Arranging method of layered fluidization air distribution plate of fluidized bed boiler

A technology of fluidized bed boiler and layout method, which is applied to fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc., can solve the complex design and manufacture of furnace water wall, difficult to control the bed pressure balance, and affect the safe operation of the boiler. and other problems, to achieve the effect of improving combustion efficiency and pollutant control ability, improving mixed working conditions, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

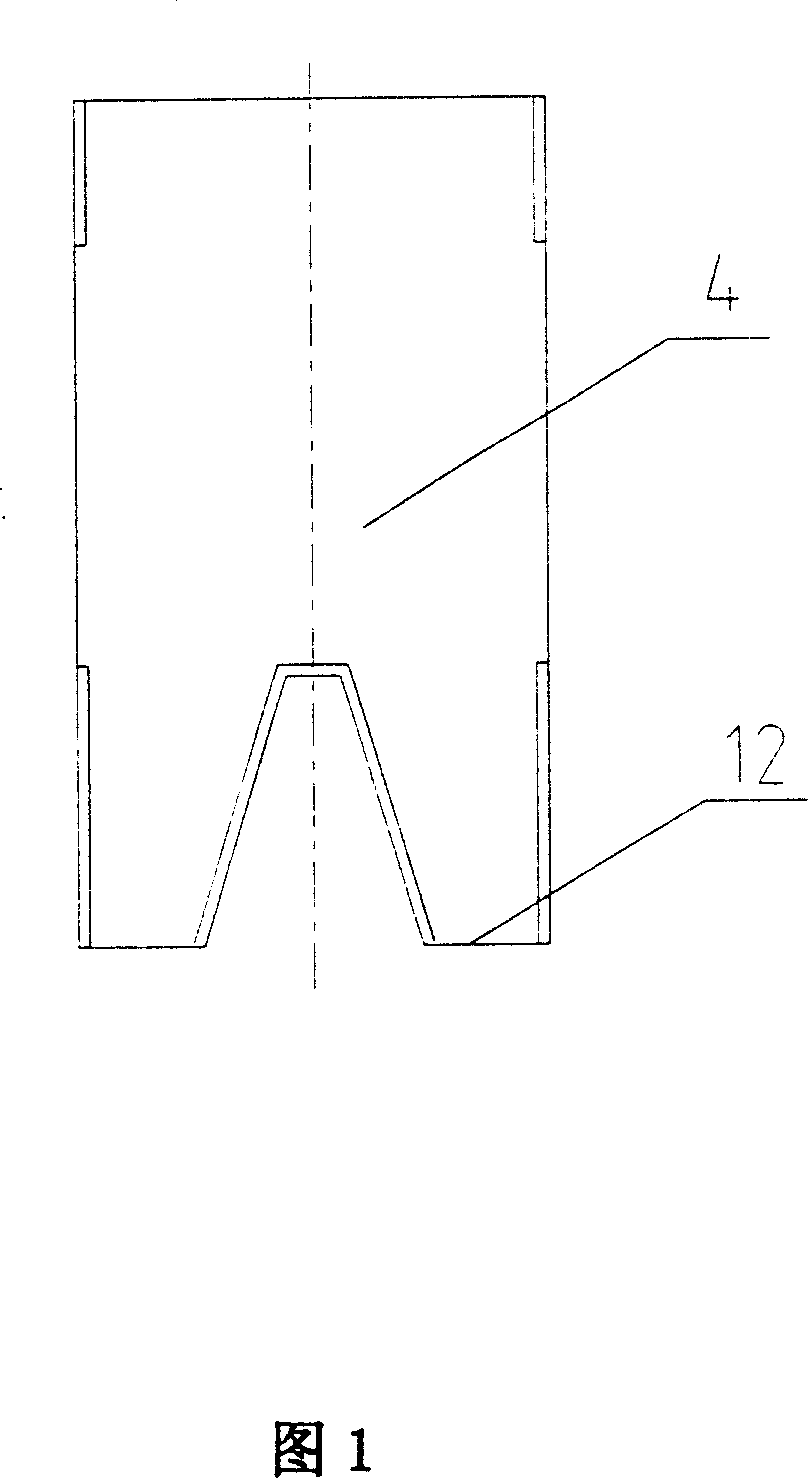

[0025] As shown in Figure 2, it is a schematic diagram of the arrangement method of the stratified fluidized air distribution plate of the fluidized bed boiler. A method of arranging the air distribution plate at the bottom of the fluidized bed boiler adopts a layered arrangement to realize the classification of the circulating fluidized bed boiler The method of adding fuel, staged air supply and staged combustion is as follows:

[0026] Step 1. Install three air distribution panels 1, 2 and 3 at the bottom of the boiler furnace 4. The air distribution panel 1 is installed at the bottom of the boiler furnace 4, which is an inverted trapezoidal or rectangular lower air distribution panel layer. , install the air distribution plate 2 and the air distribution plate 3 symmetrically on both sides of the upper part of the air distribution plate 1, and communicate with the two sides of the air distribution plate 1 to form an inverted trapezoidal upper air distribution plate layer, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com