Multi-layer inner flame combustor

A burner and inner ring technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of difficult heat flow to meet market demand, difficulty in air supplementation, structural restrictions, etc., to achieve large heat flow and meet Market demand, the effect of sufficient air supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

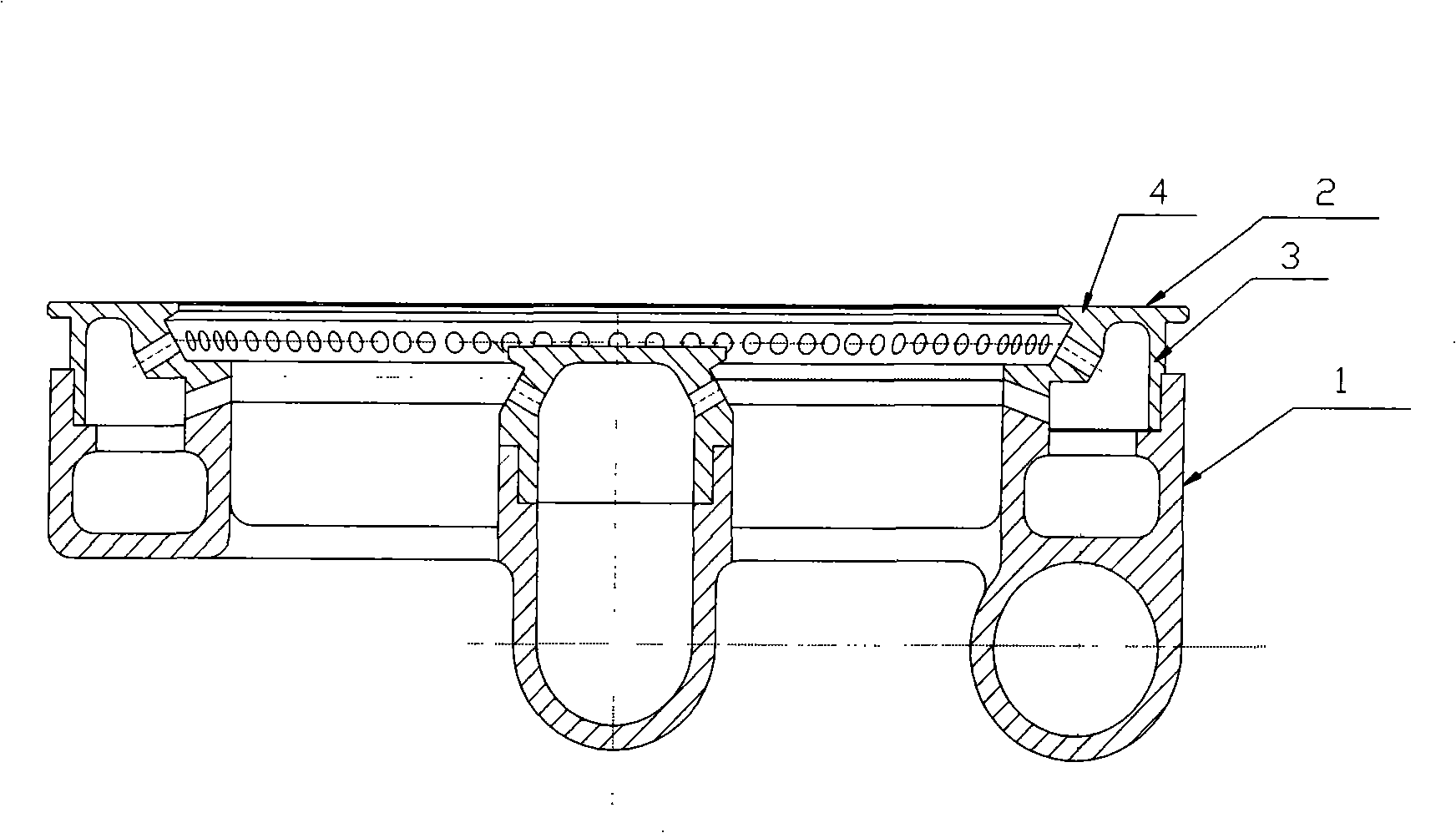

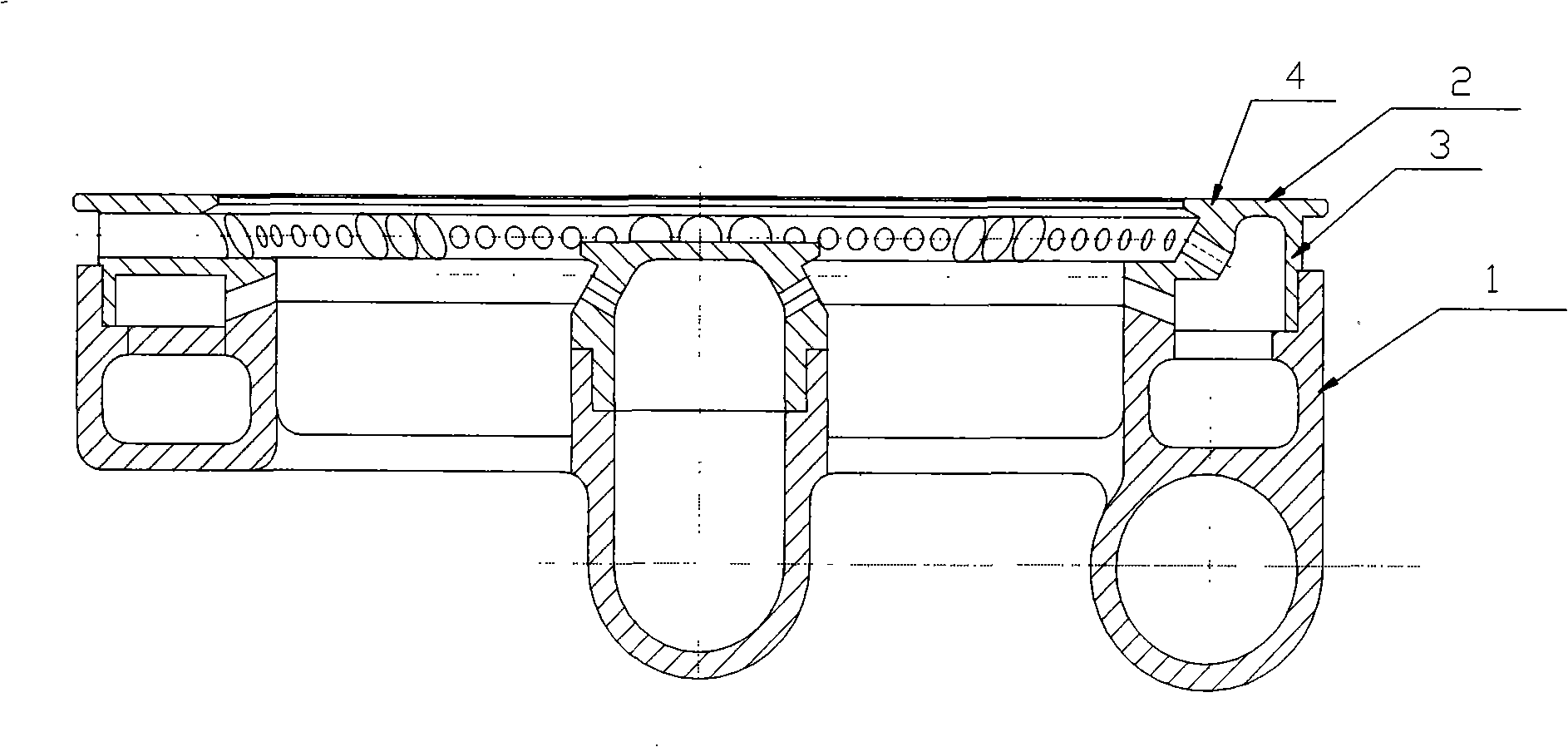

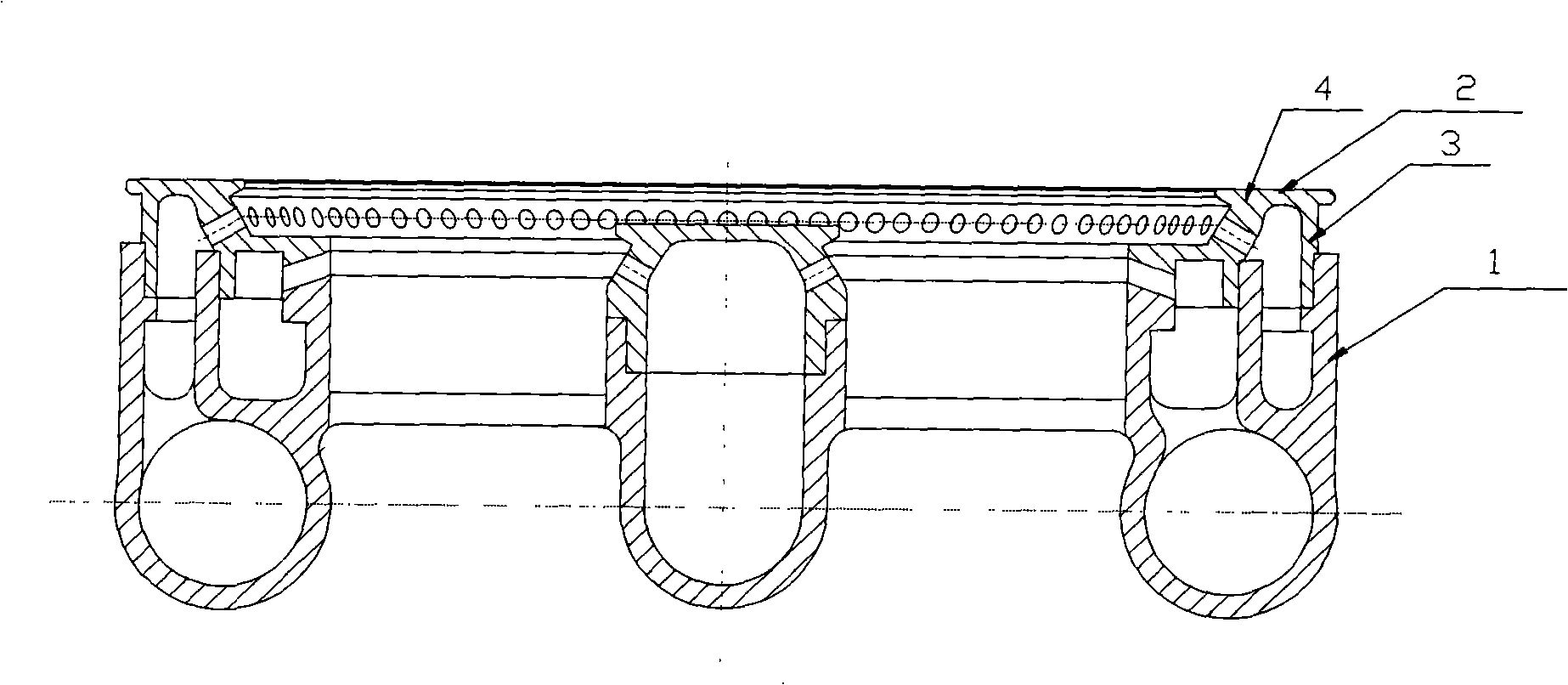

[0042](1) Implementation mode of the single-cavity fire distributor device without air passages between the fire holes on the upper layer

[0043] Implementation of the first exemplary embodiment:

[0044] On the fire distributor device 2, upper and lower layers of fire holes 301, 302 are provided along the circumference of the inner ring, and the fire hole outlet direction is inward; The height direction of the conical surface sections is single row or double row or multiple rows distributed along the circumference, and the section of the fire hole is circular; the lower fire hole is arranged at the bottom of the cylindrical section 304 of the inner ring of the main body of the fire distributor; the section of the fire hole is trapezoidal; The layer fire hole communicates with the internal cavity 305 of the main body of the fire distributor, and the conical surface section of the inner ring of the main body of the fire distributor is directly connected with the cylindrical se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com