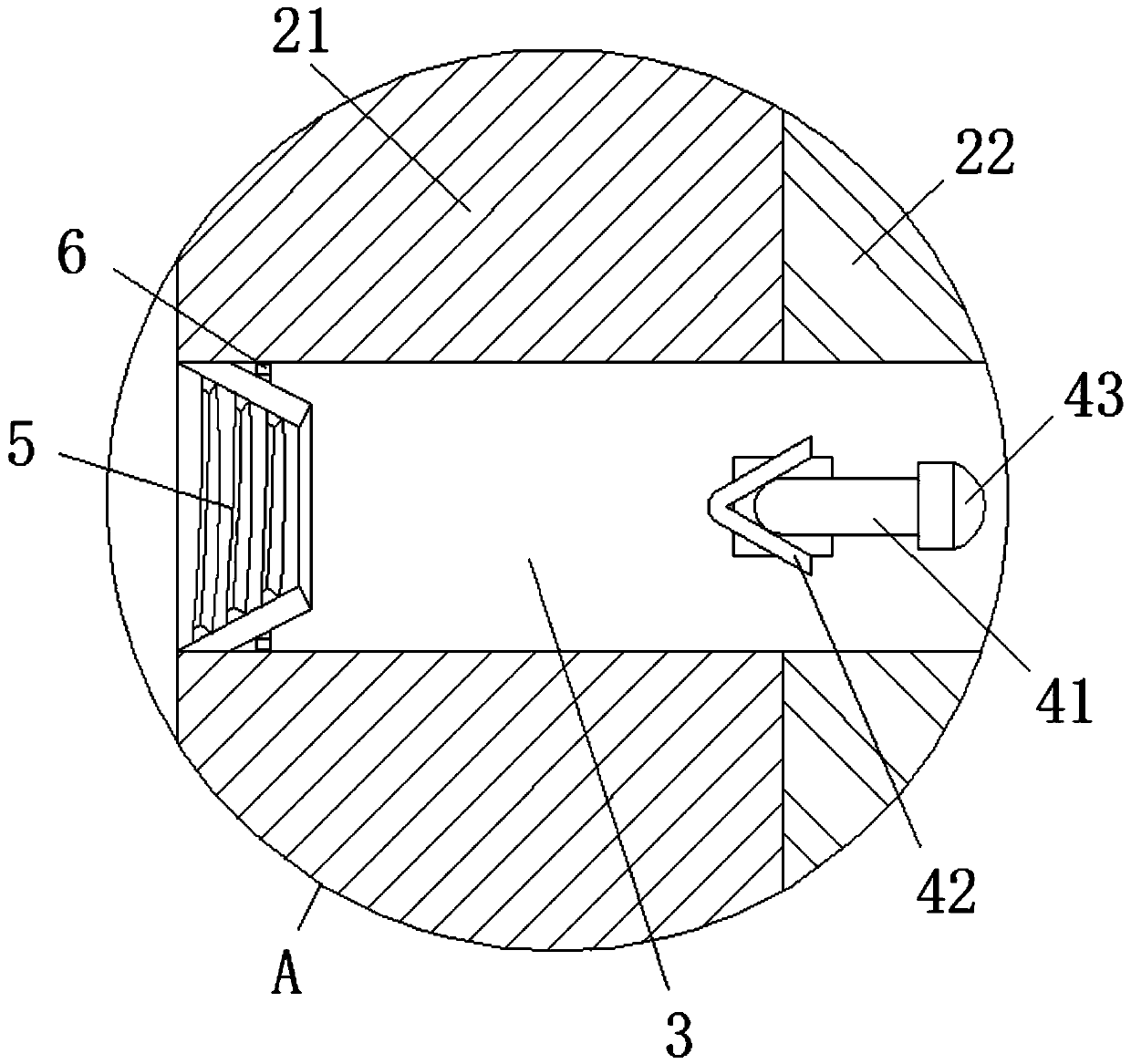

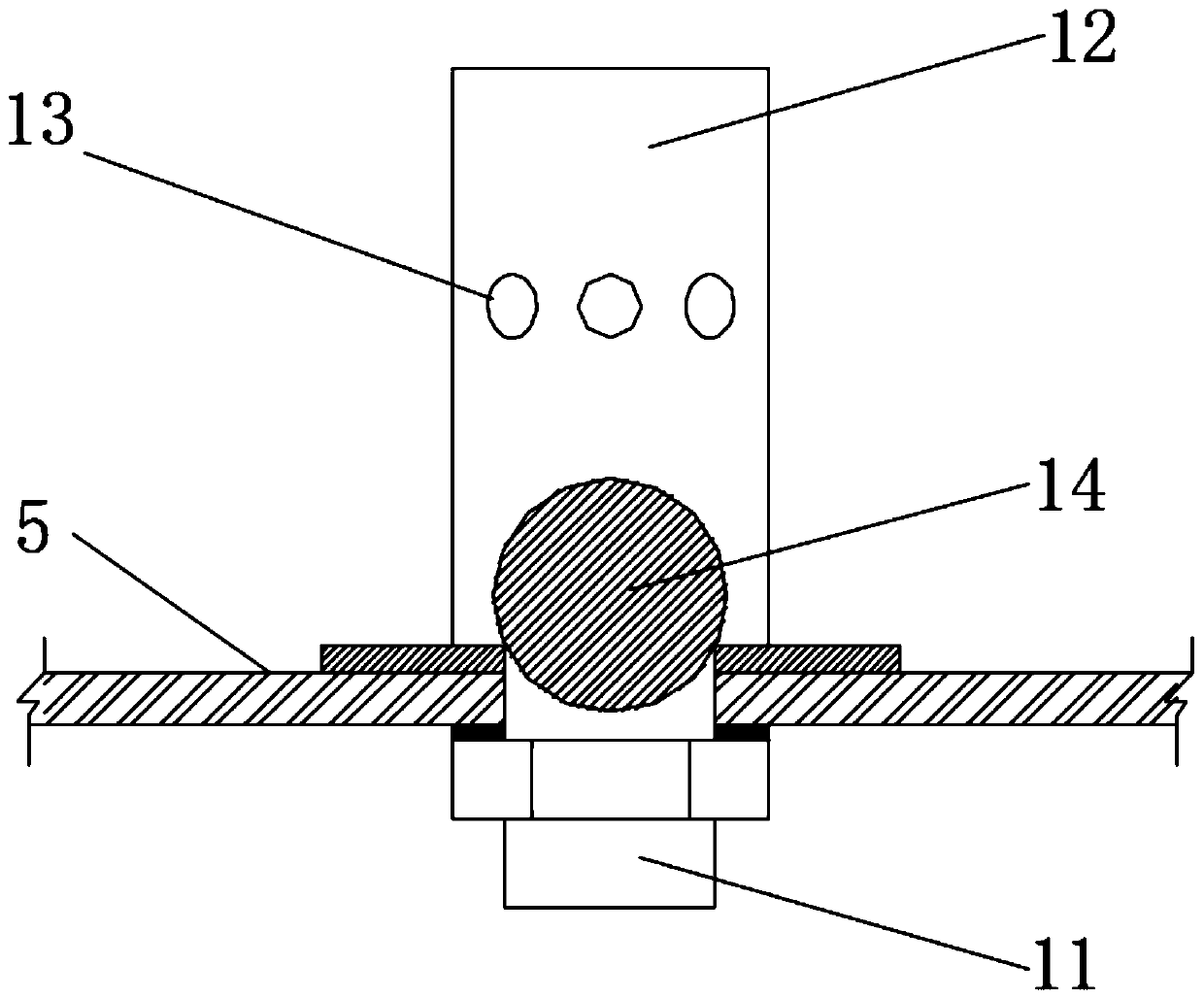

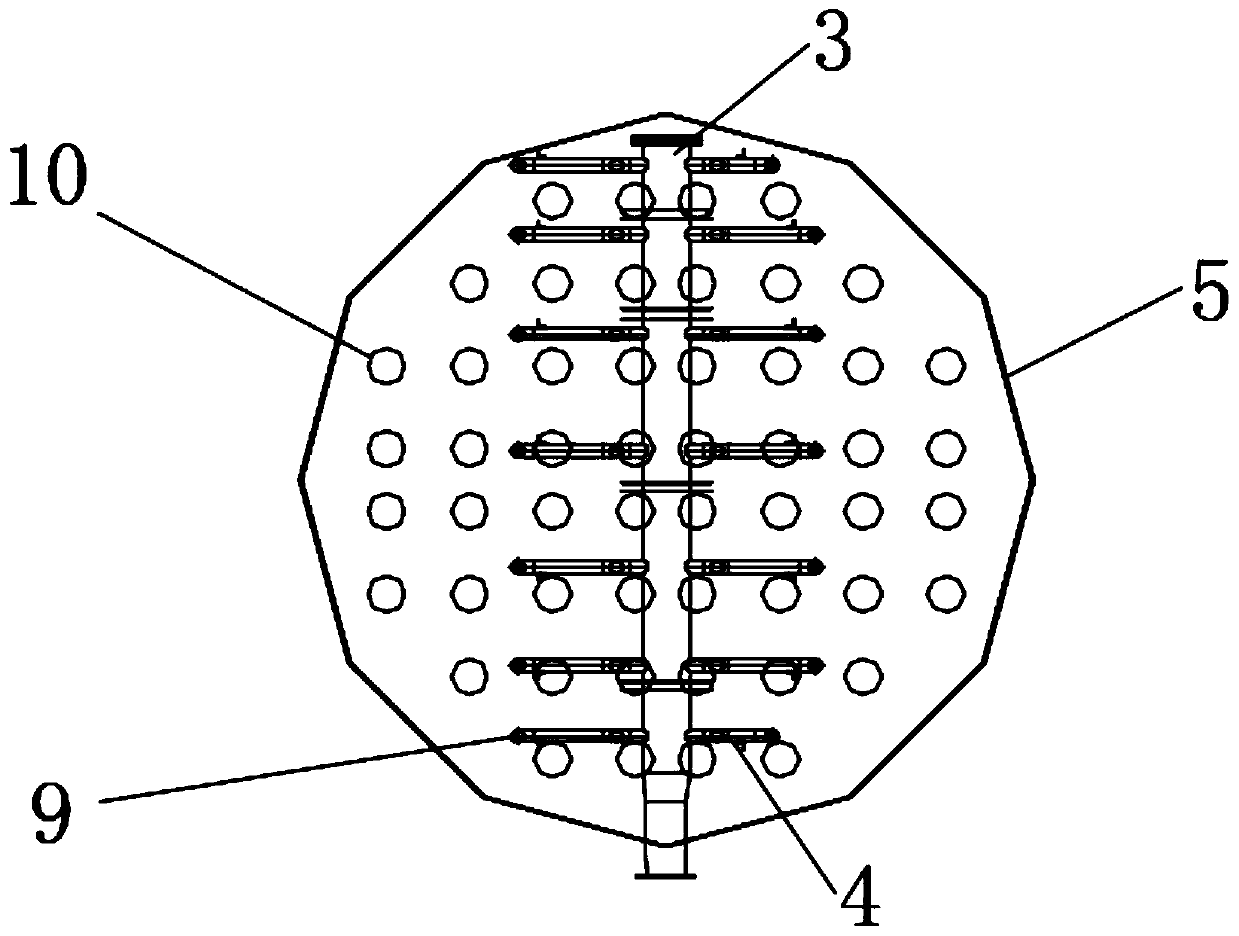

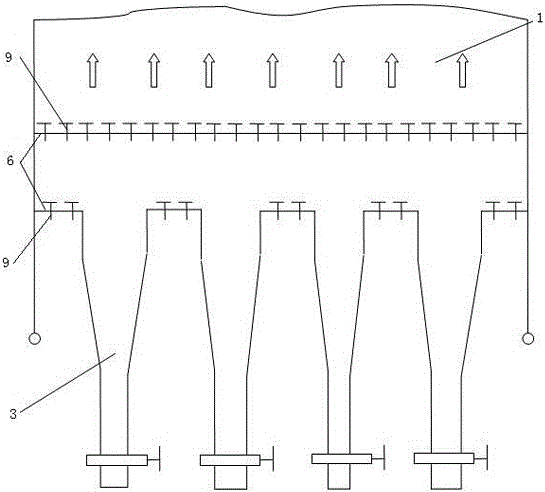

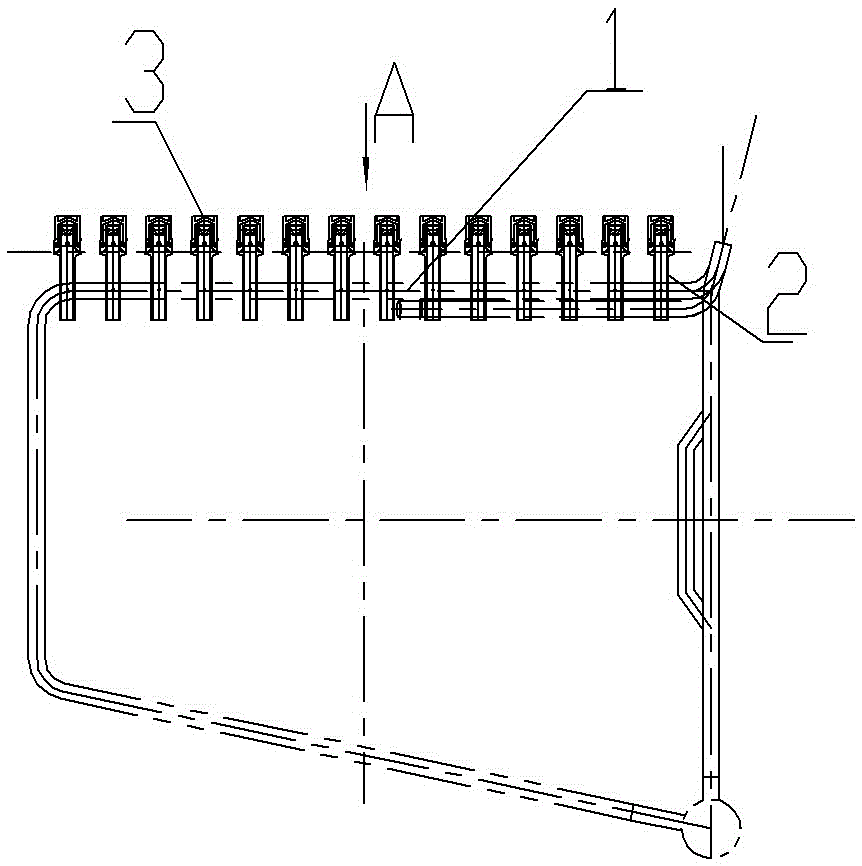

Circulating fluidized bed boiler air supply device

PendingCN106066038AImprove performanceImprove efficiencyFluidized bed combustionApparatus for fluidised bed combustionSlagAgricultural engineering

The circulating fluidized bed boiler air supply device includes the upper air distribution plate (7) with an air inlet and the air cap (1) arranged on the upper air distribution plate (7), and the air inlet of the upper air distribution plate (7) is set There is an adjustment piece (3) for adjusting the air intake volume. The present invention can control the size of each vent of the air distribution device according to needs, realize the adjustment and control of the resistance of the air distribution device, improve the performance of the air distribution device, and thus achieve the purpose of graded air distribution and uniform fluidization. Therefore, not only the efficiency of the circulating fluidized bed boiler is improved, but also the problems of wind cap wear and slag leakage can be fundamentally solved.

Owner:西安亚岱新能源科技有限公司

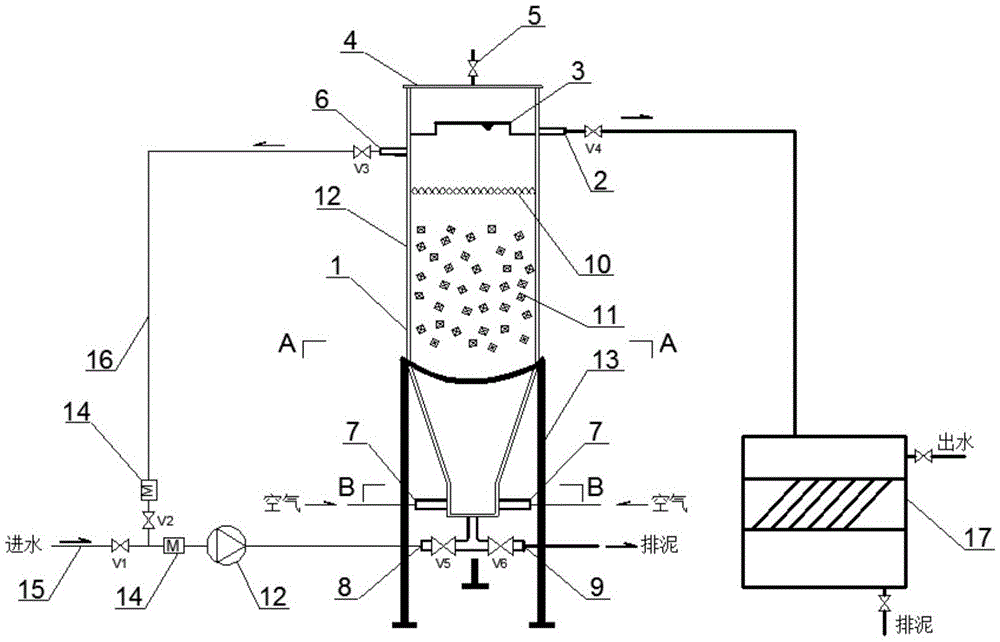

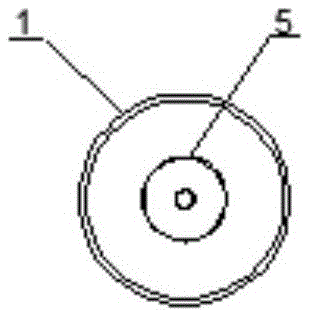

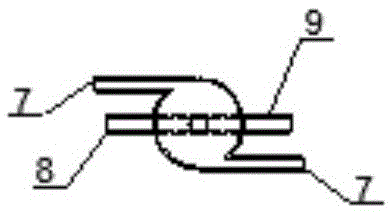

Honeycombed section biological fluidized composite reactor

InactiveCN1460651AReduce the cross-sectional areaEffective thickness controlTreatment using aerobic processesSustainable biological treatmentHoneycombProcess engineering

The biofluidized composite reactor adopts honeycomb section structure, the internal cylinder of said reactor is positioned in the centre of interior of external cylinder of said reactor, in the annular space between external cylinder and internal cylinder of the reactor even number of partion boards can be added, and the separated adjacent annular space zones are successively used as flow-lifting zone and flow-falling zone, said flow-lifting zone and flow-falling zone are limited by said honeycomb section structure, and the section area of single flow-lifting zone is reduced, so that it can better uniformly fluidize, reduce energy consumption and raise oxygen-transferring efficiency.

Owner:TSINGHUA UNIV

Primary Air Distribution Method for Circulating Fluidized Bed Boiler

InactiveCN102278744AUniform fluidizationEasy to fluidizeFluidized bed combustionApparatus for fluidised bed combustionAir preheaterFluidized bed

The invention discloses a method for distributing primary air of a circulating fluidized bed boiler, and relates to the technology of a circulating fluidized bed boiler. There is an air chamber at the bottom, and the air chambers are not connected to each other; each air chamber is connected to the air preheater of the boiler through an air pipe; each air pipe is equipped with an air flow measuring device and an adjustment device. device; when the boiler is running, adjust the air flow regulating device to control the primary air volume flowing into each air chamber. The method of the invention can improve the uniformity of the primary air distribution of the circulating fluidized bed boiler, especially the large capacity circulating fluidized bed boiler.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Novel aerobiont fluidized bed reactor and technology thereof

ActiveCN105129977AEasy to handleUniform fluidizationSustainable biological treatmentBiological water/sewage treatmentExhaust valveFluidized bed

The invention relates to a novel aerobiont fluidized bed reactor and a technology thereof. The novel aerobiont fluidized bed reactor comprises a reactor tank, a water outlet, an exhaust valve, an air inlet, a water inlet, a sludge discharge pipe, swastika-shaped biological stuffing, an outer support, a flow meter, a water inlet pipe and a tilted plate settling pond. The technology for treating sewage by means of the novel aerobiont fluidized bed reactor comprises the steps that 1, sludge is acclimated; 2, the biological stuffing is added; 3, sludge is discharged after aeration is performed; 4, sewage is led in and then aeration is performed; 5, sludge is discharged; 6, the COD removal rate is calculated; 7, the fourth, fifth and sixth steps are repeatedly executed, and the amount of sewage to be treated and the sewage amount are increased gradually after the COD removal rate is higher than 50%; 8, the amount of the sewage to be treated reaches 25-50% of the effective volume of the reactor tank, and water outlet and backflow are started when the COD removal rate is higher than 80%; 9, the treated water is drained into the tilted plate settling pond through the water outlet.

Owner:许建民

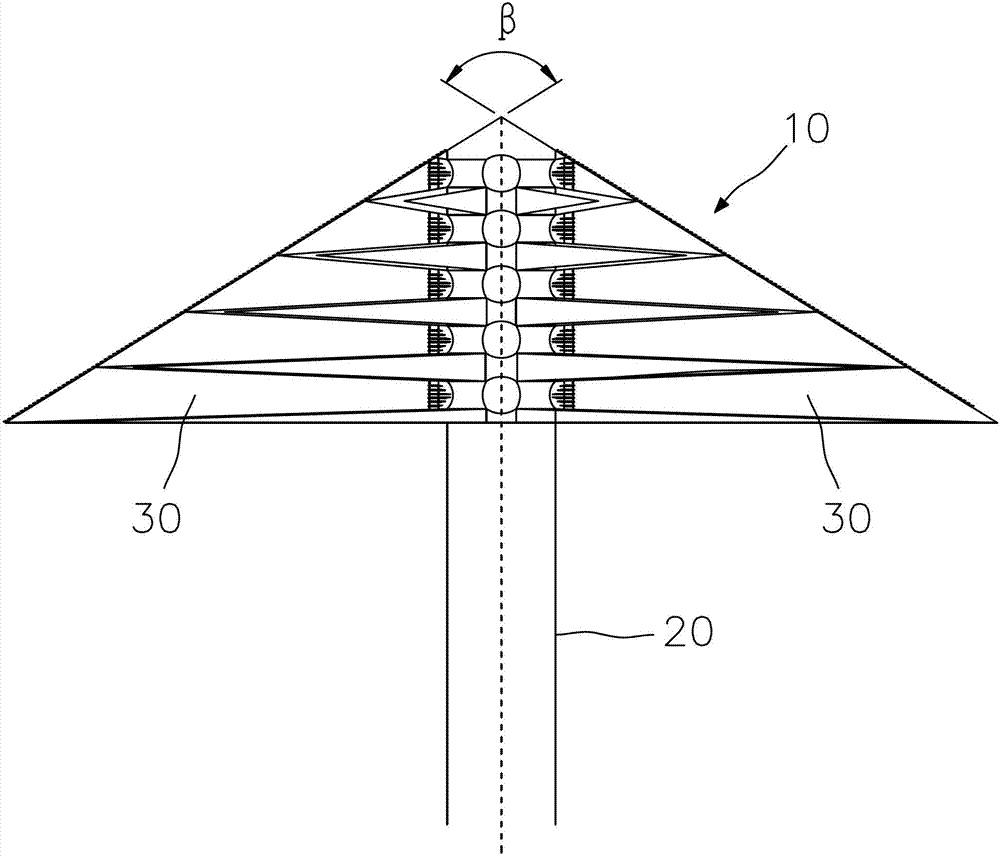

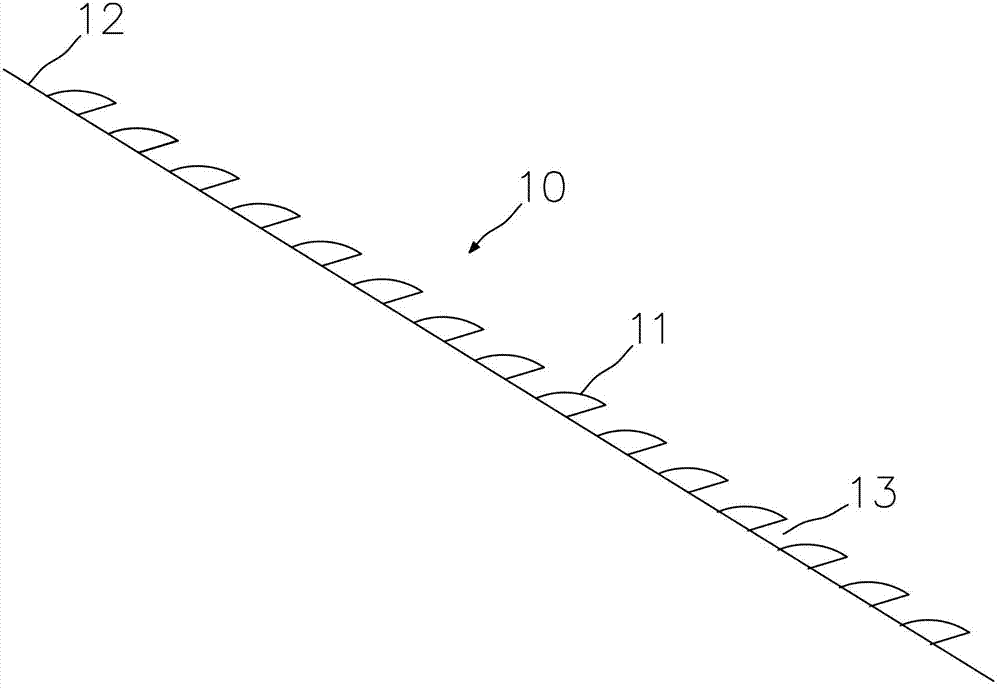

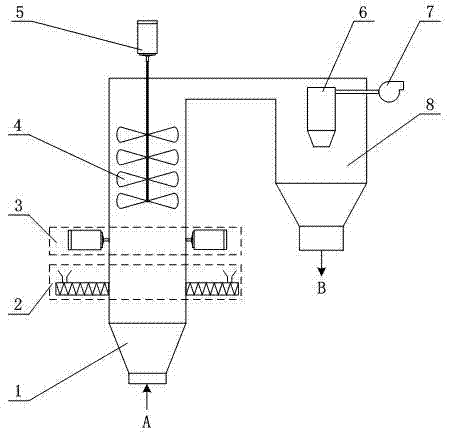

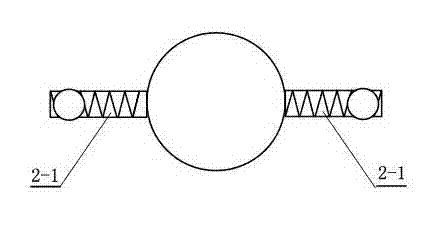

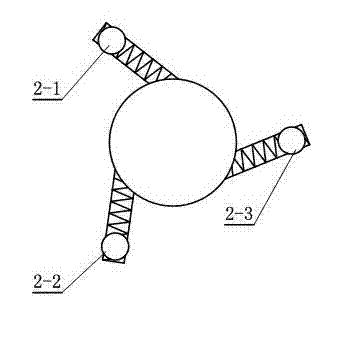

Efficient airflow classification fine-coal remover for power coal before selecting

InactiveCN102784757AEvenly dispersedSmooth dischargeGas current separationMaterial classificationGranularity

The invention belongs to the technical field of fine-coal removal and classification before washing and selecting of coal and particularly relates to an efficient airflow classification fine-coal remover for power coal before selecting. The fine-coal remover comprises the following components such as a material dispersion area, a primary classification area and a secondary classification area; in the material dispersion area, materials are collided under the impact of airflow and are dispersed mutually; in the primary classification area, the materials after dispersion are divided into primary fine particle materials and primary coarse particle materials through a 360-degree full-annular air-distribution and material-distribution mechanism; and in the secondary classification area, the primary fine particle materials are divided into secondary fine particle materials and secondary coarse particle materials through a wind power rotary driving classification mechanism, and the secondary fine particle materials and the secondary coarse particle materials are discharged out of the secondary classification area so as to finish the eventual classification. According to the invention, the material classification process includes two dispersions and two classifications, so as to solve the problem of screen blinding as well as improve classification efficiency at the same time, realize that classification granularity can be adjusted and controlled within 0-13 mm as required, meet the requirements of classification and section of whole particle dry process, and ensures that a circulating fluidized bed furnace of a mine -mouth power plant has coal to use for generating power.

Owner:ANHUI UNIV OF SCI & TECH

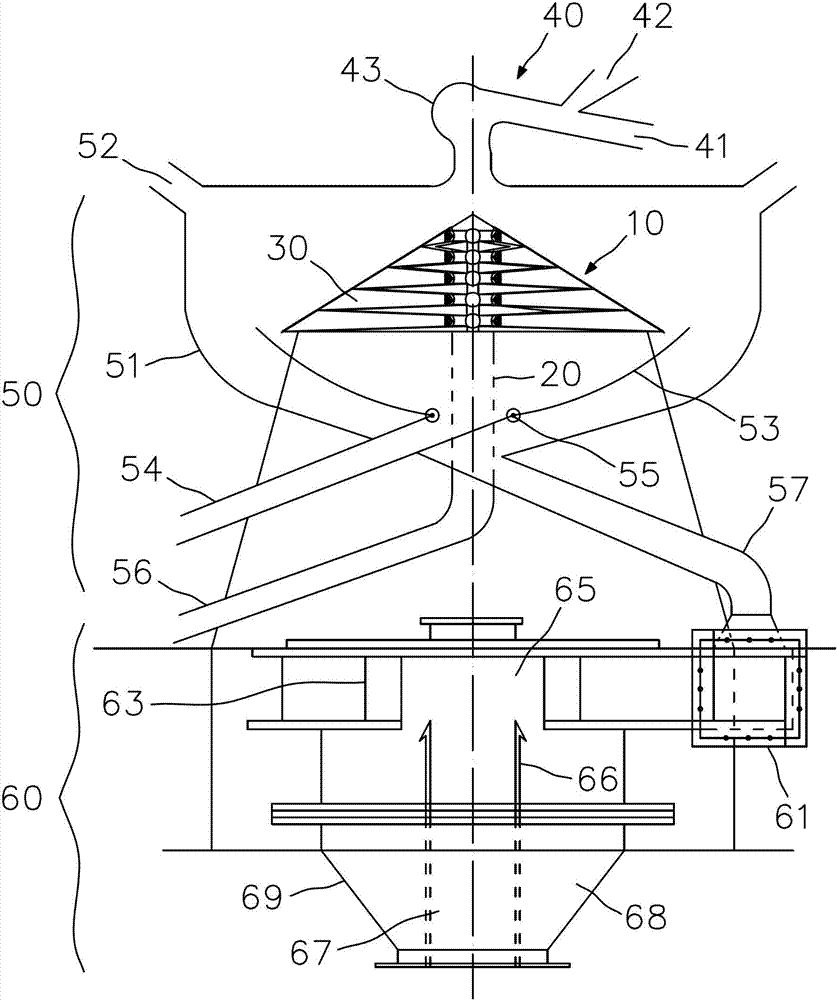

Dry-type granulation treatment waste heat recovery system

ActiveCN104388611AHigh recovery rateImprove qualityRecycling and recovery technologiesWaste heat treatmentWaste heat recovery unitSlag

The invention discloses a dry-type granulation treatment waste heat recovery system which comprises a slag storage bin, a granulation cooling unit, a primary waste heat recovery unit, a secondary waste heat recovery unit and a tertiary waste heat recovery. The system is characterized in that the top of the granulation cooling unit is provided with a first air outlet; the first air outlet is connected with a high-temperature booster fan through a pipeline; a granulator is arranged in the granulation cooling unit, positioned below a charging pipe and driven by a rotating shaft to rotate; the primary waste heat recovery unit is arranged below the granulation cooling unit; the bottom of the primary waste heat recovery unit is provided with a first fluidized bed and a slag discharge pipe; the slag discharge pipe is communicated with the secondary waste heat recovery unit; the bottom of the secondary waste heat recovery unit is provided with a spray bed; and the upper part of the secondary waste heat recovery unit is communicated with the upper part of the tertiary waste heat recovery unit. The system implements the dry-type granulation function and high-efficiency waste heat recovery, and can be widely used in the fields of steel, metallurgy and the like.

Owner:CHONGQING UNIV

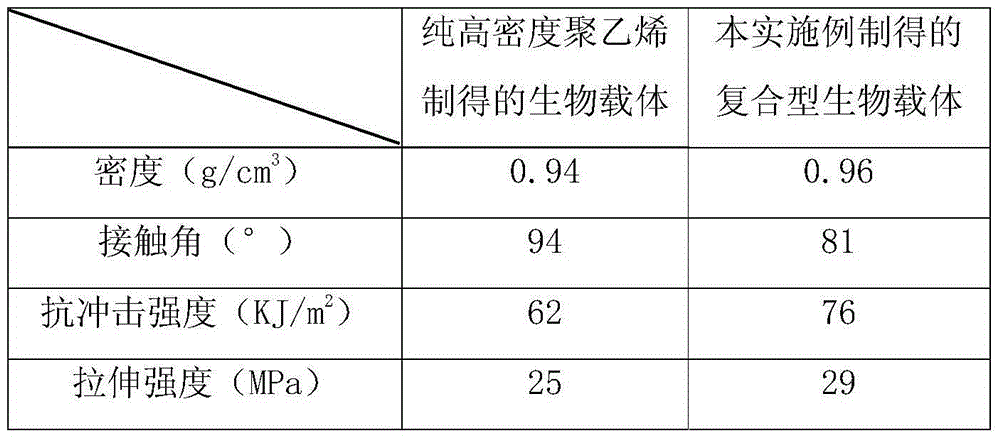

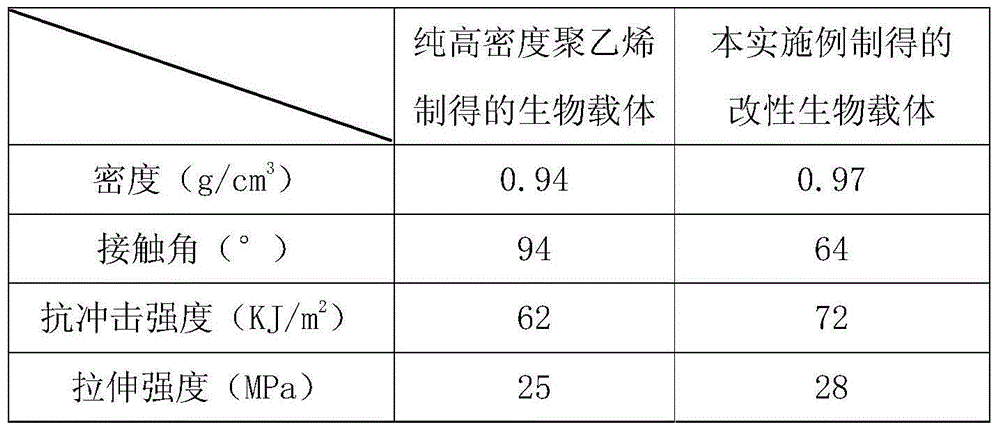

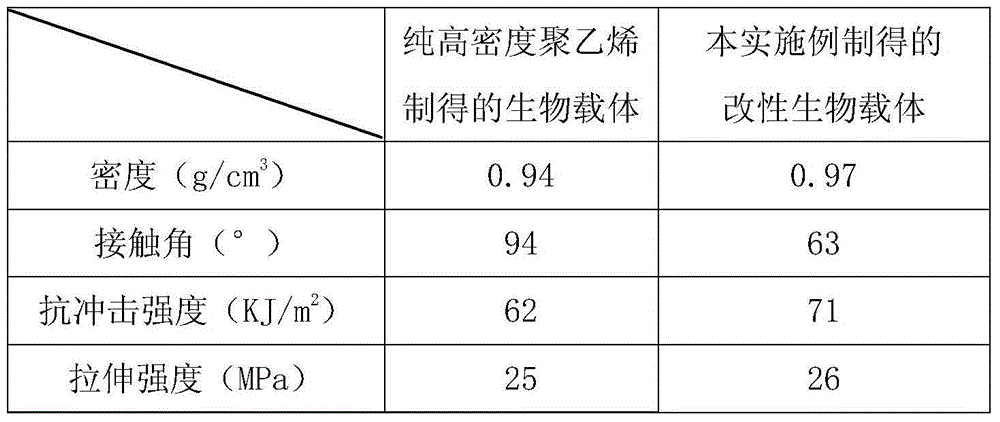

Hydrophilic biological carrier for wastewater treatment

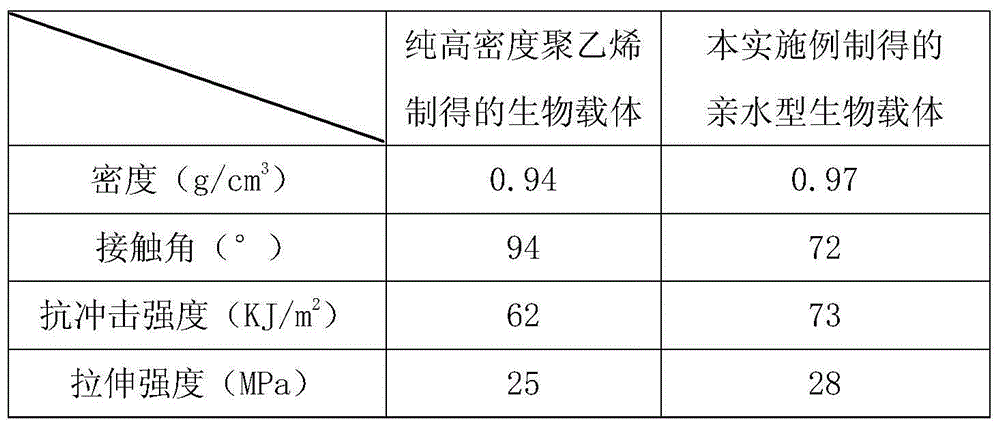

InactiveCN104860390ALower contact angleGood adhesionTreatment using aerobic processesSustainable biological treatmentDecompositionPolyvinyl alcohol

The invention provides a hydrophilic biological carrier for wastewater treatment. The hydrophilic biological carrier comprises base materials, hydrophilic functional materials and auxiliary materials, the base materials include high-density polyethylene, the hydrophilic functional materials include iron trioxide, coke and slag powder or polyvinyl alcohol, and the auxiliary materials include talcum powder. The density of the hydrophilic biological carrier for wastewater treatment is 0.93-1.05g / cm<3>, the biological carrier is rough in surface, large in specific surface area, short in membrane hanging time and high in impact resistance, can prevent microbial membranes attached to the outer surface of the carrier from falling off due to friction between the carriers in water, contact angles of sewage and the carrier are reduced, the hydrophilicity of the carrier is improved, so that microorganisms are more easily attached to the carrier, the biological carrier is provided with enhanced components of biological enzyme, the catalytic action of the biological enzyme is facilitated, the enhanced components are high in biological activity and fast in metabolism, the decomposition capacity of contamination in the water can be remarkably improved, the biological carrier contains ultraviolet-resistant components, the service life of the biological carrier is longer than 30 years, and replacement and maintenance are omitted.

Owner:大连宇都环境技术材料有限公司

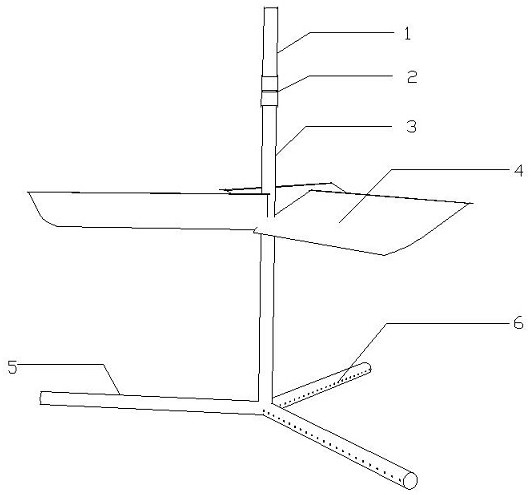

Self-driven rotary aeration device

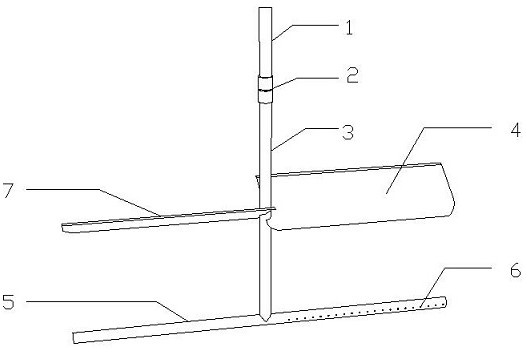

PendingCN112678946AContinuous rotary aerationPromote mixed contactSustainable biological treatmentBiological water/sewage treatmentMicroorganismThermodynamics

The invention provides a self-driven rotary aeration device which comprises a fixed air vertical pipe and a movable air vertical pipe, the fixed air vertical pipe and the movable air vertical pipe are connected through a rotary joint, inclined blades are arranged on the movable air vertical pipe, a rotary transverse pipe is arranged at the bottom end of the movable air vertical pipe, and air outlet holes are formed in the rotary transverse pipe. Compared with fixed aeration, rotary aeration has the advantages that the proportion of a bubble activity space in an aeration reactor in the whole space can be increased, uniform air distribution is promoted, uniform fluidization of the filler is promoted, the phenomena of filler accumulation or ball death and the like are prevented, and sludge sedimentation can also be prevented. Rotation of the rotating blades can also promote mixed contact of water, gas and microorganisms in the reactor, and mass transfer is enhanced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

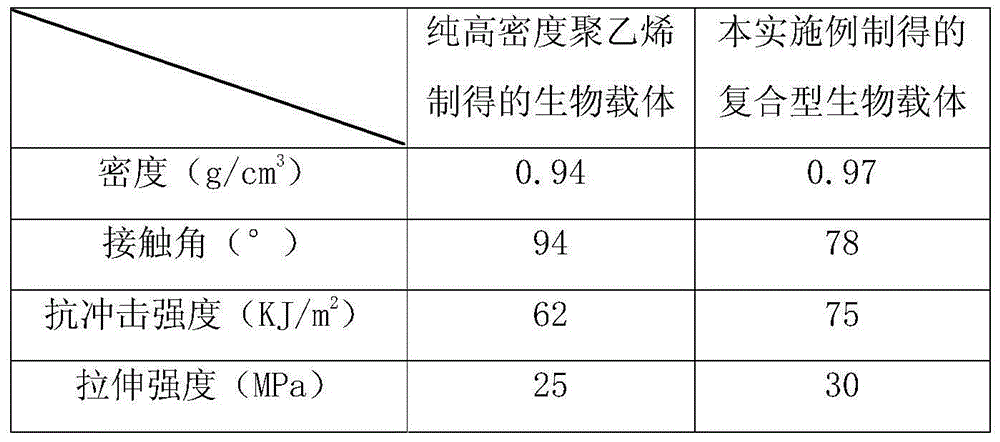

Composite biocarrier for wastewater treatment

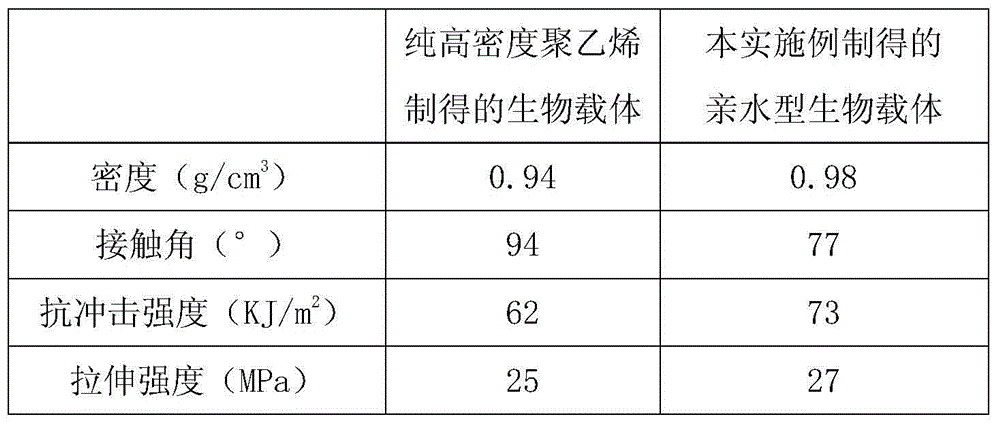

InactiveCN104891643ALower contact angleGood adhesionSustainable biological treatmentBiological water/sewage treatmentDecompositionSlag

The invention provides a composite biocarrier for wastewater treatment. The base material is high density polyethylene, the composite functional material is slag powder, ferric oxide, coke, starch, cationic polyacrylamide or polyquaternium-10, and the auxiliary material is talcum powder. The composite biocarrier for wastewater treatment provided by the invention has density of 0.93-1.05g / cm<3>. The composite biocarrier has rough surface, short film formation time, strong impact resistance, and can prevent the drop of a microbial film attached to the biocarrier outer surface in water due to friction between carriers. The biocarrier has small contact angle with sewage, the hydrophilcity of the carrier is enhanced, and microorganisms can be attached to the carrier more easily. The biocarrier contains enhancement components of bio-enzyme, can promote the catalytic effect of bio-enzyme, has high bioactivity and fast metabolism, and can significantly enhance the decomposition ability of pollutants in water. The biocarrier contains antiultraviolet components, has a service life of over 30 years, and has no need for replacement and maintenance.

Owner:大连宇都环境技术材料有限公司 +1

Spraying mechanism for fog gun machine

ActiveCN111085361AIncrease flow rateReduce initial energy supplyUsing liquid separation agentSpray nozzlesJet flowAqueous droplet

The invention relates to the technical field of fog gun machines, and discloses a spraying mechanism for a fog gun machine. The spraying mechanism comprises a gun barrel body, one end of the gun barrel body is fixedly connected with a jet sleeve, the jet sleeve comprises a left half sleeve and a right half sleeve, the left half sleeve and the right half sleeve are closed in a butting mode to formthe jet sleeve, the jet sleeve is internally provided with a jet channel, the jet channel is internally provided with an atomization device, and the atomization device is used for axially spraying atomized beads into the jet channel. According to the spraying mechanism, the atomization device is arranged in the jet channel, on the one hand, the flow speed of jet gas entering the jet channel from the gun barrel body can be further increased under the situation of decreasing of a sectional area, thus initial supplied energy of the jet gas can be reduced, on the other hand, atomization spraying is conducted in the jet channel, then atomized fog drops can be directly jetted out along with the jet gas through the fluidization action of the jet gas in the jet channel on the fog drops, the spraying effect of the spraying mechanism is better, the loss of water droplets during jetting out of the jet sleeve is reduced, and water resources are saved.

Owner:义乌市亚威机械设备有限公司

Combined fluidized bed slag cooling apparatus

ActiveCN101476721AImprove mobilityWell mixedFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention relates to a combined fluidized bed slag cooler, which comprises a body, a wind box, an air distributing device, a slag inlet pipe, a slag outlet pipe, an air inlet pipe and an air outlet pipe. The body is provided with the slag inlet pipe, and the bottom of the body is connected with the slag outlet pipe. The lower part of the body is provided with the air distributing device and connected with the wind box of the air inlet pipe, and the top of the body is connected with the air outlet pipe. The slag outlet pipe is provided with a spraying pipe for air intake inside to make the three working areas with different flowing states formed from the lower part to the upper part in the body, the lower part is a spraying area, the middle part is an annular fluidizing area, and the upper part is a suspending and settling area. The upper side of the spraying pipe is provided with a guide pipe. The outlet of the slag outlet pipe is provided with a mechanical slag outlet valve or a conveyor. The transverse and longitudinal mixing of gas-solid two-phase in the bed is obviously strengthened under the coaction of spraying air and fluidizing air. The problems of poor transverse mixing, easy accumulation of local bed materials, delamination, aggregation and the like of the fluidized bed slag cooler are solved. The furnace slag granules can be sufficiently and effectively cooled. The combined fluidized bed slag cooler is used for cooling bottom slag of a CFB boiler or other high-temperature solid granular materials.

Owner:EASTERN BOILER CONTROL CO LTD

Slag removal system and method thereof

ActiveCN107586565AGood dispersionEvenly dispersedGranular/pulverulent flues gasificationSlagInstability

The invention relates to the field of coal gasification technology, especially to a slag removal system and a method thereof. According to the invention, distribution of flow field around a slag removal pipe can be improved, instability and obstruction of slag removal due to uneven distribution of flow field are avoided, and potential safety hazards such as abrasion of a central jet pipe, etc. canbe avoided. The slag removal system comprises a gasifier, the bottom of which is provided with a gas distribution plate. A gas distribution plate zone is above the gas distribution plate. The bottomof the gas distribution plate extends downward to provide with a slag removal pipe, which penetrates through the bottom of the gasifier. A columnar slag removal channel which is communicated with thegas distribution plate zone is formed at the bottom of the gasifier and is communicated with a slag hopper system through a connection pipe nipple. One end of the connection pipe nipple, close to theslag removal pipe, is provided with an annular gas distributor, which is used for distributing gas to the gas distribution plate zone through the columnar slag removal channel. A swirl flow field is formed in the gas distribution plate zone, and ash and slag fall down under the action of the swirl flow field and are discharged through the slag hopper system.

Owner:ENN SCI & TECH DEV

Modified biocarrier used in waste water processing anaerobic tank

InactiveCN104910481ALower contact angleImprove hydrophilicityOther chemical processesTreatment with anaerobic digestion processesDecompositionWater processing

The invention provides a modified biocarrier used in a waste water processing anaerobic tank. The basic material is high-density polyethylene. The modified functional materials are active alumina, iron powder and coke. The auxiliary material is talcum powder. The modified biocarrier has a density of 0.93-1.05g / cm<3>, the surface is rough, the specific surface area is large, the impact resistance is strong, and falling-off of a microbial film adhering to the outer surface of the carrier caused by friction among the carriers can be prevented in water. The biocarrier has a small contact angle with sewage, the carrier hydrophilia is raised, and microorganisms are easy to adhere onto the carrier. The biocarrier contains enhanced components of biological enzymes and promotes catalytic action of biological enzymes, the biological activity is high, metabolism is rapid, and the decomposition capability of pollutants in water can be raised substantially. The biocarrier contains ultraviolet resistant components, the service life is more than 30 years, and replacing and maintenance are not needed.

Owner:大连宇都环境技术材料有限公司

Mixing device for lithium battery positive electrode or negative electrode preparation materials

ActiveCN102513015AAvoid Purity LossOmit stop feedingCombination devicesCell electrodesFluidized bedBaghouse

The invention relates to a mixing device for lithium battery positive electrode or negative electrode preparation materials. The device is mainly composed of a fluidized bed, spiral feeders, vibration motors, spiral agitating blades, a spiral agitating motor and a settling chamber. Specifically, the spiral feeders are arranged at the lower parts of the fluidized bed; the middle part of the fluidized bed is provided with the vibration motors; the upper part inside the fluidized bed is equipped with the spiral agitating blades, the top of which is in connection with the spiral agitating motor; the top of the fluidized bed is connected to the settling chamber, the inside of which is provided with a cyclone separator and bag-type dust collector that is connected to a fan outside the settling chamber; the lower end of the fluidized bed is provided with an air vent, by which fluidized air that does not react with the lithium battery positive electrode or negative electrode preparation materials is introduced, and the lower end of the settling chamber is provided with a material outlet. The device of the invention is characterized by strong mixing ability, fast speed, low energy consumption, high degree of automation, and ability of sealing operation, so that it can better adapt to the requirements of large-scale industrial production.

Owner:济宁市无界科技有限公司

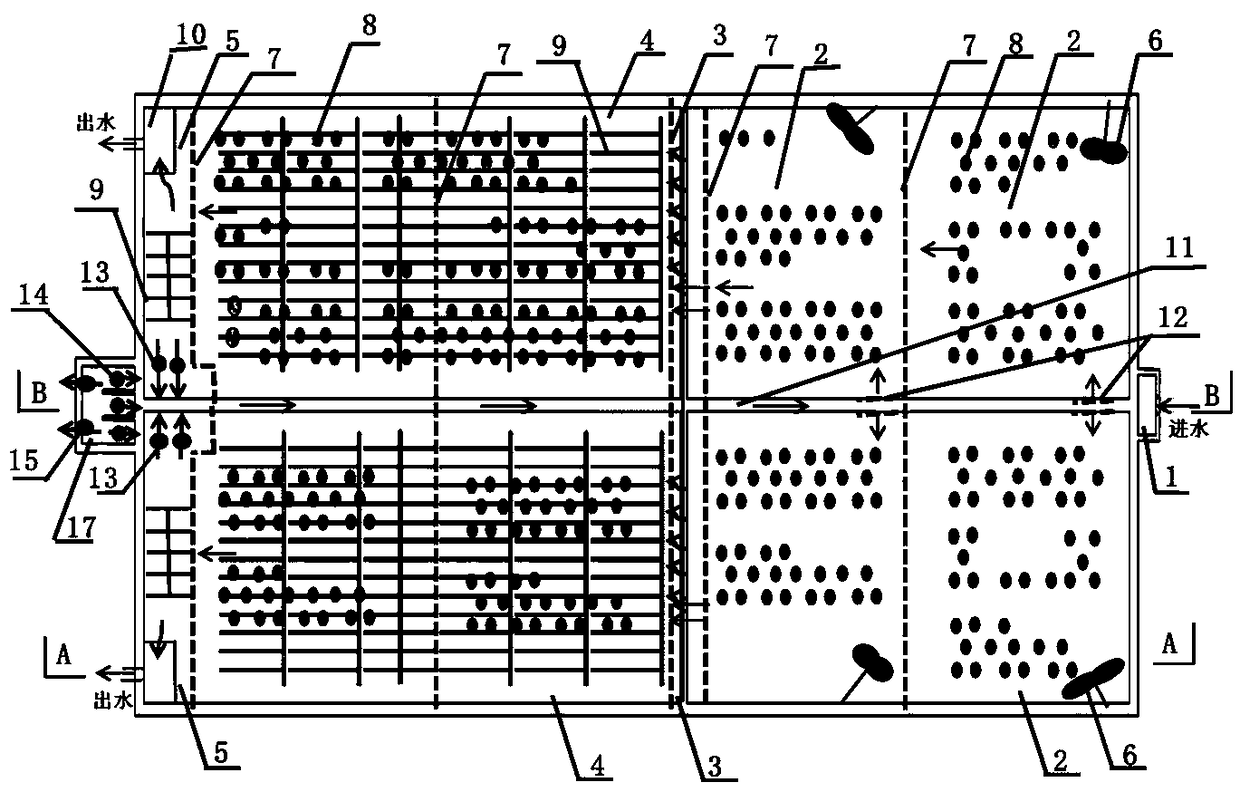

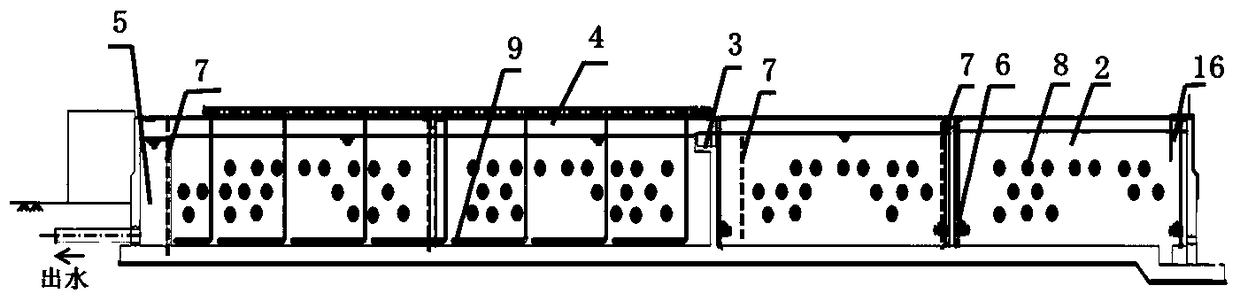

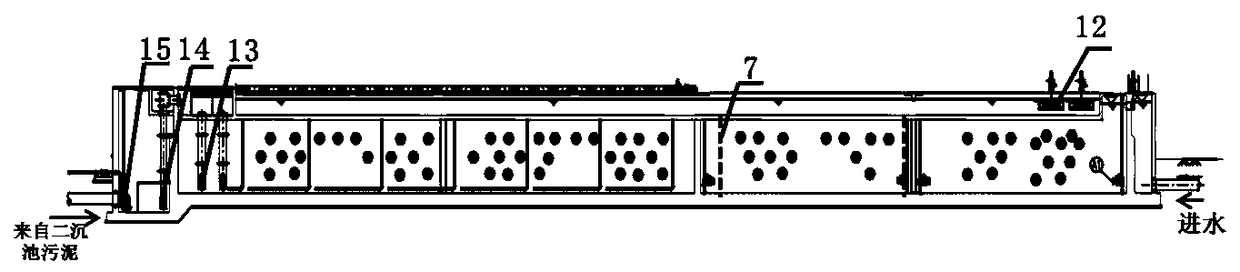

Biochemical treatment method for pharmaceutical wastewater on basis of MBBR process

PendingCN108191062APromote growthEasy to hang filmWater contaminantsBiological treatment apparatusRefluxSludge

The invention discloses a biochemical treatment method for pharmaceutical wastewater on the basis of an MBBR process and belongs to the field of industrial sewage biochemical treatment. The method involves two parallel group pools which are connected with each other and are identical in structure. Each parallel group pool comprises an MBBR anoxic zone, an MBBR aerobic zone, a sludge aerobic zone and a sludge reflux zone, wherein the MBBR anoxic zones are communicated with the MBBR aerobic zones through rectangular overflow openings in the tops of overflow partition walls, stirrers are arrangedon the inner side walls of the MBBR anoxic zones, and two suspension carrier intercepting screen meshes used for the MBBR process are arranged along the entire cross sections of the MBBR anoxic zones; the MBBR aerobic zones are communicated with the sludge aerobic zones through the intercepting screen meshed arranged along the entire cross sections of the MBBR aerobic zones. One sides of the sludge aerobic zones are provided with overflow and outflow channels; holes are formed in the outer walls of the middles of the two parallel group pools and communicated with the sludge reflux zones. According to the method, deep denitrification treatment can be carried out on the pharmaceutical wastewater with relatively low content of carbon and nitrogen so that the quality of effluent water can reach the standards stably.

Owner:济宁市孚源环保科技有限公司

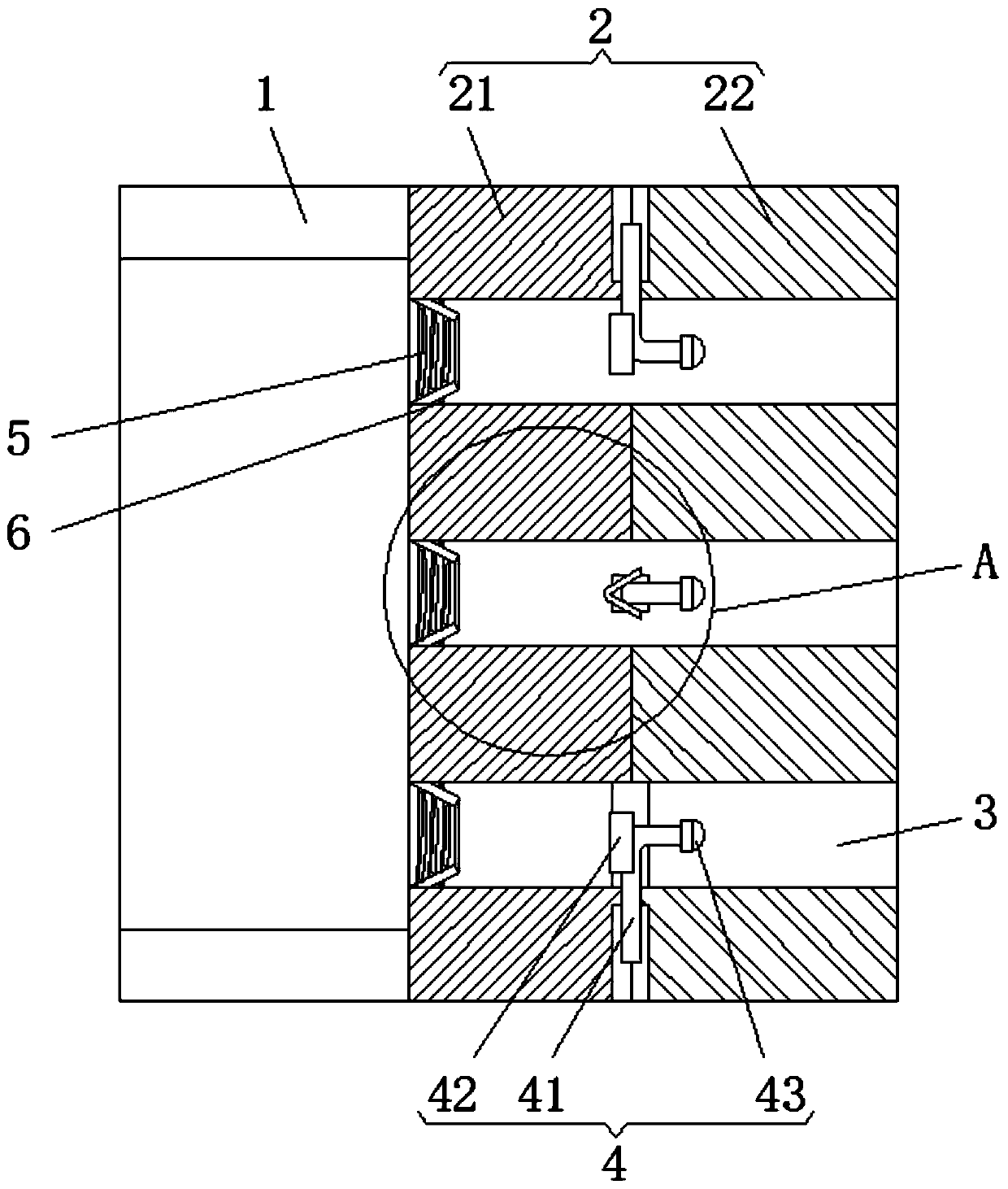

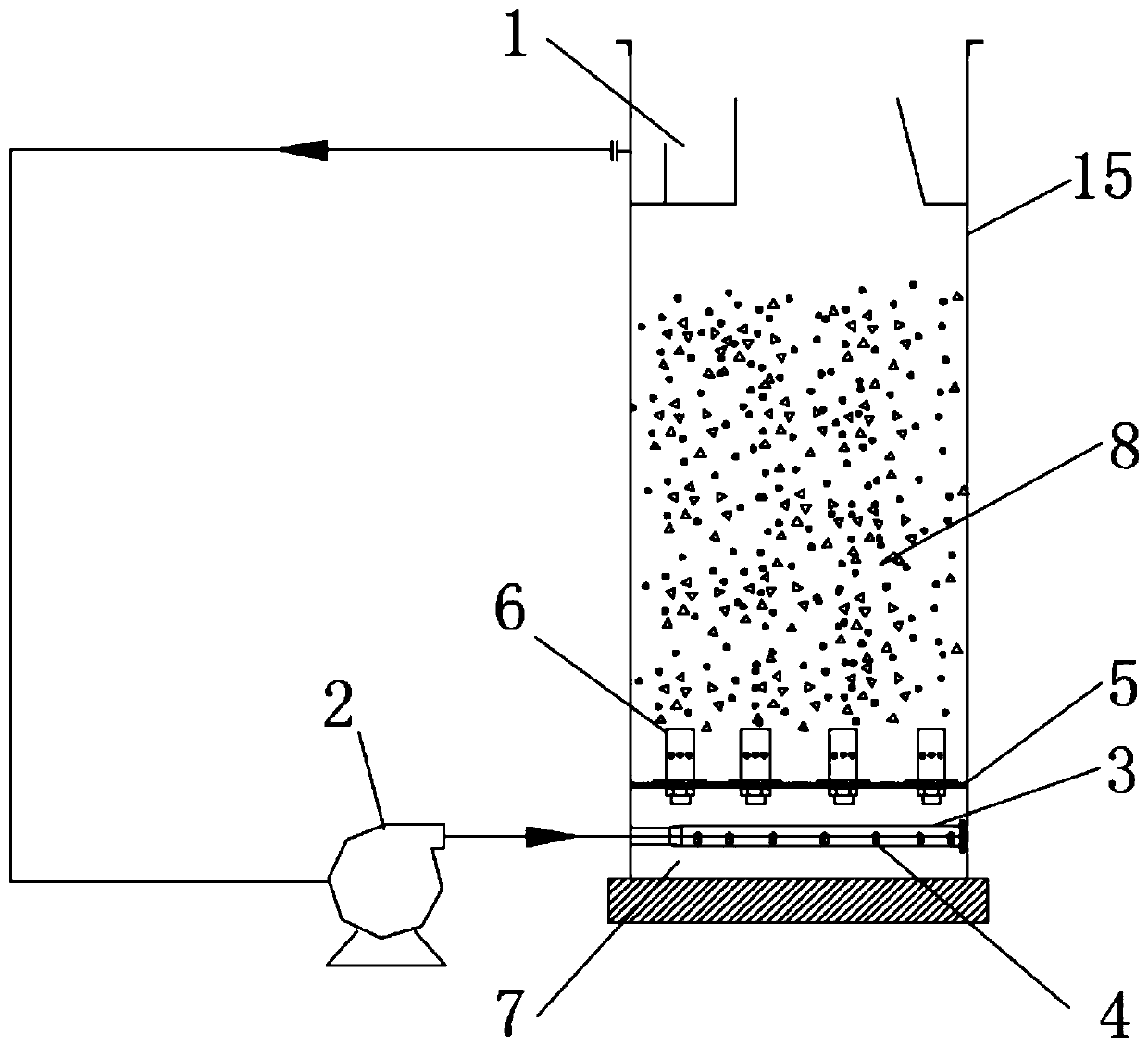

Water distribution system for tower-type fluidized bed reactor

PendingCN111573823AReduce resistanceEvenly distributedBiological treatment apparatusDistribution systemEngineering

The invention discloses a water distribution system for a tower type fluidized bed reactor, comprising a fluidized bed reactor body, a water distribution system and a backflow system. A supporting plate is arranged at the lower part of the fluidized bed reactor body, and the interior of the fluidized bed reactor body is divided into an upper fluidization area and a bottom water distribution area by the supporting plate. A plurality of water distributors which are uniformly arranged at intervals are mounted on the supporting plate, each water distributor comprises a water distributor water inlet pipe and a water distributor head which are integrally formed, the water distributor water inlet pipes are located in the water distribution area, and the water distributor heads are located in thefluidization area. A backflow water outlet groove is formed in the top of the fluidized bed reactor body and communicated with the water distribution system through the backflow system. Inlet water ofthe fluidized bed system and added chemicals of the fluidized bed system are conveyed to the water distribution area through the backflow system to be mixed and then enter the fluidization area through the water distributors after being evenly mixed, and the water distribution system is even in water distribution, not prone to blockage and capable of adapting to fluidized beds of various diameters.

Owner:NANJING BALANCE ENVIRONMENTAL TECH CO LTD

Slag discharging device of biomass circulating fluidized bed boiler

ActiveCN106287686AReduced head wearReduce invalid pressure lossFluidized bed combustionApparatus for fluidised bed combustionSlagCirculating fluidized bed boiler

The invention discloses a slag discharging device of a biomass circulating fluidized bed boiler. The slag discharging device of the biomass circulating fluidized bed boiler comprises a combustion chamber, wherein a boiler-front feeding device is connected above the combustion chamber, a large slag discharging pipe and a disintegrating slag discharging pipe are arranged below the combustion chamber, a horizontal plate is arranged on one side of the bottom of the combustion chamber, a single V-shaped screening bucket is arranged on the other side of the bottom of the combustion chamber, and located at the inclined lower part of the horizontal plate, the large slag discharging pipe is communicated with the single V-shaped screening bucket, the disintegrating slag discharging pipe is communicated with the horizontal plate, and a rotating vortex device is arranged in the single V-shaped screening bucket. The slag discharging device of the biomass circulating fluidized bed boiler has the advantages of capability of solving the problems of bad fuel adaptability, unsmooth slag discharging and the like caused by massive inert materials doped in a variety of biomass and fuel combusted by the biomass fuel circulating fluidized bed boiler, and the technical advantages of uniform air distribution, efficient fuel combustion, small abrasion of a heating surface, good equipment economy and high reliability.

Owner:HANGZHOU BOILER GRP CO LTD

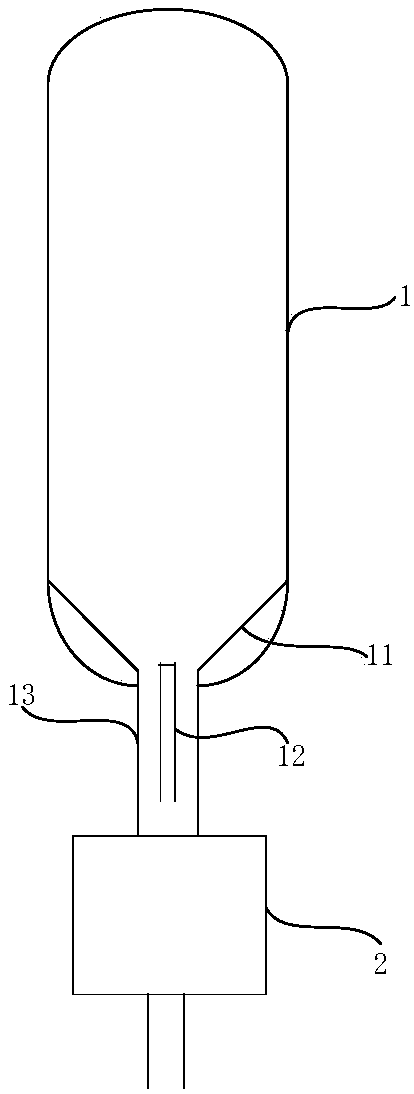

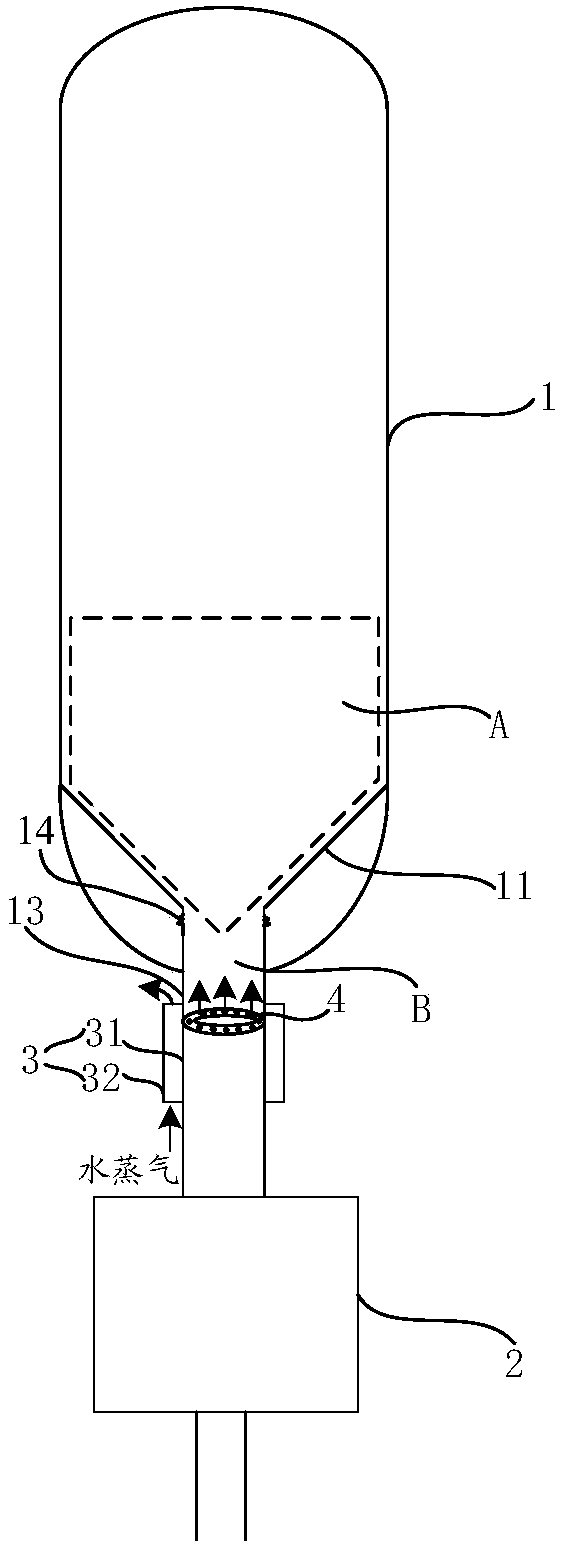

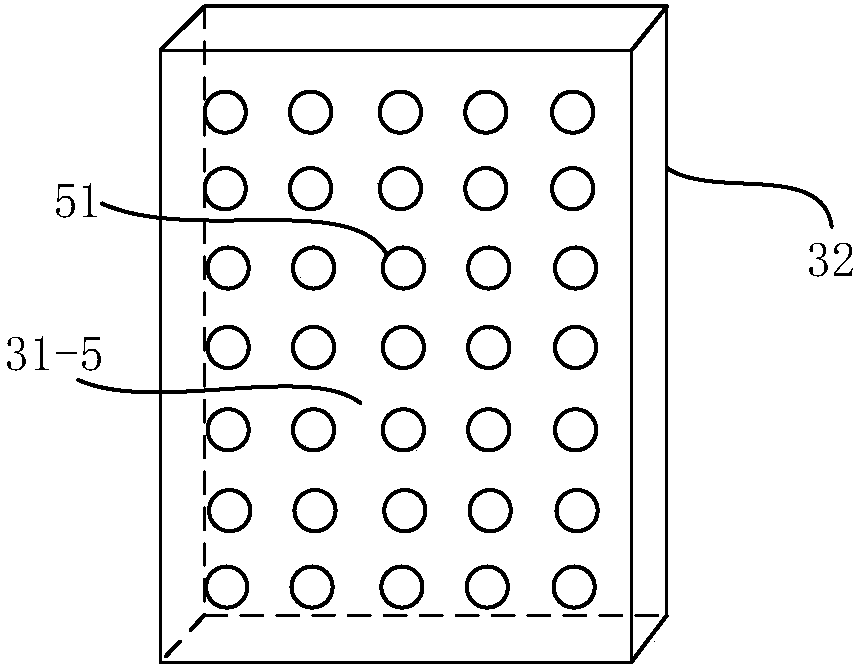

Voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking

ActiveCN109305564AThe feeding process is controllablePrevent blowbackBulk conveyorsAutomatic controlBiomass

The invention relates to a voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking, and belongs to the technical field of biomass thermal cracking. The voltagestabilization-continuous pneumatic conveying feeding system comprises a material transition bin, a conical pressure bin, a material receiving chamber and the like. A dual-material bin and a double butterfly valve design are adopted by the feeding system, so that the effects of pressure isolation, air locking and environment sealing are achieved, the feeding process is controllable, the phenomenonthat materials are reversely sprayed is avoided, and the reliability and the stability of the thermal cracking process are improved. A laser-photosensitive sensor and a PLC are used as an automatic control system, a two-stage electric butterfly valve is adopted as an execution component, and the materials automatically fall into the conical pressure bin from the material transition bin. Aerationair is added into the conical section of the conical pressure bin, and the materials in the conical pressure bin are fluidized, so that the phenomena of bridging, wall hanging and material bursting are avoided. Thermal cracking by-product non-condensable gas generated by biomass rapid thermal cracking which serves as spraying, pressurization and pressure maintaining gas is adopted by the feeding system, so that resources can be saved, self-powered energy is achieved, and pollution is avoided.

Owner:BEIJING FORESTRY UNIVERSITY

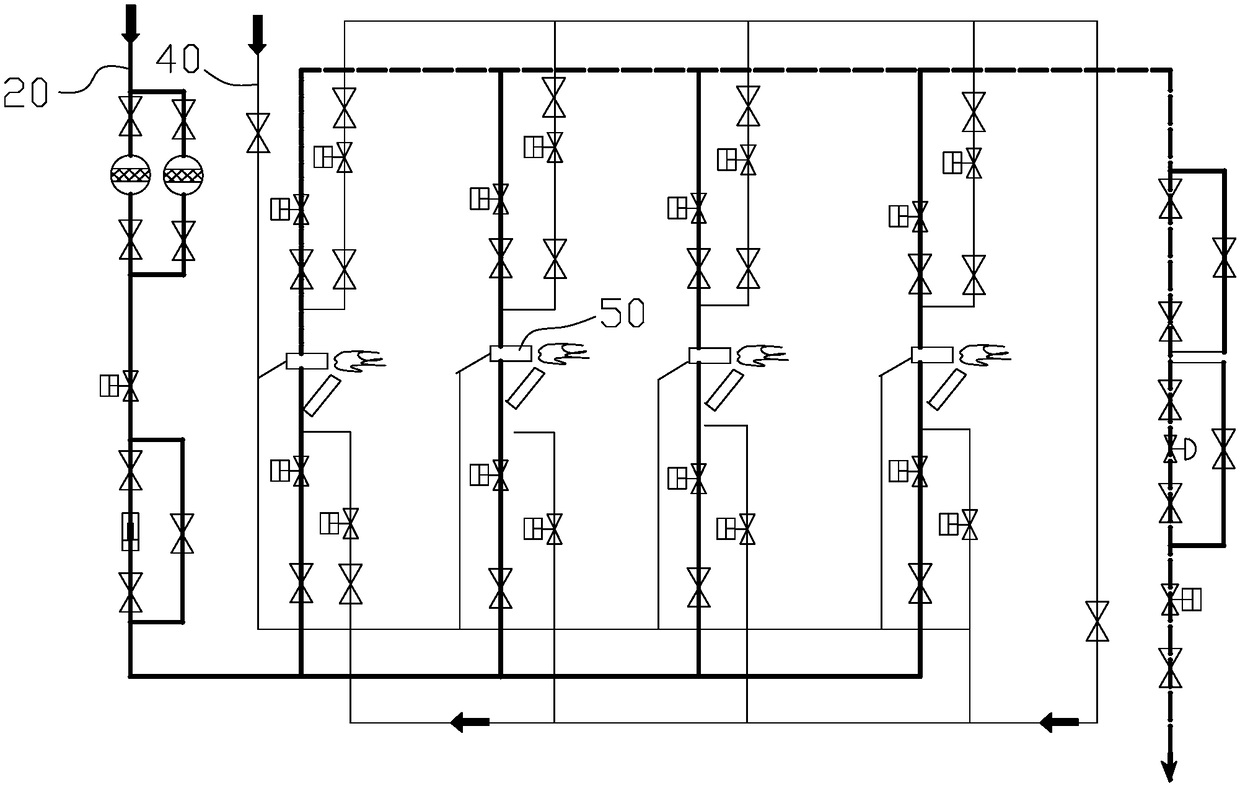

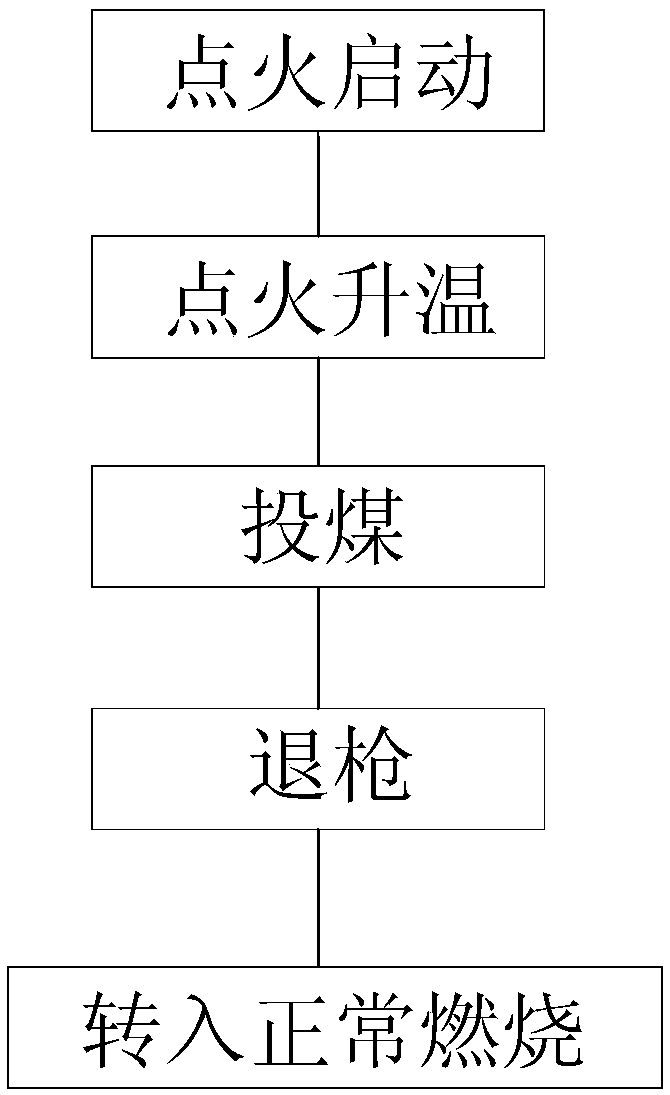

Ignition method for circulating fluidized bed boiler

ActiveCN109140431AUniform fluidizationHeating evenlyFluidized bed combustionCombustion ignitionTO-18Cold air

The invention provides an ignition method for a circulating fluidized bed boiler. In the ignition start, the thickness of a bed material is 60-80 cm, a primary air volume is adjusted to 24-260,000 Nm3 / h to ensure uniform fluidization of the bed material, after the fluidization of the bed material is uniform, the primary air volume is gradually reduced to 18,200,000 Nm3 / h, so that the bed materialis in the bubbling bed state, an ignition oil pressure is adjusted to 1.2-1.4MPa, and an ignition oil gun with a flow rate of 1200kg / h is used for igniting; during the ignition heating process, more than 90% of primary air is heated by the ignition oil gun to reduce cold air entering a furnace to not cool the bed material; when the bed temperature rises to 420-440 DEG C, pulse coal injecting is conducted; when the bed temperature rises to 620-650 DEG C, the oil gun is gradually withdrawn, and after the combustion is stabilized, the primary air volume is adjusted to be no less than 240,000 Nm3 / h to ensure normal fluidization of the bed material; when the bed temperature reaches 680-700 DEG C, coals are continuously injected, and normal combustion is entered. The ignition method can reduce the amount of fuels required for ignition.

Owner:百色百矿发电有限公司

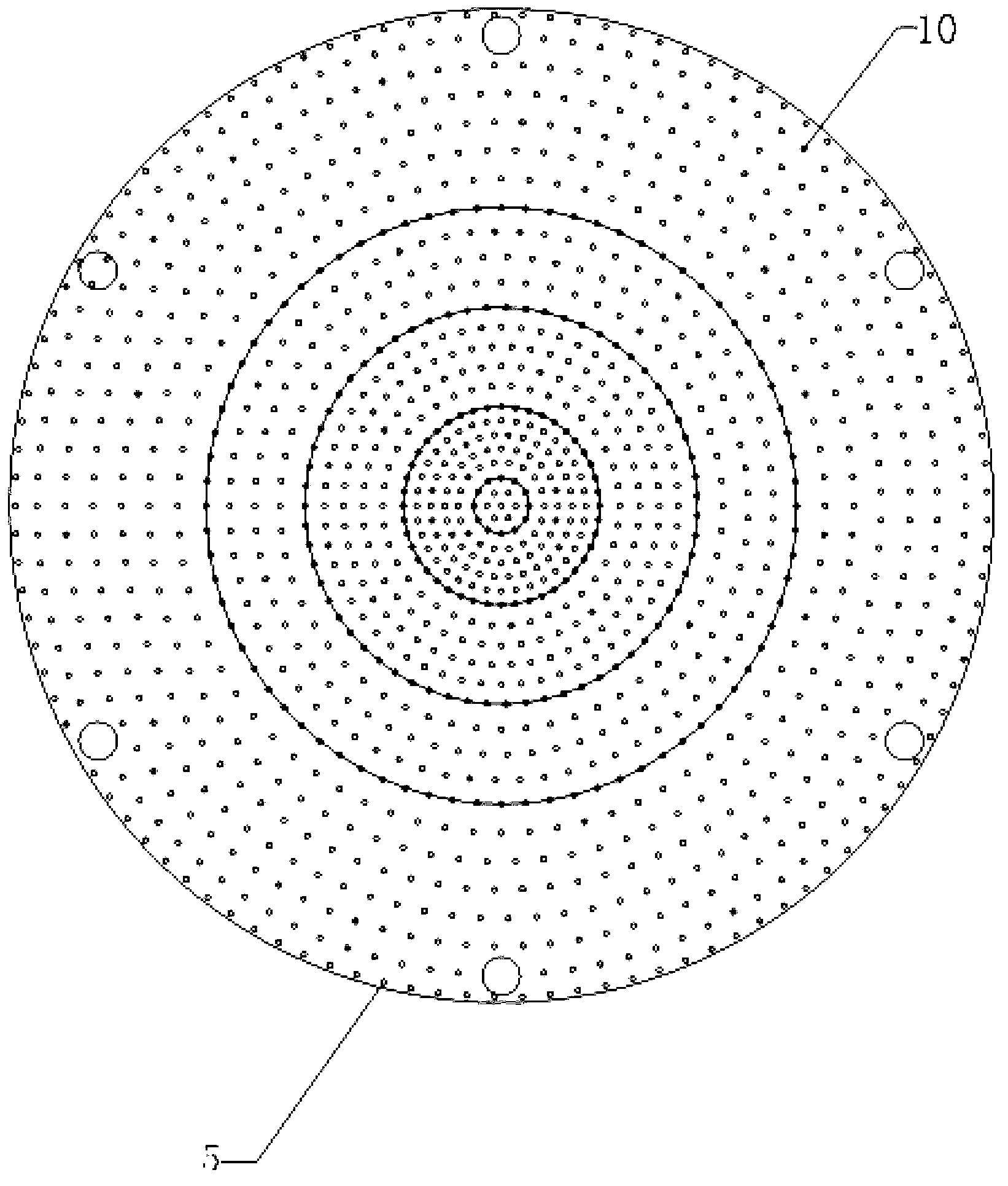

Air distribution structure of circulating fluidized bed boiler

InactiveCN106439799AIncrease air volumeEasy to cokeFluidized bed combustionApparatus for fluidised bed combustionCombustionSlag

The invention relates to the technical field of circulating fluidized bed boilers, in particular to an air distribution structure of a circulating fluidized bed boiler. By adoption of the air distribution structure of the circulating fluidized bed boiler, uniform fluidization of a bed layer can be achieved, the combustion efficiency is improved, and safe operation of the boiler is guaranteed. The air distribution structure of the circulating fluidized bed boiler comprises an air distribution plate. Connecting pipes penetrating through the air distribution plate are mounted on the air distribution plate. Air caps are mounted on the upper sections of the connecting pipes. Holes communicating with the air caps are formed in the connecting pipes. The air distribution structure of the circulating fluidized bed boiler is characterized in that the air distribution plate is divided into a central area and an edge wall area, and the edge wall area surrounds the central area; the aperture ratio of the portion, located in the edge wall area, of each connecting pipe is larger than that of the portion, located in the central area, of the connecting pipe; hole areas are arranged in the central area; each hole area comprises a slag falling pipe, and connecting pipes which are the same as the connecting pipes in the edge wall area are arranged around each slag falling pipe.

Owner:WUXI HUAGUANG BOILER

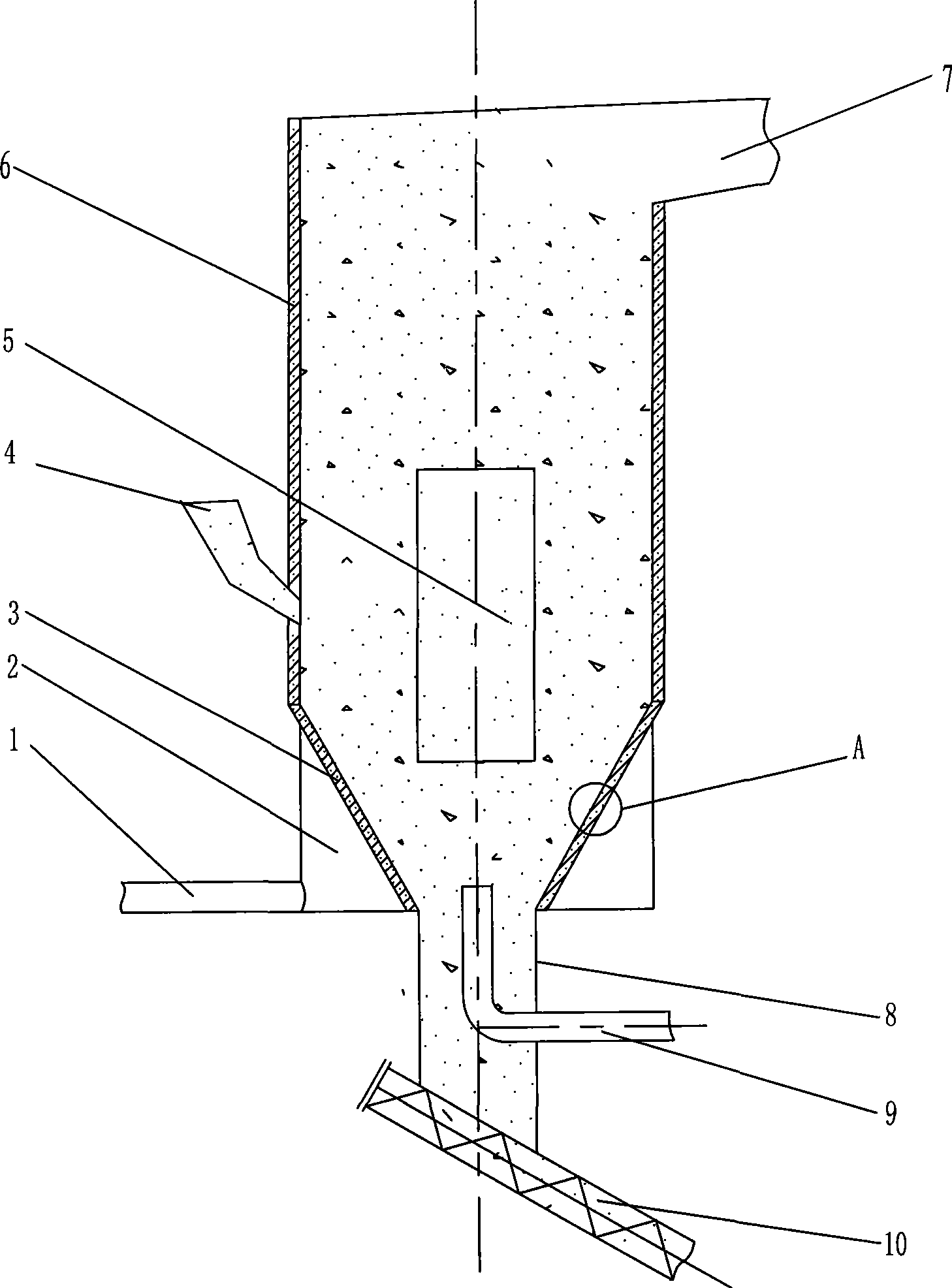

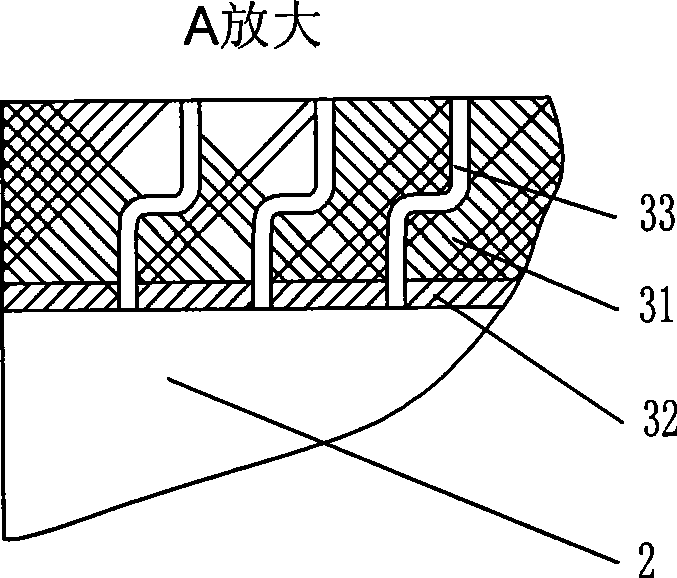

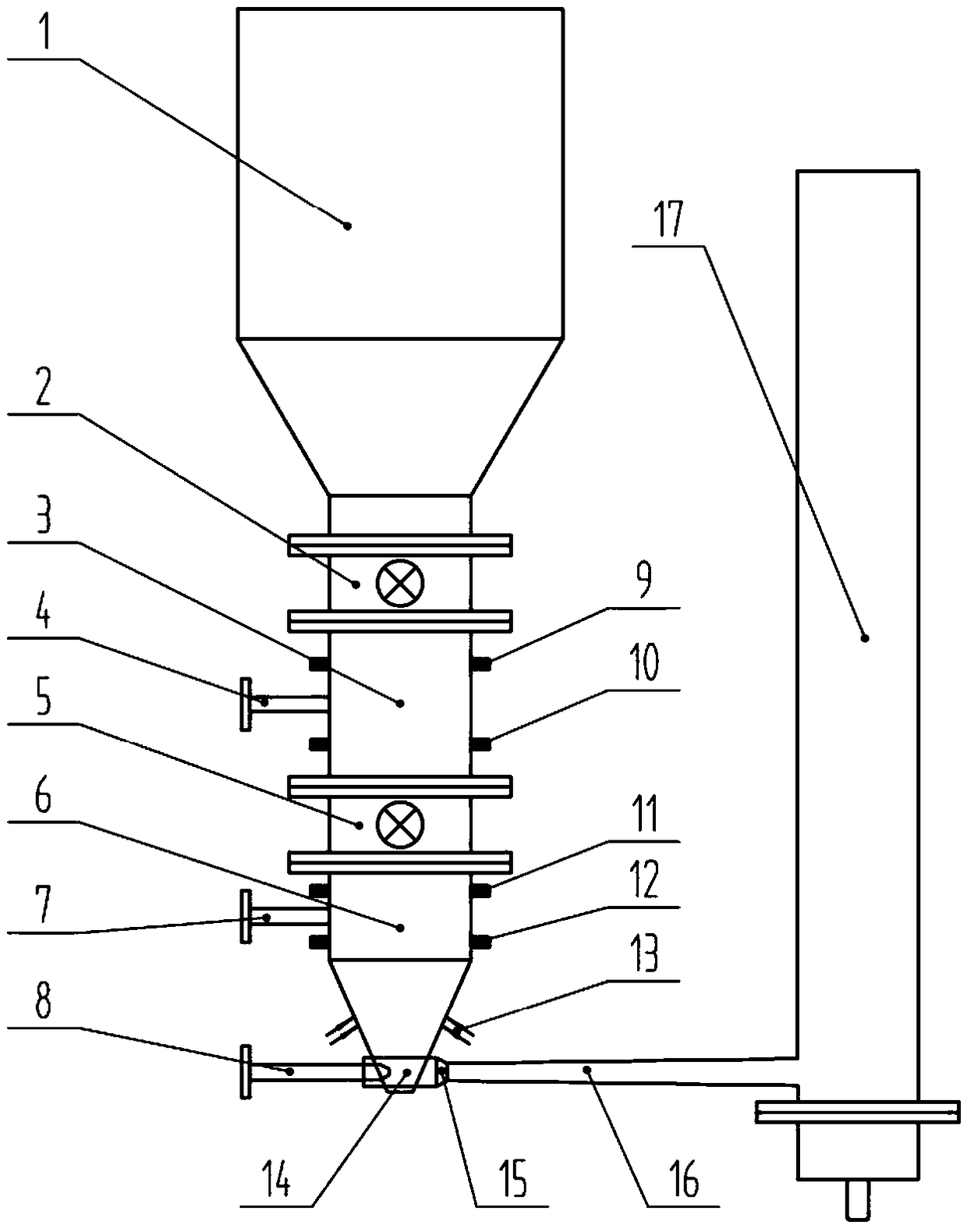

A lignite drying method and drying equipment utilizing power plant flue gas and steam waste heat

ActiveCN106382790BImprove economyImprove operational efficiencyDrying solid materials with heatDrying gas arrangementsBrown coalFlue gas

The invention discloses a brown coal drying method and device utilizing waste heat of smoke and steam of a power plant. The drying method comprises two-time drying treatment, wherein the two-time drying treatment comprises the steps that firstly, the high-temperature smoke directly discharged by a power plant coal fired boiler is utilized for conducting first-time drying treatment on damp materials, the high-temperature smoke directly makes uniform contact with the damp materials, and intermediate materials are obtained; and secondly, the high-temperature smoke and the high-temperature steam directly discharged by the power plant coal fired boiler are utilized for conducting second-time drying treatment on the intermediate materials at the same time, the high-temperature smoke directly makes uniform contact with the intermediate materials, meanwhile, the intermediate materials make uniform contact with a heat exchange pipe inflated with the steam for heat exchange, dried materials are obtained, and second-time drying treatment is achieved. The brown coal drying method and device have the beneficial effects that the power plant waste heat serves as a heat source for brown coal drying, the running economical efficiency of a power plant generator set is improved, a system for drying the brown coal and a brown coal power generation system are integrated, efficient utilization of power plant energy and optimization of a technology system are achieved, and the brown coal drying method and device belong to the poly-generation technology of the power plant.

Owner:邹平双飞成套设备有限公司

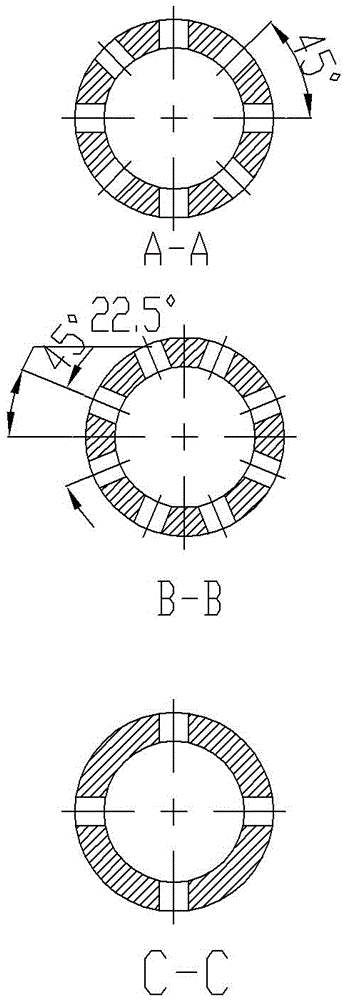

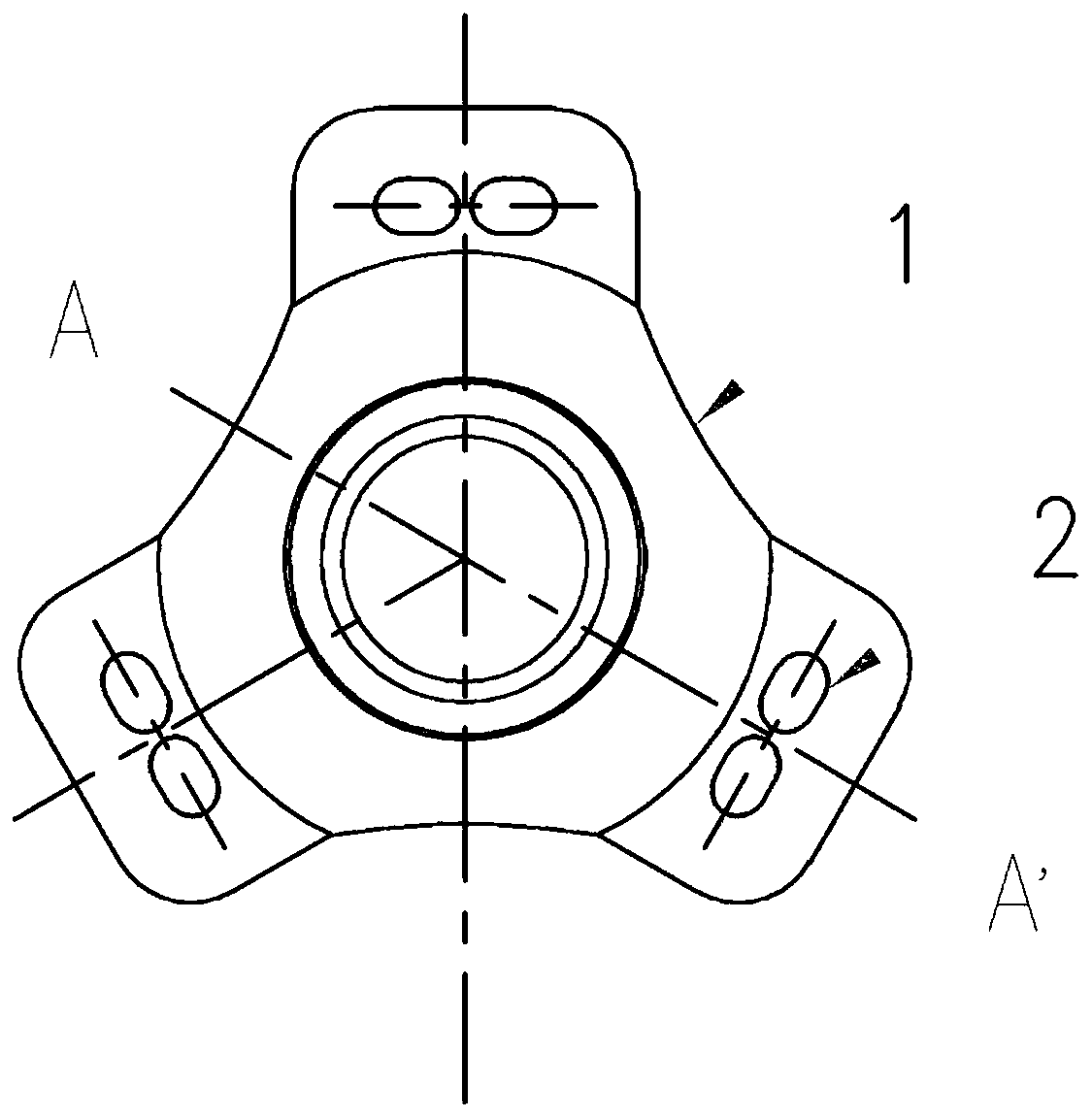

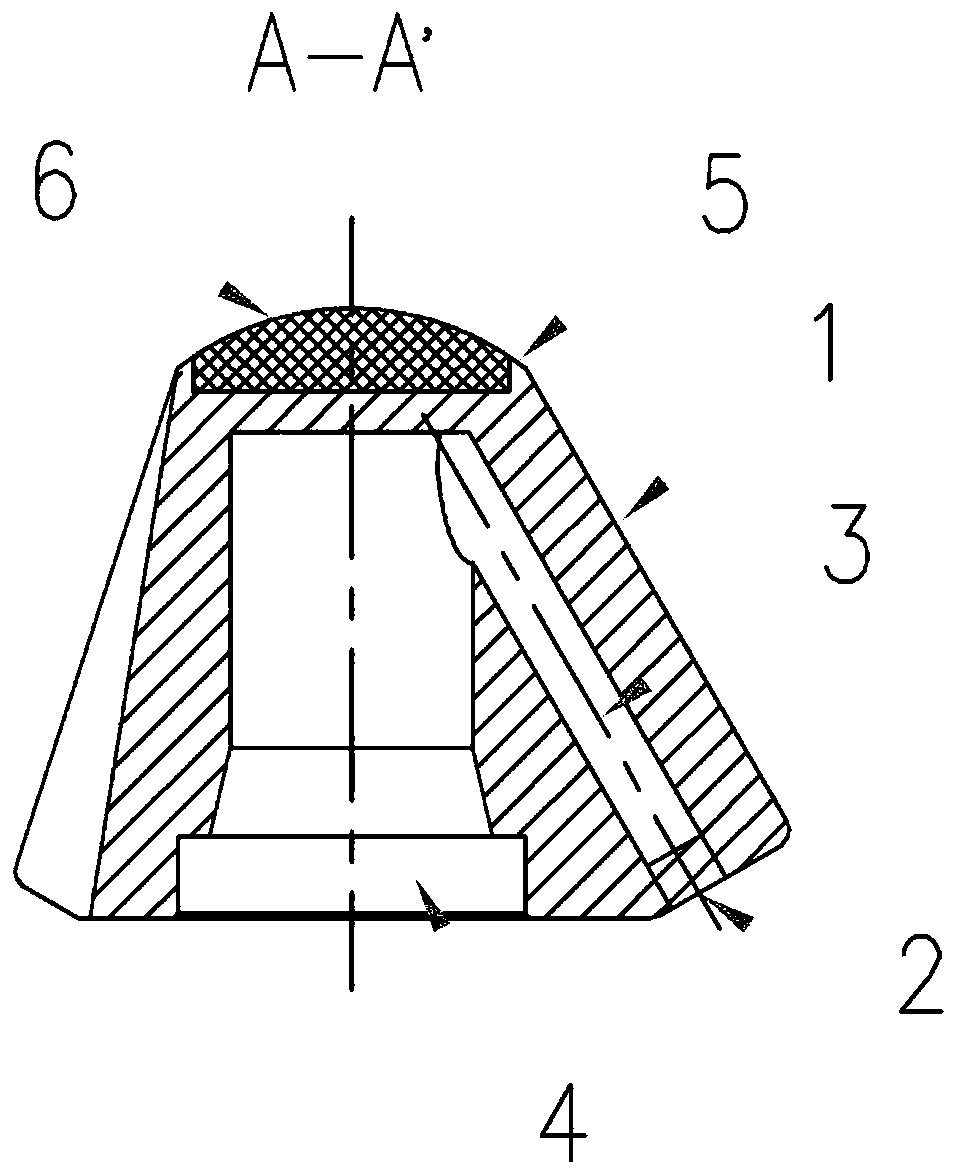

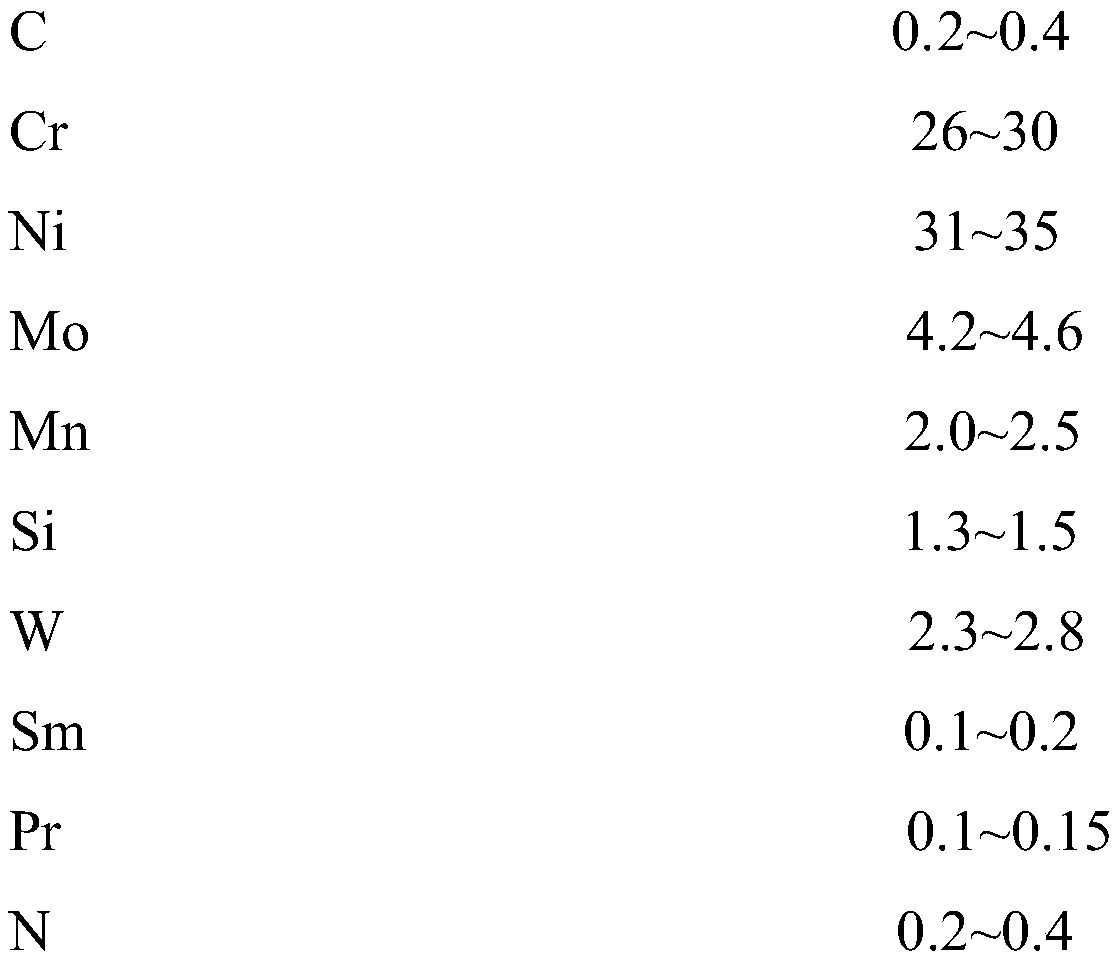

Slag-leakage-preventing air cap, preparation method thereof and circulating fluidized bed boiler

ActiveCN109869715ASimple structureSimple materialFluidized bed combustionMolten spray coatingCylindrical channelComposite ceramic

The invention discloses a slag-leakage-preventing air cap, a preparation method thereof, and a circulating fluidized bed boiler, and belongs to the field of alloy air caps. The slag-leakage-preventingair cap comprises an air cap body, an air inlet duct located in the air cap body, and one or more air outlet ducts communicating with the air inlet duct; the top of the air cap body is provided witha U-shaped structure comprising a causeway and a composite ceramic body inlaid in the causeway; the air inlet duct is a cylindrical channel; the air outlet ducts are flat conical channels and gradually become small in the direction from inlets to outlets; the air outlets of the air outlet ducts are each of an oval double-hole structure; and the included angle alpha between the air outlet directionof the air outlet ducts and the air inlet direction of the air inlet duct is 45-75 degrees. The prepared slag-leakage-preventing air cap has the advantages that slag leakage is effectively prevented,abrasion of the air outlets and the top is relieved, fluidizing is uniform, rotary bias flows and abnormal abrasion are avoided, and the service life is greatly prolonged.

Owner:刘沁昱

Novel ignition mode application of 300MW circulating fluidized bed boiler

InactiveCN110848670AReduce heat lossReduce starting fuel consumptionFluidized bed combustionCombustion ignitionPhysicsCirculating fluidized bed boiler

The invention discloses novel ignition mode application of a 300MW circulating fluidized bed boiler. Current domestic earliest 300MW circulating fluidized bed boiler units have gone into operation formany years, and due to the fact that fire coal quality is poor and fire coal is prone to being ignited, starting oil consumption of the units is high. The novel ignition mode application is characterized in that only a primary fan is started at the initial stage of ignition, other fans are shut down, and the primary air volume is adjusted, so that the boiler is in a micro bubble state. Accordingto the novel ignition mode, (1) the proper bed thickness and grain size are confirmed, wherein the material layer thickness is controlled to range from 800 mm to 900 mm; (2) cold state fluidization testing is carried out before starting, wherein bed materials are fed before the circulating fluidized bed boiler is started every time, the bed materials are conveyed into a hearth through a scraping plate coal feeder by starting a bed material system, and fluidization testing of the bed materials is carried out; (3) the temperature before ignition of the boiler is improved, wherein the pressure ofa heating heat source can be improved to 3.9 MPa from 0.8 MPa; (4) heat losses during oil feed are reduced, wherein the outlet pressure of a hearth is adjusted to range from 50 Pa to 100 Pa through an inlet and outlet valve of an induced draft fan; and (5) the proper bed temperature is selected to feed coal correctly. The novel ignition mode application of the 300MW circulating fluidized bed boiler is achieved.

Owner:大唐鸡西第二热电有限公司

Coal variable-amplitude vibration fluidized bed drying and sorting system and sorting method

ActiveCN109731667AConvey evenlyStable deliveryDrying solid materials with heatPneumatic tablesVibration amplitudeFluidized bed drying

The invention relates to a coal variable-amplitude vibration fluidized bed drying and sorting system and a sorting method and belongs to the technical field of coal drying and sorting devices. The coal variable-amplitude vibration fluidized bed drying and sorting system is used for solving the technical problem that an existing coal drying device is poor in drying effect, and the sorting efficiency is difficult to improve. The drying and sorting system comprises a drying and sorting unit, an air supply unit, a feeding unit, a discharging unit, an induced draft dust-removing unit and a supporting unit. The air supply unit and the induced draft dust-removing unit are connected with the bottom and the top of the drying and sorting unit correspondingly. The supporting unit is used for supporting the drying and sorting unit. The drying and sorting unit is internally provided with a dividing plate and is divided into a drying section bed body and a sorting section bed body, wherein the top of the drying section bed body and the top of the sorting section bed body are provided with a drying section vibration exciting device and a sorting section vibration exciting device correspondingly,and the vibration amplitude of the drying section vibration exciting device is larger than that of the sorting section vibration exciting device. The coal variable-amplitude vibration fluidized bed drying and sorting system achieves integration of drying and sorting and has the characteristics of a good drying effect, high sorting efficiency, low cost, wide application range, convenient operationand the like.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com