Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

379results about How to "Improve combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

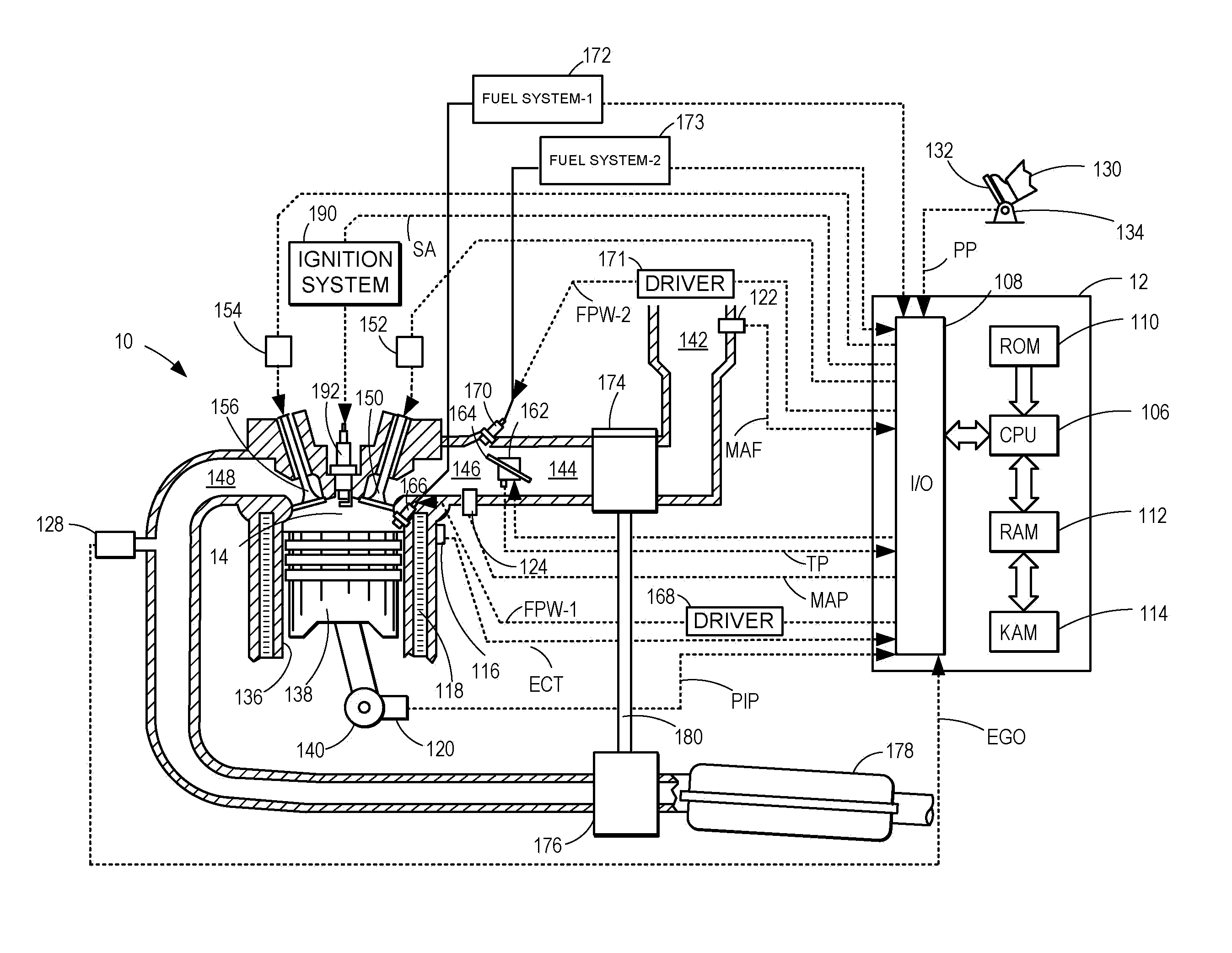

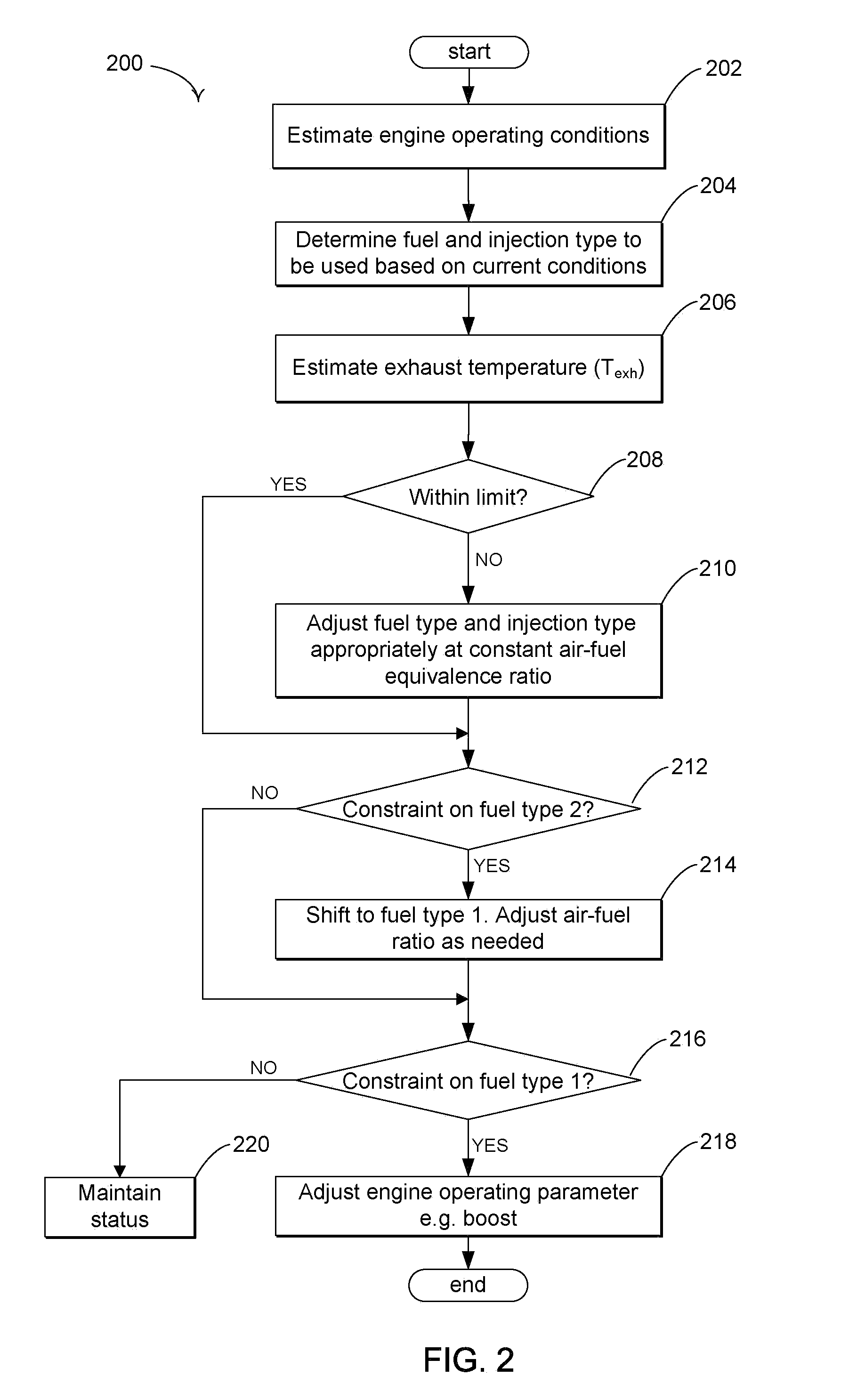

Engine exhaust temperature regulation

ActiveUS20090282810A1Improve engine performanceEasy to chargeElectrical controlInternal combustion piston enginesVaporizationInjector

In one example, a method of operating an engine in a vehicle is described. The method comprises delivering a first substance to a cylinder of the engine from a first injector; delivering a second substance to the cylinder of the engine from a second injector, where the second substance has a greater heat of vaporization than the first substance; and increasing injection of the second substance responsive to an exhaust over-temperature condition.

Owner:FORD GLOBAL TECH LLC

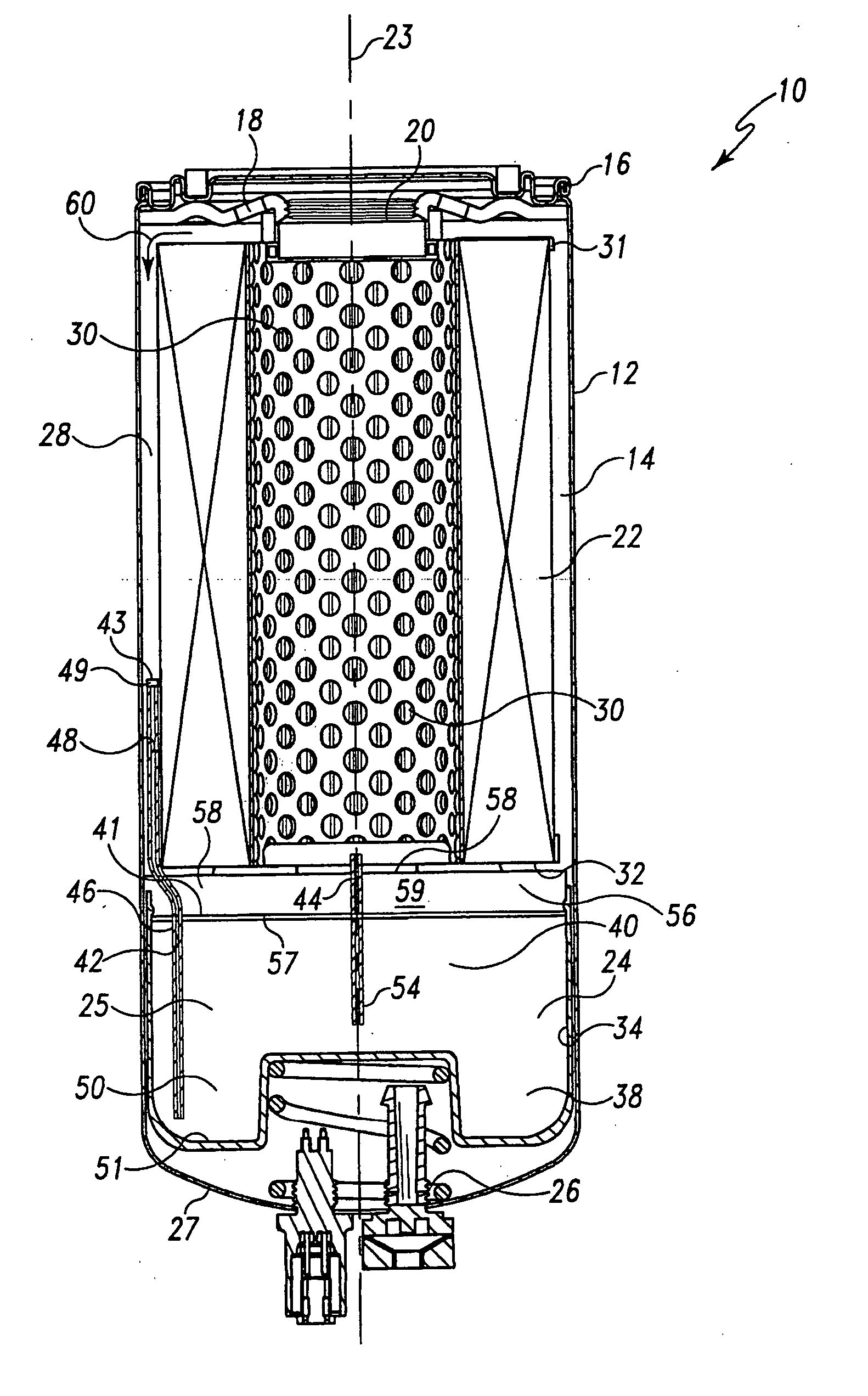

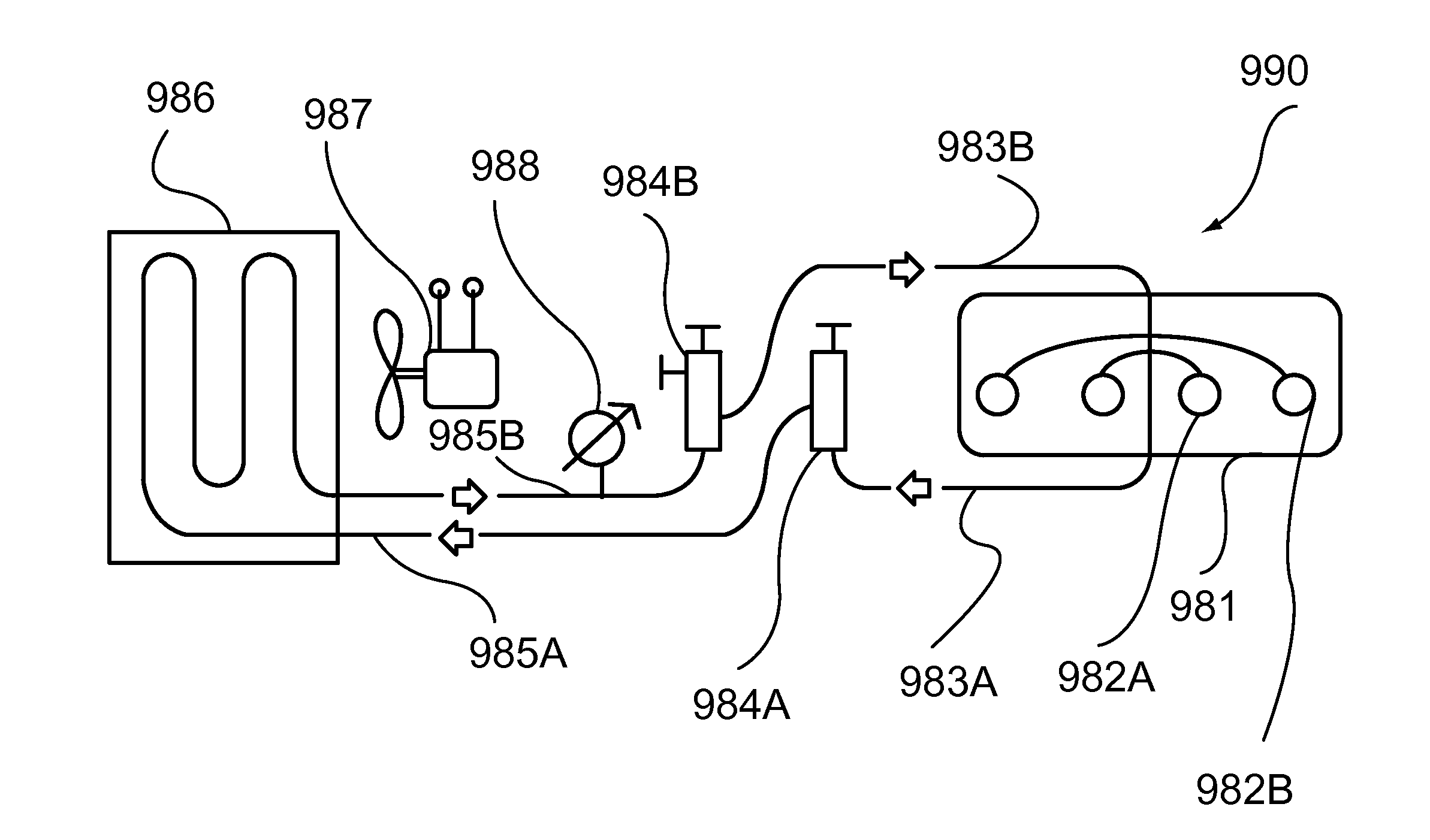

Pressure gradient dosing system for fluid supply

ActiveUS20060180537A1Avoid damageReduce componentsSolid sorbent liquid separationLiquid displacementDelivery systemFluid supply

A pressure gradient dosing system is provided for a fluid supply system. A flow passage has first and second pressure zones having a pressure gradient therebetween. An additive reservoir in an additive delivery system responds to the pressure gradient to release additive to the flow passage.

Owner:CUMMINS FILTRATION INC

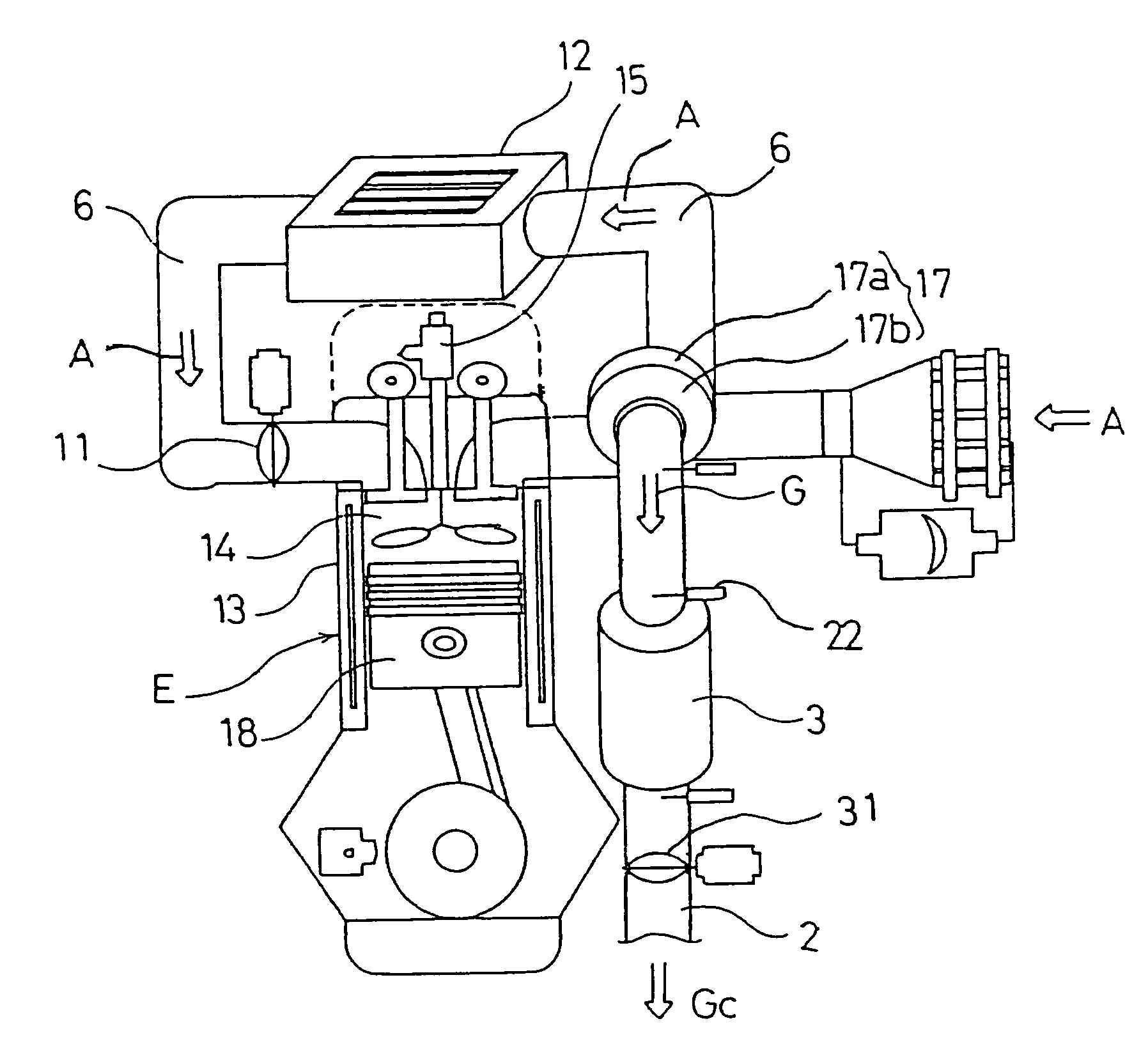

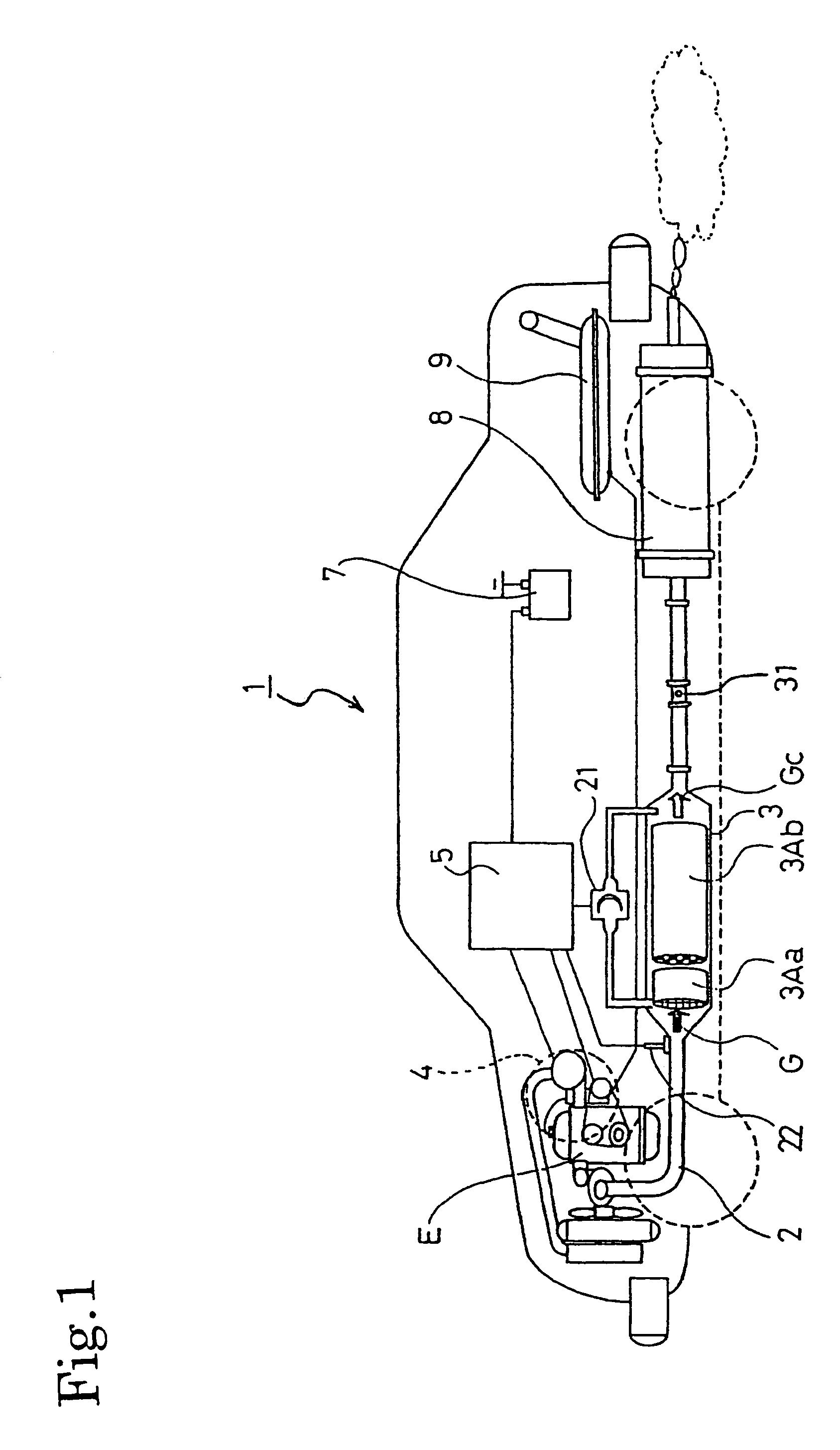

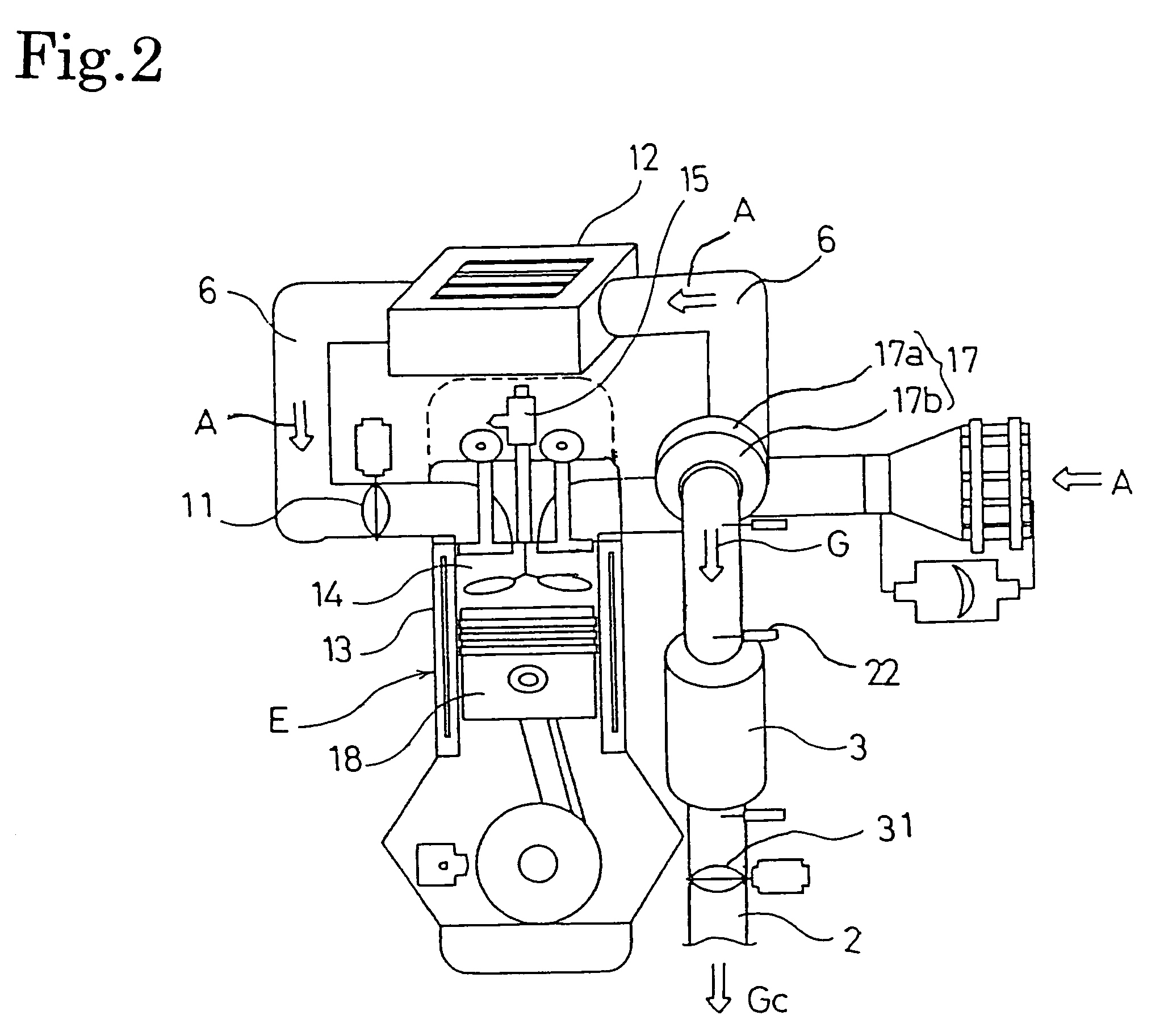

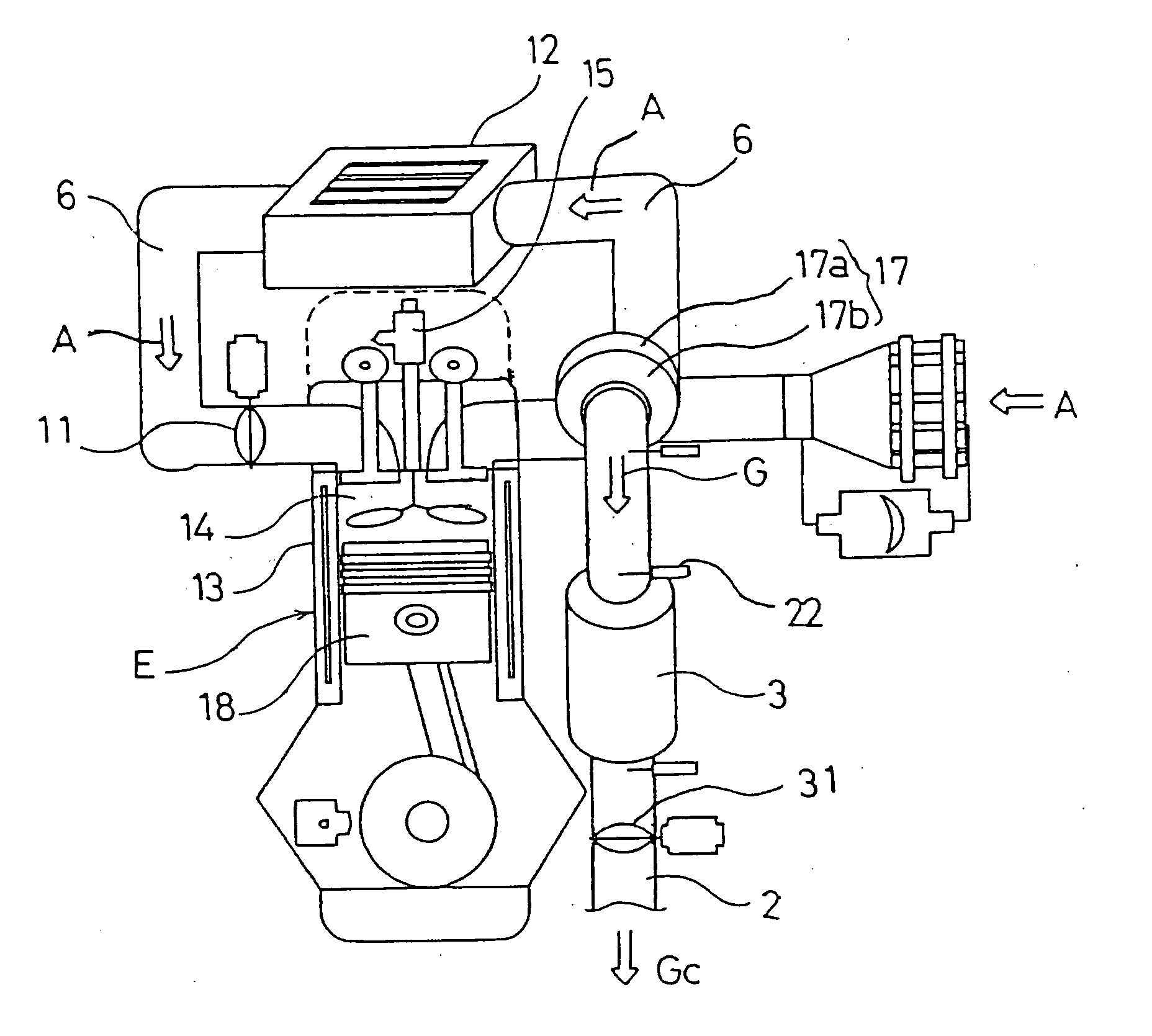

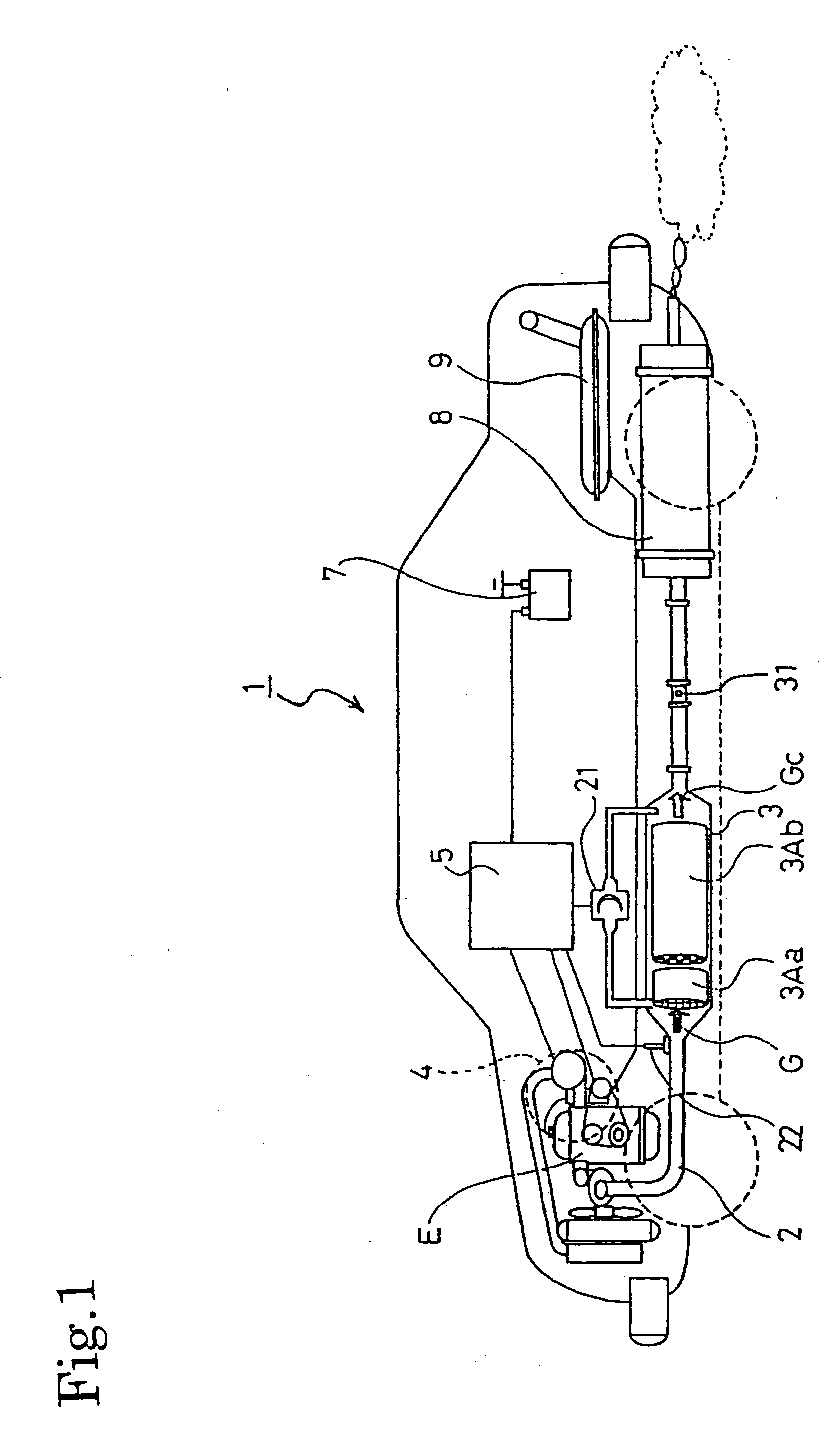

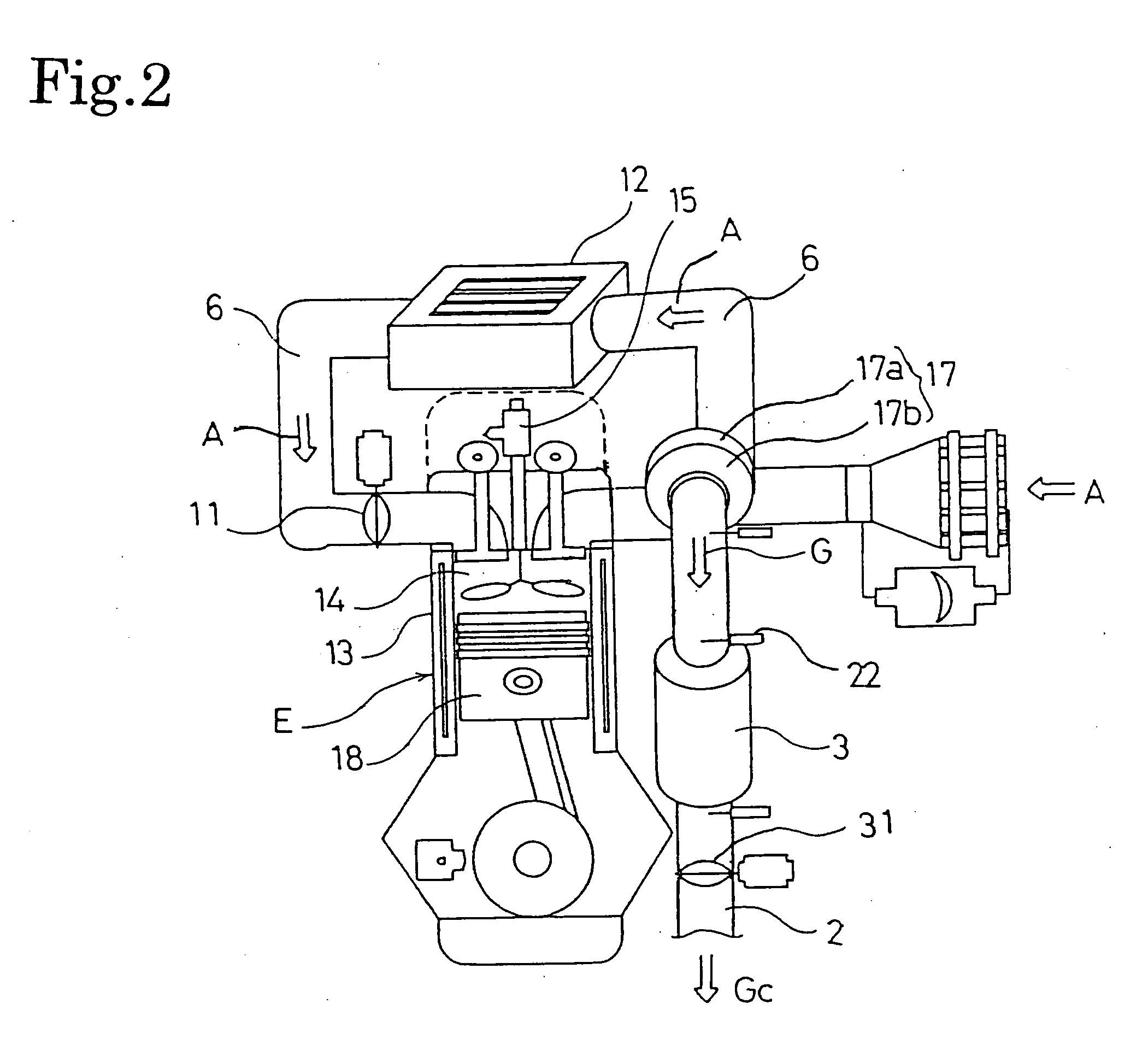

Exhaust gas purifying system

ActiveUS6966179B2Efficiently raising temperature of exhaust gasLower outlet temperatureElectrical controlInternal combustion piston enginesThrottle controlLow load

To provide an exhaust gas purifying system capable of forcibly regenerating DPF by efficiently raising the temperature of exhaust gas even when an exhaust gas temperature is very low at the time of low load and low engine speed such as an idling operation. In an exhaust purifying system (1) having an exhaust throttling valve (31) and a DPF (3) in an exhaust passage and having regeneration control means (P1) for regenerating the DPF (3), the regeneration control means (P1) is provided with an exhaust gas temperature detection means (P22), a fuel injection control means (P11), and an exhaust throttling control means (P12) and includes regeneration control for performing the exhaust gas temperature raising control through the multistage delay injection by the fuel injection control means (P11) and through the exhaust throttling of the exhaust throttling valve (31).

Owner:ISUZU MOTORS LTD

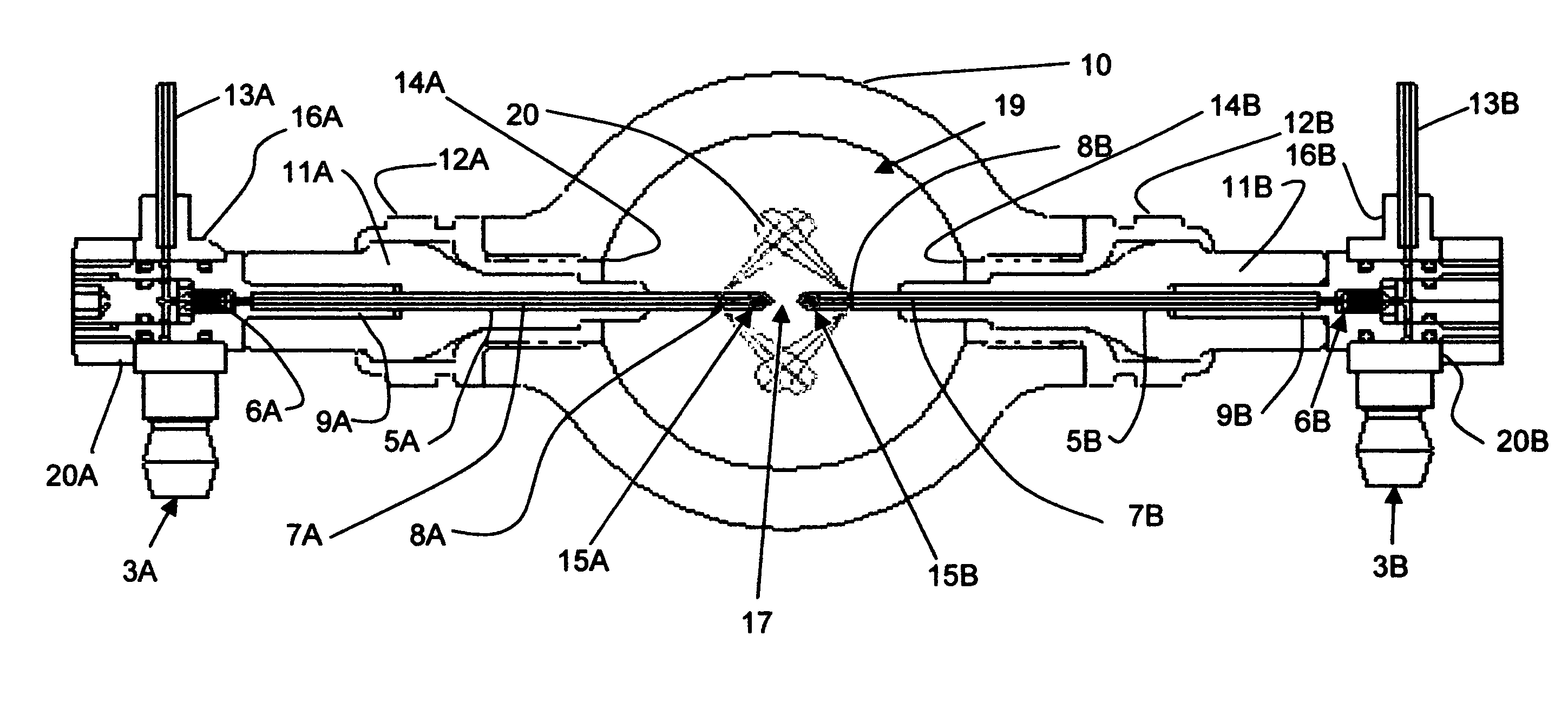

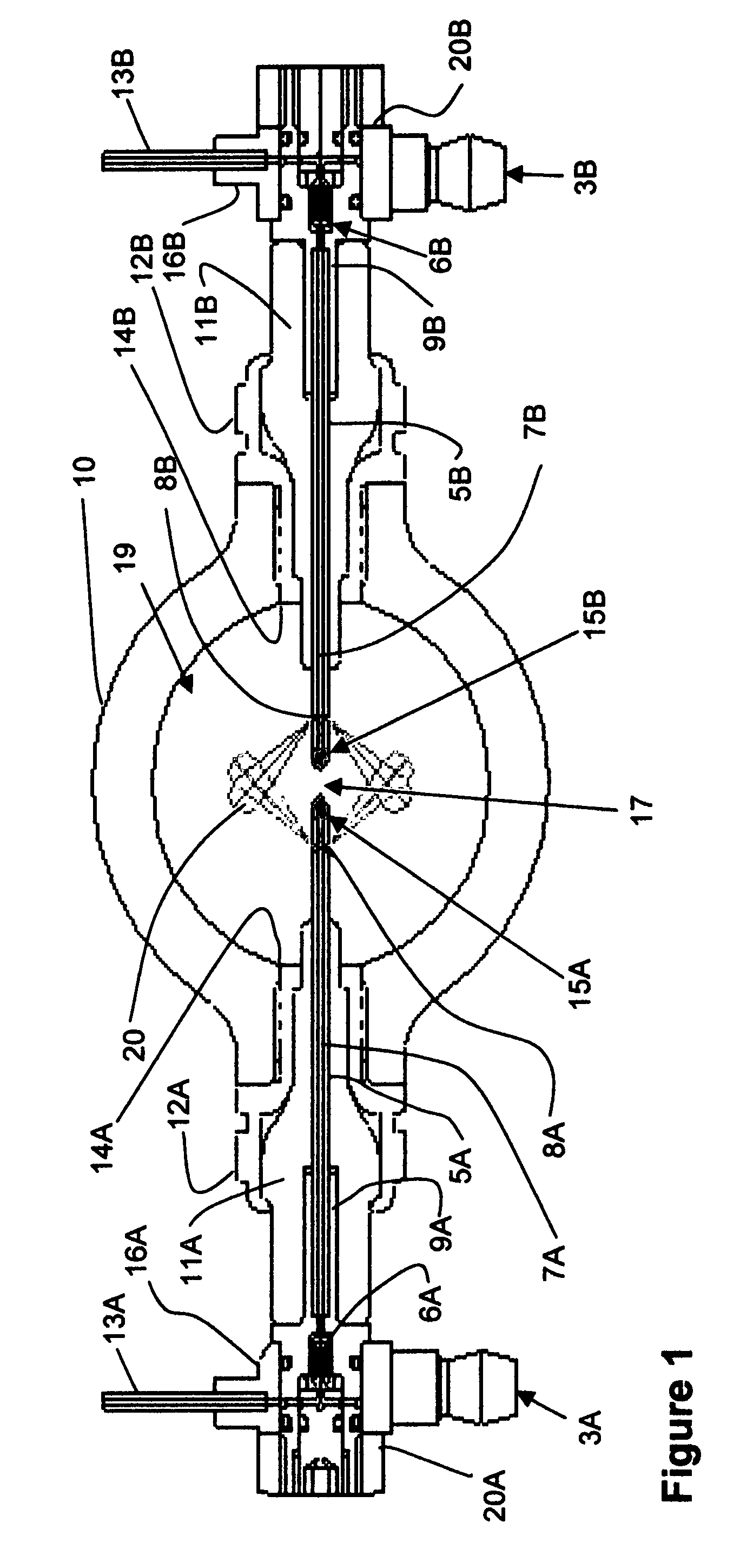

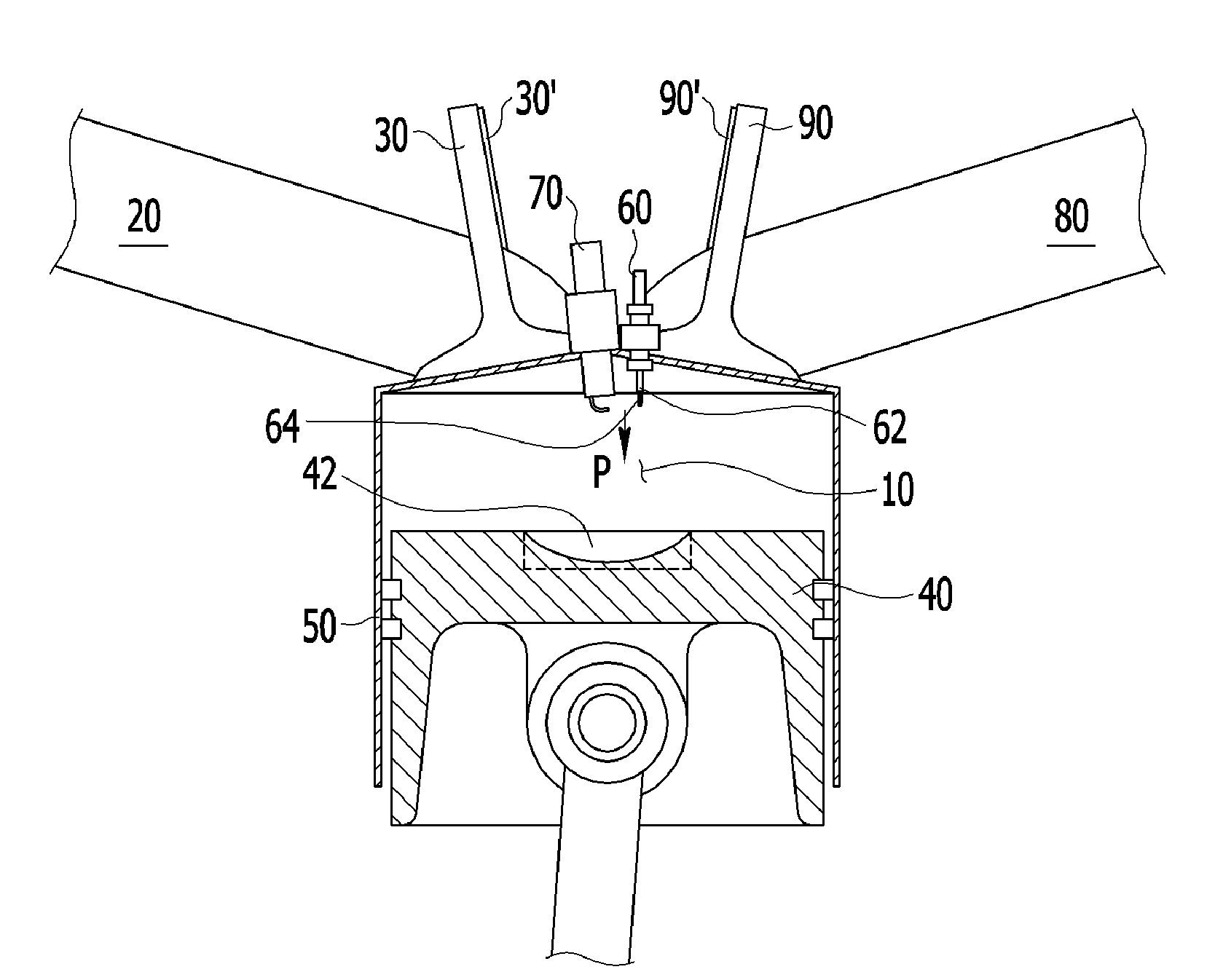

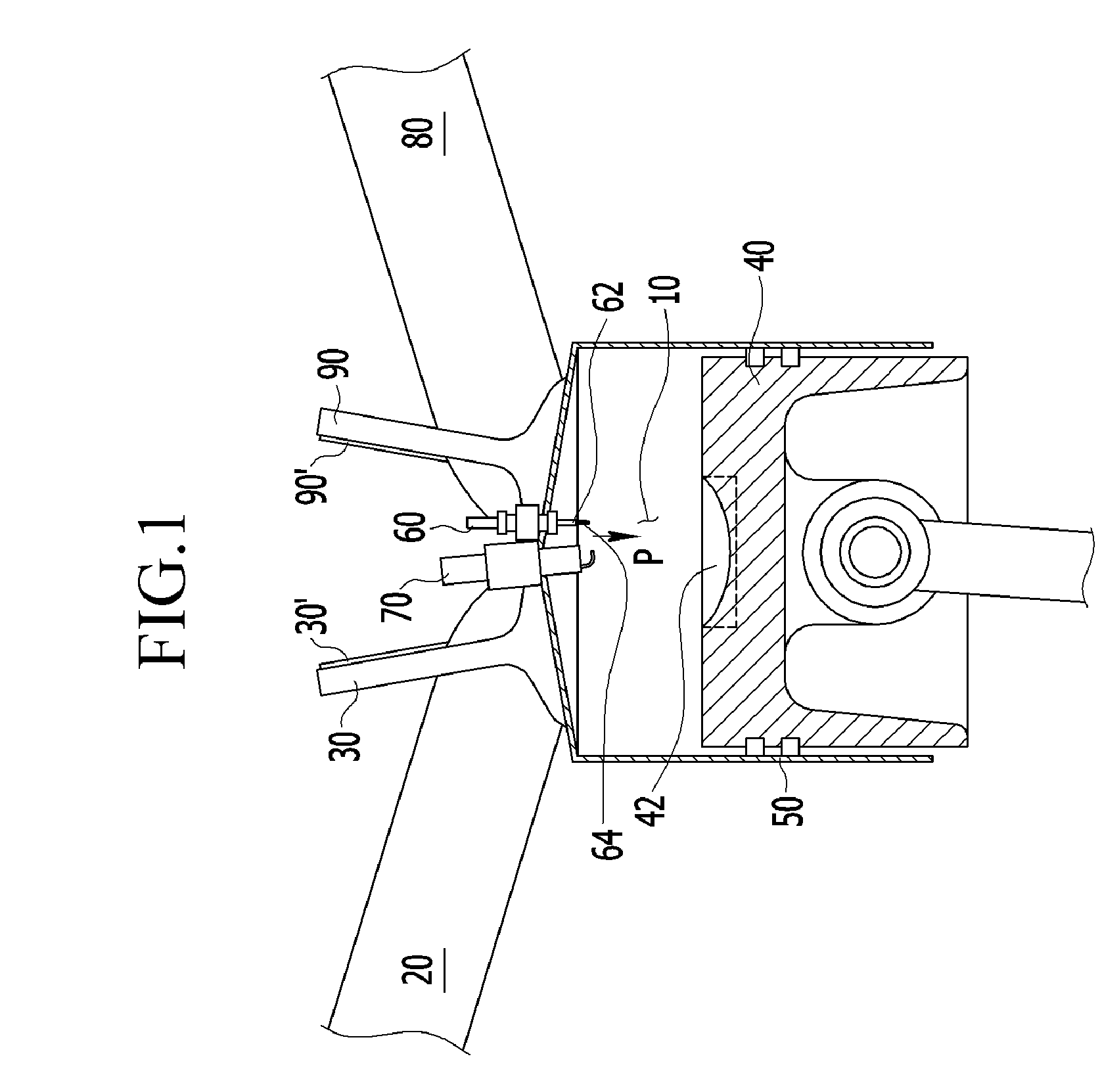

Spark ignition and fuel injector system for an internal combustion engine

InactiveUS7650873B2Avoid excessive heat buildupImprove engine efficiencyCombustion enginesFuel injection apparatusCombustion chamberCapillary channel

An improved spark ignition system for an internal combustion engine that includes a pair of electrodes disposed to extend from opposite sides and into a combustion chamber to form a spark gap between them that is central to the combustion chamber. Each electrode is integral with a conductive fuel delivery tube that contains a capillary passage and fuel outlet ports adjacent the electrode. The heat from combustion conducted into the electrodes and fuel delivery tubes is used to vaporize the fuel within the capillary passages before it exits the outlet ports as an atomized fog into the combustion chamber adjacent the spark gap. The vaporization of the fuel flowing in the capillary passages absorbs energy from the electrodes and thus performs a cooling effect on the electrodes. The spacing of the electrodes from opposite sides of the cylinder also allows a design that can utilize and increased spark gap to produce a larger spark across the gap.

Owner:ADVANCED PROPULSION TECH

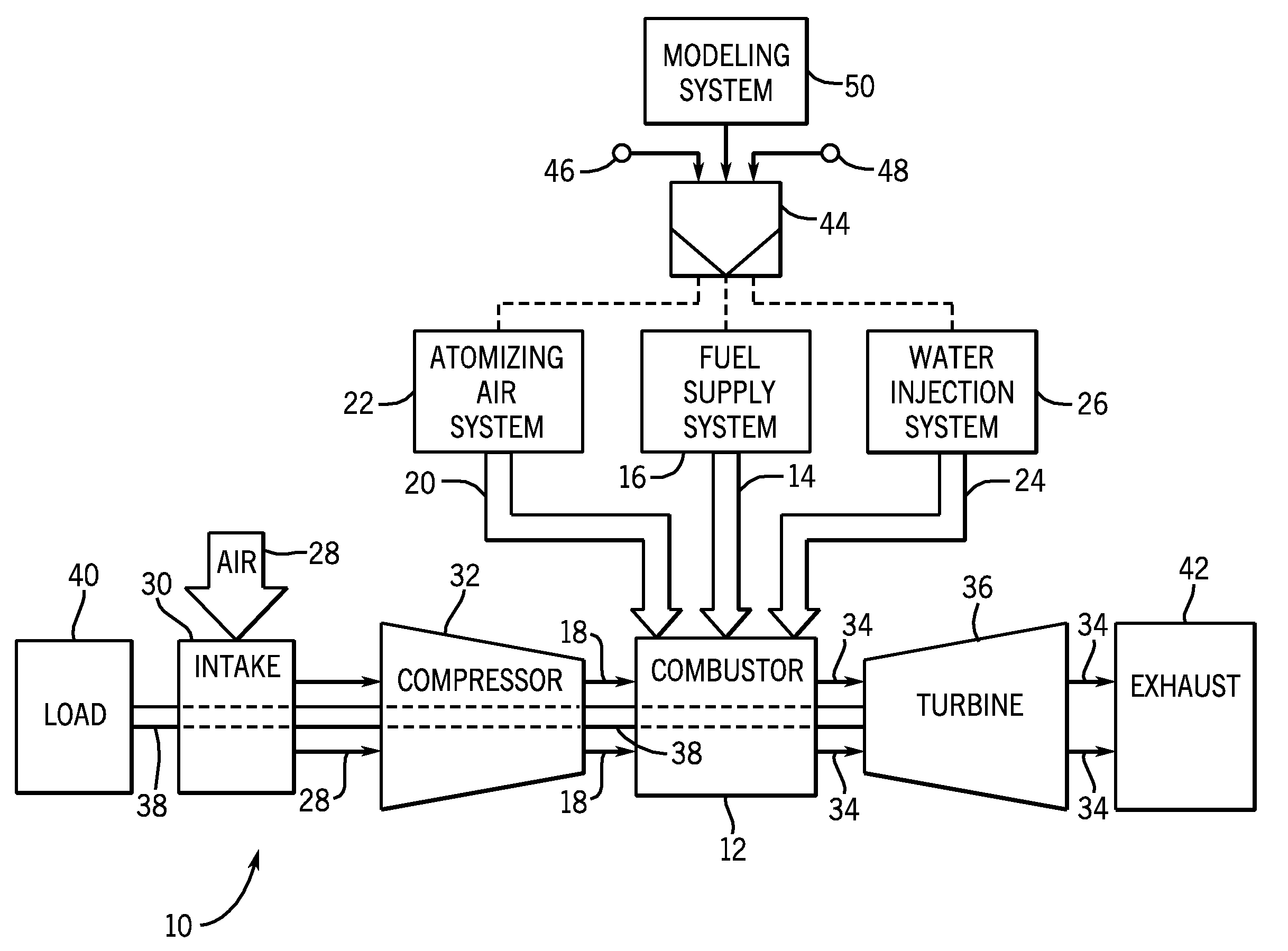

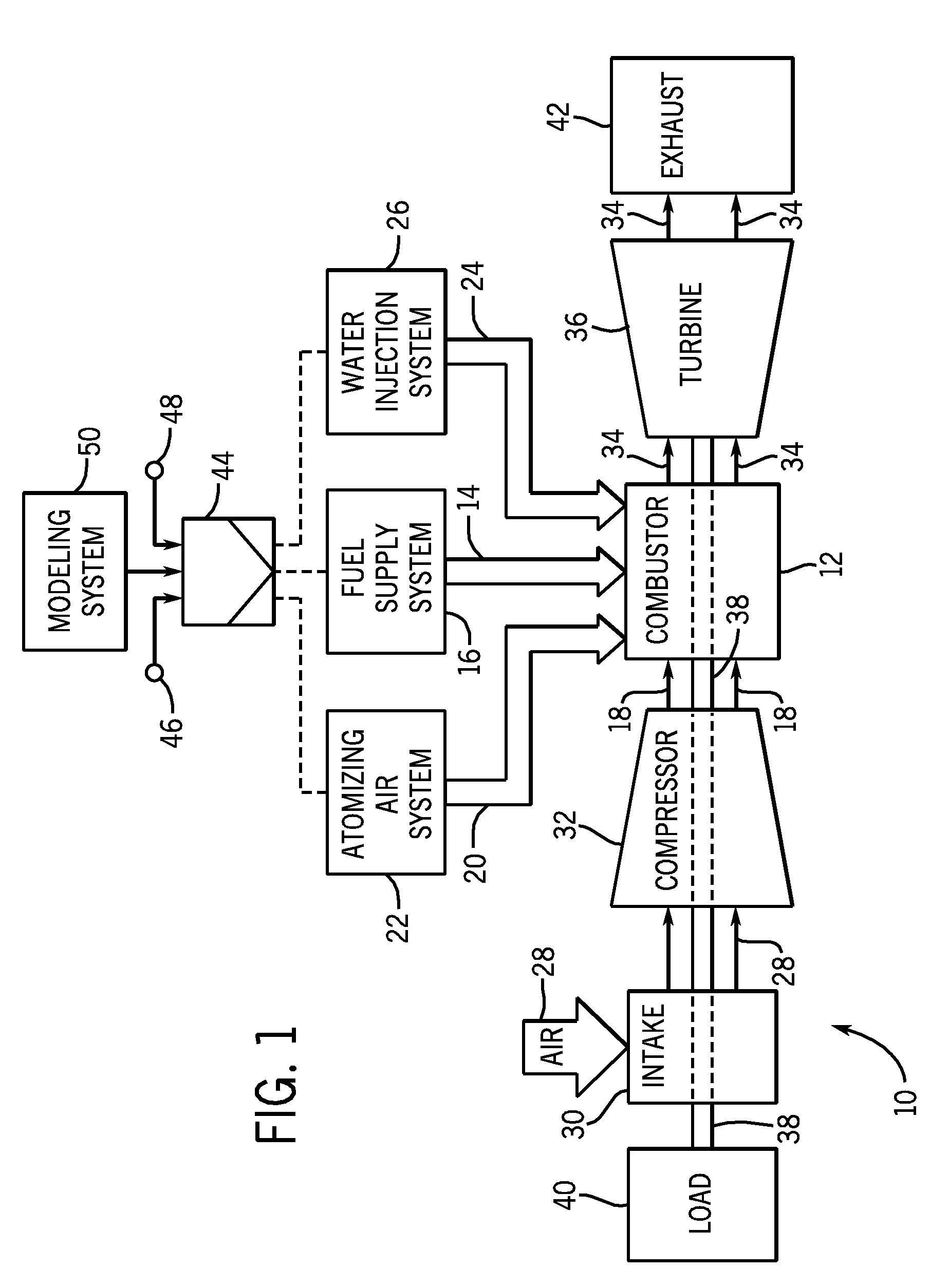

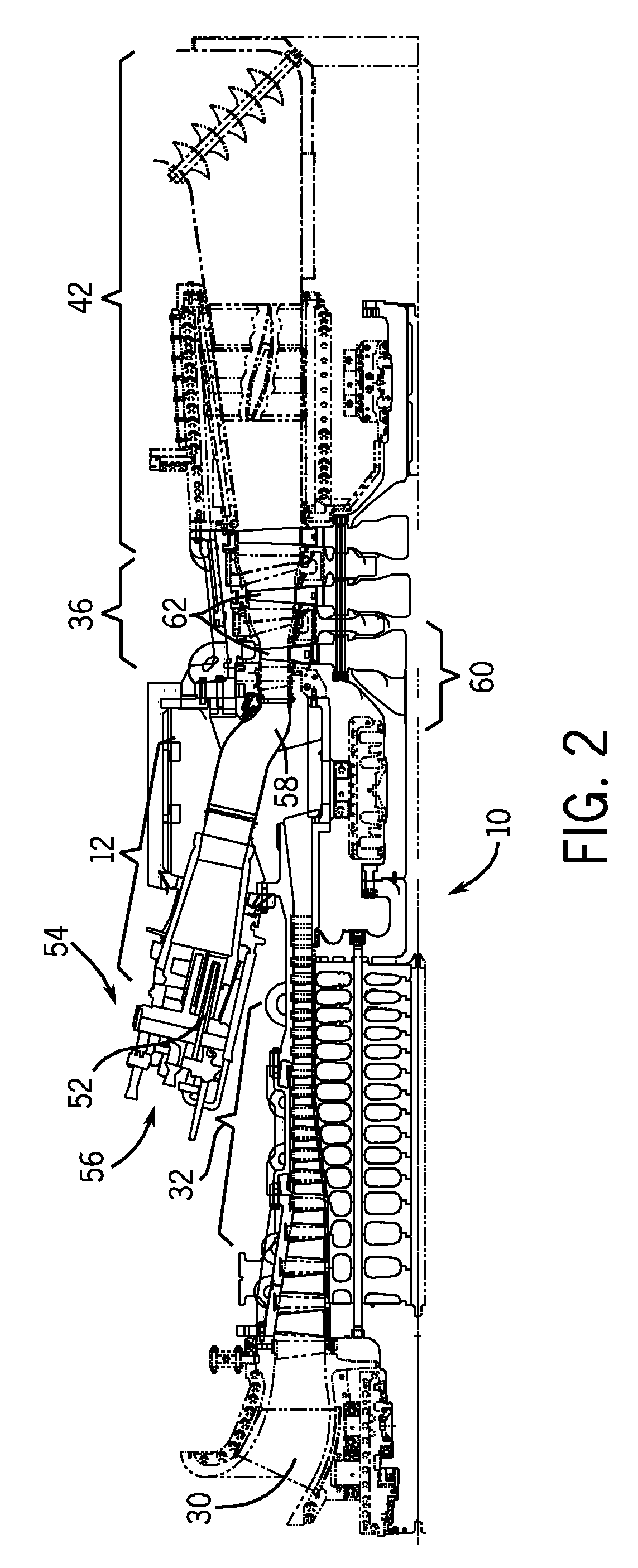

Methods and systems for inducing combustion dynamics

InactiveUS20100287943A1Increase combustion dynamicReduce combustion dynamicPulsating combustionEngine fuctionsDynamic methodCombustion

Methods and systems are provided for inducing combustion dynamics within turbine engines to remove combustion deposits within the turbine engine during operation of the turbine engine.

Owner:GENERAL ELECTRIC CO

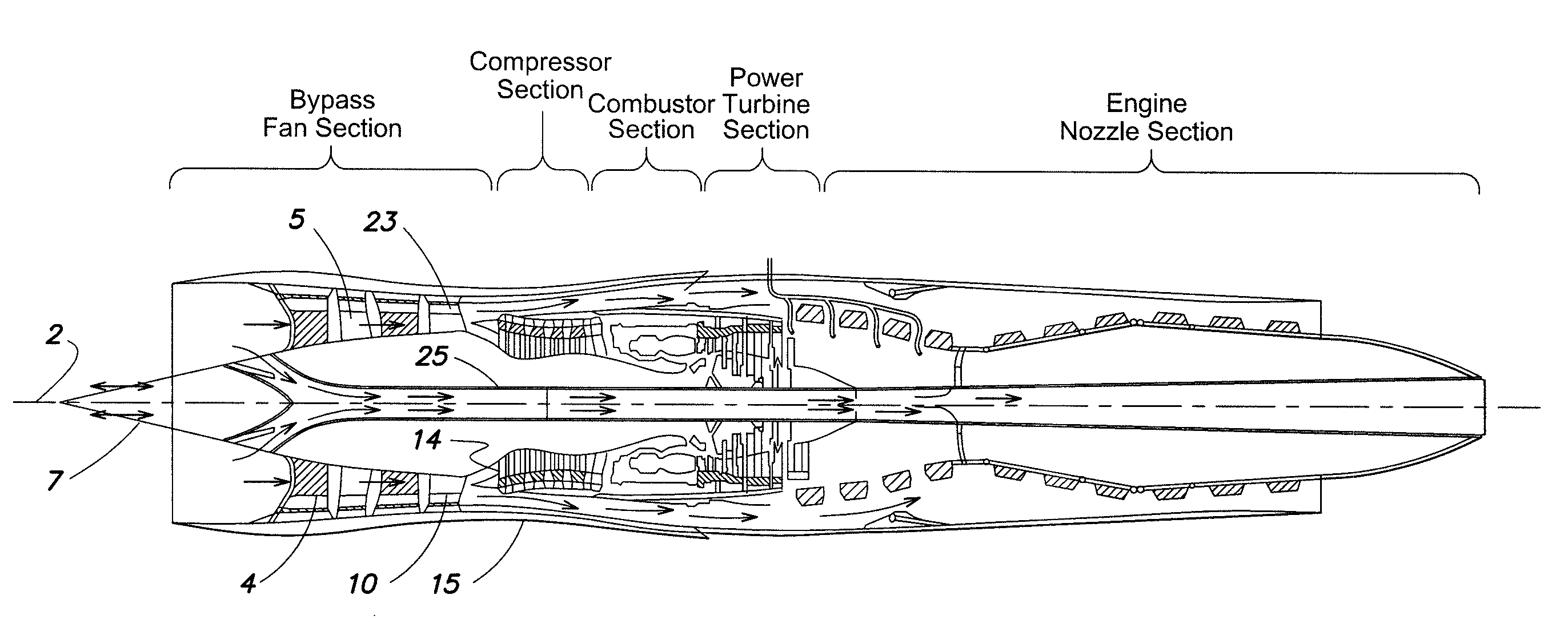

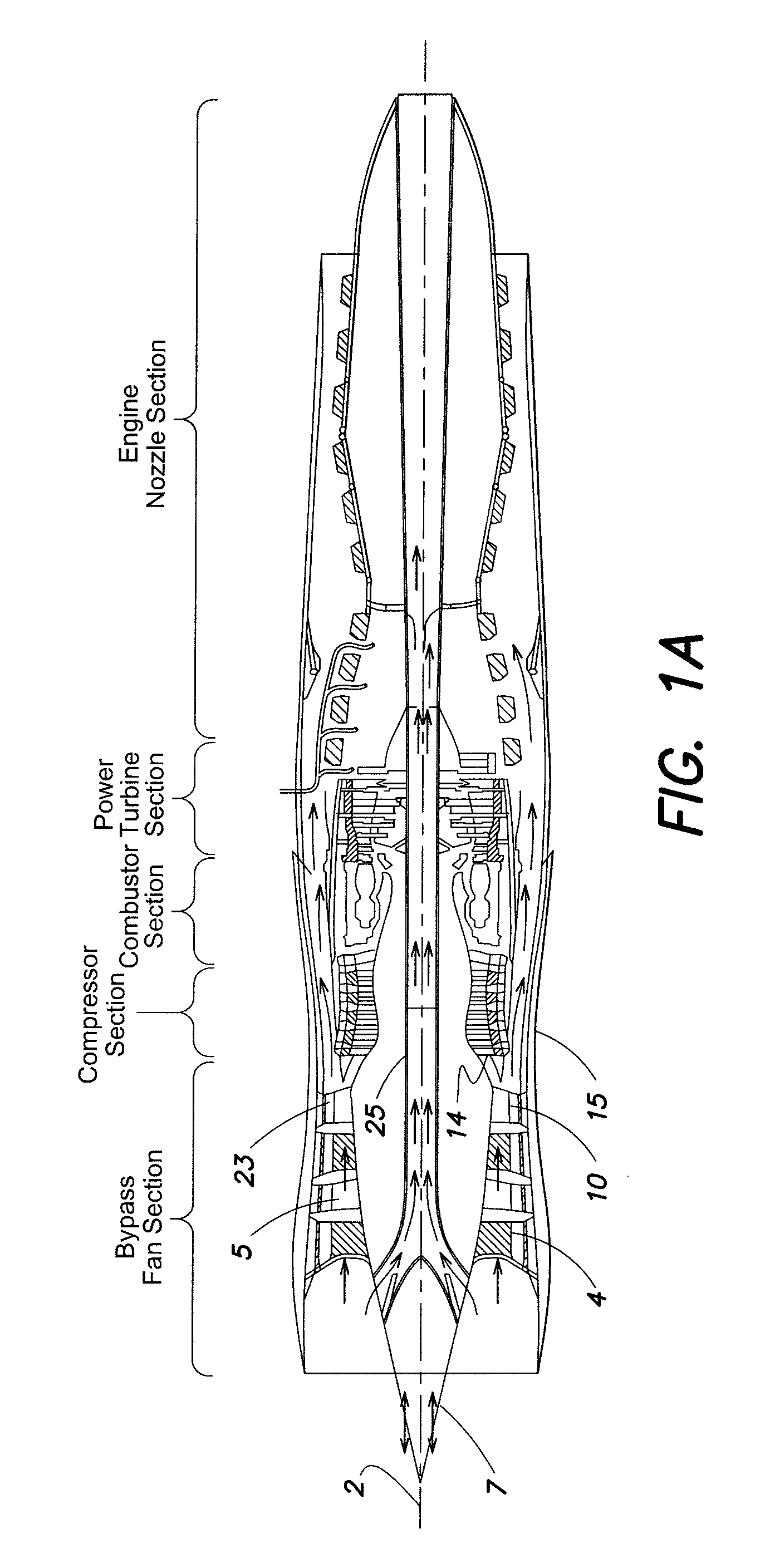

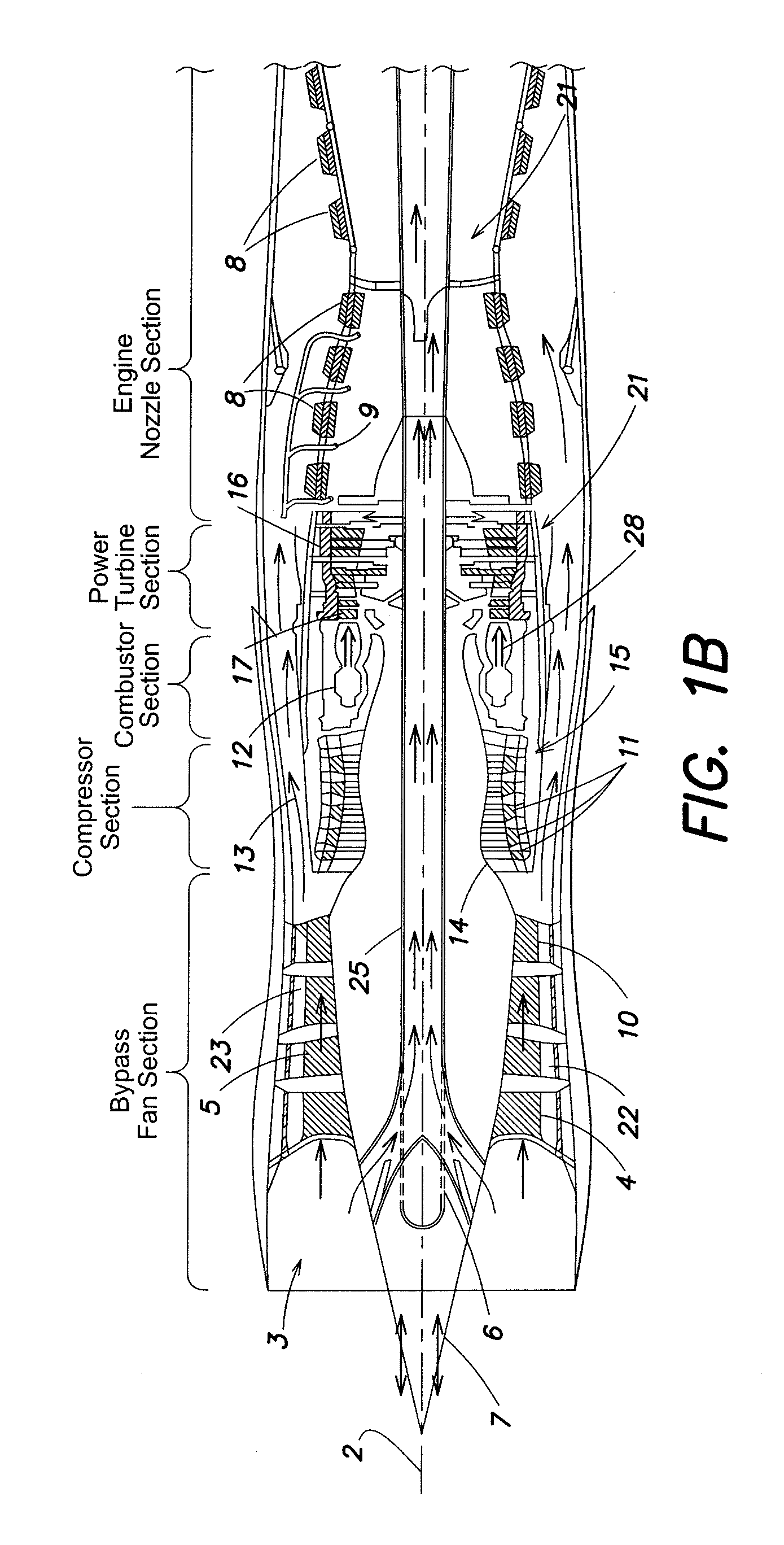

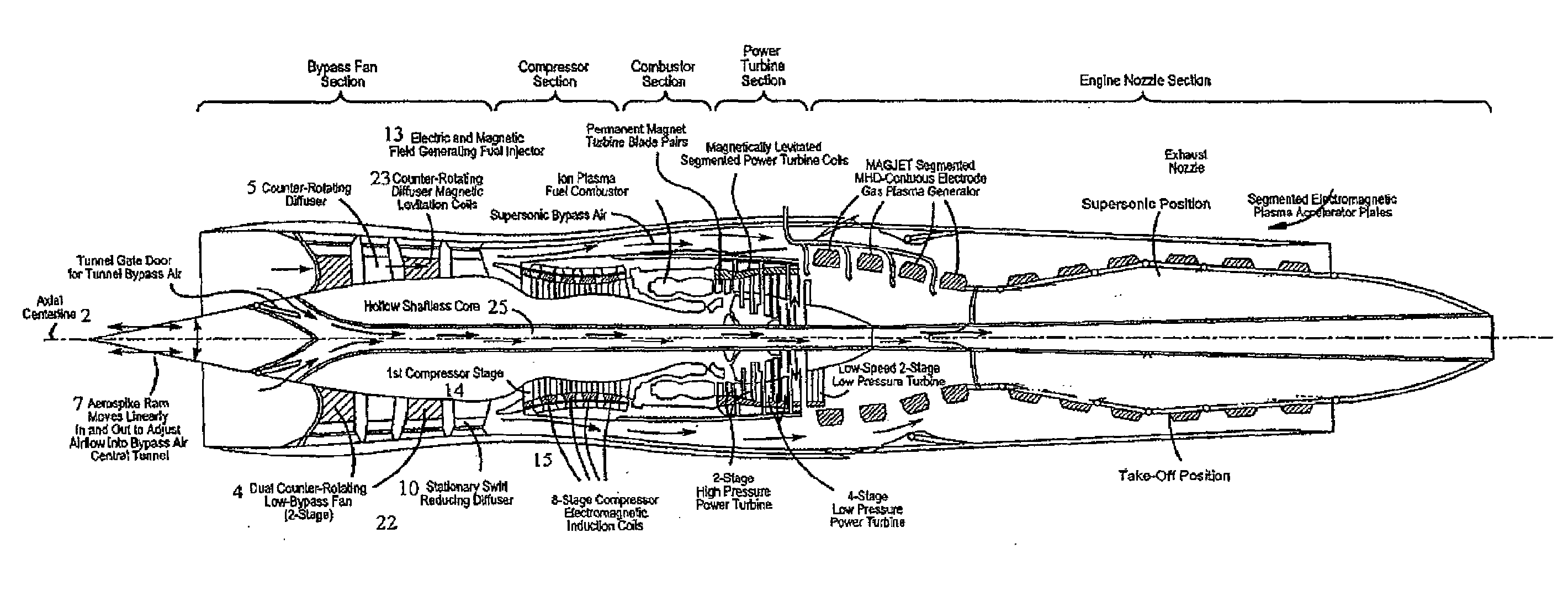

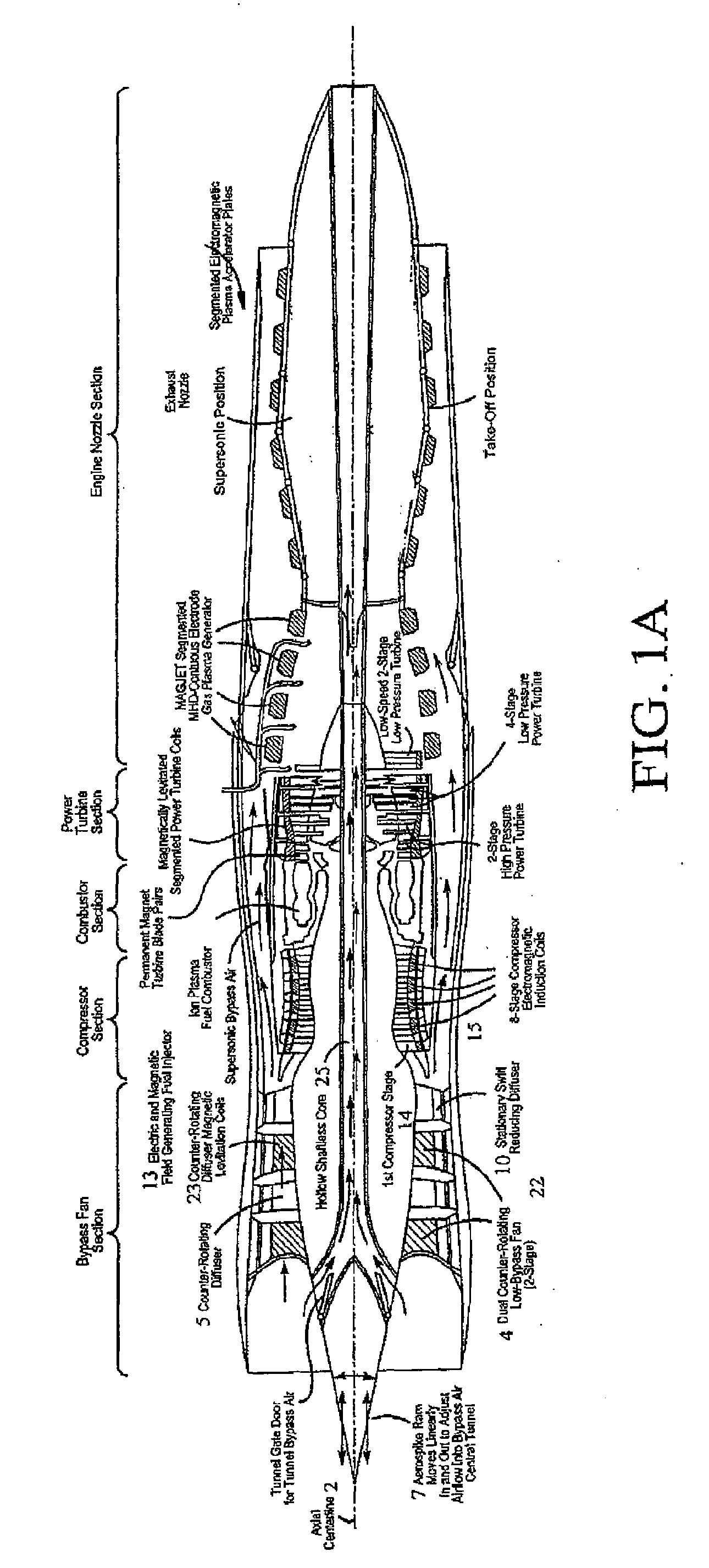

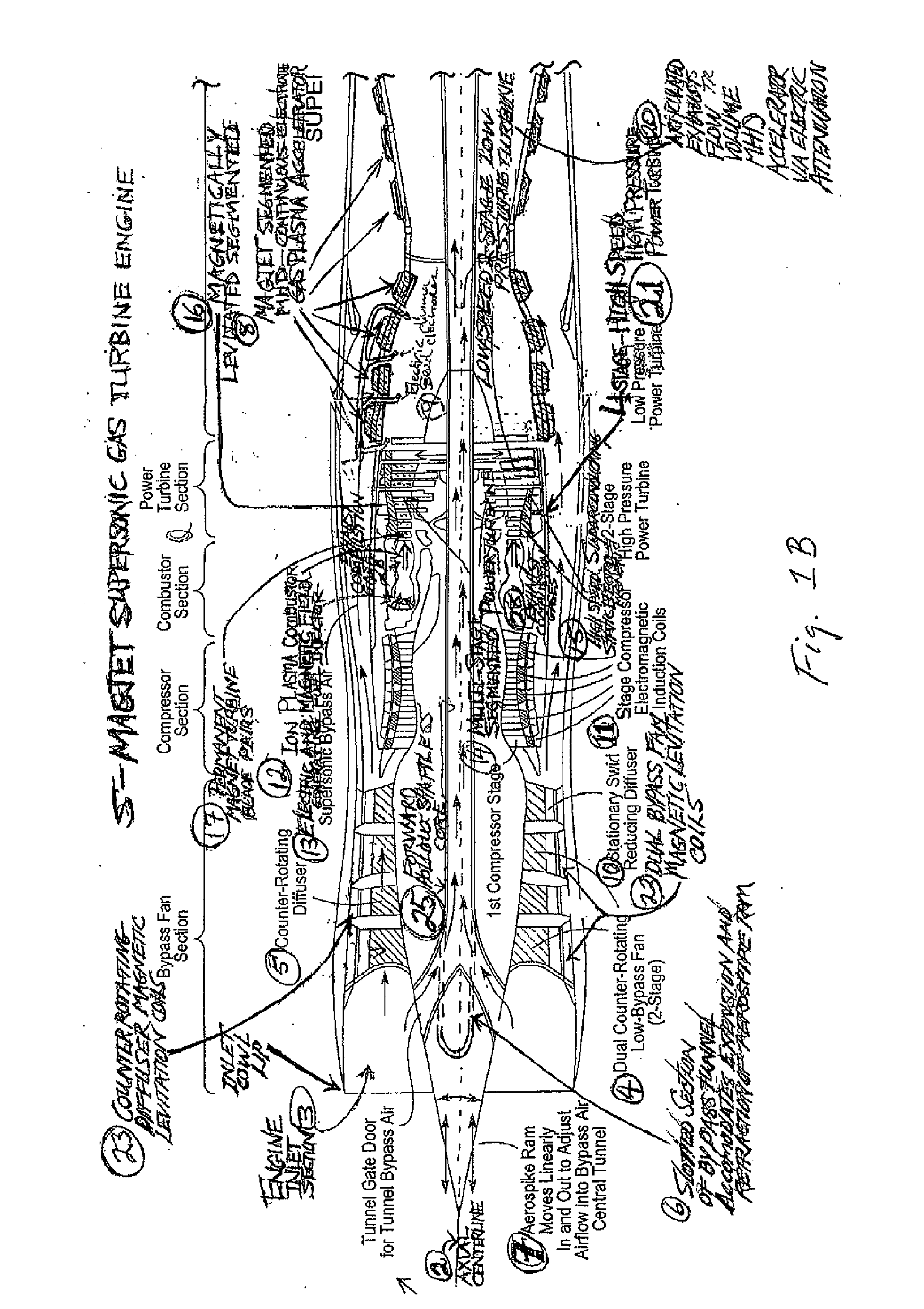

Magnetic advanced generation jet electric turbine

ActiveUS8365510B2Maximizes propulsion efficiencyImprove combustionGas turbine plantsEnergy production using magneto-hydrodynamic generatorsAviationElectric power system

Supersonic Magnetic Advanced Generation Jet Electric Turbine (S-MAGJET) described herein, and a subsonic derivative, MAGJET, integrate a gas power turbine, superconducting electric power and propulsion generation, and magnetic power flux field systems along with an ion plasma annular injection combustor which utilizes alternative petroleum-based fuel and combustion cycles to create a hybrid turbine turbomachine for aerospace propulsion. The propulsion unit is able to achieve a dramatic increase in horsepower, combustion and propulsion efficiency, and weight reduction. In addition, the turbomachinery structures may be disposed within an exo-skeleton architecture that achieves an increase in thrust to weight ratio with a concomitant increase in fuel efficiency and power generation over traditional gas turbine technology today. The engine continuously adjusts the temperature, pressure and mass airflow requirements using an electromagnetic power management system architecture. Engine performance may be controlled across the entire desired flight envelope, whether subsonic, transonic or supersonic flight conditions.

Owner:SONIC BLUE AEROSPACE

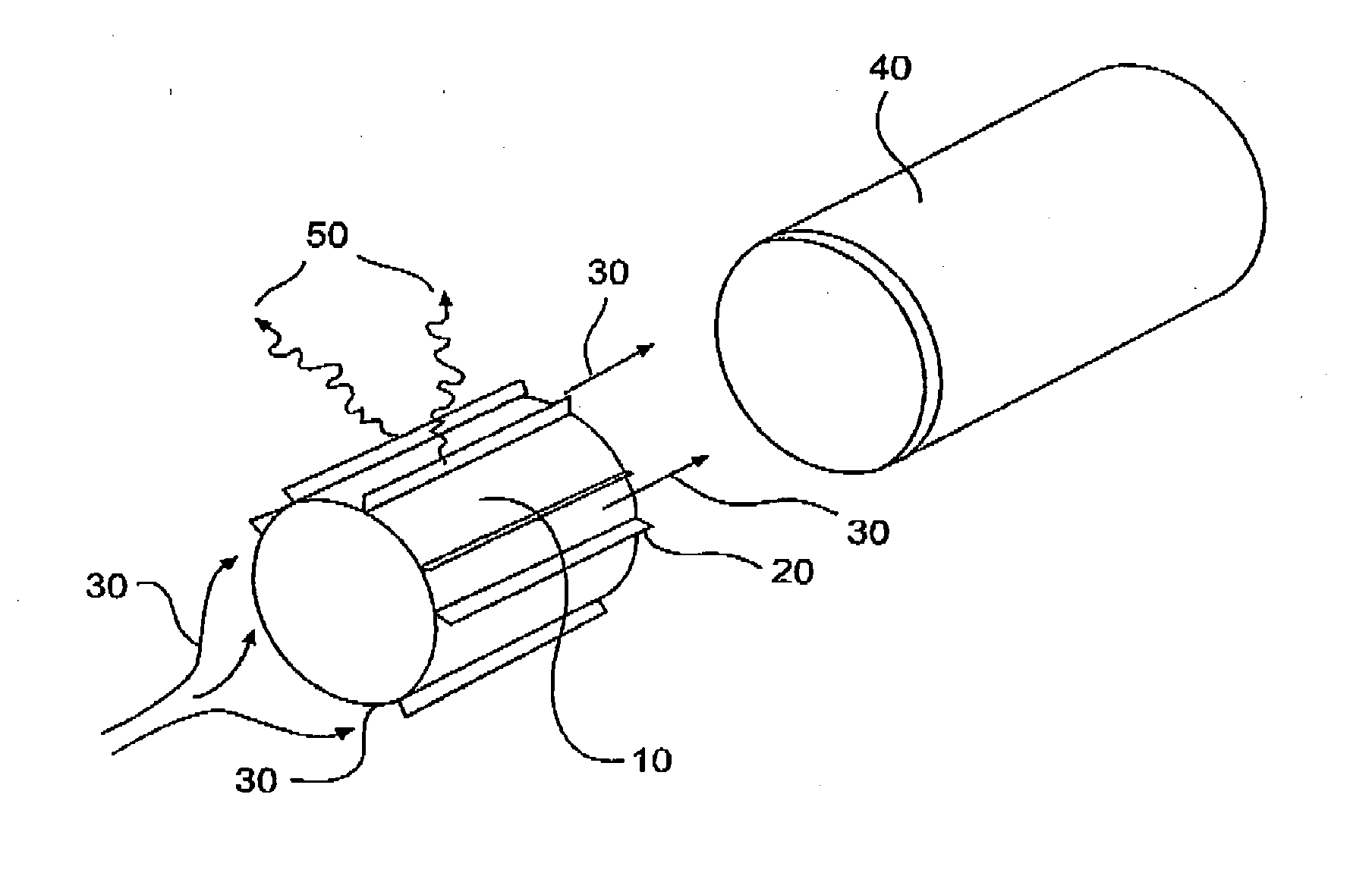

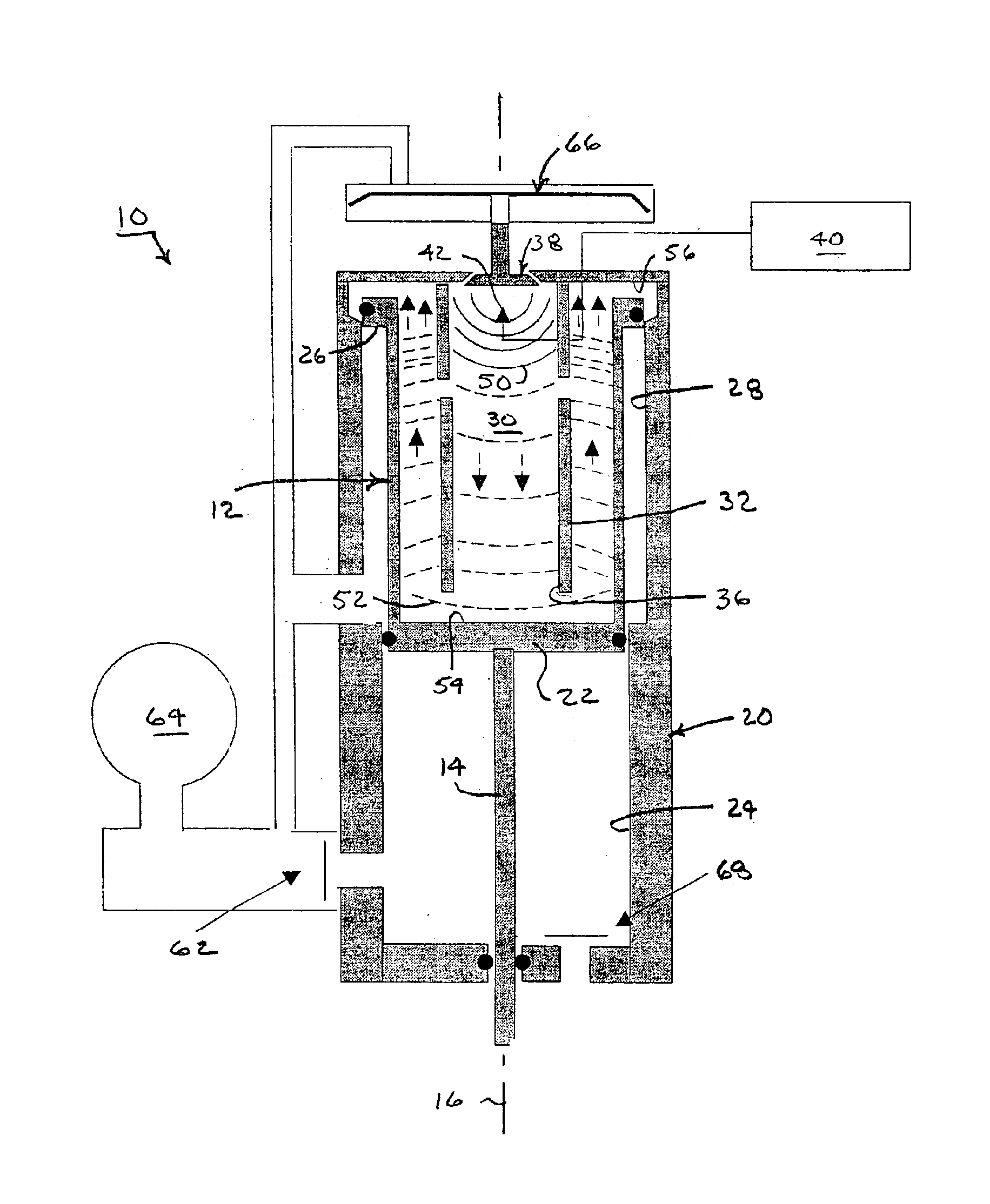

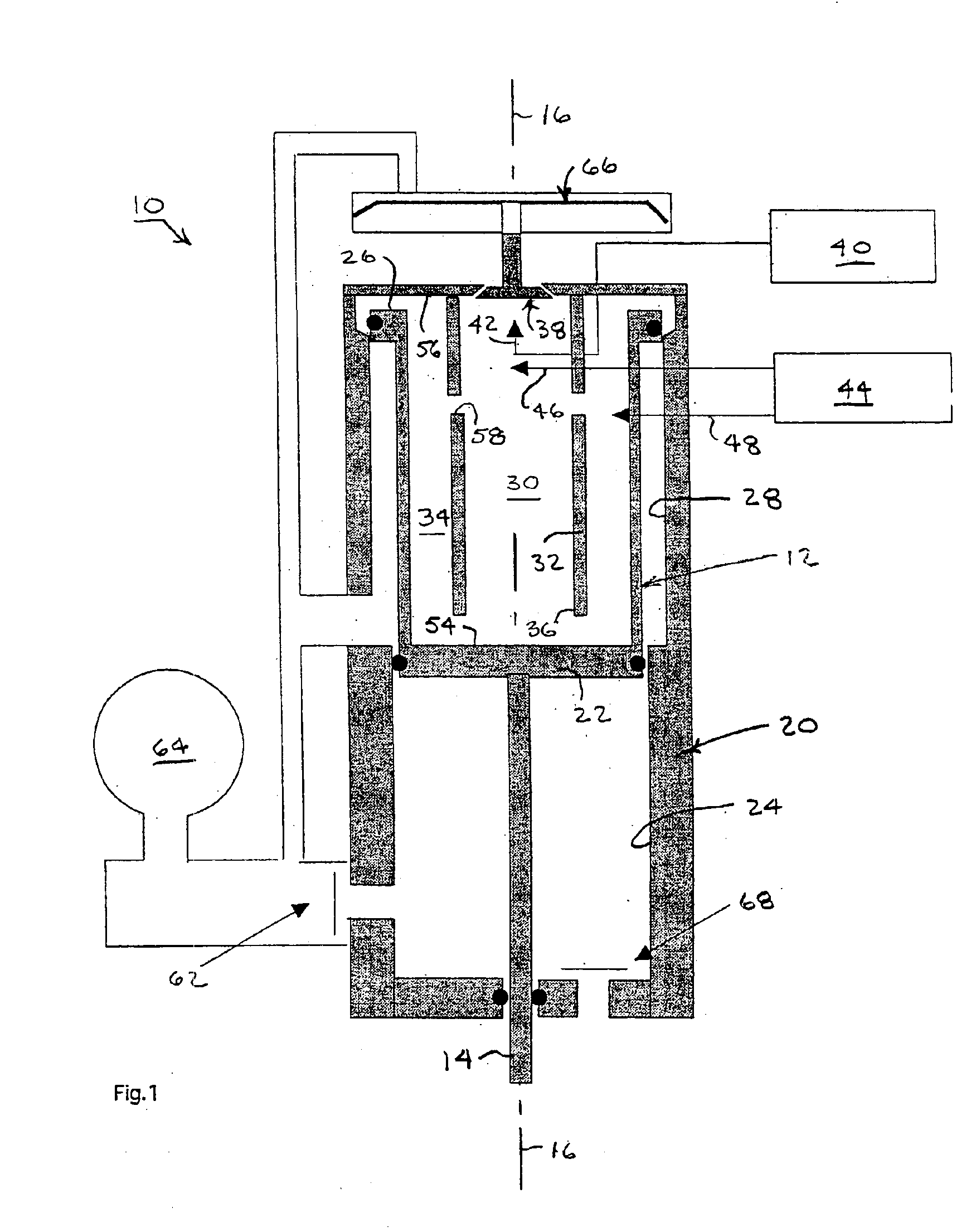

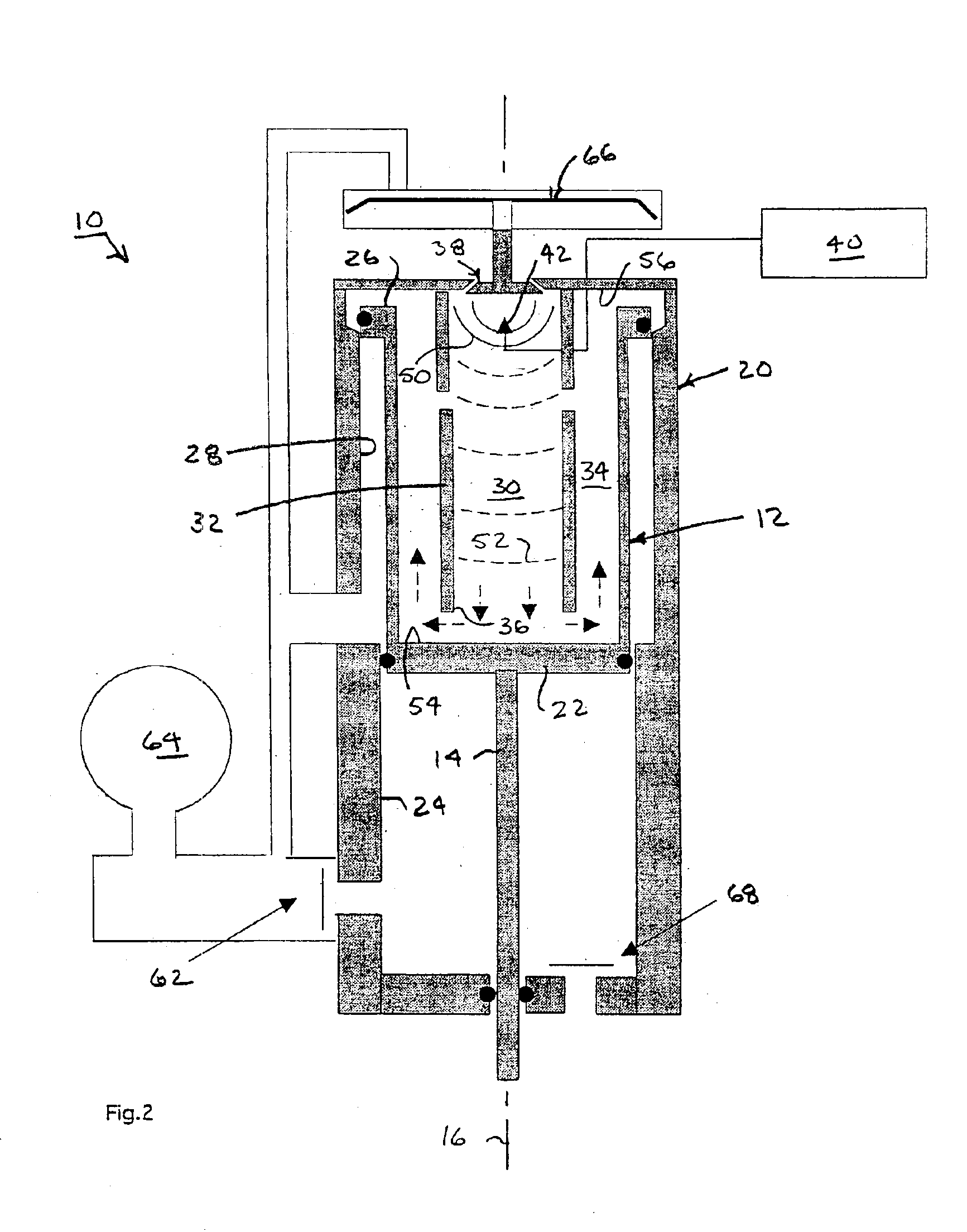

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS20050016507A1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

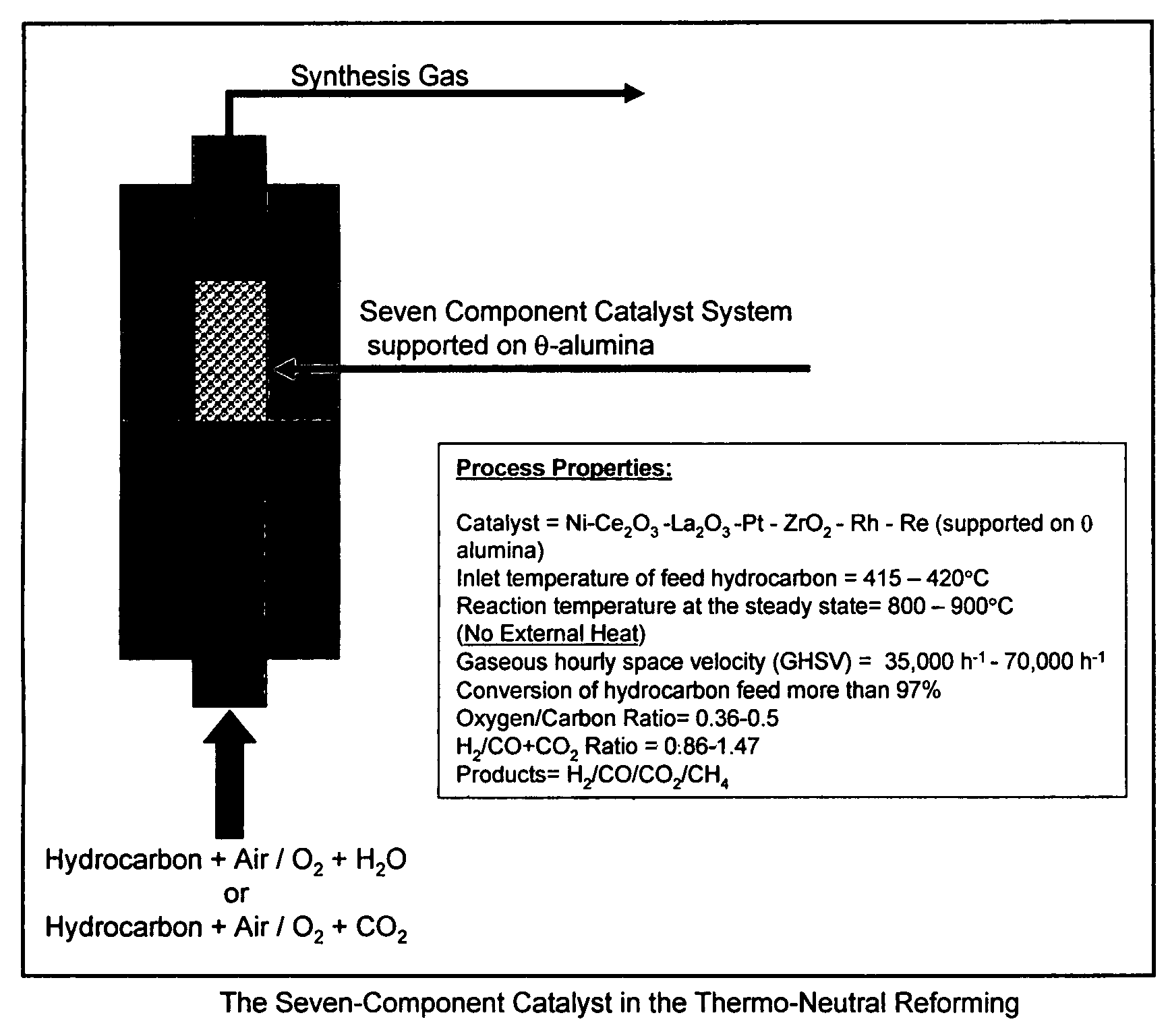

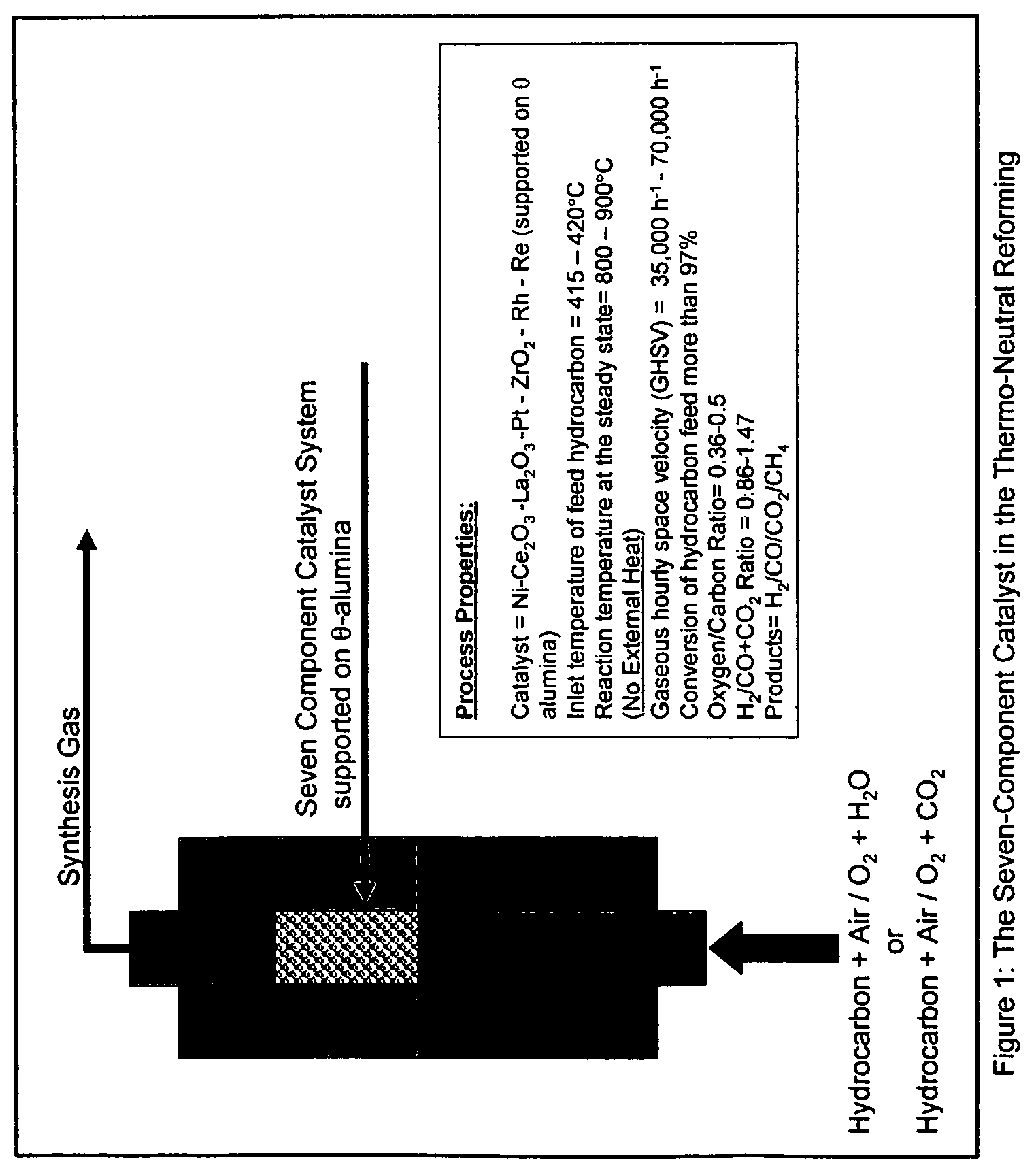

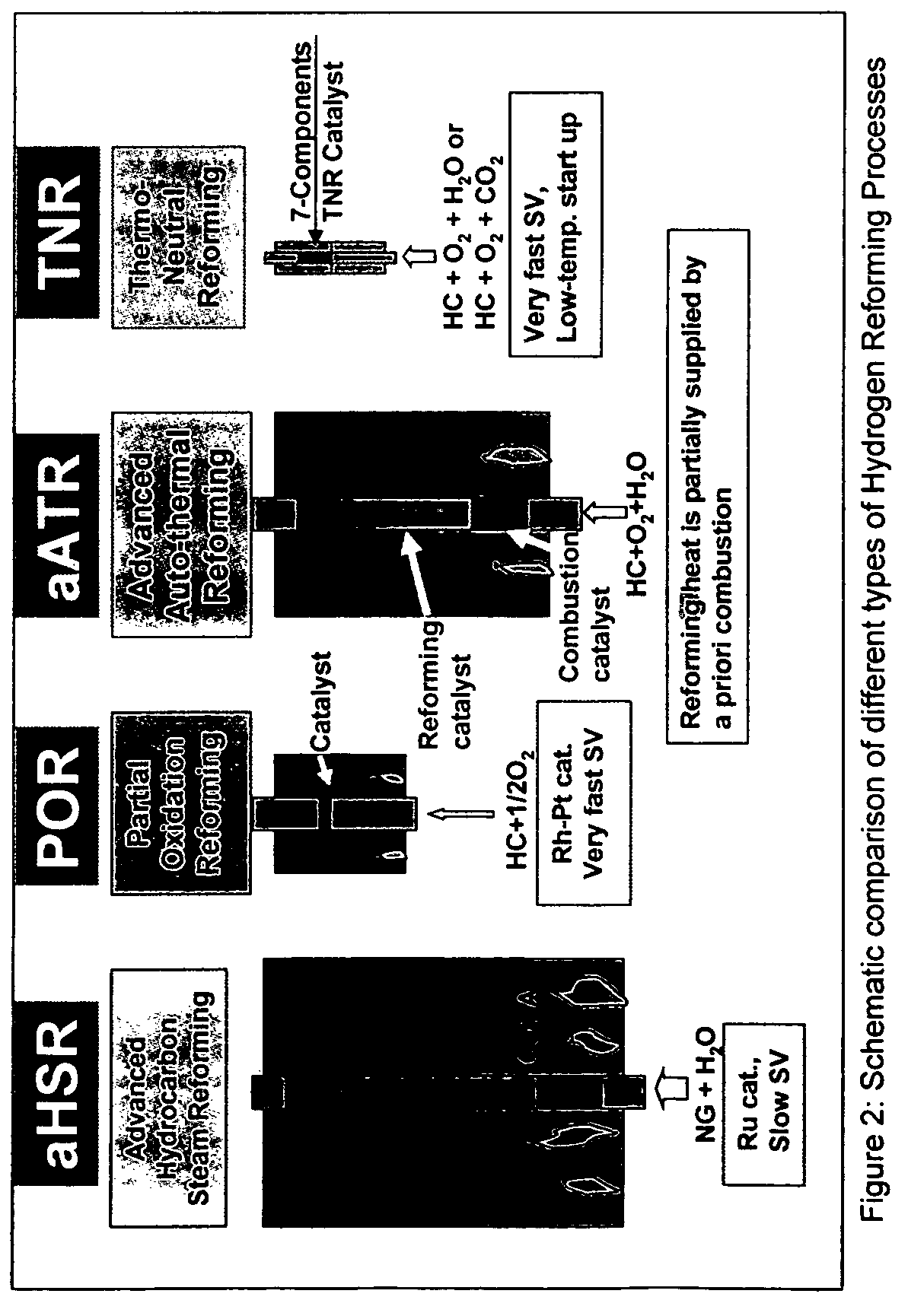

Oil-based thermo-neutral reforming with a multi-component catalyst

ActiveUS7700005B2Enhance the activity of the base metal-supported thermo-neutral reforming catalystProcesses liquid hydrocarbon fuels efficiently and reliablyHydrogenHydrocarbon from carbon oxidesSteam reformingCombustion

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

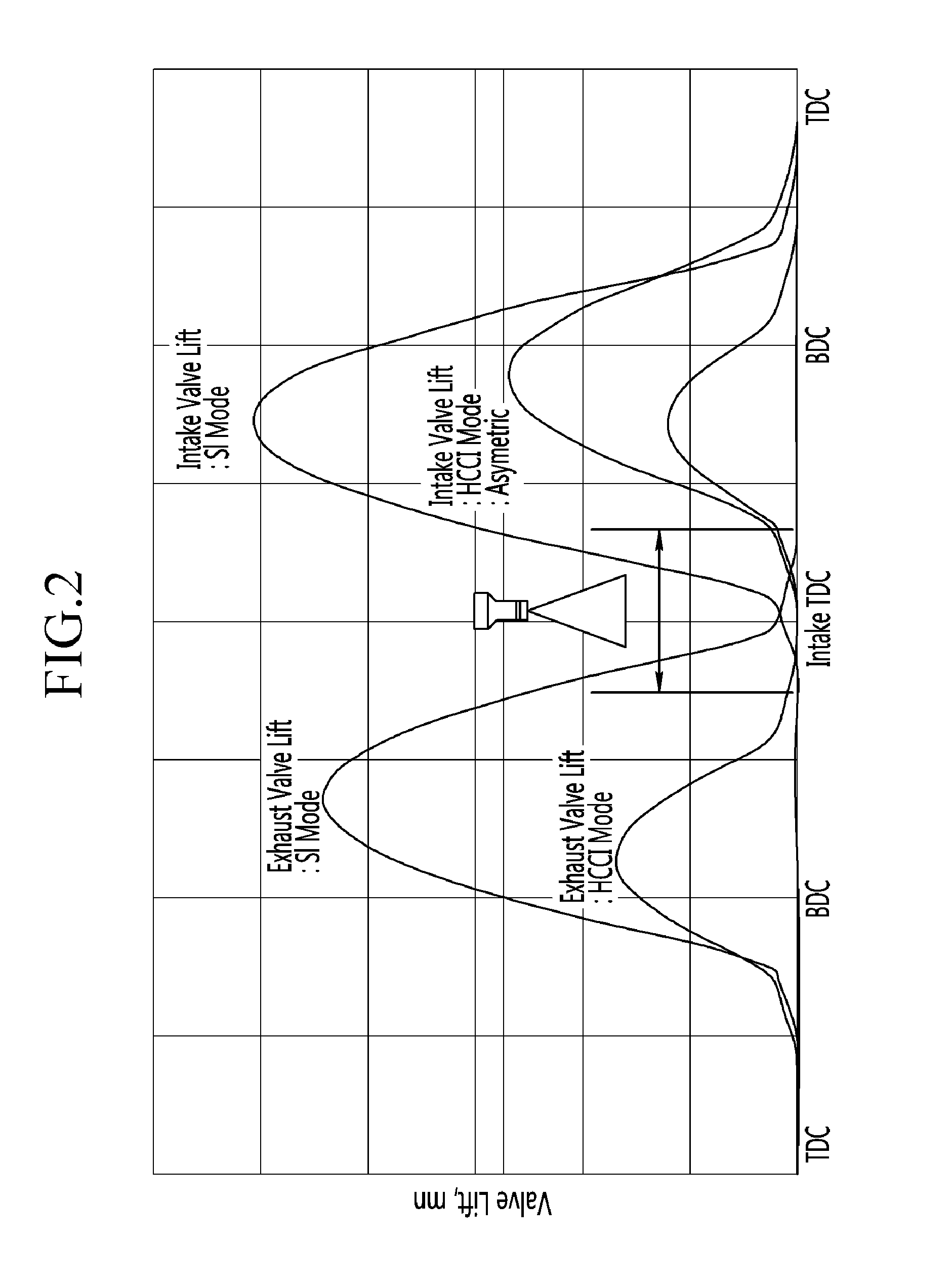

Compression ignition gasoline engine

ActiveUS20110108001A1Suppress excessive self-ignitionRapid increase of combustion noiseValve arrangementsElectrical controlCombustion chamberExhaust valve

A compression ignition gasoline engine uses low-cetane number fuel, such as gasoline. The engine includes a combustion control device having an injector directly injecting fuel into a combustion chamber, intake and exhaust valves, and a variable valve device changing a valve timing, in which the compression ignition gasoline engine includes: at least two intake valves and two exhaust valves; a spark plug positioned at the center portion of the combustion chamber; and an injector positioned adjacent to the spark plug toward the center portion of the combustion chamber, in which the exhaust valve is a symmetric valve lift in which the lift and the opening section of the tow exhaust valves are the same in low lift, and the intake valve is an asymmetric valve lift in which the lift and the opening of the two intake valves are different in the low lift.

Owner:HYUNDAI MOTOR CO LTD

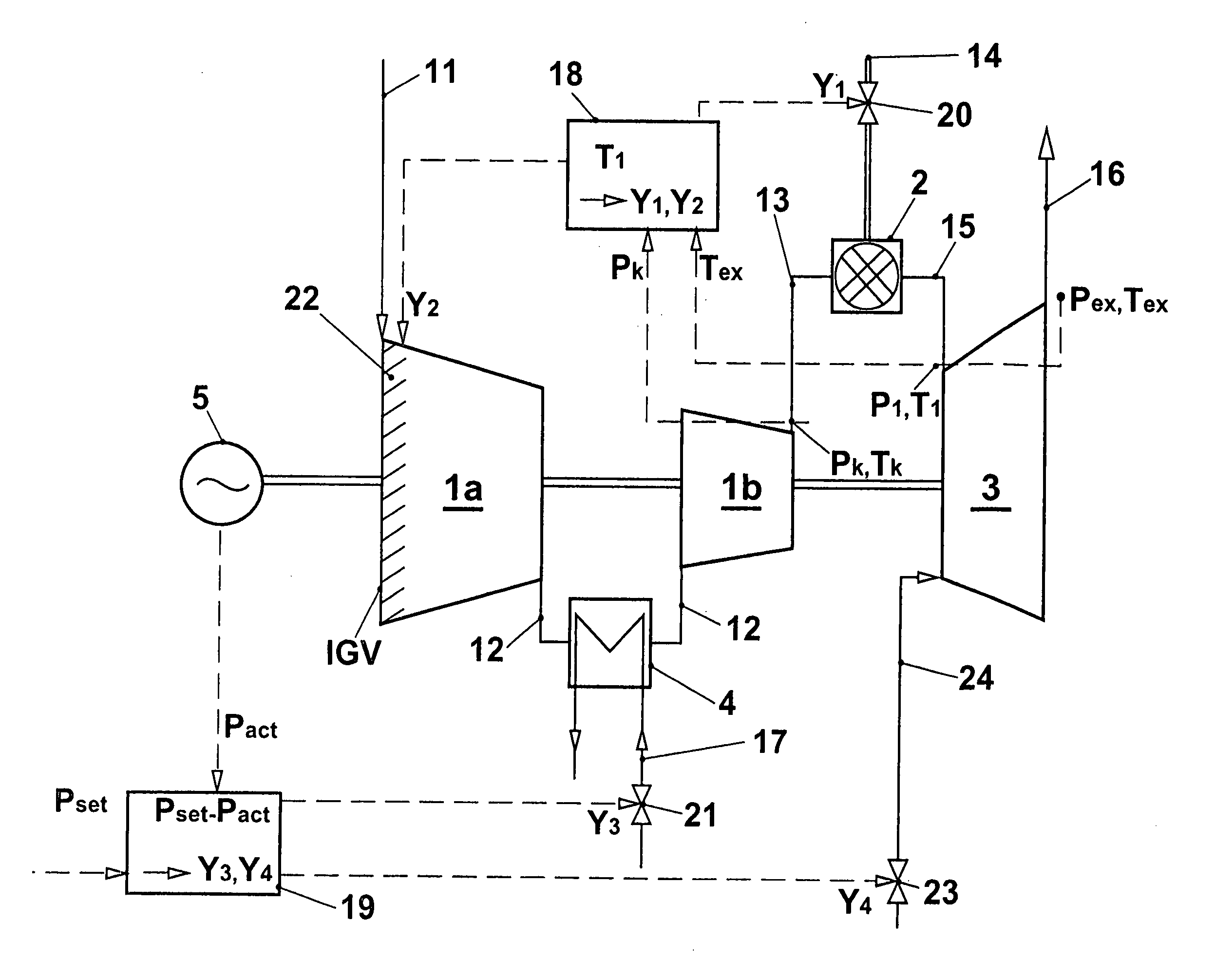

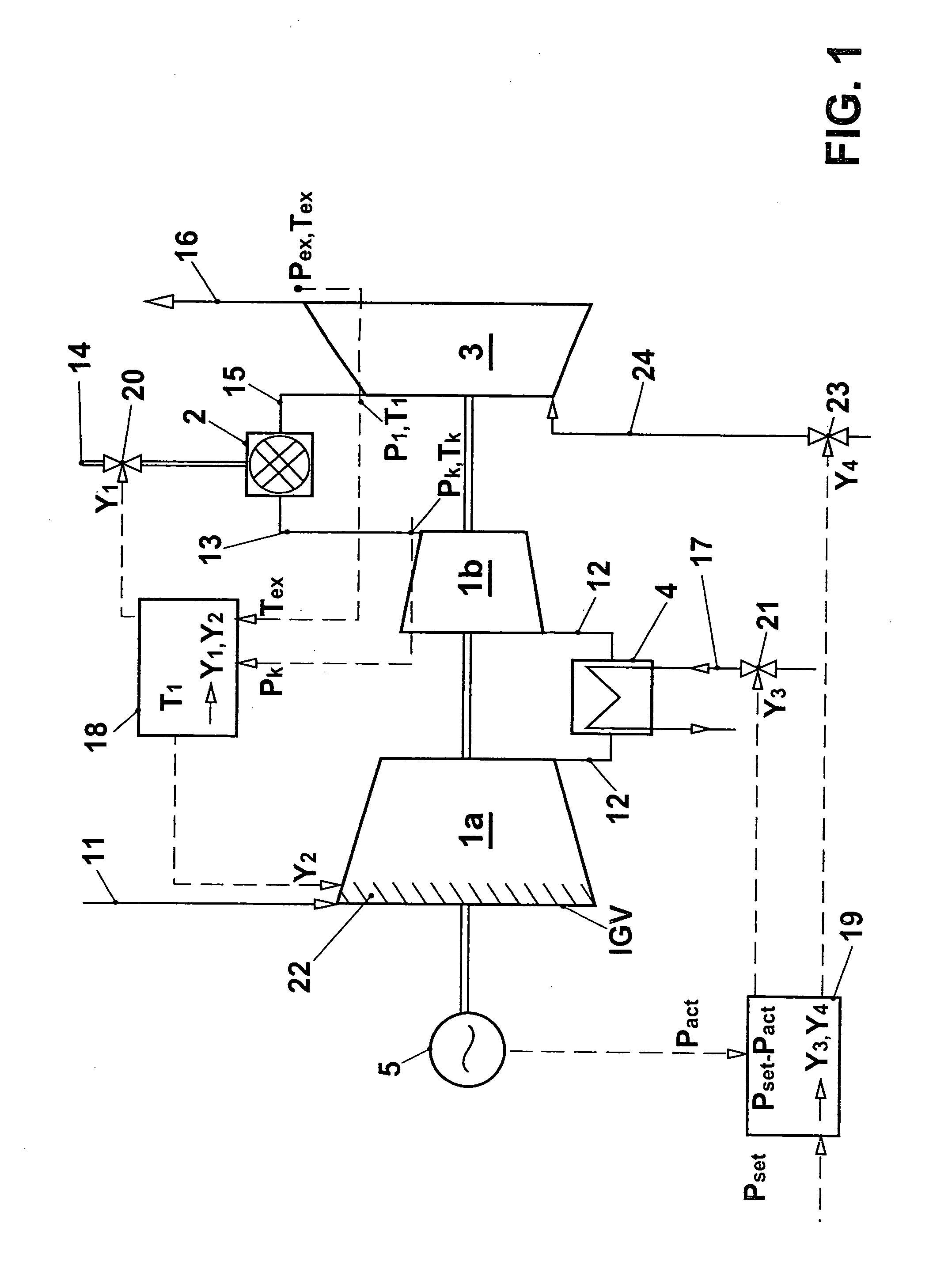

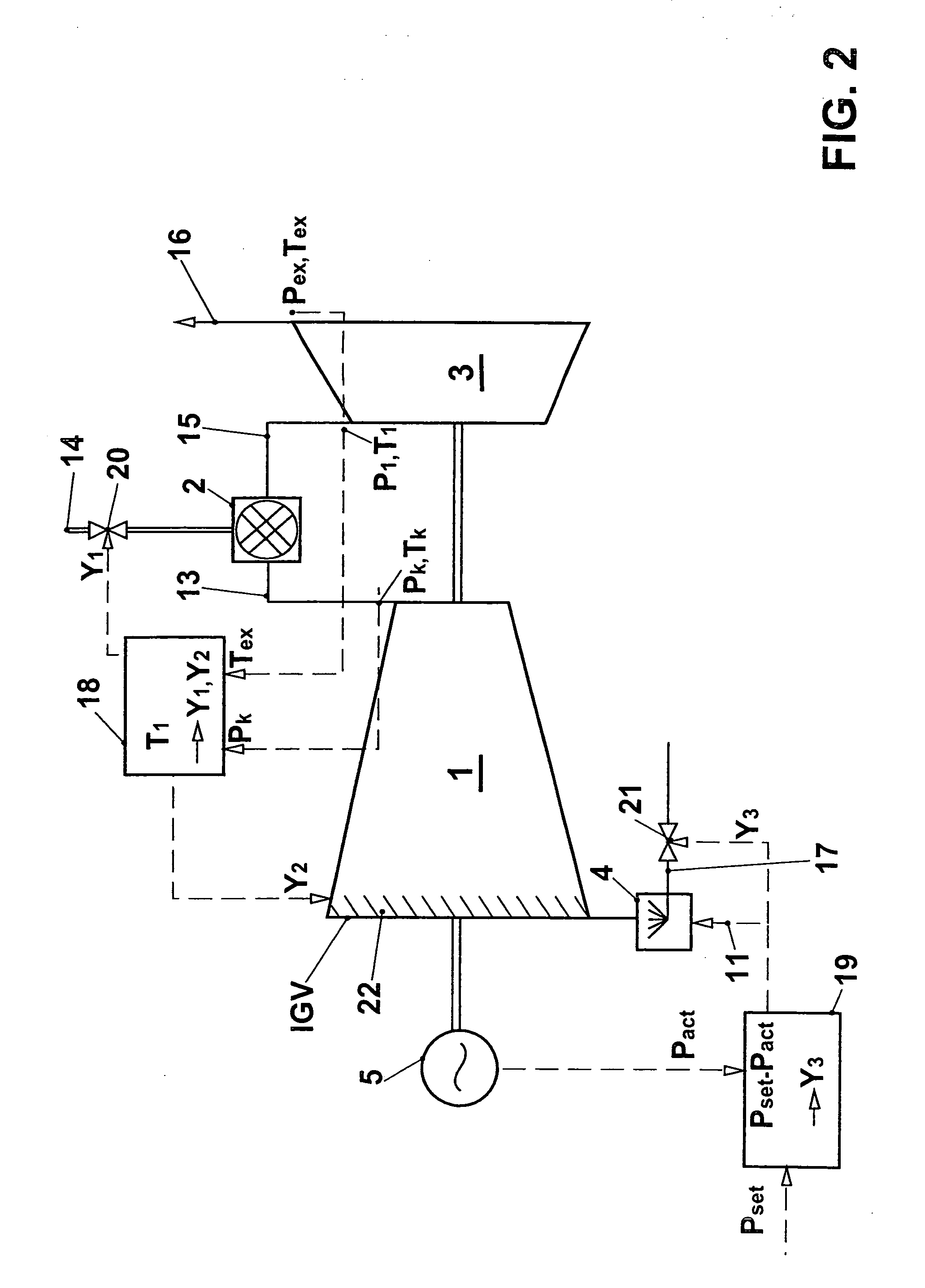

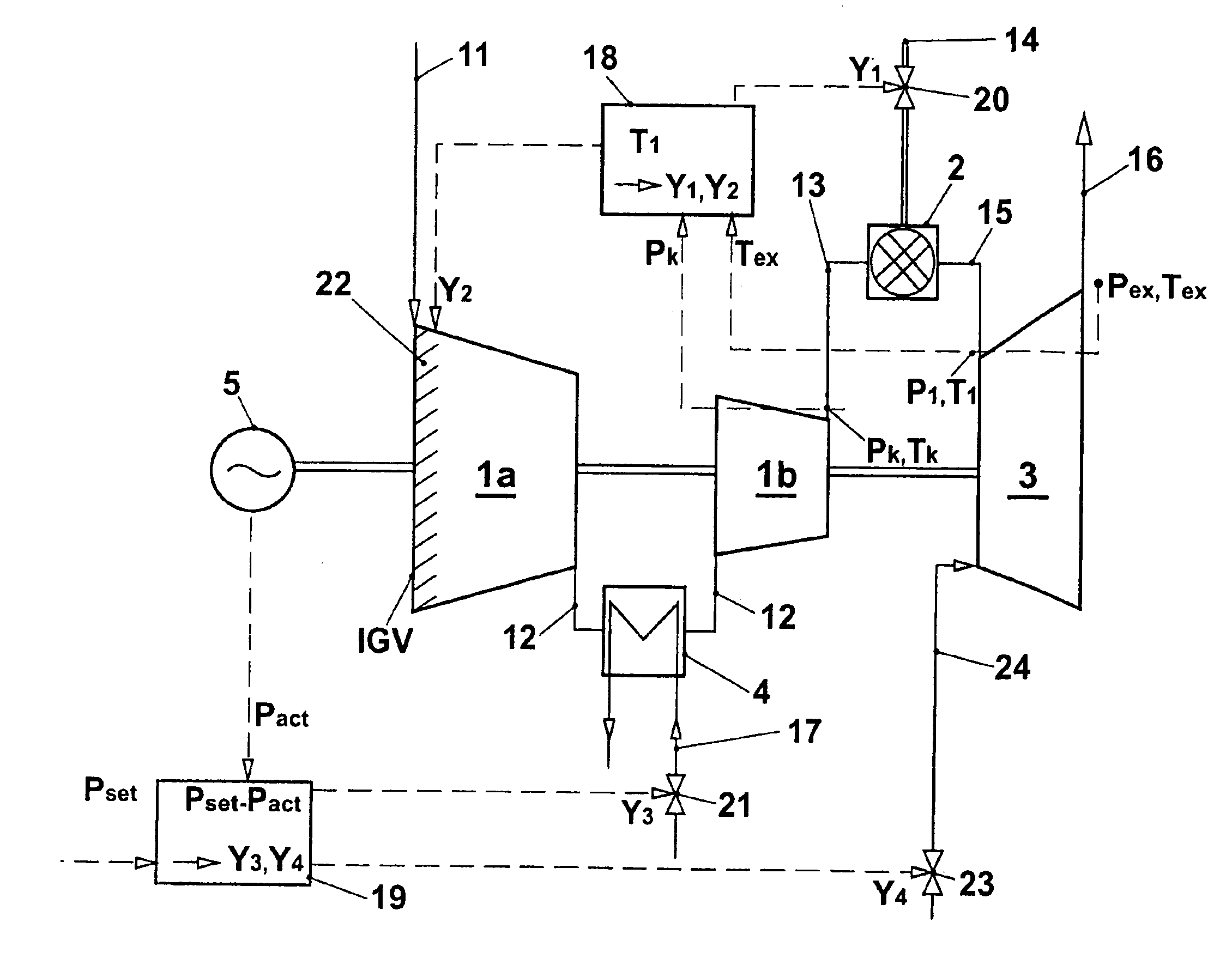

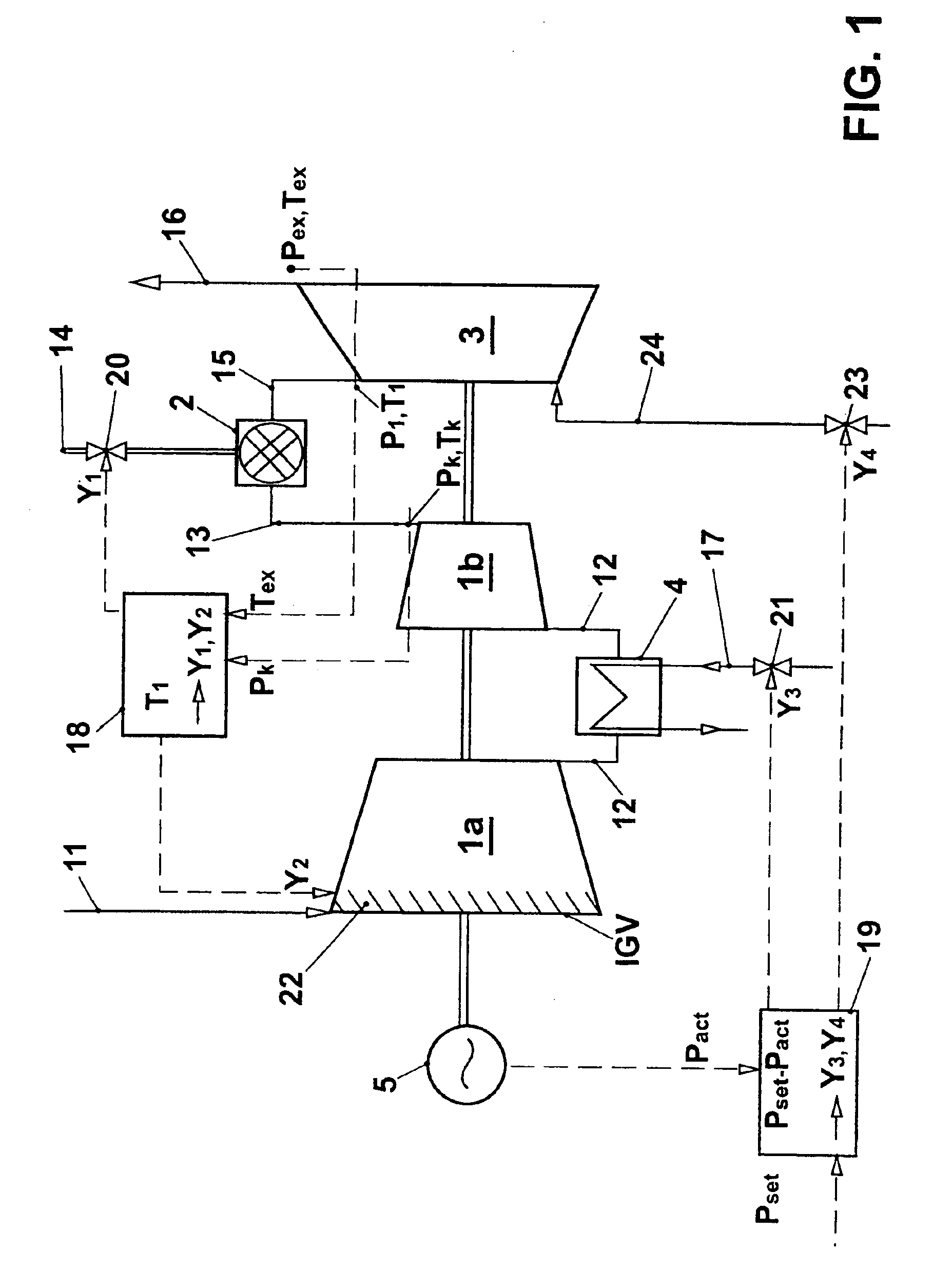

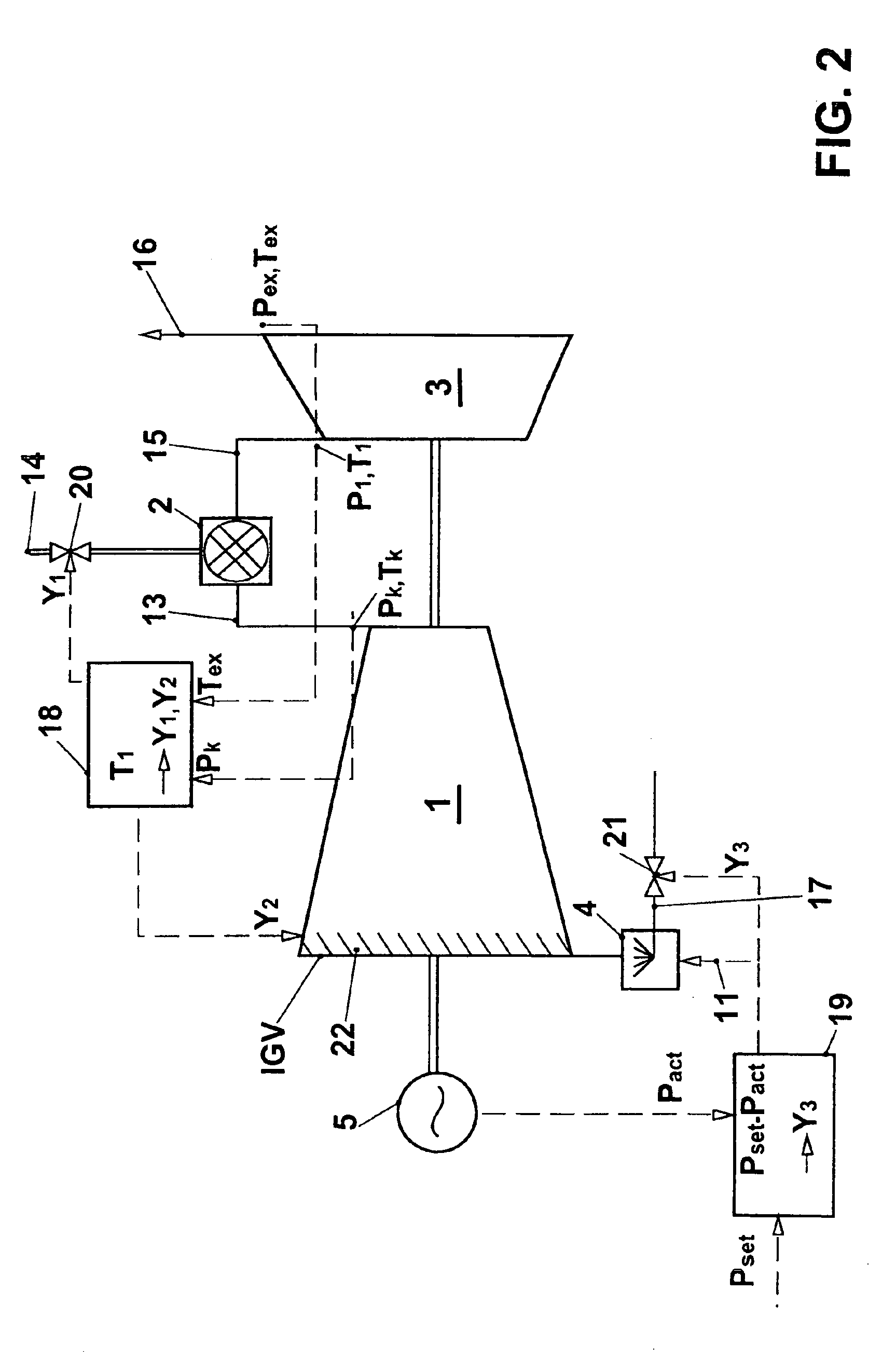

Method for operating a gas turbine group

InactiveUS20050109033A1Increase powerReduces compressor outlet temperatureEngine fuctionsGas turbine plantsCooling powerLimit value

A gas turbine group is provided with at least one cooling apparatus for cooling the working medium before and / or during the compression. The cooling power of the cooling apparatus can be adjusted by suitable means. A controller controls the cooling power of the cooling apparatus as a function of a control deviation in the useful power of the gas turbine group. The cooling controller interacts with other controllers of the gas turbine group in such a way that the gas turbine group is itself always operated at least close to its full load operating state. In this context, it is preferable for the inlet guide vane row of the compressor to be maximally open, and for the hot-gas temperature on entry into the turbines to be controlled so that it is constantly at an upper limit value.

Owner:ANSALDO ENERGIA IP UK LTD

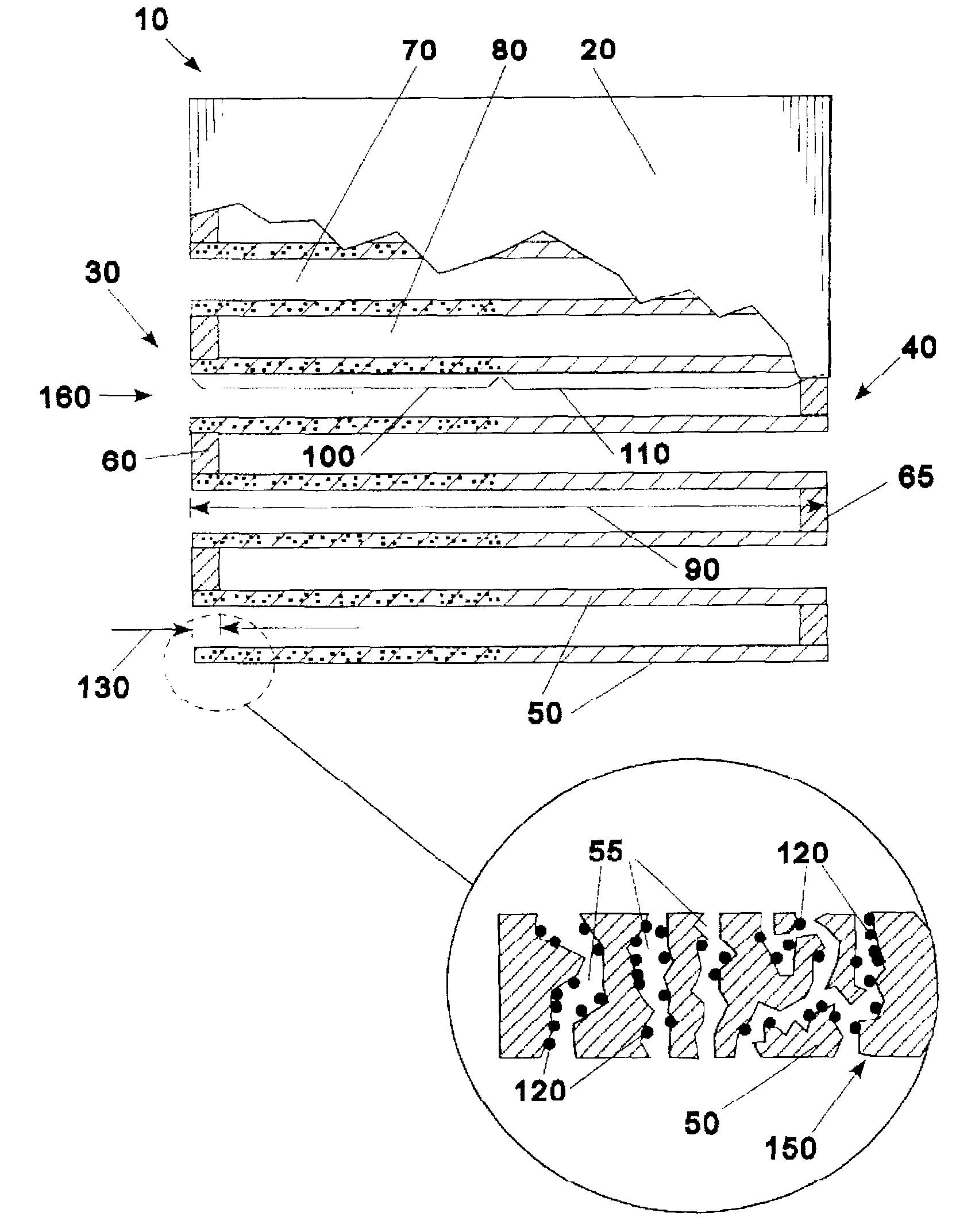

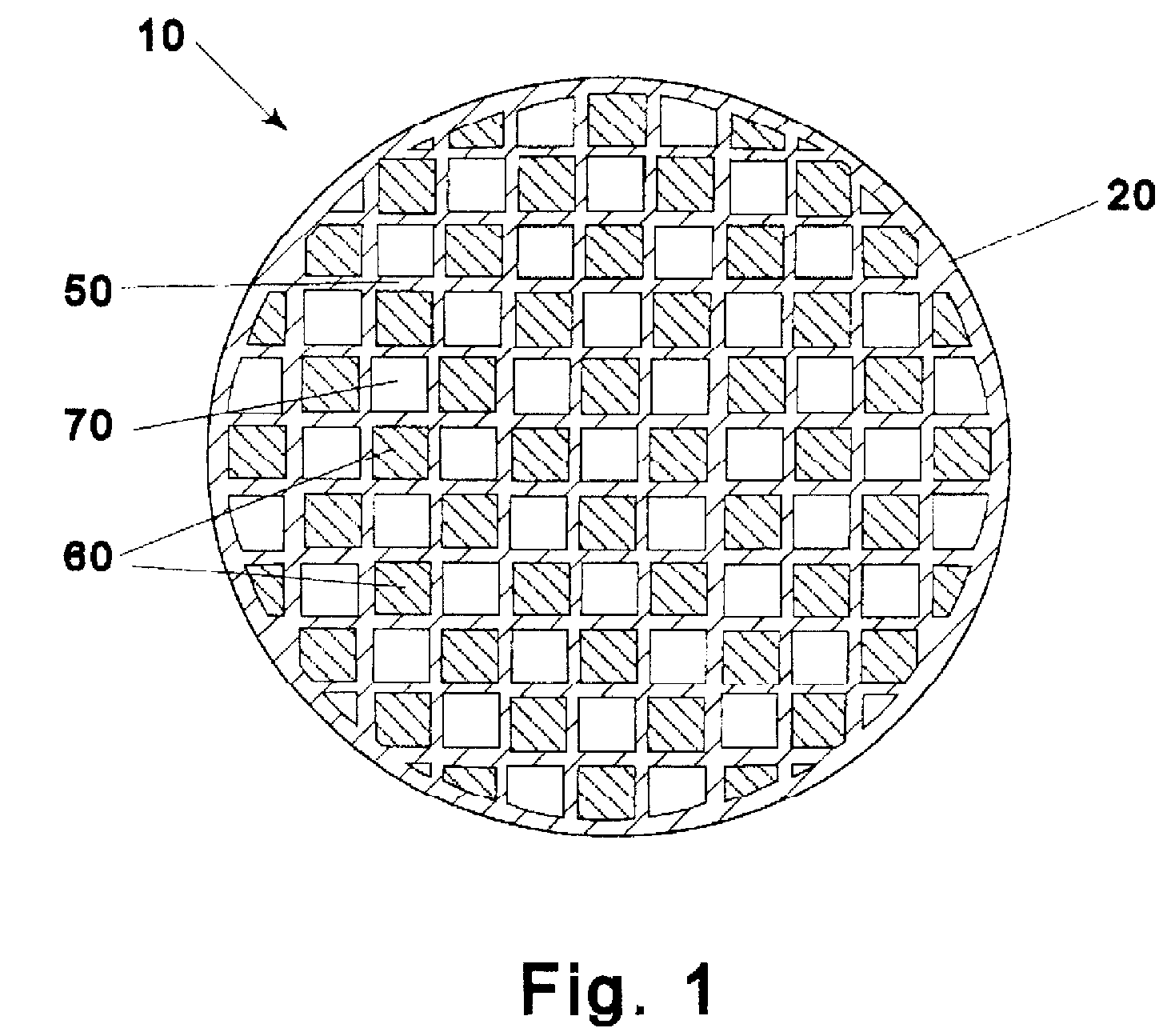

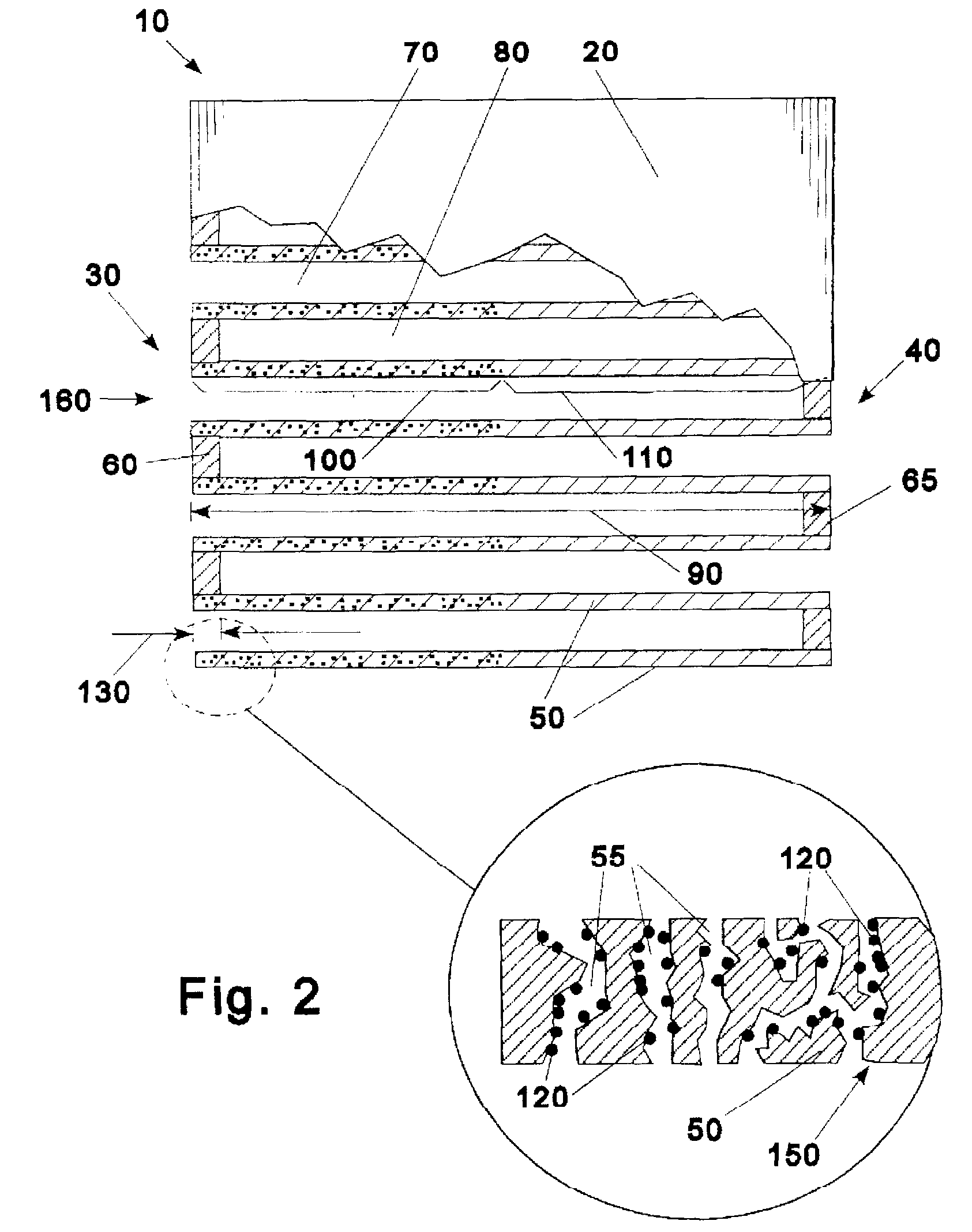

Zone catalyzed soot filter

InactiveUS7772151B2Improve combustionIncrease resistanceCombination devicesDispersed particle filtrationPorositySoot

A catalyzed soot filter is comprised of a monolithic ceramic honeycomb body that has a catalyzed inlet zone that has a catalyst within the walls of the ceramic honeycomb inlet end to at most about 45% of the length of the catalyzed soot filter. The catalyzed inlet zone has a porosity that is at least ⅓ the porosity of a wall of the ceramic honeycomb that does not have a catalyst in the wall.

Owner:DOW GLOBAL TECH LLC

Exhaust gas purifying system

ActiveUS20050044845A1Increase exhaust pressureImprove combustion performanceElectrical controlInternal combustion piston enginesThrottle controlLow load

To provide an exhaust gas purifying system capable of forcibly regenerating DPF by efficiently raising the temperature of exhaust gas even when an exhaust gas temperature is very low at the time of low load and low engine speed such as an idling operation. In an exhaust purifying system (1) having an exhaust throttling valve (31) and a DPF (3) in an exhaust passage and having regeneration control means (P1) for regenerating the DPF (3), the regeneration control means (P1) is provided with an exhaust gas temperature detection means (P22), a fuel injection control means (P11), and an exhaust throttling control means (P12) and includes regeneration control for performing the exhaust gas temperature raising control through the multistage delay injection by the fuel injection control means (P11) and through the exhaust throttling of the exhaust throttling valve (31).

Owner:ISUZU MOTORS LTD

Magnetic advanced generation jet electric turbine

ActiveUS20110138765A1Improve combustion efficiencyImprove propulsion efficiencyGas turbine plantsEnergy production using magneto-hydrodynamic generatorsAviationFuel efficiency

Supersonic Magnetic Advanced Generation Jet Electric Turbine (S-MAGJET) described herein, and a subsonic derivative, MAGJET, integrate a gas power turbine, superconducting electric power and propulsion generation, and magnetic power flux field systems along with an ion plasma annular injection combustor which utilizes alternative petroleum-based fuel and combustion cycles to create a hybrid turbine turbomachine for aerospace propulsion. The propulsion unit is able to achieve a dramatic increase in horsepower, combustion and propulsion efficiency, and weight reduction. In addition, the turbomachinery structures may be disposed within an exo-skeleton architecture that achieves an increase in thrust to weight ratio with a concomitant increase in fuel efficiency and power generation over traditional gas turbine technology today. The engine continuously adjusts the temperature, pressure and mass airflow requirements using an electromagnetic power management system architecture. Engine performance may be controlled across the entire desired flight envelope, whether subsonic, transonic or supersonic flight conditions. With bypass fan(s), compressor stages and turbine segments controlled electrically in a shaftless turbine design, the S-MAGJET maximizes the propulsion efficiencies over a broader range of operating conditions compared to current art of turbine technology and at much higher thermodynamic and aerodynamic efficiencies.

Owner:SONIC BLUE AEROSPACE

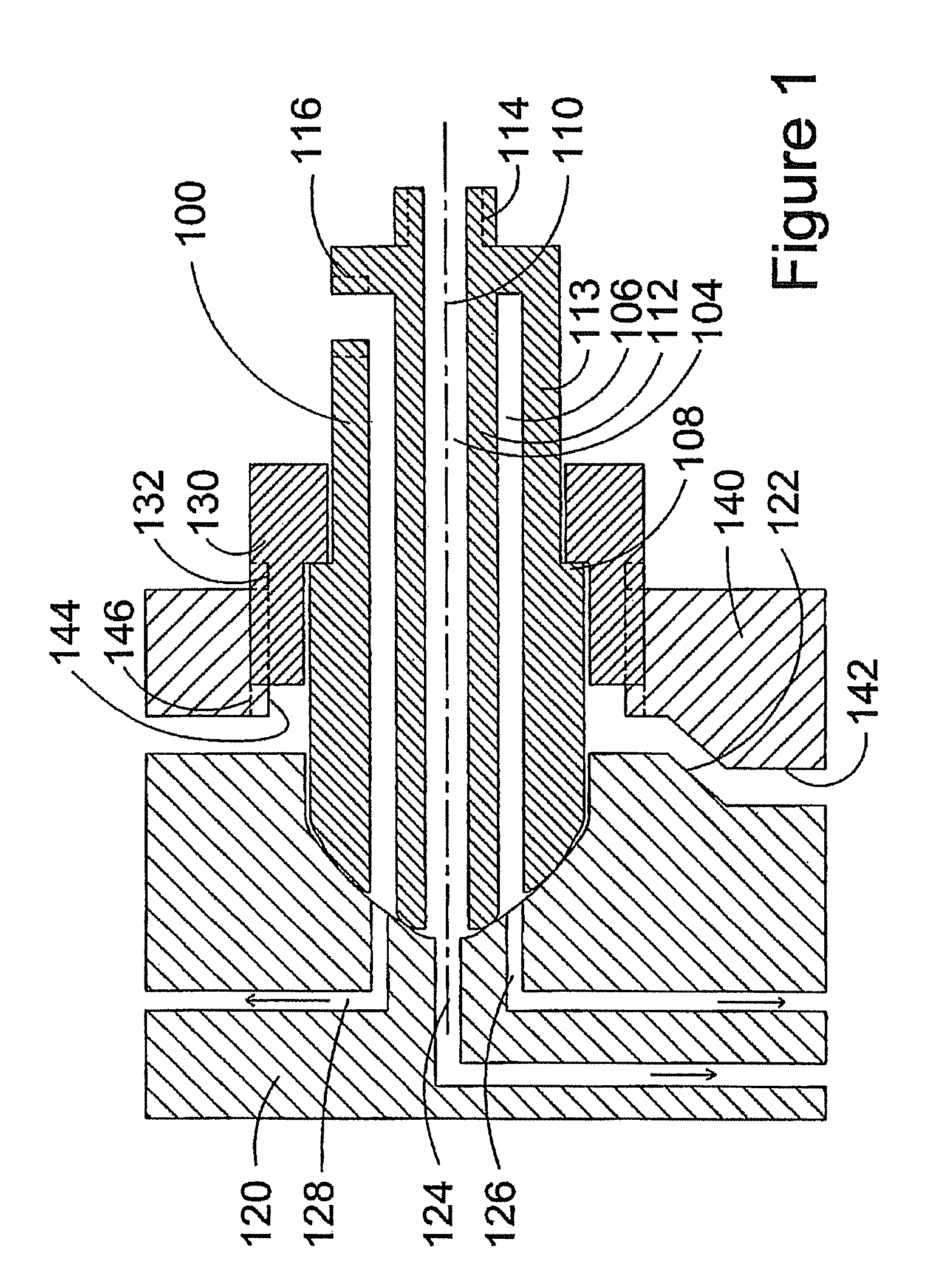

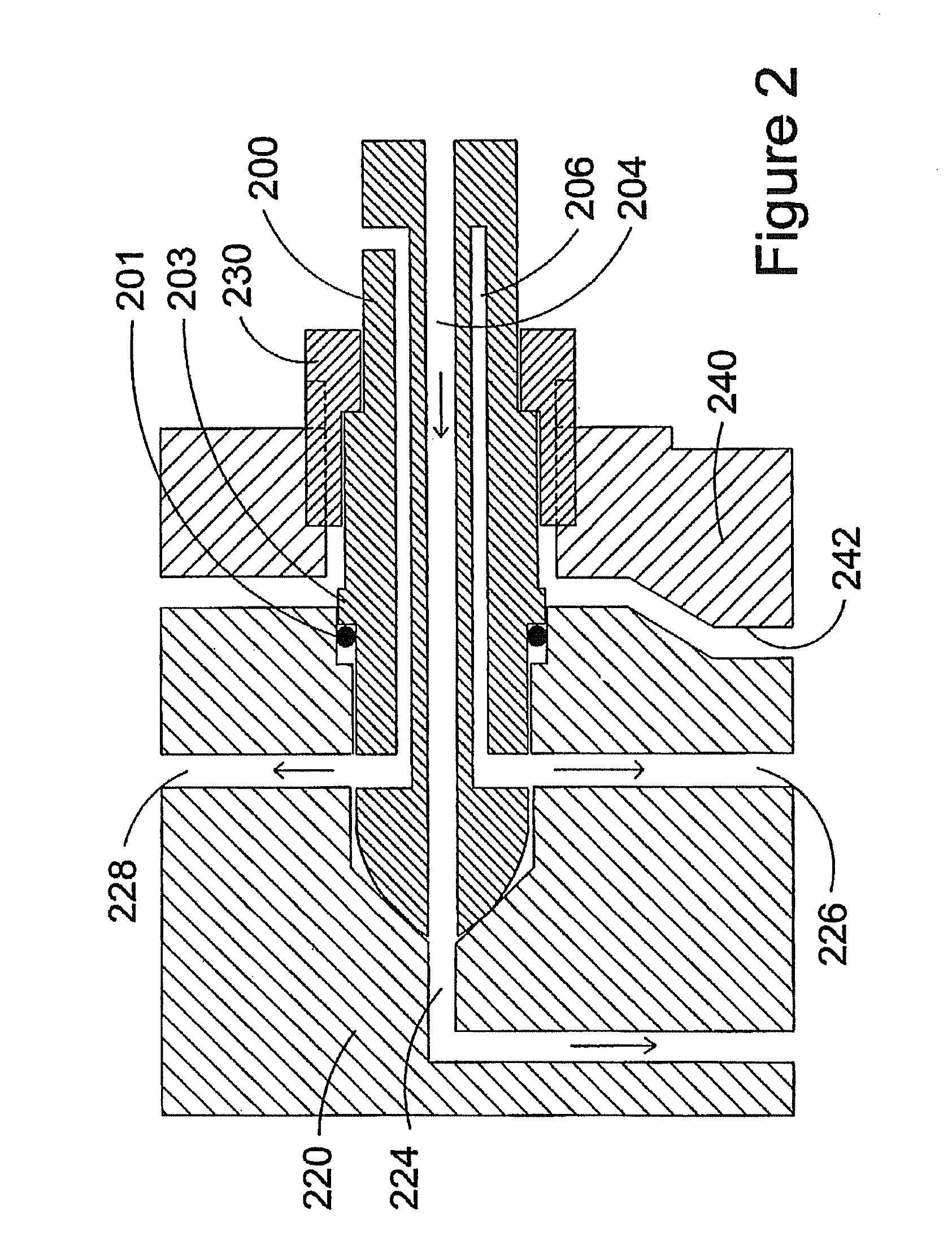

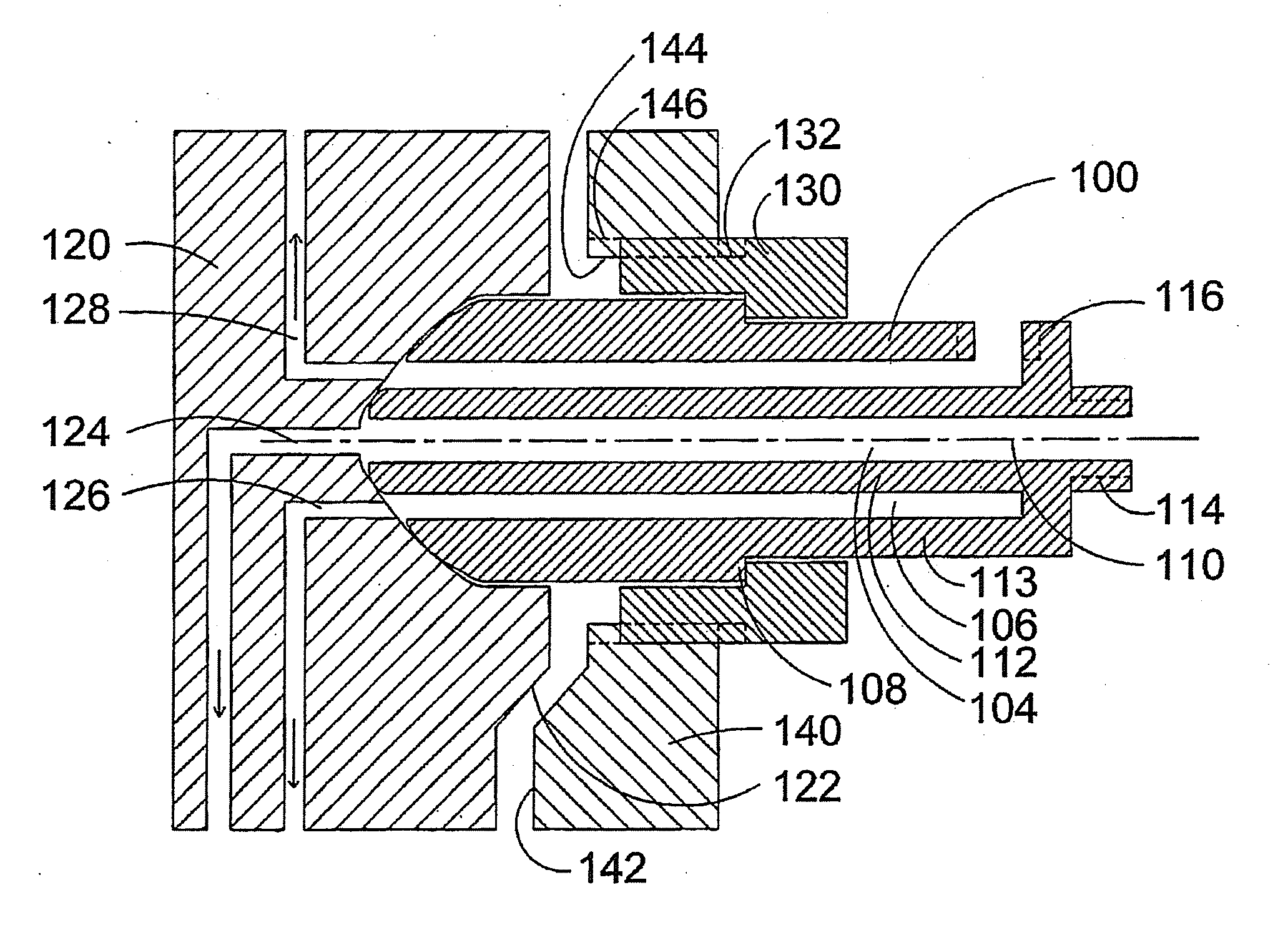

Dual fuel connector

ActiveUS8272368B2Simple pipelineFacilitates installation and removalInternal combustion piston enginesFuel injection apparatusCylinder headFuel injection

A dual fuel connector separately supplies two different fuels to fluidly isolated fuel passages within a fuel injection valve of an internal combustion engine. The dual fuel connector comprises a body with separate fluid connections to the first fuel inlet, the second fuel inlet, a first fuel rail and a second fuel rail. A first fuel passage within the body is in fluid communication with the first fuel rail and the first fuel inlet. A second fuel passage within the body is in fluid communication with the second fuel rail and the second fuel inlet, and wherein the first fuel passage is fluidly isolated from the second fuel passage. The dual fuel connector supplies two different fuels to a fuel injection valve, for engines that are not designed with a cylinder head that has internal bores that can serve as fuel rails.

Owner:WESTPORT FUEL SYST CANADA INC

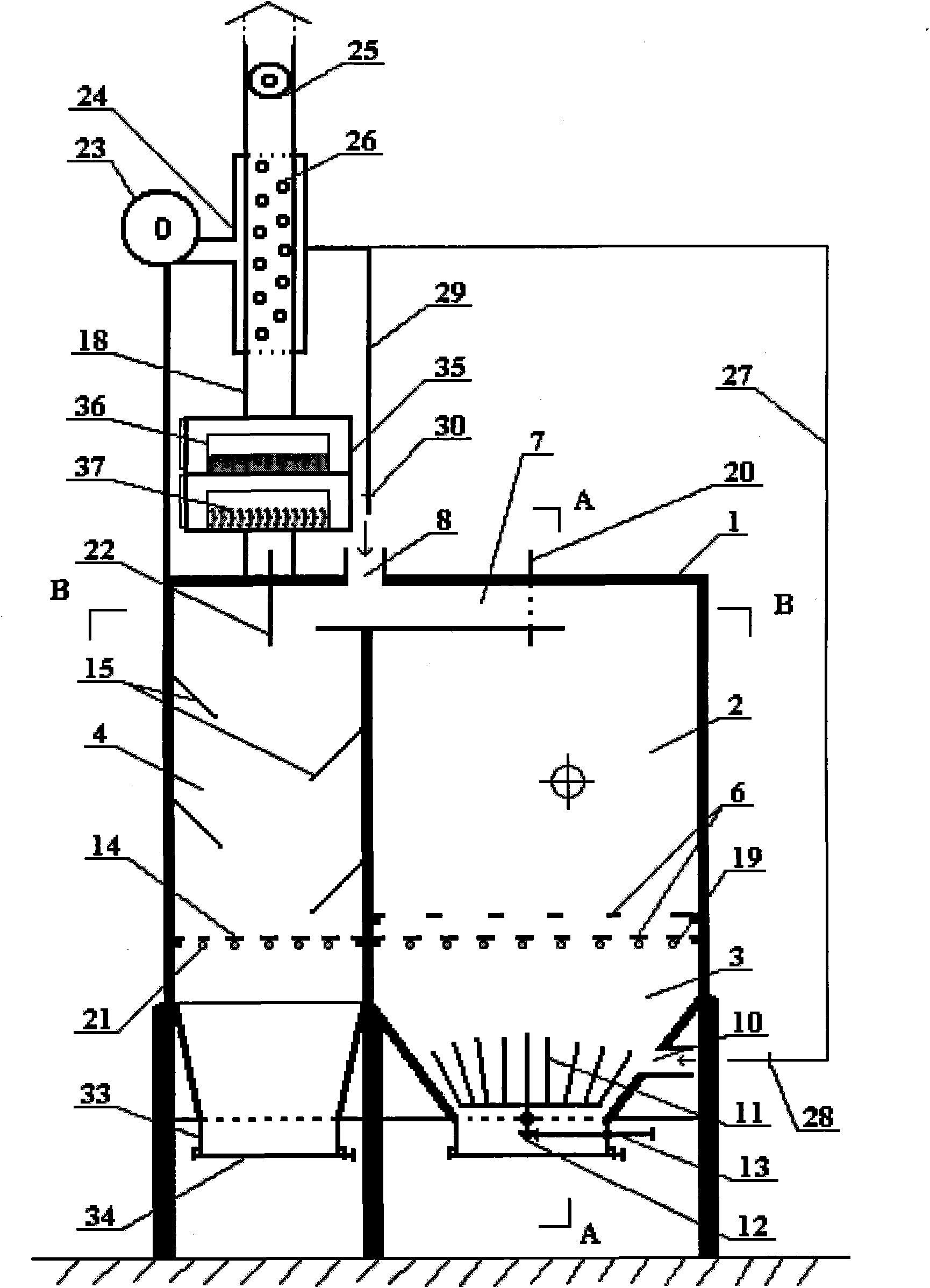

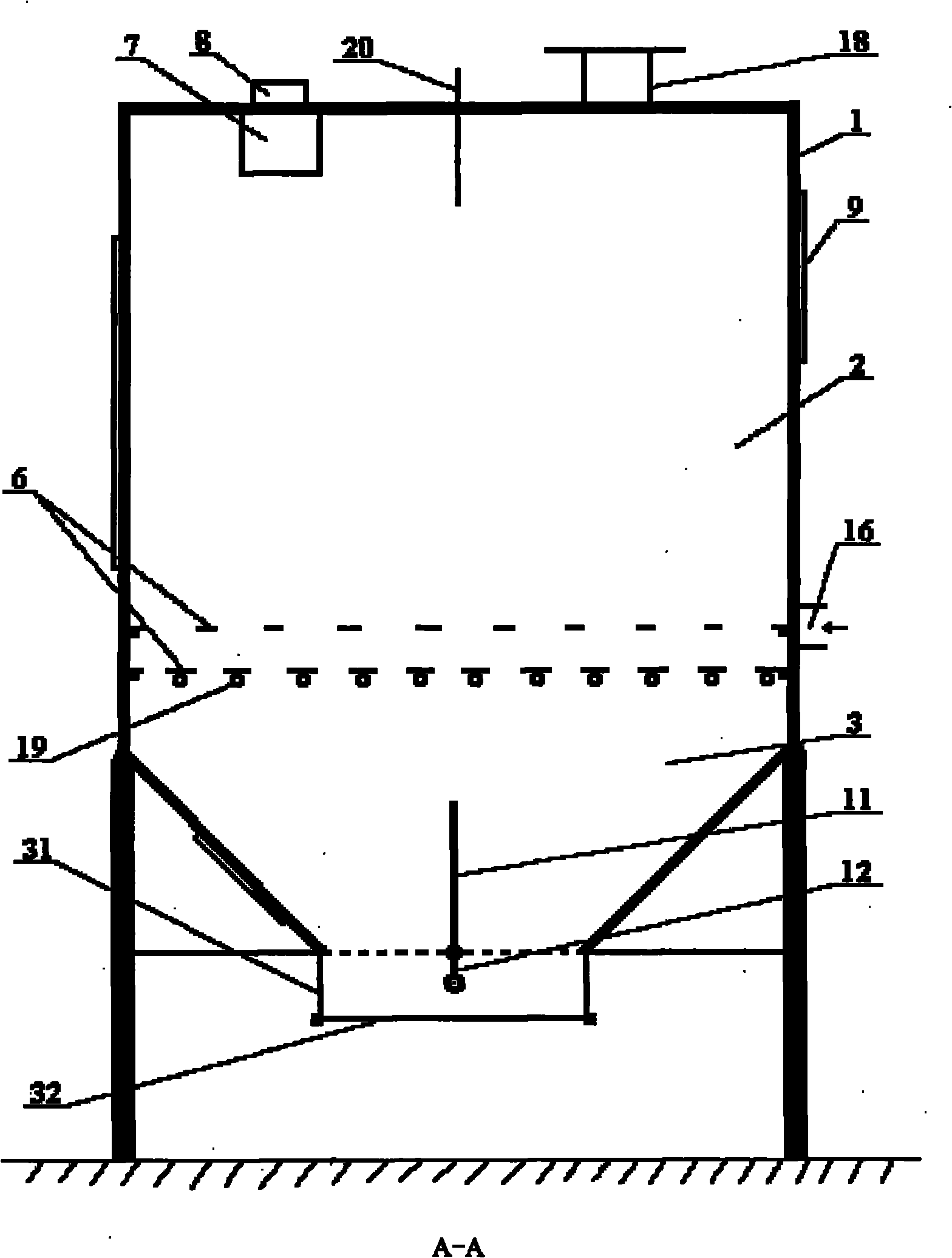

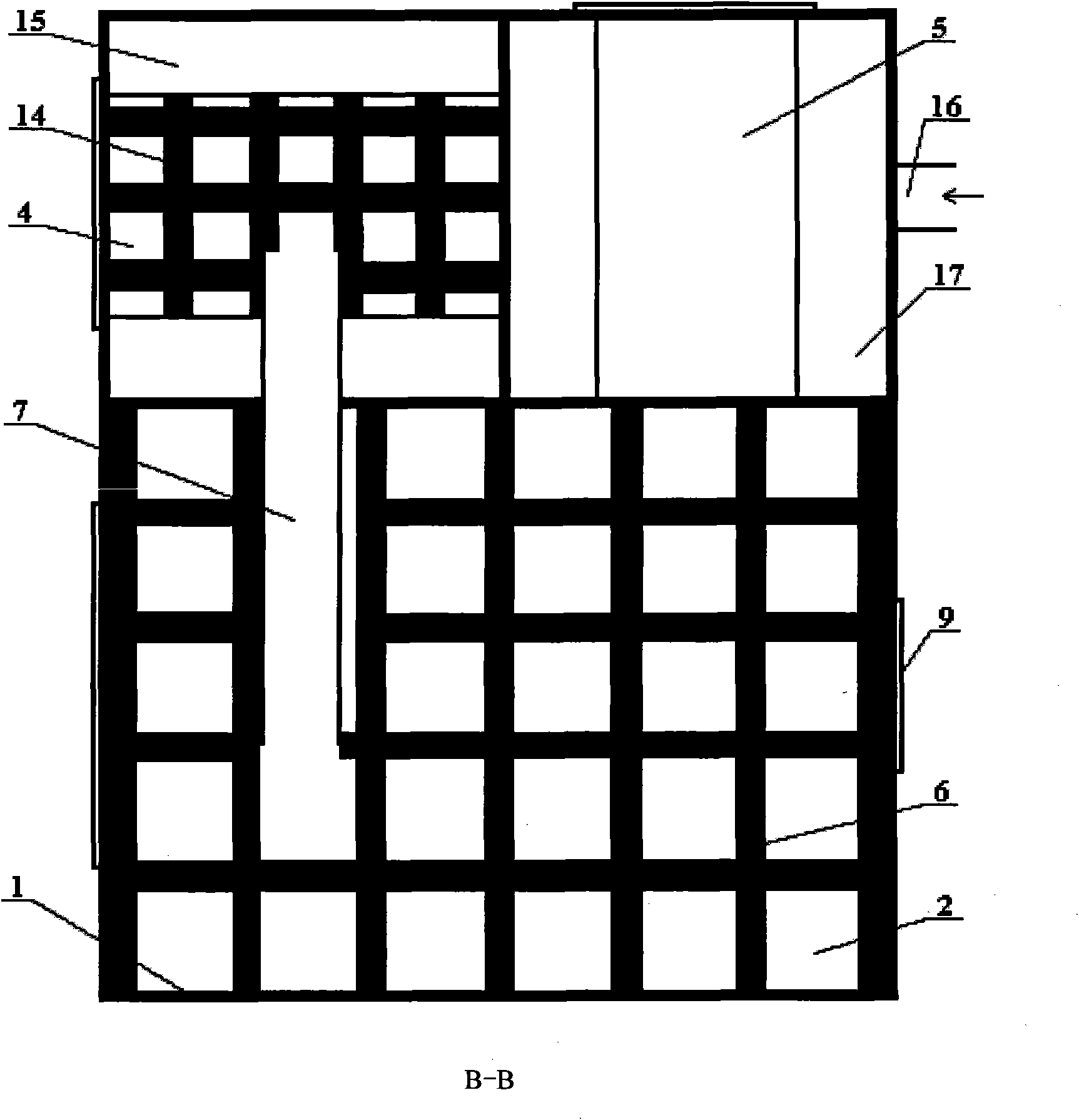

Small efficient medicinal rubbish pyrolysis incinerator

InactiveCN102042601AProblem Solving Using Unitary Furnace StructureLarge capacity reduction ratioIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberGas phase

The invention discloses a small efficient medicinal rubbish pyrolysis incinerator, which belongs to rubbish burning treatment equipment and solves the problems that a gas combustion chamber has simple structure, an auxiliary fuel is needed, the temperature cannot be accurately measured or controlled, and defects are produced in cloth bag dust removal and the like. The hearth of the incinerator consists of a pyrolysis and gasification chamber, a solid-phase burn-out chamber, a gas-phase combustion chamber and a flue gas treatment chamber; the solid-phase burn-out chamber is positioned below the pyrolysis and gasification chamber and communicated through a netlike fire grate; the gas-phase combustion chamber is arranged in parallel to the pyrolysis and gasification chamber, and the top of the gas-phase combustion chamber is communicated with a flue; the flue gas treatment chamber is arranged in parallel to the gas-phase combustion chamber and the pyrolysis and gasification chamber; and the gas-phase combustion chamber is communicated with the lower part of the flue gas treatment chamber, the gas-phase combustion chamber and the flue gas treatment chamber are provided with a fireproof baffle plate respectively, and the lower part of the gas-phase combustion chamber is provided with the netlike fire grate. The temperature in the incinerator is measured and controlled in real time through an electric heating and automatic temperature measurement and control system. A high-temperature granule dust removal and filter device avoids regeneration of dioxin, and the cost is reduced. The incinerator effectively and cleanly burns the medicinal rubbish on the aspects of incinerator shape design, ignition and combustion modes, temperature measurement and control, high-temperature flue gas treatment and the like.

Owner:杨显志

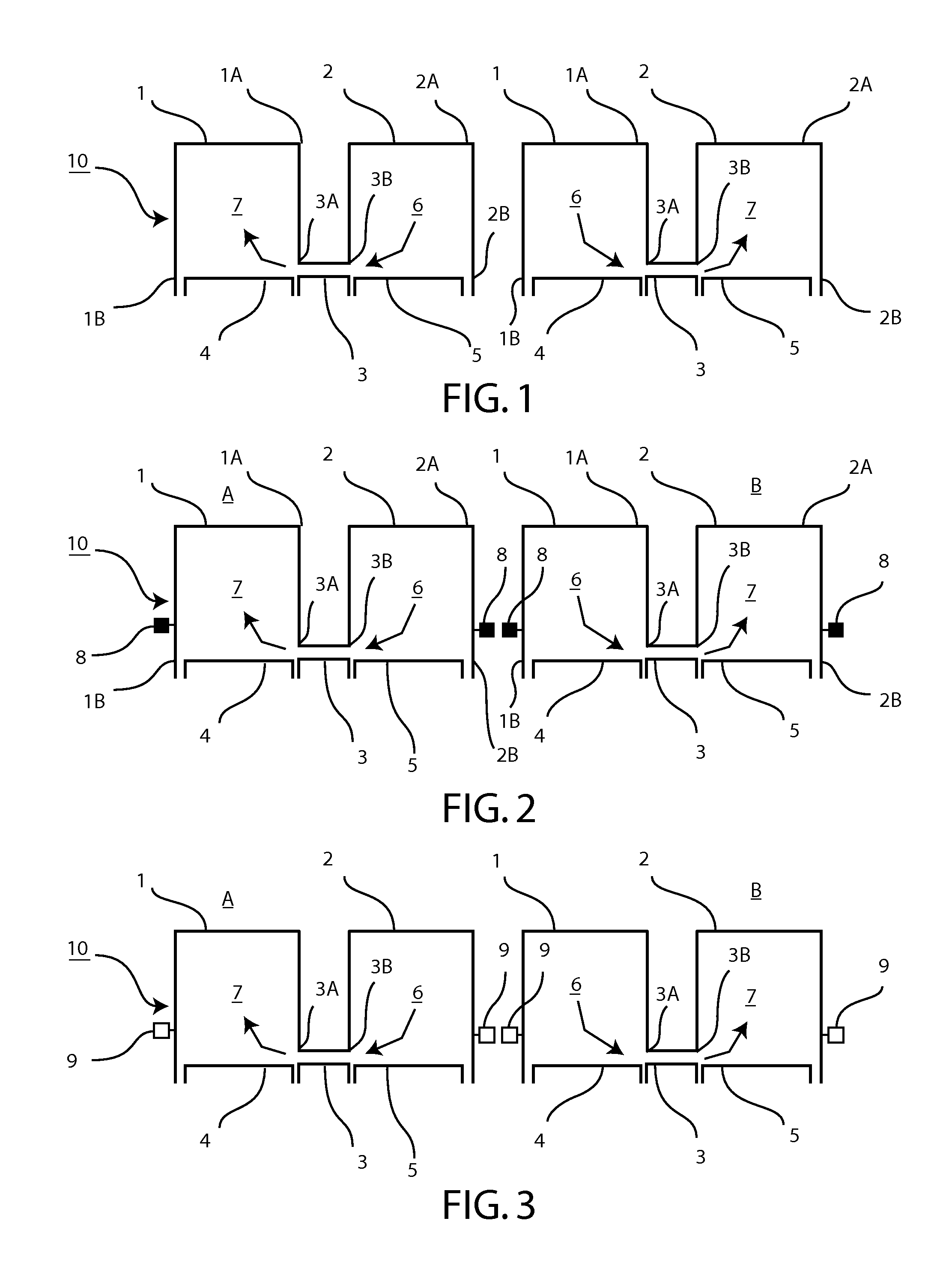

Internal combustion engines with surcharging and supraignition systems

InactiveUS20100229806A1Improve engine efficiencyImprove combustion efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesCombustionExternal combustion engine

An internal combustion engine includes first and second cylinder assemblies each to repeatedly carry out combustion cycle including intake, compression, combustion with expansion, and exhaust processes. In a surcharging system of the invention, the first cylinder assembly is coupled to the second cylinder assembly in gaseous communication to apply a charge of exhaust gas produced from a first combustion cycle of the first cylinder assembly to a compression process of a second combustion cycle of the second cylinder assembly. In a supraignition system of the invention, the first cylinder assembly is coupled to the second cylinder assembly in gaseous communication to apply a charge of ignition gas produced from a first combustion cycle of the first cylinder assembly to a compression process of a second combustion cycle of the second cylinder assembly. Buffer vessels coupled in gaseous communication with corresponding cylinder assemblies are also used in surcharging and supraignition processes.

Owner:KEMENY ZOLTAN A

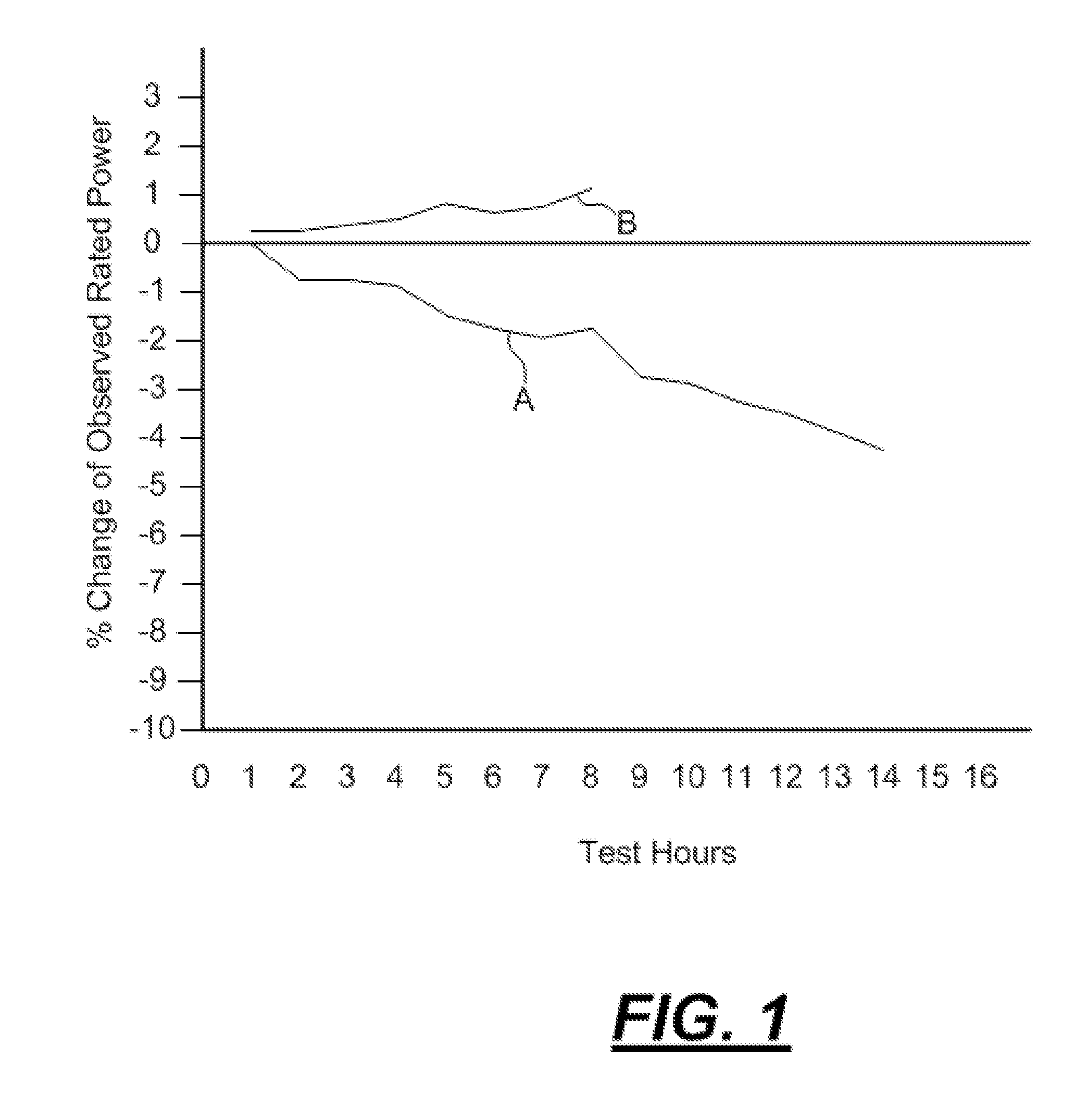

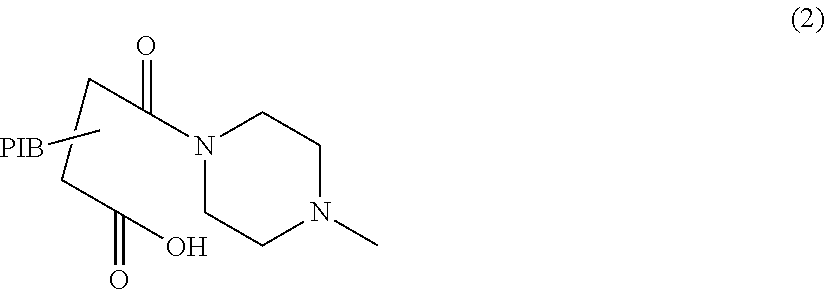

Diesel fuel additive

ActiveUS20120102826A1Improve engine performanceImprove performanceOrganic chemistryLiquid carbonaceous fuelsNitrogenEngineering

A diesel fuel additive composition, a fuel containing the fuel additive, a method for improving diesel engine performance using the additive. The diesel fuel additive includes a reaction product of (a) a hydrocarbyl-substituted acylating agent and (b) a reactant selected from the group consisting of a nitrogen-containing compound, a hydroxyl-containing compound, and water that provides a reaction product selected from the group consisting (1) a mono-amide / mono-acid or metal free mono-acid salt thereof, (2) a diacid or metal free diacid salt thereof, and (3) mono-ester / mono-acid or metal free mono-acid salt thereof. The reaction product includes at least about 10 molar percent acid groups based on total moles of the reaction product.

Owner:AFTON CHEMICAL

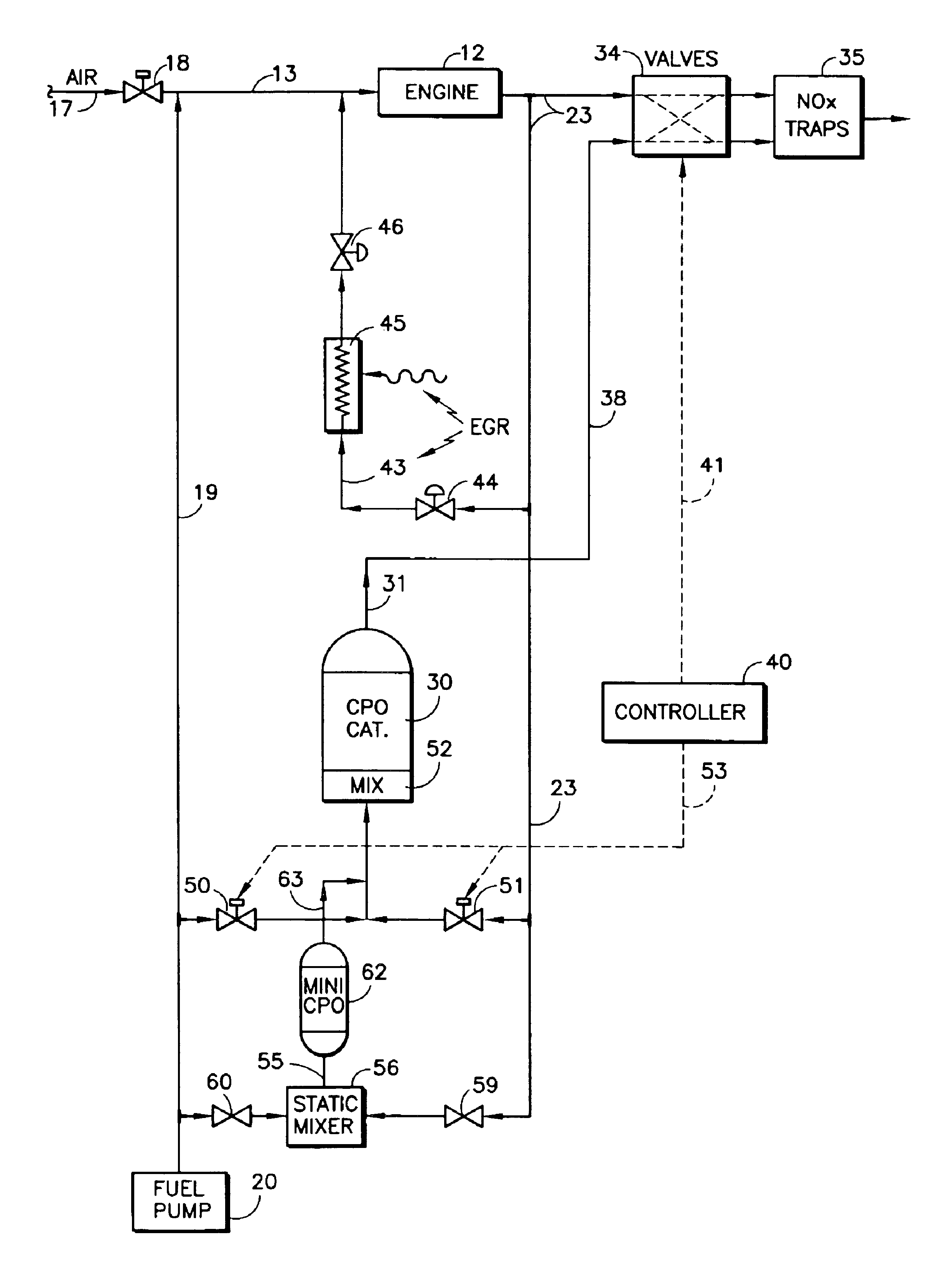

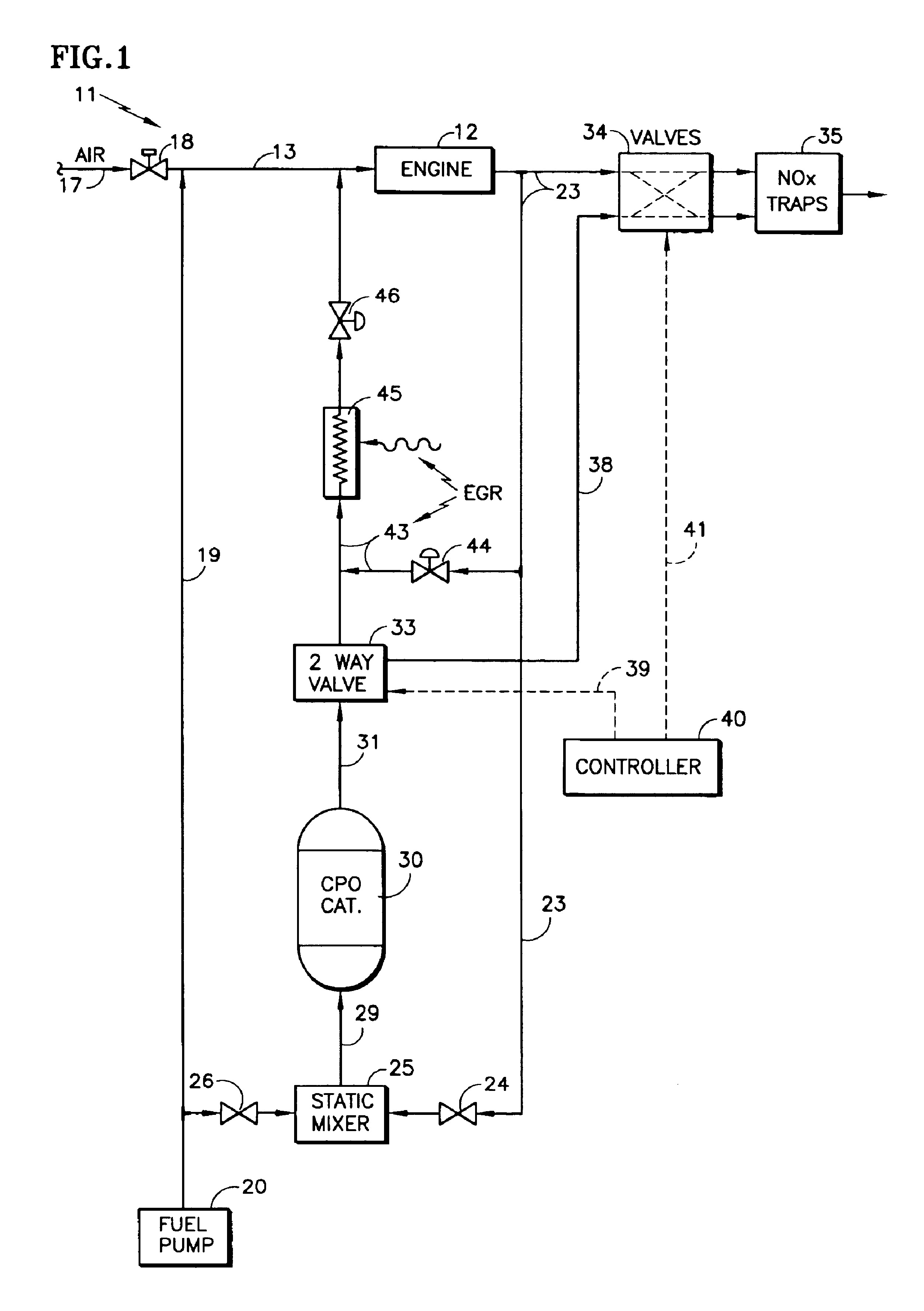

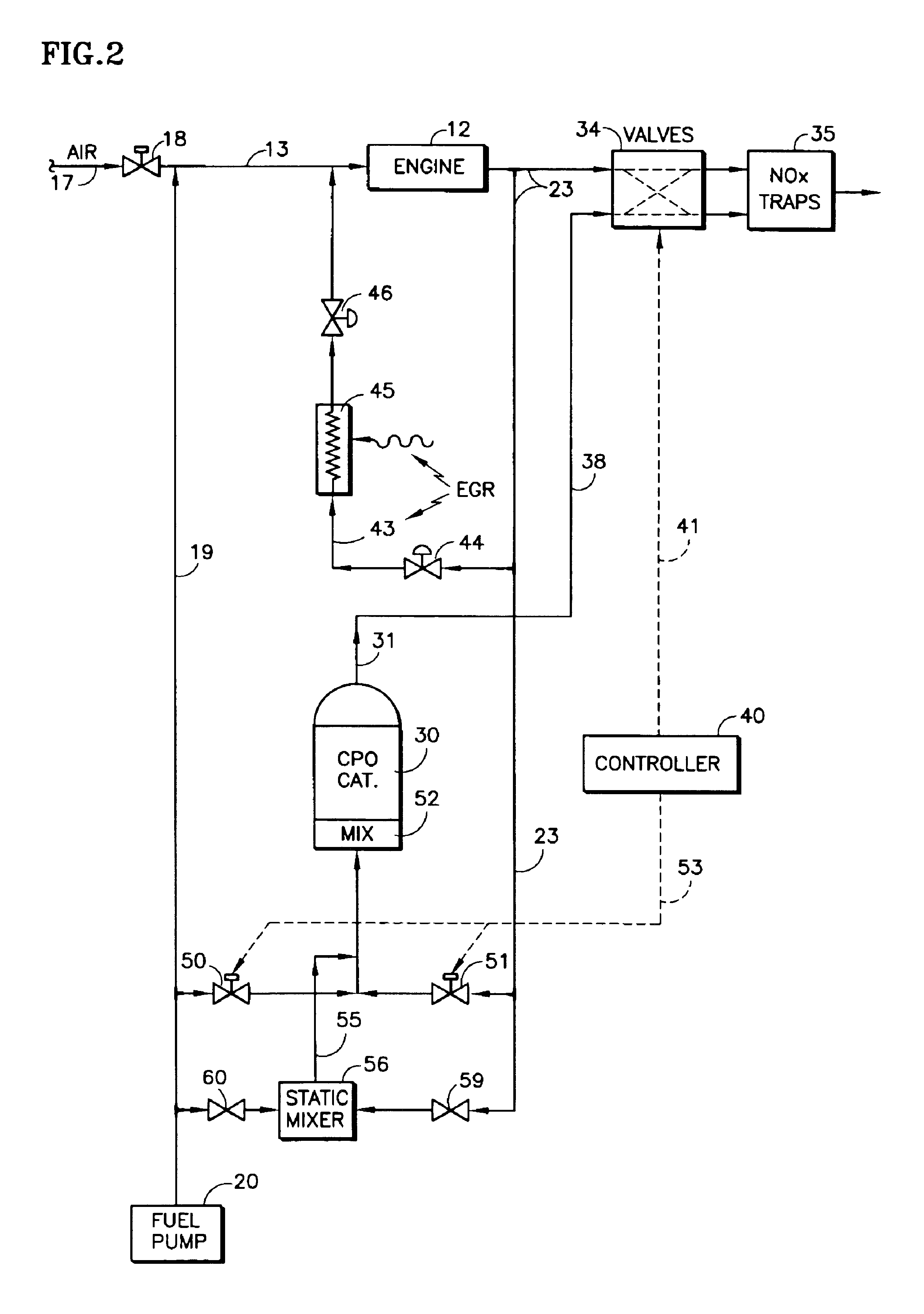

Intermittent application of syngas to NOx trap and/or diesel engine

InactiveUS6964156B2Increase profitImprove cleanlinessHydrogenInternal combustion piston enginesSyngasProcess engineering

A catalytic partial oxidizer (30) provides syngas (hydrogen and carbon monoxide) to an apparatus intermittently using syngas such as valves (34) feeding NOx traps (35), for brief periods of time. During turndown times when syngas is not being used, either the output of the CPO is diverted (33) to the inlet (13) of an engine (12) through the engine gas recycle (EGR) system (43-46), or the amount of fuel (19) and exhaust (23) applied to the CPO is reduced (24, 26; 59, 60) so that the CPO merely stays warm and in a reduced state, thereby being ready to restart immediately. A mini-CPO (62) may provide syngas and heat to the major CPO (30) during the turndown time when syngas is not being used by the NOx traps.

Owner:SHELL OIL CO

Fuel Injection System of Internal Combustion Engine

InactiveUS20080053408A1Improve combustionReduce NOxElectrical controlInternal combustion piston enginesInjection pressureInjection port

A fuel injection system deliberately utilizing after injection so as to improve the engine combustion and reduce soot and NOx, wherein at least one operating valve is provided for operating a first injection port group and second injection port group, after injection is performed consecutively after main injection in a high load region, fuel is injected from the first injection port group and second injection port group at the time of main injection, fuel is injected from the first injection port group at the time of after injection, the actual injection pressure near the first injection port during the after injection period is higher than the actual injection pressure near the first injection port during the main injection period, the operating valve opens the first injection port group to start the injection, then the operating valve opens the second injection port group simultaneously or in a short time as well to perform the main injection, the operating valve closes the second injection port group, then performs the after injection, and the operating valve closes the first injection port group and ends the injection after the elapse of a time longer than simultaneously or a short time from after start of after injection.

Owner:TOYOTA JIDOSHA KK

Gas turbine combustor and gaseous fuel supply method for gas turbine combustor

ActiveUS20090223226A1Increase in cost and unstable combustionUnstable combustionContinuous combustion chamberTurbine/propulsion fuel flow conduitsFuel supplyGas turbines

A combustor includes two upstream parts of fuel supply system supplying gaseous fuels of two types having different heating values from each other, a three-way fuel transfer valve merging the two upstream parts of fuel supply system with each other, a plurality of gaseous fuel supply subsystems supplying a combustion chamber with the gaseous fuels supplied through the three-way fuel transfer valve and branched, and a plurality of burners injecting, corresponding to each of the gaseous fuel supply subsystems, the gaseous fuel supplied from the gaseous fuel supply subsystem into the combustion chamber.

Owner:MITSUBISHI POWER LTD

Method for operating a gas turbine group

InactiveUS7104071B2Increase powerIncrease mass flowEngine fuctionsGas turbine plantsCooling powerLimit value

A gas turbine group is provided with at least one cooling apparatus for cooling the working medium before and / or during the compression. The cooling power of the cooling apparatus can be adjusted by suitable means. A controller controls the cooling power of the cooling apparatus as a function of a control deviation in the useful power of the gas turbine group. The cooling controller interacts with other controllers of the gas turbine group in such a way that the gas turbine group is itself always operated at least close to its full load operating state. In this context, it is preferable for the inlet guide vane row of the compressor to be maximally open, and for the hot-gas temperature on entry into the turbines to be controlled so that it is constantly at an upper limit value.

Owner:ANSALDO ENERGIA IP UK LTD

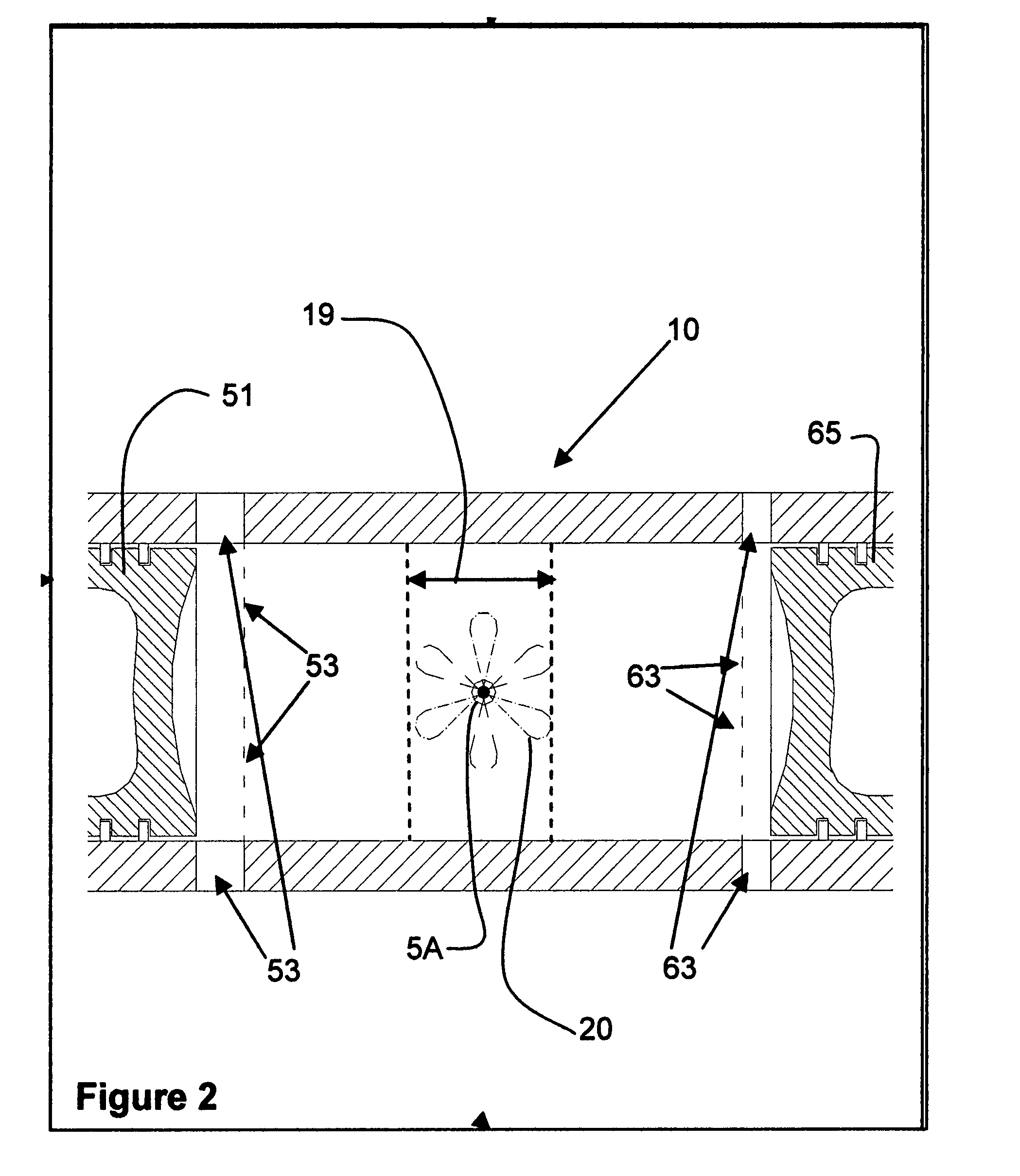

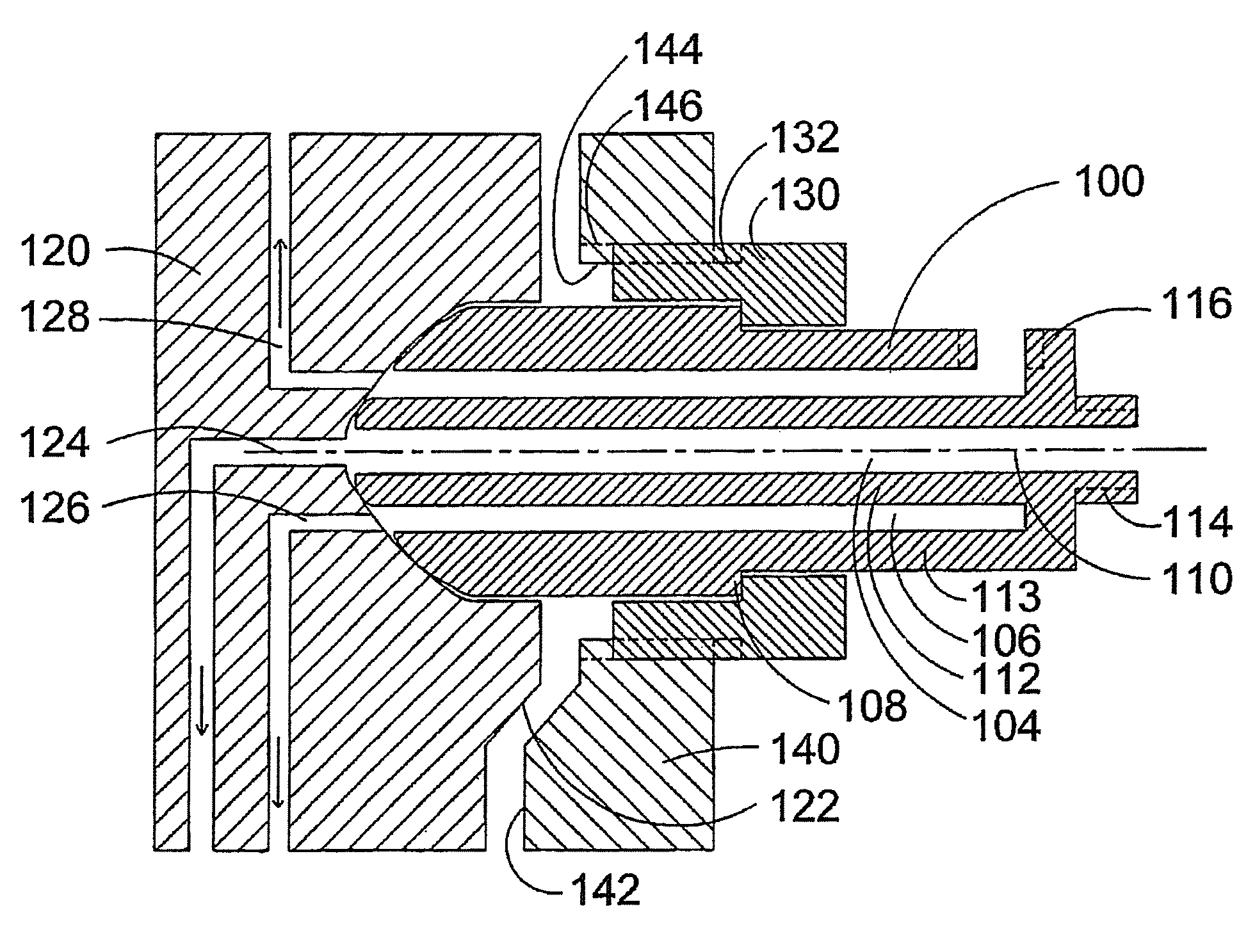

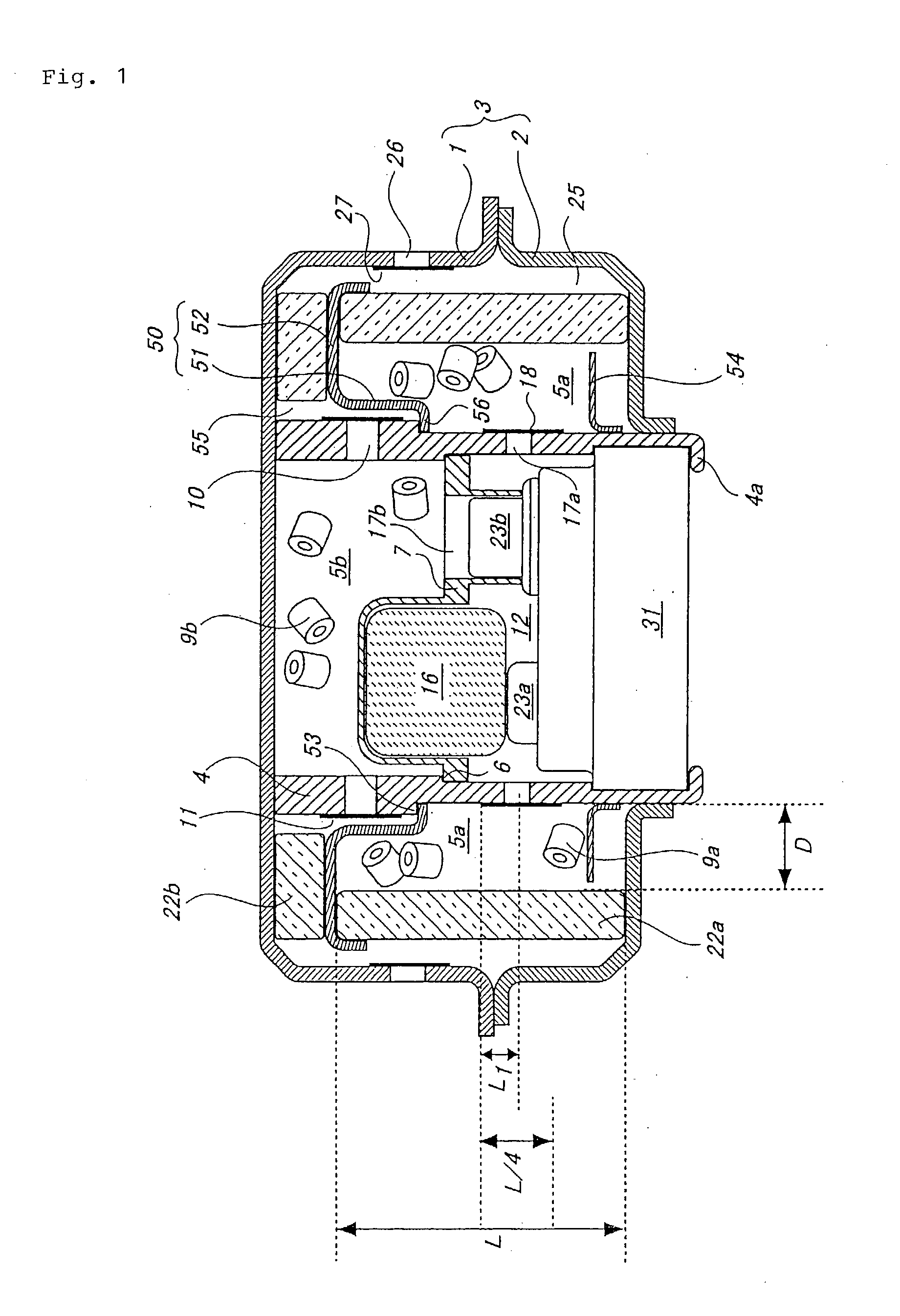

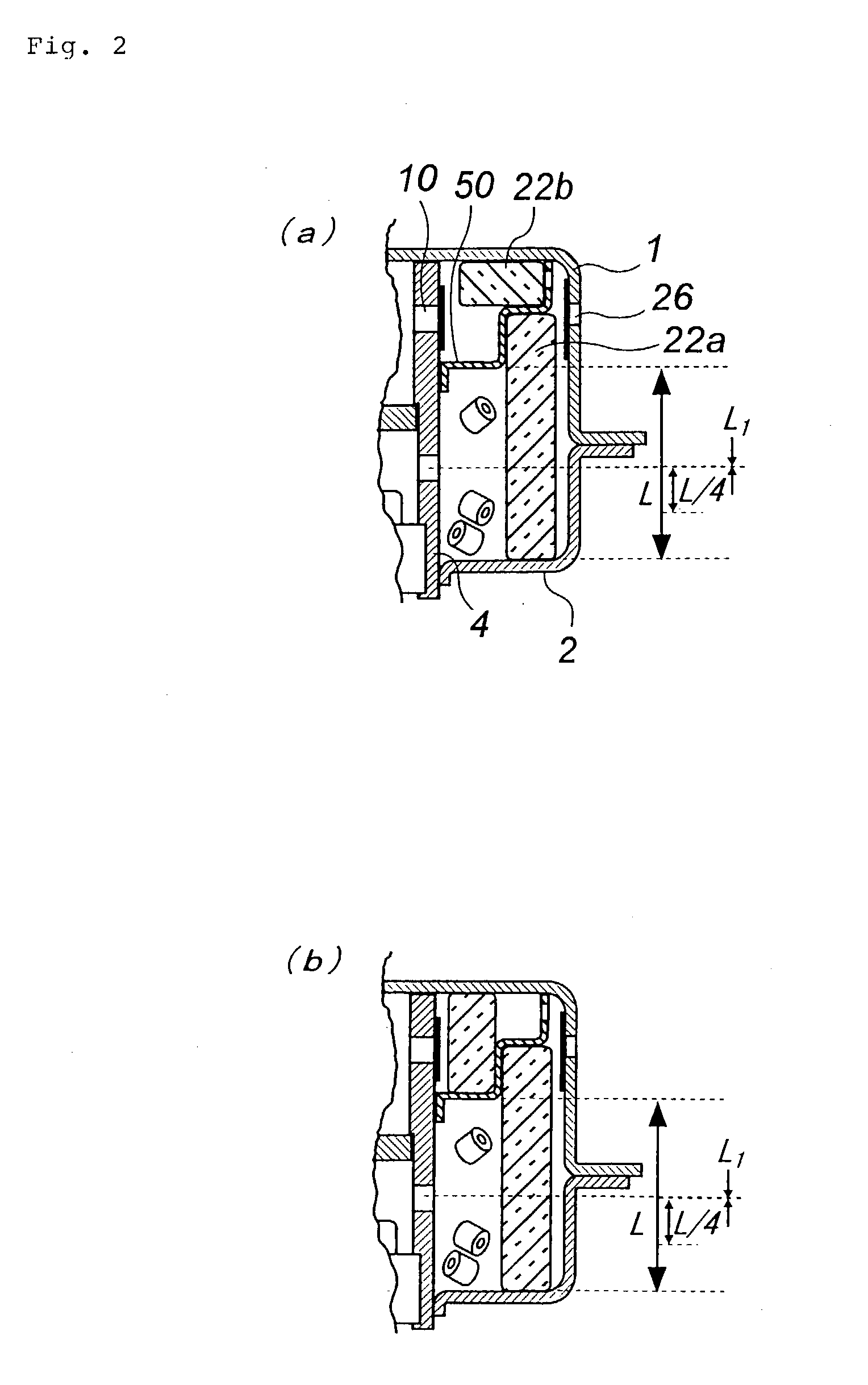

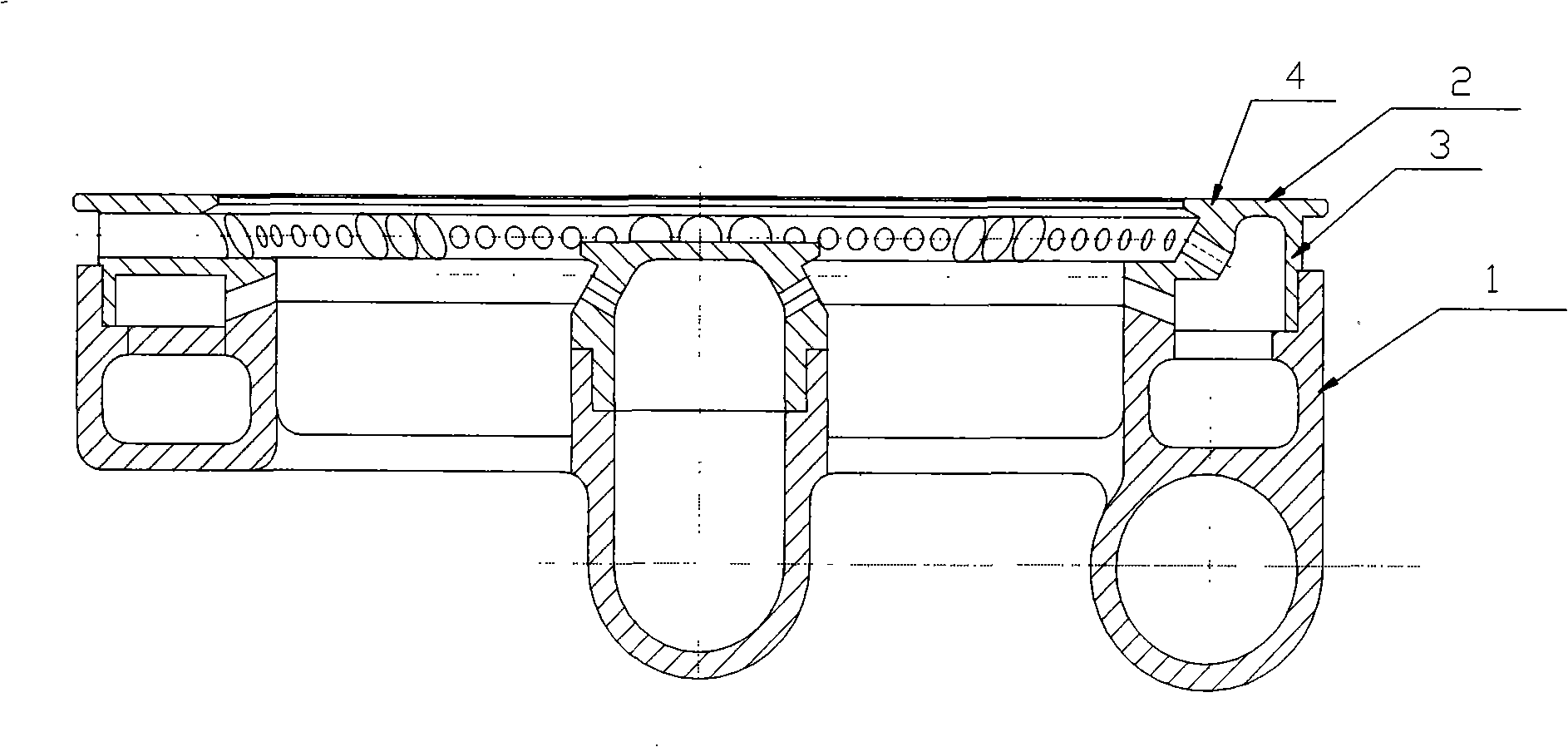

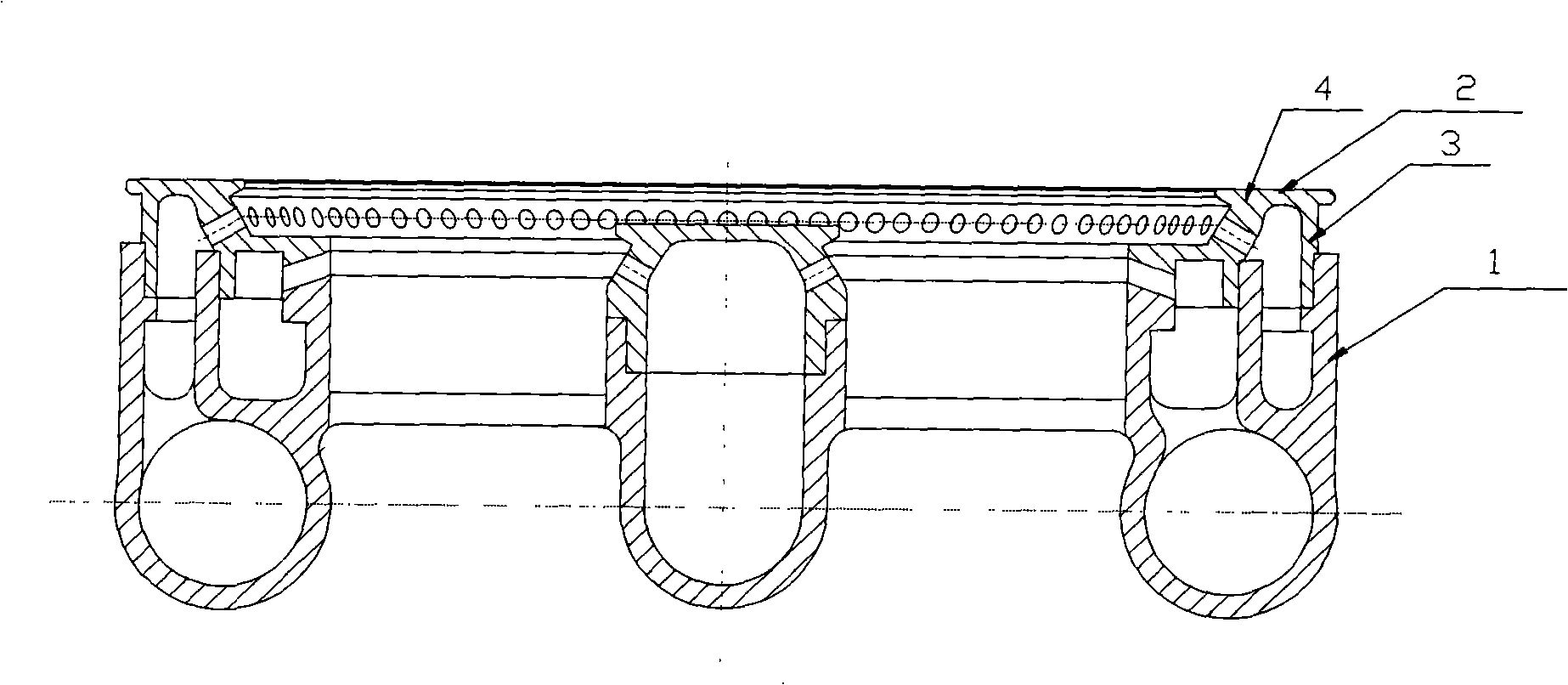

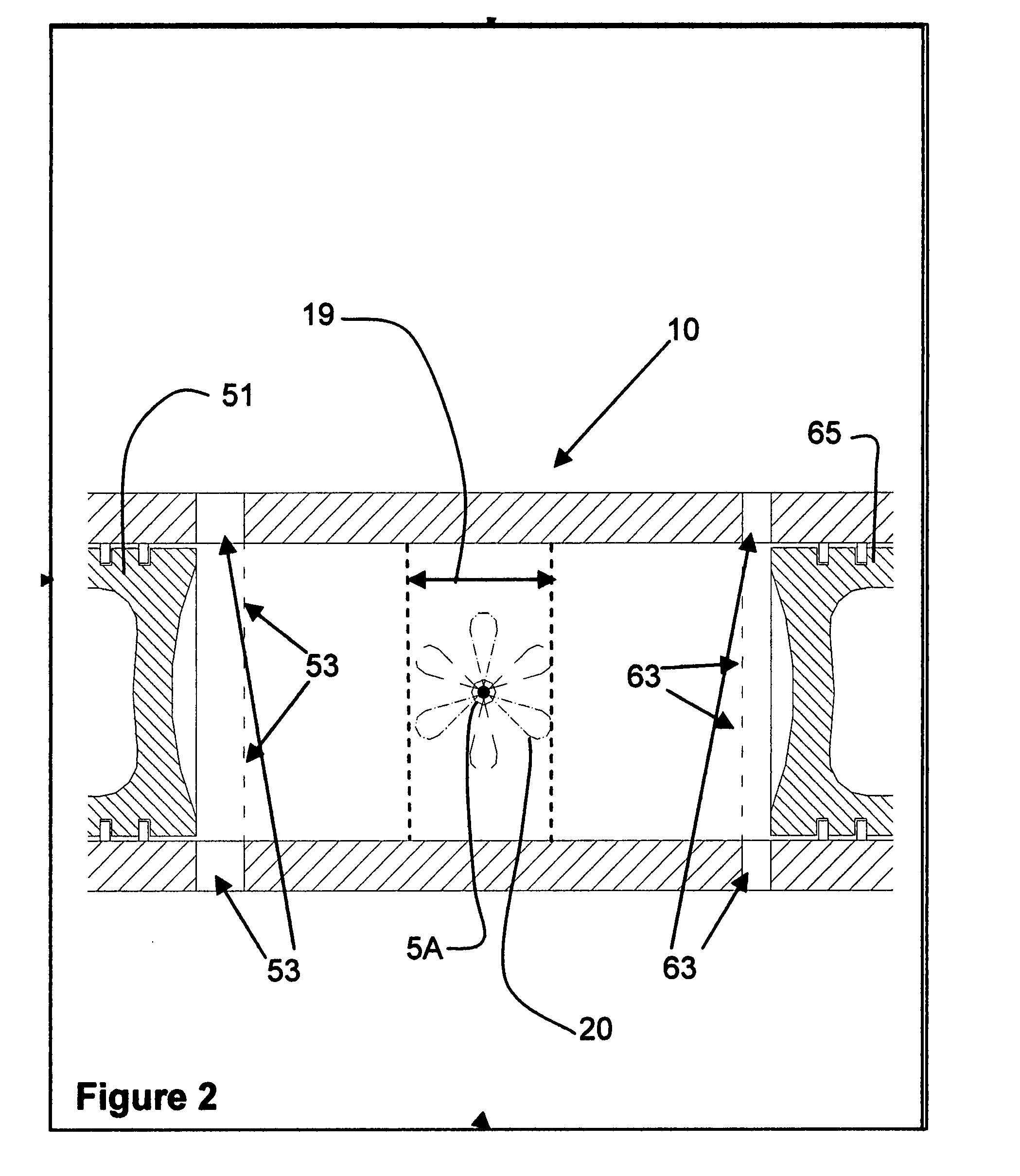

Gas generator for air bag and air bag device

InactiveUS20030132623A1Improve combustionEasy to ignitePedestrian/occupant safety arrangementCombustion chamberNuclear engineering

The present invention provides a gas generator in which ignition and combustion performance of a gas generating agent and operation performance are enhanced. An inner cylindrical member 4 is disposed in a cylindrical housing 3, an annular first combustion chamber 5a is provided radially in the outside of the inner cylindrical member 4, and, in the combustion chamber 5a, a ratio (D / L) of its radial average distance (D) to its axial average length (L) is adjusted to be in the range of 0.2 to 2.0. The invention provides a gas generator for an air bag capable of reducing a size of the gas generator and easily and reliably adjusting a capacity of a combustion chamber which accommodates the gas generating agent, and also provides a retainer for such a gas generator. The invention provides a retainer which changes a flow of a gas ejected from a through-hole of an inner cylindrical member provided in the housing and has a cylindrical portion for collecting fluid and semifluid combustion products included in the gas, and provides a gas generator for an air bag using such a retainer. The invention provides a gas generator for an air bag comprising, in a housing having a gas discharging port, a inner cylindrical member having a cylindrical peripheral wall, and two combustion chambers defined by the inner cylindrical member, in which a gas generating agent to be ignited for generating a working gas is charged in the respective combustion chambers, and working gases generated in the respective combustion chambers pass through different flow-paths and reach the gas discharging port. The present invention further provides a gas generator for an air bag in which, in a housing having a gas discharging port, an inner cylindrical member having a cylindrical peripheral wall is disposed, two combustion chambers are defined by the inner cylindrical member, a gas generating agent which is burnt to generate a working gas is charged in each of the combustion chambers, and working gases generated in the respective combustion chambers pass through different flow-paths to reach a coolant means.

Owner:DAICEL CHEM IND LTD

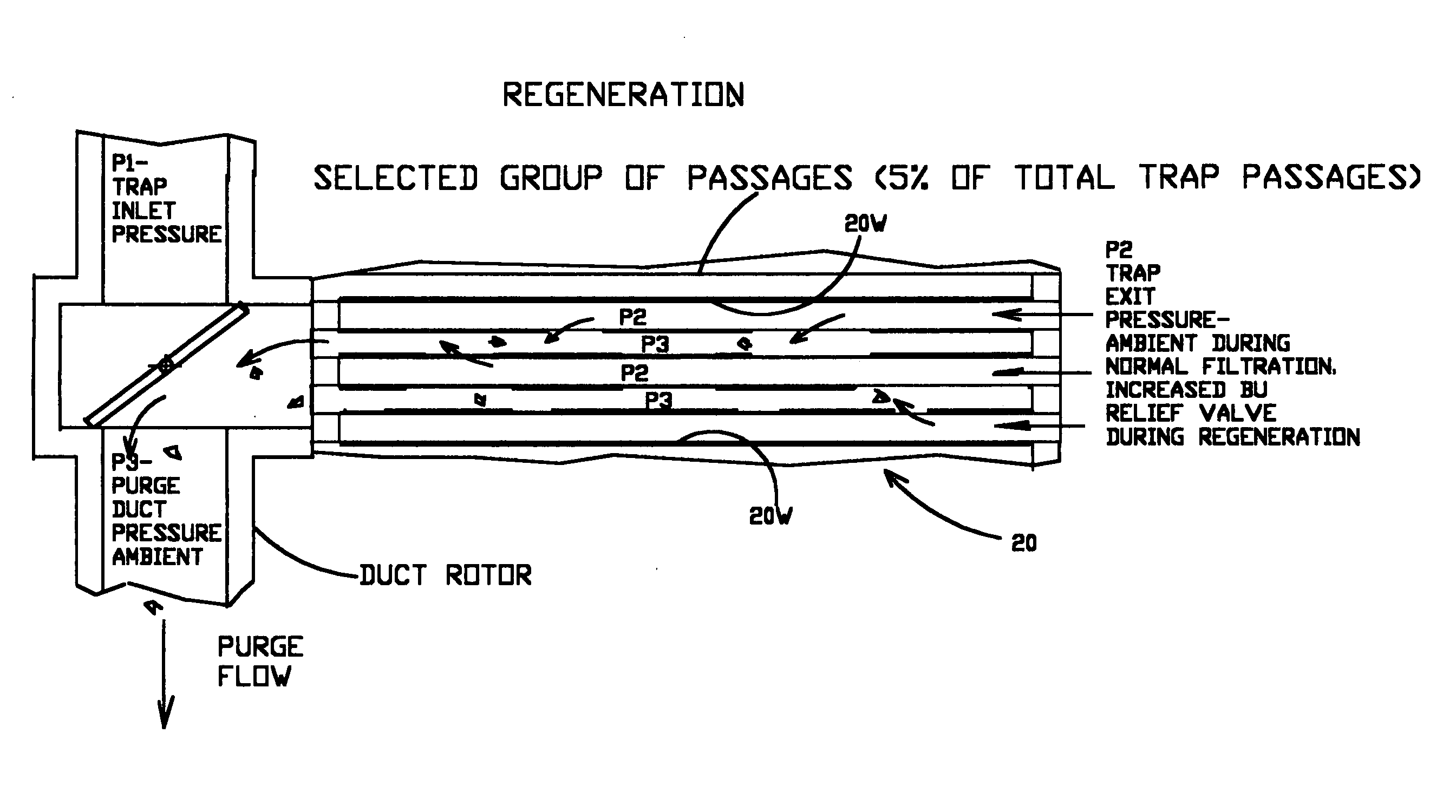

Dual Fuel Connector

ActiveUS20110108004A1Simple pipelineEasy to installInternal combustion piston enginesHollow article cleaningCylinder headEngineering

A dual fuel connector separately supplies two different fuels to fluidly isolated fuel passages within a fuel injection valve of an internal combustion engine. The dual fuel connector comprises a body with separate fluid connections to the first fuel inlet, the second fuel inlet, a first fuel rail and a second fuel rail. A first fuel passage within the body is in fluid communication with the first fuel rail and the first fuel inlet. A second fuel passage within the body is in fluid communication with the second fuel rail and the second fuel inlet, and wherein the first fuel passage is fluidly isolated from the second fuel passage. The dual fuel connector supplies two different fuels to a fuel injection valve, for engines that are not designed with a cylinder head that has internal bores that can serve as fuel rails.

Owner:WESTPORT FUEL SYST CANADA INC

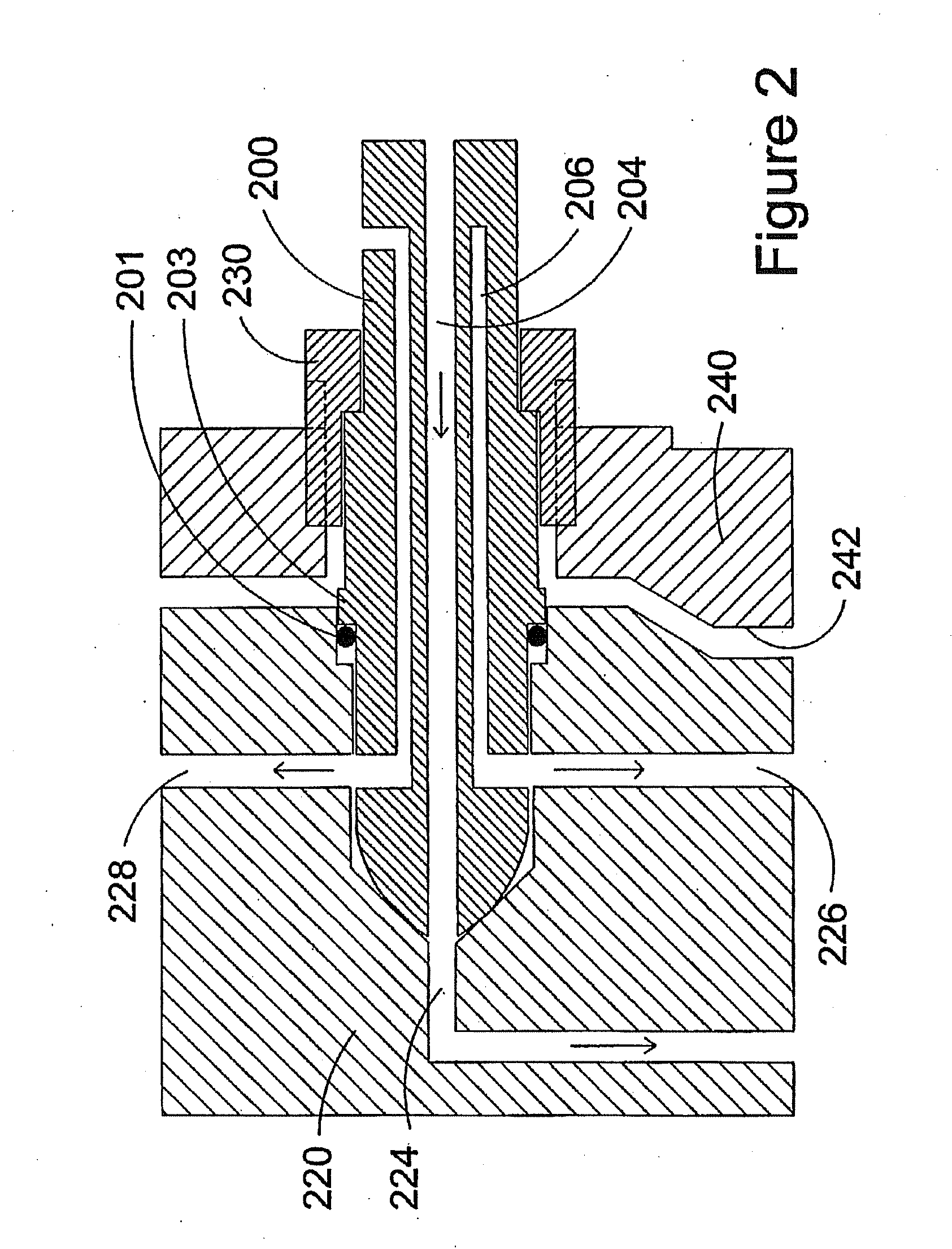

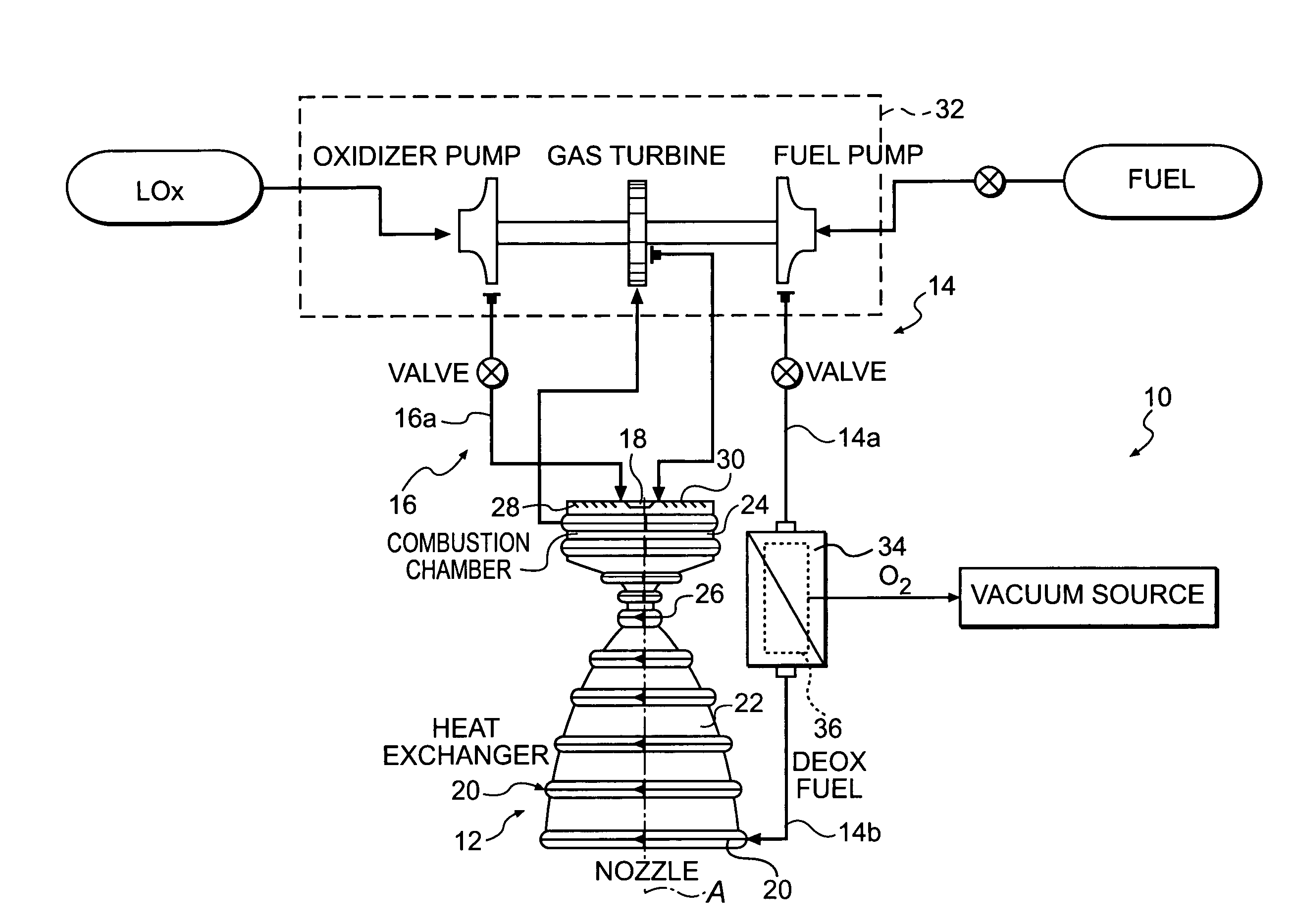

Hydrocarbon-fueled rocket engine with endothermic fuel cooling

InactiveUS20100257839A1Improve combustion stabilityImprove mixing efficiencyCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberKerosene

A rocket engine utilizes a kerosene-based fuel in a supercritical state which is catalytically converted to lighter hydrocarbons with heat from a thrust chamber assembly which operates as a heat exchanger. This process is facilitated by a fuel stabilization deoxygenator system which removes dissolved oxygen and / or by inerting the internal surfaces of the fuel-cooled combustion chamber wall passages by applying a zeolite-based catalyst coating to permit the fuel to be heated beyond normal temperature ranges. The supercritical kerosene-based fuel is passed through a turbine and injected into the combustion chamber to burn with the gaseous oxidizer. An increased mixing efficiency between the gaseous components results in an increase in combustion efficiency and increased stability of combustion.

Owner:UNITED TECH CORP

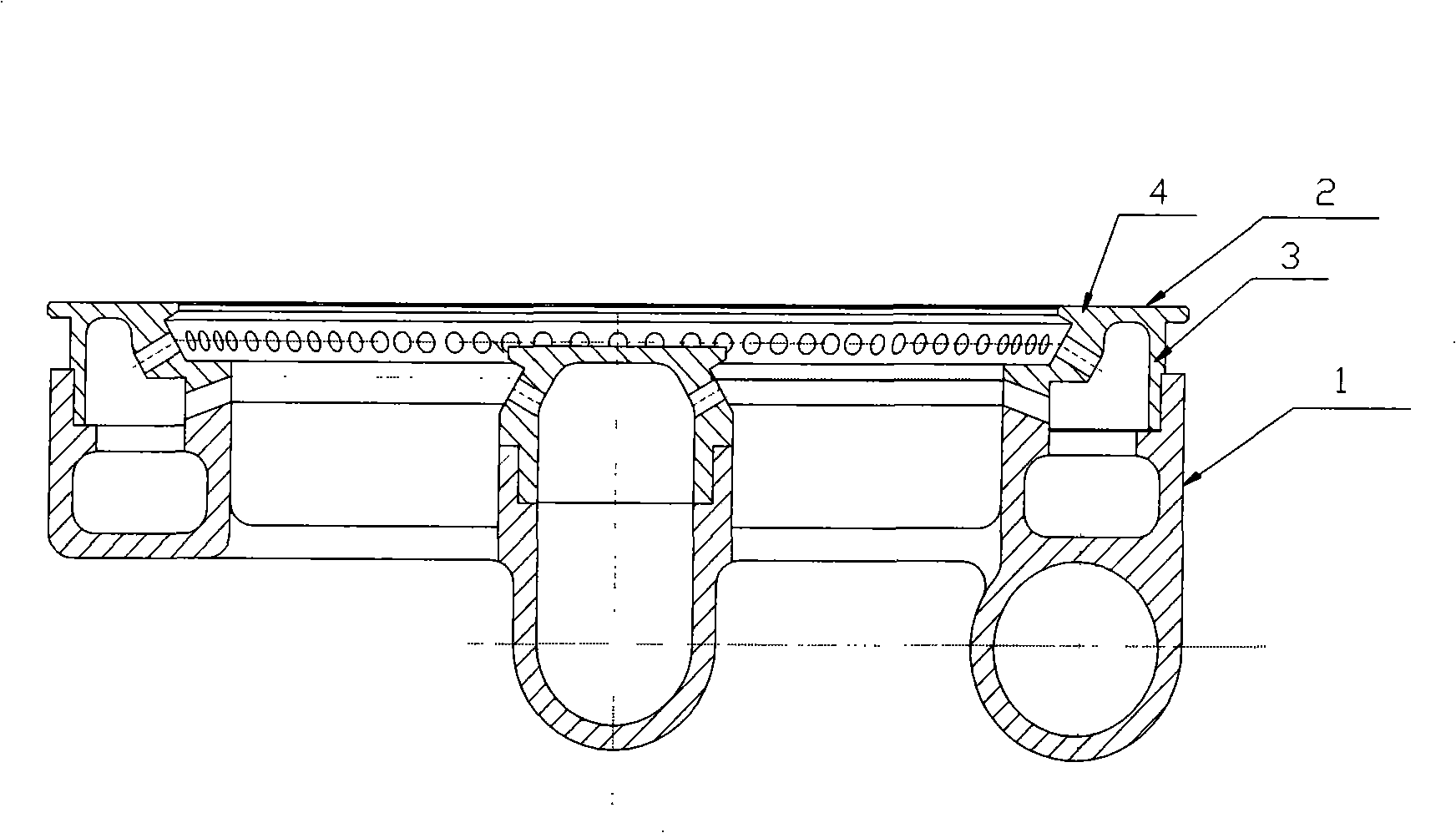

Multi-layer inner flame combustor

The invention discloses a multilayer inner flame combustor which consists of a combustor body and a distributor device, two fire orifice layers of an upper layer and a lower layer are arranged on the distributor device, and fire orifice outlets are arranged inwards; air channels are arranged or not arranged between fire orifices in the upper layer; a single inner chamber or two independent inner chambers are arranged; the two independent inner chambers are arranged so as to independently adjust flame in the upper and the lower layers; the air channels are arranged so as to lead air supplement to be more sufficient. The multilayer inner flame combustor is characterized by double-layered cyclonic flame, large heat transfer rate, high thermal efficiency, low CO and NOx content in flue gas and unblocked fire orifices, and the like, and can be widely used in inner flame gas cookers.

Owner:周建基 +1

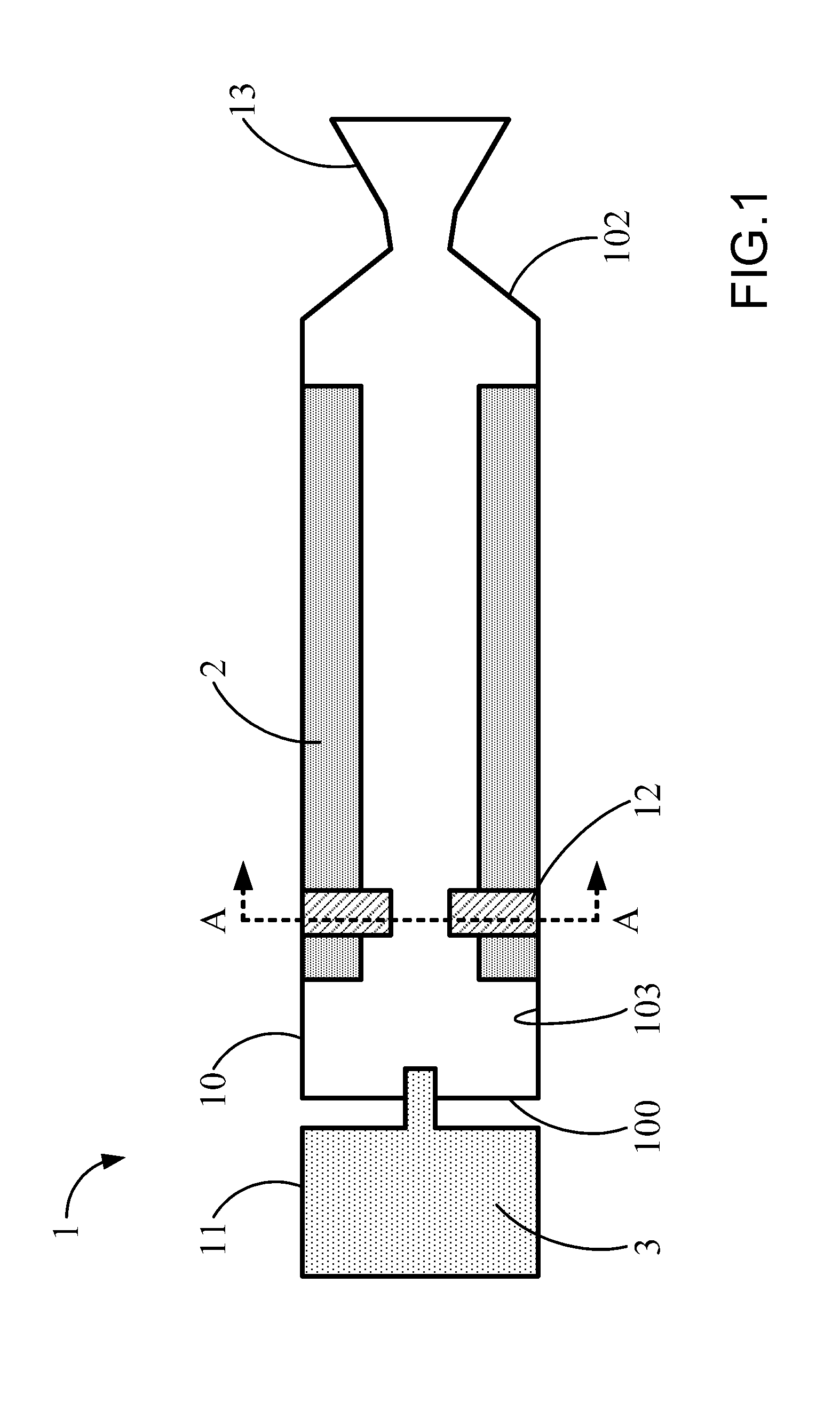

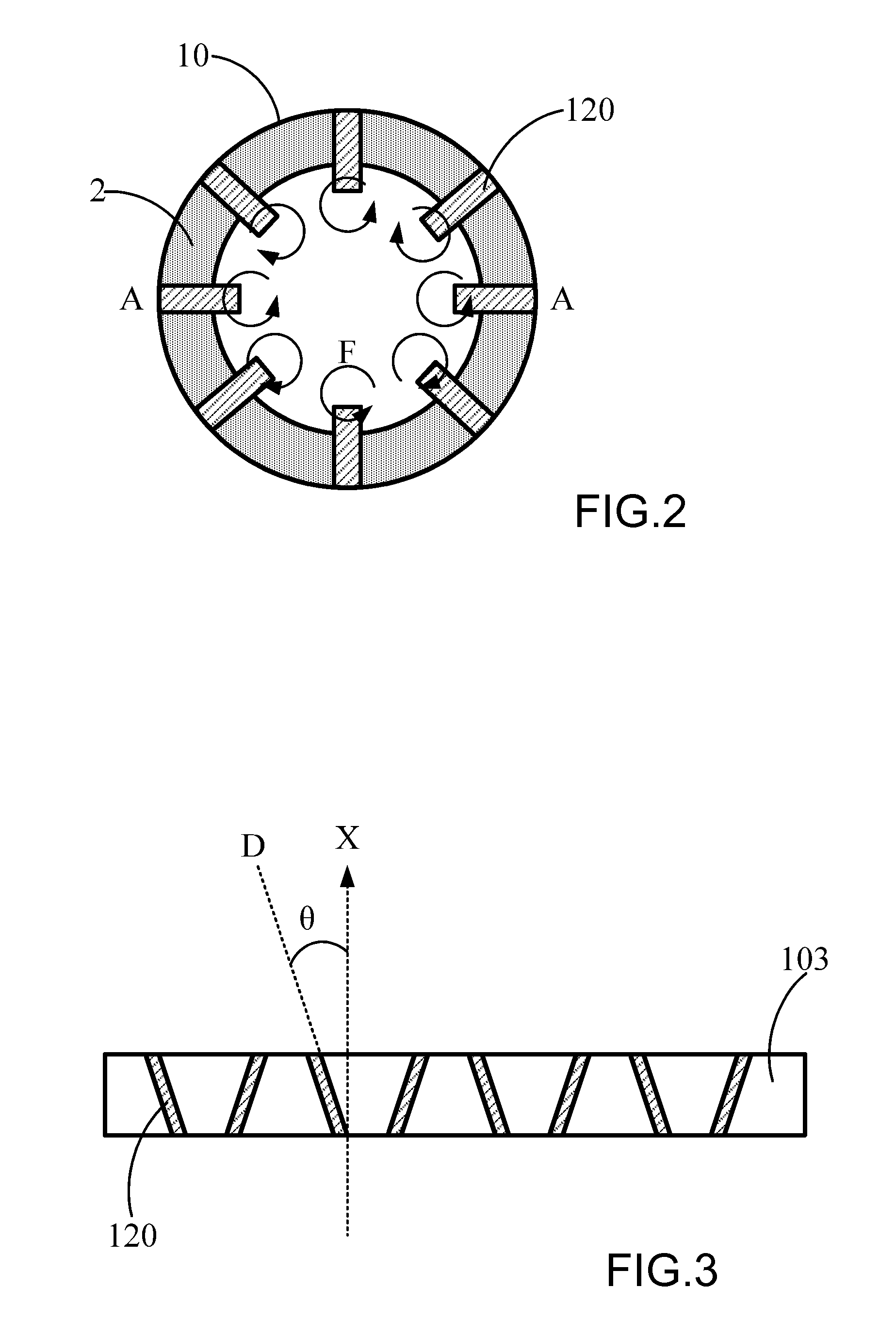

Motor

ActiveUS20110203256A1Enhance mix efficiency and combustion rateEnhance performanceRocket engine plantsInjectorCombustion chamber

The present invention provides a motor including a combustion chamber, an oxidizer injector, a vortex generators and a nozzle. The combustion chamber can be used to dispose a solid fuel, and the oxidizer injector is used to control the flow rate of an oxidizer and to inject the oxidizer into the combustion chamber. The vortex generators is disposed on the inner wall of the combustion chamber for generating eddies to enhance the mixing of the fuel and the oxidizer. Additionally, the nozzle is connected with the combustion chamber for exhausting the gas generated by the combustion of the propellants.

Owner:NAT APPLIED RES LAB

Spark ignition and fuel injector system for an internal combustion engine

InactiveUS20080006238A1High voltage potentialImprove ignition and combustionCombustion enginesFuel injection apparatusInjectorSpark-ignition engine

An improved spark ignition system for an internal combustion engine that includes a pair of electrodes disposed to extend from opposite sides and into a combustion chamber to form a spark gap between them that is central to the combustion chamber. Each electrode is integral with a conductive fuel delivery tube that contains a capillary passage and fuel outlet ports adjacent the electrode. The heat from combustion conducted into the electrodes and fuel delivery tubes is used to vaporize the fuel within the capillary passages before it exits the outlet ports as an atomized fog into the combustion chamber adjacent the spark gap. The vaporization of the fuel flowing in the capillary passages absorbs energy from the electrodes and thus performs a cooling effect on the electrodes. The spacing of the electrodes from opposite sides of the cylinder also allows a design that can utilize and increased spark gap to produce a larger spark across the gap.

Owner:ADVANCED PROPULSION TECH

Resonant combustion chamber and recycler for linear motors

InactiveUS6874452B2Improve combustionImprove efficiencyFree piston enginesNailing toolsCombustion chamberLinear motor

A combustion chamber system for a spark-ignited linear motor includes an open-ended primary combustion chamber located within a secondary combustion chamber. An unrestricted opening between the primary and secondary combustion chambers provides for more efficient scavenging of combustion byproducts. A compression wave trigged by a spark-ignited flame front within the primary combustion chamber is reflected within the secondary combustion. Upon return, the compression wave effectively closes the unrestricted opening of the primary combustion chamber by colliding with the flame front and forcing flame jets through smaller openings in the primary combustion chamber into the secondary combustion chamber for accelerating combustion within the secondary combustion chamber.

Owner:ADAMS JOSEPH S

Internal combustion engines with surcharging and supraignition systems

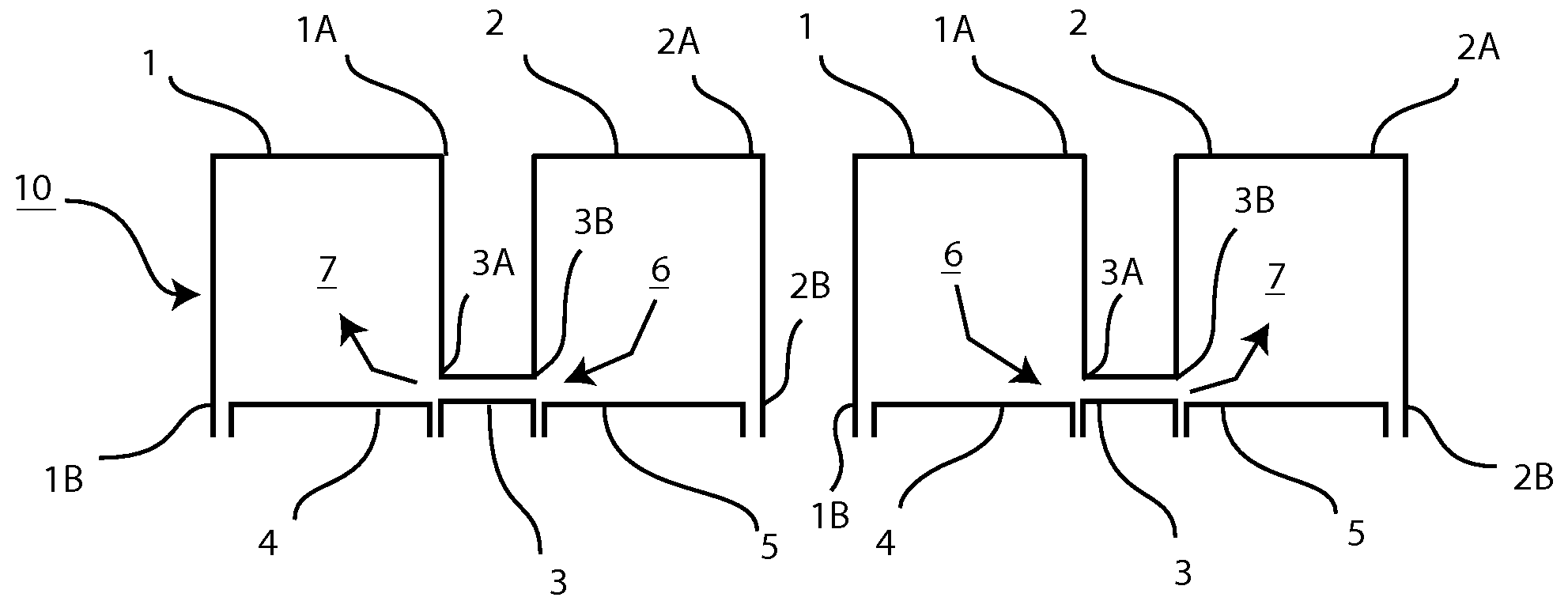

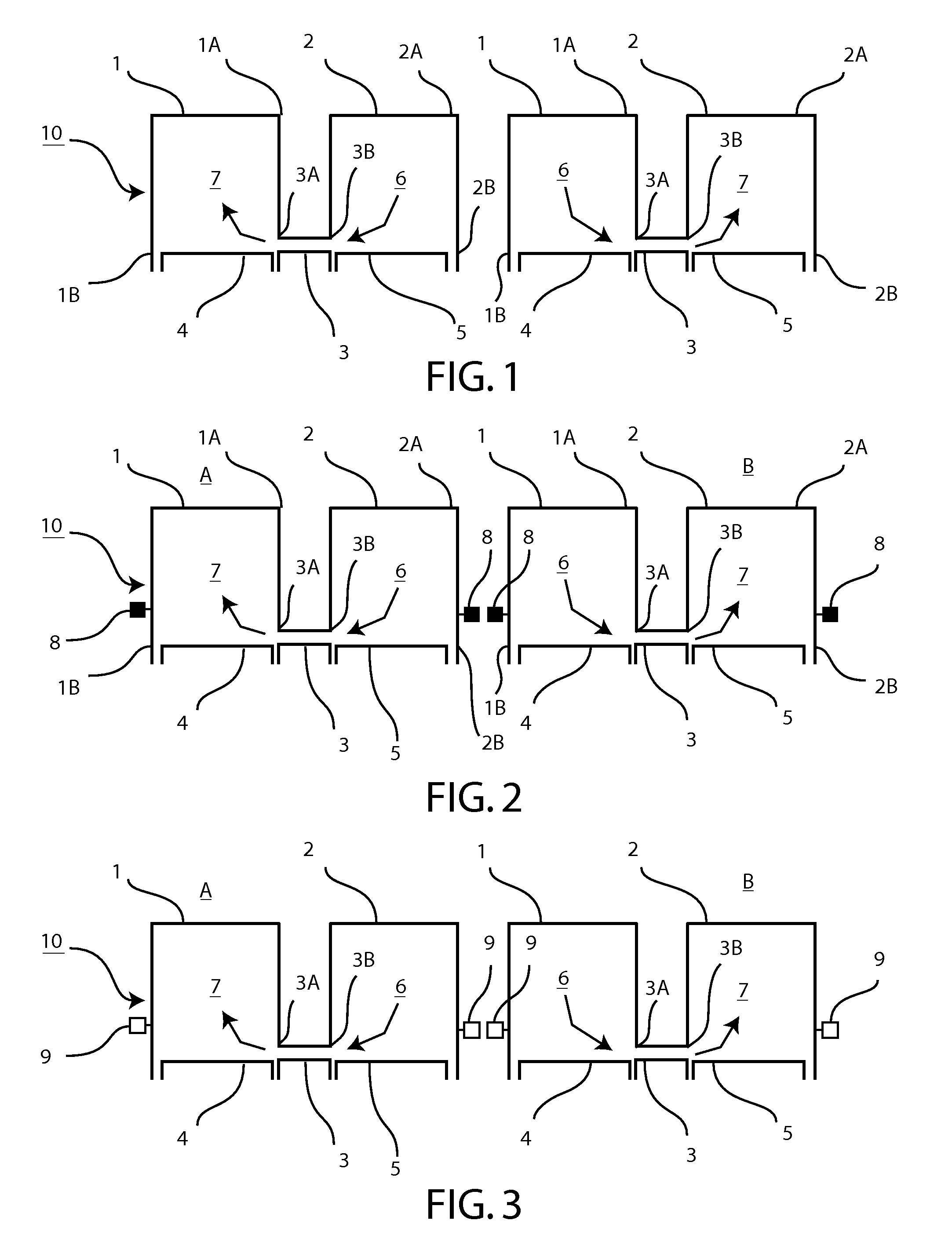

InactiveUS20090145398A1Improve combustionImprove efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelCombustionExternal combustion engine

An internal combustion engine includes first and second cylinder assemblies each to repeatedly carry out a combustion cycle including intake, compression, combustion, and exhaust processes. In a surcharging system of the invention, the first cylinder assembly is coupled to the second cylinder assembly in gaseous communication to apply a charge of exhaust gas produced from a first combustion cycle of the first cylinder assembly to a compression process of a second combustion cycle of the second cylinder assembly. In a supraignition system of the invention, the first cylinder assembly is coupled to the second cylinder assembly in gaseous communication to apply a charge of ignition gas produced from a first combustion cycle of the first cylinder assembly to a compression process of a second combustion cycle of the second cylinder assembly. Buffer vessels coupled in gaseous communication with corresponding cylinder assemblies are also used in surcharging and supraignition processes.

Owner:2014 LLC

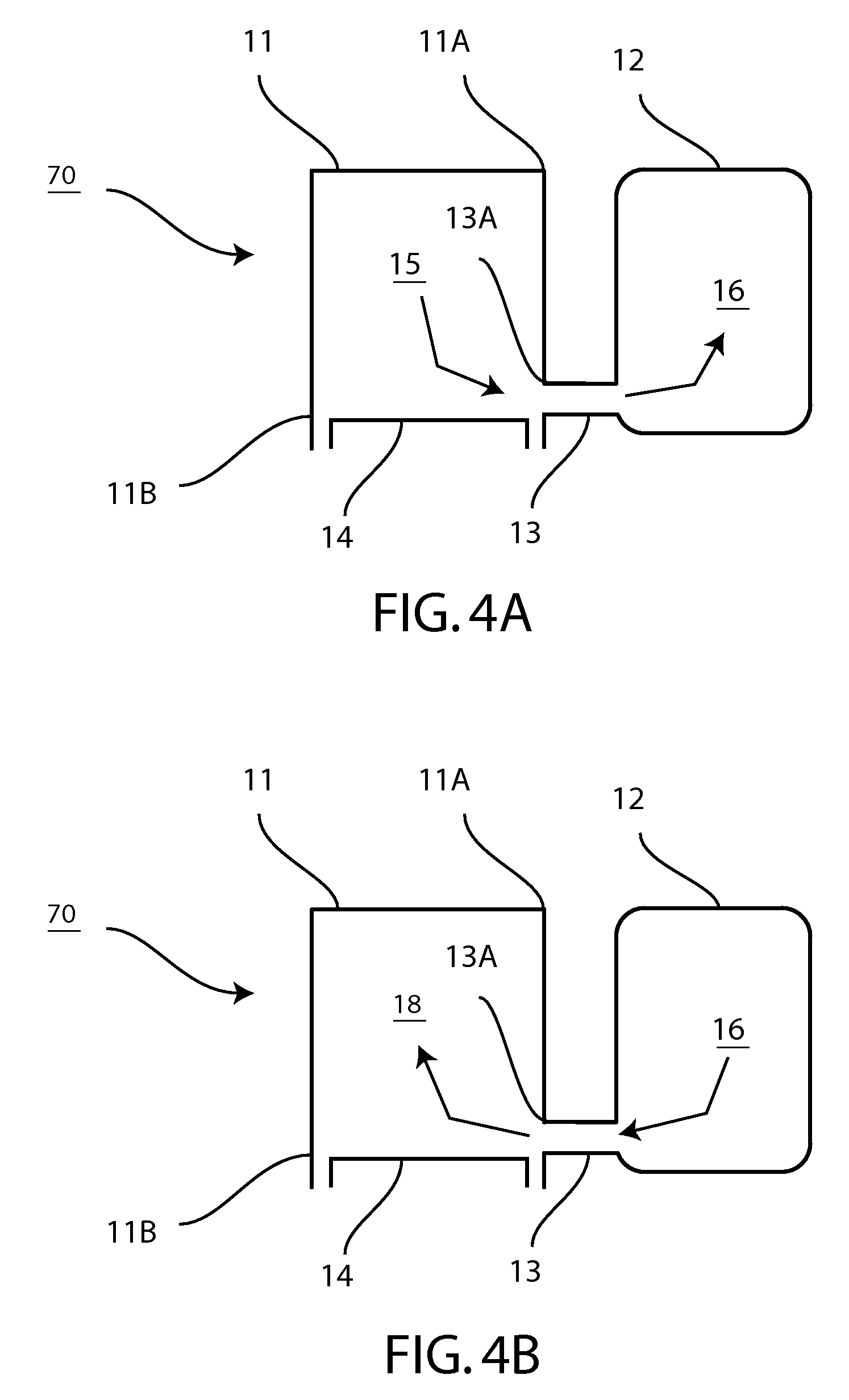

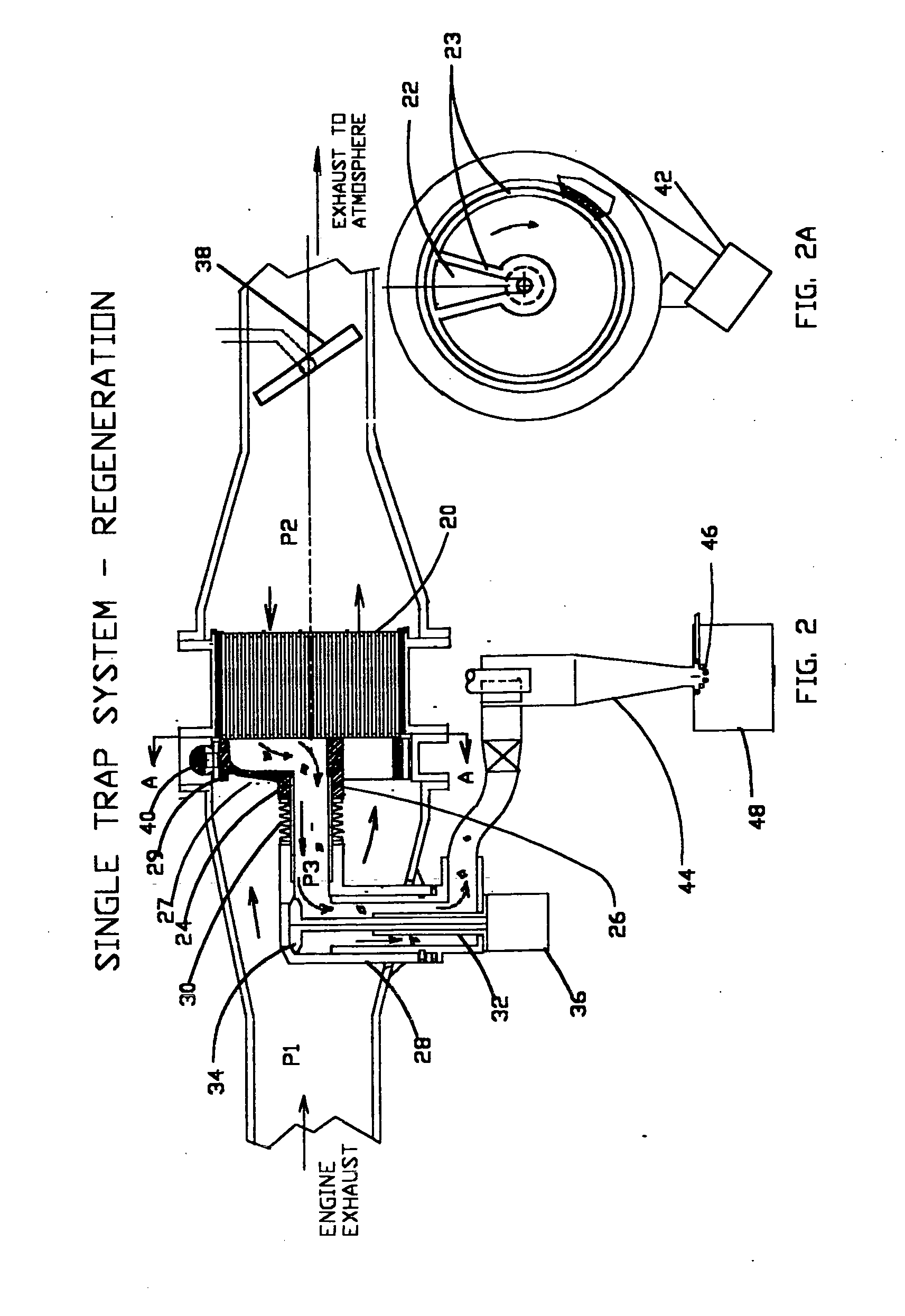

Particulate trap system and method

InactiveUS20100269488A1Effective dislodgingEfficient removalGas treatmentInternal combustion piston enginesParticulatesControl system

A particulate trap system for an exhaust system of an internal combustion engine includes a monolithic wall-flow particulate trap having a plurality of contiguous porous walls, and a remotely actuated relief valve downstream of said trap for periodically creating a reverse pressure throughout the exhaust system upstream of the relief valve and including said trap. A reversing apparatus periodically creates a reverse pressure drop across a portion of the contiguous porous walls of said trap to dislodge accumulated particulate and cause a portion of the filtered exhaust gas to flow back through said portion of the contiguous porous walls to remove particulate therefrom. A control system actuates the relief valve and the reversing apparatus. In one embodiment the system is utilized on a vehicle and the reversing apparatus includes a relief valve that is also operative as an exhaust break. Regeneration includes the steps of: creating a backpressure in the entire exhaust system from a location downstream of the trap; creating a reverse pressure drop across only a portion of the porous walls to dislodge accumulated particulate therefrom; and causing a portion of filtered exhaust gas to flow back through said portion of the porous walls to carry the dislodged particulate out of the trap.

Owner:ILLINOIS VALLEY HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com