Copper-chromium-based TGr-titanium film thread pipe type air preheater and pipe film component

An air preheater, copper-chromium-based technology, applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of increased volatile matter, air pollution, insufficient combustion, etc., and achieve enhanced heat transfer capacity , high air temperature, good combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

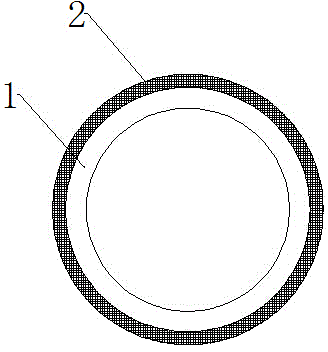

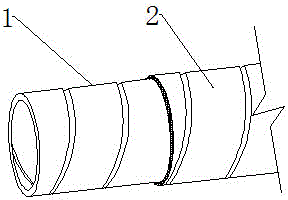

[0015] attached Figure 1-2 It is a specific embodiment of the present invention. The invention is a copper-chromium-based TGr-titanium film threaded tubular air preheater and tube film components, including a base pipe 1 and a copper-chromium-based TGr-titanium film layer 2, and the outer side of the base pipe 1 is provided with a copper-chromium-based TGr - Titanium film layer 2 .

[0016] Further, the weight percent of the main components of the copper-chromium-based TGr-titanium film layer 2 is: TGr-50 10%, MnO2 5%, CuO 9%, NiO 3%, LiCO3 2%, B2O3 6%, TiO2 9% , Pb2O3 2%, MnO2 5%, K2O 5%, SiO2 44%.

[0017] Further, the processing technology of a copper-chromium-based TGr-titanium film threaded tubular air preheater and tube-film components includes the following steps: preparing charged copper-chromium-based TGr-titanium powder—pretreatment—embossing ——Automatic spraying——Sintering—Cooling off-line——Assembly.

[0018] Further, the base pipe 1 is a threaded pipe, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com