Indirect cooling tower with cooling triangles arranged obliquely

A cooling triangle and cooling tower technology, applied in the field of indirect cooling towers, can solve the problems of affecting the heat exchange effect, small heat exchange area, and not fully utilizing the inner area of the tower, so as to achieve reasonable air flow direction, high cooling efficiency, and reduced The effect of construction investment and land cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

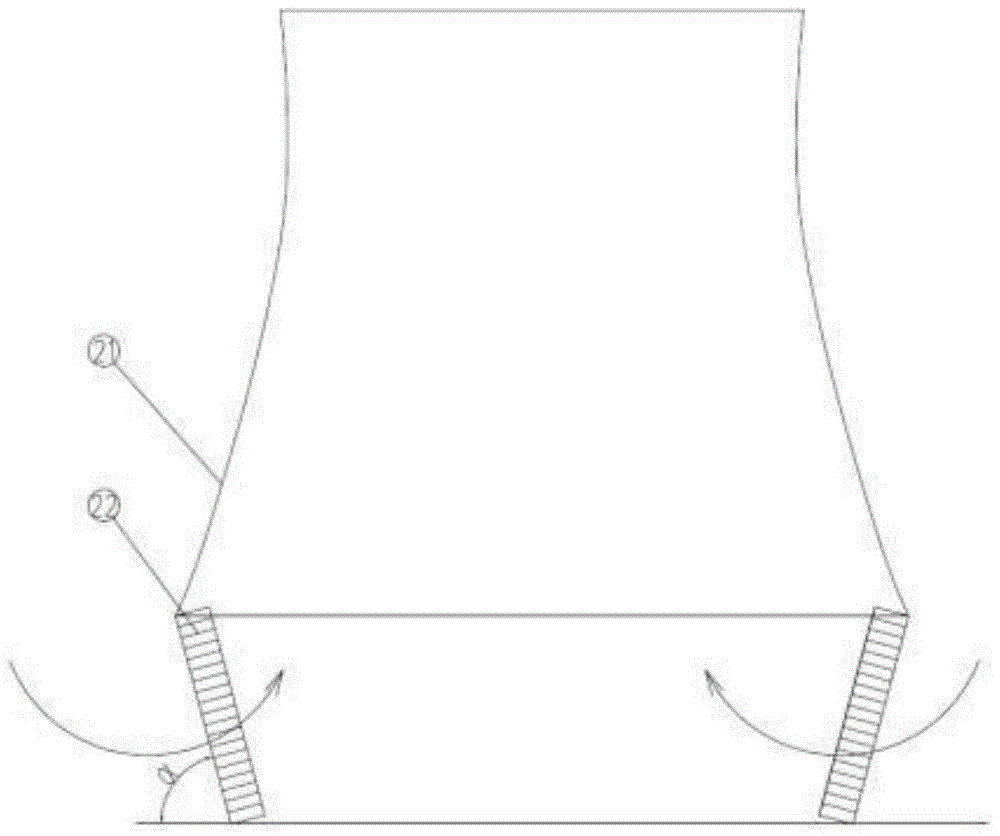

[0041] Such as figure 2 Shown is an indirect cooling tower structure with an inclined cooling triangle, which is composed of a tower tube 21 and an inclined cooling triangle 22 .

[0042] The angle between the cooling triangle 22 and the ground is α=40-75°,

[0043] The cooling triangle 22 is located at the inner edge of the bottom diameter of the intercooling tower barrel 21 .

[0044] Compared with the current vertically arranged cooling triangle, the adoption of the above structure leads to:

[0045] 1. When the height of the air inlet and the diameter of the bottom of the tower remain unchanged, the heat dissipation area of the inclined cooling triangle is larger than that of the vertical cooling triangle, the water temperature at the outlet of the cooling tower is lowered, and the power supply coal consumption of the power plant is reduced.

[0046] 2. When the heat dissipation area and the height of the air inlet remain unchanged, the diameter of the bottom of the t...

Embodiment 2

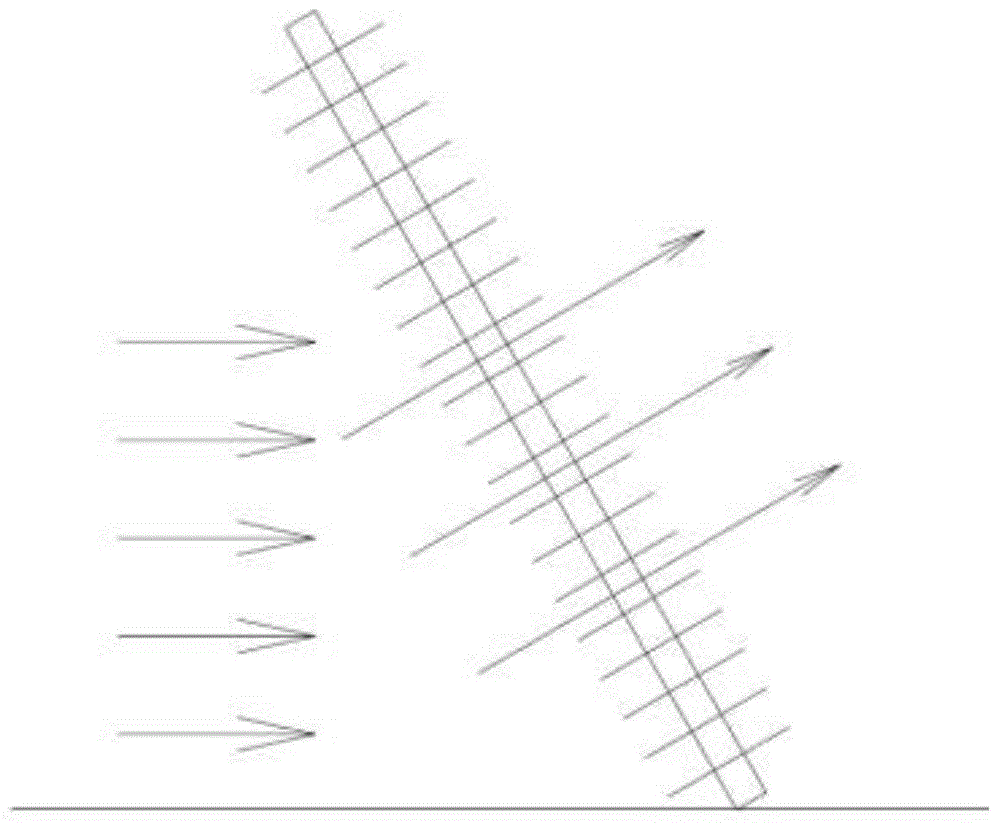

[0049] Figure 4 It is an intercooling tower with segmented oblique cooling triangles, which is composed of a tower tube 31 and segmented oblique cooling triangles 32. The structural diagram of the segmented oblique cooling triangles 32 is as follows Figure 5 shown.

[0050] The segmented inclined cooling triangle 32 is composed of 3 to 10 small cooling triangles, each of which has independent water inlet and outlet pipelines and valves, which can be switched on and off independently.

[0051] The highest section of the small cooling triangle is perpendicular to the inner wall of the tower, and the angle β between the lowest section of the small cooling triangle and the ground is 75-90°.

[0052] The angle α formed by the top of the highest section of small cooling triangle and the bottom of the lowest section of small cooling triangle is 40-75°.

[0053] For the convenience of processing, all the small cooling triangles have the same length, and the included angles between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com