Control device and method for decreasing carbon content of fly ash of 300MW coal-fired unit

A technology for fly ash carbon content and coal-fired units, applied in combustion methods, combustion control, fuel supply adjustment, etc., can solve the problem that the primary wind pressure on both sides of the outlet of the air preheater cannot meet the difference of volatile matter at the same time, and achieve Effects of reducing carbon content in fly ash, reducing coal consumption for power supply, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

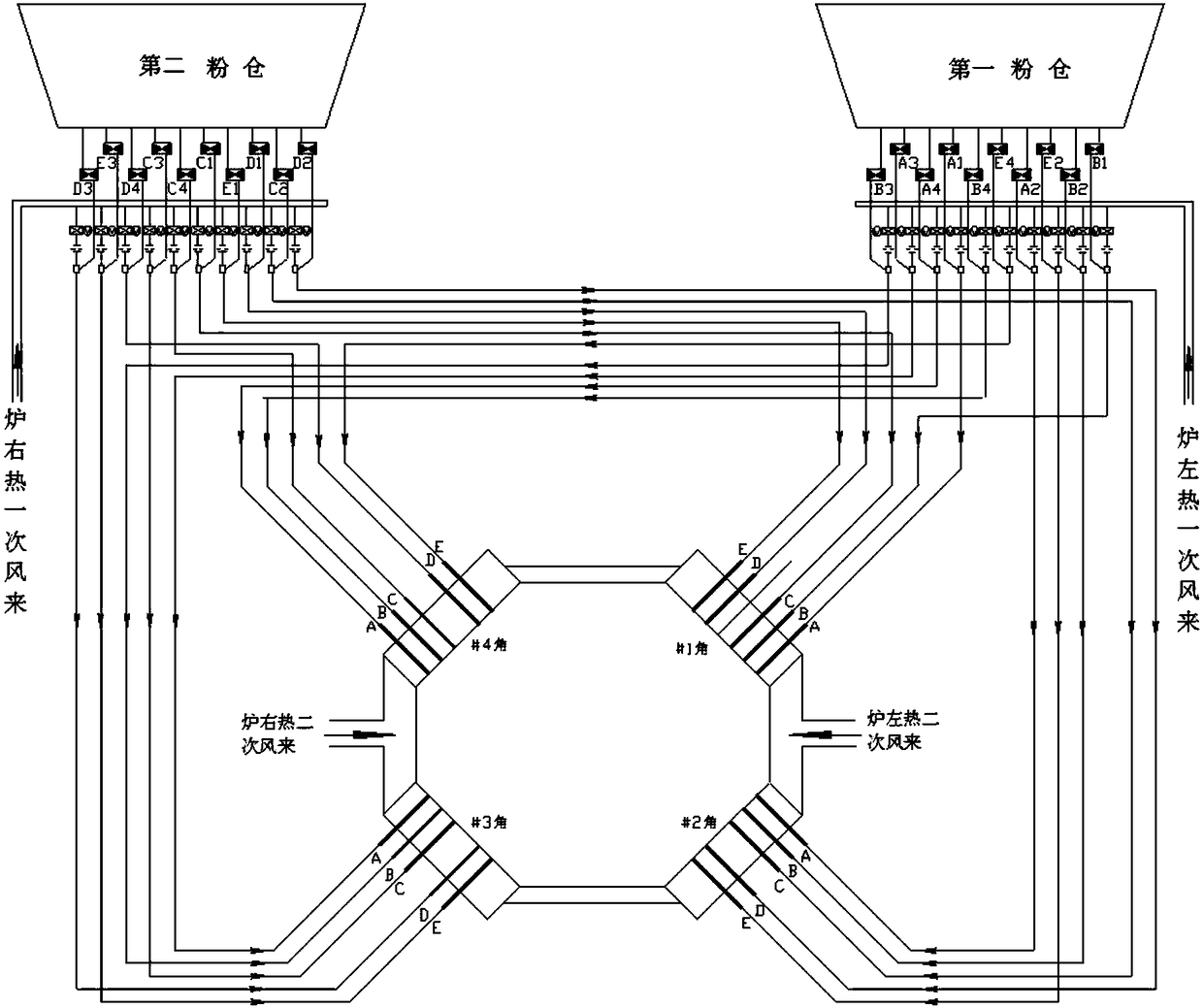

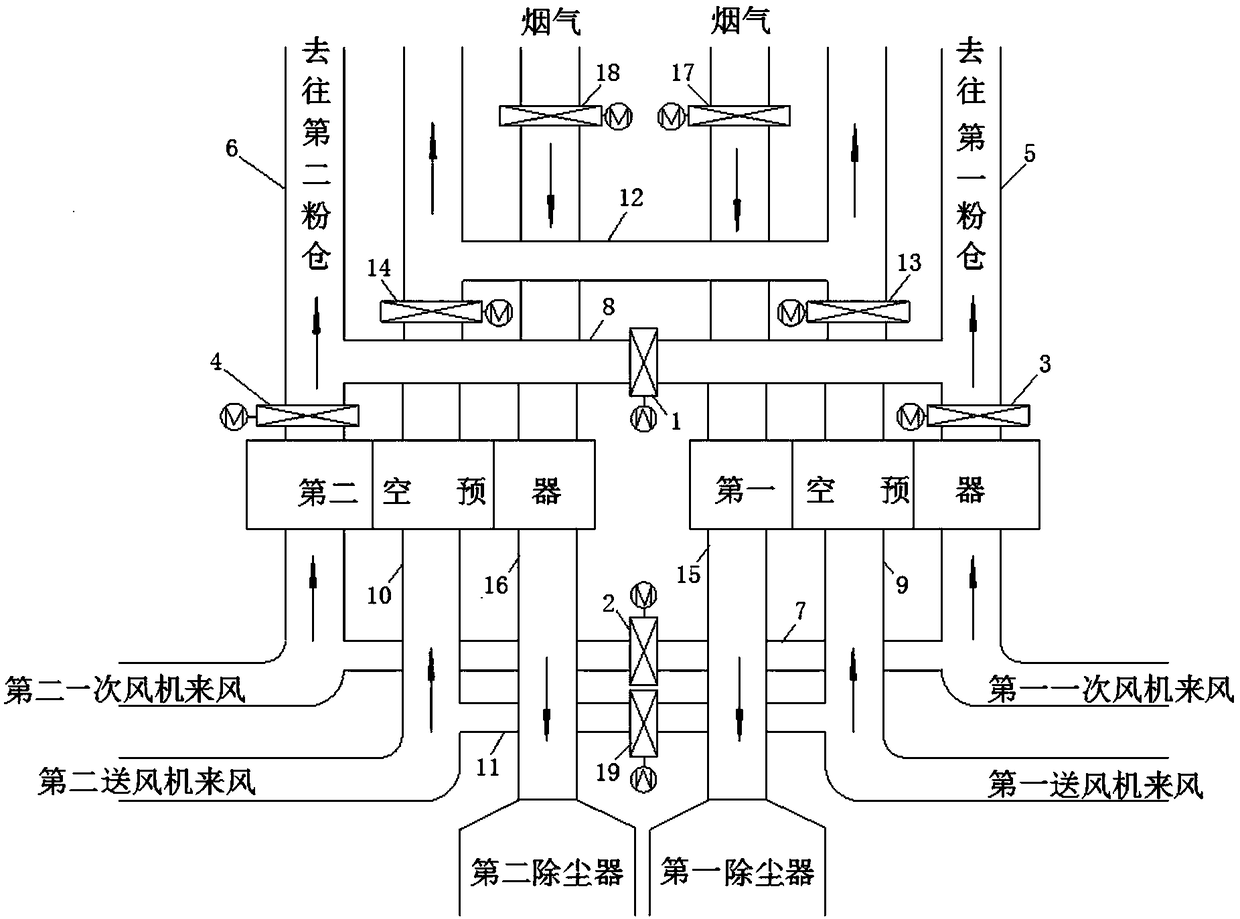

[0034] see figure 2 , this embodiment includes the first primary air duct connecting the first primary fan and the first powder silo, the second primary air duct connecting the second primary fan and the second powder silo, the first air preheater and the second primary air duct Two air preheaters;

[0035] Wherein the first air preheater and the second air preheater are arranged on the first primary air duct and the second primary air duct respectively, and the first primary air duct and the second primary air duct enter the air preheater and After leaving the air preheater, there are interconnected air preheater inlet primary air main pipes and air preheater outlet primary air main pipes, and the air preheater inlet primary air main pipes are equipped with controlled air preheater inlet primary air main pipes. The pipe connection door is used to control the on-off of the primary air main pipe at the inlet of the air preheater;

[0036] The primary air main pipe of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com