Energy-saving boiler feed pump drive system for thermal power plant

A technology for boiler feed water pumps and thermal power plants, which is applied in the direction of machines/engines, pumps, liquid variable capacity machinery, etc. It can solve the problems of low operating efficiency and achieve the goals of reducing project cost, simplifying the system, and reducing the power consumption rate of the plant Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

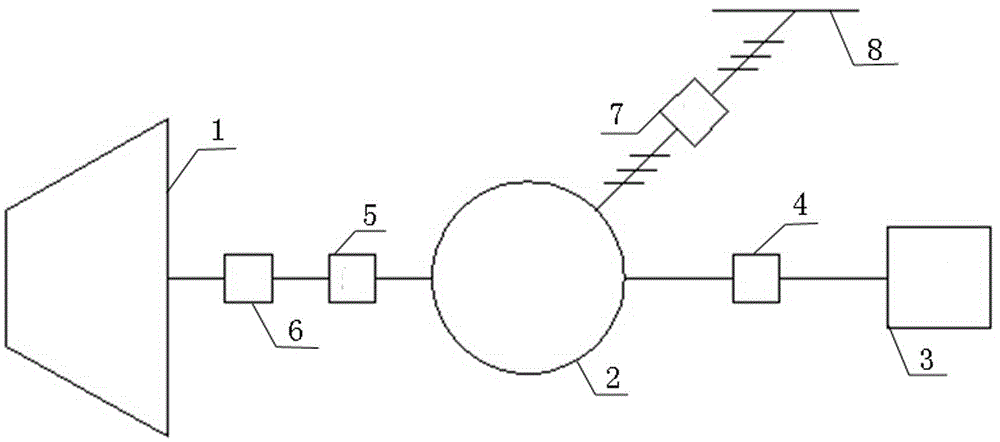

[0023] Embodiment one: if figure 1 As shown, an energy-saving boiler feed water pump drive system used in a thermal power plant includes a small steam turbine 1, a synchronous motor 2, a planetary gear speed control device 4, a synchronous automatic clutch 5, a reduction gearbox 6 and a synchronous switch 7. The driving end of the steam turbine 1 is connected to the input end of the synchronous automatic clutch 5 through the reduction gear box 6, the output end of the synchronous automatic clutch 5 is connected to one end of the synchronous motor 2, and the other end of the synchronous motor 2 is connected to the synchronous automatic clutch 5 through the planetary gear speed regulating device 4. The water pump 3 is connected, and the synchronous motor 2 is connected to the factory bus 8 through the synchronous switch 7 .

[0024] When the air-cooled unit is in normal operation, take the 660MW air-cooled unit equipped with 2×50% capacity feed water pump set as an example, when...

Embodiment 2

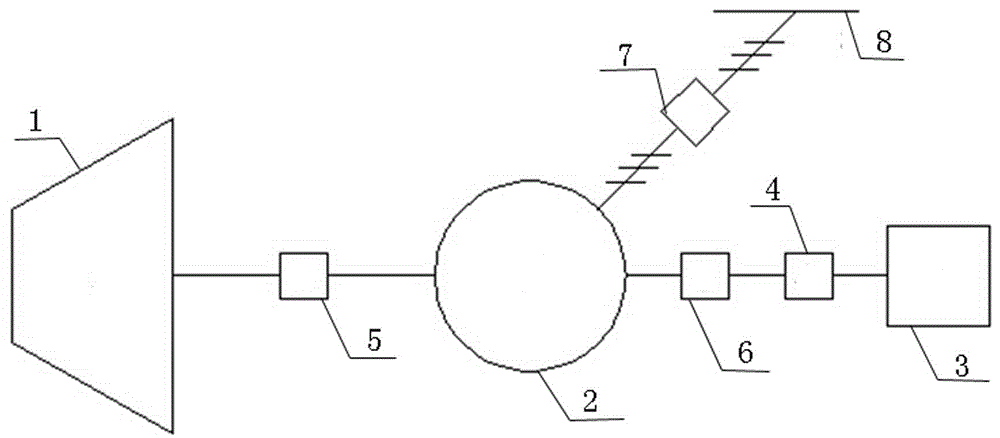

[0027] Embodiment two: if figure 2 As shown, an energy-saving boiler feed water pump drive system used in a thermal power plant includes a small steam turbine 1, a synchronous motor 2, a planetary gear speed control device 4, a synchronous automatic clutch 5, a reduction gearbox 6 and a synchronous switch 7. The driving end of the steam turbine 1 is connected to one end of the synchronous motor 2 through the synchronous automatic clutch 5, and the other end of the synchronous motor 2 is connected to the feed water pump 3 through the reduction gearbox 6 connected in sequence, the planetary gear speed regulating device 4, and the synchronous motor 2 through the synchronous The switch 7 is connected to the plant bus 8 .

[0028] A small steam turbine with a design speed of 3000rpm is used to drive a 2-pole synchronous motor through a synchronous automatic clutch. The synchronous motor is decelerated to 1500rpm through a reduction gearbox, and then drives the water pump through a...

Embodiment 3

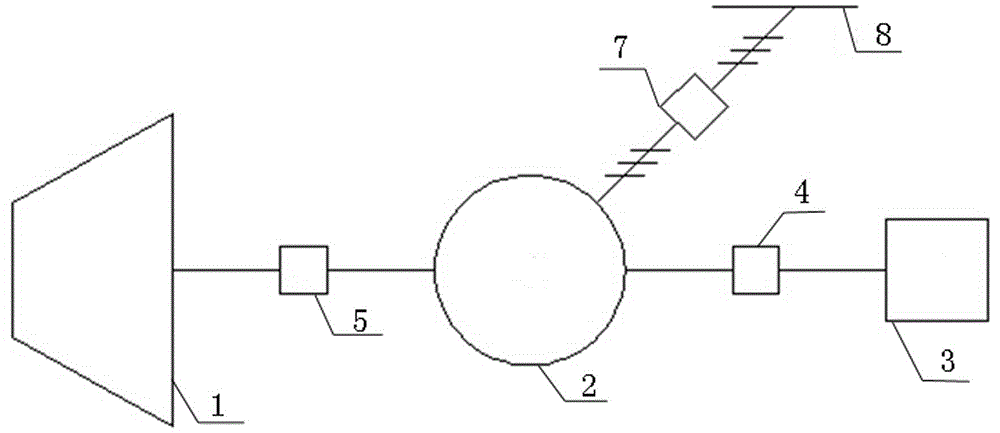

[0029] Embodiment three: as image 3 As shown, an energy-saving boiler feed water pump drive system for a thermal power plant includes a small steam turbine 1, a synchronous motor 2, a planetary gear speed control device 4, a synchronous automatic clutch 5 and a synchronous switch 7, and the driving end of the small steam turbine 1 The synchronous automatic clutch 5 is connected to one end of the synchronous motor 2, the other end of the synchronous motor 2 is connected to the feed water pump 3 through the planetary gear speed regulating device 4, and the synchronous motor 2 is connected to the plant bus 8 through the synchronous switch 7.

[0030] A small steam turbine with a design speed of 3000rpm is used to drive a 2-pole synchronous motor through a synchronous automatic clutch, and a planetary gear speed regulating device with an input speed of 3000rpm is used to drive the water pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com