Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Reduce coal consumption for power supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

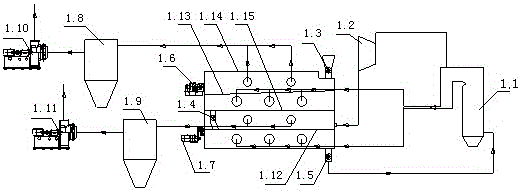

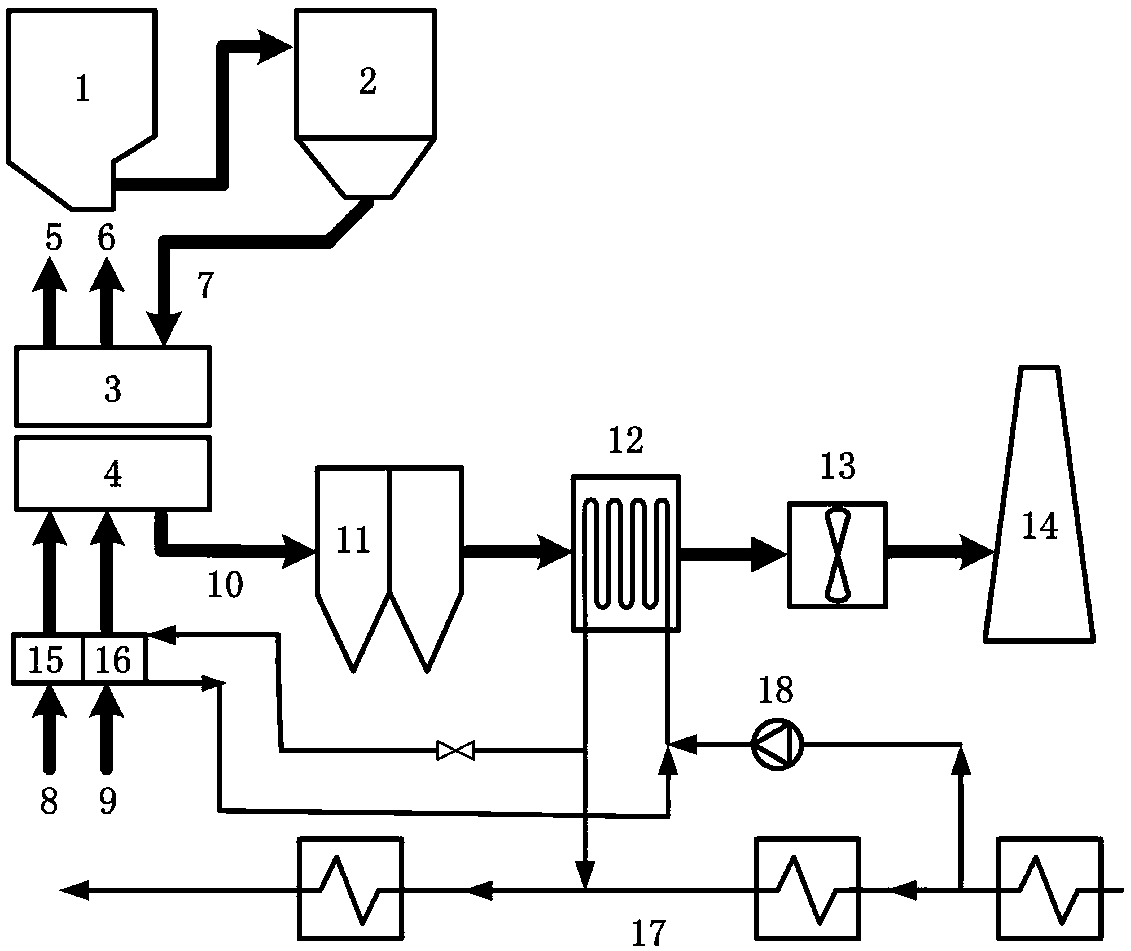

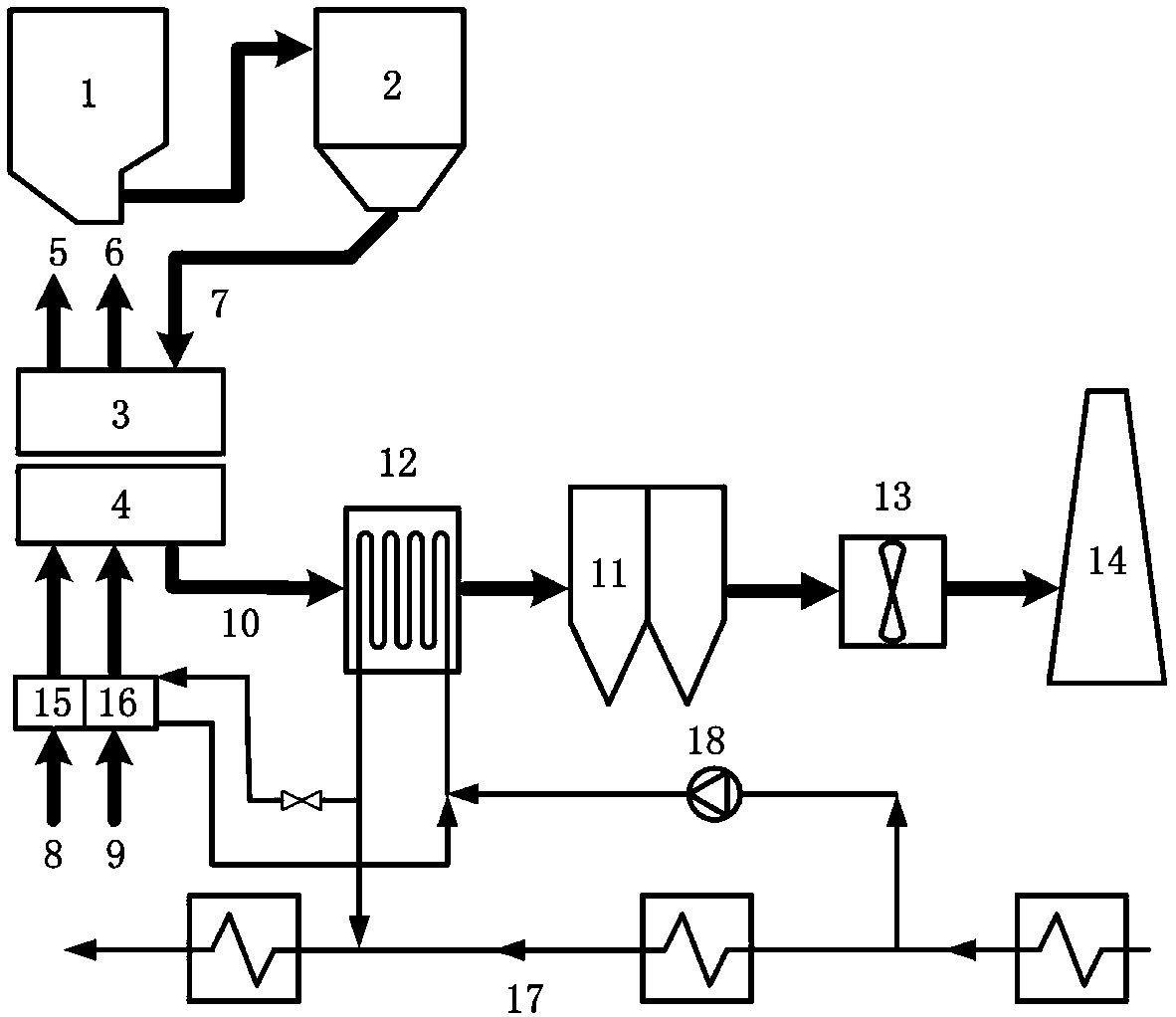

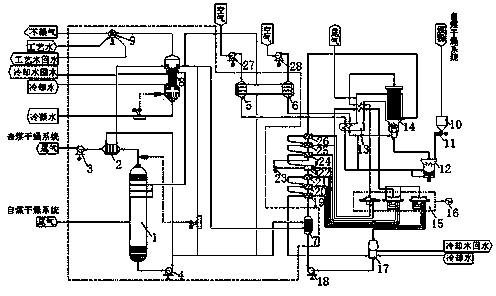

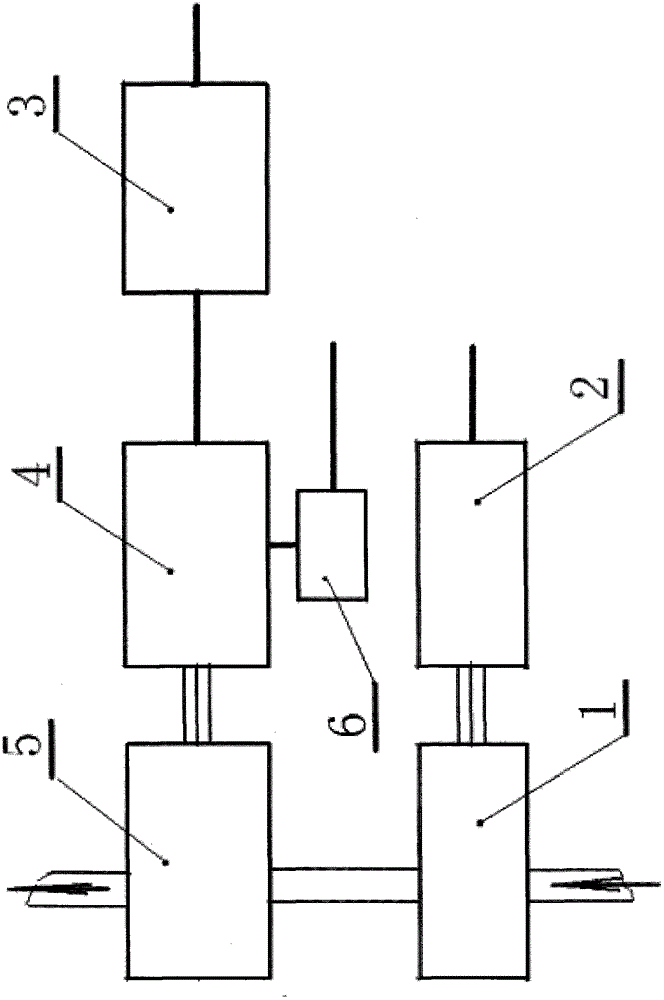

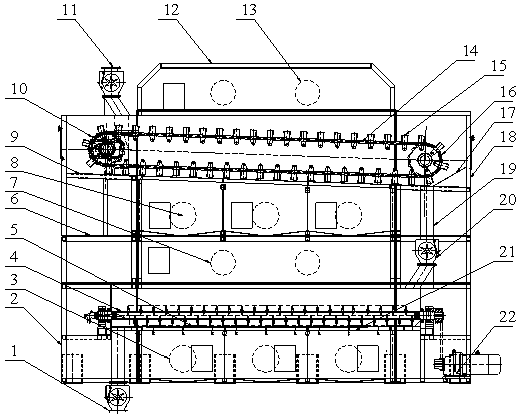

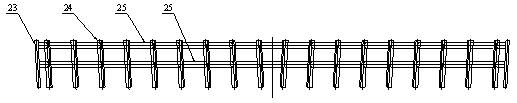

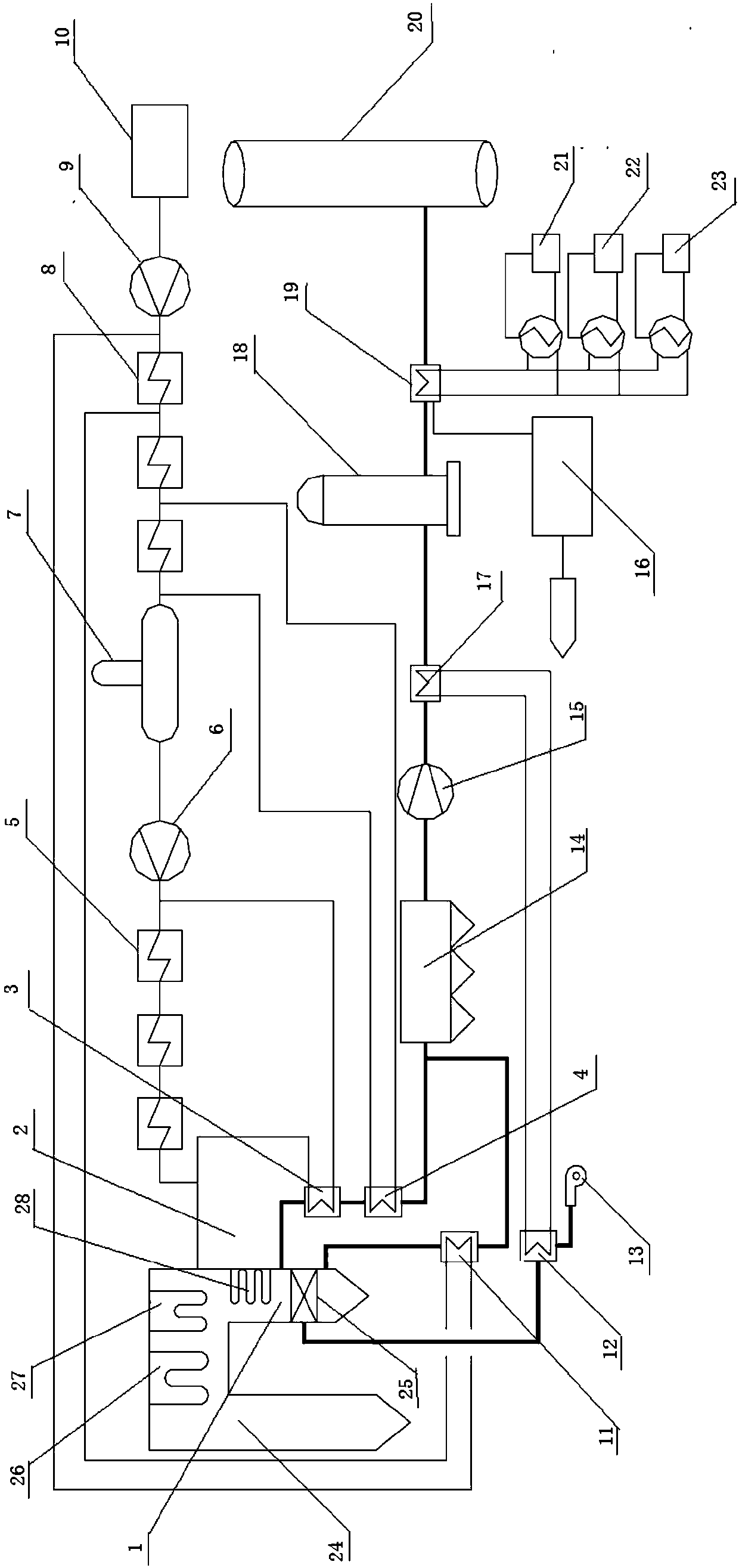

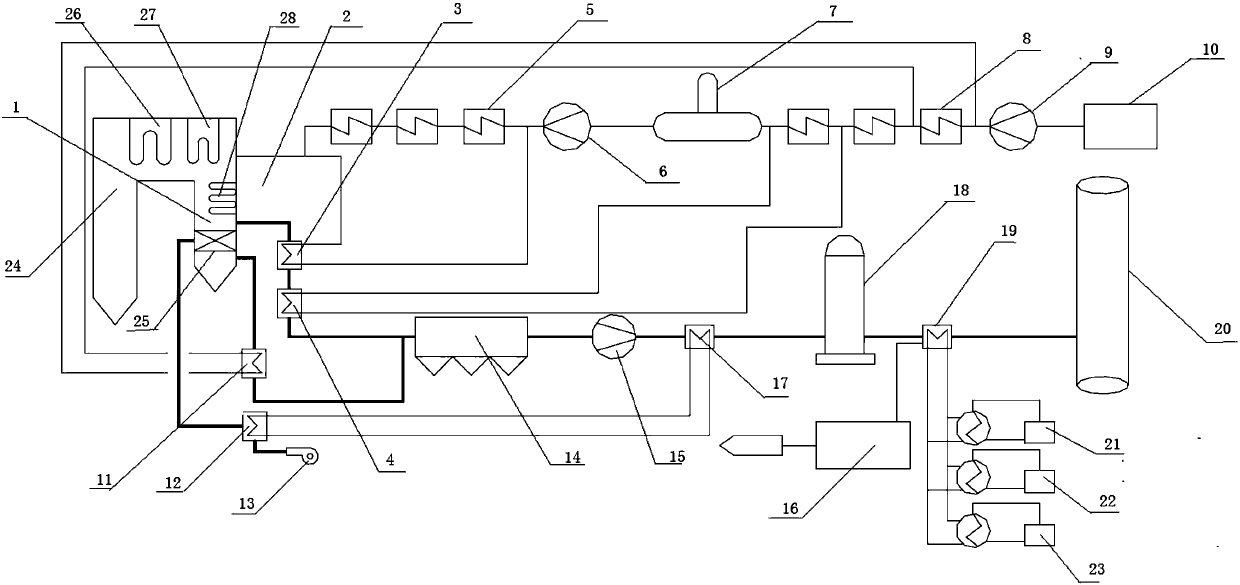

Brown coal drying method and device utilizing waste heat of smoke and steam of power plant

ActiveCN106382790AImprove economyImprove operational efficiencyDrying solid materials with heatDrying gas arrangementsBrown coalProcess engineering

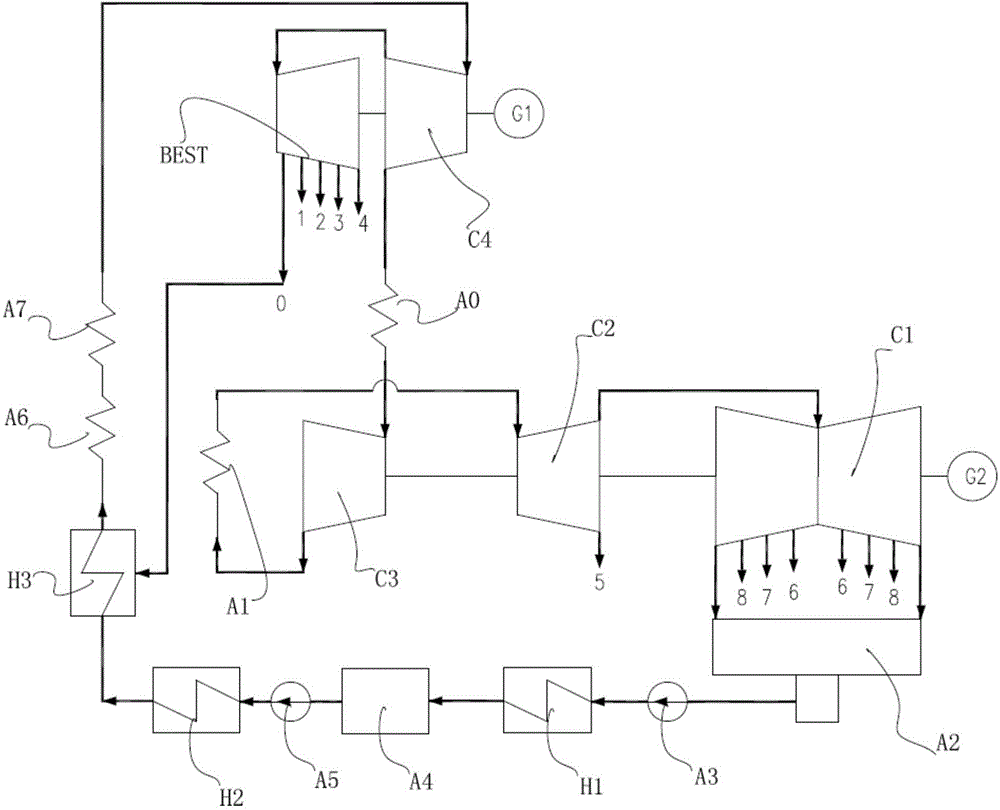

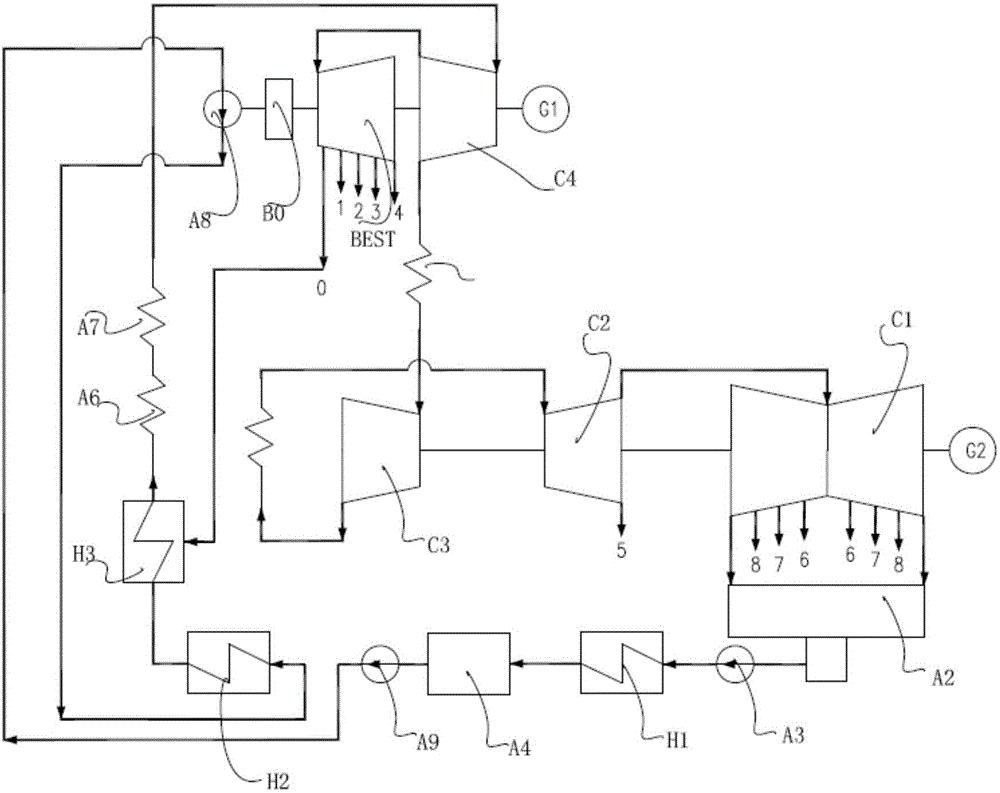

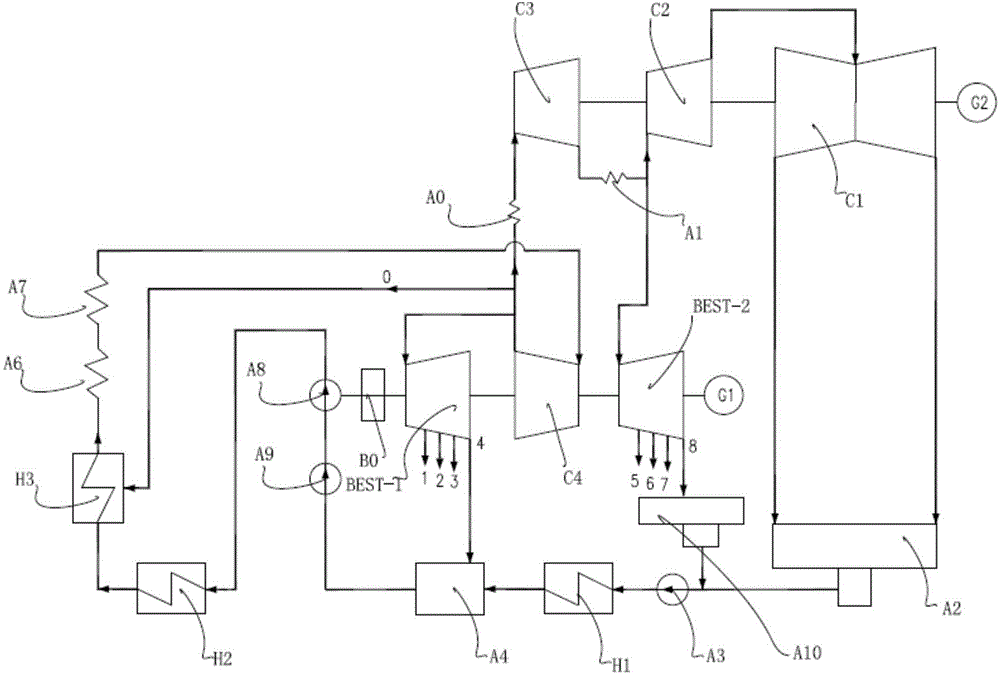

The invention discloses a brown coal drying method and device utilizing waste heat of smoke and steam of a power plant. The drying method comprises two-time drying treatment, wherein the two-time drying treatment comprises the steps that firstly, the high-temperature smoke directly discharged by a power plant coal fired boiler is utilized for conducting first-time drying treatment on damp materials, the high-temperature smoke directly makes uniform contact with the damp materials, and intermediate materials are obtained; and secondly, the high-temperature smoke and the high-temperature steam directly discharged by the power plant coal fired boiler are utilized for conducting second-time drying treatment on the intermediate materials at the same time, the high-temperature smoke directly makes uniform contact with the intermediate materials, meanwhile, the intermediate materials make uniform contact with a heat exchange pipe inflated with the steam for heat exchange, dried materials are obtained, and second-time drying treatment is achieved. The brown coal drying method and device have the beneficial effects that the power plant waste heat serves as a heat source for brown coal drying, the running economical efficiency of a power plant generator set is improved, a system for drying the brown coal and a brown coal power generation system are integrated, efficient utilization of power plant energy and optimization of a technology system are achieved, and the brown coal drying method and device belong to the poly-generation technology of the power plant.

Owner:邹平双飞成套设备有限公司

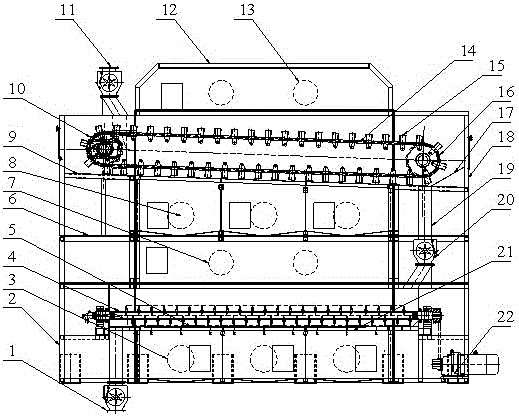

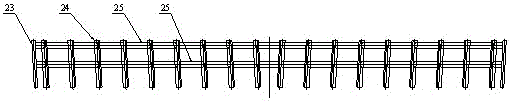

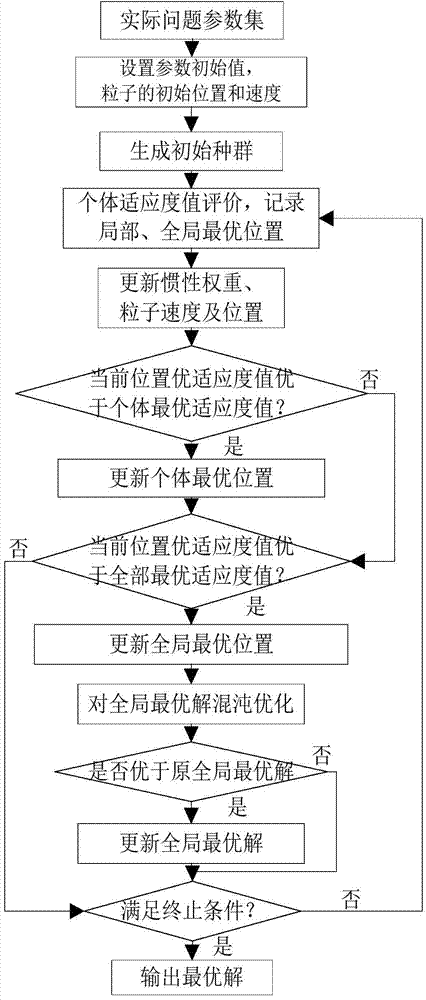

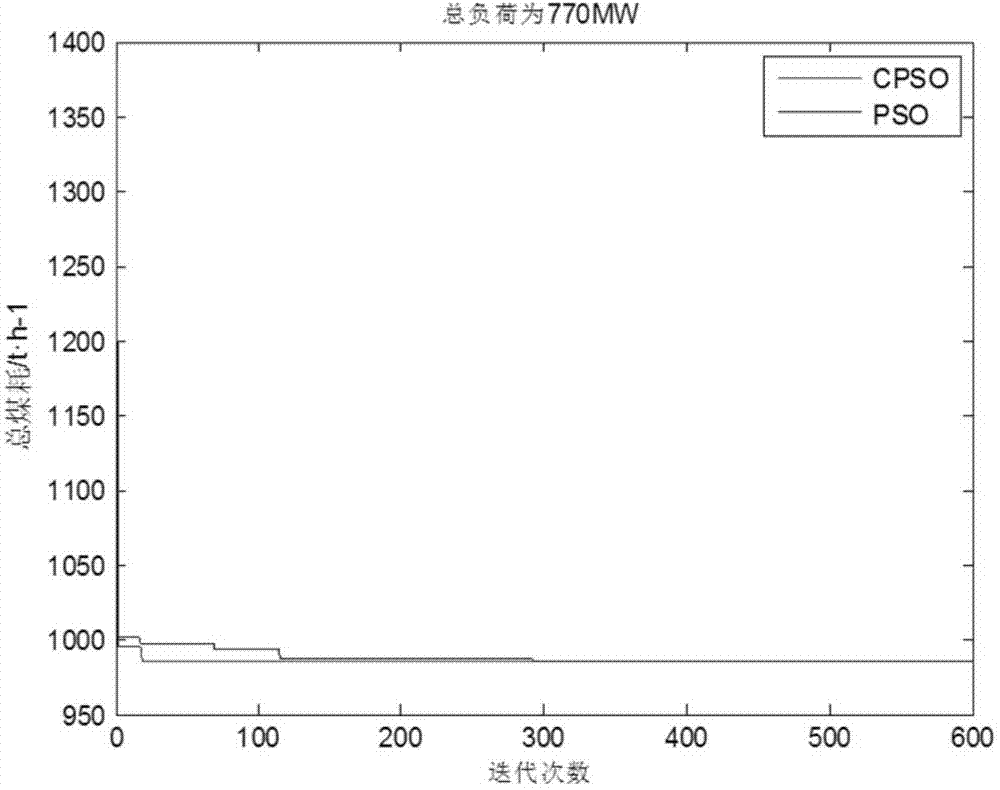

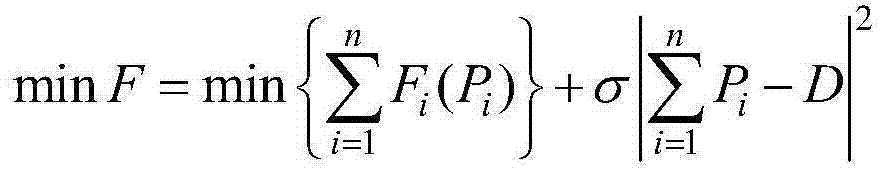

Chaos particle swarm based thermal power unit load optimal distribution method

ActiveCN104850908AReduce coal consumptionReduce coal consumption for power supplyForecastingSystems intergating technologiesGenerating unitParticle swarm algorithm

The invention relates to a chaos particle swarm based thermal power unit load optimal distribution method, which comprises the steps of fitting a coal consumption characteristic curve according to coal consumption characteristic parameters of a power generating unit, establishing a load optimal distribution model, converting the load optimal distribution model into a non-restraint problem through a penalty function method, distributing the total generation power to each unit by being combined with a chaos particle swarm algorithm, and finally acquiring an optimal load distribution result of each unit. Compared with the prior art, the method provided by the invention can distribute the optimal output point of each power generating unit scientifically and reasonably under the given total generation power, thereby enabling power supply coal consumption of the unit after optimization to be obviously reduced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

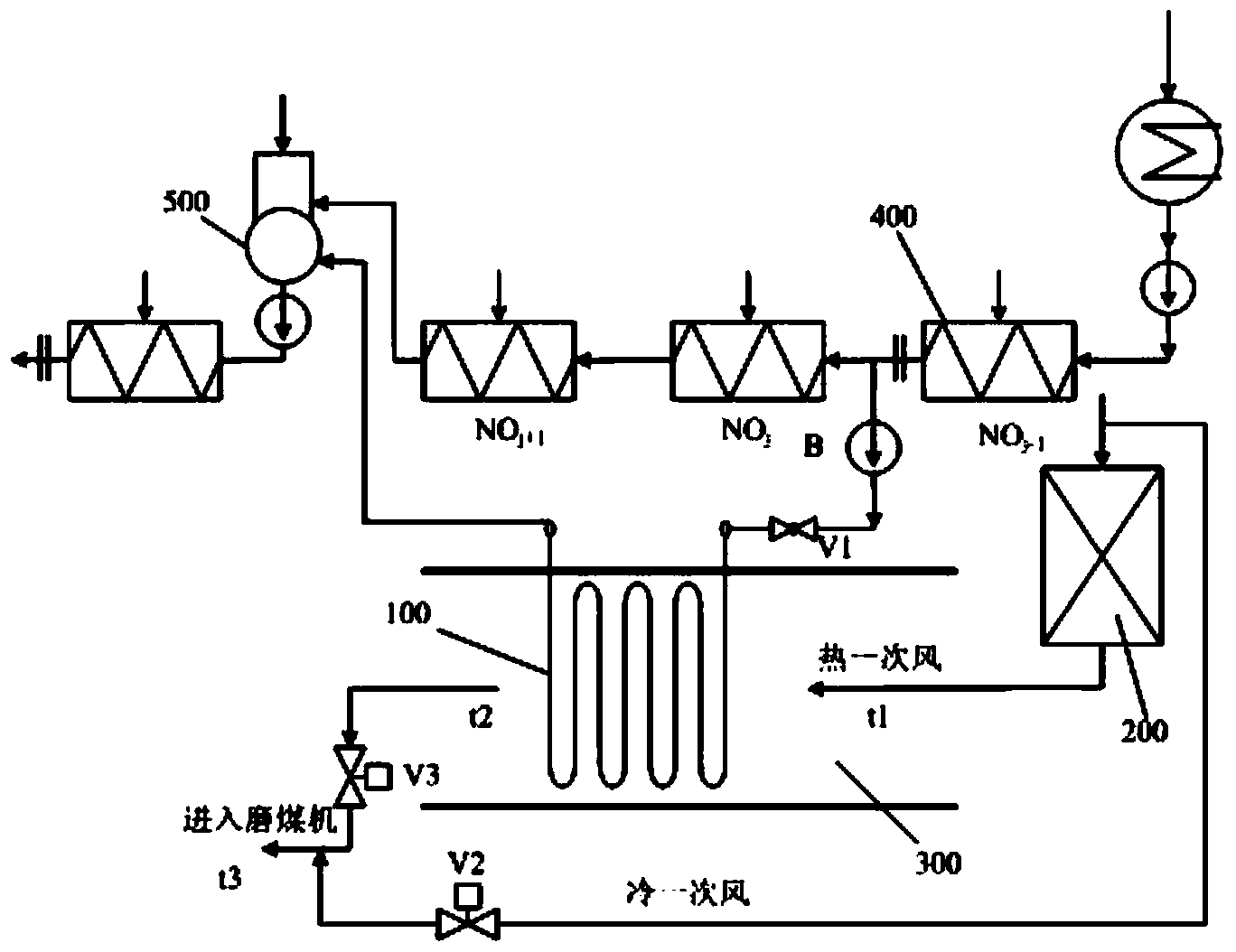

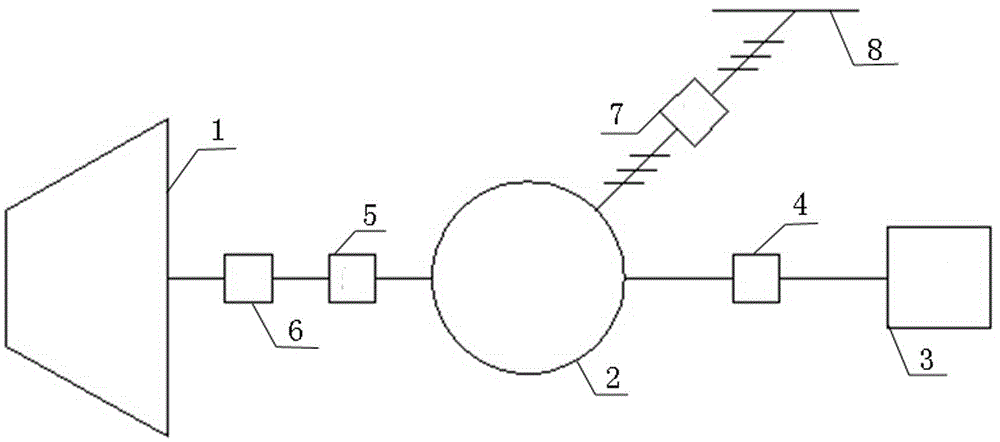

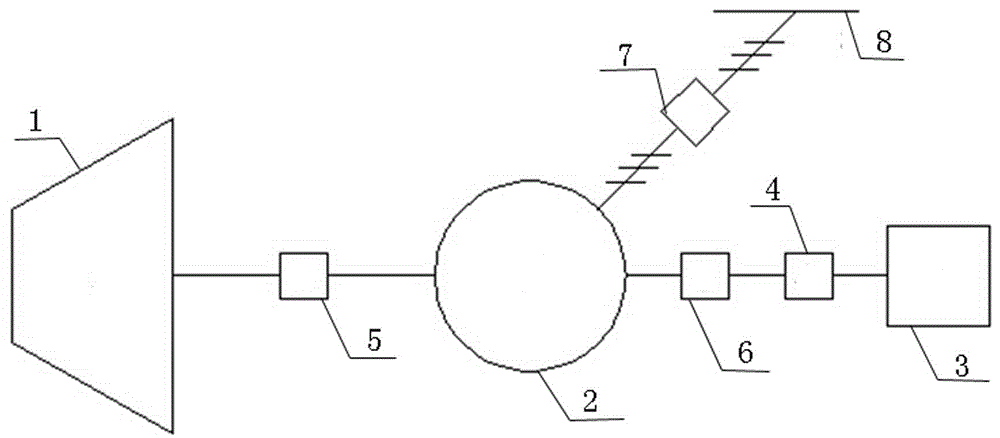

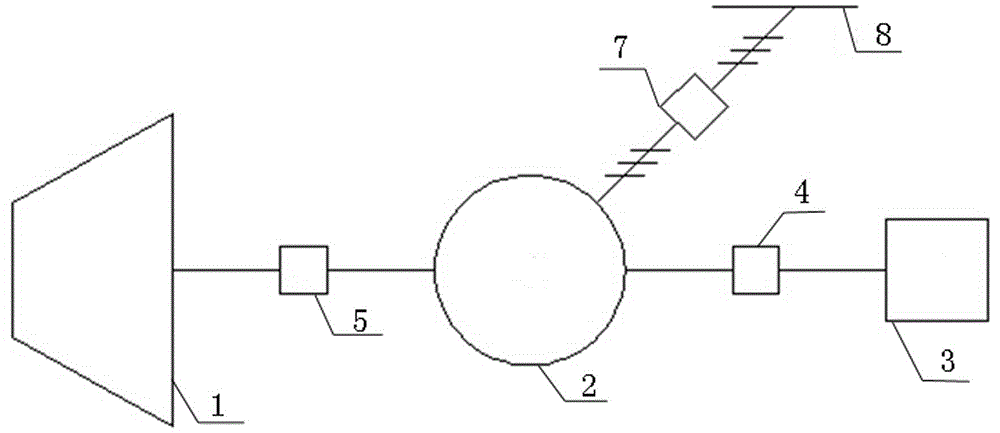

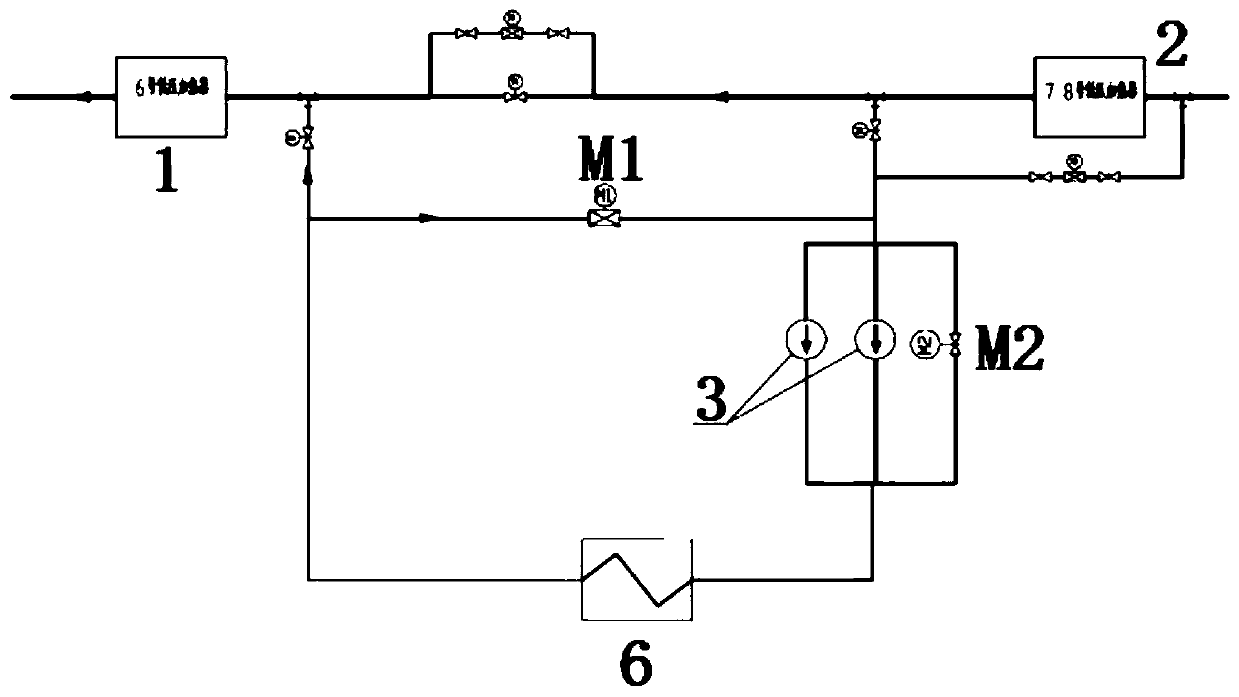

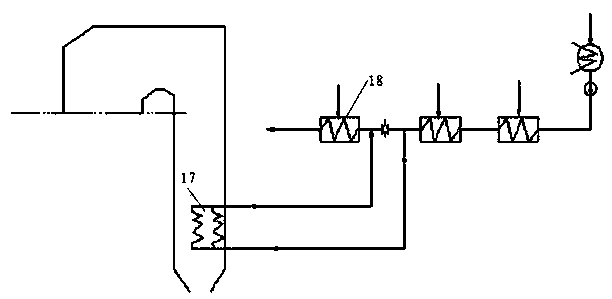

Primary air cooler heat regenerative system and controlling method

ActiveCN103438686AReduce cooling air volumeLower exhaust gas temperatureDrying gas arrangementsGrain treatmentsAir preheaterWater use

The invention discloses a primary air cooler heat regenerative system and a controlling method. According to the primary air cooler heat regenerative system and the controlling method, a primary air cooler is arranged in a primary heat air duct of an outlet of a boiler air heater, low-pressure supplied water used as cooling water is introduced by a coal-fired unit low-pressure water-supply heat regenerative system, heat of primary heat wind is absorbed, the heated supplied water is sent back to a unit deaerator, the flow of the cooling water is adjusted so as to enable the temperature of the primary wind to be reduced to meet the temperature requirement of drying medium at the inlet of a coal mill. By means of the technical scheme, the cold wind amount of a side road of a boiler air preheater can be greatly reduced, the smoke exhausting temperature of the boiler is reduced, the power-supply coal consumption of the unit is reduced, and the stable operation of the unit is not affected.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

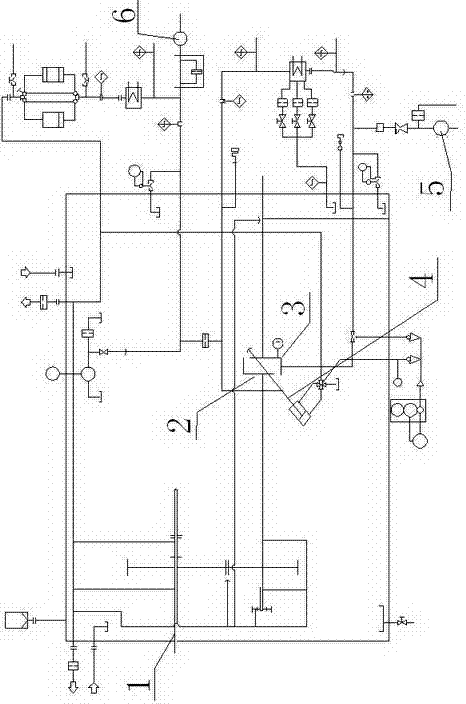

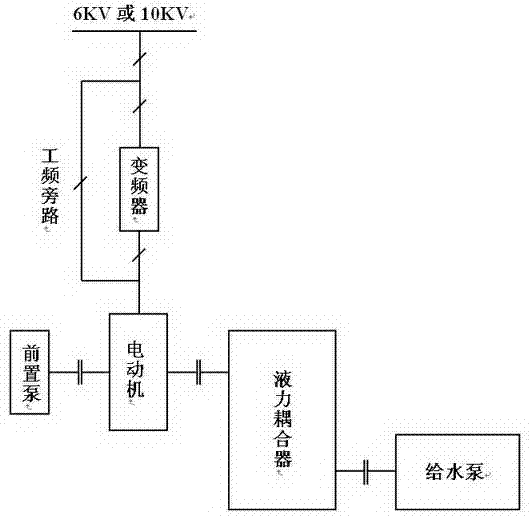

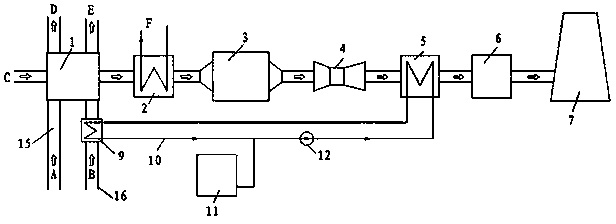

Energy saving system of electrically driven feed pump of power frequency-variable frequency switching type liquid coupling

InactiveCN102865232AReduce electricity consumptionSimple structurePump controlPump installationsFrequency changerFluid coupling

The invention relates to an energy saving system of an electrically driven feed pump of a power frequency-variable frequency switching type liquid coupling, and belongs to the technical field of energy saving transformation of electrically driven feed pump sets driven by a liquid coupling in a power station. the energy saving system is characterized in that a frequency converter and a power-frequency bypass is arranged between a power supply frequency converter and a motor on the condition that the connection type of original electrically driven feed pump sets are cont changed. According to the energy saving system, the frequency converter and the power-frequency bypass are mounted between the power supply breaker and the motor, the power frequency-variable frequency power supply is input in the motor by switching, a front-mounted pump is coaxially driven by one end of the motor, a liquid coupling input shaft is coaxially driven by the other end of the motor, a feed pump is driven by a liquid coupling output shaft, and a lubrication pump and a working oil pump are designed and mounted in a liquid coupling lubricating oil system and a working oil system, so that the same liquid coupling has two operation manners; for meeting requirements of the power frequency-variable frequency operation manners of the feed pump sets, the front-mounted pump is changed into a front-mounted pump which can operate in both a constant speed manner and a variable speed manner. The energy saving system of the electrically driven feed pump of the power frequency-variable frequency switching type liquid coupling is simple in structure and rational in design, and has two operation manners including a volume-velocity-regulated speed-regulation type liquid coupling in a power-frequency constant speed input process and a pump-pulley-regulated speed-increase gear box in a variable frequency speed-regulation input process.

Owner:张文海 +1

System and method for preventing ammonium bisulfate from blocking air preheater after SCR denitration modification

PendingCN107642793AAvoid cloggingAvoid condensationCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a system and method for preventing ammonium bisulfate from blocking an air preheater after SCR denitration modification. In the system, the average temperature of the overallheating surface of the air preheater is increased by cancelling the area of a cold-section heating surface of a traditional rotary air preheater, so that the ammonium bisulfate ash blocking of the airpreheater is prevented; meanwhile, the excess heat of exhaust smoke is absorbed by low-pressure and low-temperature economizers arranged in a connecting gas flue from a dust remover to an induced draft fan to control the temperature of the exhaust smoke, and the economical efficiency of a unit is improved; the control over a primary hot air temperature and a secondary hot air temperature of an outlet of the air preheater is achieved through air heaters installed on a primary cold air duct and a secondary cold air duct respectively, on the premise that it is ensured that the secondary hot airtemperature is slightly reduced, the volume of cold air mixed into the primary hot air is reduced, the temperature of the exhaust smoke of a boiler is reduced, and the boiler efficiency is improved. By means of the system, the problem that ammonium bisulfate blocks the rotary air preheater after the SCR denitration modification of the coal-fired boiler can be solved, and moreover, the net coal consumption rate can be saved by 1.1 g / kwh.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST

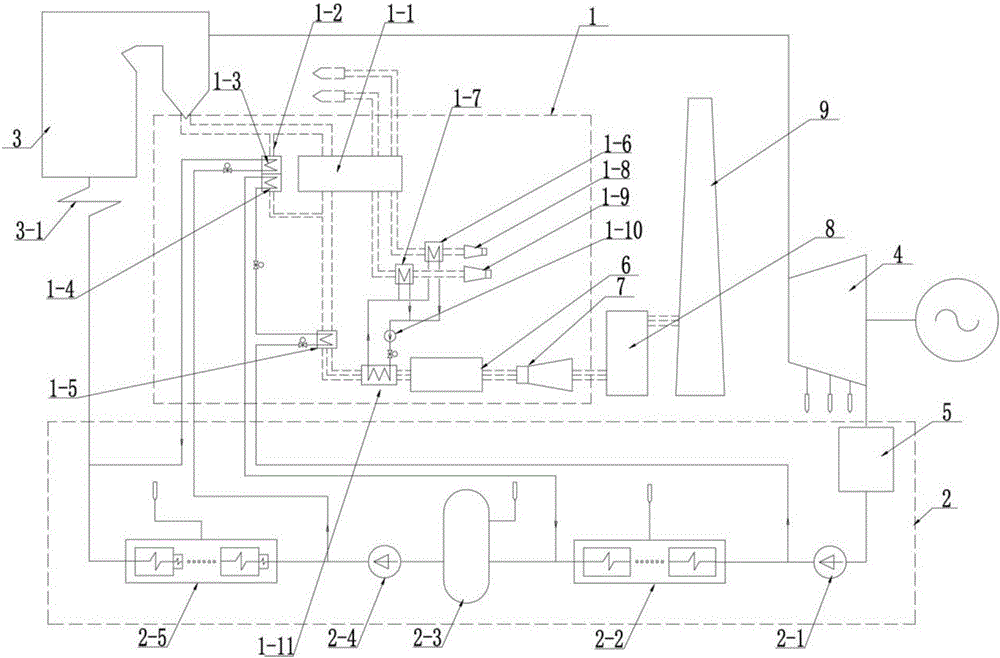

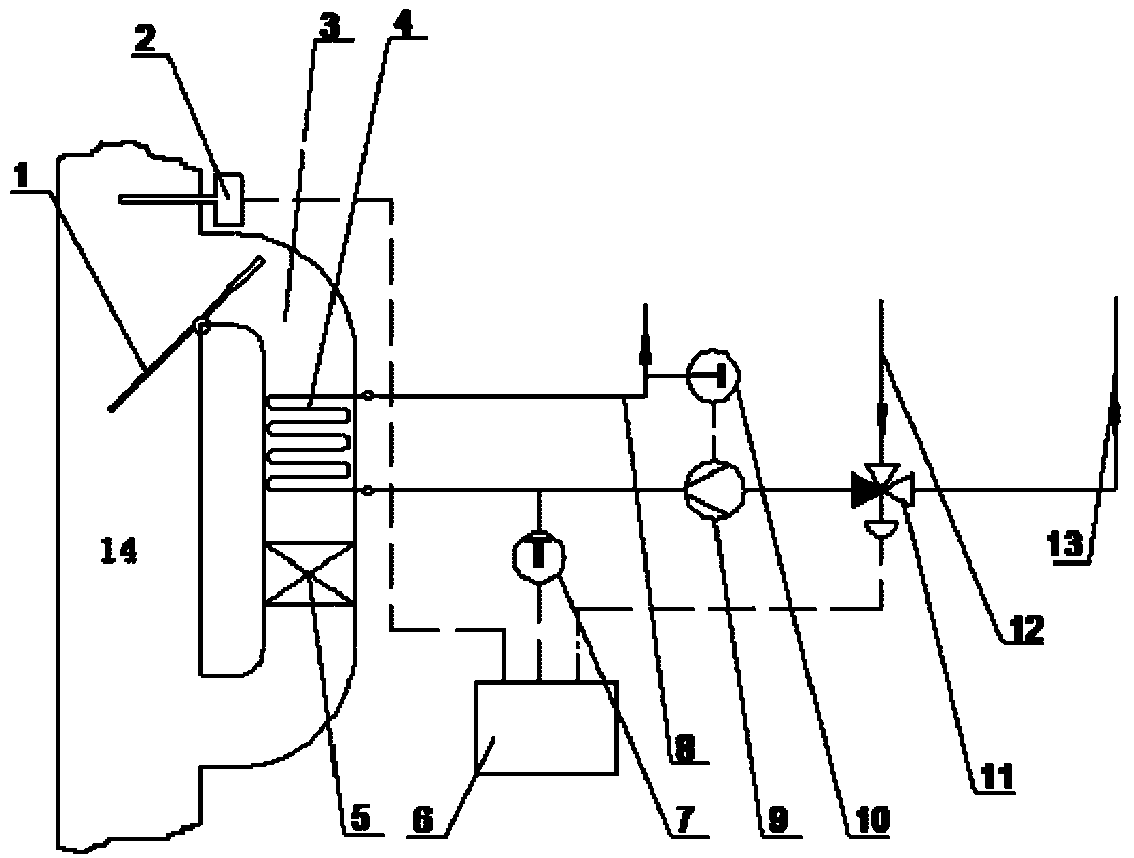

Turbine-boiler gathered heat energy circulating residual heat reuse system

ActiveCN106090880AEffective protectionImprove efficiencyCombustion processIndirect carbon-dioxide mitigationThermal energyPower equipment

The invention discloses a turbine-boiler gathered heat energy circulating residual heat reuse system and belongs to the technical field of energy conservation and emission reduction of heat energy power equipment. The system comprises a boiler, a boiler-side tail heat energy gathering flue gas system, a steam turbine and a turbine-side combined heat exchange water supply system, wherein a coal saver is arranged on the boiler; the front side of the boiler-side tail heat energy gathering flue gas system is connected to the boiler, the back side thereof is successively connected to a desulfurizing absorption tower and a chimney, the front side of the turbine-side combined heat exchange water supply system is connected to a condenser and the back side thereof is connected to the coal saver, and the boiler-side tail heat energy gathering flue gas system is connected to the turbine-side combined heat exchange water supply system through a condensed water heat exchange system and a water supply heat exchange system. The system disclosed by the invention recovers heat in the flue gas to heat boil feed water and condensed water, so as to push out highly extracted steam and lowly extracted steam, so that the steam turbine efficiency is improved; heat in the flue gas is recovered to heat air so as to improve the boiler efficiency; heat in the tail flue gas is recovered so as to improve the dedustor efficiency, the desulfuration water consumption is reduced and the energy-saving environmental-friendly contributing value is improved.

Owner:JINGNENG (XILINGUOLE) POWER CO LTD

Energy-saving boiler feed pump drive system for thermal power plant

InactiveCN104314786ASimple systemReduce project costPumpsPositive-displacement liquid enginesSynchronous motorEngineering

The invention provides an energy-saving boiler feed pump drive system for a thermal power plant and solves the configuration problem of the water feed pump of a current thermal power generating unit and the problem that the water feed pump is high in energy consumption. A synchronous automatic clutch is disposed between a small steam turbine and a synchronous motor. A planet gear speed regulating device is disposed between the synchronous motor and the water feed pump. The synchronous motor is connected into a plant bus through a synchronizing switch. The water feed pump can be driven by the small steam turbine or the motor, the reliability is higher than a traditional steam pump manner or electric pump manner, optimized operation according to unit back pressure conditions can be achieved, and the drive manner of the water feed pump can be switched timely to save energy. An independent steam discharge cooling system for the small steam turbine is not needed, steam discharged from the small steam turbine can be directly discharged into a mainframe steam discharge system, influence on water feed adjusting due to the fact the shaft power of the small steam turbine is affected by back pressure sudden drop caused by high back pressure and heavy winds does not need to be worried about even for direct air cooling units, and system simplification and project construction cost lowering are facilitated.

Owner:DATONG COAL MINE GRP +1

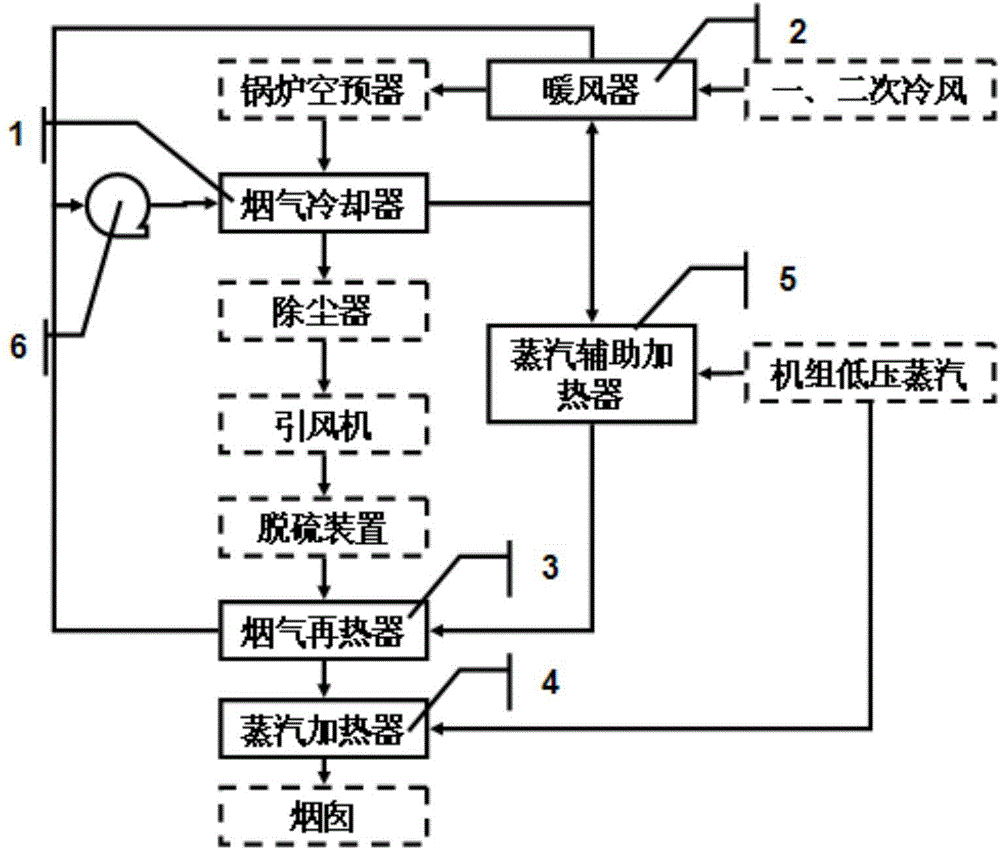

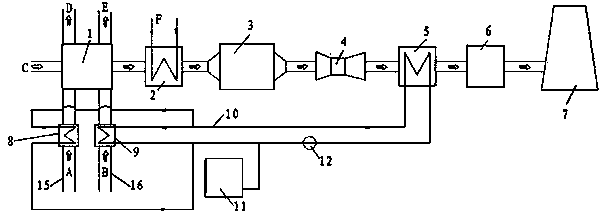

Combined steam smoke MGGH system and flue gas treatment technology

InactiveCN104566424AReduce corrosionReduce foulingLighting and heating apparatusFlue gasProcess engineering

The invention provides a combined steam smoke MGGH system. The combined steam smoke MGGH system comprises a boiler air pre-heating device, wherein the boiler air pre-heating device is connected with a flue gas cooler, the flue gas cooler is connected with a dust remover, the dust remover is connected with an induced draft fan, the induced draft fan is connected with a desulfurization device, the desulfurization device is connected with a flue gas re-heating device, the flue gas re-heating device is connected with a steam heater, and the steam heater is connected with a chimney. The combined steam smoke MGGH system is characterized in that the steam heater is arranged between the flue gas re-heating device and the chimney, a steam auxiliary heater is arranged between the flue gas cooler and the flue gas re-heating device, and the flue gas re-heating device is connected with the flue gas cooler through a variable frequency circulating pump. The combined steam smoke MGGH system and a flue gas treatment technology thereof mainly solve the problem that due to the fact that flue gas temperature is not high enough, an existing MGGH system uses steam to assist in heating, and can significantly reduce steam consumption and engineering cost investment.

Owner:CHONGQING CLP ENERGY SAVING TECH SERVICE

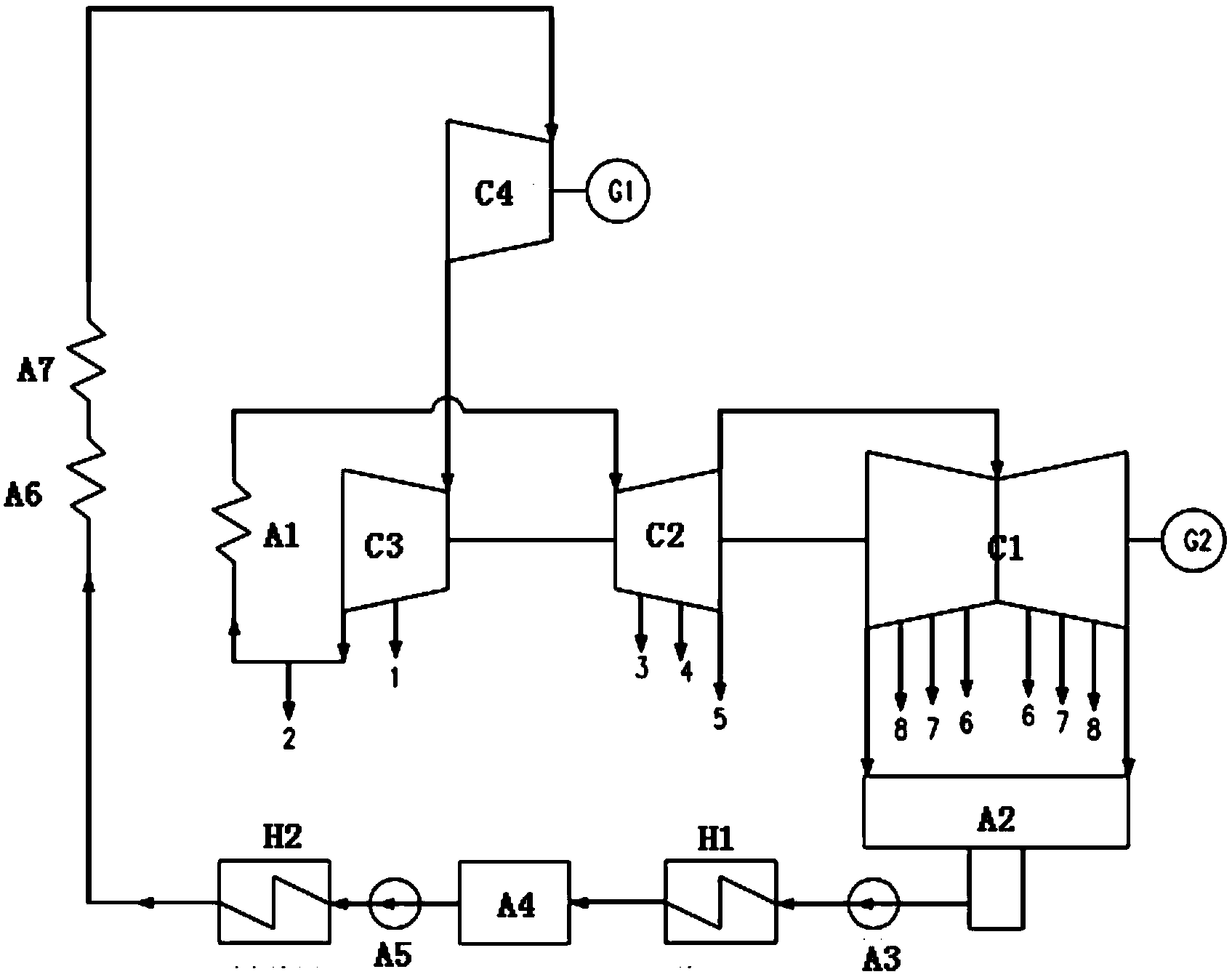

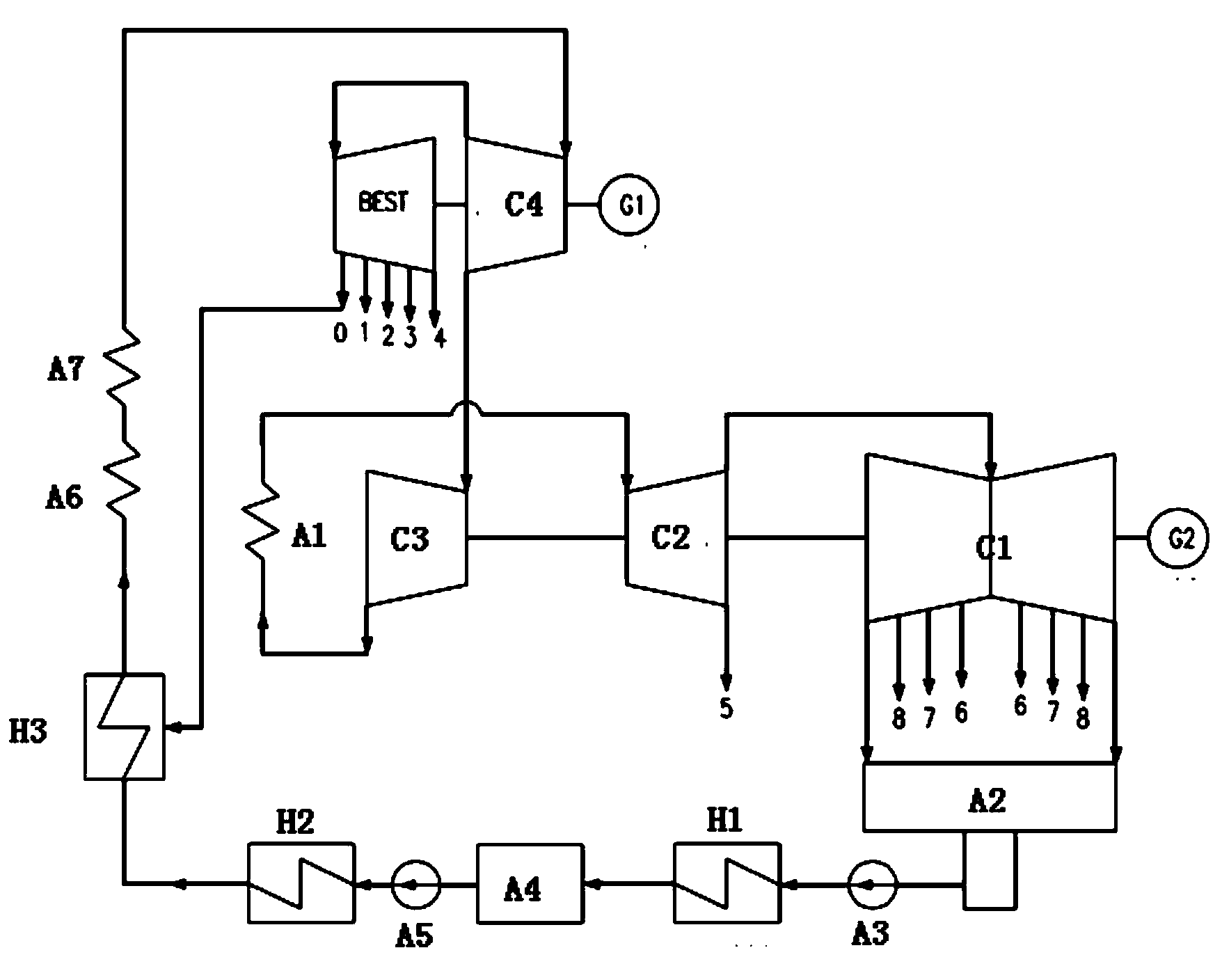

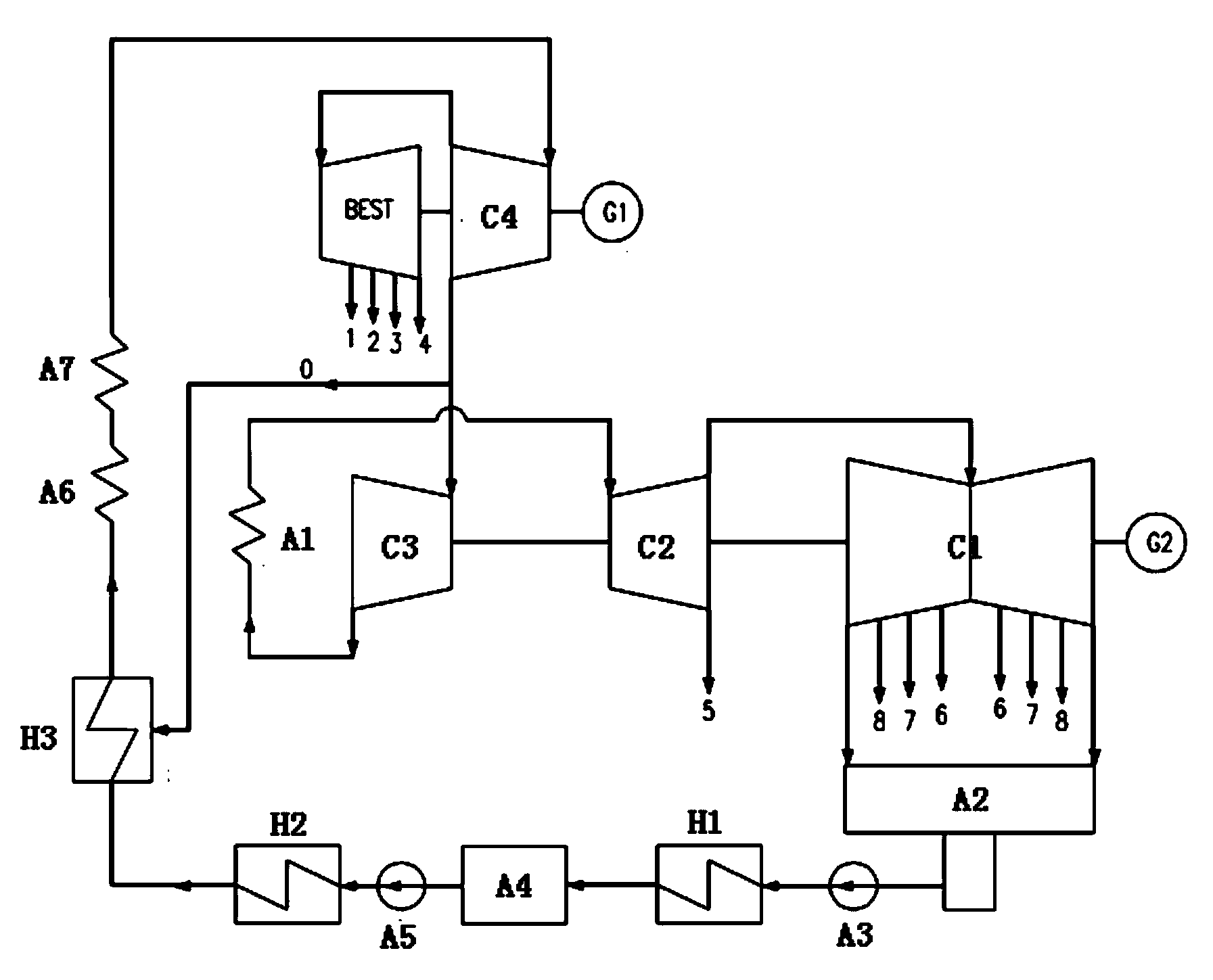

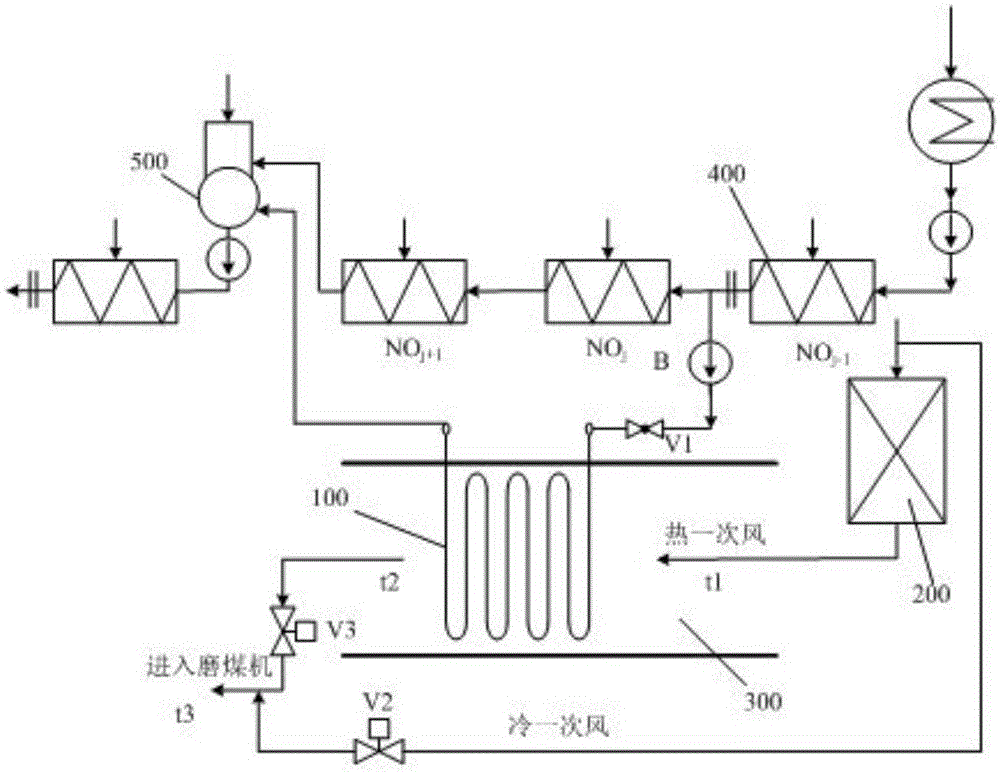

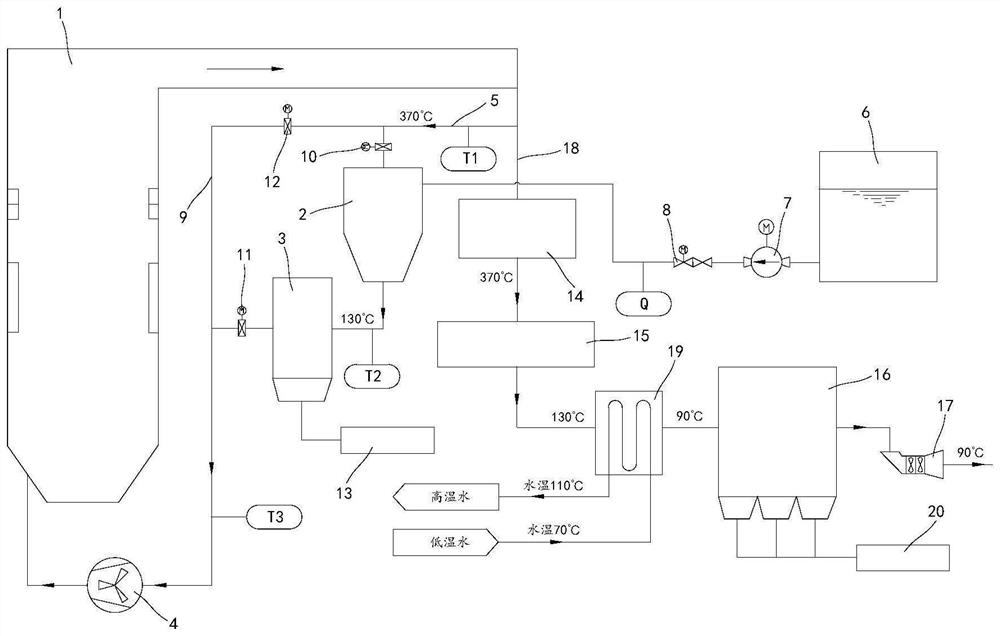

Method of utilizing coal drying exhaust steam to reduce coal consumption of coal-fired power generator set and recovering water

ActiveCN103968659AReduce coal consumption for power supplyIncrease temperatureDrying solid materialsProcess engineeringThermal water

The invention relates to a method of utilizing coal drying exhaust steam to reduce coal consumption of a coal-fired power generator set and recovering water. The method is to add a heat and water recovery system between a coal drying system and the coal-fired power generator set, wherein the heat and water recovery system can convert heat and water vapor carried by the dry tail gas to heat and water carried by hot water, and then the hot water carrying a lot of heat is used for preheating carrier gas entering the coal drying system, air entering a coal-fired boiler system and condensed water after condensing steam by a steam turbine in order to realize efficient transfer of the heat carried by the dry tail gas to the coal-fired power generator set, reduce the coal consumption for the coal-fired power generator set and recover water. The method is characterized by completely recovering and utilizing heat and water vapor carried by the dry tail gas, so as to obviously reduce the coal consumption of a power plant, and conform to the national industry policy of energy conservation and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

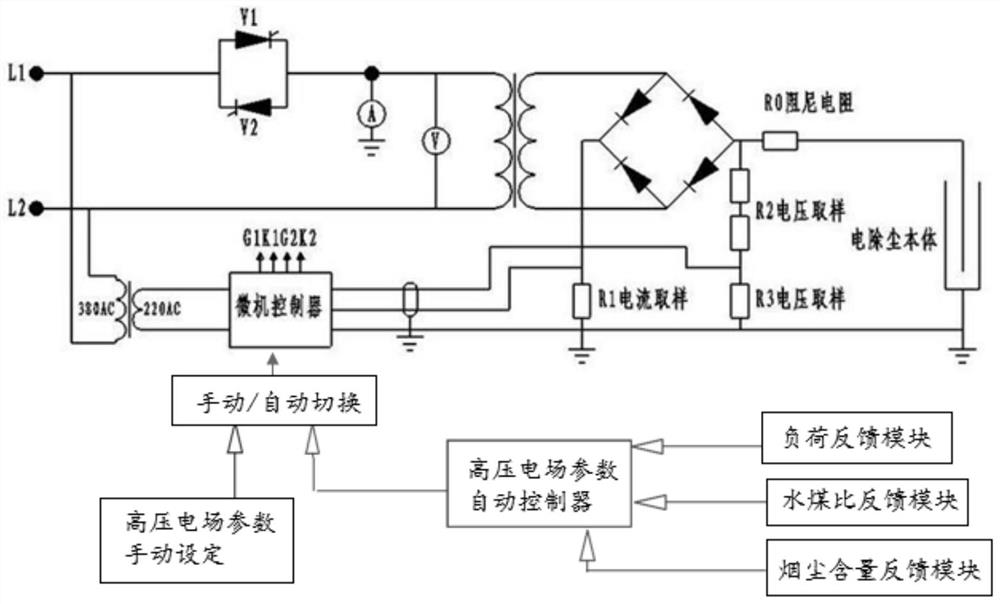

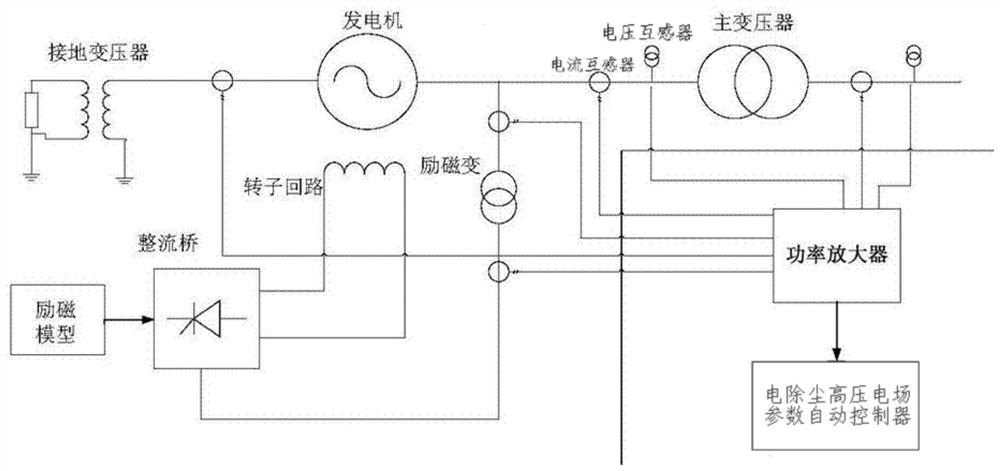

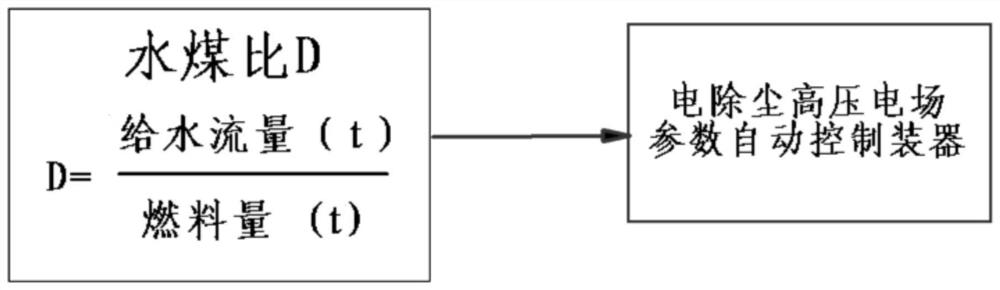

System for reducing power consumption of electrostatic dust collector and control method thereof

ActiveCN111974551AImprove power generation efficiencyEmission reductionElectric supply techniquesControl theoryDust emission

The invention provides a system for reducing power consumption of an electrostatic dust collector and a control method thereof. The input end of a microcomputer controller of the system is further connected with a manual / automatic switching module, the input end of the manual / automatic switching module is connected with a high-voltage electric field parameter manual setting module and a high-voltage electric field parameter automatic controller, and the input end of the high-voltage electric field parameter automatic controller is connected with a load feedback module, a water-coal ratio feedback module and a smoke content feedback module. The method comprises the following steps: acquiring parameters such as the unit load P of a generator set, the water-coal ratio D of a power generationsteam boiler and the smoke content G of a total exhaust port of a power plant; operating parameters of a high-voltage electric field of the electrostatic dust collector are automatically adjusted; flexibly adjusting the secondary voltage U2 and the secondary current I2 of the high-voltage electric field of the electrostatic dust collector according to the actual field work condition of a power plant. the power consumption of the electrostatic dust collector is reduced, the power supply coal consumption of a coal-fired power plant is reduced, the overall power generation benefit of a unit is improved, meanwhile, smoke dust emission is reduced, and contributions are made to environmental protection.

Owner:淮南洛河发电有限责任公司

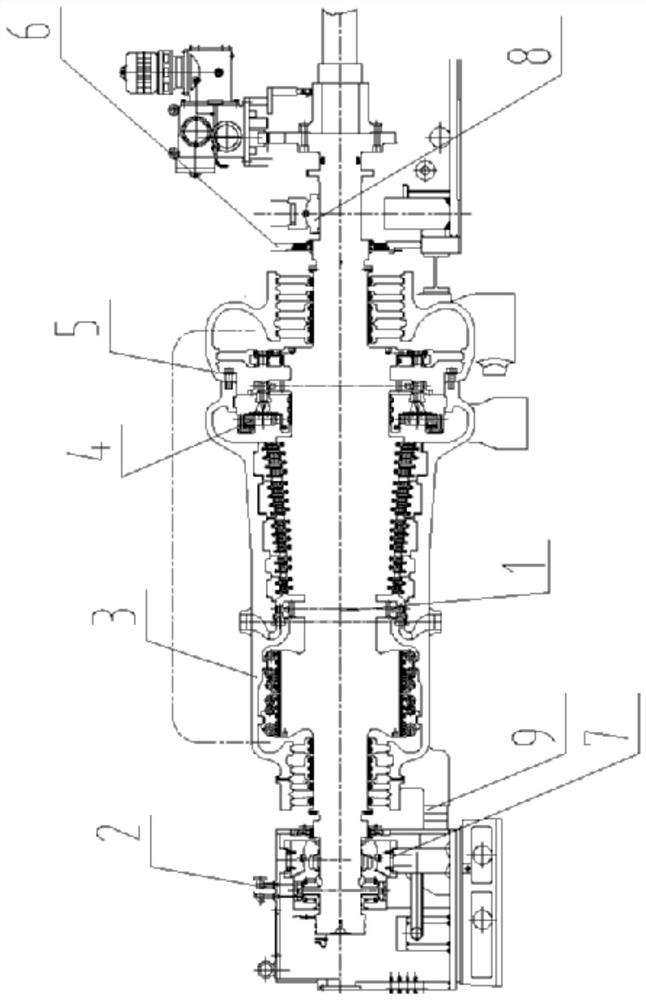

Water-feeding pump system driven by high-speed synchronous motor

ActiveCN103147955ANo lossImprove transmission efficiencyPump installationsPositive-displacement liquid enginesSynchronous motorFluid coupling

The invention discloses a water-feeding pump system driven by a high-speed synchronous motor, and relates to an efficient, energy saving and speed governing electric water-feeding pump system which is used in a large and medium-sized thermal power generating unit. The water-feeding pump system comprises a low rotational speed front-mounted pump, a low rotational speed front-mounted pump motor, an intermediate frequency variable-frequency power supply, a high-speed synchronous motor, a high rotational speed water-feeding pump and a static excitation device, wherein the high-speed synchronous motor is driven by the intermediate frequency variable-frequency power supply; the rotational speed is steplessly adjustable in a range from 60 rpm to 6,000 rpm; and the high-speed synchronous motor and the high rotational speed water-feeding pump are in direct connection through opposite wheels. Problems that an existing speed governing electric water-feeding pump adopts speed governing operation of a speed increase gear and a hydrodynamic coupler, the transmission loss is large, the response speed is slow, the adjusting dead zone is large, impact of starting on station service buses is obvious and the like are solved. The comprehensive transmission efficiency of the water-feeding pump system driven by the high-speed synchronous motor is higher than that of a steam feed pump system remarkably, heat consumption of a steam turbine generator unit is reduced remarkably, and the net coal consumption rate of the generator unit is decreased.

Owner:章礼道

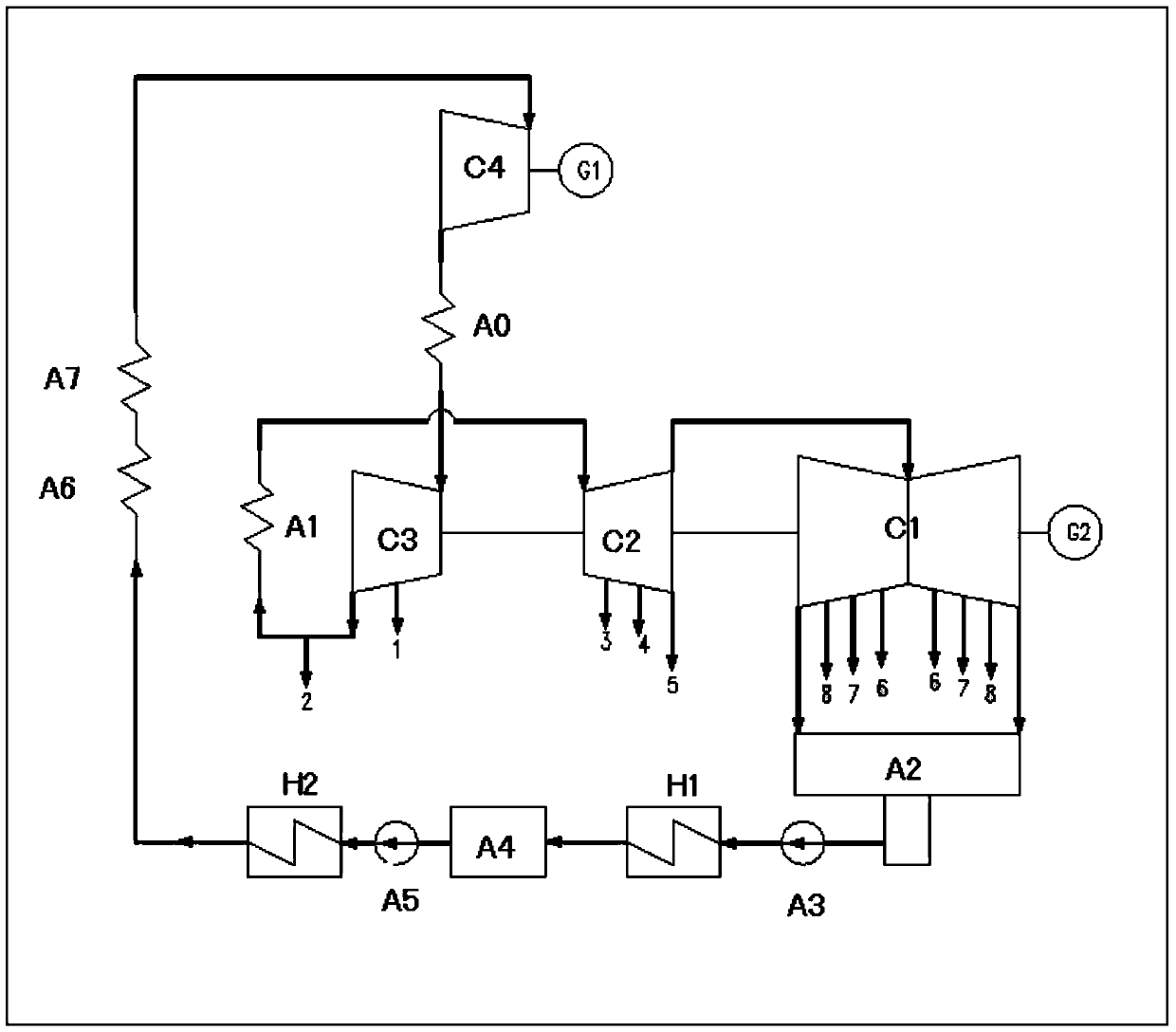

Single reheat pressurizing steam turbine thermodynamic system

ActiveCN103821574AGreat effortImprove thermal efficiency of power generationSteam useCoalEngineering

The invention discloses a single reheat pressurizing steam turbine thermodynamic system. The single reheat pressurizing steam turbine thermodynamic system is characterized in that a high parameter steam turbine generator set is provided with a back pressure steam extraction cylinder, the back pressure steam extraction cylinder and an ultra-high pressure cylinder are arranged to be separated or combined, a heat return and single reheat thermodynamic circulation system is provided with a second high pressure heater used for heat return, and extracted steam of the second high pressure heater is guided and connected from exhausted steam of the back pressure steam extraction cylinder. According to the single reheat pressurizing steam turbine thermodynamic system, the electricity generation heat efficiency is further improved, coal consumption for power supply is reduced, and the capacity of the set is obviously improved.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

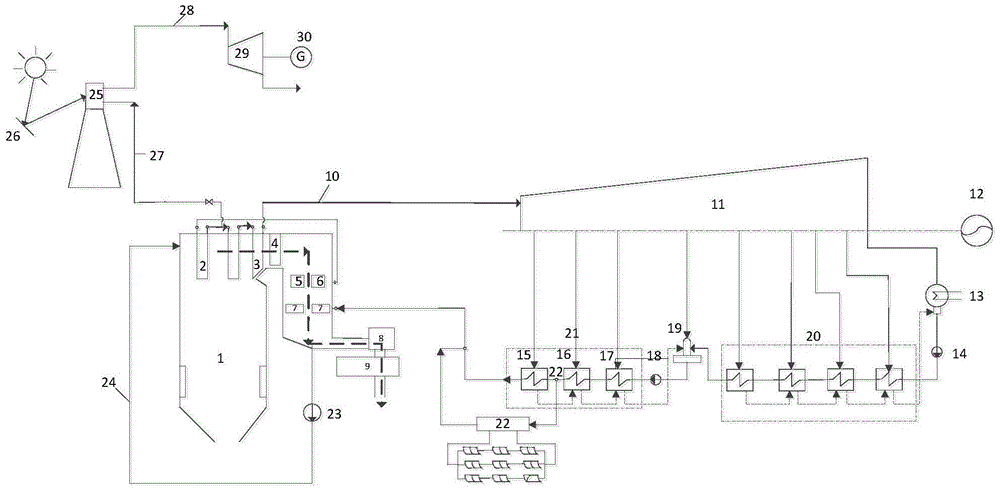

Solar auxiliary coal-fired power generation system with compound heat collecting mode

InactiveCN105697249AExpand the scope of absorptionReduce coal consumption for power supplyFrom solar energyMachines/enginesHearthSuperheater

The invention belongs to the technical field of solar power generation, and in particular, relates to a solar auxiliary coal-fired power generation system with a compound heat collecting mode. The system is characterized by adopting a mode of connecting compound solar energy into a coal-fired unit; tank type solar energy is connected to one part of high-voltage heaters in parallel; tower type solar energy heats one part of high-temperature steam extracted behind a platen superheater; a tower type solar heat collector absorbs heat for generating electricity through work; cold smoke is extracted between a coal economizer and denitration equipment by a recirculating fan, and is injected in the top of a boiler hearth for mixing with high-temperature smoke; the tank type solar energy and the high-voltage heaters are arranged side by side to replace one part of heat sources of a heat return system to cause the flow increment of reheated steam; the tower type solar energy can replace superheated steam of a boiler to reduce the flow of reheated steam; and the two replacing modes can mutually counteract one part of influence effects on the flow of the reheated steam, so that the safety of a heated surface of the boiler is facilitated. The system largely reduces the whole power supply and coal consumption of the unit through gradient utilization of solar resources.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

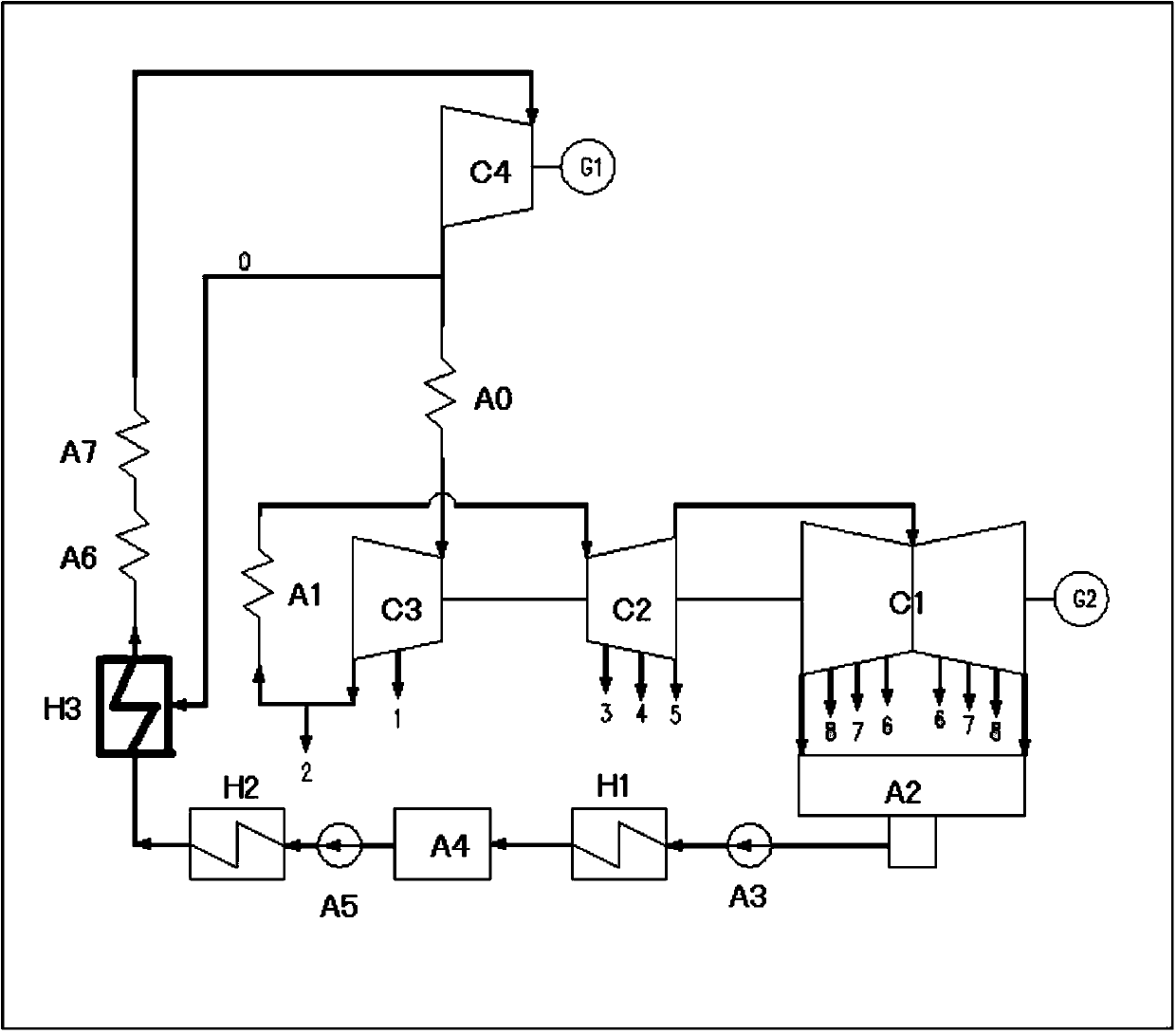

Double-reheat supercharged steam turbine thermal system

ActiveCN103806966AGreat effortImprove thermal efficiency of power generationSteam useEngineeringHigh pressure

The invention discloses a double-reheat supercharged steam turbine thermal system which is characterized in that a high parameter steam turbine generating set is provided with a back pressure steam extraction cylinder; the back pressure steam extraction cylinder and an ultrahigh pressure cylinder are set into a split or combined structure; a regeneration and double-reheat thermal cycle system is provided with a second high pressure heater for regeneration; steam extraction of the second high pressure heater is led from steam exhaust of the back pressure steam extraction cylinder. The double-reheat supercharged steam turbine thermal system disclosed by the invention further improves thermal efficiency of electricity generation, reduces power supply coal consumption, and obviously increases the unit output.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

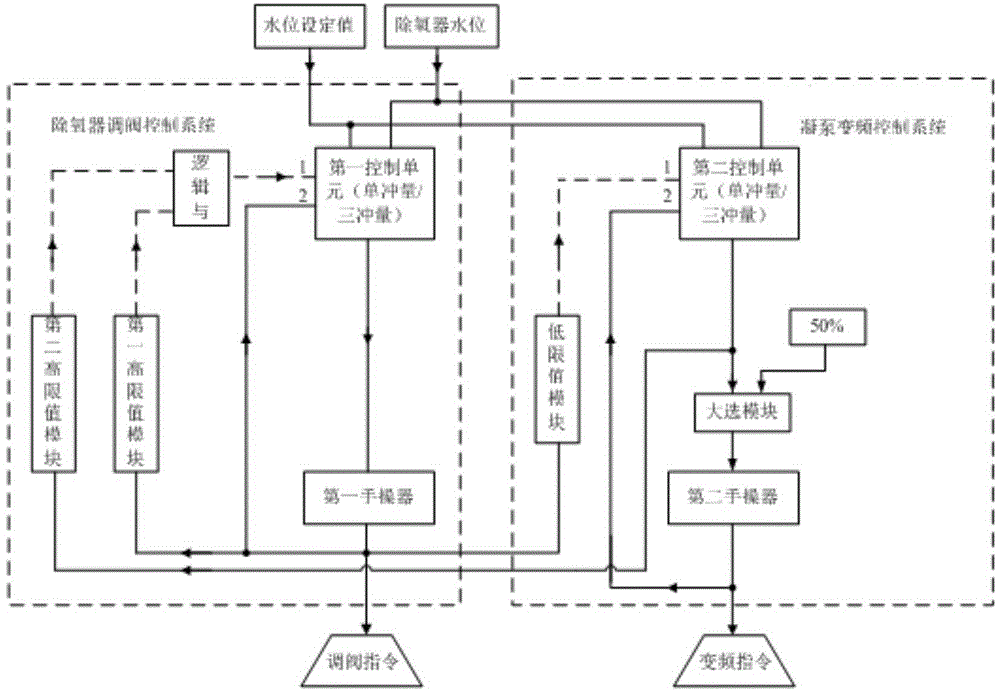

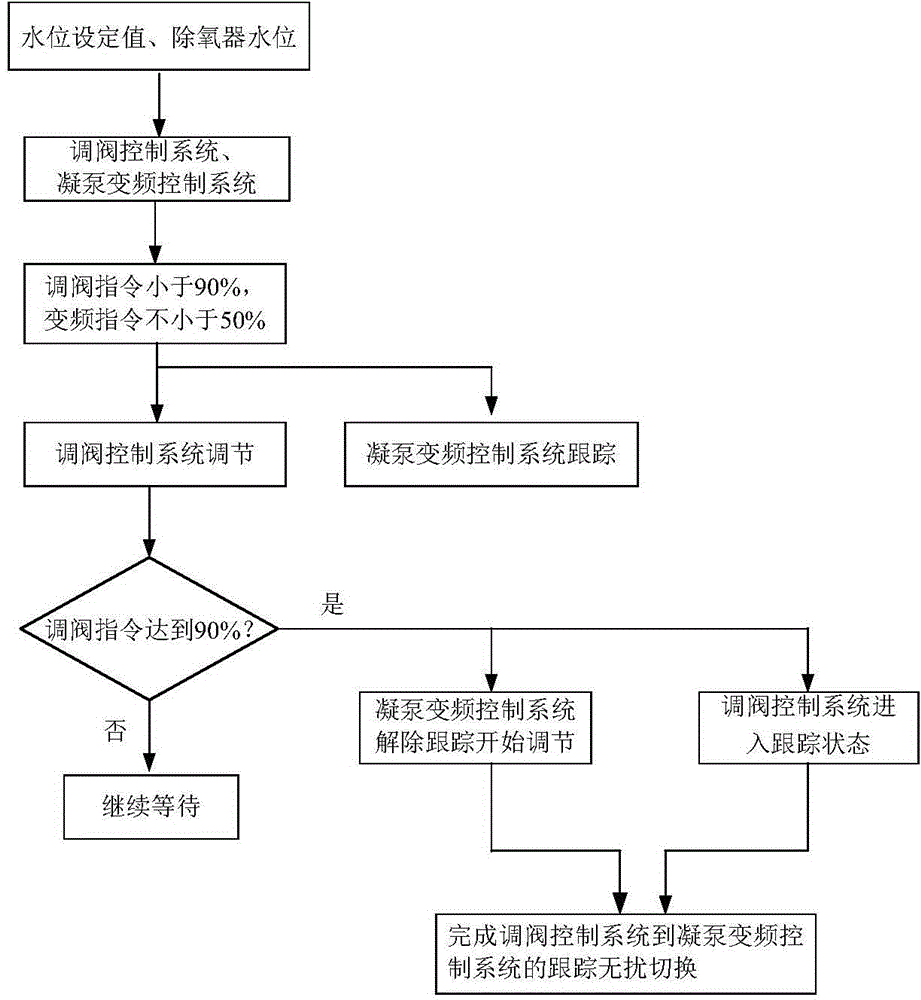

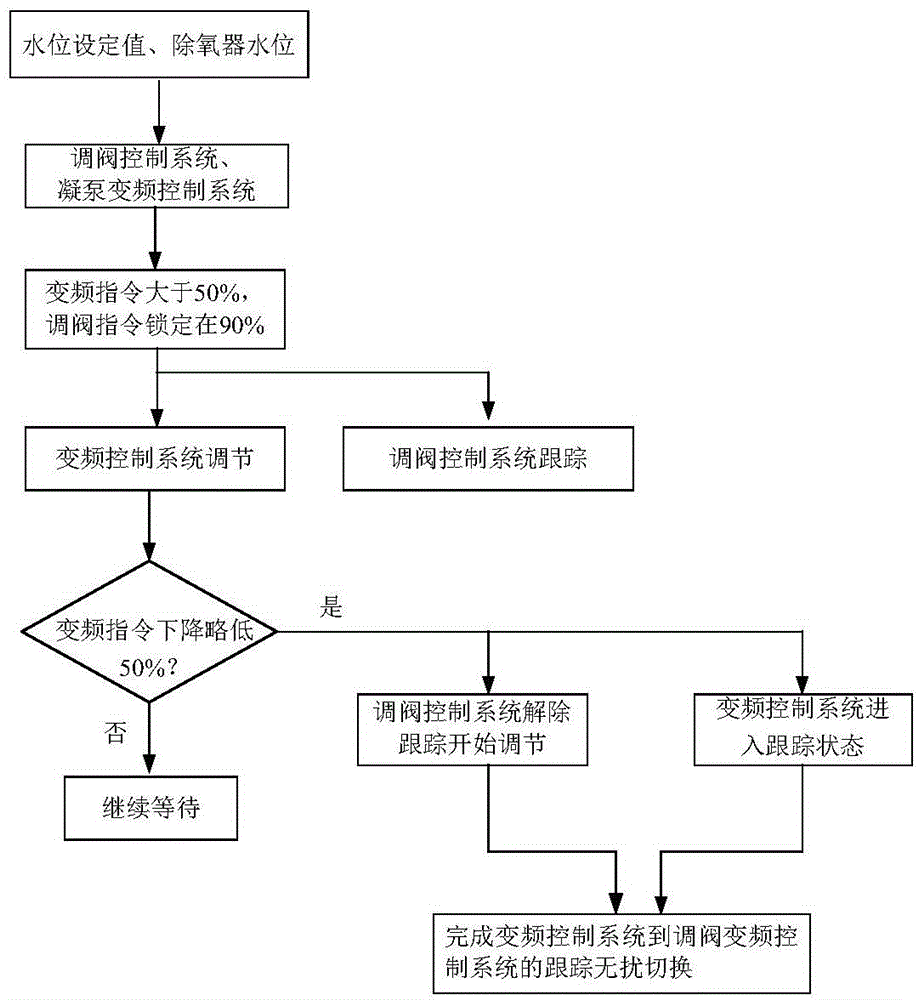

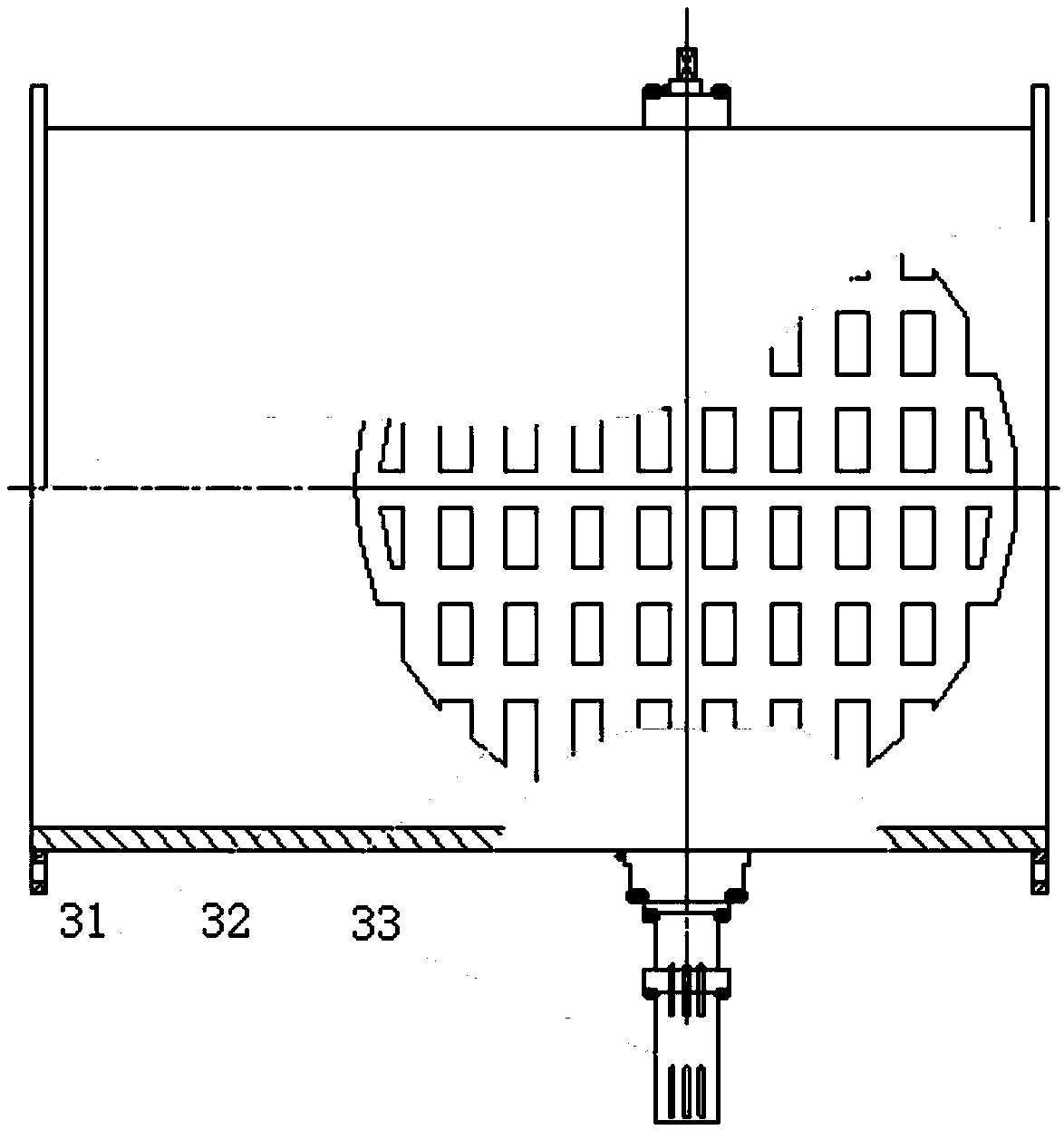

Deoxygenator water level whole-course control system and method with tracking under condensate pump frequency conversion condition

ActiveCN104090589AIncrease the level of automationGood energy saving effectLevel controlFrequency conversionControl system

The invention discloses a deoxygenator water level whole-course control system and method with tracking under a condensate pump frequency conversion condition. The system comprises a first control unit of a deoxygenator valve adjusting control system which is used for obtaining a deoxygenator water level set value and a process variable deoxygenator water level, and a second control unit of a condensate pump frequency conversion control system. The first control unit and the second control unit, according to a value of a load, determine whether the system is at an adjusting state or a tracking state, the first control unit then controls a first manual operator corresponding to the deoxygenator valve adjusting control system to adjust a deoxygenator water level through a valve adjusting instruction, and the second control unit controls the corresponding condensate pump frequency conversion control system through a frequency conversion instruction and then adjusts the deoxygenator water level through a second manual operator. By using the scheme, it is ensured that a valve adjusting mode and a frequency conversion mode are simultaneously automatically input, and interference-free switching is realized when the two modes are converted, such that the automation level is improved, and the energy conservation effect is also enhanced.

Owner:STATE GRID CORP OF CHINA +1

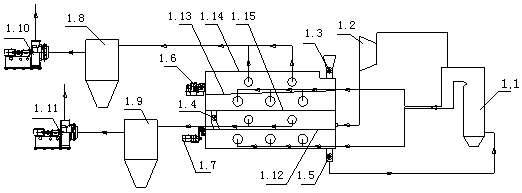

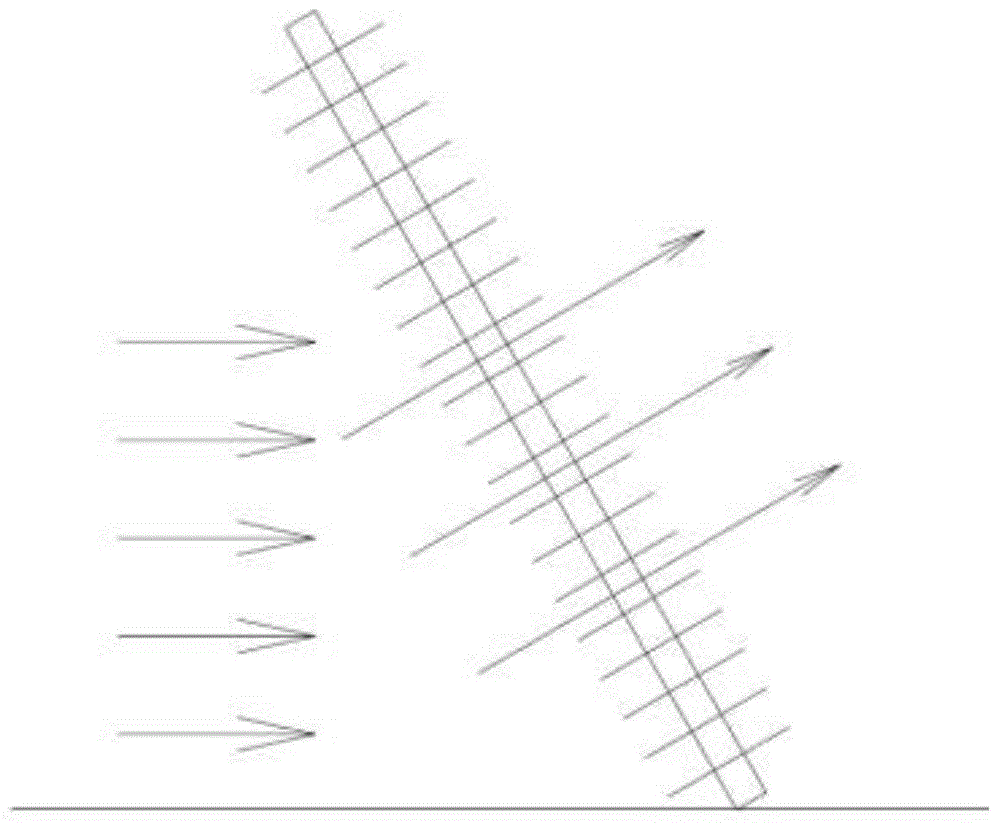

Intelligent pulverized coal concentration, speed and fineness on-line monitoring leveling system and method thereof

InactiveCN108826352ADensity automatic adjustmentConcentration speed automatic adjustmentFuel supply regulationMeasurement deviceClosed loop

The invention discloses an intelligent pulverized coal concentration, speed and fineness on-line monitoring leveling system. The system comprises a pulverized coal concentration, speed and fineness integrated measuring device and an on-line leveling device which are installed in a primary air pipe between a coal mill outlet and a boiler inlet, and the pulverized coal concentration, speed and fineness integrated measuring device and the on-line leveling device are in communication connection with a boiler air and pulverized coal on-line balance system; and the pulverized coal concentration, speed and fineness integrated measuring device is used for collecting concentration, speed and fineness signals of pulverized coal in the primary air pipe, the boiler air and pulverized coal on-line balance system is used for controlling the on-line leveling device to adjust the flow and flowing speed of the pulverized coal inside a coal mill outlet pulverized coal pipe according to a pulverized coalsignal and a current opening signal of the on-line leveling device. According to the intelligent pulverized coal concentration, speed and fineness on-line monitoring leveling system, the integrated on-line measuring and leveling closed loop technology is adopted, primary air and pulverized coal thermal state leveling is achieved, and assistance is provided for achieving optimized burning, improving the boiler efficiency and reducing the net coal consumption rate.

Owner:南京新瓦特智控科技有限公司

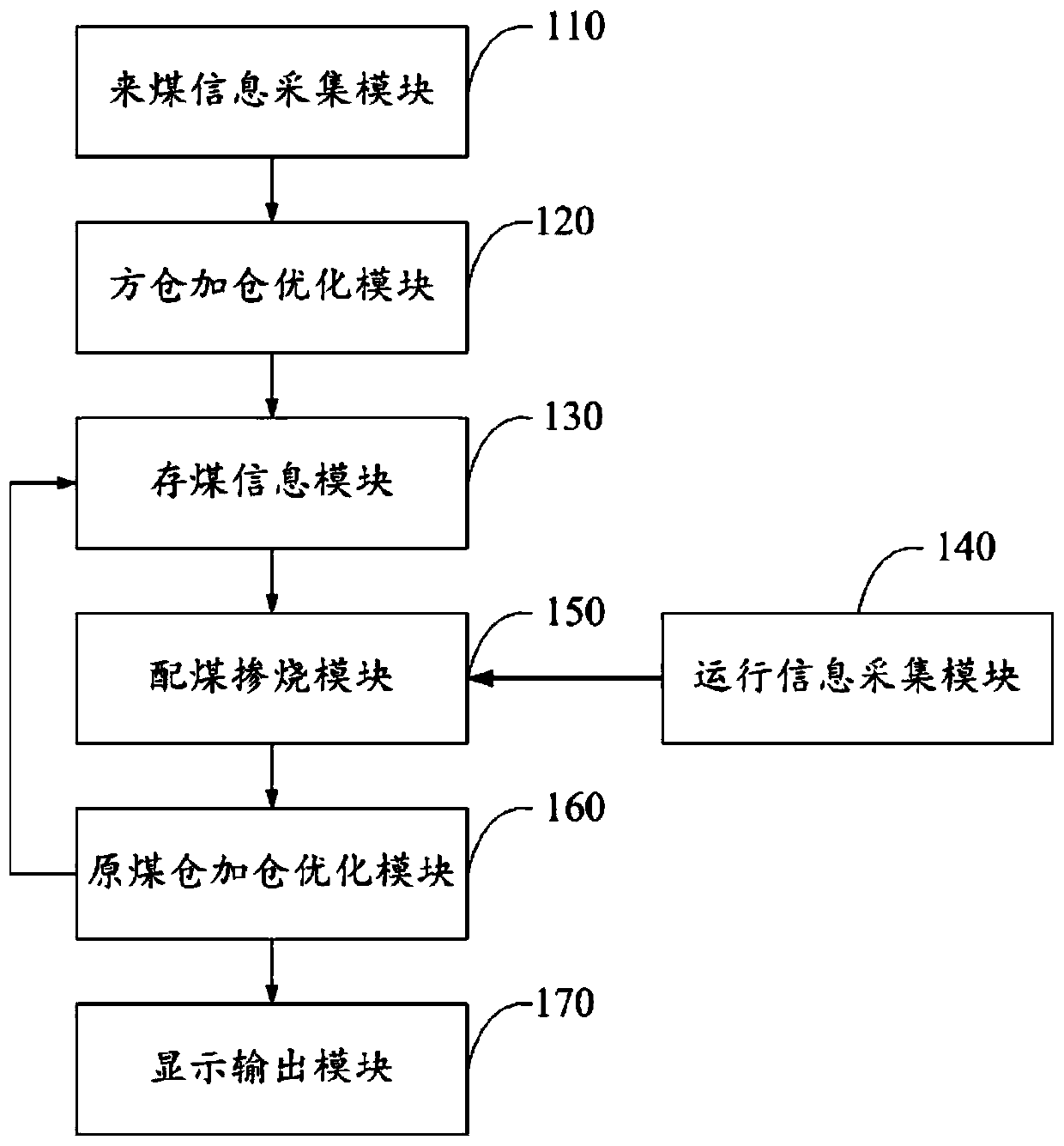

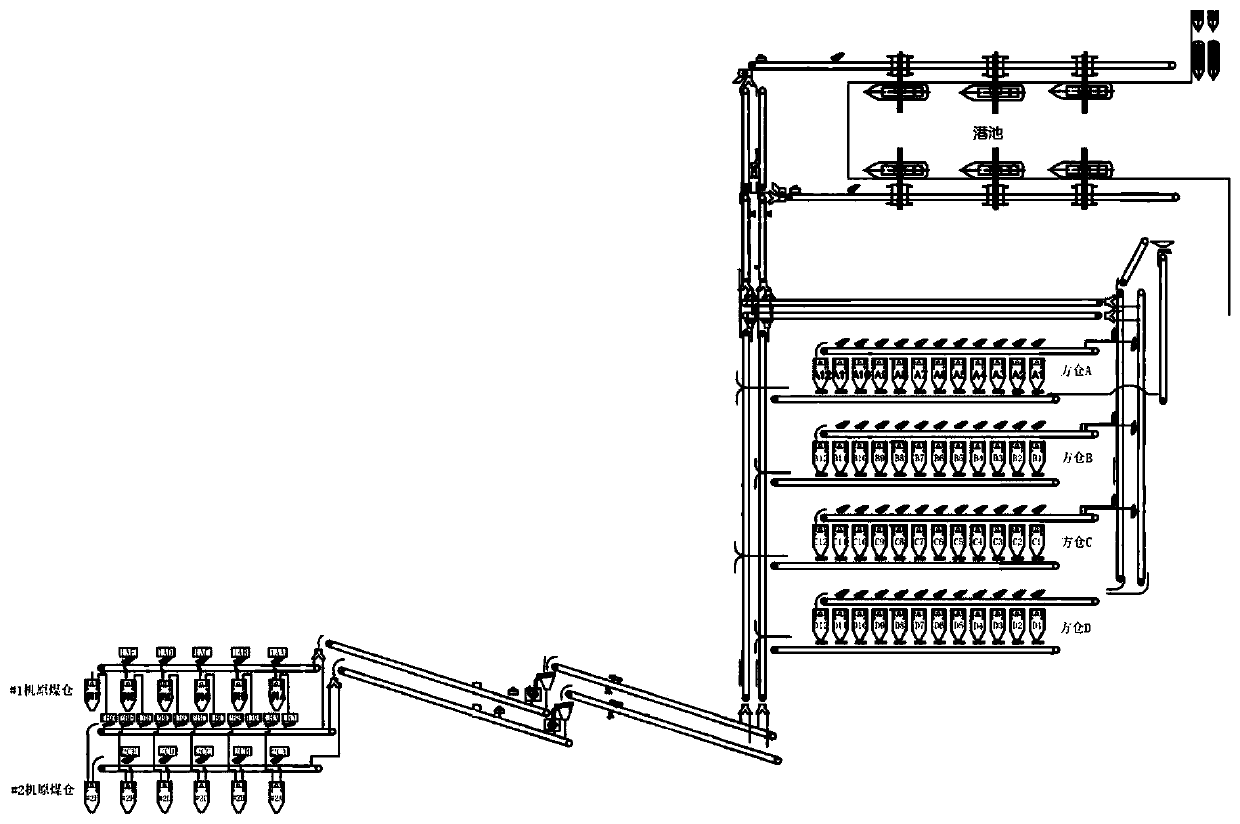

Coal dispatching system and method for cluster type coal plant

InactiveCN111506028ARealize reasonable schedulingImprove coal efficiencyTotal factory controlProgramme total factory controlCoal plantBunker

The invention provides a coal dispatching system and method for a cluster type coal plant. The system comprises an incoming coal information collection module which is used for collecting the incomingcoal information of the coal plant, a bunker adding optimization module which is used for generating a bunker adding strategy, a coal storage information module which is used for acquiring and counting the coal storage information of each bunker of the coal plant, an operation information acquisition module which is used for acquiring the operation information of a coal generator set, a coal blending combustion module which is used for generating a coal blending combustion strategy according to the unit operation information and the coal storage information, a raw coal bunker adding optimization module which is used for generating a final raw coal bunker adding strategy based on the coal blending combustion strategy and updating the coal storage information of each bunker, and a display output module which is used for displaying the coal storage information of each bunker, the bunker adding strategy information and the coal blending combustion strategy information. According to the technical schemes, the problems of low unit coal efficiency and high power supply coal consumption existing in existing coal dispatching of the cluster honeycomb type coal plant are solved, the coal efficiency of the generator set can be improved, the power supply coal consumption is reduced, and economic benefits are guaranteed.

Owner:HUANENG POWER INT INC +1

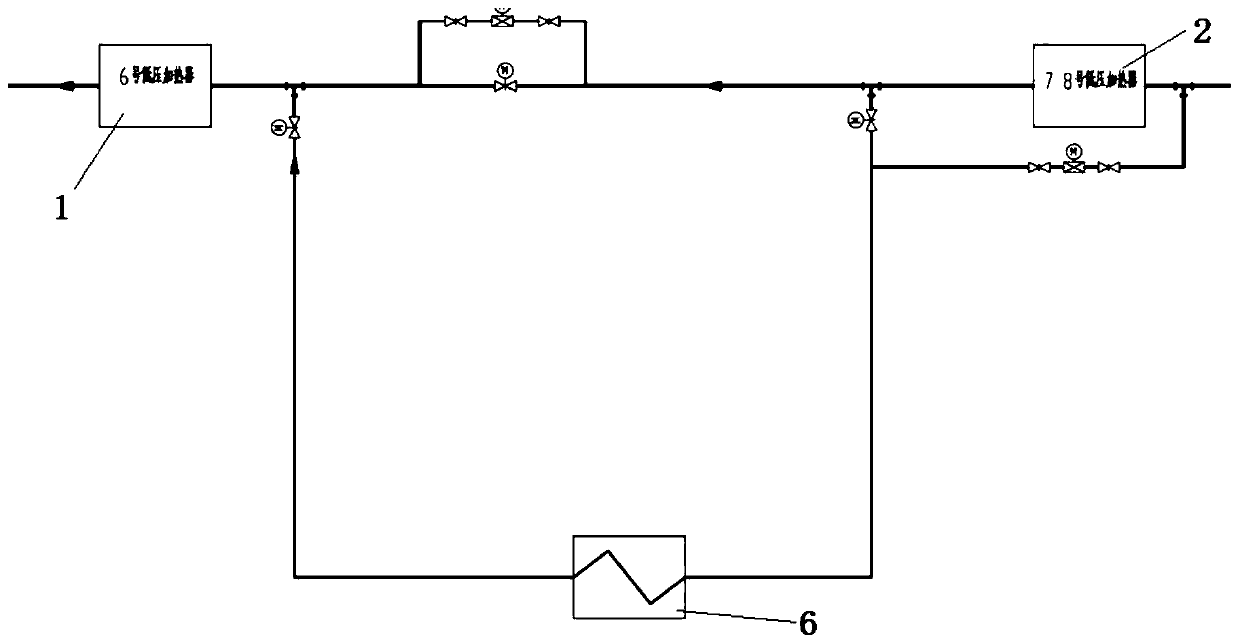

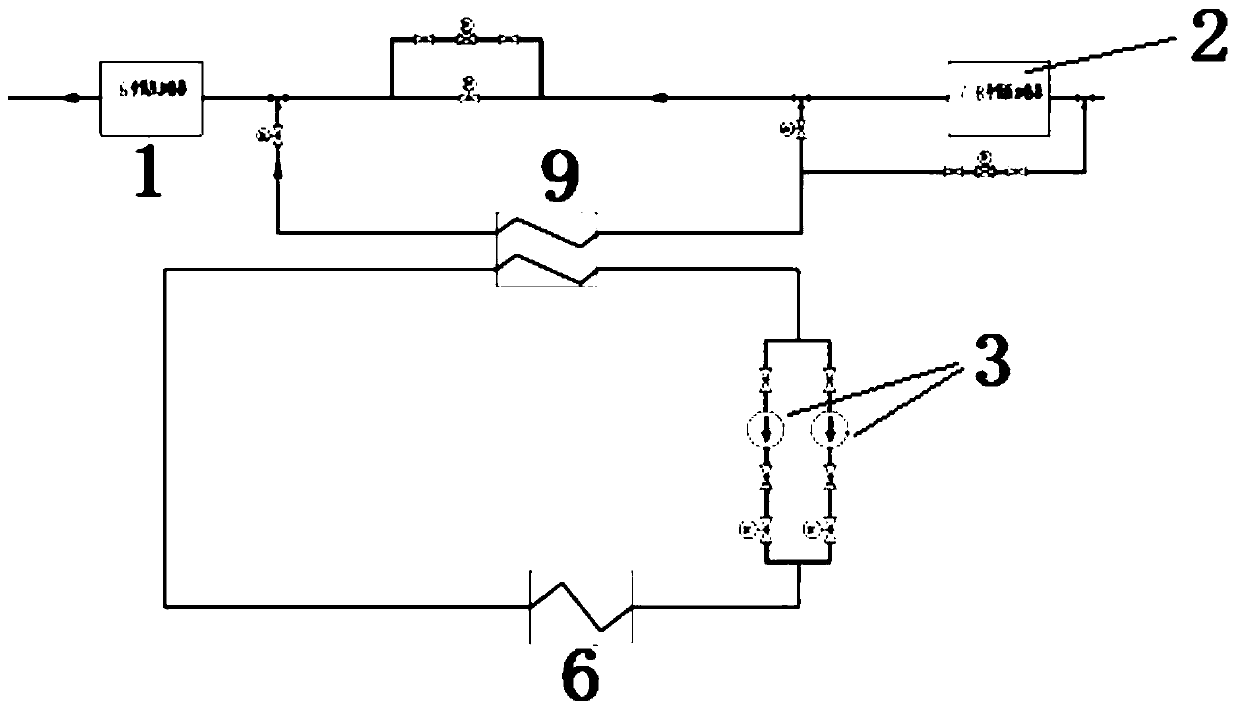

Hot water recirculation system for waste heat recovery of flue gas

PendingCN110864274ACondensate flow is stableReduce power consumptionRecuperative heat exchangersFeed water supplyEnergy conservationAir heater

The invention provides a hot water recirculation system for waste heat recovery of flue gas, and belongs to the technical field of thermal power energy conservation. The hot water recirculation systemis characterized in that heaters and a flue gas waste heat recovery heat exchanger are connected in parallel to access an adjusting valve; a gate valve and a booster water pump are additionally arranged, and the adjusting valve ensures that condensed water flow entering the flue gas waste heat recovery heat exchanger when an extracting and condensing steam turbine is operated under the steam extraction working condition is stable; a bypass valve is arranged at the booster water pump, the booster water pump does not operate when the steam turbine is in a pure condensing condition, the bypass valve is opened, the system relies on the unit condensation water pump margin to form an open cycle, the power consumption of the system can be reduced, and the power supply coal consumption is reduced; and after the flue gas waste heat recovery heat exchanger is added, an air heater is additionally arranged, so that the flue gas waste heat recovery system realizes multiple modes of operation, theload regulation range is large, and the unit adaptability is good. According to the hot water recirculation system, the waste heat recovery rate of the smoke exhaust is improved, the initial investment of the equipment is reduced, the adjustment is flexible, the energy-saving effect is remarkable, and the engineering implementation difficulty is reduced.

Owner:石家庄良村热电有限公司 +1

Primary air cooler heat recovery system and control method

ActiveCN103438686BReduce cooling air volumeLower exhaust gas temperatureDrying gas arrangementsGrain treatmentsAir preheaterWater use

The invention discloses a primary air cooler heat regenerative system and a controlling method. According to the primary air cooler heat regenerative system and the controlling method, a primary air cooler is arranged in a primary heat air duct of an outlet of a boiler air heater, low-pressure supplied water used as cooling water is introduced by a coal-fired unit low-pressure water-supply heat regenerative system, heat of primary heat wind is absorbed, the heated supplied water is sent back to a unit deaerator, the flow of the cooling water is adjusted so as to enable the temperature of the primary wind to be reduced to meet the temperature requirement of drying medium at the inlet of a coal mill. By means of the technical scheme, the cold wind amount of a side road of a boiler air preheater can be greatly reduced, the smoke exhausting temperature of the boiler is reduced, the power-supply coal consumption of the unit is reduced, and the stable operation of the unit is not affected.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

A lignite drying method and drying equipment utilizing power plant flue gas and steam waste heat

ActiveCN106382790BImprove economyImprove operational efficiencyDrying solid materials with heatDrying gas arrangementsBrown coalFlue gas

The invention discloses a brown coal drying method and device utilizing waste heat of smoke and steam of a power plant. The drying method comprises two-time drying treatment, wherein the two-time drying treatment comprises the steps that firstly, the high-temperature smoke directly discharged by a power plant coal fired boiler is utilized for conducting first-time drying treatment on damp materials, the high-temperature smoke directly makes uniform contact with the damp materials, and intermediate materials are obtained; and secondly, the high-temperature smoke and the high-temperature steam directly discharged by the power plant coal fired boiler are utilized for conducting second-time drying treatment on the intermediate materials at the same time, the high-temperature smoke directly makes uniform contact with the intermediate materials, meanwhile, the intermediate materials make uniform contact with a heat exchange pipe inflated with the steam for heat exchange, dried materials are obtained, and second-time drying treatment is achieved. The brown coal drying method and device have the beneficial effects that the power plant waste heat serves as a heat source for brown coal drying, the running economical efficiency of a power plant generator set is improved, a system for drying the brown coal and a brown coal power generation system are integrated, efficient utilization of power plant energy and optimization of a technology system are achieved, and the brown coal drying method and device belong to the poly-generation technology of the power plant.

Owner:邹平双飞成套设备有限公司

Novel flue gas waste heat recycling method

PendingCN110030861AReduce the efficiency of SO3 removalImprove the efficiency of SO3 removalRecuperative heat exchangersEmission preventionFlue gasProcess engineering

The invention discloses a novel flue gas waste heat recycling method. The novel flue gas waste heat recycling method is characterized in that flue gas temperatures of all sections of the tail portionof a flue of a boiler are different, so that high-temperature flue gas heat exchangers of corresponding energy levels, medium-temperature flue gas heat exchangers of corresponding energy levels, low-temperature flue gas heat exchangers of corresponding energy levels and low-low-temperature flue gas heat exchangers of corresponding energy levels are additionally arranged at different positions in the flue so as to fully and deeply utilize flue gas waste heat and achieve energy conservation and emission reduction; the different grades of the flue gas waste heat at the tail portion of the boileris comprehensively utilized, moreover, according to flue gas waste heat resources and different use requirements provided by users, different flow division and different proportions of different coldsources and all stages of flue gas waste heat are achieved by virtue of all stages of heat exchange equipment, and finally energy level matching and gradient utilization are achieved; according to thenovel flue gas waste heat recycling method, the flue gas exhaust temperature is effectively reduced, the generating capacity is increased, the coal consumption is reduced, the dust removal efficiencyand the desulfurization efficiency are improved, the desulfurization water consumption is reduced, a chimney is protected, and the problem of environmental protection up-to-standard emission of enterprises is solved to a certain extent.

Owner:NANJING GUONENG ENVIRONMENTAL PROTECTION ENG

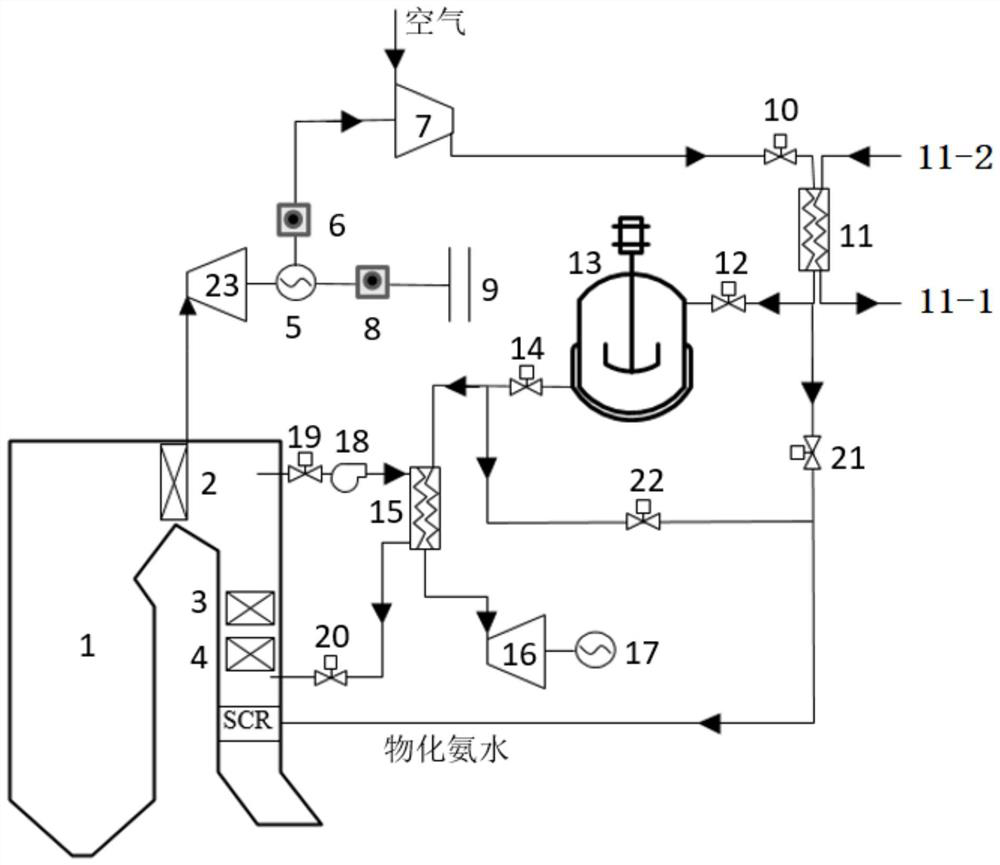

Deep peak shaving system and method for compressed air energy storage coupled thermal power generating unit

PendingCN113090509AIncrease power generationImprove energy efficiencyPositive displacement pump componentsGas turbine plantsEngineeringSuperheater

The invention discloses a deep peak shaving system and method for a compressed air energy storage coupled thermal power generating unit. A turbine is connected with a first generator, the first generator is connected with a compressor, and the compressor is connected with a heat inlet of a condenser. A heat outlet of the condenser is divided into two paths, one path is connected with an air storage tank, and the other path is connected with an SCR ammonia spraying materialization system. An outlet of the air storage tank is divided into two paths, one path is connected with the SCR ammonia spraying materialization system, and the other path is connected with a cold inlet of a heater. A cold outlet of the heater is connected with an expansion machine, and the expansion machine is connected with a second generator. A heat inlet of the heater communicates with a tail flue of a boiler, and a connection point is located between a high-temperature superheater and a low-temperature superheater. The heat inlet of the heater is provided with a smoke extraction device. A heat outlet of the heater communicates with the tail flue of the boiler, and a connection point is located between an economizer and an SCR denitration device. The deep peak shaving system and method can meet the requirement for flexible and deep peak shaving of a thermal power plant unit, and have the characteristic of high economical efficiency.

Owner:XIAN THERMAL POWER RES INST CO LTD

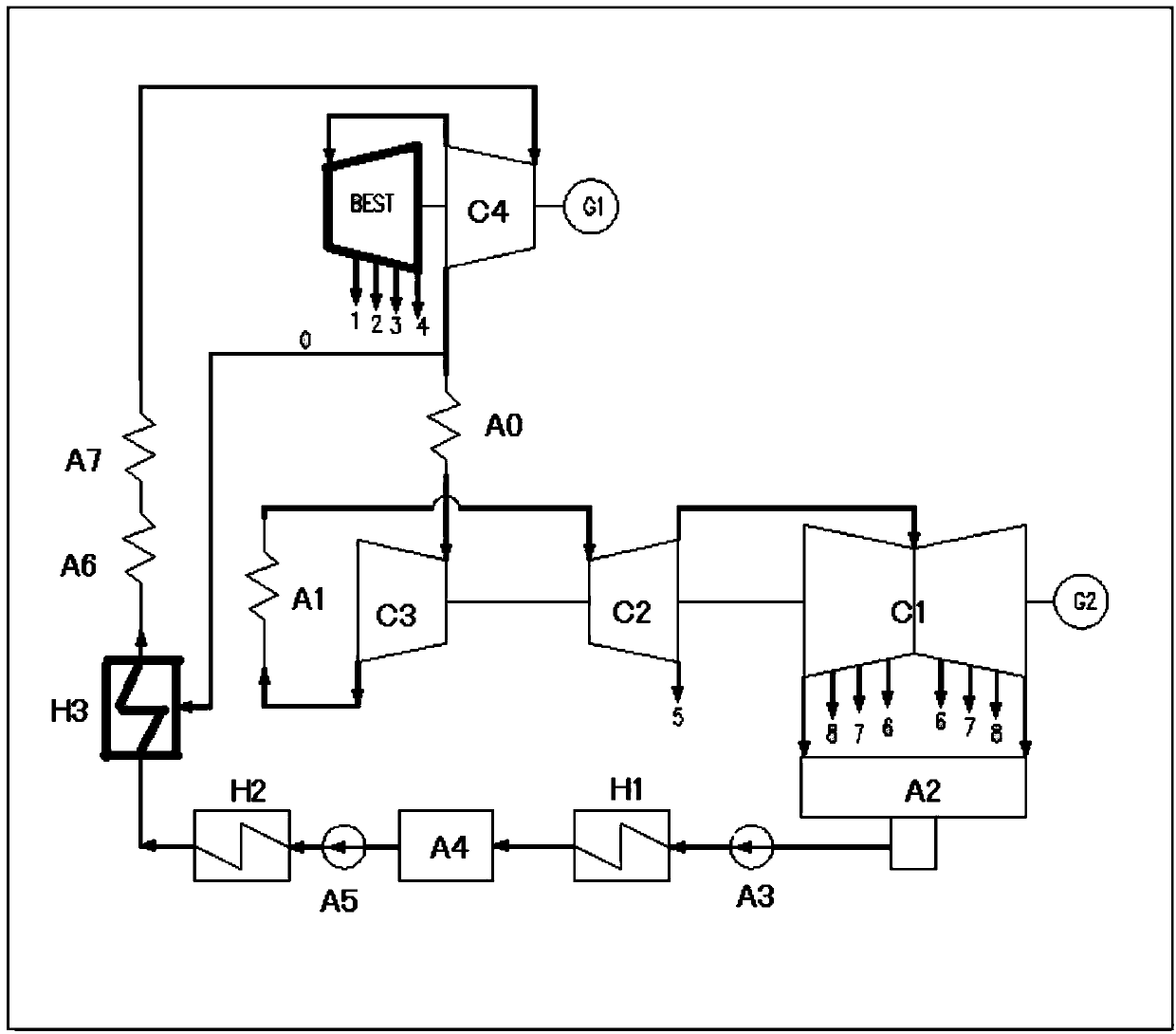

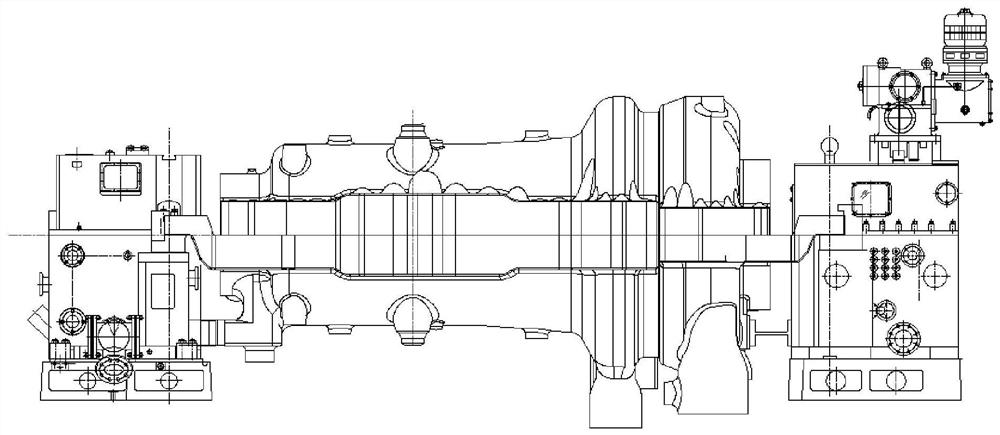

Pressurization main machine coaxial driving feed water pump system comprising pure condensing steam extraction small steam turbine

ActiveCN105822360AGreat effortImprove thermal efficiency of power generationMachines/enginesElectricityEngineering

The invention provides a pressurization main machine coaxial driving feed water pump system comprising a pure condensing steam extraction small steam turbine. The pressurization main machine coaxial driving feed water pump system is additionally provided with a second back pressure steam extraction steam cylinder. The steam inlet end of the second back pressure steam extraction steam cylinder is connected with the steam outlet end of a high pressure cylinder. The steam outlet end of the second back pressure steam extraction steam cylinder is connected with the water inlet end of a condensate pump after steam is condensed through a second condenser. The pressurization main machine coaxial driving feed water pump system comprising the pure condensing steam extraction small steam turbine can further improve the thermal efficiency of electricity generation and reduce electricity supply coal consumption; and meanwhile, the unit output is increased to generate more electricity, and the rate of return on investment is increased.

Owner:国能浙江北仑第一发电有限公司 +2

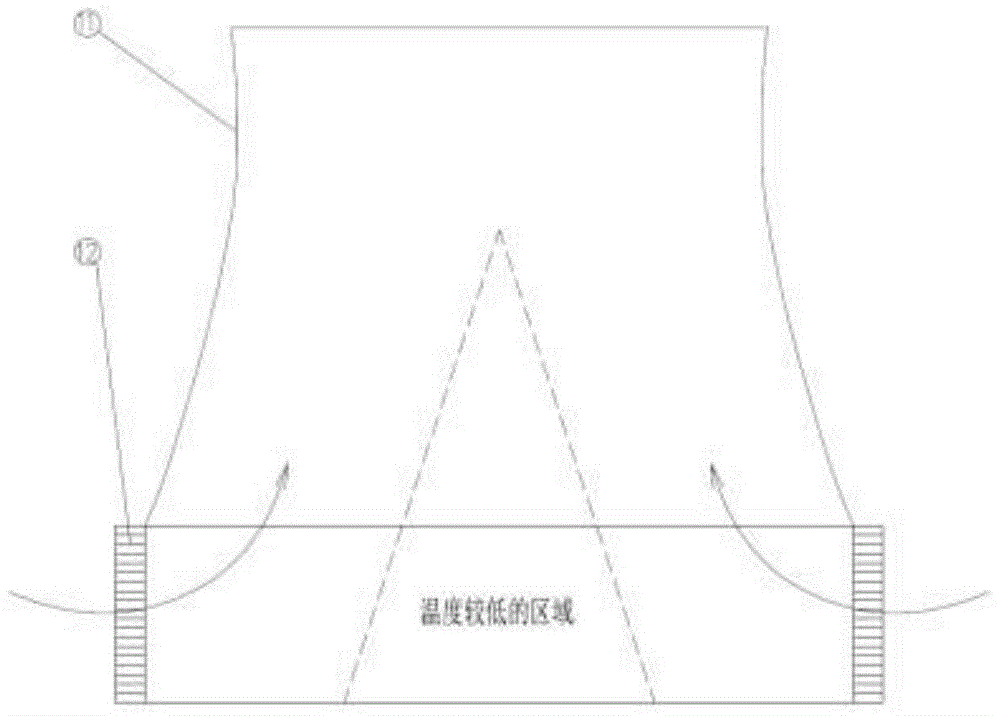

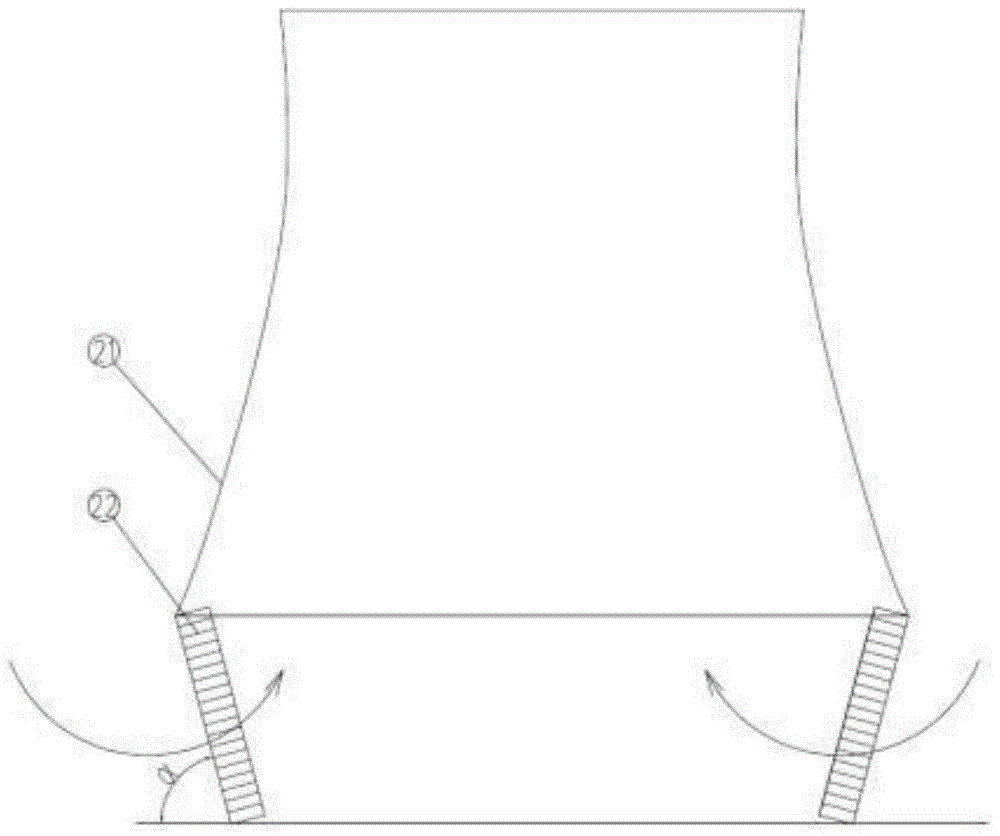

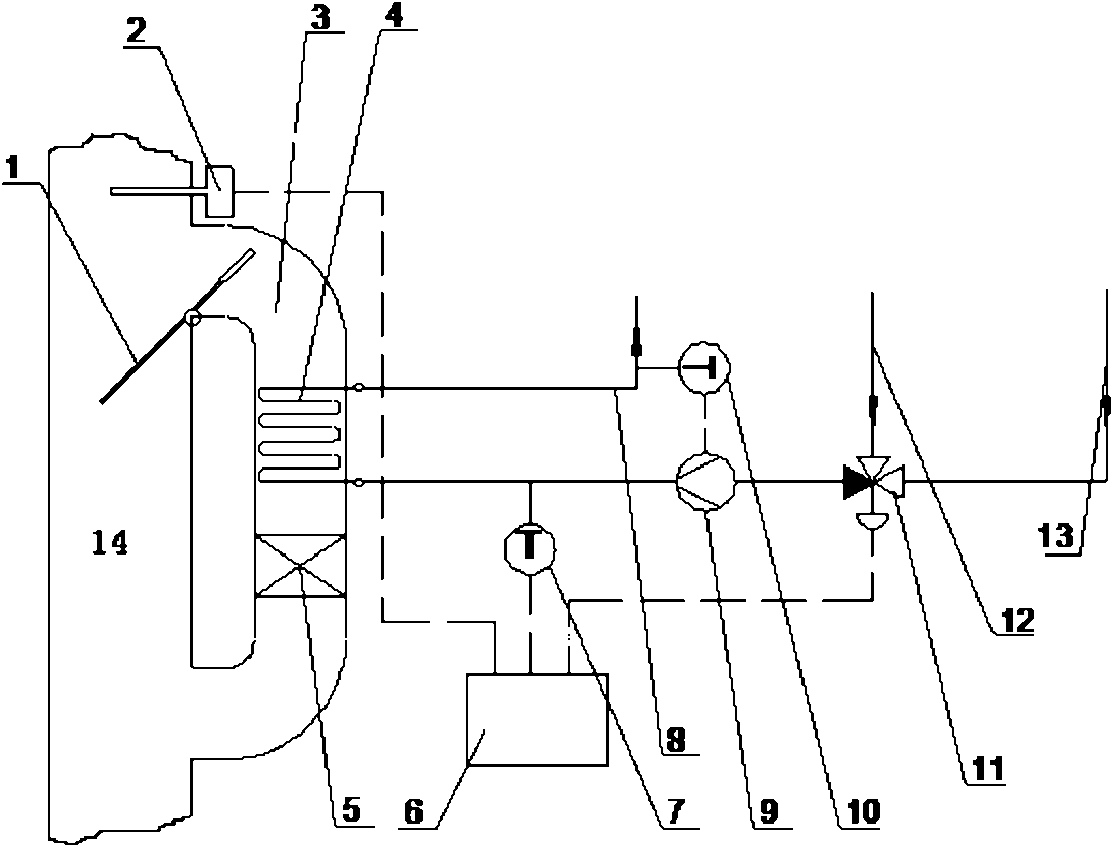

Indirect cooling tower with cooling triangles arranged obliquely

InactiveCN104697356AReduce water temperatureReduce coal consumption for power supplyTrickle coolersCooling towerEngineering

The invention discloses an indirect cooling tower with cooling triangles arranged obliquely, and particularly relates to an indirect cooling tower with cooling triangles arranged obliquely and segmented cooling triangles arranged obliquely. The indirect cooling tower comprises an indirect cooling tower drum and the cooling triangles arranged obliquely. After the structure is adopted, the indirect cooling tower has the following advantages that under the condition of the same diameter of the tower drum, the heat dissipation area can be increased; on the premise of ensuring the same heat dissipation area, the diameter of the tower drum of the cooling tower can be greatly reduced, occupied area and construction investment can be reduced, and the natural circulation power of the cooling tower can be increased; it can be effectively avoided that cross ventilation occurs in a crosswind environment to reduce the cooling efficiency; a temperature field and a flow field in the tower are more uniform.

Owner:SHANDONG UNIV

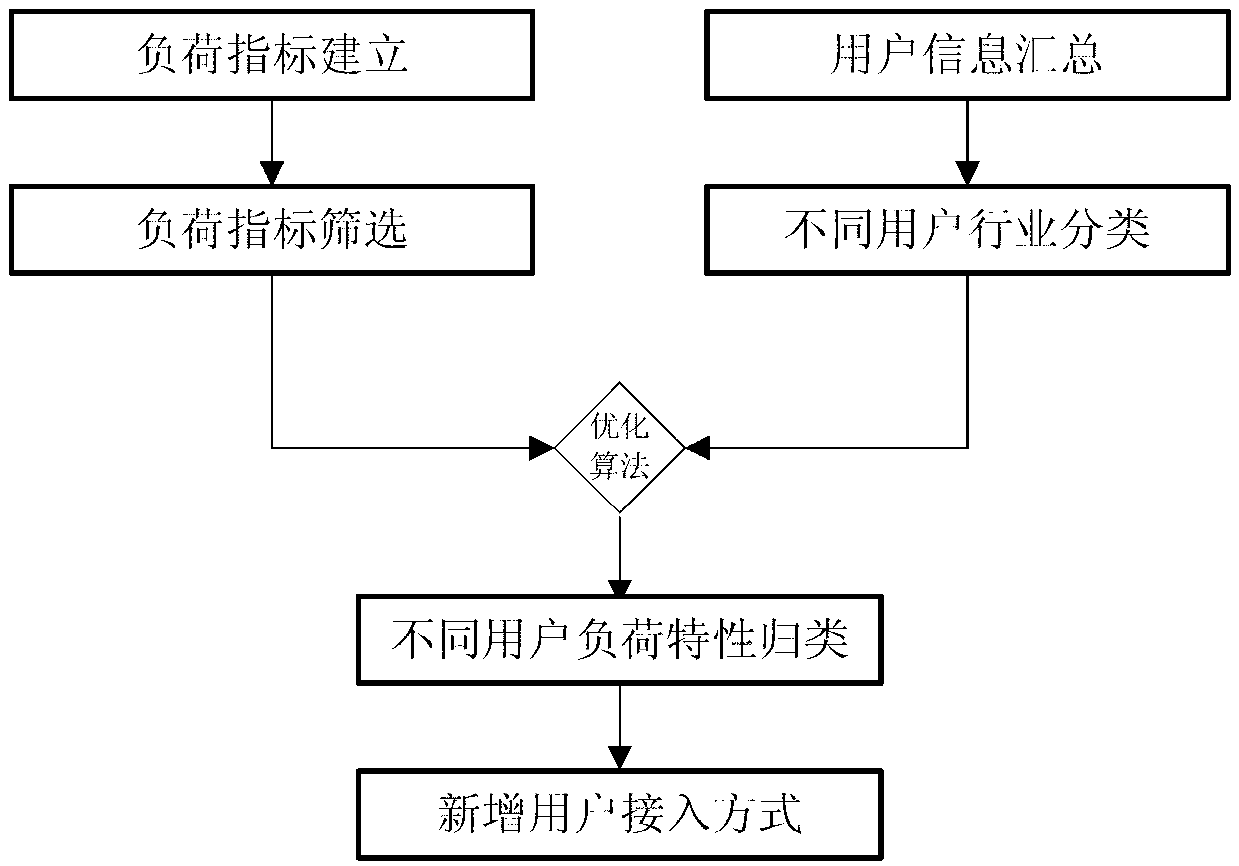

Processing method for optimizing connecting information of new consumers of power distribution network

ActiveCN103345659AReduce lossImprove operational efficiencyForecastingOperational costsElectric power system

The invention relates to a processing method for optimizing connecting information of new consumers of a power distribution network. The processing method for the optimizing connecting information of the new consumers of the power distribution network comprises the following steps of (1) carrying out industry classification on the new power consumers , meanwhile, carrying out analysis on the connected power distribution network, (2) carrying out matching on the new consumers and the power distribution network according to a different consumer combination optimization algorithm, and (3) obtaining the optimizing connecting information of the new consumers. Compared with the prior art, the processing method for the optimizing connecting information of the new consumers of the power distribution network has the advantages of improving operating efficiency of power generation and supply devices, reducing operating cost of a power system, reducing consumption of resources, being beneficial to environmental protection and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Exhaust gas waste heat recovery and emission reduction comprehensive application system for coal-fired boiler in thermal power plant

ActiveCN102305413BReduce low temperature corrosionImprove performanceCombustion processIndirect carbon-dioxide mitigationExpansion tankAir preheater

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

Smoke waste heat recovery system of power station boiler and method thereof

InactiveCN101696794BAvoid dust accumulationAvoid corrosionFeed-water heatersRecovery methodEngineering

The invention discloses a smoke waste heat recovery system of a power station boiler and a method thereof, belonging to the technical field of energy saving. The system comprises a bypass flue, a baffle plate, an acid dew point instrument, a backwater heater, a bypass flue fan, a controller, a backwater inlet temperature sensor, a backwater leading-in pipeline, a backwater frequency conversion water pump, a backwater outlet temperature sensor, an electric three-way adjusting valve, a mediate-temperature leading-out pipeline and a low-temperature backwater leading-out pipeline. The recovery method is characterized in that the controller adjusts the electric three-way adjusting valve to enable the acid dew point temperature to be less than the temperature of backwater entering the backwaterheater all the time; and the temperature of backwater flowing out of the backwater heater is ensured to be equal to the temperature threshold value of a backwater outlet of the system through a temperature control transducer. The invention avoids dust accumulating on a backwater heat exchanger, ensures that smoke completely enters the bypass flue, and avoids the low-temperature corrosion and dew formation of a heat exchanging system. The requirement of the system on the backwater temperature is satisfied through changing the rotate speed of the backwater frequency conversion water pump so that the steam extraction capacity is reduced, and the coal consumption for power supply is also reduced.

Owner:SHANGHAI JIAO TONG UNIV

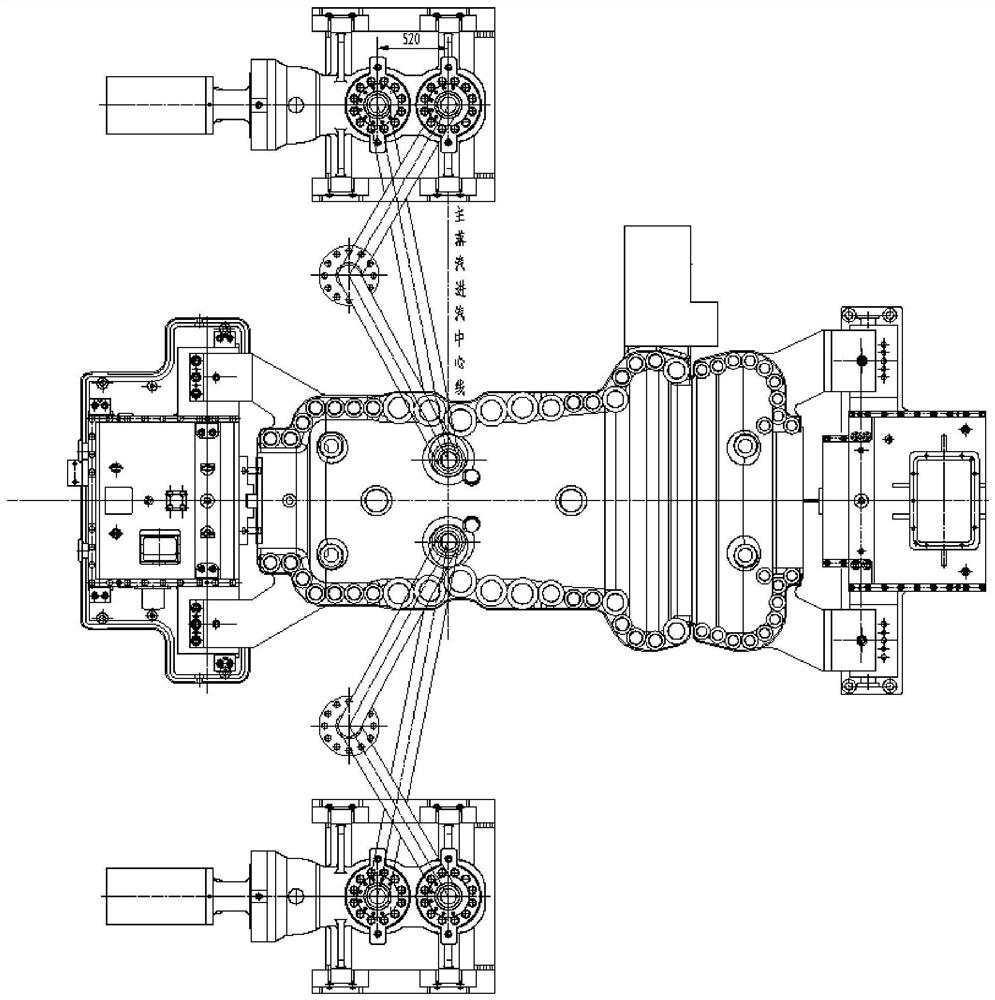

45MW ultrahigh-pressure reaction type backpressure steam turbine

PendingCN113464219AImprove cycle efficiencyImprove securityMachines/enginesEngine componentsUltra high pressureEngineering

The invention discloses a 45MW ultrahigh-pressure reaction type backpressure steam turbine, and relates to the field of steam turbines. The problems that an existing backpressure steam turbine is low in main steam parameter, high in cost, low in unit circulation efficiency, high in power supply coal consumption, low in energy utilization rate and large in pollution discharge amount are solved. One end of a rotor is inserted into a side face through hole of a front bearing box, the rotor is rotatably connected with the front bearing box, the other end of the rotor sequentially penetrates through the front portion and the rear portion of an air cylinder and then is inserted into a side face through hole of a rear bearing box, the rotor is rotatably connected with the rear bearing box, and a rotary partition plate is arranged between the inner wall of the rear portion of the air cylinder and the outer wall of the rotor. The invention belongs to the field of steam turbines.

Owner:HARBIN TURBINE

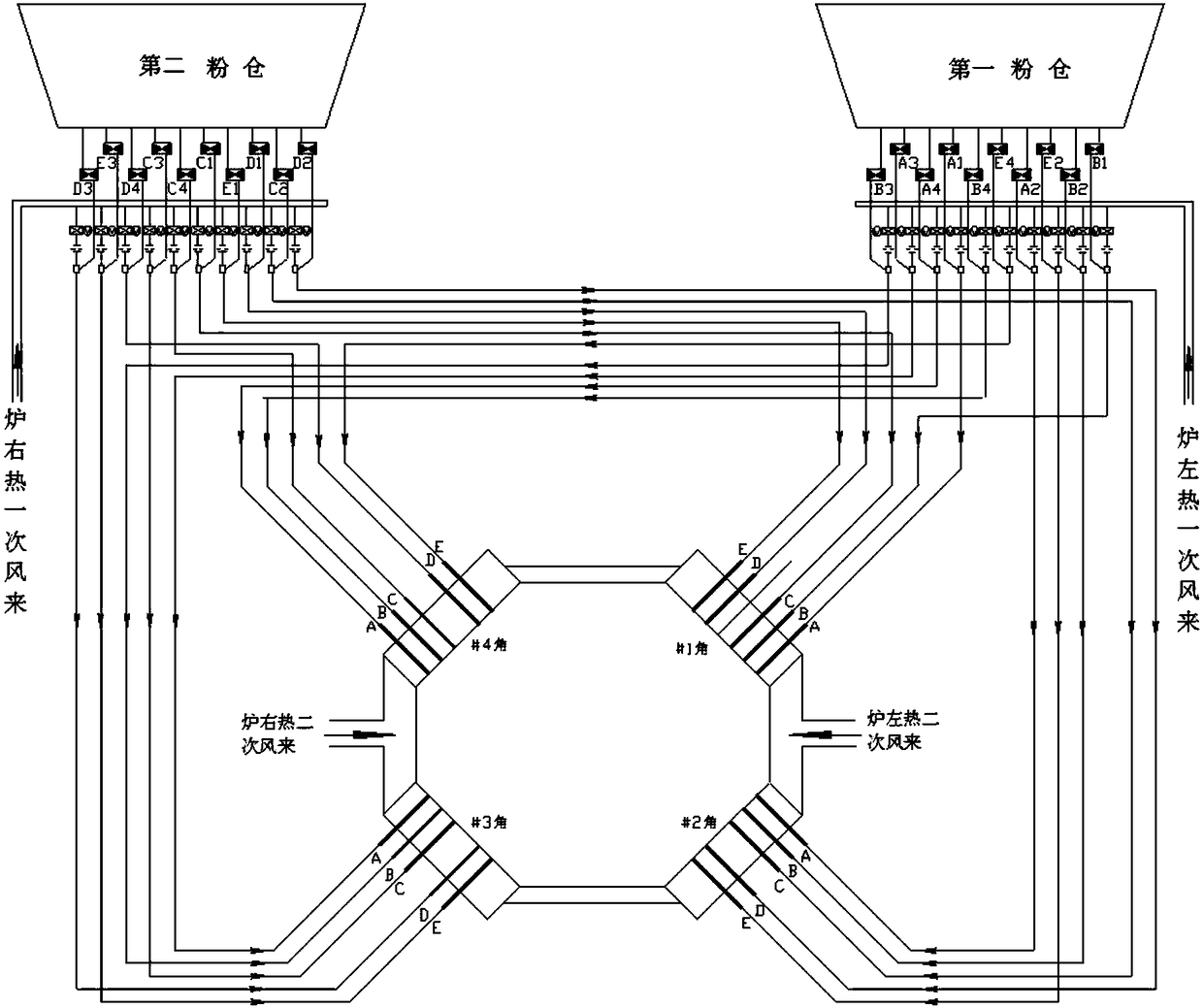

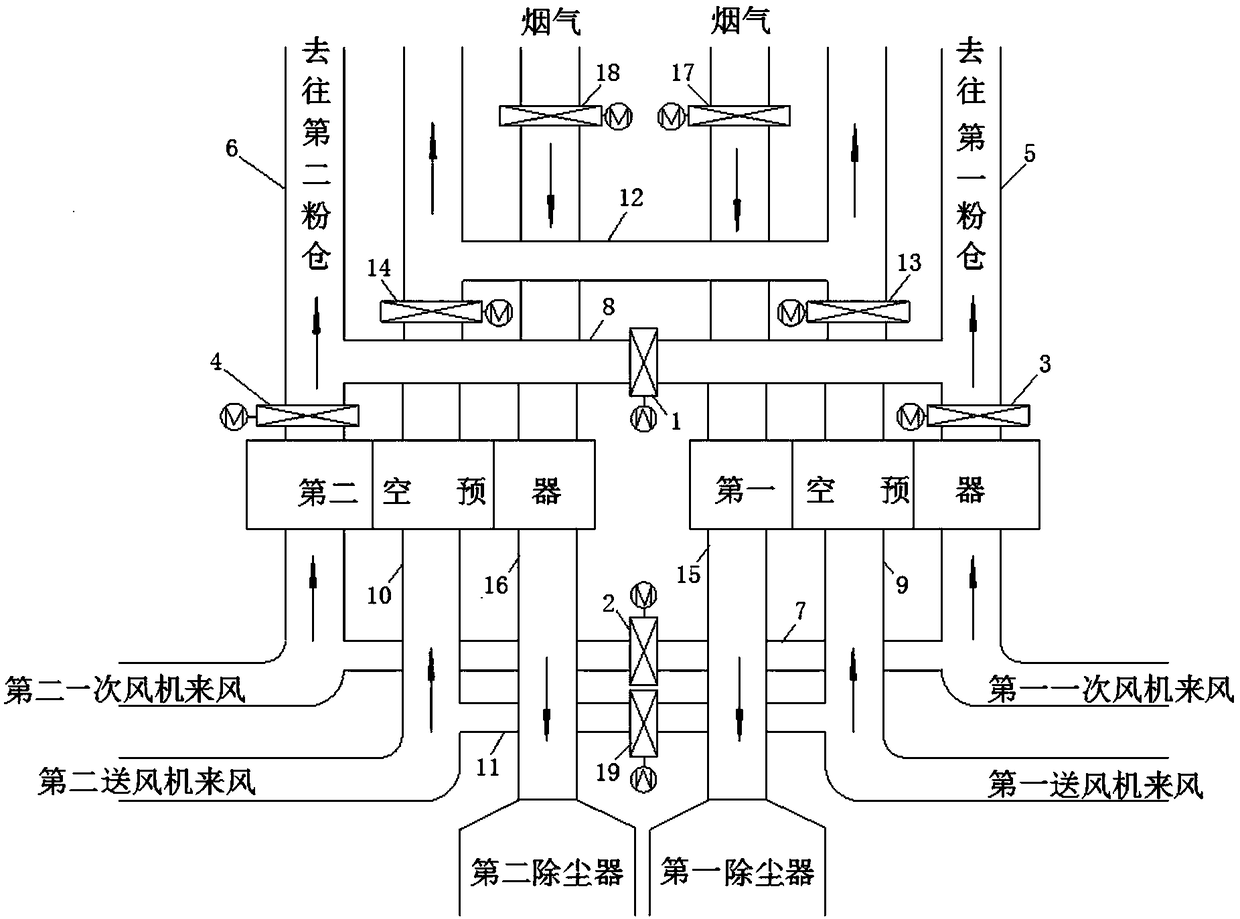

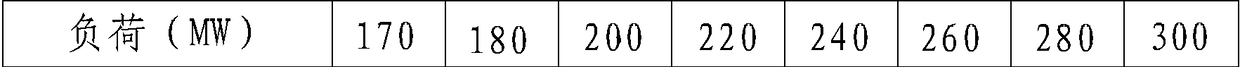

Control device and method for decreasing carbon content of fly ash of 300MW coal-fired unit

ActiveCN108386865AReduce carbon contentImprove combustion efficiencyFuel supply regulationIndirect carbon-dioxide mitigationCombustionEngineering

The invention discloses a control device and method for decreasing carbon content of fly ash of a 300MW coal-fired unit. The device comprises a first primary air pipe for connecting a first primary fan with a first dust bin, a second primary air pipe for connecting a second primary fan with a second dust bin, a first air pre-heater and a second air pre-heater, wherein a controlled interconnectionvalve of a primary air head pipe of an air pre-heater outlet is arranged on the primary air head pipe of the air pre-heater outlet and is used for controlling the connection and disconnection of the primary air head pipe of the air pre-heater outlet. According to the technical scheme, the device has the technical effects that the primary fans at the left side and the right side are independently controlled to achieve different capacities, thus different primary air pressure can be generated, and as a result, different types of coal dust of the two coal dust bins can be conveyed and can synchronously combust while a boiler runs; thorough combustion is achieved; and the purposes of decreasing the carbon content of the fly ash and improving the boiler combustion efficiency can be achieved. With the adoption of the device and the method, the annual average reduction amount of the carbon content of the coal dust is 3.5% or over; and the annular average net coal consumption rate is reduced by 4.4 g standard coal per kilowatt hour.

Owner:CHANGAN YIYANG POWER GENERATING CO LTD

A coupled treatment system and method based on circulating flue gas and desulfurization wastewater

ActiveCN111470568BReduce coal consumption for power supplySmall volume flowWater/sewage treatmentWaste water treatment from gaseous effluentsAir preheaterFlue gas

The invention relates to the technical field of wastewater treatment, and discloses a coupled treatment system based on circulating flue gas and desulfurization wastewater, including an evaporation crystallization system, a circulating flue gas system, and a flue gas exhaust system; a boiler, an evaporative crystallizer, a first dust collector and The circulation fans are connected through pipelines to form a circulation flue gas channel, and the circulation hot smoke is used as a heat source for evaporation and crystallization, and then enters the first dust collector for dust removal treatment, and finally is sent back to the boiler through the circulation fan; boiler, SCR reactor , the air preheater, the second dust collector and the induced draft fan are connected through pipelines to form a flue gas exhaust channel. While completing the evaporation treatment of unit desulfurization wastewater, the above-mentioned system realizes the classification treatment of high-chloride fly ash and ordinary fly ash, reduces the energy consumption of circulating fan operation, and greatly improves the treatment capacity of unit desulfurization wastewater. In addition, the present invention also provides a coupled treatment method based on circulating flue gas and desulfurization wastewater.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com