Circulating fluidized bed boiler unit for high efficiency combustion of biomass and recovery of waste heat

A circulating fluidized bed and waste heat recovery technology, applied in the field of boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

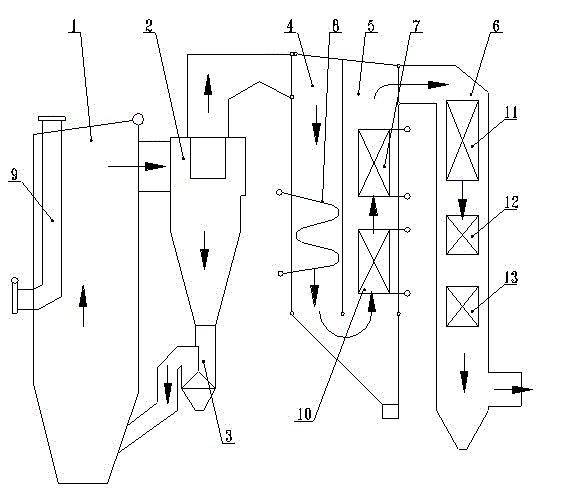

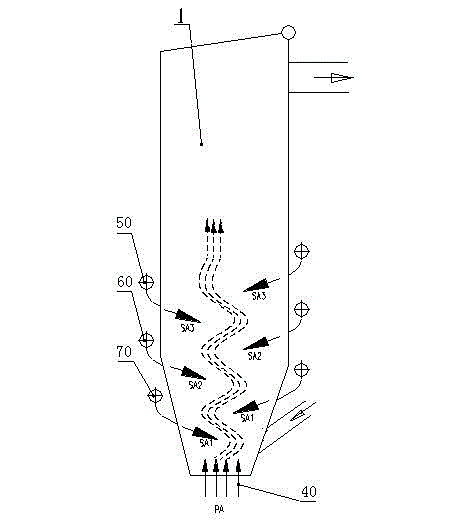

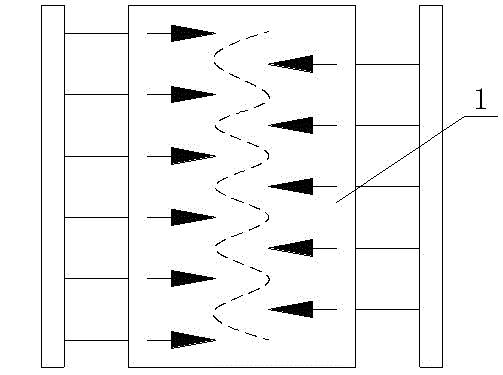

[0044] The technical solution of the present invention will be further specifically described below through the embodiments in conjunction with the accompanying drawings.

[0045] like figure 1 , 2 , A circulating fluidized bed boiler device for efficient biomass fuel combustion and waste heat recovery shown in 3 and 4 has a furnace, and the furnace adopts a large cross-sectional structure that is 50% larger than a conventional fluidized bed boiler to ensure that the furnace The rising speed of the flue gas in the furnace is about 3.2~3.8 m / s; prolonging the residence time of the fuel particles in the furnace is conducive to improving the primary combustion rate of the fuel, thereby improving the combustion efficiency accordingly, and increasing the circulation of materials in the furnace A large amount of materials can effectively suppress the high temperature generated by the rapid combustion of volatile components; the lower combustion chamber of the furnace is laid with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com