Air preheater and quartered-bin ventilation method thereof

An air preheater and ventilation method technology, applied in the field of machinery industry, can solve the problems of low wall temperature of metal partitions, easy formation of ash blocking, low temperature corrosion of metal partitions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

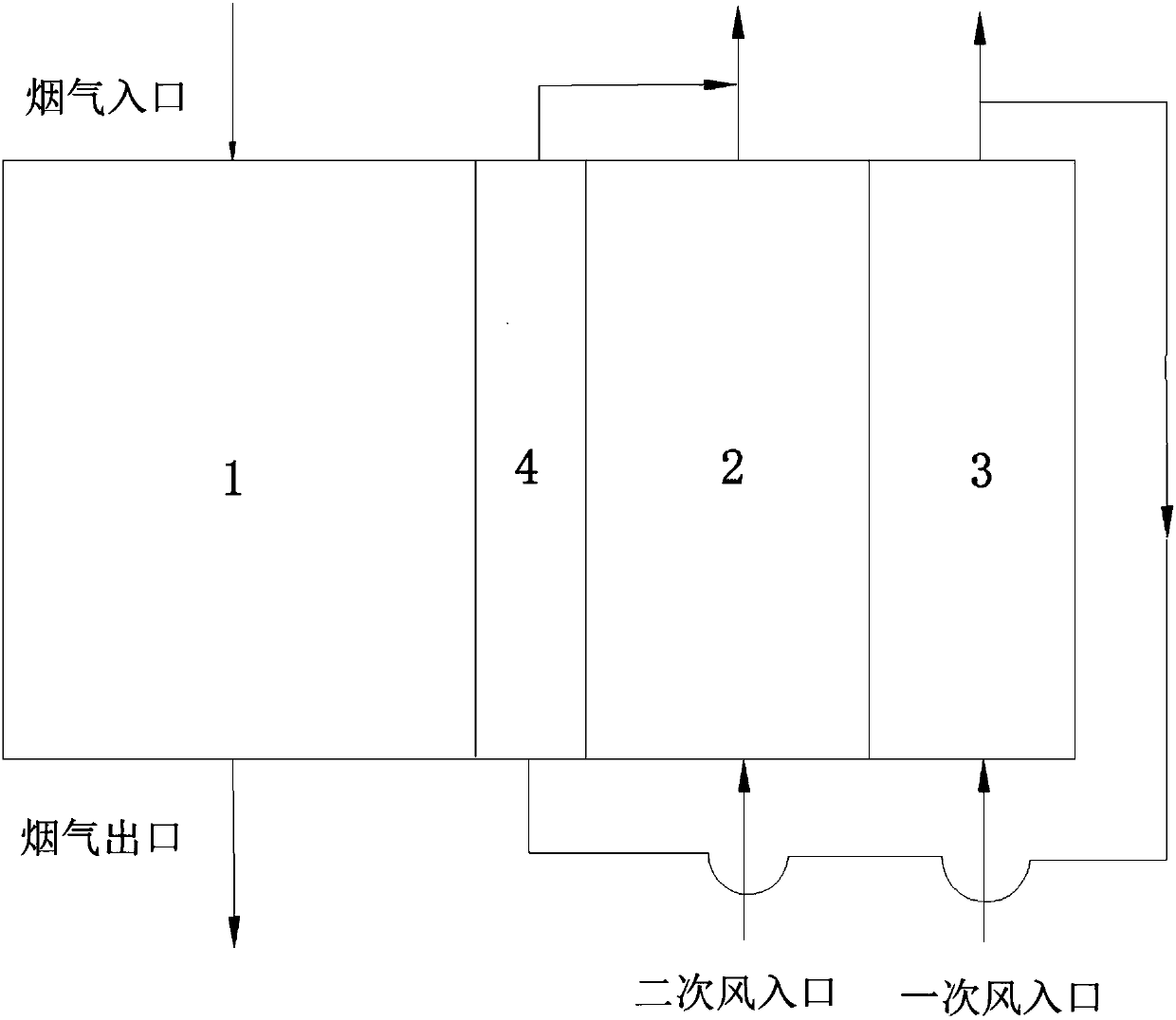

[0031] The embodiment of the present invention discloses a four-part bin ventilation method for an air preheater, which introduces the hot primary air at the outlet of the primary air bin into the hot primary air bin, which can significantly increase the temperature in the secondary air bin and improve the metal insulation. The temperature of the plate can reduce the low-temperature corrosion of the air preheater and prevent the air preheater from clogging. The embodiment of the present invention also discloses an air preheater, which has a hot primary air bin, which is used to introduce the hot primary air heated by the primary air bin for circulation, which can significantly increase the temperature in the secondary air bin and increase the metal The temperature of the partition can reduce the low-temperature corrosion of the air preheater and prevent the air preheater from clogging.

[0032] The technical solutions in the embodiments of the present invention will be clearly an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com