Novel flue gas waste heat recycling method

A flue gas waste heat and flue gas heat exchanger technology, which is applied in the direction of combustion methods, heat exchangers, indirect heat exchangers, etc., can solve the problems of single-stage utilization and insufficient utilization of flue gas waste heat, and reduce Maintenance cost, avoid condensation corrosion and dust plugging, reduce the effect of chimney rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

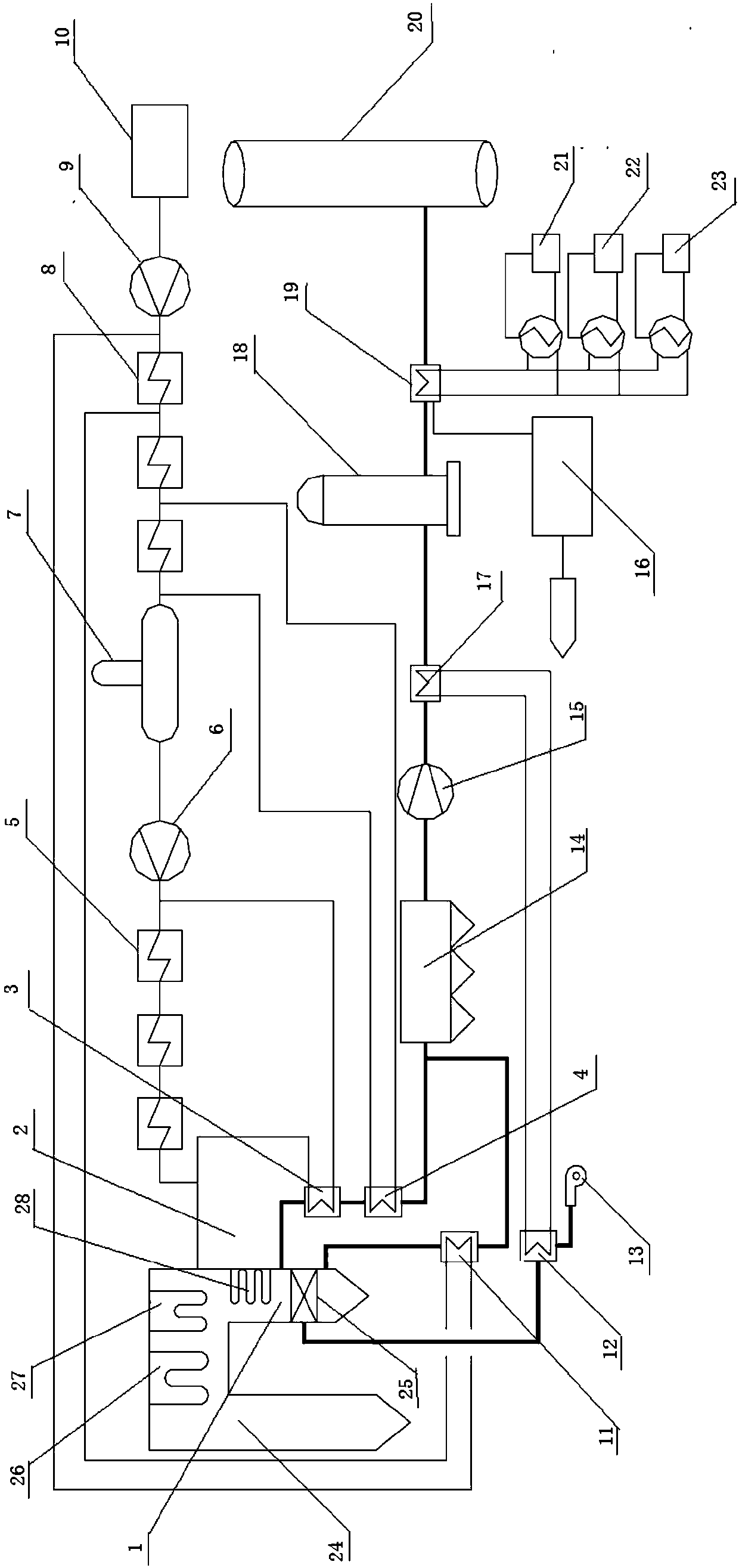

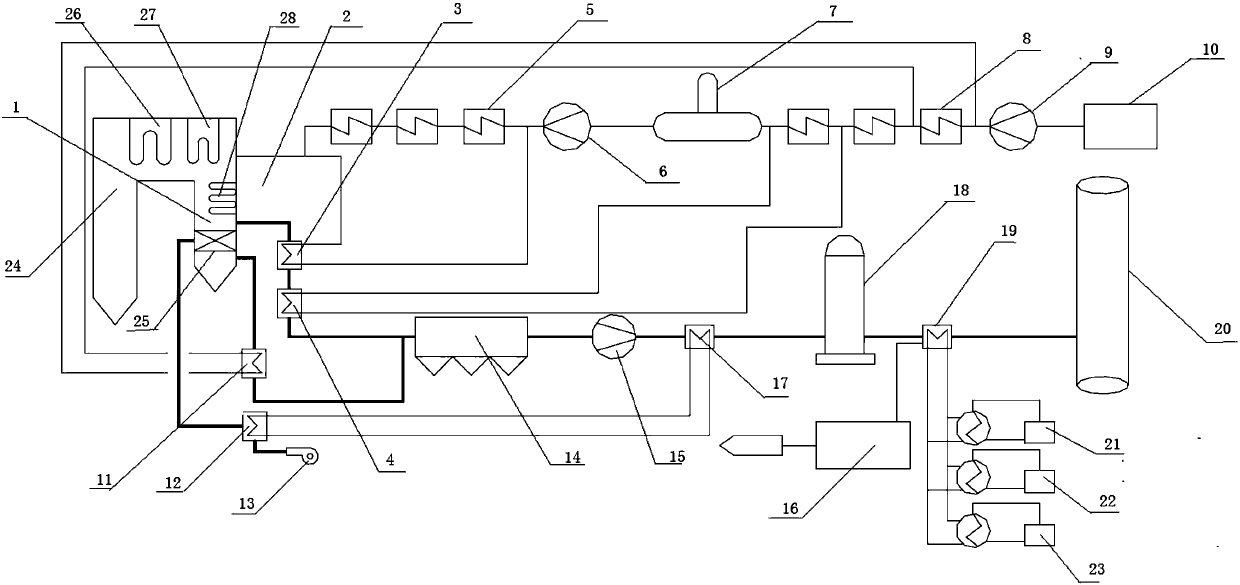

[0031] The present invention as figure 1 As shown, the present invention can deeply recover and utilize the waste heat of industrial boiler flue gas. The flue gas temperature is gradually lowered from about 300°C to about 60°C. The new flue gas waste heat recovery and utilization system can match the energy level as much as possible according to the amount and grade of flue gas waste heat and the needs of users, and select the appropriate power plant boiler flue gas waste heat energy level under the conditions of thermodynamic principles and technical and economic principles. Recovery systems and equipment maximize waste heat.

[0032] (1), the high-temperature flue 1 of the air preheater 25 inlet is bypassed out of an auxiliary flue 2, and the flue gas flow rates of the main flue 1 and the auxiliary flue 2 respectively account for 60-40% of the total flue gas volume; A high-temperature heat exchanger 3 is arranged in the auxiliary flue 2, and the high-temperature heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com