Air preheating and flue gas waste heat utilizing system and method

A technology of flue gas waste heat and air preheating, applied in the directions of preheating, combustion method, feed water heater, etc., can solve the problems of not realizing energy cascade utilization, reducing cycle thermal efficiency and economy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

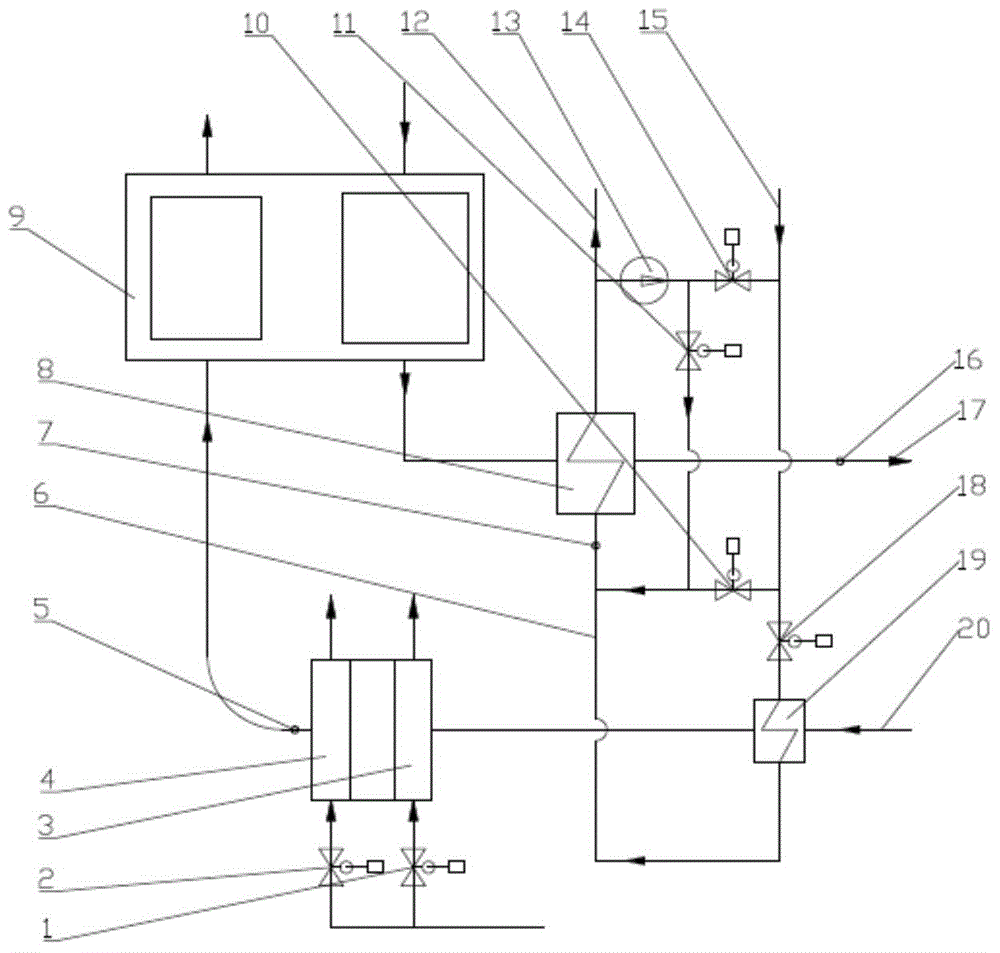

[0065] A new type of air preheating and waste heat utilization system proposed by the present invention, as attached figure 1 As shown, the main equipment of the system includes: flue gas channel 17 , air channel 20 , air preheater 9 , condensate flue heat exchanger 8 and condensate air channel heat exchanger 19 .

[0066] Both the flue gas passage 17 and the air passage 20 are connected to the air preheater 9 ; the flue gas in the flue gas passage 17 transfers part of the heat to the air in the air passage 20 through the air preheater 9 .

[0067] The condensed water flue heat exchanger 8 is arranged on the flue gas passage 17 after the air preheater 9 (along the direction of flue gas flow); the condensed water air passage heat exchanger 19 is arranged before the air preheater 9 (along the direction of the flue gas flow). On the air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com