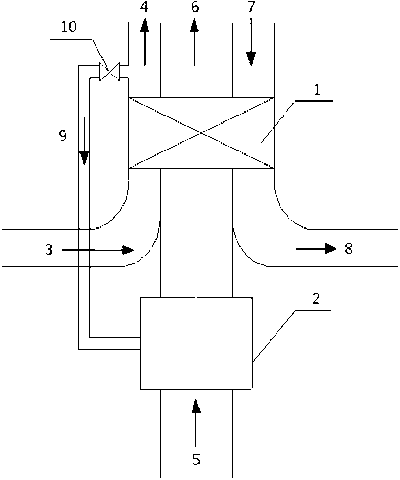

System for increasing the temperature of secondary air at inlet of air pre-heater

An air preheater and secondary air technology, applied in the field of boiler smoke exhaust, achieves the effects of simple structure, improved air temperature, and convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Such as figure 1 As shown, a system for increasing the air temperature of the secondary air at the inlet of the air preheater. The bottom of the air preheater 1 is provided with a primary air inlet pipe 3, a secondary air inlet pipe 5 and a flue gas outlet 8. The air preheater The top of 1 is provided with a primary air outlet pipe 4, a secondary air outlet pipe 6 and a flue gas inlet 7, and a mixer 2 is arranged in the middle of the secondary air inlet pipe 5 of the air preheater 1. The outlet of the air outlet pipe 4 is connected with a hot air circulation pipe 9, the hot air circulation pipe 9 is connected to the mixer 2, and the hot air from the primary air outlet pipe 4 is introduced into the mixer 2, and the two The cold air in the secondary air inlet pipe 5 is fully mixed to obtain mixed air with a temperature higher than that of the cold air in the secondary air inlet pipe 5, and then the mixed air continues to enter the air preheater 1 through the secondary air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com