Slag-leakage-preventing air cap, preparation method thereof and circulating fluidized bed boiler

A technology of anti-leakage slag and air cap, which is applied to fluidized bed combustion equipment, combustion methods, furnaces, etc., and can solve problems such as wear on the top of the air outlet, rotational deflection of fluidized wind, and short service life.

Active Publication Date: 2019-06-11

刘沁昱

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to solve the problems of slag leakage, serious wear of the air outlet and the top of the air cap of the circulating fluidized bed boiler in the prior art, the rotation and deflection of the fluidized wind, and the short service life, the invention provides a high-temperature wear-resistant alloy, which uses the alloy Leakage-proof slag cap and preparation method thereof

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

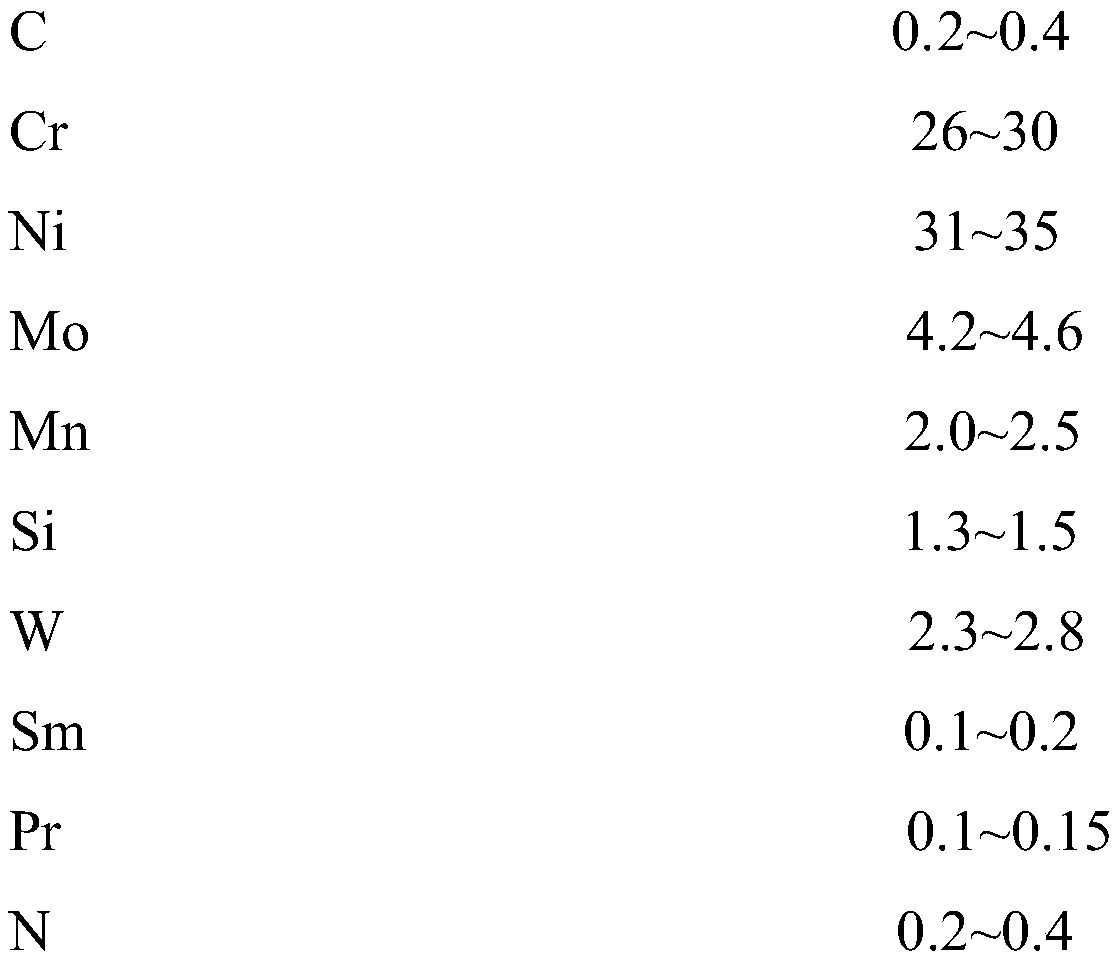

Embodiment 1

[0076]

[0077]

Embodiment 2

[0079]

Embodiment 3

[0081]

[0082]

[0083] On the other hand, the present invention also provides a slag leakage prevention hood made of the above-mentioned high temperature resistant alloy, and the specific structure is referred to the following examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

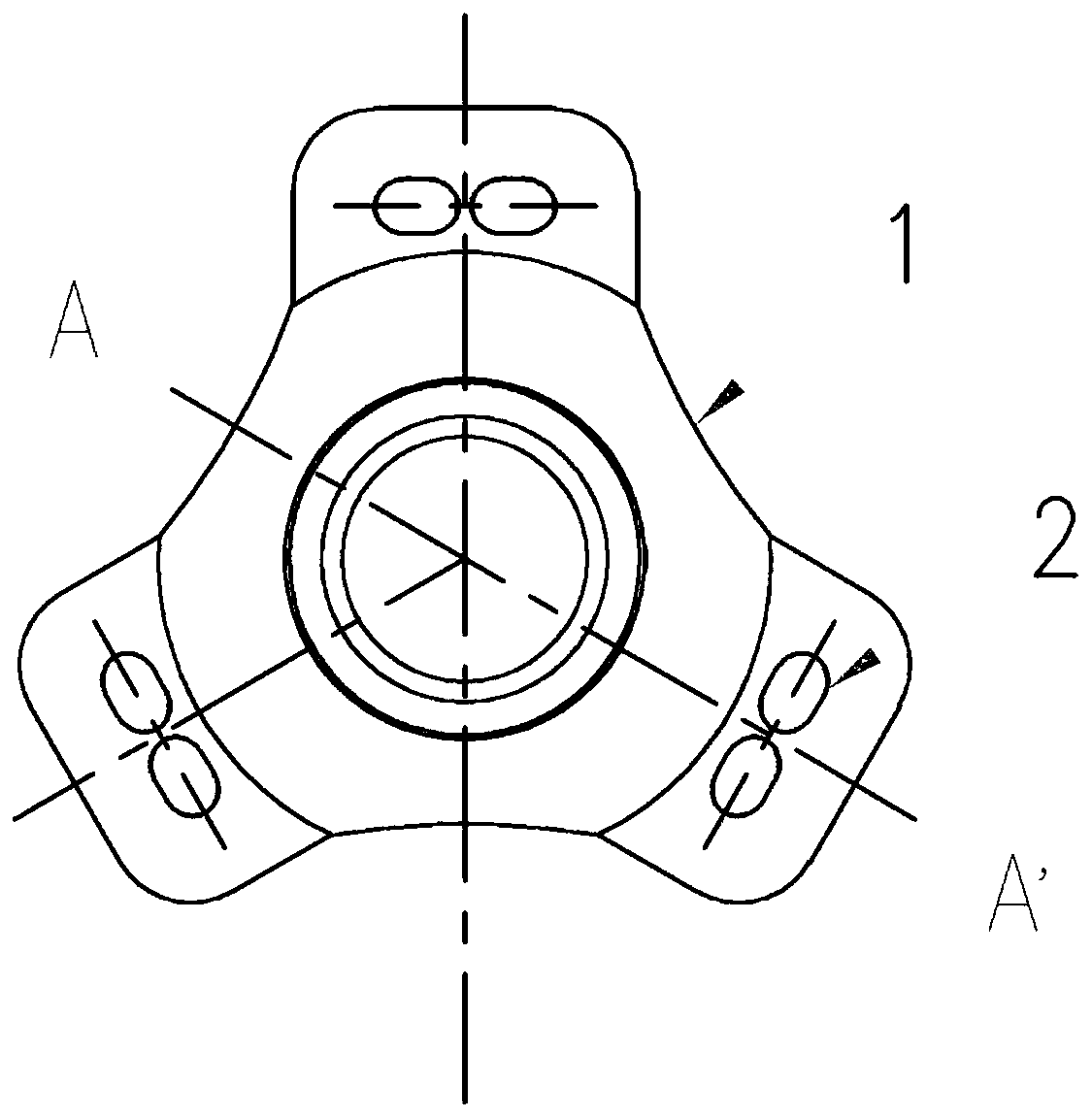

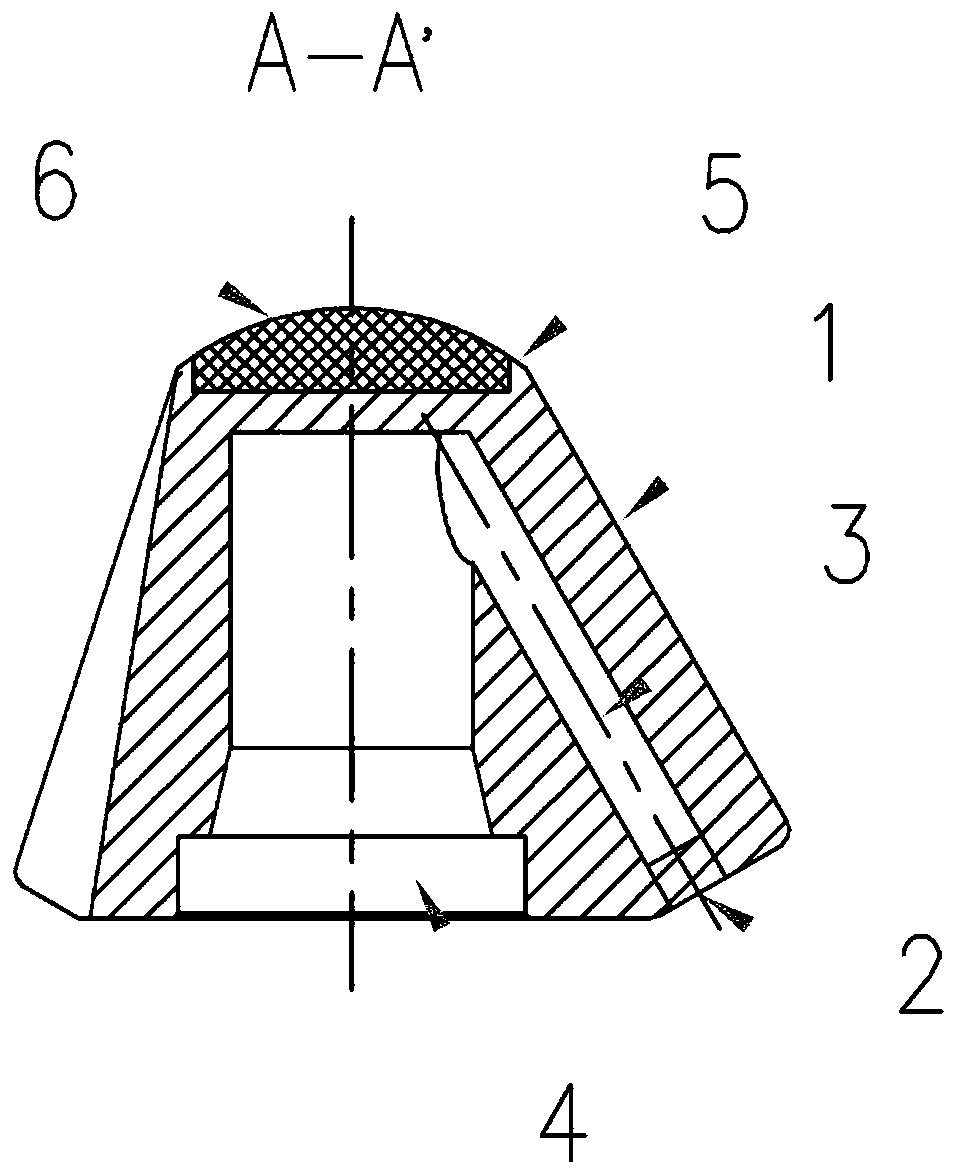

The invention discloses a slag-leakage-preventing air cap, a preparation method thereof, and a circulating fluidized bed boiler, and belongs to the field of alloy air caps. The slag-leakage-preventingair cap comprises an air cap body, an air inlet duct located in the air cap body, and one or more air outlet ducts communicating with the air inlet duct; the top of the air cap body is provided witha U-shaped structure comprising a causeway and a composite ceramic body inlaid in the causeway; the air inlet duct is a cylindrical channel; the air outlet ducts are flat conical channels and gradually become small in the direction from inlets to outlets; the air outlets of the air outlet ducts are each of an oval double-hole structure; and the included angle alpha between the air outlet directionof the air outlet ducts and the air inlet direction of the air inlet duct is 45-75 degrees. The prepared slag-leakage-preventing air cap has the advantages that slag leakage is effectively prevented,abrasion of the air outlets and the top is relieved, fluidizing is uniform, rotary bias flows and abnormal abrasion are avoided, and the service life is greatly prolonged.

Description

technical field [0001] The invention relates to an anti-leakage slag cap, in particular to a high-temperature resistant anti-leakage slag cap and a preparation method thereof, and a circulating fluidized bed boiler comprising the anti-leakage slag cap. Background technique [0002] The combustion method of the circulating fluidized bed boiler is different from that of the pulverized coal boiler. The combustion is carried out through the fluidization of the fuel in the furnace. The fluidization state directly affects the combustion effect of the fuel, the stability of the boiler operation and the efficiency of the boiler. The primary wind blown out by the air distribution board hood has the lifting effect and the eeling effect. Therefore, the air cap is a crucial component in the circulating fluidized bed boiler. [0003] If the structure of the air distribution plate hood is unreasonable or if there is a problem during use, it will directly affect the normal fluidization of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23C10/20C22C30/02C22C33/06C21D9/00C23C4/134

Inventor 刘少光刘沁昱

Owner 刘沁昱

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com