Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce low temperature corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

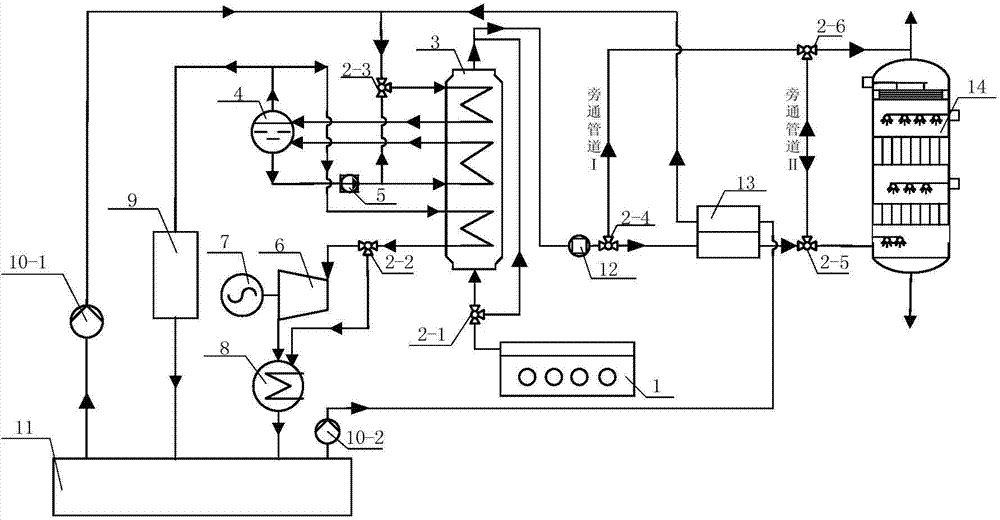

Waste heat recovery device for marine diesel engine exhaust

ActiveCN103925025AAvoid wastingImprove energy utilizationSteam engine plantsEngineeringDiesel engine

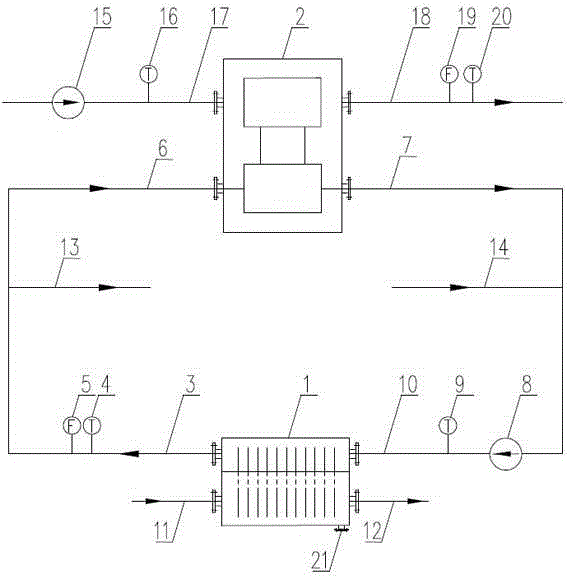

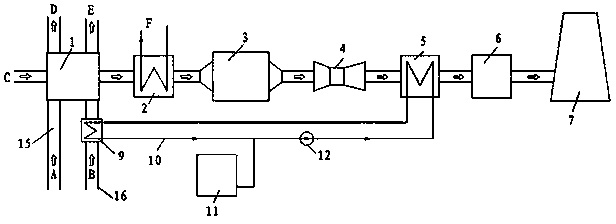

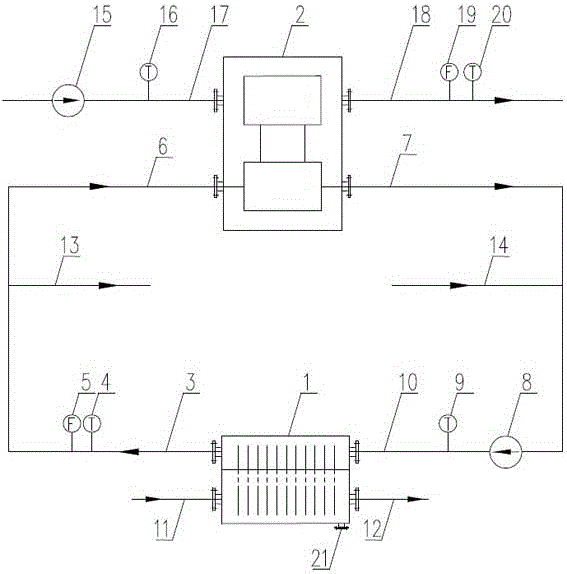

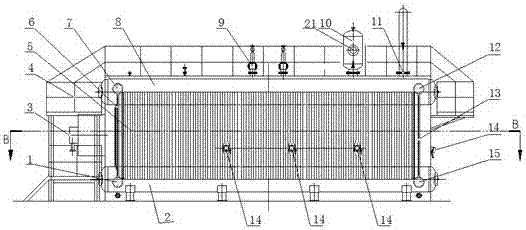

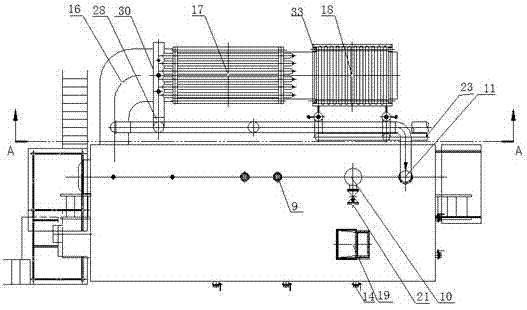

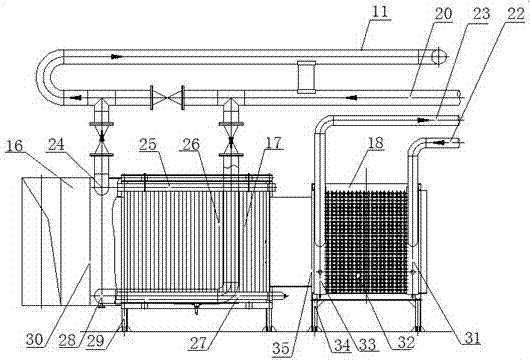

The invention provides a waste heat recovery device for marine diesel engine exhaust. The waste heat recovery device mainly comprises a marine diesel engine, a heat recovery boiler, a steam turbine generator set, a condenser, a corrosion-resistant plate-fin heat exchanger, a desulfurizing tower and the like. In the waste heat recovery device, the marine diesel engine exhaust passes through the heat recovery boiler to generate steam, part of steam is used for marine steam-consuming equipment, and the remaining steam is input to the steam turbine generator set to generate electric energy. In order to increase the waste heat recovery rate of the marine diesel engine exhaust and enhance the desulfurizing efficiency of the desulfurizing tower at the same time, the corrosion-resistant plate-fin heat exchanger is arranged between the heat recovery boiler and the desulfurizing tower so as to further lower the temperature of the exhaust. The waste heat recovery device can fully recover the waste heat of the marine diesel engine exhaust, so that the utilization range of the waste heat is enlarged, and the utilization efficiency of the waste heat is improved; in addition, low-temperature corrosion on the heated surface of the tail of the heat recovery boiler can be effectively relieved, the defects that in the prior art, energy saving is poor, environmental friendliness is poor, cost is high and reliability is poor are overcome, and the purposes of saving energy, being environmentally friendly, lowering cost and improving equipment reliability are achieved.

Owner:HARBIN ENG UNIV

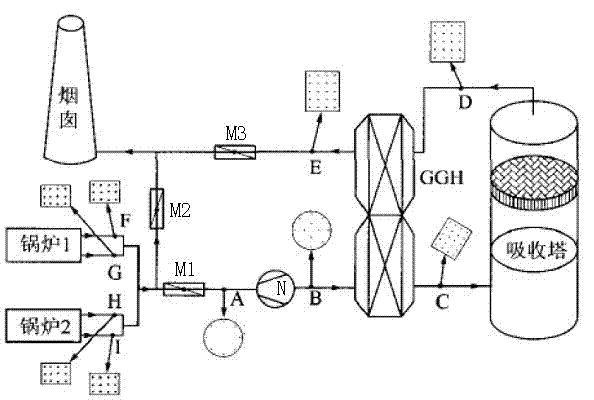

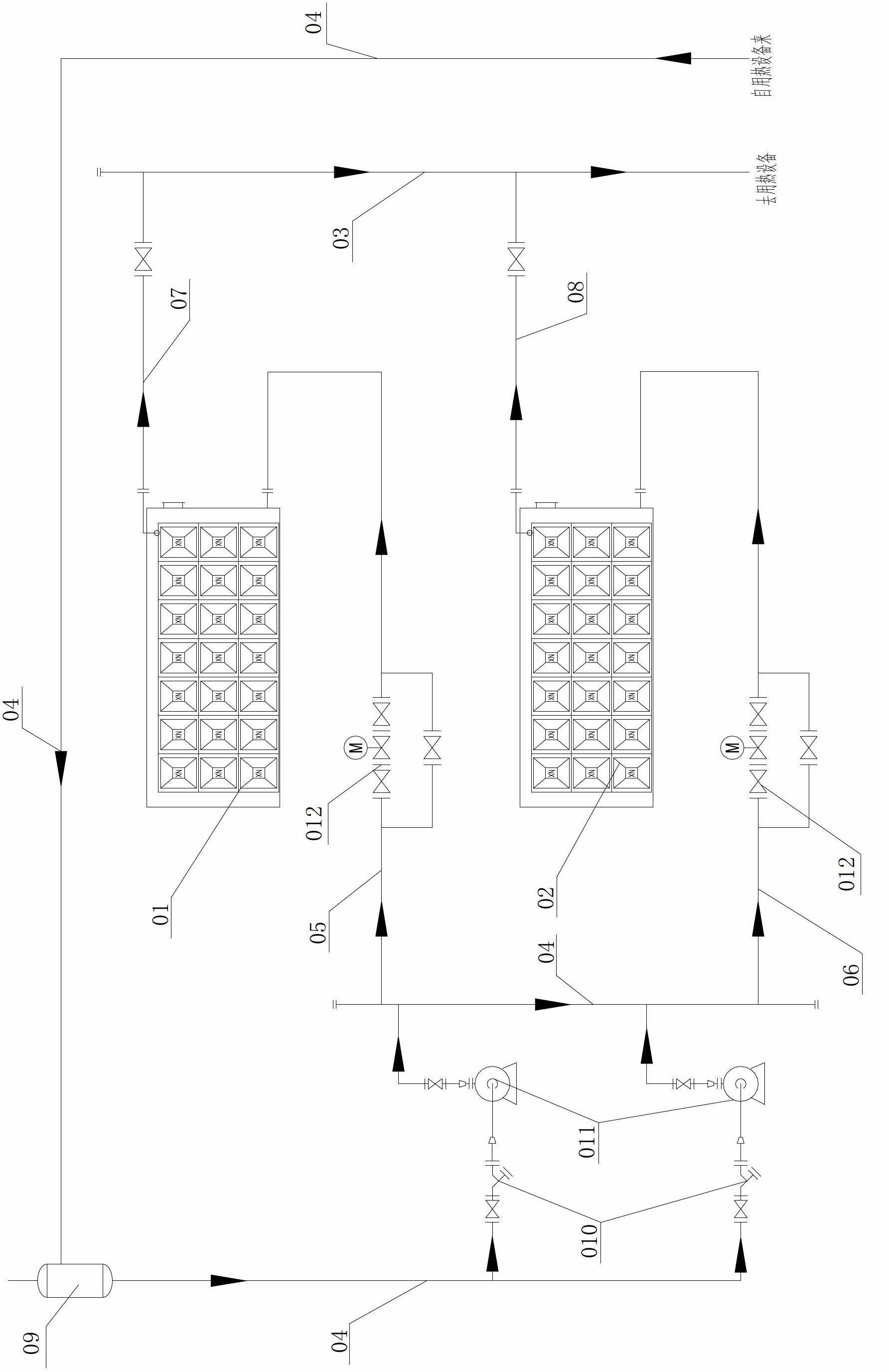

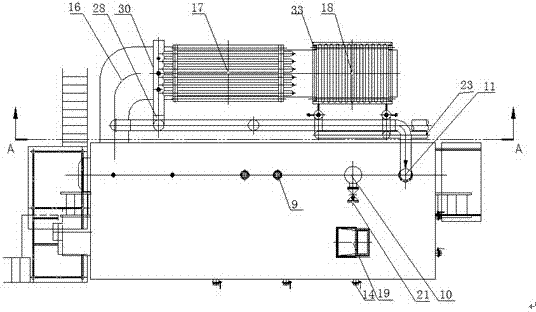

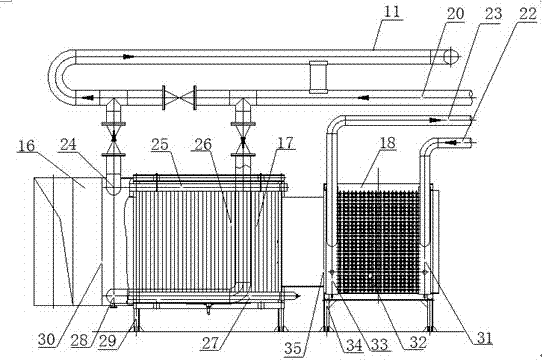

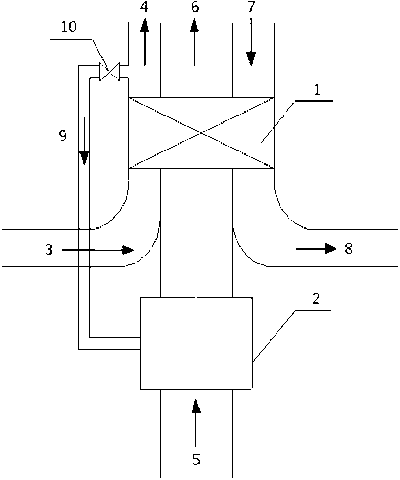

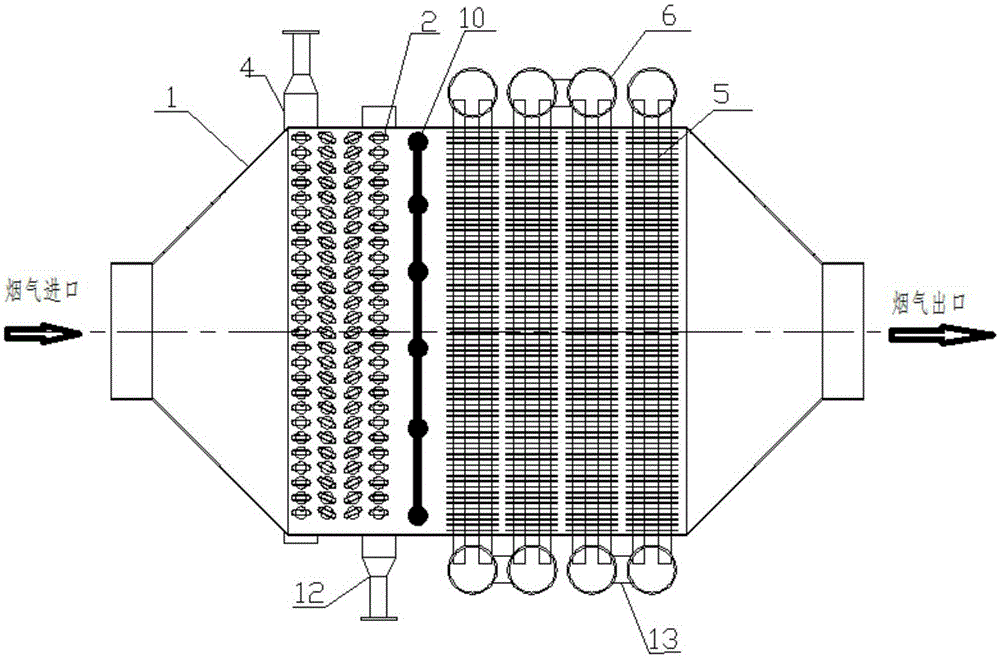

Composite phase change heat exchange system for flue gas heat recovery of boiler

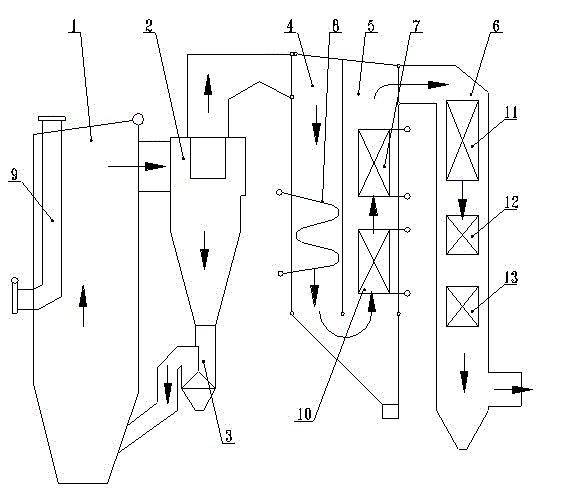

InactiveCN102410549ARealize integrationEfficient recyclingLighting and heating apparatusWater savingHeat conducting

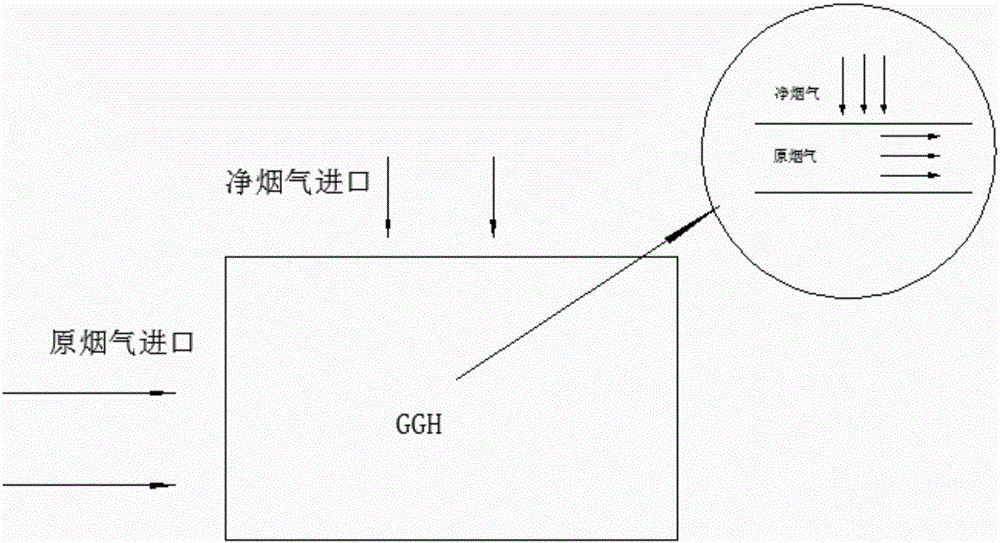

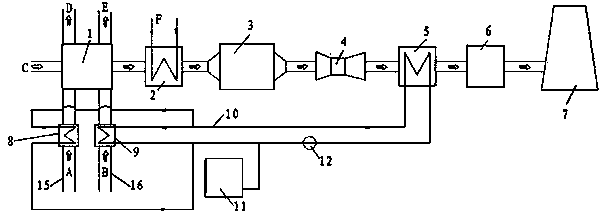

The invention discloses a composite phase change heat exchange system for flue gas heat recovery of boiler, comprising an original coal saving device of the boiler and an air pre-heater, a dust remover and a desulfurization tower; a heat conducting oil heater, a stage I composite phase changer, a stage II composite phase changer, a stage III composite phase changer, and a temperature adjusting system matched with the stage I, state II and stage III composite phase changers are disposed in the flue; the temperature adjusting system can be used for conveniently adjusting the wall surface temperature of the phase change heat exchanger; the heat conducting oil is used as the heat source of the stage III phase change heat exchanger, so as to improve the flue purity and reach the flue discharge requirement. The invention can solve the difficult problem that it is difficult to dispose the evaporation section of the heat exchange round tube in vertical flue or oblique flue, so as to realize the integrated compact arrangements of the evaporation section and condensation section of the phase change heat exchanger; the disadvantage of GGH is overcome; the hazard degree of low-temperature corrosion is decreased, so as to realize the targets of energy saving, water saving and emission reduction.

Owner:王海波

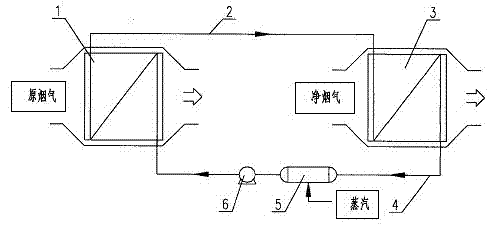

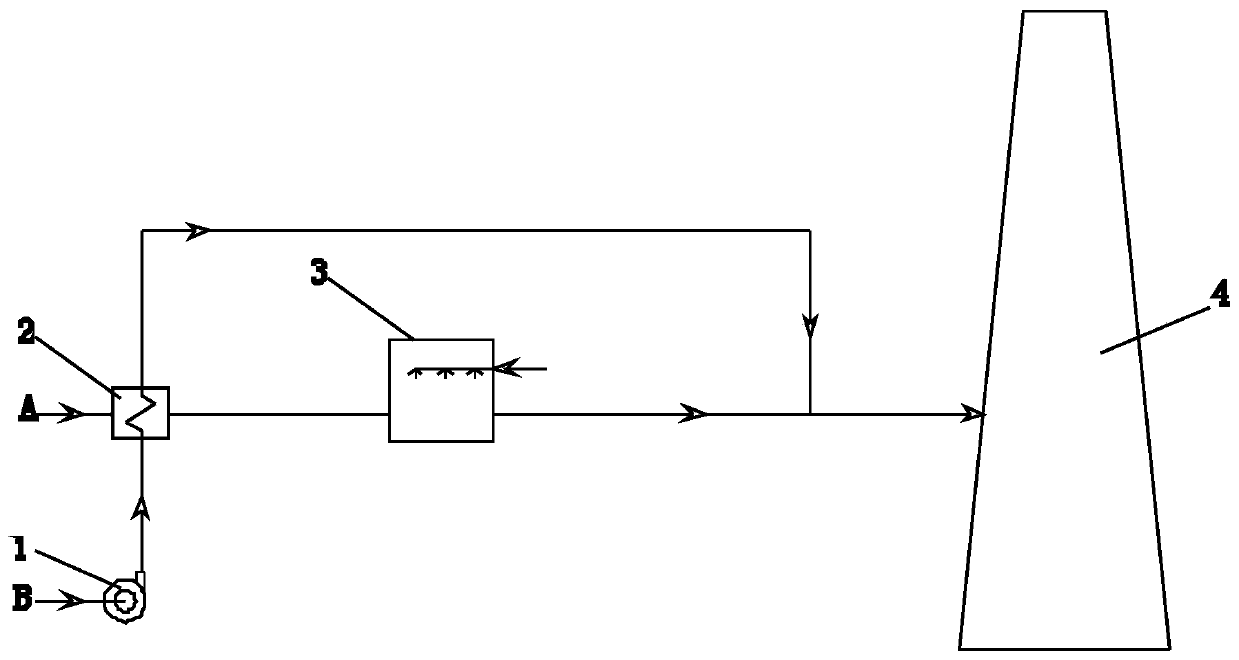

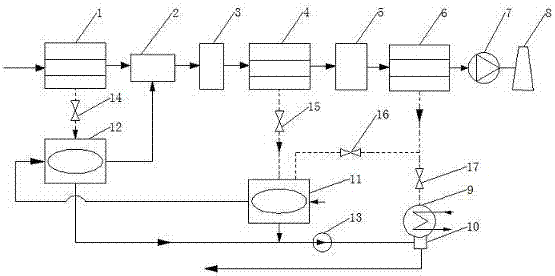

Waste heat recovery system and method with discharged smoke waste heat as heat source of air heater

The invention discloses a waste heat recovery system and method with discharged smoke waste heat as a heat source of an air heater. According to the waste heat recovery system and method with the discharged smoke waste heat as the heat source of the air heater, a low-temperature economizer and the air heater are connected through a pipeline to form a first circulation loop, a circulating pump is arranged on an inlet pipeline of the low-temperature economizer, and an air heater intake water regulating valve is arranged on an inlet pipeline of the air heater; and the low-temperature economizer is connected with the circulating water side of a condensed water heater through a pipeline to form a second circulation loop, the condensed water side of the condensed water heater is connected with a low-pressure heater in parallel through a pipeline, and a booster pump is arranged on a condensed water connecting pipeline between the condensed water side of the condensed water heater and the low-pressure heater. The system and method have the advantages that the air heater is reserved, low-temperature corrosion of an air preheater is relieved, the low-temperature economizer recovers discharged smoke waste heat of a boiler, and power generation coal consumption of a steam turbine is reduced; and meanwhile, the defects that since the air heater consumes low-pressure suction steam of the steam turbine, the heat consumption of the steam turbine is increased, the temperature of discharged smoke is increased, and the heat efficiency of the boiler is reduced are overcome, and the problems that a low-temperature economizer pipeline system is high in cost and operating reliability requirement are solved.

Owner:FUJIAN LONGKING

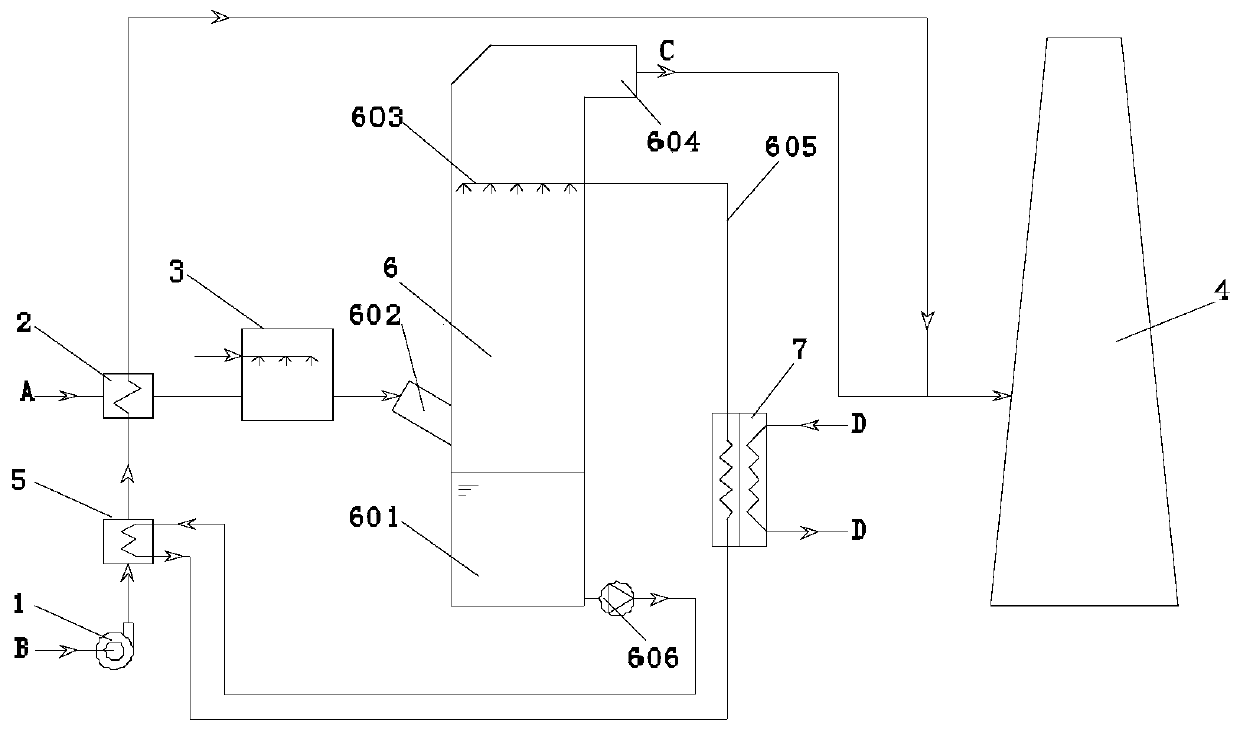

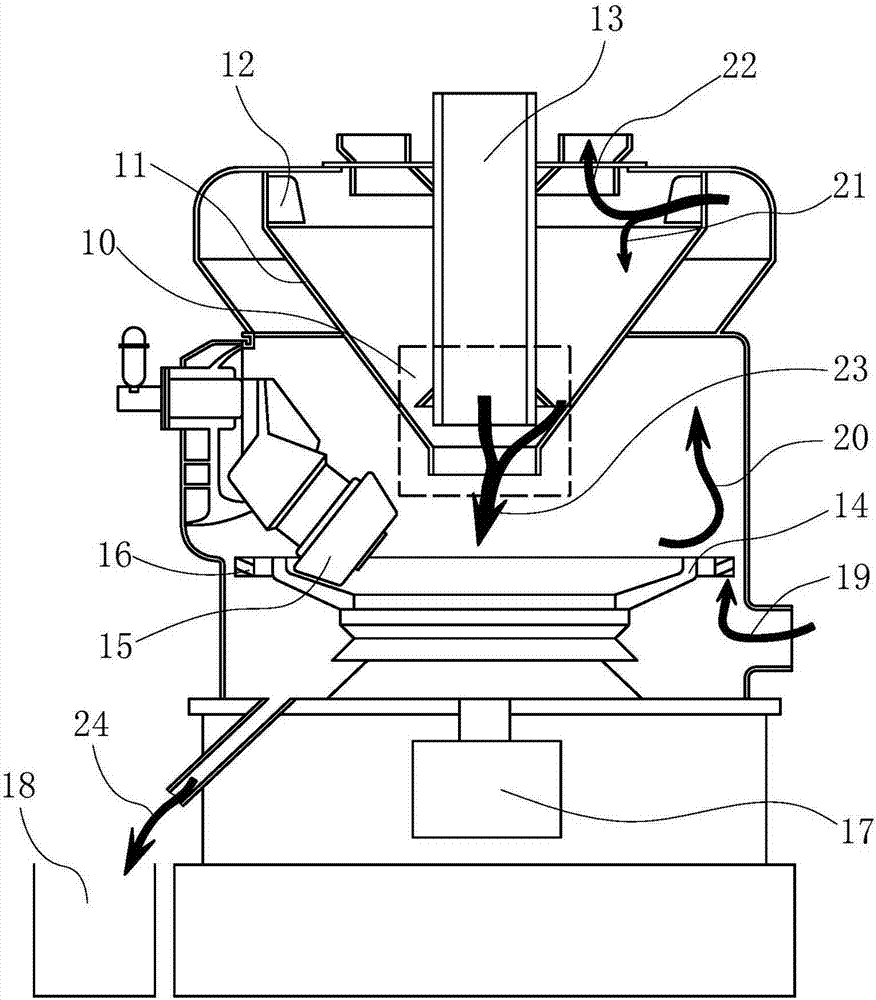

Device and method for recycling smoke condensate heat energy of gas boiler in heat pumping mode

ActiveCN103954039AEasy to control temperatureIncrease profitHeat pumpsHeat recovery systemsEngineeringThermal water

The invention relates to a device and a method for recycling smoke condensate heat energy of a gas boiler in a heat pumping mode. The device and method for recycling the smoke condensate heat energy of the gas boiler with high heat energy recycling rate do not exist at present. The device provided by the invention comprises a high-efficient condensate heat exchanger, a primary circulating water heat exchanger outlet pipe, a smoke inlet pipe and a smoke outlet pipe, and is characterized by further comprising a heat pump unit, a primary circulating water heat pump inlet pipe, a primary circulating water heat pump outlet pipe, a primary circulating water pump, a domestic hot water taking pipe, a primary circulating water replenishing pipe, a secondary circulating water pump, a secondary circulating water heat pump inlet pipe and a secondary circulating water heat pump outlet pipe, wherein one end of the primary circulating water heat pump outlet pipe and one end of the primary circulating water replenishing pipe are both connected with the other end of a primary circulating water heat exchanger inlet pipe; the secondary circulating water pump is mounted on the secondary circulating water heat pump inlet pipe; a secondary circulating water heat pump outlet temperature gauge is mounted on the secondary circulating water heat pump outlet pipe. The device provided by the invention is high in heat energy recycling rate.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

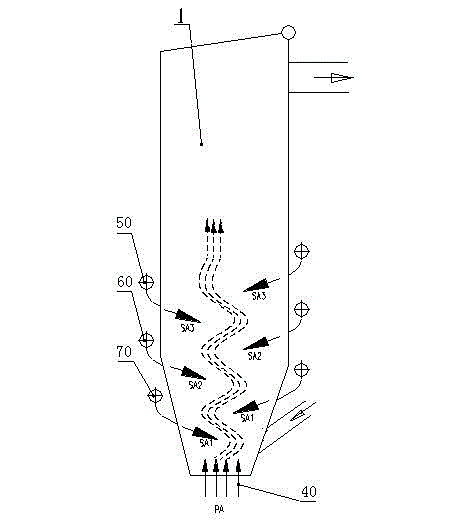

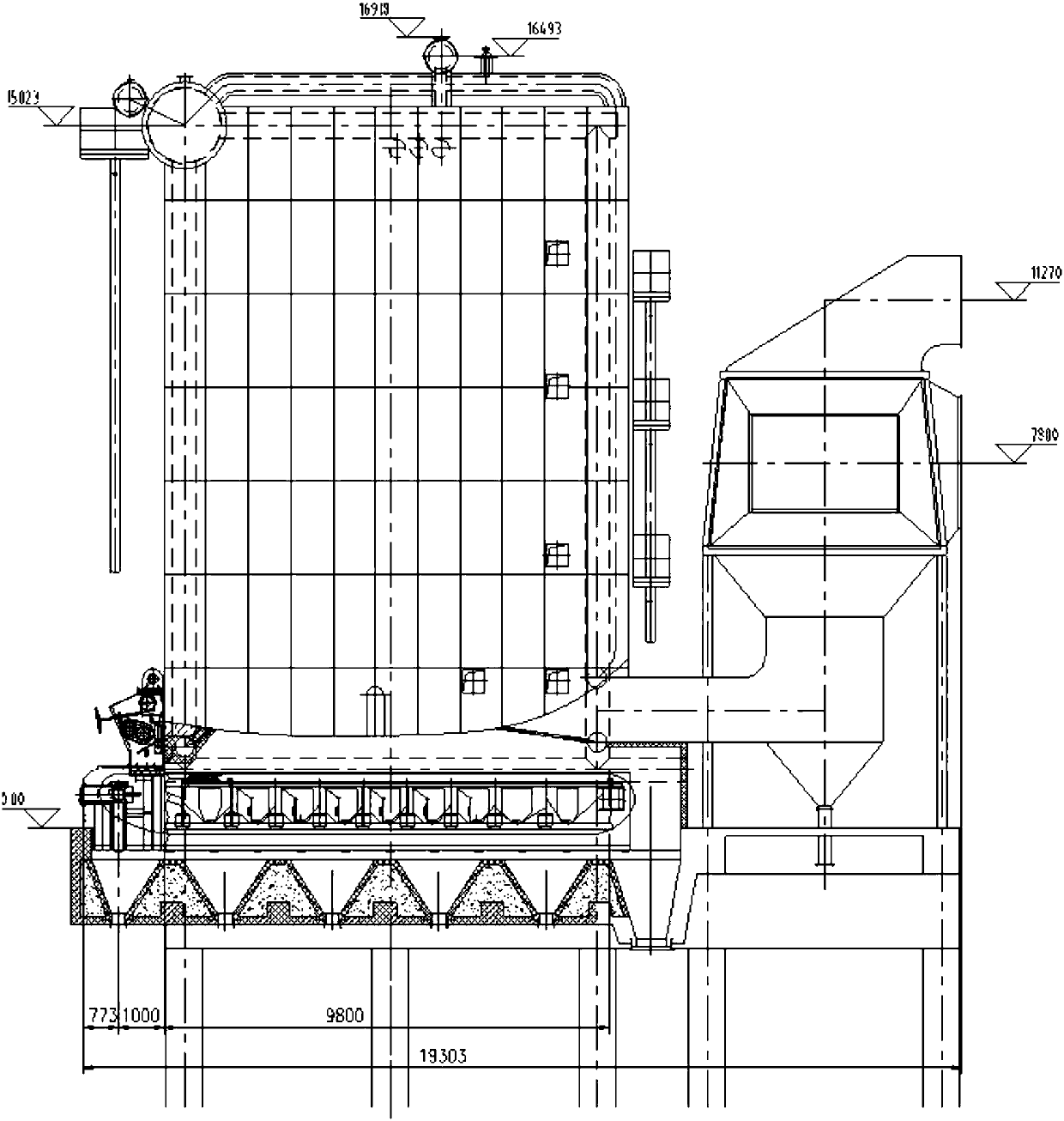

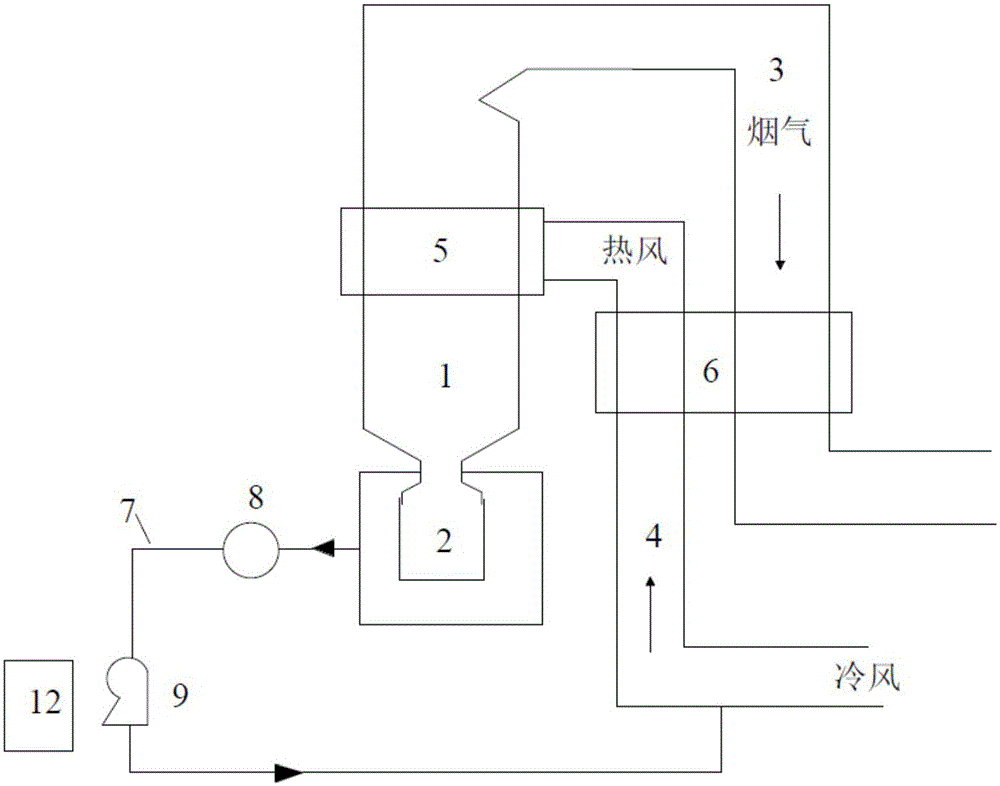

Circulating fluidized bed boiler unit for high efficiency combustion of biomass and recovery of waste heat

InactiveCN103148479AUniform and reasonable temperature fieldNo fusion bonding occursFluidized bed combustionApparatus for fluidised bed combustionEngineeringSuperheater

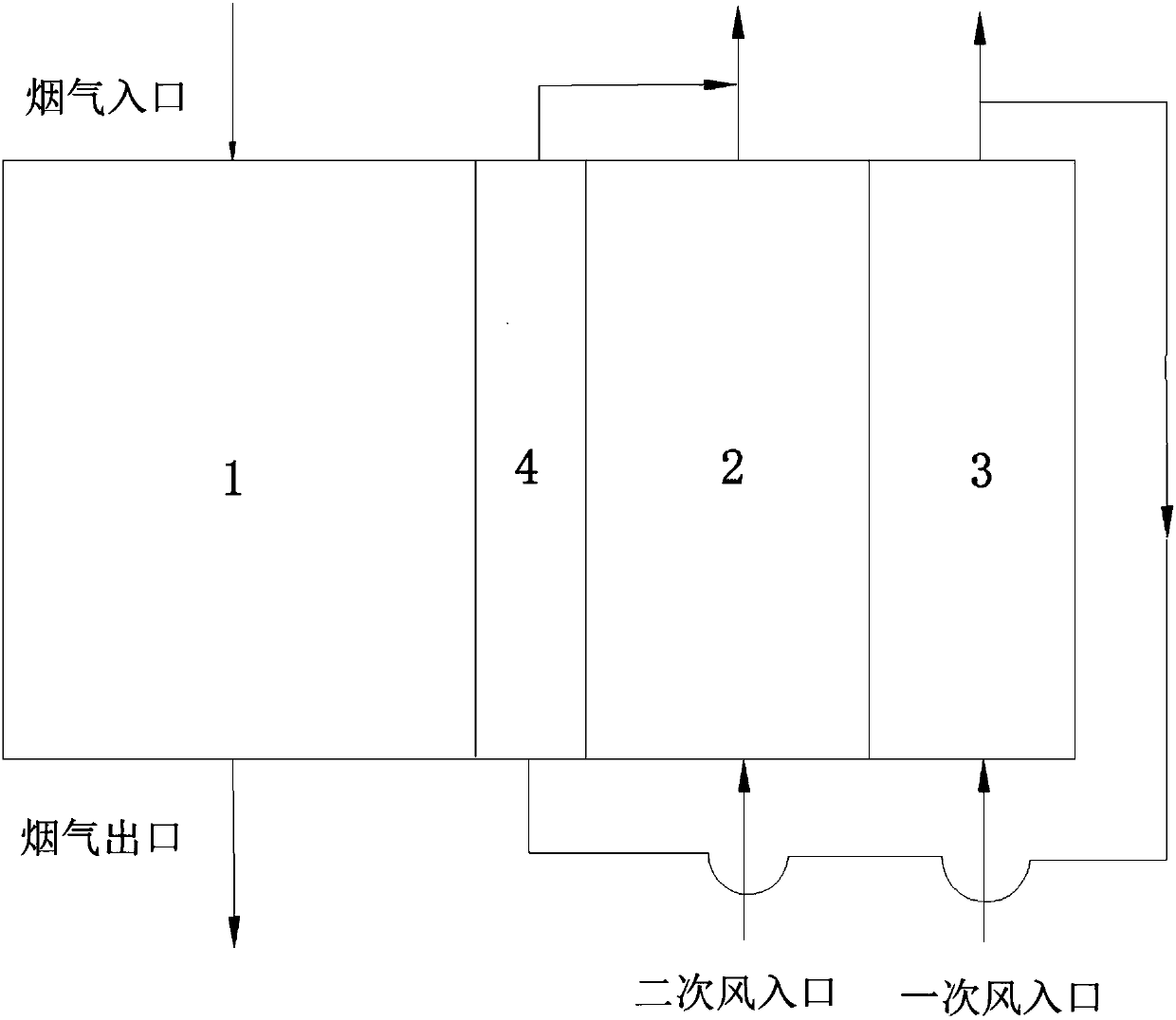

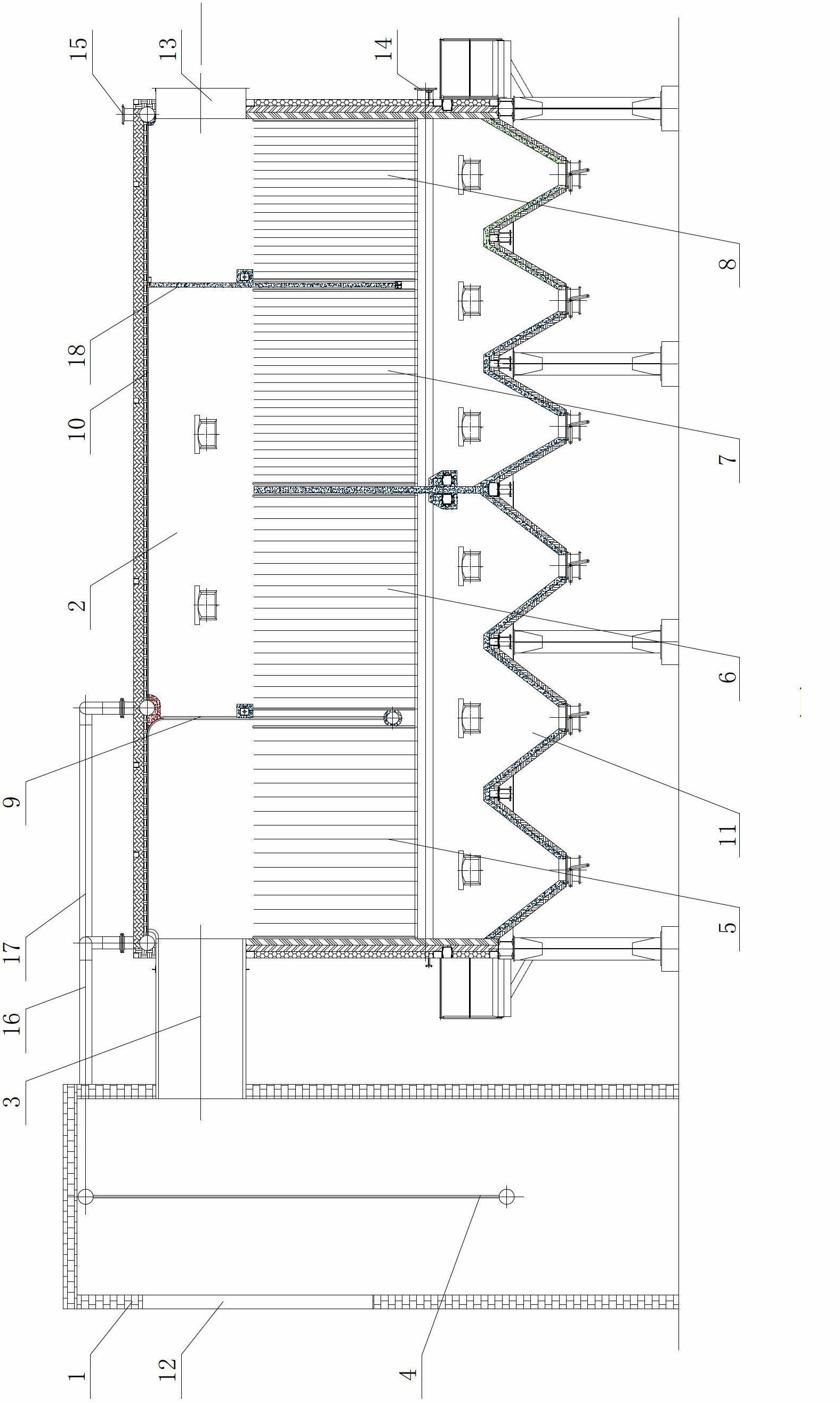

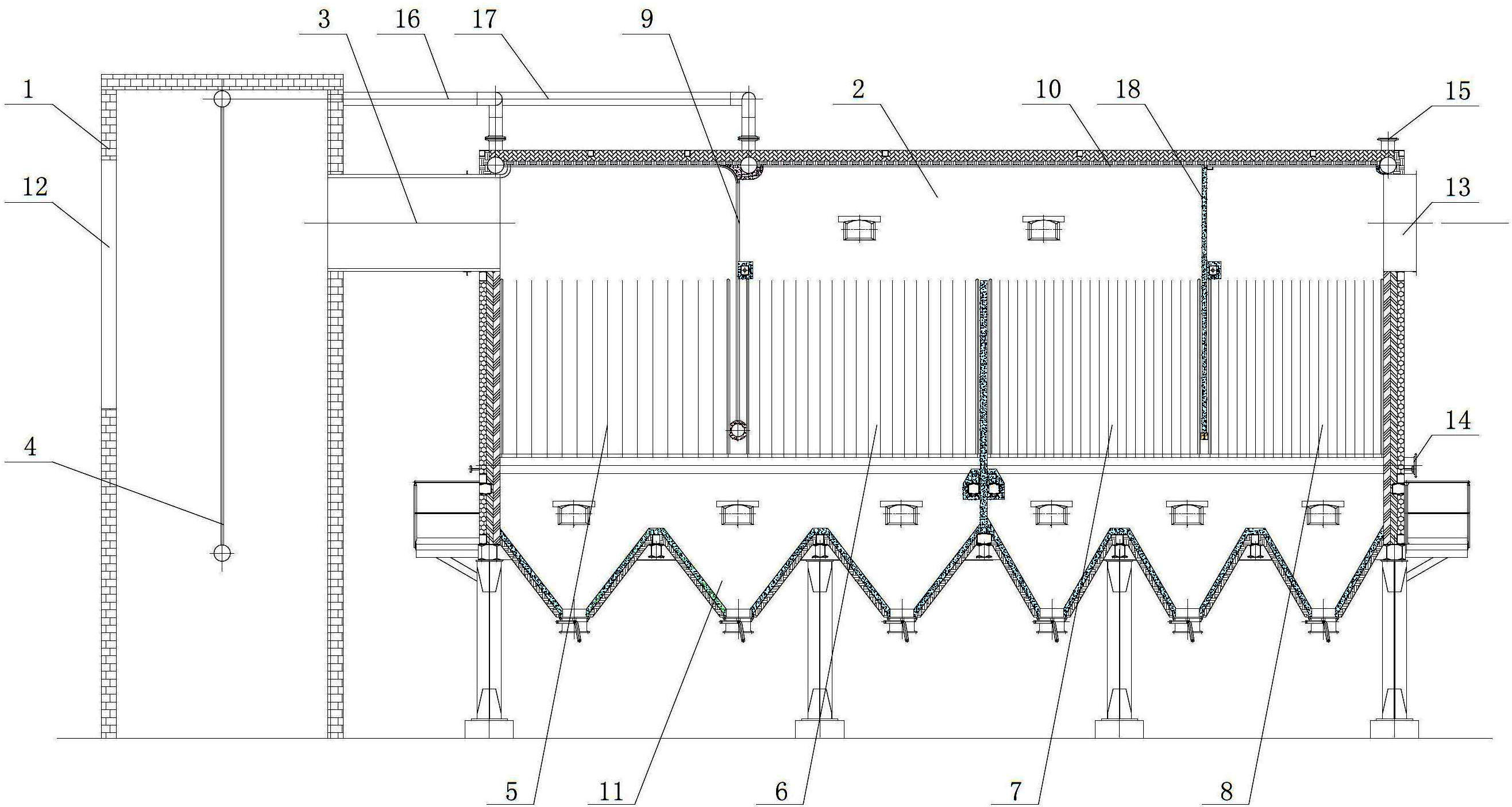

The invention relates to a circulating fluidized bed boiler unit for high efficiency combustion of biomass and recovery of waste heat. The circulating fluidized bed boiler unit comprises a hearth, a tail flue and a secondary air distribution system and is characterized in that the tail flue is provided with three tandem parallel channels, i.e., a first tail flue, a second tail flue and a third tail flue , an inlet of the first tail flue is connected with a horizontal flue outlet of a cyclone separator, the outlet steers 180 DEG and is then connected with an inlet of the second tail flue, an outlet of the second tail flue steers 180 DEG and is then connected with an inlet of the third tail flue, a heating surface is arranged in the tail flue, a coarse-pitch tipping-tube medium-temperature superheater is arranged in the first tail flue, the secondary air distribution system is an air distribution structure with upper-lower and horizontally left-right staggered junction formed by air distribution units staggerly arranged at the lower part, the waist part and the central part of the front and rear walls of the hearth, and the air distribution structure enables multiple layers of secondary air jet to be mutually crosswise sprayed into the hearth in a height direction and a horizontal direction. The boiler unit provided by the invention has high combustion efficiency, discharges a small amount of CO, reduces fly ash content in flue gas and guarantees that main steam parameters accord with design requirements.

Owner:HANGZHOU BOILER GRP CO LTD

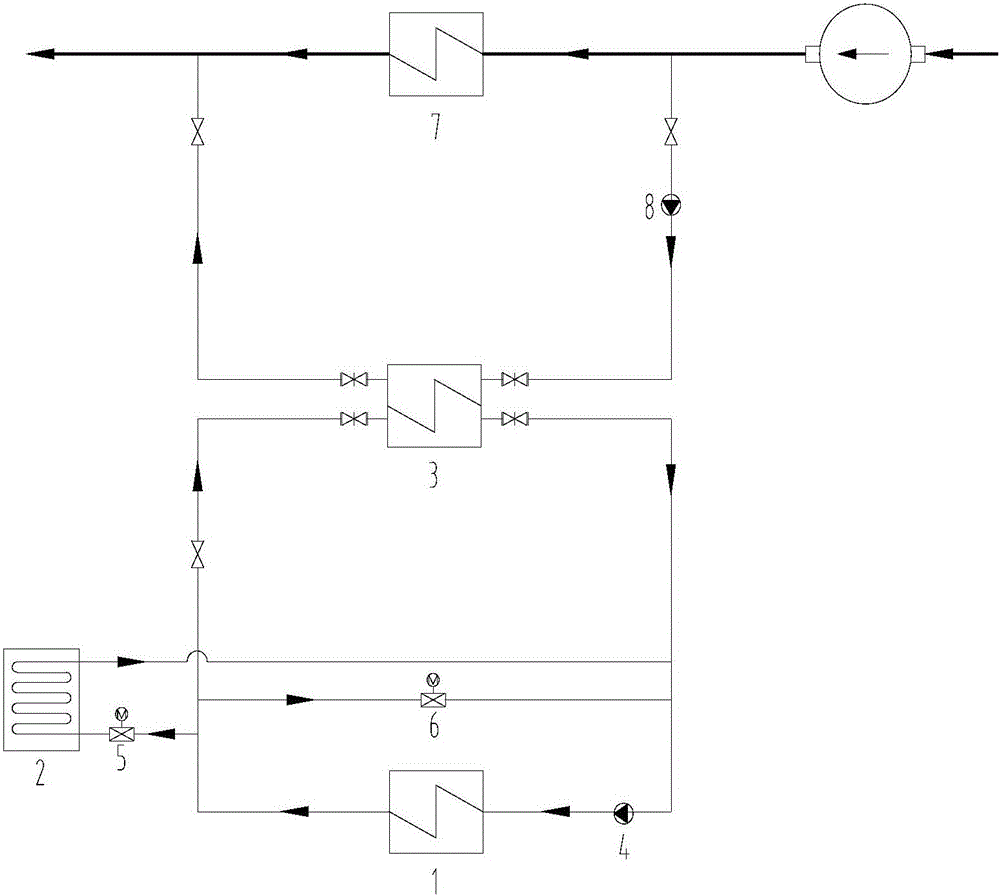

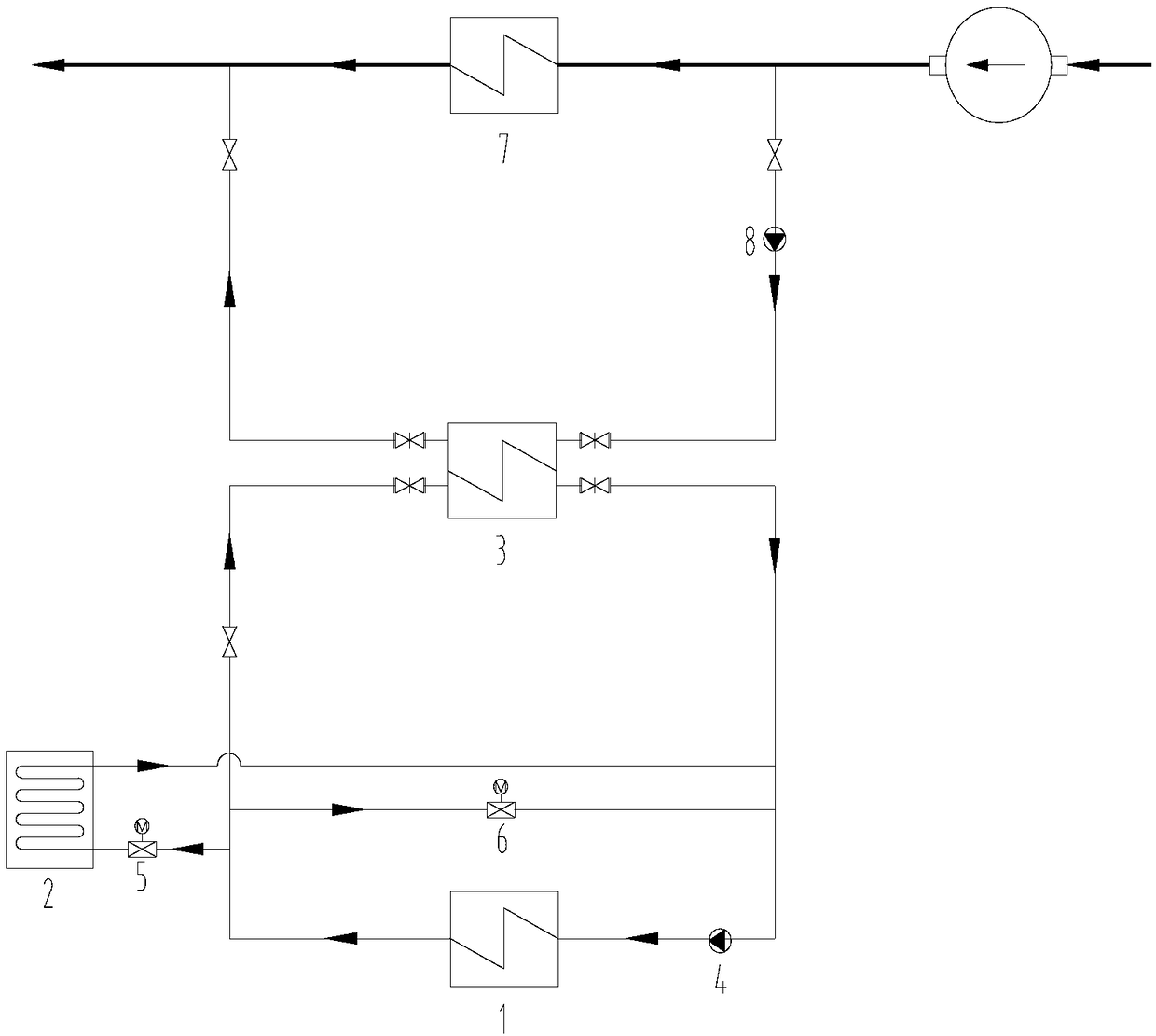

Finned tube low-pressure economizer system using boiler waste heat

InactiveCN103697456ARaise the inlet temperatureExtended service lifeFeed-water heatersEngineeringWater temperature

A finned tube low-pressure economizer system using boiler waste heat comprise a water inlet pump (1), a low-pressure heating area I (2), a low-pressure heating area II (3), a low-pressure heating area III (4), a recirculating pipe (5) and a low-pressure economizer (6). The system is characterized in that the recirculating pipe (5) is parallelly connected between the low-pressure heating area I (2) and the low-pressure economizer (6), the condensate entering from the water inlet pump (1) passes the low-pressure heating area I (2) and the low-pressure heating area II (3) and flows out from the low-pressure heating area III (4), the outlet and inlet water temperature of the low-pressure economizer (6) is adjusted through an inlet water temperature adjusting valve (10) and automatic opening and closing of the recirculating pipe (5), and the outlet water temperature of the low-pressure heating area I (2) is allowed to meet the requirement. By the finned tube low-pressure economizer system, low-temperature corrosion is lowered, the service life of the low-pressure economizer is prolonged, and the low-pressure economizer is allowed to be in the optimal waste heat recycling state.

Owner:JIANGSU ZHENGTONG HONGTAI INC

Anaerobic pyrolysis treatment system and method for garbage

The invention discloses an anaerobic pyrolysis treatment system for garbage. The Anaerobic pyrolysis treatment system comprises a pyrolysis device, a solid thermal carrier furnace, a purification device and an intermediate bunker, wherein a pretreatment unit comprises a separation unit, a crushing unit and a drying unit; the separation unit, the crushing unit and the drying unit are sequentially connected in series; the drying unit is connected with the pyrolysis device; the pyrolysis is connected with the purification device and the intermediate bunker respectively; the solid thermal carrier furnace comprises a hearth, a gas-solid separation device, a waste heat recycling unit and a return feeder; the waste heat recycling unit comprises an air preheater, an economizer and an over heater; the purification device is connected with the hearth of a combustion unit through two pipelines; the intermediate bunker is connected with the return feeder of the solid thermal carrier furnace; in the solid thermal carrier furnace, the return feeder is connected with the hearth; the hearth is connected with the gas-solid separation device; the gas-solid separation device is connected with the pyrolysis device and the waste heat recycling unit respectively; the waste heat recycling unit comprises the over heater, the economizer and the air preheater.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Furnace kiln wet flue gas white-elimination system

PendingCN110180335AReduce the temperatureImprove waste heat recovery efficiencyGas treatmentRecuperative heat exchangersSocial benefitsProcess systems

The invention discloses a furnace kiln wet flue gas white-elimination system, and relates to a white-elimination process of a wet flue gas after spray cooling of furnace kiln flue gas. The system comprises a gas-gas heat exchanger, a flue gas spray cooling apparatus and a fan. A flue gas and air are subjected to heat exchange, the flue gas after cooling enters the flue gas spray cooling apparatus,the wet flue gas after cooling is mixed with hot air to obtain a mixture, the mixture is heated and dehumidified, and then discharging is carried out through a chimney, and thus the white-eliminationrequirement is realized. The process system is simple, emission of air pollution and secondary pollutants is reduced while the consumption of a spray cooling liquid is reduced during a flue gas cooling process, and at the same time, the demand of flue gas white elimination is solved, so that the system has multiple purposes. Moreover, the implementation cost is low, and economic and social benefits are remarkable.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

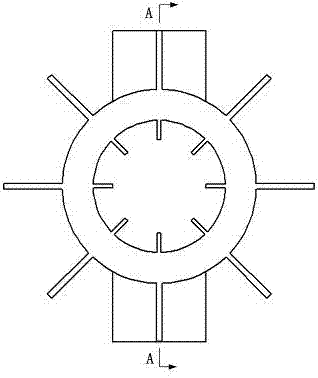

Air preheater and quartered-bin ventilation method thereof

PendingCN107702134AReduce low temperature corrosionAvoid cloggingCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention discloses a quartered-bin ventilation method of an air preheater. The ventilation method comprises the steps that flue gas is made to pass through a flue gas bin of the air preheater inthe first direction; primary air is made to pass through a primary air bin of the air preheater in the second direction, and the primary air bin is adjacent to the flue gas bin; secondary air is madeto pass through a secondary air bin of the air preheater in the second direction, and the secondary air bin is adjacent to the primary air bin; and hot primary air exhausted from an outlet of the primary air bin is guided into a hot primary air bin, the hot primary air is made to pass through the hot primary air bin in the second direction, and the hot primary air bin is adjacent to the flue gas bin and the secondary air bin. According to the quartered-bin ventilation method, the hot primary air at the outlet of the primary air bin is guided into the hot primary air bin, the temperature of theinterior of the secondary air bin can be obviously increased, the temperature of metal partition plates is increased, accordingly, low-temperature corrosion of the air preheater is relieved, and theair preheater is prevented from being blocked by ash. The invention further provides the air preheater, the quartered-bin ventilation method is applied to the air preheater, and ash blocking can be avoided.

Owner:HANGZHOU E ENERGY ELECTRIC POWER TECH

Organic heat carrier waste-heat furnace and waste-heat furnace system

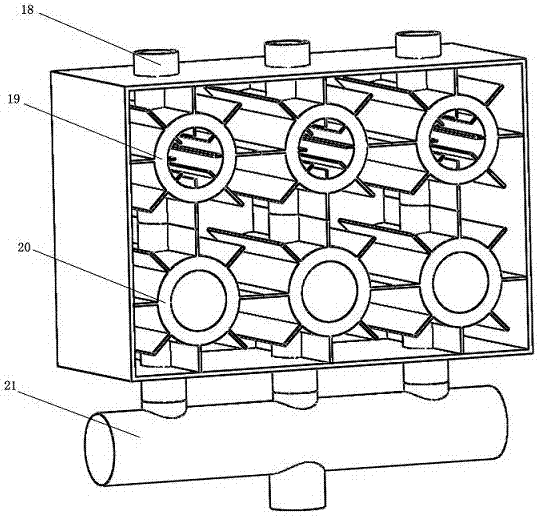

ActiveCN102679751AIncrease disturbanceLarge flow cross-sectional areaIncreasing energy efficiencyWaste heat treatmentFlueConvection

The invention discloses an organic heat carrier waste-heat furnace which comprises a waste-heat furnace body and a settling chamber, wherein one side wall of the settling chamber is provided with a smoke inlet, and the other side wall of the settling chamber is connected with one side of the waste-heat furnace body through a flue; the other side wall of the waste-heat furnace body is provided with a smoke outlet, the settling chamber is internally provided with a settling chamber diaphragm-type wall pipe screen, the top of the settling chamber diaphragm-type wall pipe screen is connected with the top of the settling chamber, and the bottom of the settling chamber diaphragm-type wall pipe screen is provided with a smoke channel; the waste-heat furnace body is internally provided with a plurality of mutually parallel convection sections, each adjacent convection sections are separated by smoke folding devices, each adjacent smoke folding devices are arranged in a stagger manner, and smoke entering the adjacent convection sections turns; and the convection sections comprise a plurality of pipe screens which are mutually parallel arranged, the spacing between each adjacent pipe screens is more than 100 mm, the design can be used for ensuring the smoke entering the adjacent convection sections to turn, increasing the disturbance of the smoke, realizing the effective segregation of the smoke, reducing the smoke flow rate and reducing the abrasion of a heating surface.

Owner:WUXI XINENG BOILER

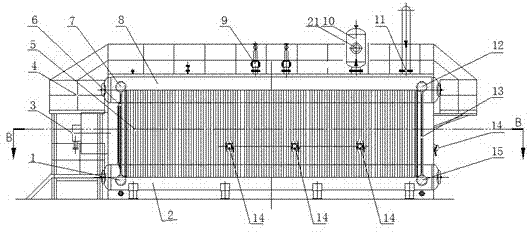

Variable-flue-cross-section tubular air preheater

ActiveCN107860022AIncrease job securityHigh working reliabilityCombustion processIndirect carbon-dioxide mitigationAir preheaterCoupling

The invention discloses a variable-flue-cross-section tubular air preheater. The air preheater comprises an air preheater shell and adopts a horizontal arrangement mode. Smoke flows in from a lower smoke inlet and flows out from an upper smoke outlet. The outer surface of a heat exchange tube bundle horizontally arranged is scoured in the flowing process, and air flows in the heat exchange tube. Heat is continuously transferred to the air by the smoke through the wall surface of the heat exchange tube, and the flow rate of the smoke is gradually reduced with the gradual decline of the temperature of the smoke in order to prevent severe safety risk caused by dust deposition on the back surface of the heat exchange tube bundle close to the smoke outlet due to the too-large decrease of the flow rate of the smoke. By adopting the design of a constant pressure smoke flowing channel, the cross section of the smoke inlet is larger than the cross section of the smoke outlet, and the smoke flowing channel is gradually reduced, so that the smoke flow rate of the smoke outlet still can be kept larger than or equal to the smoke flow rate of the smoke inlet under the condition that the temperature of the smoke is gradually reduced. The design can increase the wall temperature of the heat exchange tube by about 10-30DEG C than a vertical arrangement mode and effectively reduce the low-temperature corrosion and dust deposition coupling function of the heat exchange tube at the smoke side.

Owner:XI AN JIAOTONG UNIV

Membrane water-wall compound return water condensing type natural gas hot water boiler

ActiveCN104501397AHigh thermal efficiencyLow costCombustion technology mitigationWater heatersPipeflowEconomizer

Disclosed is a membrane water-wall compound return water condensing type natural gas hot water boiler. The natural gas hot water boiler is characterized in that a gas collector is connected with a primary pipe network water supply pipe (21) in pipelines; return water of a primary pipe network return water pipe (20) in the pipelines sequentially passes a lower water header, a lower header, a first heat exchanging pipe, an upper header and an upper water header of an economizer and a rear-membrane type water wall, a mid-partition membrane type water wall, a left-membrane type water wall, a front-membrane type water wall and a convection bank of a hearth (5) to be finally converged in an upper boiler barrel; the pipelines further include a secondary network water return pipe (22) and a secondary pipe network water supply pipe (23), and return water of the secondary pipe network return water pipe sequentially passes a branched water header (31), a second heat exchanging pipe (32) and a water header (33) of a condenser; one end of the water header is connected with the secondary pipe network water supply pipe while the other end is plugged. The membrane water-wall compound return water condensing type natural gas hot water boiler has certain universality, heat utilization rate of the boiler is increased, fuel cost during operation is lowered, and service life of boiler equipment is prolonged.

Owner:JIANGSU SIFANG BOILER

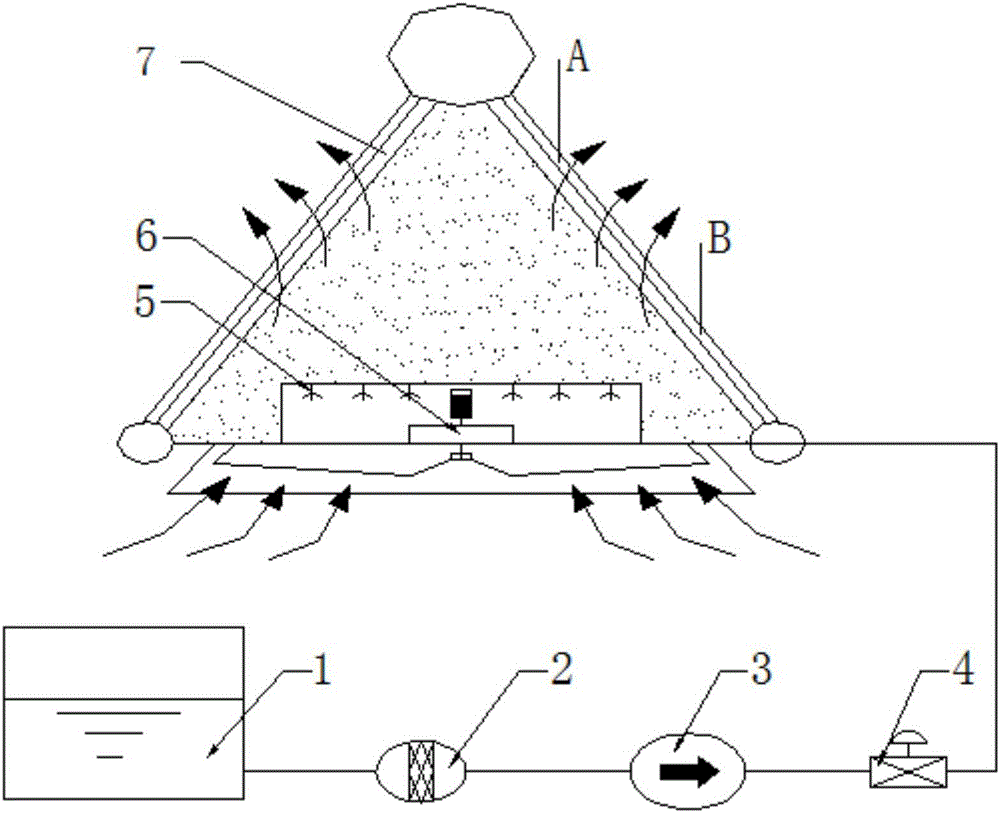

Waste heat circulation system for direct air cooling tower

InactiveCN106225005AIncrease profitResolve refluxCombustion processSteam/vapor condensersCooling towerEngineering

The invention discloses a waste heat circulation system for a direct air cooling tower. The waste heat circulation system is composed of a desalting water tank, a filter screen, a high-pressure pump, a regulating valve and an air cooling unit, wherein the desalting water tank, the filter screen, the high-pressure pump, the regulating valve and the air cooling unit are sequentially connected through pipelines. The air cooling unit is composed of a direct air cooling tower and a draught fan located on the lower portion of the interior of the air cooling unit, wherein the direct air cooling tower is formed by obliquely building fin pipes. Spray nozzles are further arranged above the draught fan. Air flows into the air cooling unit above through the spray nozzles. Multiple sets of air suction pipelines are arranged on the exterior of the direct air cooling tower in parallel and are fixed above the interval spaces of the adjacent fin pipes in the axial direction of the fin pipes correspondingly. Air suction openings are further formed in the lower portions of the air suction pipelines. Waste heat air between the fin pipes enters the air suction pipelines through the air suction openings. The output ends of the air suction pipelines are in butt joint with air feeder air feed pipelines of a boiler. Hot air at an outlet of a direct air cooling condenser is used for air used for boiler combustion, recycling of hot air at an outlet of the direct air cooling tower is achieved, the utilization rate of fuel is increased, thermal pollution is reduced, and the effects of energy conservation and emission reduction are achieved.

Owner:JILIN ELECTRIC POWER RES INST LTD

System for increasing the temperature of secondary air at inlet of air pre-heater

InactiveCN102829486ARaise secondary air inlet air temperatureLower exhaust gas temperatureCombustion processIndirect carbon-dioxide mitigationAir preheaterAir cycle

The invention relates to a smoke discharge technology for a boiler, and in particular to a system for increasing the temperature of secondary air at an inlet of an air pre-heater. The system is characterized in that a mixer is arranged in the middle of a secondary air inlet pipeline of the air pre-heater; a hot air circulating pipeline is connected and arranged at an outlet of a primary air outlet pipeline of the air pre-heater; and the hot air circulating pipeline is communicated with the mixer to guide primary air to the mixer to regulate hot air. With the structure, the resistance loss of the system is low, the temperature of the secondary air at the inlet of the air pre-heater can be effectively increased, and low-temperature corrosion can be reduced; the goal of effectively reducing the design smoke discharge temperature of the boiler at the design phase of a power plant can be achieved; and through the arrangement of a smoke baffle, air temperature can be regulated according to the practical situation of the power plant, and the operation is convenient and simple.

Owner:中国东方电气集团有限公司

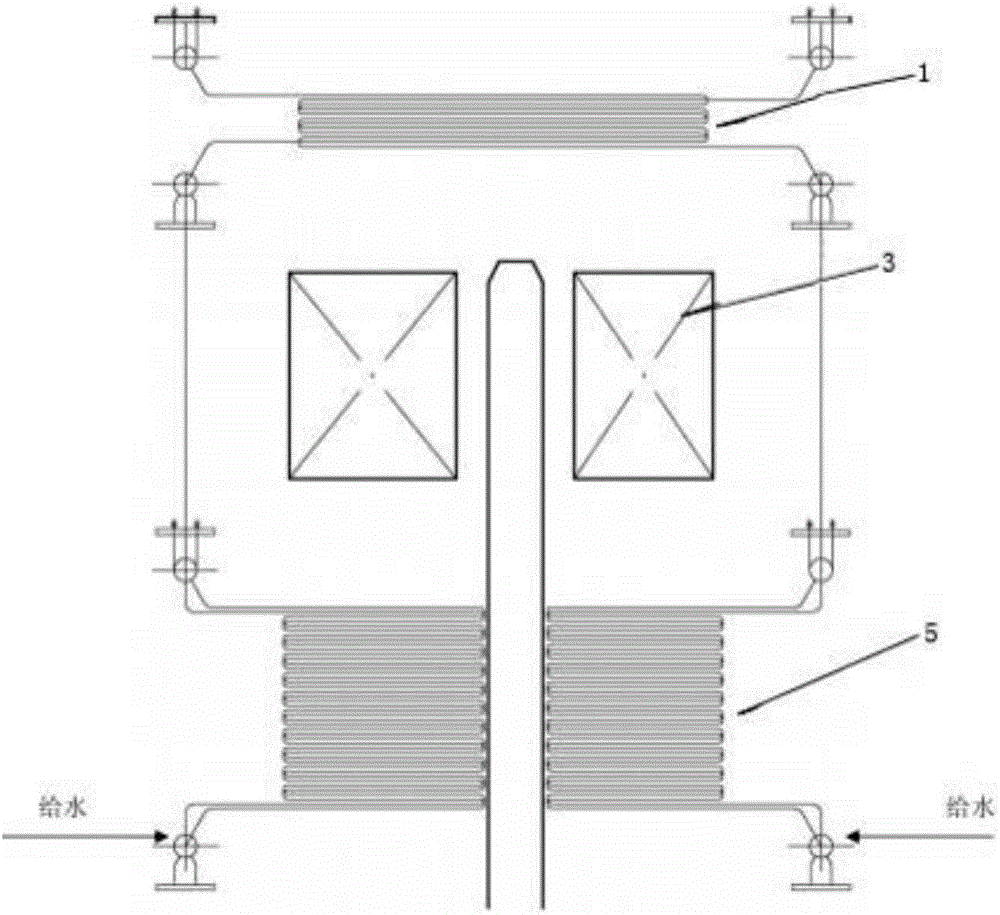

Boiler system capable of combining oxygen-enriched air and air combustion

InactiveCN106322367AMeet operational requirementsImprove the problem of low temperatureIndirect carbon-dioxide mitigationAir/fuel supply for combustionEngineeringEconomizer

The invention discloses a boiler system capable of combining oxygen-enriched air and air combustion. The system can combine combustion of two work conditions of oxygen-enriched air and air. Tail double flues are designed on the boiler system. Economizers and preheaters are alternately arranged, circulation primary air and circulation secondary air are independently preheated, and the different requirements for the temperature and pressure of the circulation primary air and the circulation secondary air and the hot air temperature under different combustion work conditions are met. Meanwhile, a GGH system is designed at the tail portion, the inflow combustion supporting gas temperature is increased, and heat exchange in the preheaters is reduced so as to increase the exhausting temperature and reduce the low-temperature corrosion. The circulation primary air oxygen injection position and the circulation secondary air oxygen injection position are independently designed, oxygen injection is conducted on the primary air behind preheater units, oxygen injection is conducted on the secondary air before the preheater units, and therefore the hot air temperature is increased; and the hot air temperature under the oxygen-enriched air work condition is closer to the hot air temperature under the air work condition, and finally, smooth switching running of combining of two combustion work conditions of oxygen-enriched air and air is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

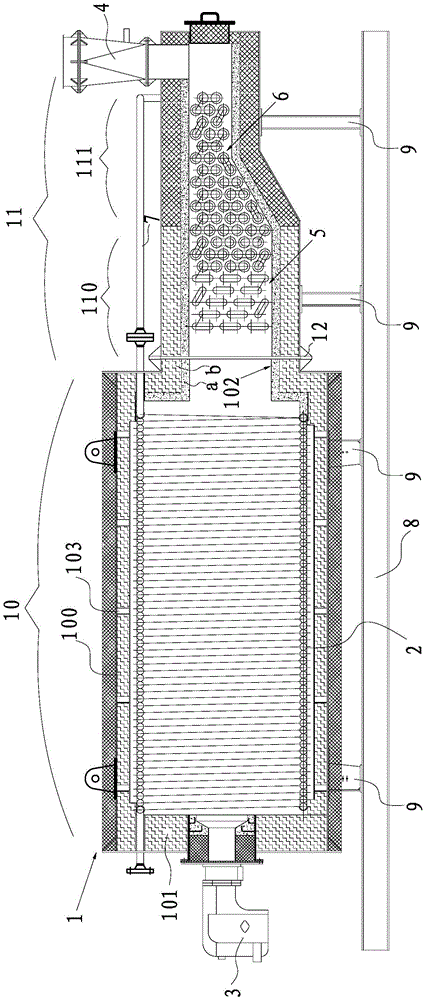

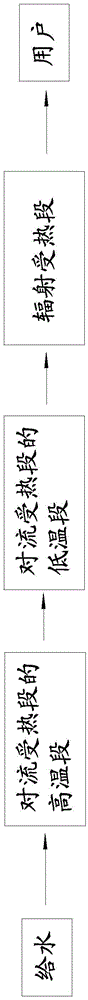

A skid-mounted water injection boiler

The invention discloses a skid-mounted water injection boiler, which includes a furnace body, a furnace tube, a burner, and a chimney, wherein the furnace body includes a radiation heating section and a convection heating section, and the furnace tube is a spiral coil tube along the length of the furnace body. The direction extension is located in the radiation heating section, the chimney is located at the tail of the convection heating section, and the water injection boiler also includes a preheating tube located in the convection heating section for preheating the water or medium injected into the furnace tube, and along the convection heating section. The extension direction is arranged on the right side of the preheating pipe and connected with the heating pipe, the connecting pipe for connecting the heating pipe with the furnace pipe, the skid seat arranged under the furnace body along the extending direction of the furnace body, And connecting seats respectively used for connecting the radiation heating section and the convection heating section to the skid base. The invention not only enables the furnace tube to be heated evenly in the radiant section, but also effectively reduces the low-temperature corrosion at the tail end of the furnace body. At the same time, the furnace body and the burner are integrated into a skid, which is convenient for transportation and on-site installation.

Owner:JIANGNAN BOILERS & PRESSURE VESSELS ZHANGJIAGANG

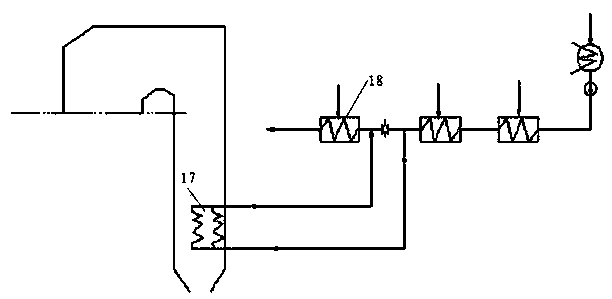

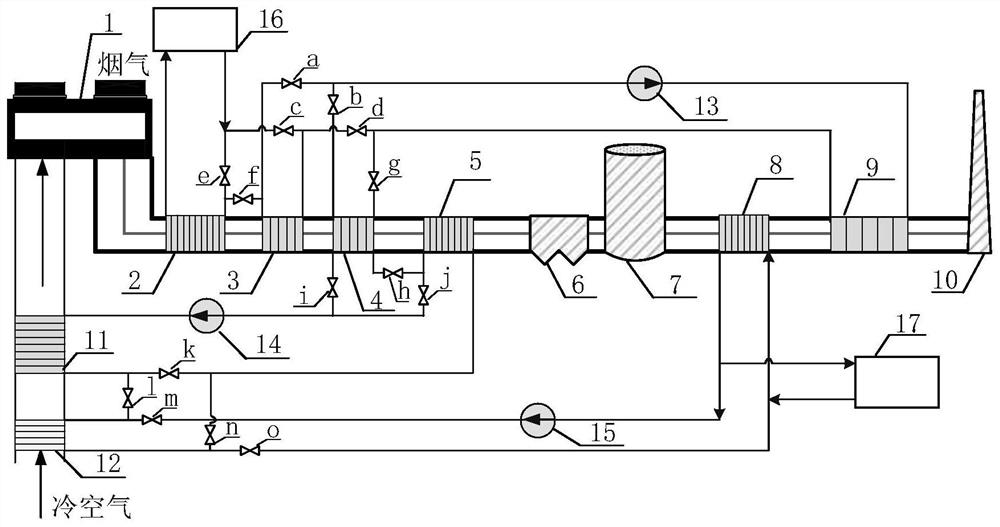

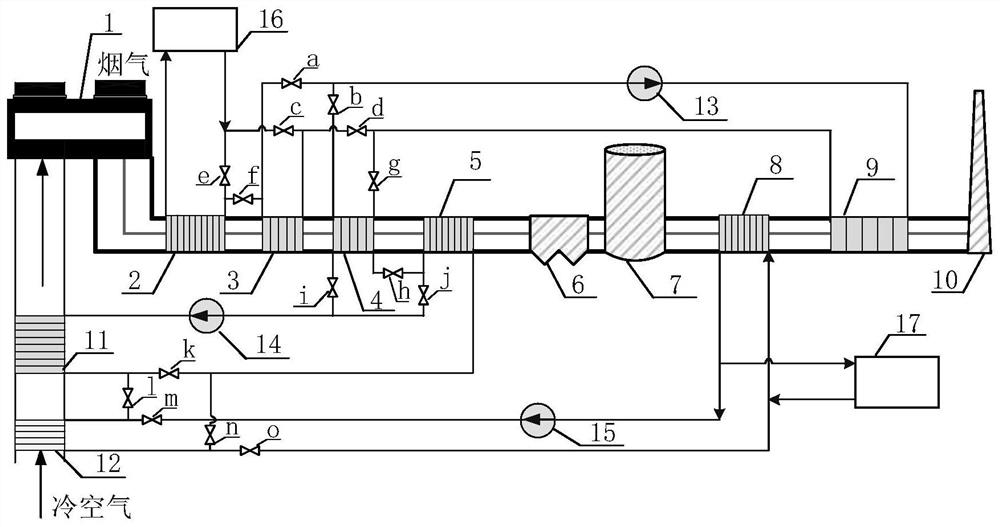

Exhaust gas waste heat recovery and emission reduction comprehensive application system for coal-fired boiler in thermal power plant

ActiveCN102305413BReduce low temperature corrosionImprove performanceCombustion processIndirect carbon-dioxide mitigationExpansion tankAir preheater

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

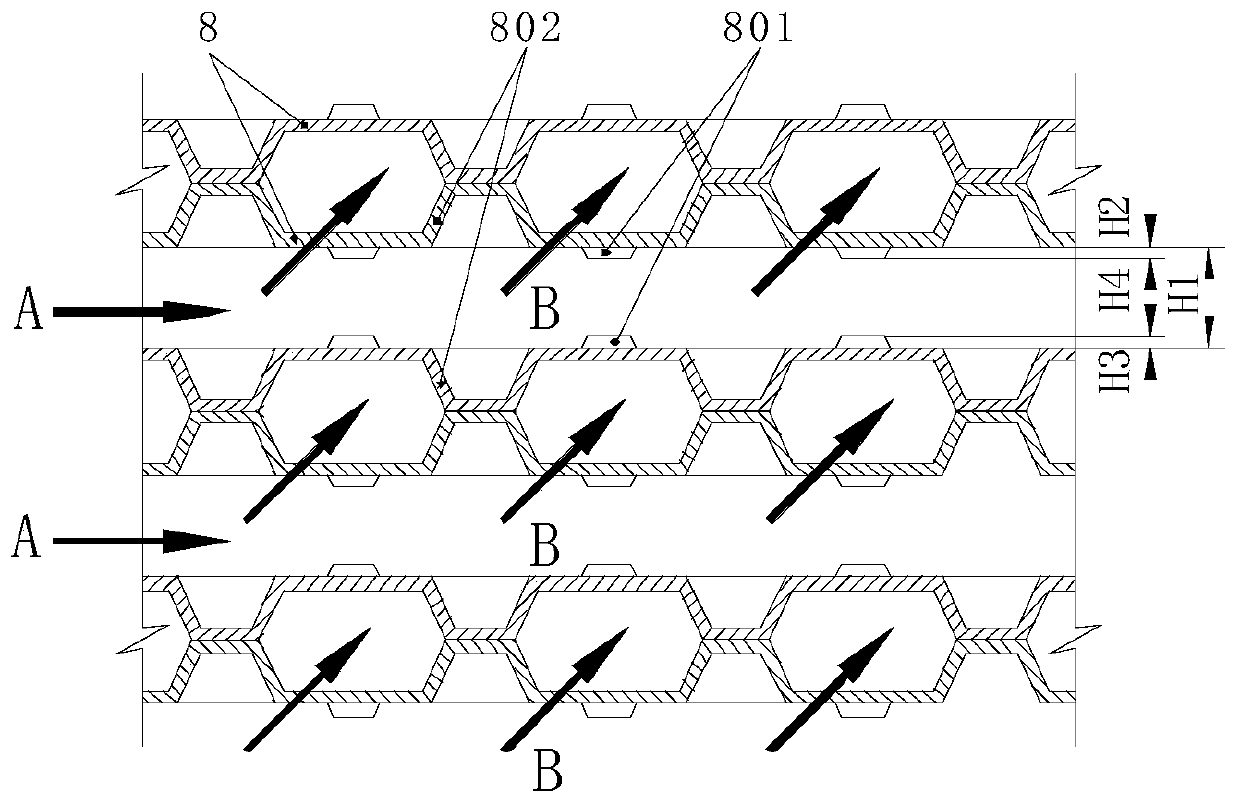

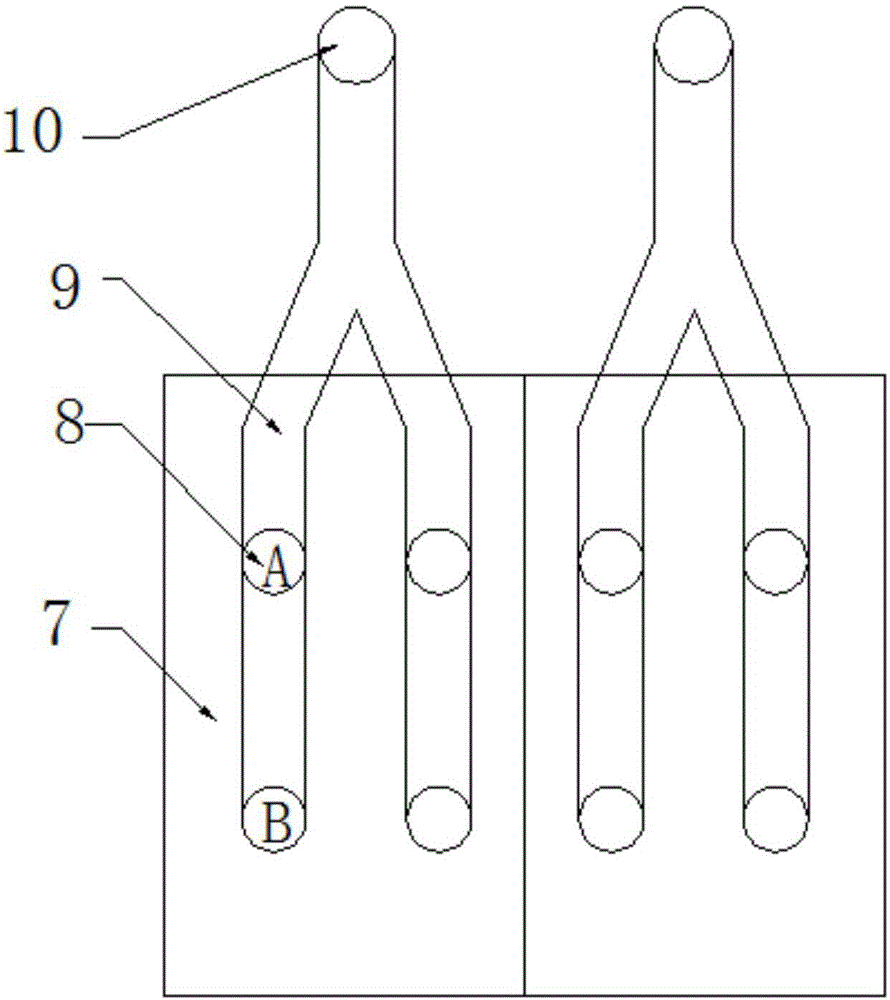

System for recovering water vapor in smoke and heat by membrane method and heat exchange module

PendingCN107062298AReduce low temperature corrosionRaise the cold junction temperatureGas treatmentCombustion processWater recoveryAir heater

The invention discloses a system for recovering water vapor in smoke of a thermal power plane and heat based on a composite membrane, and a heat exchange module with a front-loaded air heater. A water recovery device adopts three-grade arrangement, and is provided with the front-loaded air heater for recovering the heat of the water vapor. A high-temperature water recovery device is arranged in front of an air preheater; the temperature of the recovered water vapor is higher; the recovered water vapor serves as a heat source of the air heater; a medium-temperature water recovery device is arranged in front of a desulfurization tower; the heat of the recovered water vapor serves as a heat source of the front-loaded air heater for heating environmental air; a low-temperature water recovery device is arranged behind the desulfurization tower; the temperature of the recovered water vapor is lower; and the recovered water vapor can be directly fed in a steam condenser for condensation. The heat exchange module with the front-loaded air heater mainly consists of a water vapor conveying pipe, an I-grade heat exchange module, an II-grade heat exchange module and a dewatering header. The system is huge in application potential on the aspects of water conservation and energy conservation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

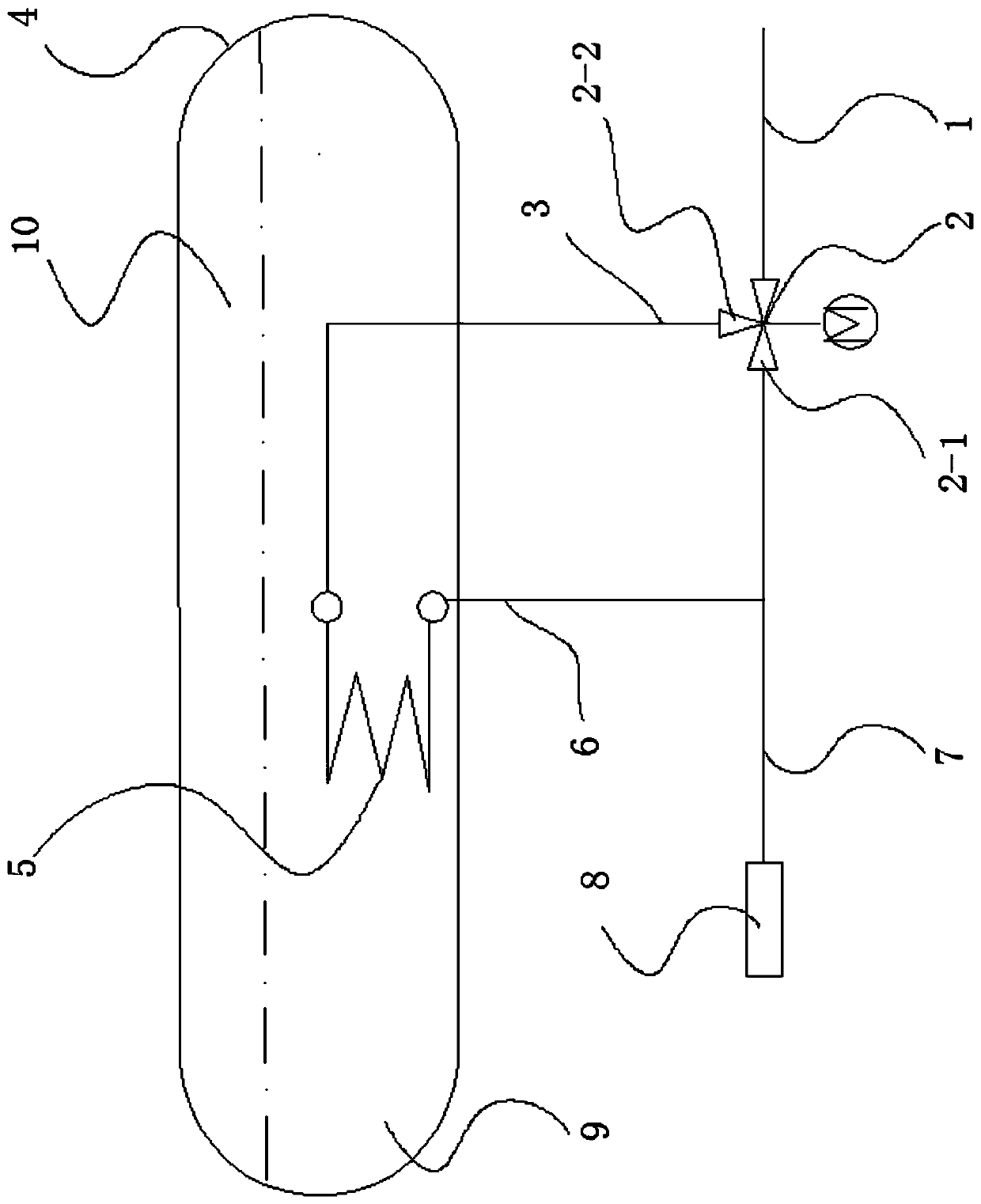

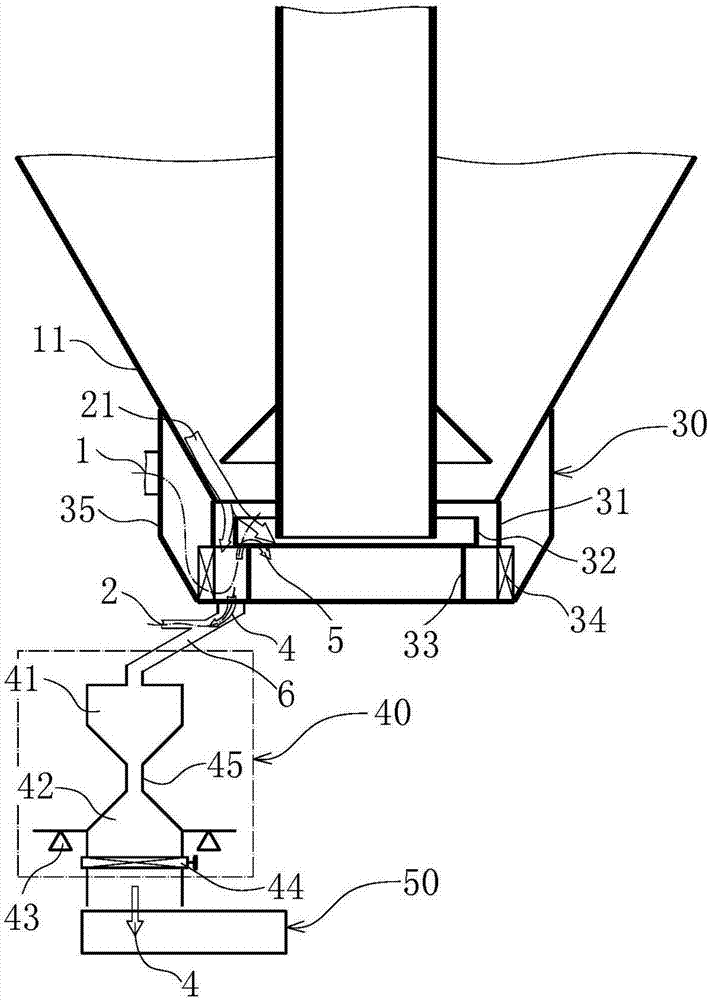

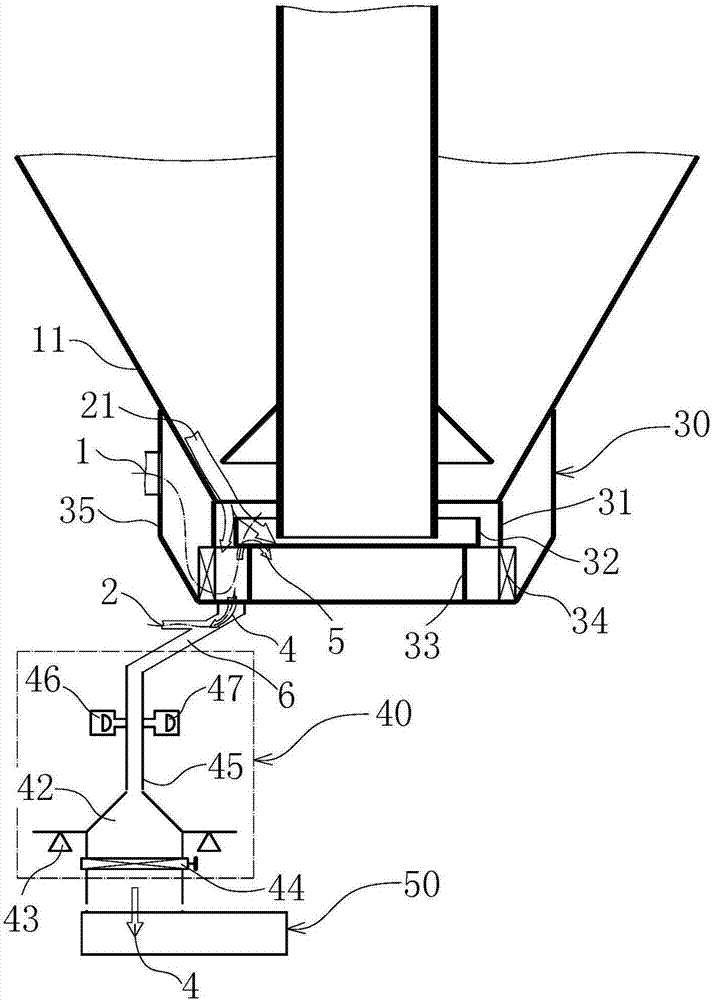

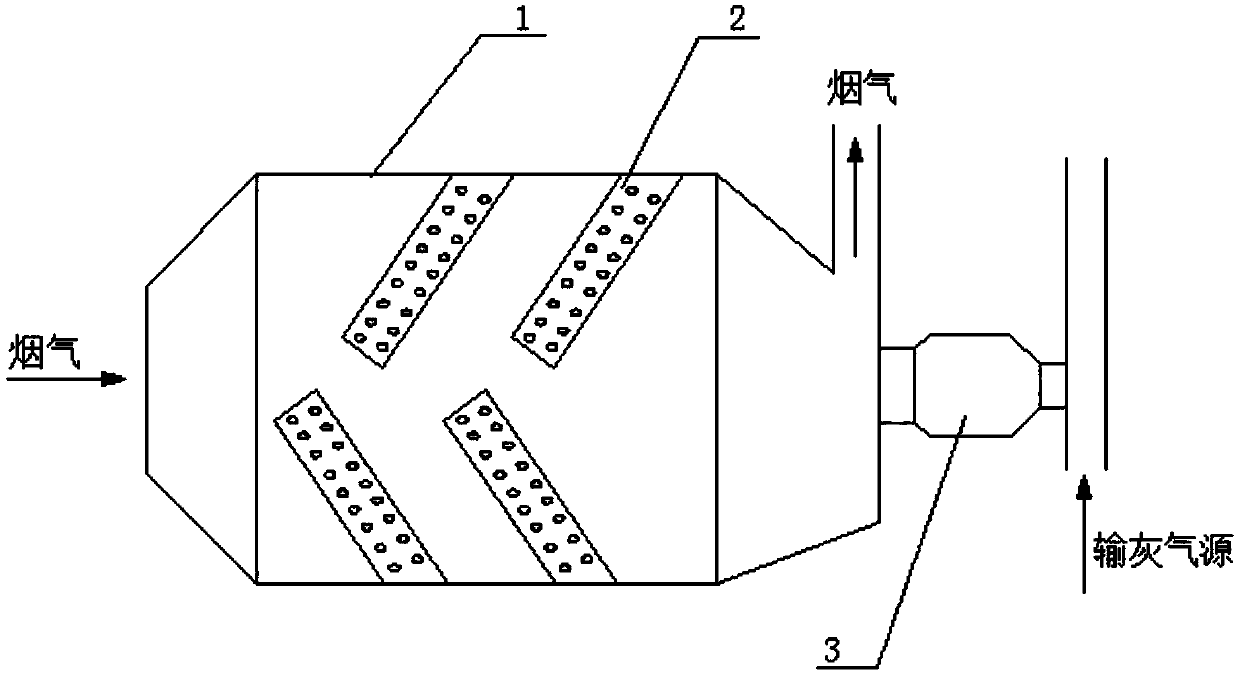

Device for controlling smoke exhaust temperature of refuse burning waste heat boiler

InactiveCN110779006AReduce low temperature corrosionSolve corrosiveFeed-water heatersTemperature controlEnvironmental engineering

The invention provides a device for controlling smoke exhaust temperature of a refuse burning waste heat boiler, and belongs to the smoke exhaust temperature control technology field of the refuse burning waste heat boiler. The device for controlling the smoke exhaust temperature of the refuse burning waste heat boiler comprises a main water feed pipeline, a water feed three way regulation valve,a heater inlet pipeline, a boiler barrel, a heater, a heater outlet pipeline, a main water feed mixing pipeline and a coal economizer collecting box, wherein an inlet of the water feed three way regulation valve communicates with the main water feed pipeline, an outlet I of the water feed three way regulation valve communicates with an inlet of the main water feed mixing pipeline, an outlet II ofthe water feed three way regulation valve communicates with the heater inlet pipeline, the heater inlet pipeline communicates with a heater inlet, a heat outlet communicates with the heater outlet pipeline, the heater outlet pipeline communicates with an inlet of the main water feed mixing pipeline, an outlet of the main water feed mixing pipeline communicates with the coal economizer collecting box, and the heater is arranged in a water phase area of the boiler barrel.

Owner:HARBIN BOILER

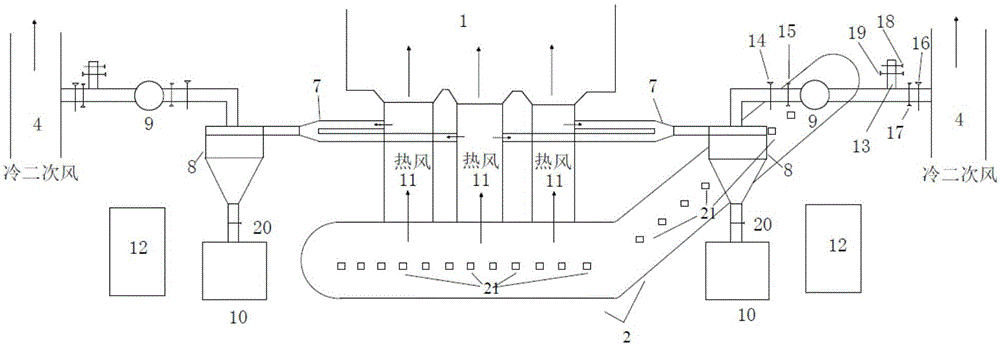

Device for recovering hot air of dry type slag removal machine and reducing disorganized air leakage of bottom of hearth and application thereof

ActiveCN105020726AReduce the amount of cooling waterReduce emission concentrationLighting and heating apparatusIsolation valveSlag

The invention provides a device for recovering hot air of a dry type slag removal machine and reducing disorganized air leakage of the bottom of a hearth. The device comprises a suction pipeline, a cyclone separator, a suction fan, a control device, a ventilation bypass, a first control damper, a first isolation valve, a second control damper, a second isolation valve, a third control damper and a third isolation valve. The cyclone separator, the first control damper, the first isolation valve, the suction fan, the ventilation bypass, the second isolation valve and the second control damper are sequentially arranged on the suction pipeline from the inlet to the outlet. The third isolation valve and the third control damper are sequentially arranged on the ventilation bypass from the inlet to the outlet. A slag gate box is arranged at the bottom of the cyclone separator. By means of the device, the disorganized air leakage of the bottom of a furnace is changed to organized air supply, and the thermal efficiency of the furnace is improved to close to the optimum value; the flame center height of the hearth is controlled, temperature reduction water quantity of a superheater and a reheater is reduced, cocking which may happen to the platen superheater is reduced, NOx emission concentration is lowered, and remarkable comprehensive benefits to the unit are achieved.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

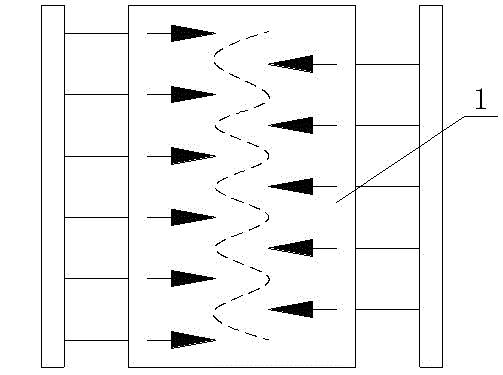

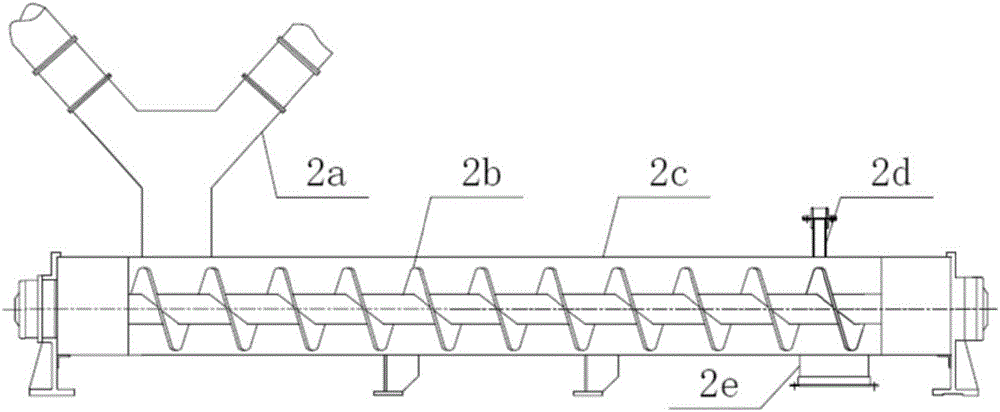

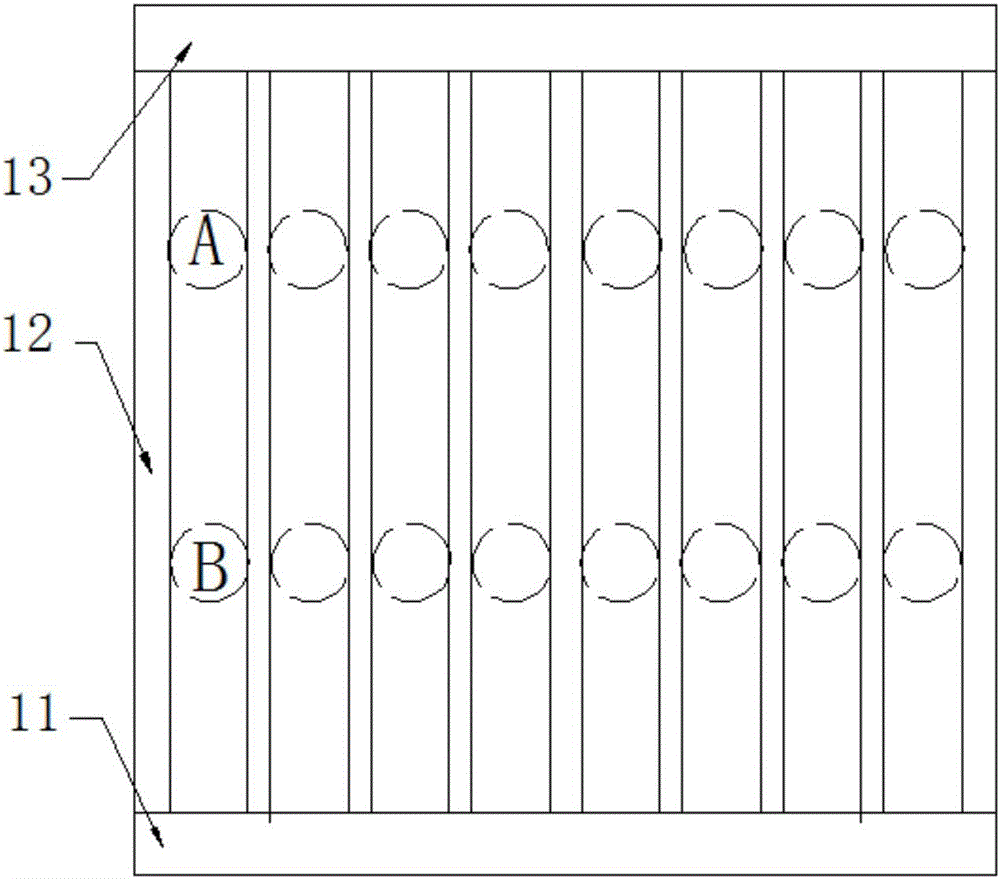

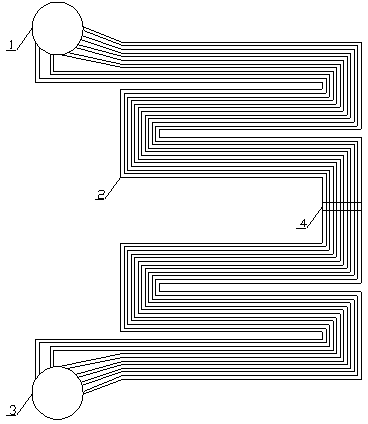

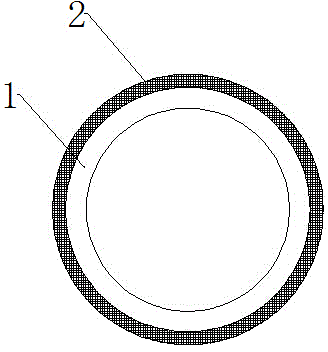

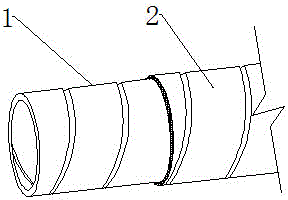

Low-pressure economizer with finned tubes

InactiveCN103697455AExtended service lifeReduce low temperature corrosionFeed-water heatersEngineeringEconomizer

A low-pressure economizer with finned tubes consists of an inlet header (1), finned tube rows (2) and an outlet header (3). The finned tube rows (2) are divided into the upper section and the lower section, the inlet header (1) is connected with the front six finned tube rows of the upper section, and the outlet header (3) is connected with the rear six rows of the finned tube rows (2). The low-pressure economizer is characterized in that the upper section of the finned tube rows (2) and the lower section thereof are welded integrally by an installation weld junction (4). The front six finned tube rows are made of ND steel, so that low-temperature corrosion is decreased, and the service life of the low-pressure economizer is prolonged. Due to the finned tubes of the new specification, heat exchange area is guaranteed while ash accumulation is reduced, and the low-pressure economizer stays at the best state for exhaust heat recovery.

Owner:JIANGSU ZHENGTONG HONGTAI INC

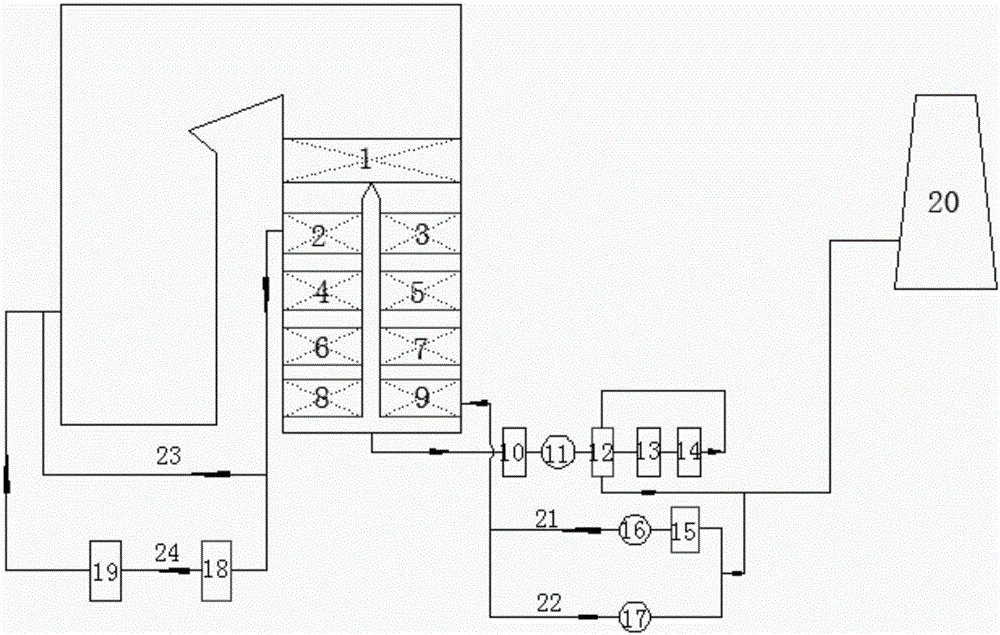

Coal-fired power plant low-temperature flue gas water recovery and waste heat utilization coupling system and operation method

ActiveCN112283694AReduce irreversible lossReduce coal consumptionIndirect carbon-dioxide mitigationChimneysAir preheaterEconomizer

The invention discloses a coal-fired power plant low-temperature flue gas water recovery and waste heat utilization coupling system and an operation method. The system comprises a rotary air preheater, a low-temperature economizer, a first part adjustable flue gas heat exchanger, a second part adjustable flue gas heat exchanger, a low-temperature flue gas cooler, an electric dust remover, a desulfurizing tower, a flue gas condenser, a flue gas reheater, a chimney, a first-stage air heater, a second-stage air heater, a plurality of circulating water pumps and a plurality of control valves. Low-temperature flue gas waste heat is recovered to a steam turbine regenerative system through the multiple flue gas heat exchangers or used for preheating air, and unit coal consumption is reduced; water is recovered through the flue gas condenser; flue gas is reheated through the flue gas reheater, and low-temperature corrosion to the chimney is reduced; and operation of the adjustable flue gas heat exchangers is controlled through the control valves, the adjustable flue gas heat exchangers are connected with other flue gas heat exchangers in series to work together under different working conditions, the temperature of the flue gas entering the electric dust remover is maintained to be 90 DEG C or above, the temperature of circulating water entering the low-temperature flue gas cooler is 70 DEG C or above, and therefore safe operation of the system under different environment temperatures is achieved.

Owner:XI AN JIAOTONG UNIV

A flue gas heater with defogging function

A smoke heater with a defogging function comprises an outer shell. Four rows of waist circular tubes are arranged at the front end of a straight section of the outer shell. The first row of waist circular tubes and the fourth row of waist circular tubes are arranged vertically and are communicated with a water inlet collecting box and a water outlet collecting box respectively. The second row of waist circular tubes and the third row of waist circular tubes are arranged in a V shape. The four rows of waist circular tubes are connected through waist circular tube connecting bending heads to form a snake-shaped pipe. The waist circular tubes are arranged in a narrow-gap mode. A plurality of rows of finned pipes which are arranged horizontally are arranged at the back end of the straight section of the outer shell. The finned pipes are communicated with collecting boxes arranged at the two ends of the outer shell. The four rows of waist circular tubes and the multiple rows of finned pipes form a heat exchanging pipe bundle which divides the smoke heater into a wet smoke zone and a dry smoke zone. The smoke heater can heat smoke and further lower droplet content in the smoke, defogging and heating are combined, smoke temperature is raised, so that smoke lift force is improved, contaminant dispersing concentration is lowered, lime rain is avoided, smoke humidity is lowered, and corrosion on a flue and a chimney from acid droplets is lowered.

Owner:XI AN JIAOTONG UNIV

A medium-speed coal pulverizer with ash reduction and desulfurization device

The invention discloses a medium-speed coal mill with a deashing desulfurizing device, comprising a coal feeding pipe, a conical shell, a coarse powder separator retainer, a grinding ring and the deashing desulfurizing device.The conical shell is disposed outside the coal feeding pipe.The coarse powder separator retainer is disposed at the top of the conical shell.The grinding ring is disposed below the conical shell.The deashing desulfurizing device comprises am impurity separating module, an impurity discharge pipe and an impurity sensing module; the impurity separating module is disposed at the bottom of the conical shell of the medium-speed coal mill, the impurity sensing module is disposed outside the medium-speed coal mill, and the impurity separating module and the impurity sensing module are communicated through the impurity discharge pipe.The medium-speed coal mill with the deashing desulfurizing device has the advantages that output of the coal mill is increased, power consumption per unit powder production is reduced, equipment abrasion is reduced, water-cooled wall high-temperature corrosion and lagging tendency is reduced, low-temperature corrosion of boiler tail heated surface is reduced, sulfur emission of power plants is reduced and running cost of a desulfurizing system is reduced; the removed impurity is recyclable, and benefit can be maximized.

Owner:南京博沃科技发展有限公司

Device and method for recovering gas-fired boiler flue gas condensation heat energy by means of heat pump

ActiveCN103954039BEasy to control temperatureIncrease profitHeat pumpsHeat recovery systemsFlue gasThermal water

The invention relates to a device and a method for recycling smoke condensate heat energy of a gas boiler in a heat pumping mode. The device and method for recycling the smoke condensate heat energy of the gas boiler with high heat energy recycling rate do not exist at present. The device provided by the invention comprises a high-efficient condensate heat exchanger, a primary circulating water heat exchanger outlet pipe, a smoke inlet pipe and a smoke outlet pipe, and is characterized by further comprising a heat pump unit, a primary circulating water heat pump inlet pipe, a primary circulating water heat pump outlet pipe, a primary circulating water pump, a domestic hot water taking pipe, a primary circulating water replenishing pipe, a secondary circulating water pump, a secondary circulating water heat pump inlet pipe and a secondary circulating water heat pump outlet pipe, wherein one end of the primary circulating water heat pump outlet pipe and one end of the primary circulating water replenishing pipe are both connected with the other end of a primary circulating water heat exchanger inlet pipe; the secondary circulating water pump is mounted on the secondary circulating water heat pump inlet pipe; a secondary circulating water heat pump outlet temperature gauge is mounted on the secondary circulating water heat pump outlet pipe. The device provided by the invention is high in heat energy recycling rate.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

A membrane-type water-cooled wall composite return water condensing natural gas hot water boiler

ActiveCN104501397BHigh thermal efficiencyLow costCombustion technology mitigationWater heatersWater pipeEconomizer

Owner:JIANGSU SIFANG BOILER

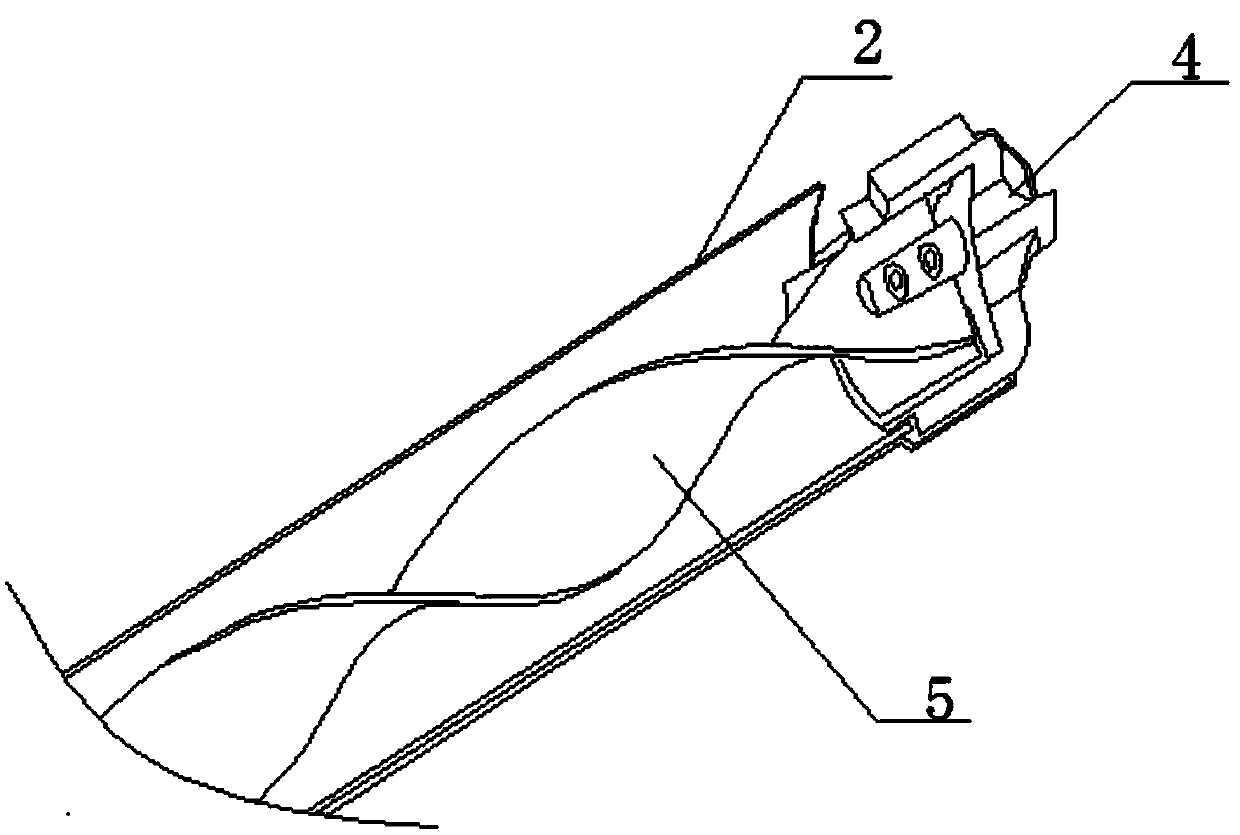

Copper-chromium-based TGr-titanium film thread pipe type air preheater and pipe film component

InactiveCN104930900AIncrease the heating areaEfficient use ofCombustion processIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention belongs to the technical field of new energy, efficient energy saving and energy saving of high-energy-consuming industries such as a power industry and particularly relates to a copper-chromium-based TGr-titanium film thread pipe type air preheater and a pipe film component. According to the copper-chromium-based TGr-titanium film thread pipe type air preheater and the pipe film component, a base pipe and a copper-chromium-based TGr-titanium film layer are included. The copper-chromium-based TGr-titanium film layer is arranged on the outer side of the base pipe. The copper-chromium-based TGr-titanium film thread pipe type air preheater and the pipe film component have the advantages that the heating area can be increased through threads, so that air side heat transferring capacity is greatly improved, meanwhile, flue gas flow speed is reasonably selected, under ripple disturbance, ash deposition phenomena hardly exist, heat transferring capacity is improved, so that wall temperature is improved, low-temperature corrosion is lowered, flue gas side heat is well used, the burning state is improved, and efficiency is improved.

Owner:济南屹林科技有限公司

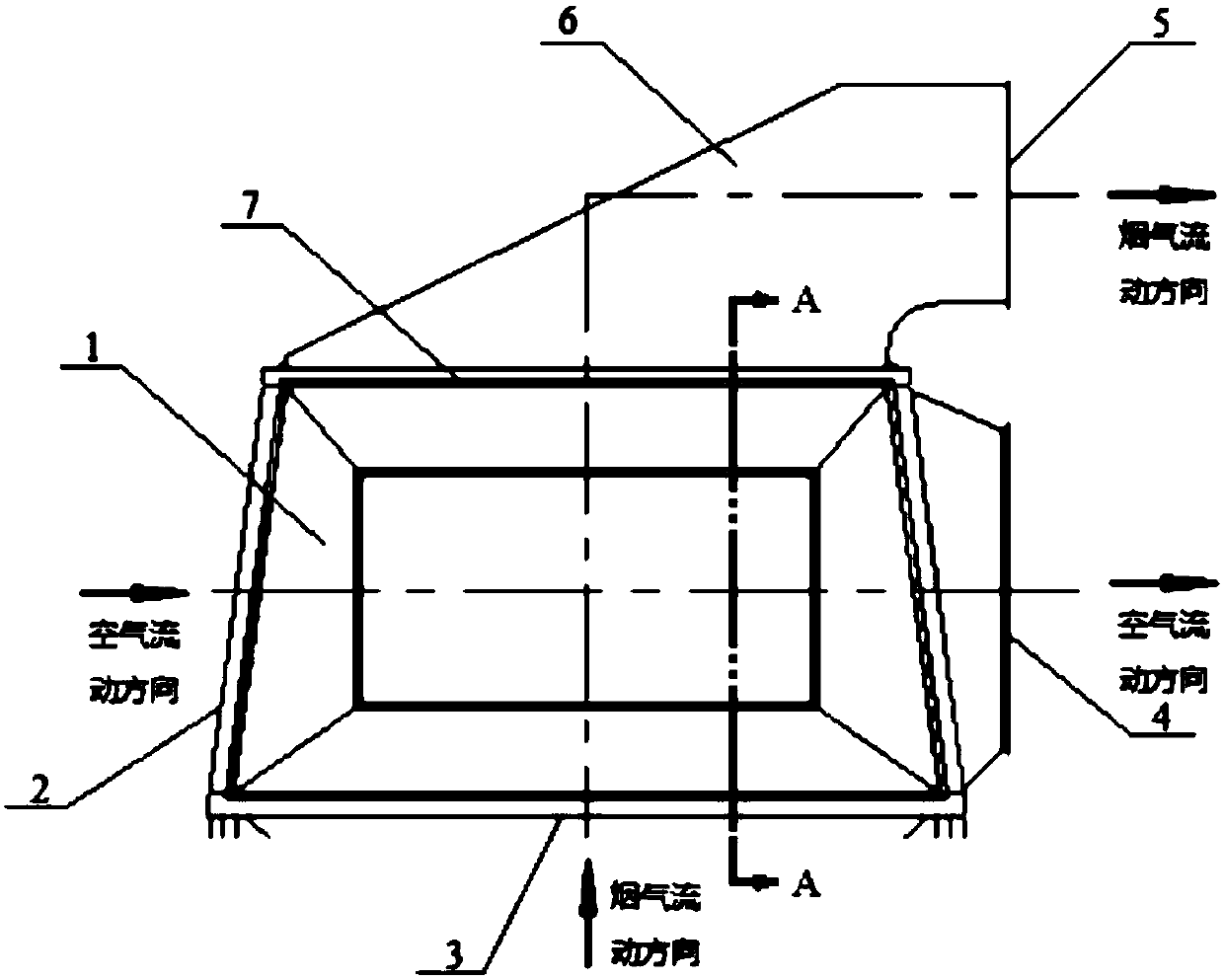

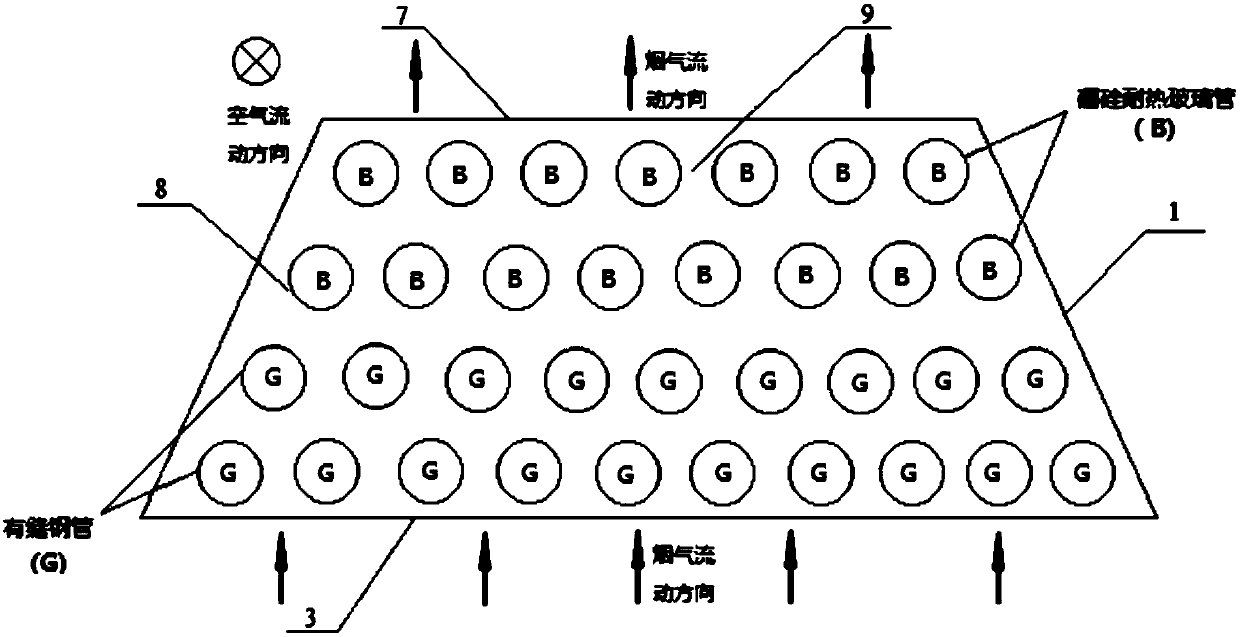

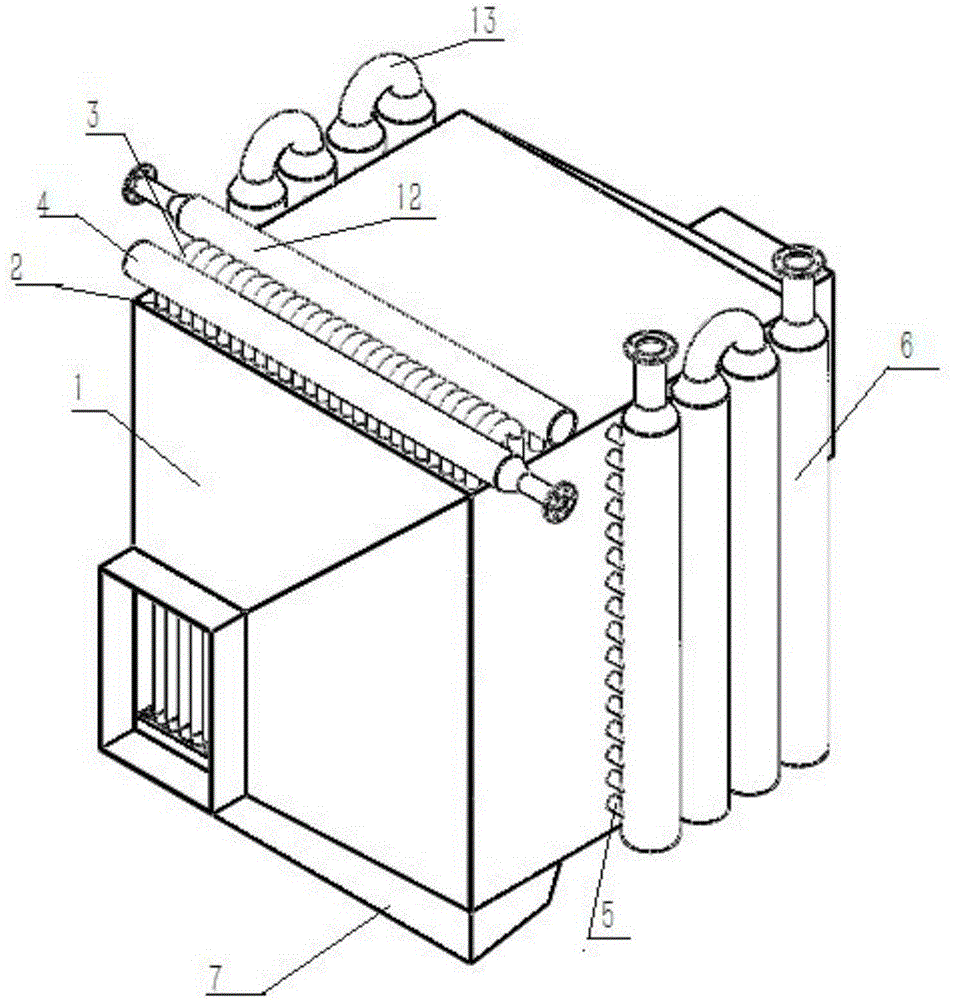

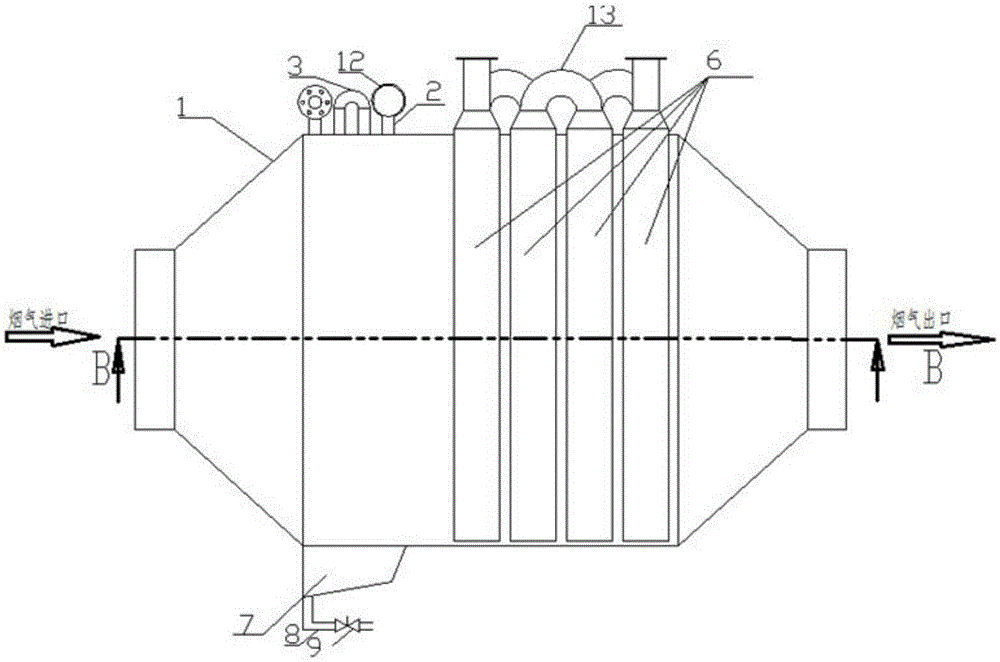

A horizontal enamel tube air preheater

ActiveCN107062297BIncrease the heat transfer coefficient K valueIncreased turbulenceCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention discloses a horizontal-type enamel pipe air pre-heater. According to the horizontal-type enamel pipe air pre-heater, the problems that in the prior art, the air pre-heater is low in heat exchanging efficiency and large in size, and a pipe can be frequently replaced caused by the fact that the heat exchanging pipe is prone to being damaged are solved. The air pre-heater has the effects that heat exchanging efficiency is high, the size is reduced, and the phenomenon that the pipe is frequently replaced because of corrosion and damage is avoided. According to the technical scheme, the horizontal-type enamel pipe air pre-heater comprises a pre-heater shell and a storehouse pump; the pre-heater shell is of a horizontal-type structure, a smoke inlet is formed in one side of the pre-heater shell, and a smoke outlet is formed in the other side of the pre-heater shell; an enamel pipe heat exchanging pipe is arranged in the pre-heater shell and adopts a TEPEE pipe discharging mode and is internally provided with a spiral twisted stripe driven through the air flow rate; and the storehouse pump is arranged on the side of the smoke outlet of the pre-heater shell, and therefore accumulated dust on the enamel pipe heat exchanging pipe can be output in time.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +3

Coupling system and operation method of low temperature flue gas water recovery and waste heat utilization in coal-fired power stations

ActiveCN112283694BReduce irreversible lossReduce coal consumptionIndirect carbon-dioxide mitigationChimneysAir preheaterEconomizer

The invention discloses a low-temperature flue gas water recovery and waste heat utilization coupling system and operation method of a coal-fired power station. device, low-temperature flue gas cooler, electrostatic precipitator, desulfurization tower, flue gas condenser, flue gas reheater, chimney, first and second air heaters, multiple circulating water pumps and multiple control valves; through multiple The flue gas heat exchanger recovers the waste heat of the low-temperature flue gas to the steam turbine recuperation system or is used for preheating the air to reduce the coal consumption of the unit; the water is recovered through the flue gas condenser; the flue gas is reheated through the flue gas reheater to reduce the impact on the chimney Low-temperature corrosion; the operation of the flue gas heat exchanger can be adjusted through the control valve, and it can work together with other flue gas heat exchangers in series under different working conditions to ensure that the temperature of the flue gas entering the electrostatic precipitator is maintained above 90°C, ensuring that the flue gas entering the electrostatic precipitator The circulating water temperature of the low-temperature flue gas cooler is above 70°C to meet the safe operation of the system under different ambient temperatures.

Owner:XI AN JIAOTONG UNIV

A waste heat recovery system and method using smoke waste heat as a heater heat source

The invention discloses a waste heat recovery system and method with discharged smoke waste heat as a heat source of an air heater. According to the waste heat recovery system and method with the discharged smoke waste heat as the heat source of the air heater, a low-temperature economizer and the air heater are connected through a pipeline to form a first circulation loop, a circulating pump is arranged on an inlet pipeline of the low-temperature economizer, and an air heater intake water regulating valve is arranged on an inlet pipeline of the air heater; and the low-temperature economizer is connected with the circulating water side of a condensed water heater through a pipeline to form a second circulation loop, the condensed water side of the condensed water heater is connected with a low-pressure heater in parallel through a pipeline, and a booster pump is arranged on a condensed water connecting pipeline between the condensed water side of the condensed water heater and the low-pressure heater. The system and method have the advantages that the air heater is reserved, low-temperature corrosion of an air preheater is relieved, the low-temperature economizer recovers discharged smoke waste heat of a boiler, and power generation coal consumption of a steam turbine is reduced; and meanwhile, the defects that since the air heater consumes low-pressure suction steam of the steam turbine, the heat consumption of the steam turbine is increased, the temperature of discharged smoke is increased, and the heat efficiency of the boiler is reduced are overcome, and the problems that a low-temperature economizer pipeline system is high in cost and operating reliability requirement are solved.

Owner:FUJIAN LONGKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com