A heating electrode process and device for spraying powder in electric arc furnace

A technology for heating electrodes and electric arc furnaces, applied in the field of electric arc furnace smelting, to achieve the effects of shortening the operation cycle of a single furnace, saving power consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

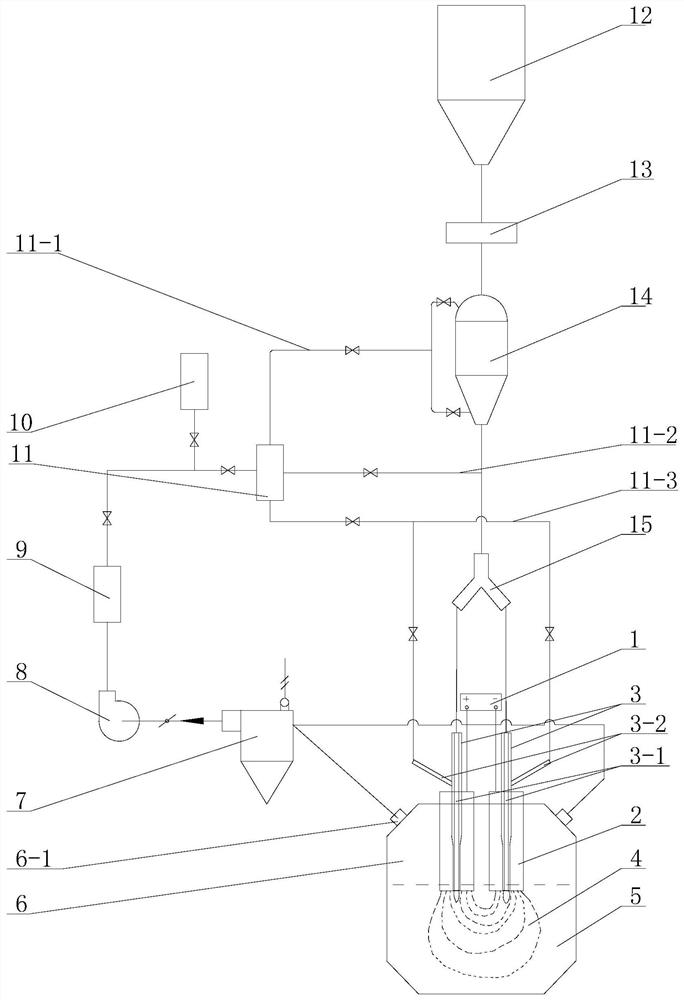

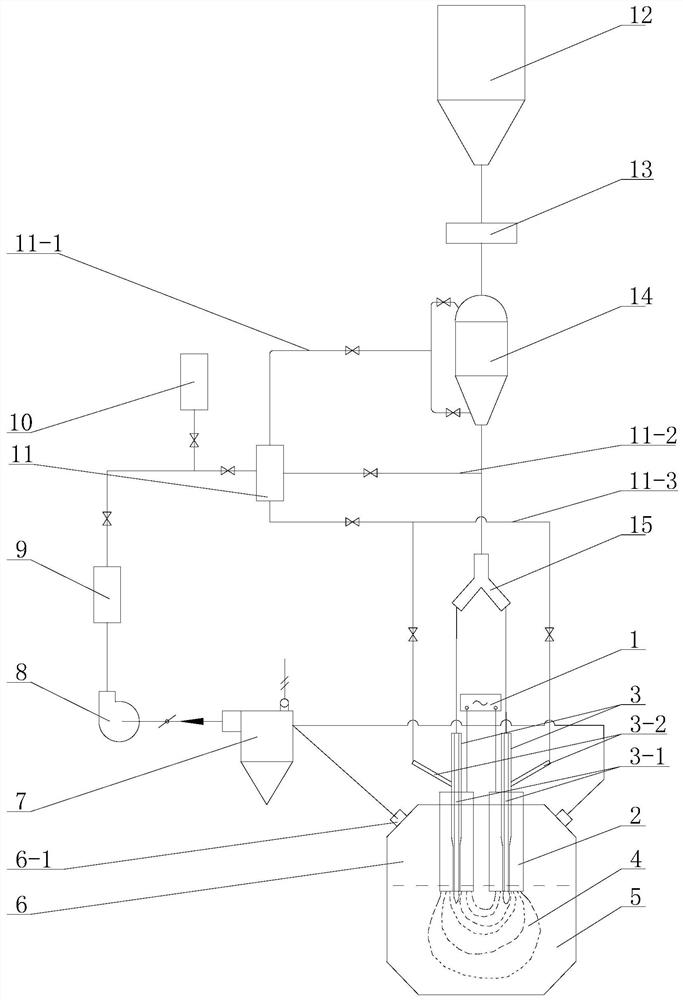

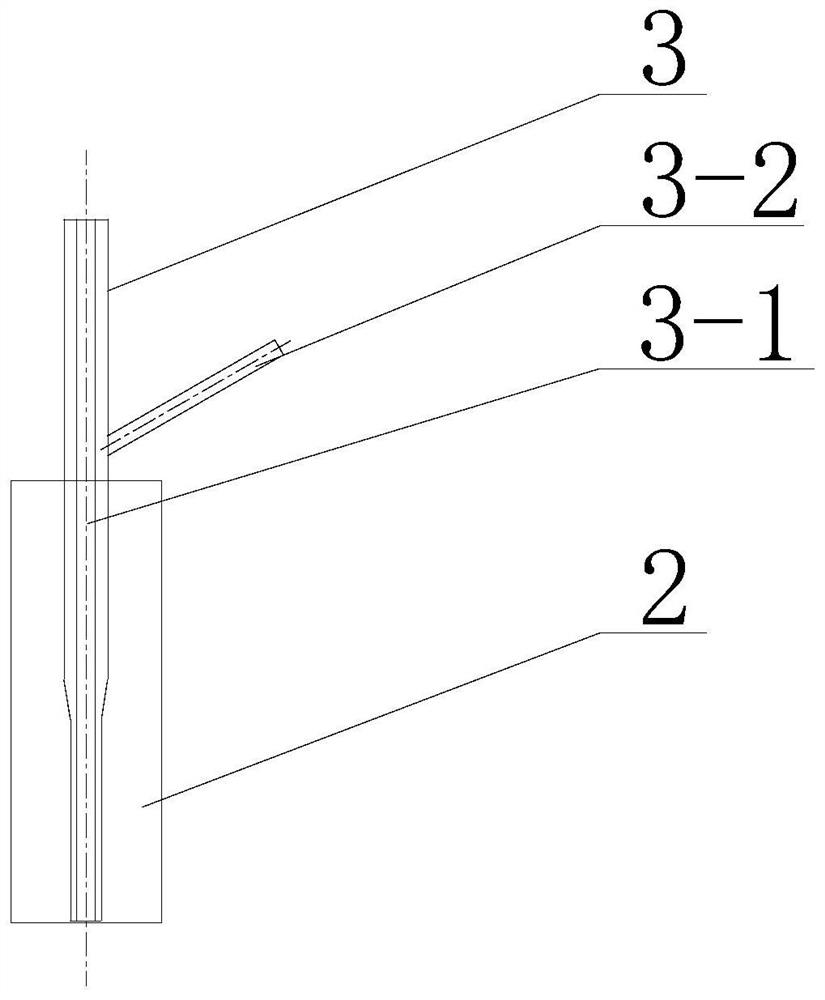

[0059] like figure 1 As shown, a double top electrode DC electric arc furnace can spray powder heating electrode process and device, which is used for smelting reduction and smelting of metallurgical waste slag. like image 3 and 4 As shown, the graphite electrode 2 is a hollow electrode, and a powder spray gun 3 is inserted in the middle. The powder spray gun 3 is divided into two layers: inner and outer layers, wherein the inner layer is the central channel 3-1, which is used for injecting the reducing agent pulverized coal, and the outer layer is the annular channel 3 -2, it is used to blow protective gas nitrogen and assist in blowing the reducing agent pulverized coal. The double-electrode discharge heats the metallurgical waste slag in the electric arc furnace. The high-temperature electric arc melts the solid metallurgical waste slag and forms a molten pool. The arc forms a strong stirring force. The injected reducing agent pulverized coal is dispersed into the entire...

Embodiment 2

[0063] like figure 2 As shown, a double top electrode ladle refining furnace can spray a heating electrode process and a device for tempering agent, which is used for the refining of molten steel. like image 3 and 4 As shown, the graphite electrode 2 is a hollow electrode, and a powder spray gun 3 is inserted in the middle. The powder spray gun 3 is divided into two layers: inner and outer layers, wherein the inner layer is the central channel 3-1, which is used for spraying the conditioning agent quicklime, and the outer layer is the annular channel 3 -2, It is used for spraying protective gas nitrogen and assisting in blowing the conditioning agent quicklime. The double electrode discharge heats the molten steel in the ladle refining furnace, and the high-temperature electric arc forms a strong stirring force. The quicklime is sprayed into the entire molten pool with the arc stirring, and the high-temperature chemical reaction with the molten steel is completed, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com