A skid-mounted water injection boiler

A skid-mounted boiler technology, applied in water heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of small effective coefficient of radiation heat transfer, low-temperature corrosion of the heating surface at the tail, and high requirements for furnace insulation materials. It achieves the effects of convenient transportation and on-site installation, avoiding low-temperature corrosion, and compact structure and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

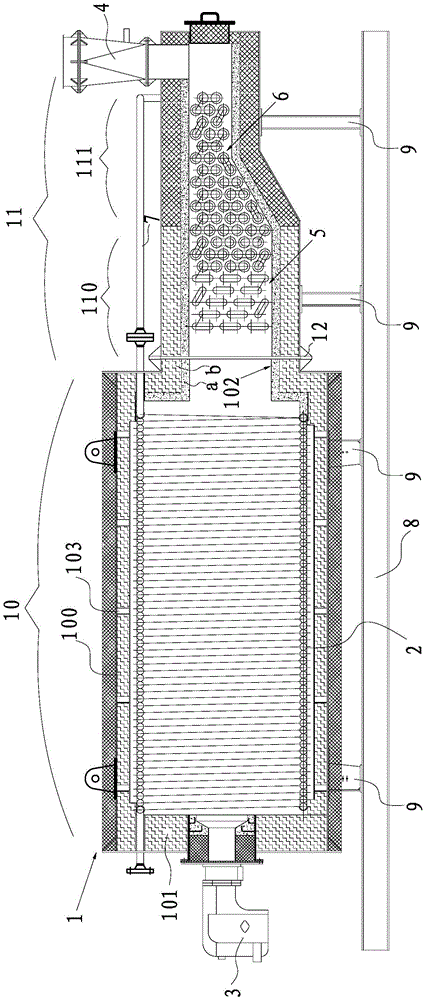

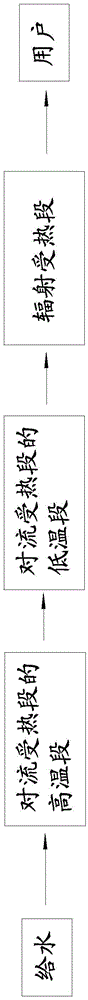

[0020] Such as figure 1 and figure 2 As shown, the skid-mounted water injection boiler provided in this example includes a furnace body 1 extending along the horizontal direction, a furnace tube 2 arranged inside the furnace body 1, and is arranged at one end of the furnace body 1 and communicates with the furnace body 1. The burner 3, the chimney 4 that is arranged on the other end of body of heater 1. Wherein the furnace body 1 includes a radiation heating section 10 and a convection heating section 11, the furnace tube 2 is a spiral coil and extends along the length direction of the furnace body 1 and is located in the radiation heating section 10, the chimney 4 is located at the tail of the convection heating section 11, and the water injection The boiler also includes a preheating tube 5 located in the convection heating section 11 for preheating the water or medium injected into the furnace tube to raise the temperature, and is arranged on the right side of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com