A flue gas heater with defogging function

A flue gas heater and functional technology, applied in the field of flue gas heaters, can solve the problems of low efficiency of the demister, increase of system complexity, space occupation and cost, etc., to avoid lime rain, increase temperature, and reduce corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

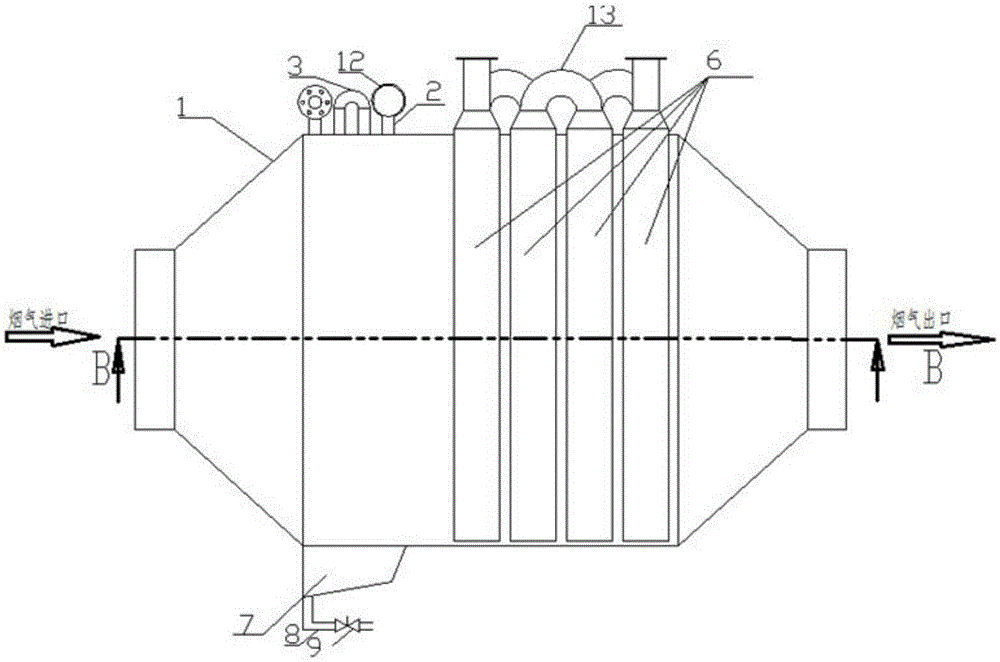

[0031] When the present invention is used, the inlet flue of the flue gas heater is connected through the outlet flue of the desulfurization tower, and the outlet flue of the flue gas heater is connected through the inlet flue of the chimney.

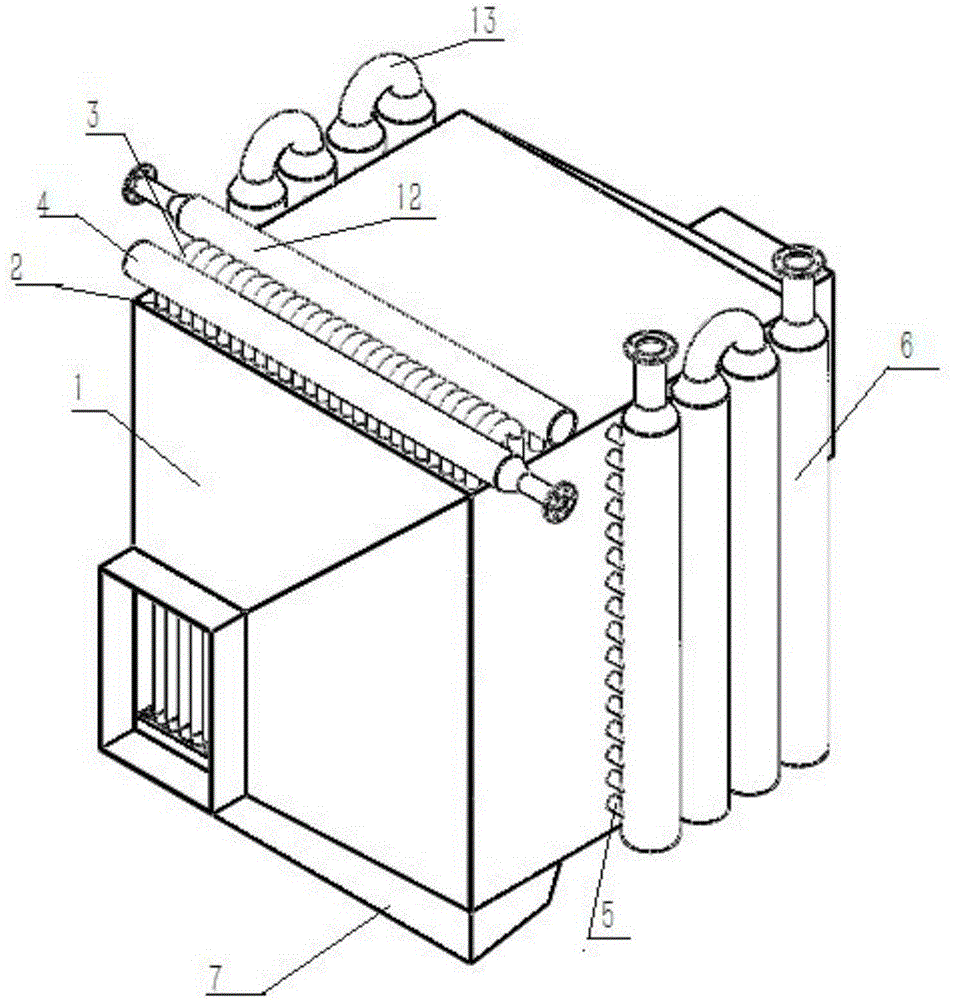

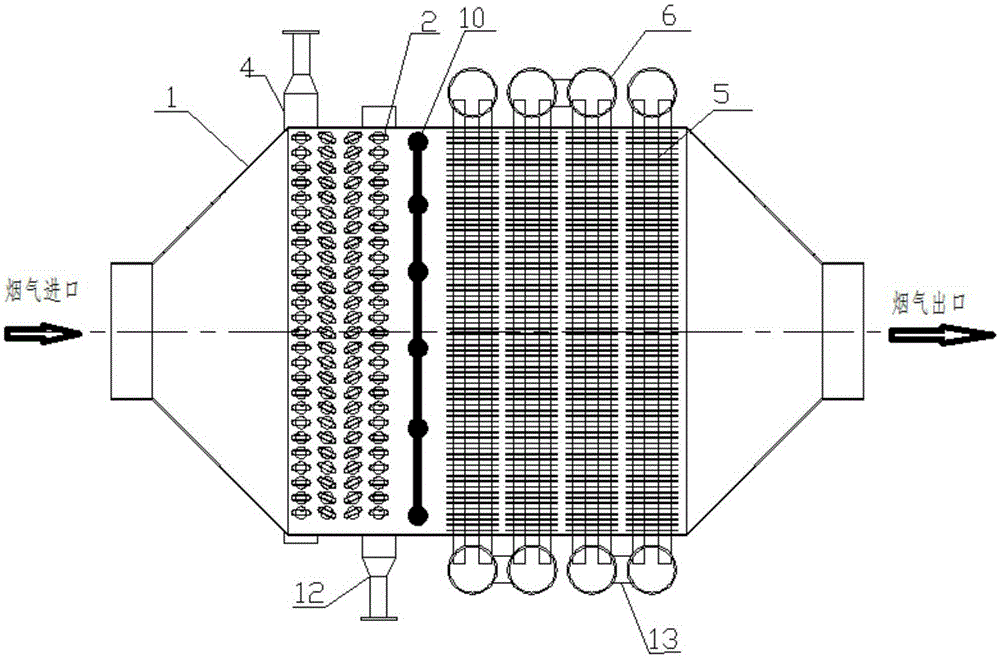

[0032] Such as Figure 1 to Figure 5 As shown, a flue gas heater with defogging function of the present invention includes a casing 1, four rows of round pipes 2 are arranged at the front end of the straight section of the casing 1, and the first row and the fourth row of round pipes 2 are arranged vertically. , and communicate with the water inlet header 4 and the water outlet header 12 respectively, the second row and the third row of round pipes 2 are arranged in a figure-eight shape, and the four rows of round pipes 2 are connected by connecting elbows 3 of round pipes, A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com