Waste incineration device

A waste incineration and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as polluted air, insufficient waste combustion, and laborious and time-consuming problems, so as to improve efficiency, reduce manual labor intensity, and reduce waste. The effect of small environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

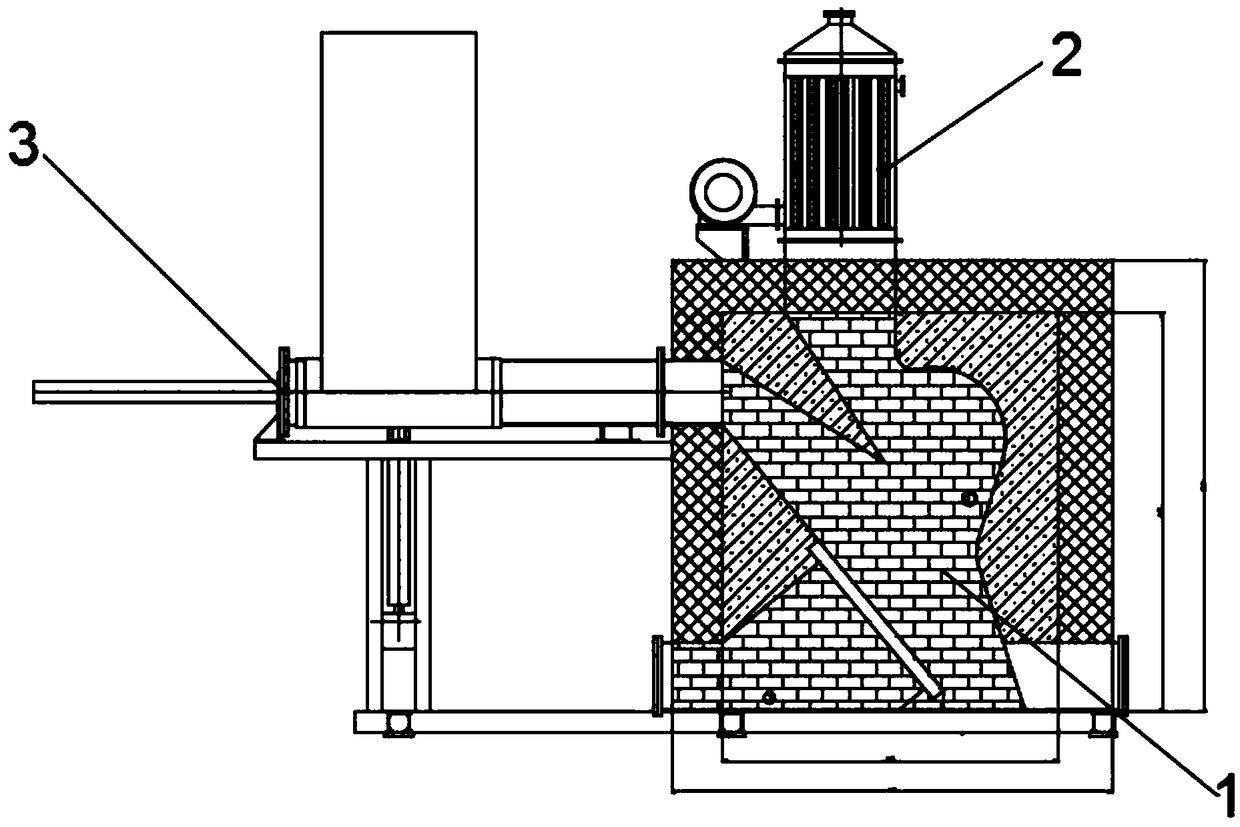

[0039] Such as figure 1 As shown, a garbage incinerator includes an incinerator 1, a feeding system 3 and a heat exchanger 2, the feeding system 3 is arranged on one side of the incinerator 1, and the discharge of the feeding system 3 The mouth is docked with the feed port 105 of the incinerator 1, the heat exchanger 2 is arranged on the flue gas port 107 at the upper end of the incinerator 1, the inlet at the lower end of the heat exchanger 2 is connected to the flue gas port 107 docking and fixing;

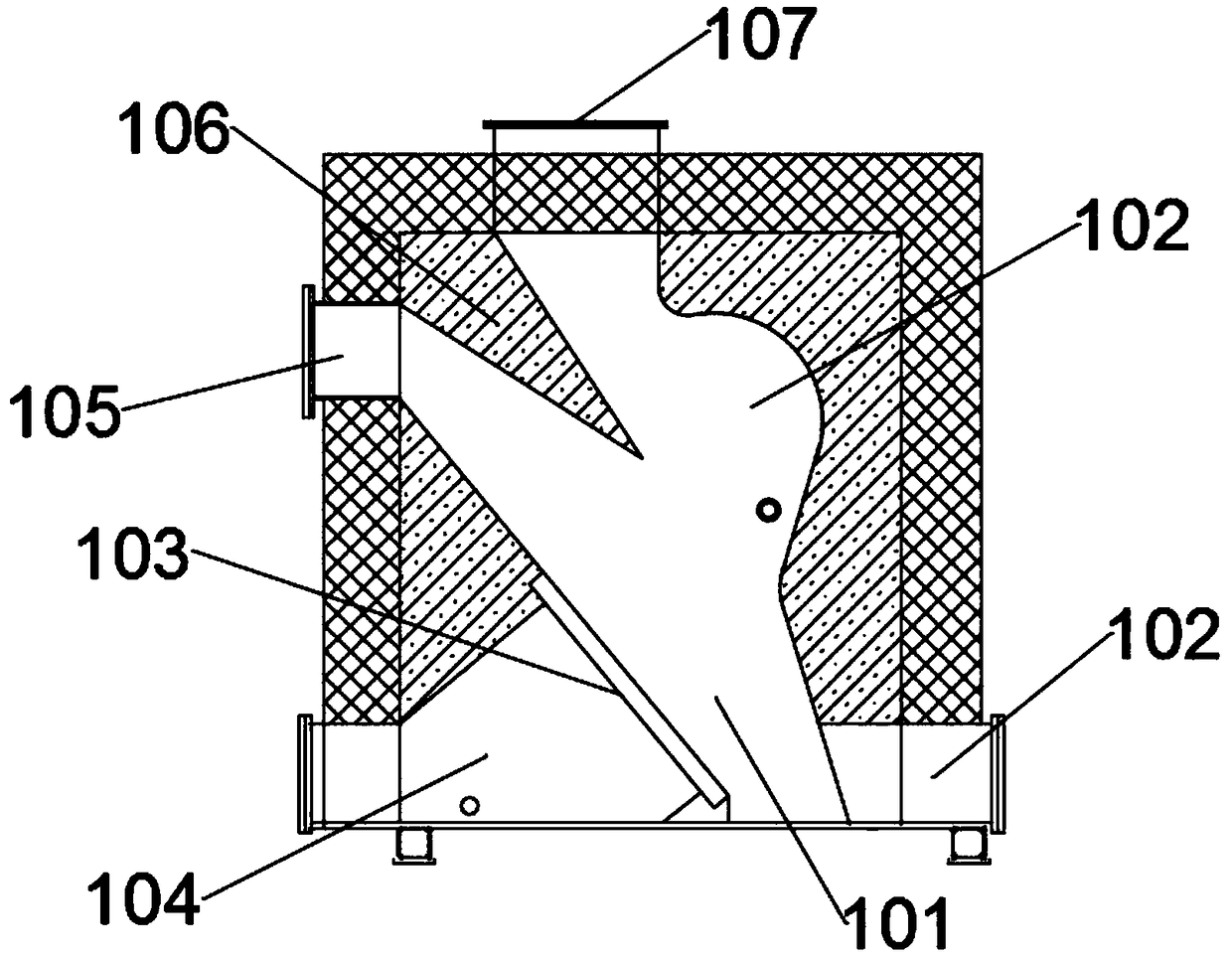

[0040] Such as figure 2As shown, the incinerator 1 includes a furnace body, and the furnace body includes a first combustion chamber 101 and a second combustion chamber 102 from bottom to top. The ash bin 104 is connected, the other side of the first combustion chamber 101 is provided with a slag removal port 108, the second combustion chamber 102 is a hemispherical cavity, and the top of the grate 103 is provided with the first combustion chamber 101 The feed port 105 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com