45MW ultrahigh-pressure reaction type backpressure steam turbine

A back-pressure steam turbine and reactionary technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low unit cycle efficiency, large pollution emissions, low energy utilization rate, etc., to avoid low energy utilization rate , high cycle efficiency, and the effect of shortening the length of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

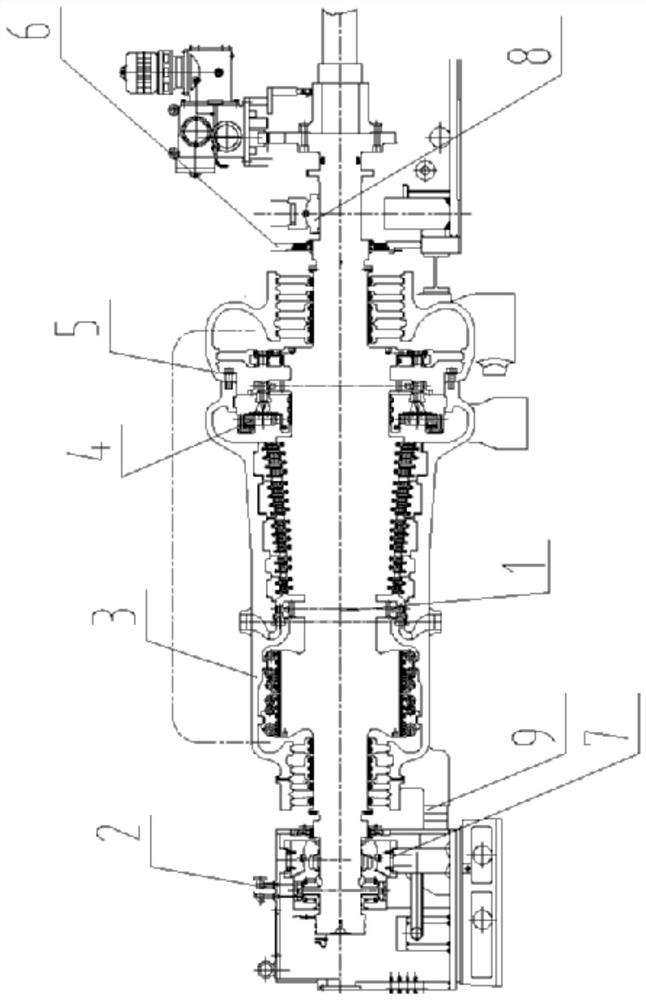

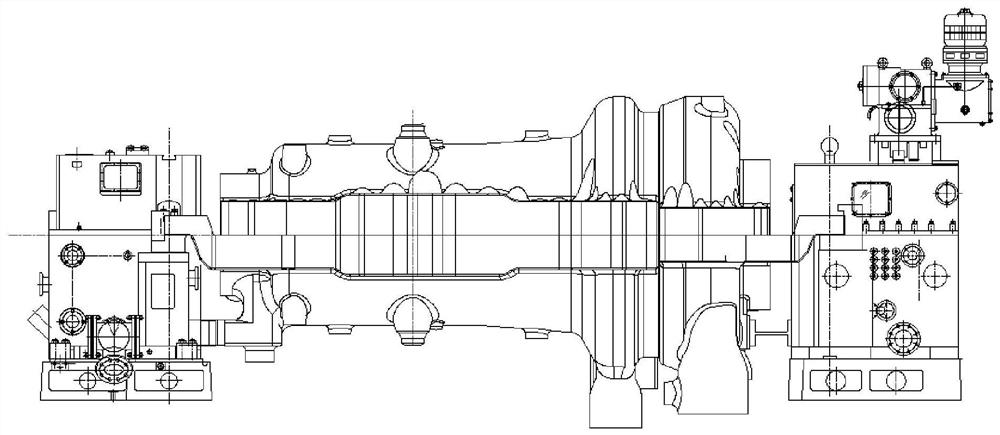

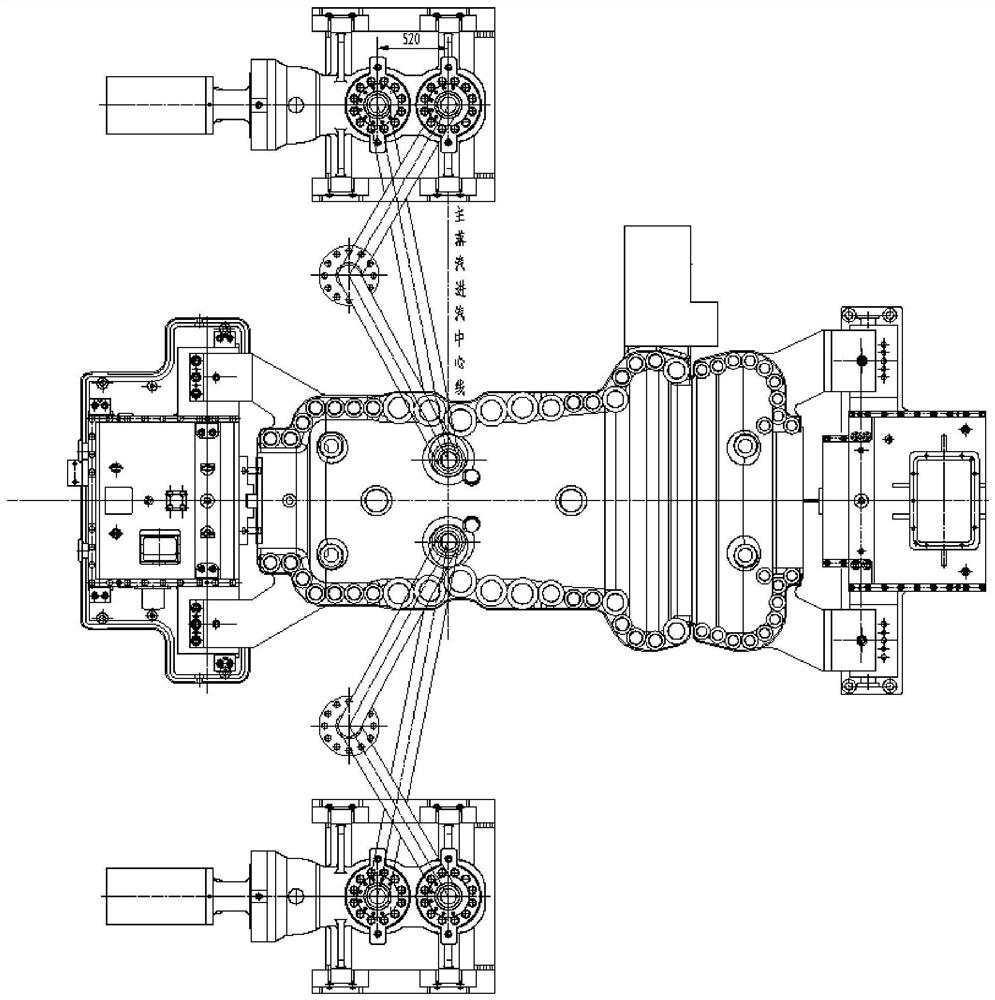

[0023] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, a 45MW ultra-high pressure reactionary backpressure steam turbine described in this embodiment includes a rotor 1, a front bearing housing 2, a cylinder front 3, a rotary partition 4, a cylinder rear 5 and a rear bearing housing 6;

[0024] One end of the rotor 1 is inserted into the side through hole of the front bearing box 2, and the rotor 1 is rotationally connected with the front bearing box 2, and the other end of the rotor 1 passes through the front part 3 of the cylinder and the rear part 5 of the cylinder in turn, and then is inserted into the rear bearing In the side through hole of the box 6, and the rotor 1 is rotationally connected with the rear bearing box 6, and a rotary partition 4 is provided between the inner wall of the rear part 5 of the cylinder and the outer wall of the rotor 1;

[0025] In this specific embodiment, when in use, the rear bearing box 6 is ...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment is a further limitation on the steam turbine described in Embodiment 1, a 45MW ultra-high pressure reaction back pressure steam turbine described in this embodiment, the side of the front bearing box 2 is through A front bearing 7 is embedded in the hole, and one end of the rotor 1 is fixedly connected with the inner ring of the front bearing 7 .

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the steam turbine described in Embodiment 1. For a 45MW ultra-high pressure reactionary backpressure steam turbine described in this embodiment, the side of the rear bearing housing 6 is through A rear bearing 8 is embedded in the hole, and the other end of the rotor 1 is fixedly connected with the inner ring of the rear bearing 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com