Water distribution system for tower-type fluidized bed reactor

A fluidized bed reactor, water distribution system technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Production and processing accuracy requirements are very high and other problems, to achieve the effect of reducing water distribution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, and the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

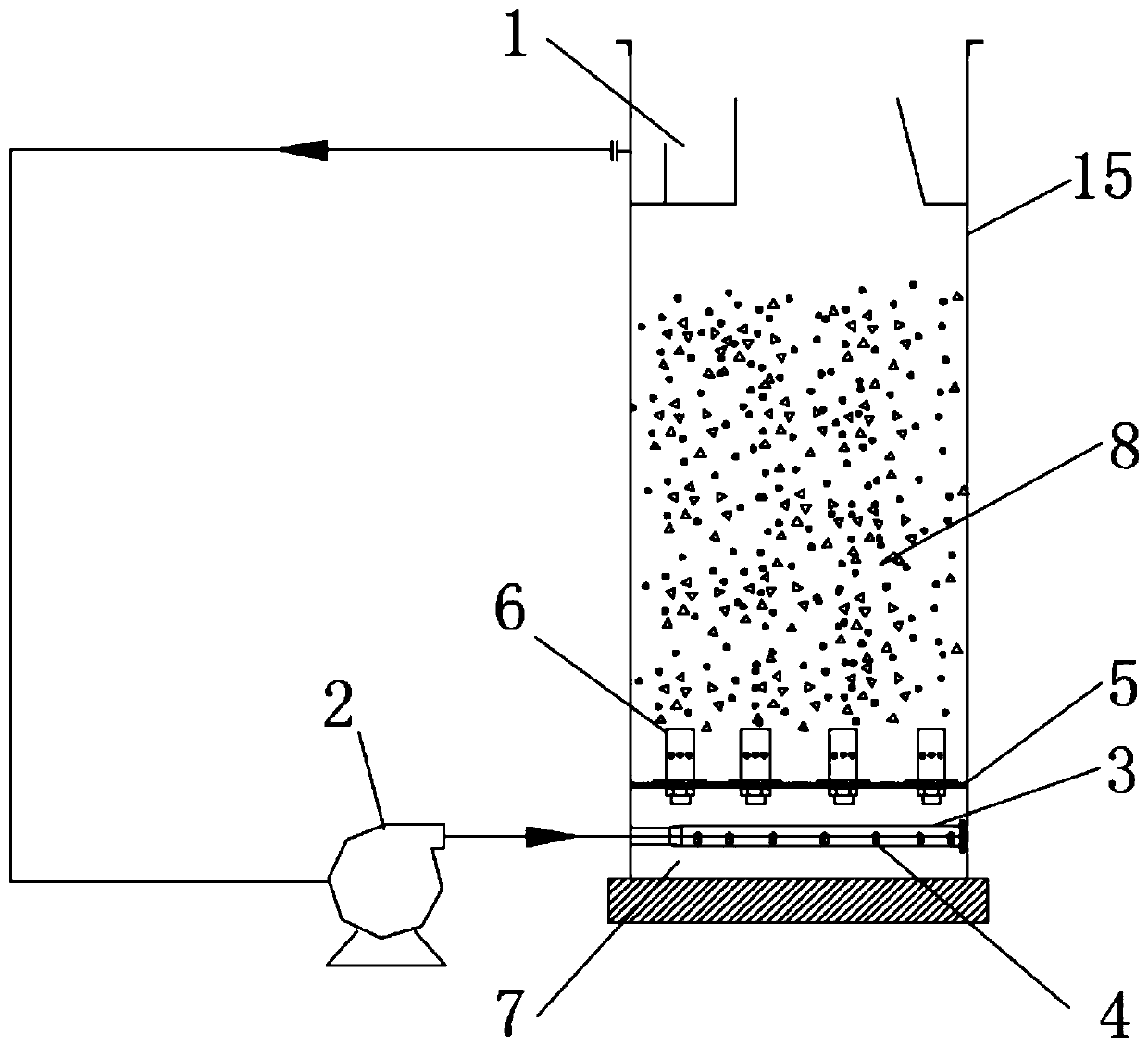

[0030] Such as figure 1 As shown, the present invention provides a water distribution system for a tower fluidized bed reactor, including a fluidized bed reactor body 15 equipped with a solid particle carrier, a water distribution system and a reflux system.

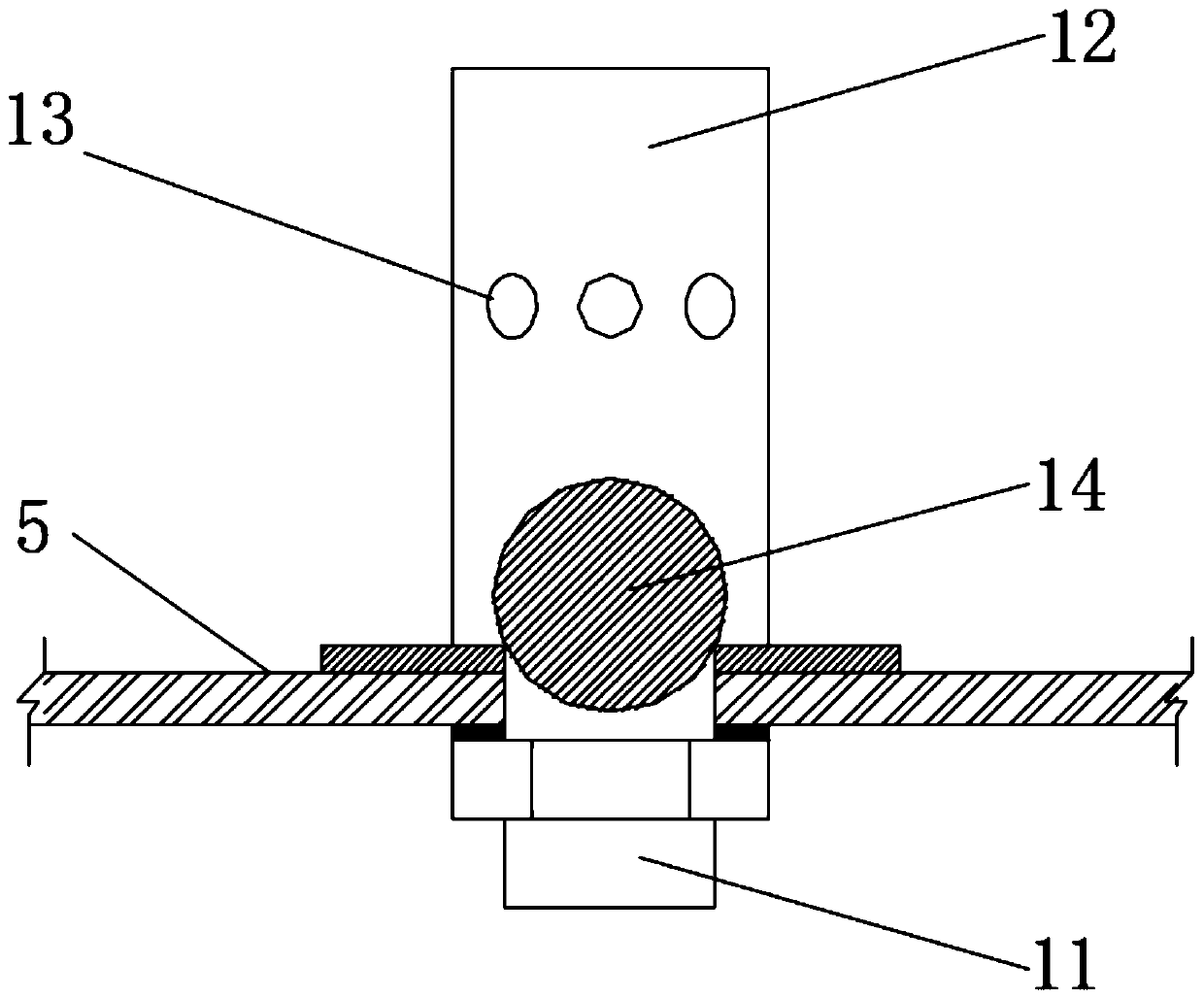

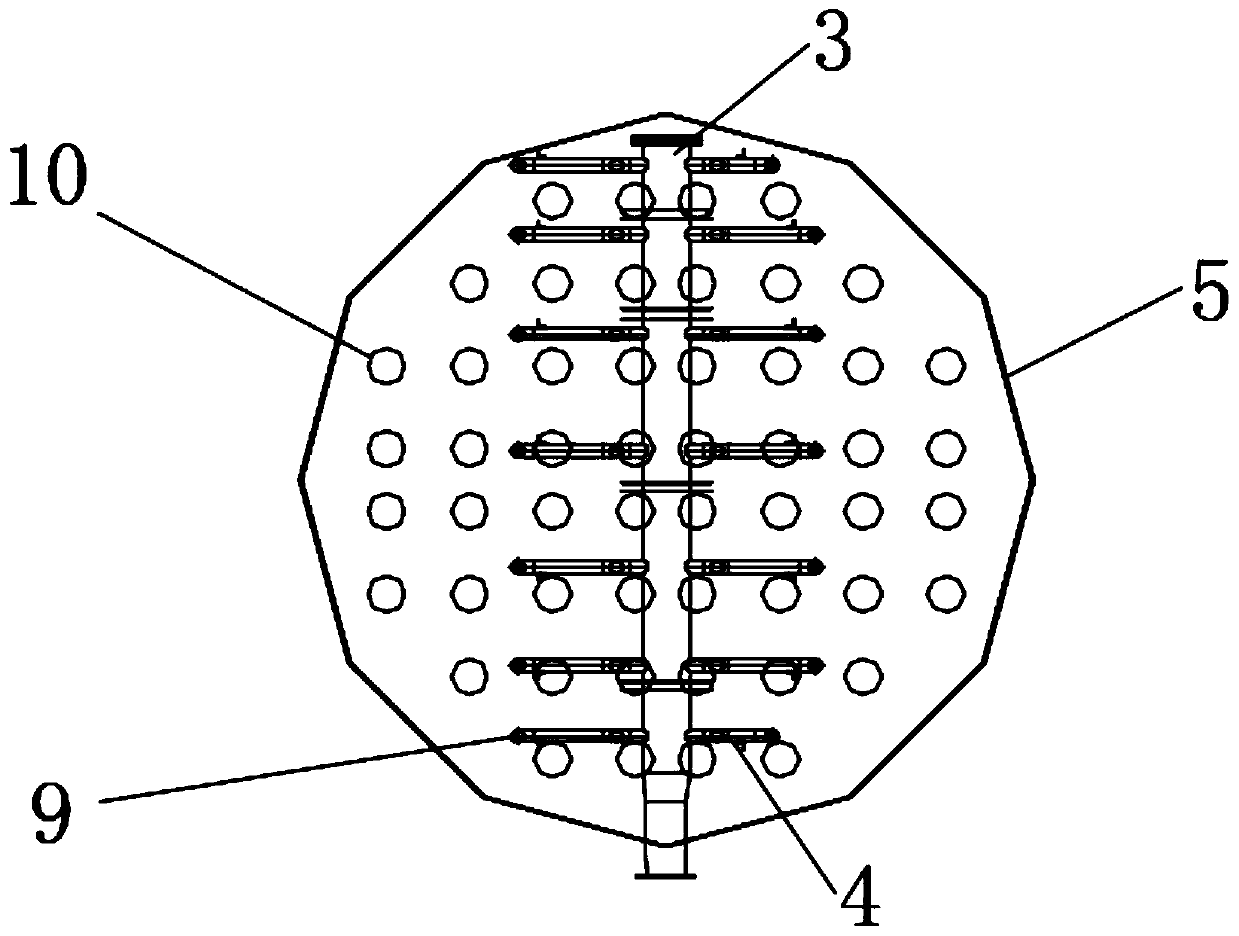

[0031] The lower part of the fluidized bed reactor body 15 is provided with a support plate 5, and the support plate 5 in this embodiment is preferably a steel plate. More preferably, the support plate 5 is welded and fixed to the inner wall of the fluidized bed reactor body 15 . The support plate 5 divides the interior of the fluidized bed reactor body 15 into an upper fluidized zone 8 and a bottom water distribution zone 7. A plurality of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com