Device for recovering hot air of dry type slag removal machine and reducing disorganized air leakage of bottom of hearth and application thereof

A slag remover and unorganized technology, applied in the field of electric power equipment, can solve the problems of increased desuperheater and reheater desuperheating water volume, reduced secondary air volume, high air leakage rate at the bottom of the furnace, and reduced NOx emission concentration, The effect of reducing the amount of desuperheating water and obvious comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

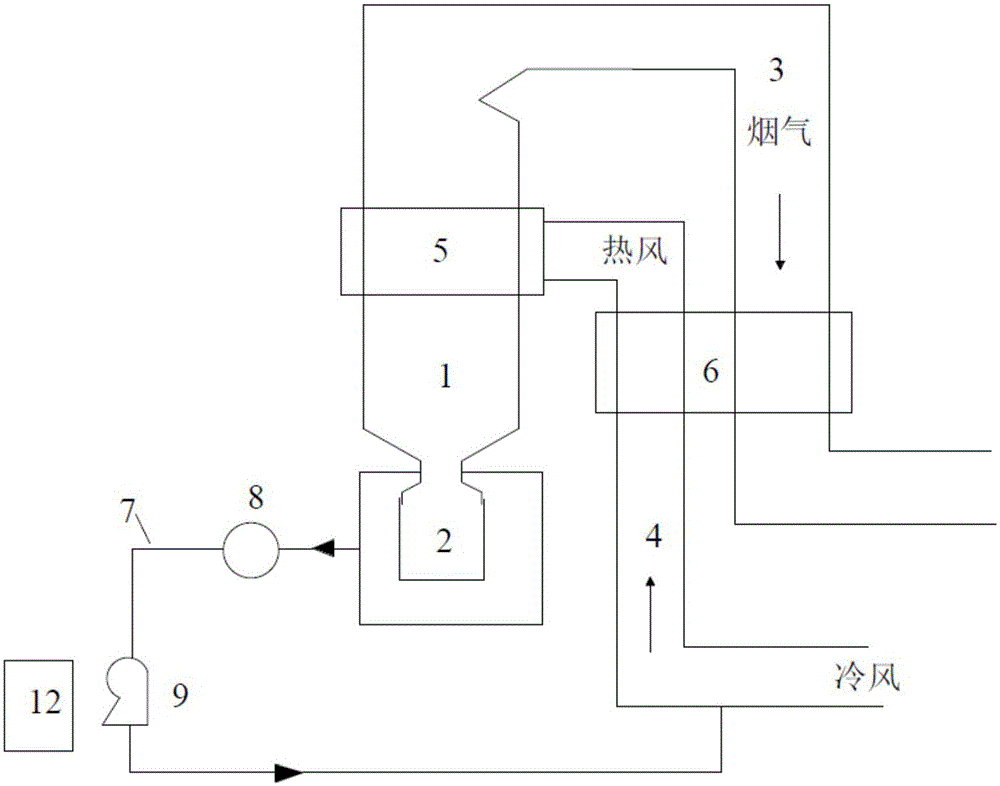

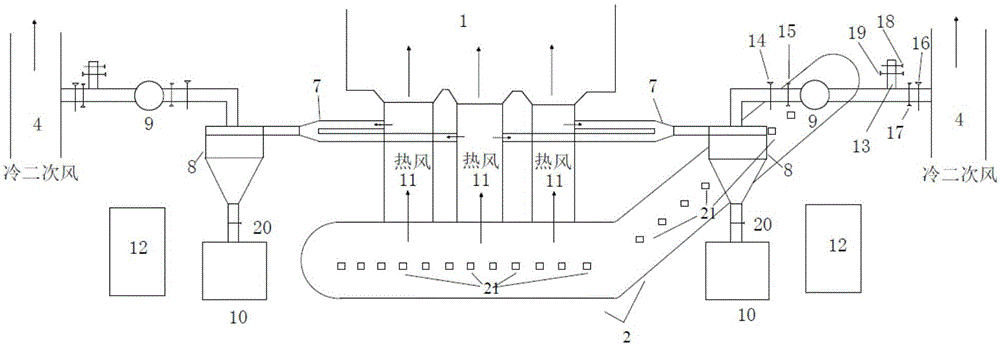

[0019] Equipment for recovering hot air from dry-type slag remover to reduce fugitive air leakage at the bottom of the furnace, see figure 1 and figure 2 , including boiler furnace 1, dry slag remover 2, flue 3, secondary air duct 4, burner 5, air preheater 6, suction pipe 7, cyclone separator 8, suction fan 9, slag Lock box 10, control device 12, ventilation bypass 13, first damper 14, first isolation door 15, second adjustment damper 16, second isolation door 17, third adjustment damper 18, third isolation door 19, plug Panel door 20; dry slag remover 2 is installed at the bottom of boiler furnace 1 and connected through slag pipe 11, flue 3 is installed at the top of boiler furnace 1, and secondary air duct 4 passes through air preheater 6 and burner 5 It is connected with the boiler furnace 1; the burner 5 is respectively connected with the flue 3 and the secondary air duct 4; the slag pipe 11 is connected with the secondary air duct 4 through the suction pipe 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com