Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Precision balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

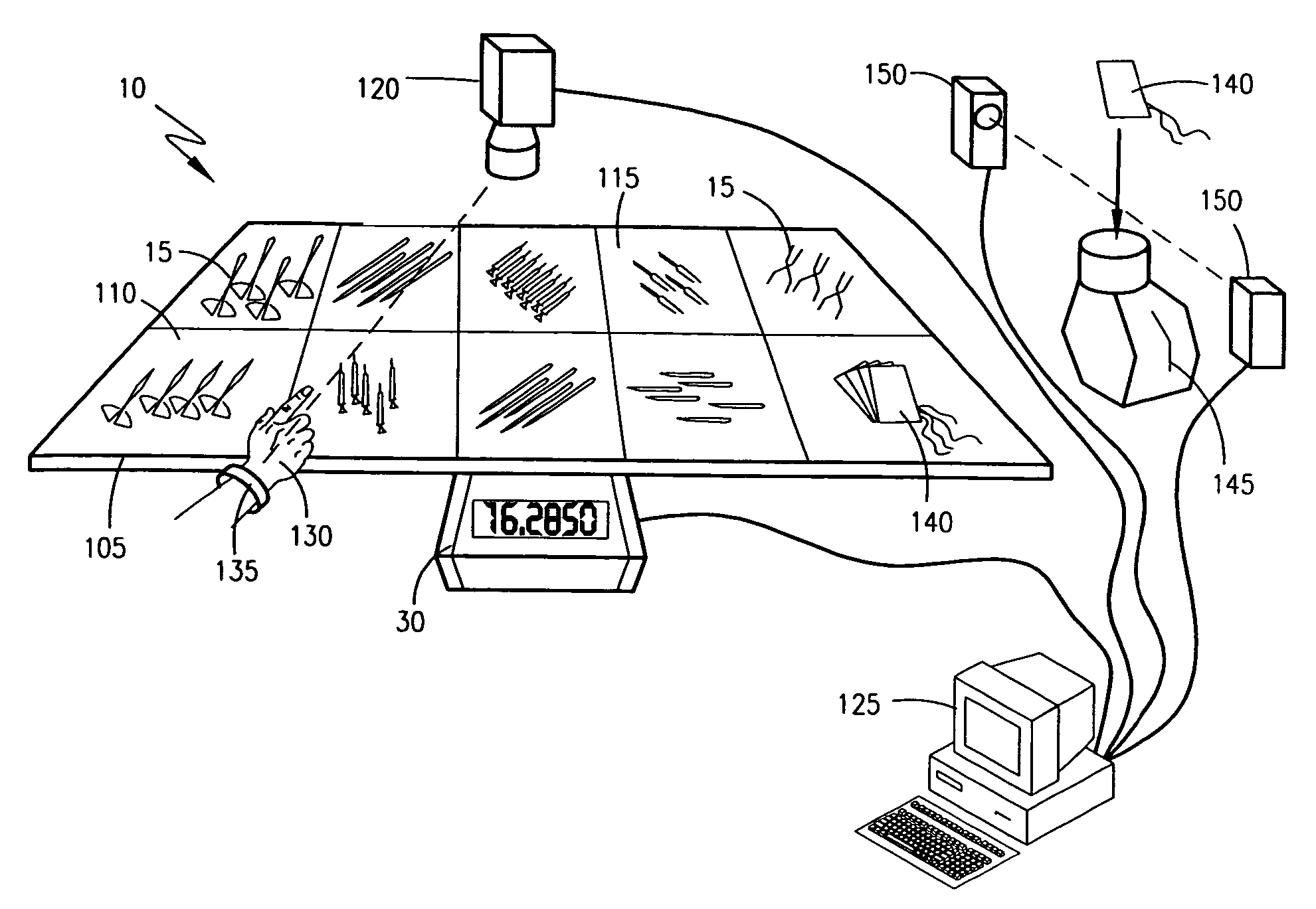

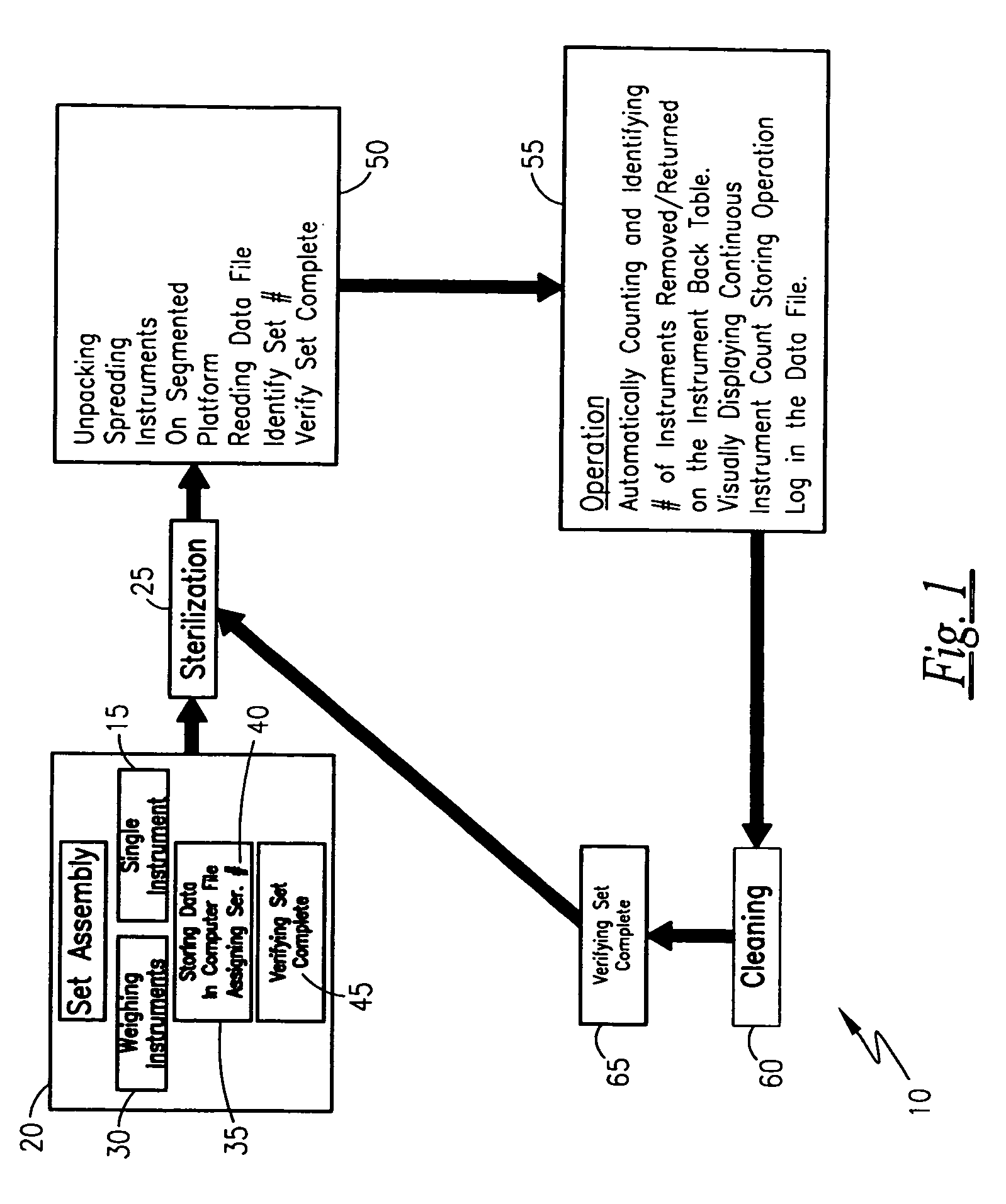

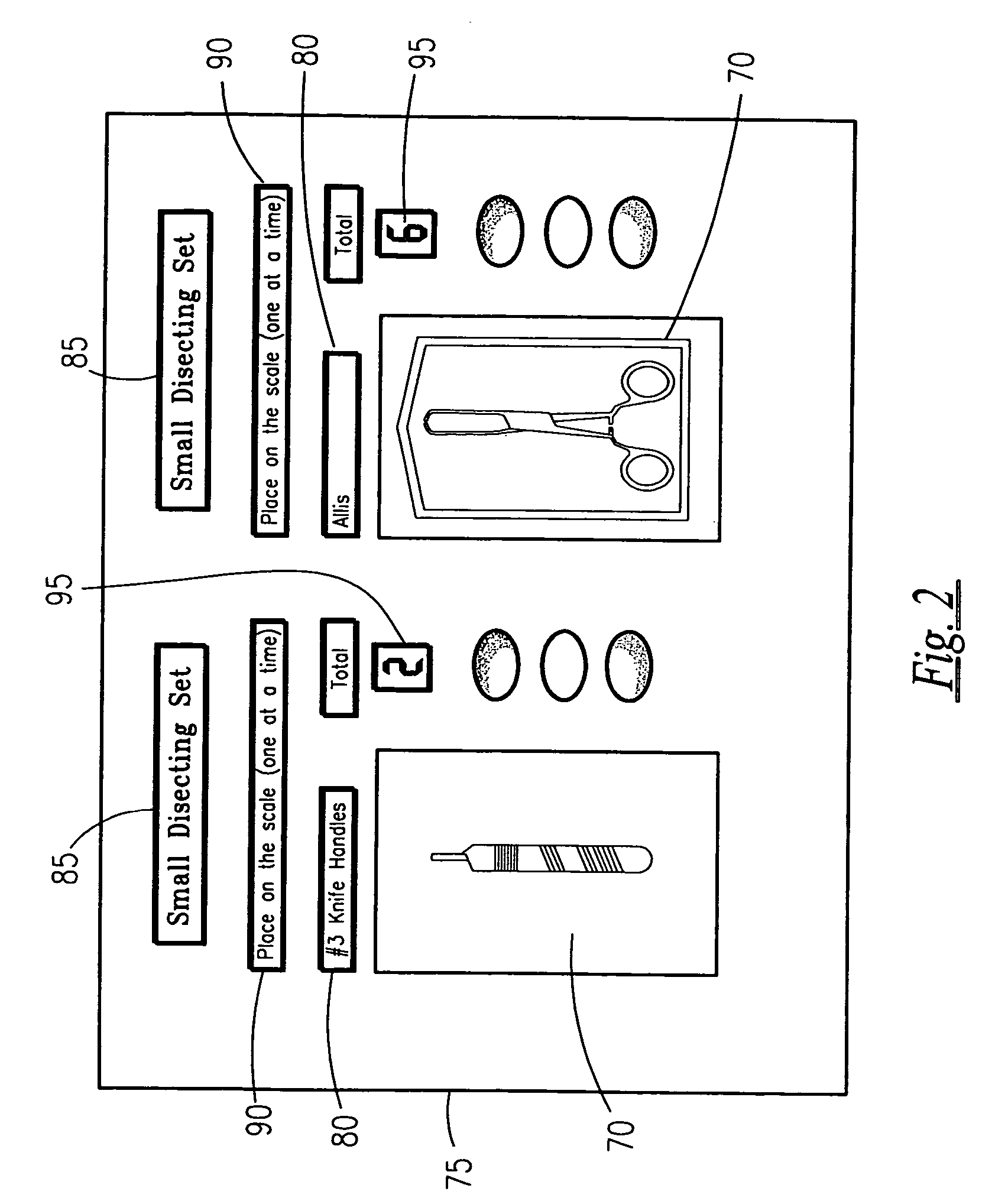

Method and equipment for automated tracking and identification of nonuniform items

InactiveUS7180014B2Increased real-time accounting accuracyShorten the time spanSurgeryDigital computer detailsSurgical operationImaging processing

An apparatus comprising of a segmented instrument tray, precision scale, image processing system, photoelectric sensors and a Personal Computer (PC) is disclosed. Said apparatus provides an automated and accurate tracking of surgical instruments used during surgical operating procedure by counting and identifying a specific quantity and instrument type, which are removed from a sterilized instrument tray to be used during the procedure and subsequently returned to the tray upon procedure completion, thus preventing an accidental leaving of an instrument inside of a patient and significantly reducing time spent by the operation staff for the instrument accounting.

Owner:FARBER BORIS +3

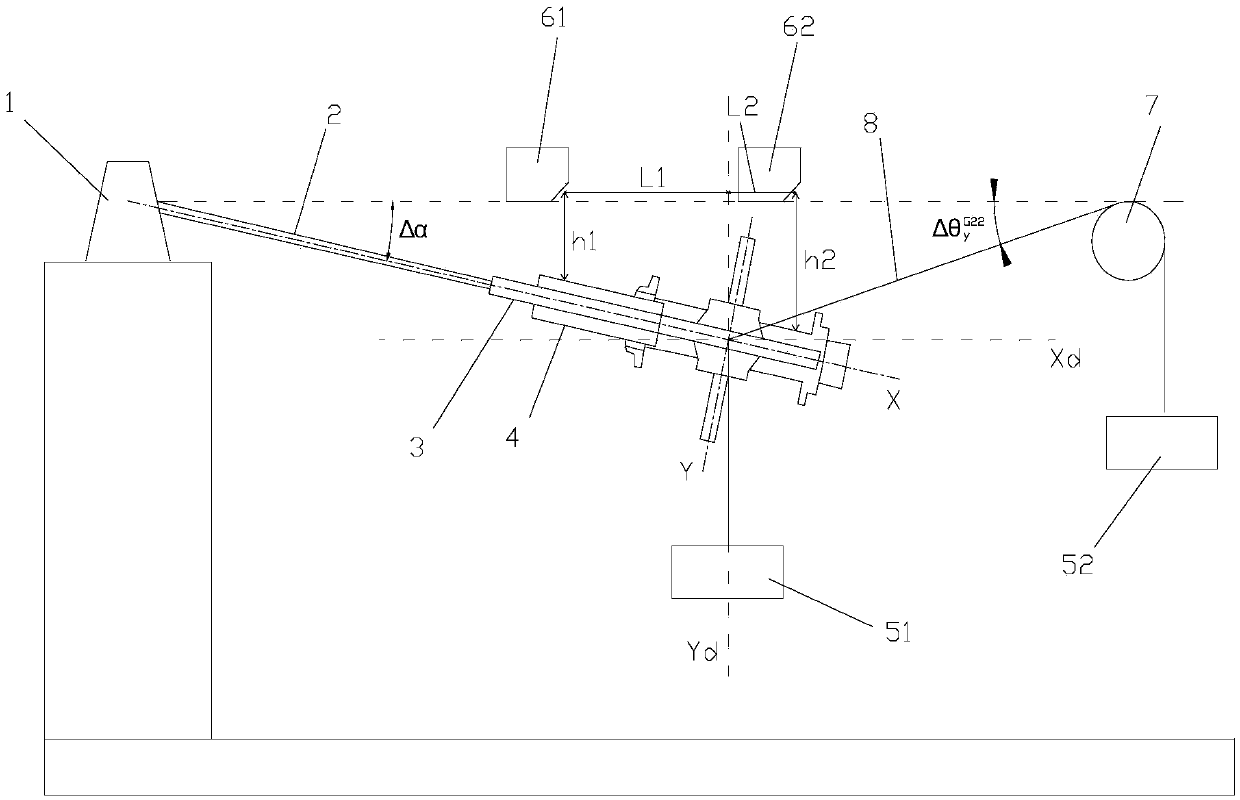

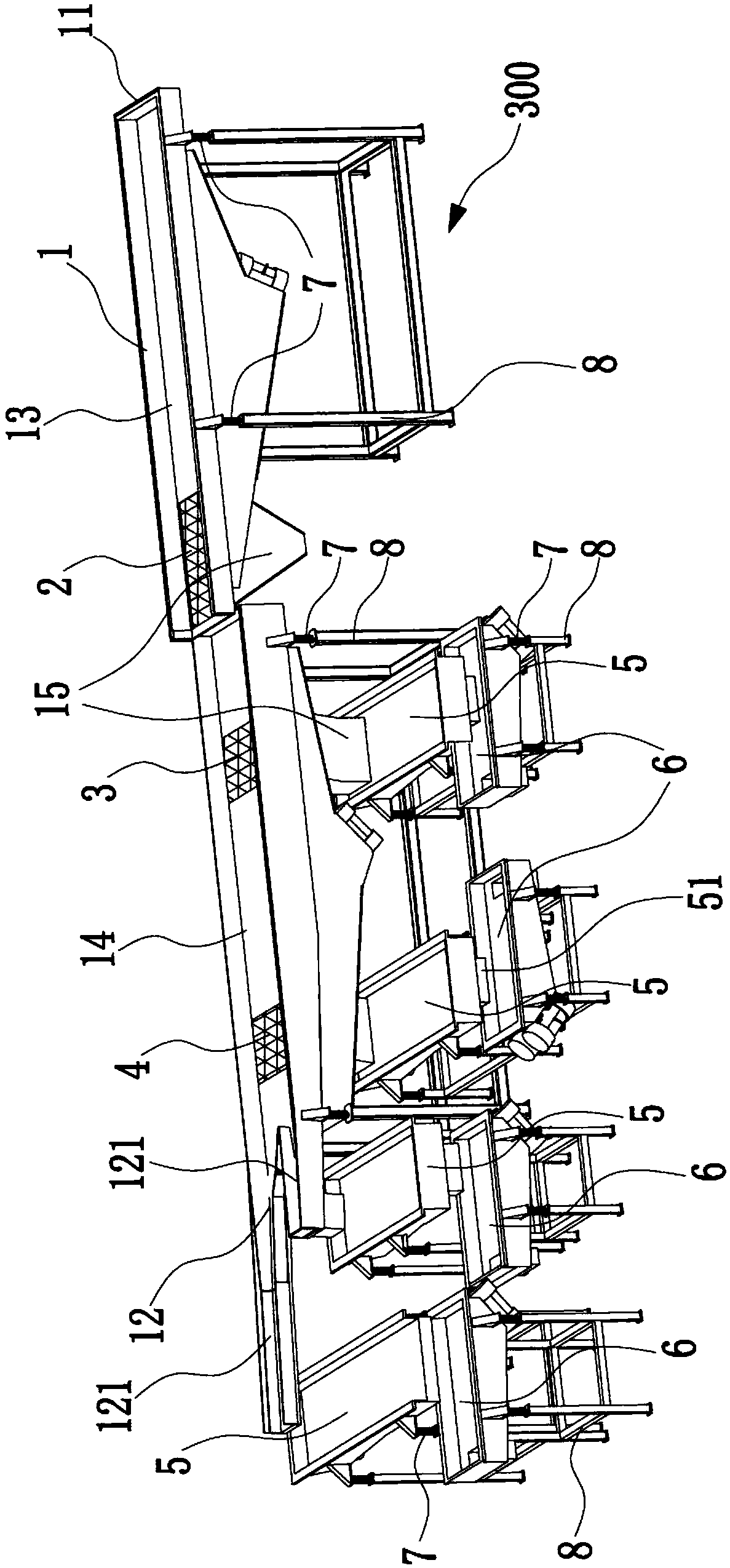

Wind-tunnel balance body shafting static correction system and wind-tunnel balance body shafting static correction method

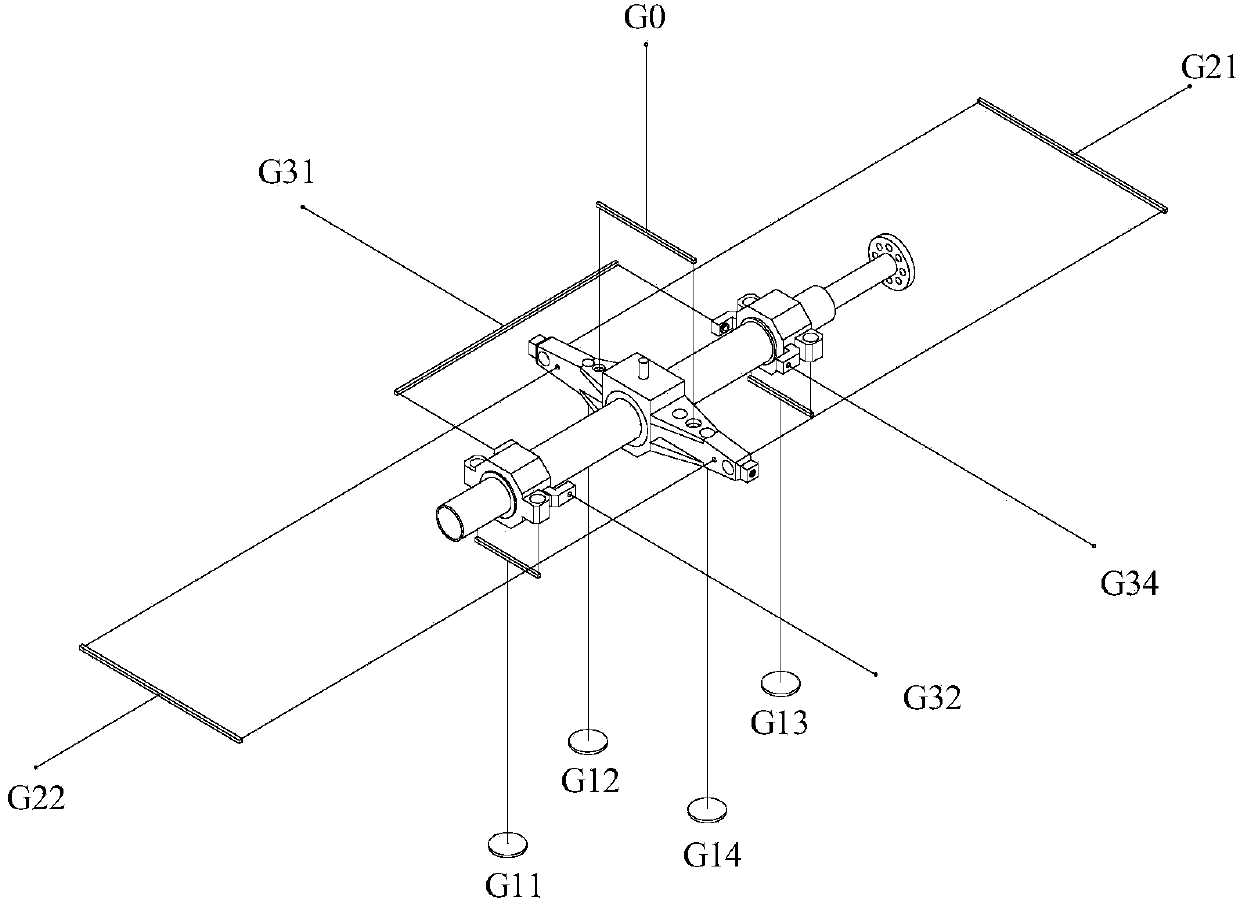

The invention provides a wind-tunnel balance body shafting static correction system and a wind-tunnel balance body shafting static method. The system comprises a rigid base, a supporting rod, a loading head, totally seven displacement sensors and a load generating device, wherein the rigid base is used for providing a stable support; one end of the supporting rod is fixed on the rigid base, and the other end of the supporting rod is connected with one end of a balance; the loading head is used for replacing a model and is connected to a model connecting end of the balance; the seven displacement sensors are used for measuring the linear displacement and angular displacement of the balance along three directions and are symmetrically arranged around a correction core of the balance along three directions; two displacement sensors are respectively arranged in each direction; one displacement sensor is arranged along an axial direction; the load generating device is connected with the loading head through a connecting piece, so that a load is applied to the loading head. The system is simple in structure, and the cost is saved; the static correction efficiency is improved, the correction time is shortened, and the wind-tunnel balance body shafting static correction system is actually a simple, feasible and high-precision balance shafting static scheme.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

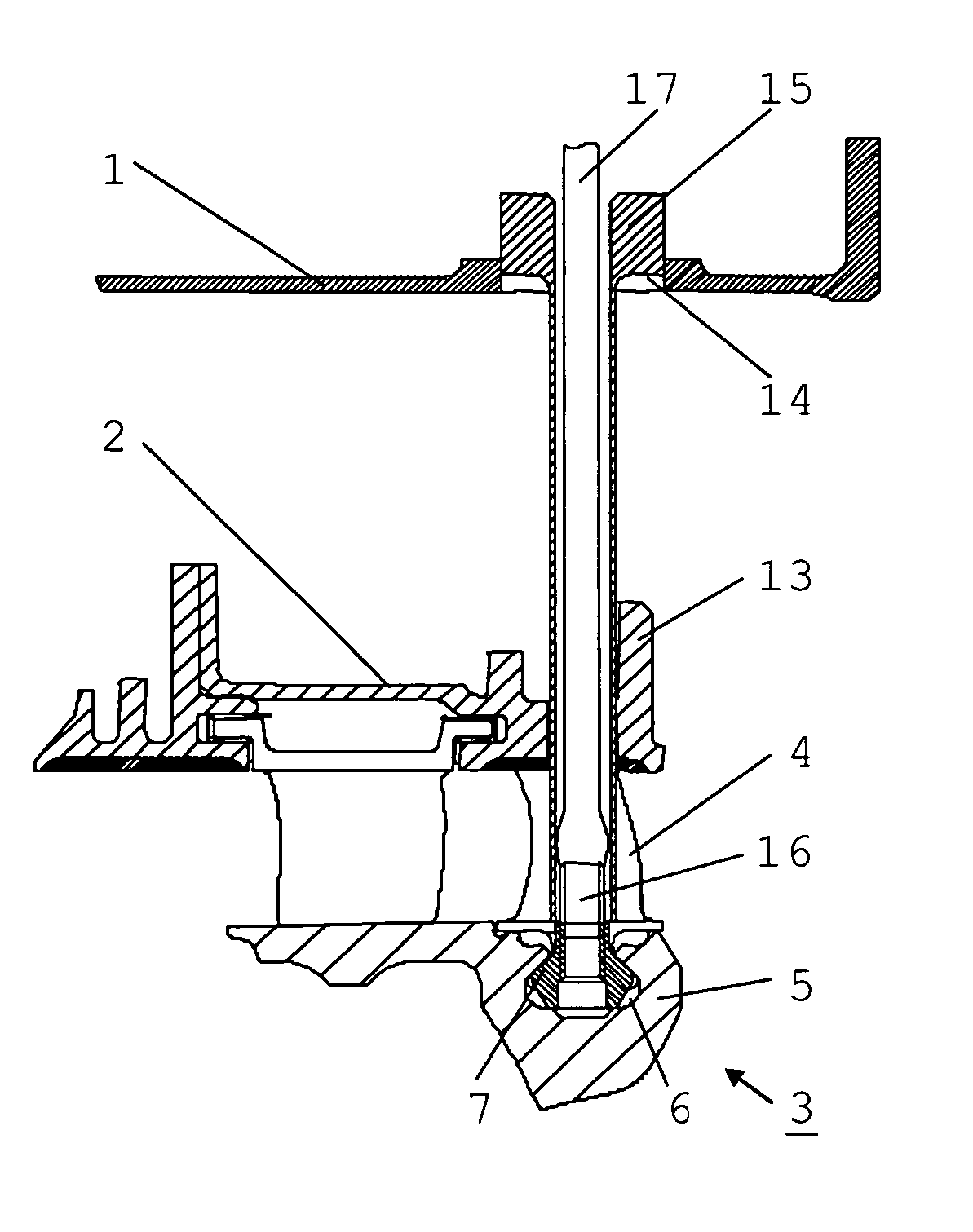

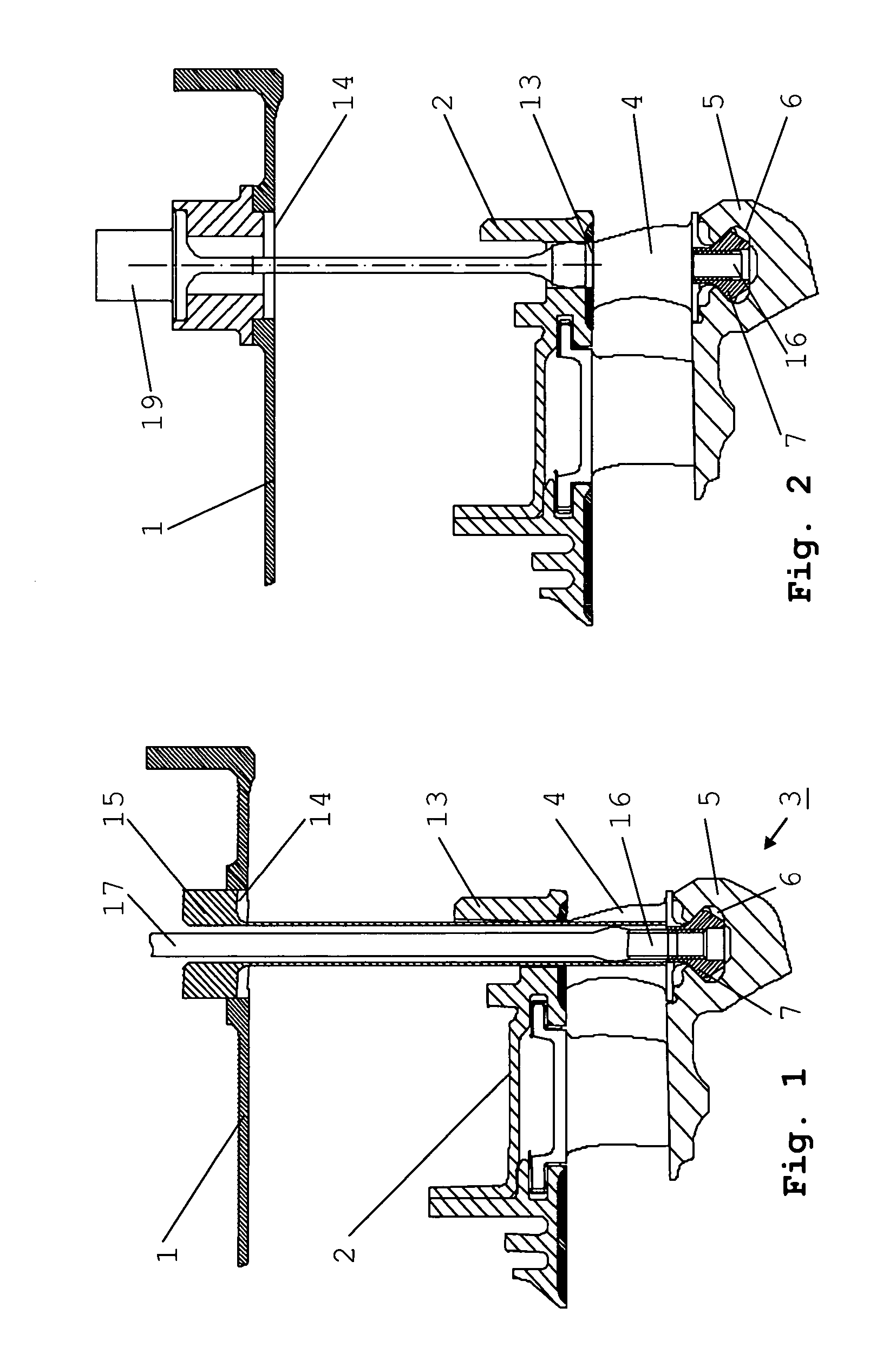

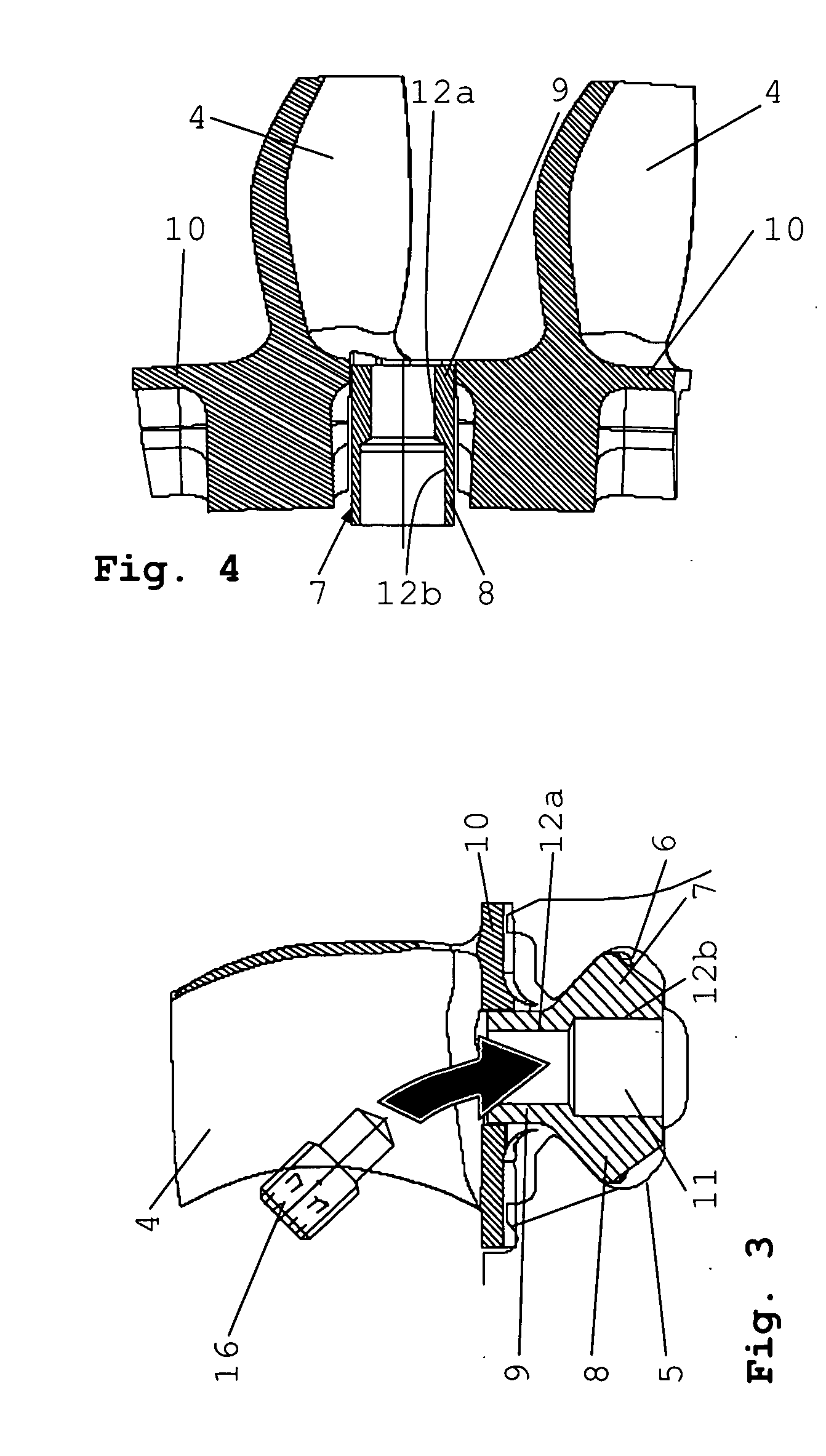

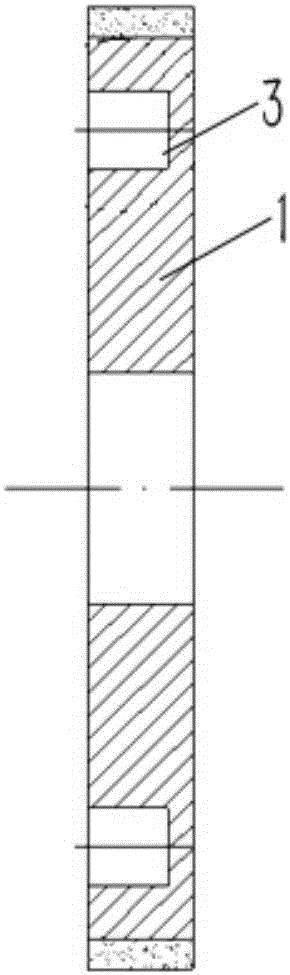

Arrangement for precision balancing the rotor of a gas turbine engine

InactiveUS20060266114A1Extended service lifeLow costBlade accessoriesStatic/dynamic balance measurementTurbineGuide tube

For precision balancing of the rotor (3) that, in fully assembled condition of a gas turbine engine, is encompassed by an inner and an outer case, inserts (7) with a through hole (11) and a female threaded section are positioned at an even spacing in at least one circumferential groove (6) of the rotor disks (5) that receives the roots of the rotor blades (4). A temporarily installed guide tube (15) that runs through the openings (13, 14) connects to the through hole that in a certain rotor position is in line with the openings (13, 14) in the inner and outer cases (1, 2) for inserting and screwing in a balancing screw (16).

Owner:ROLLS ROYCE DEUT LTD & CO KG

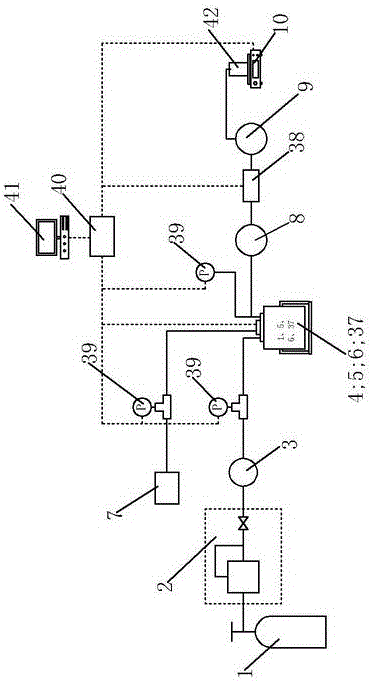

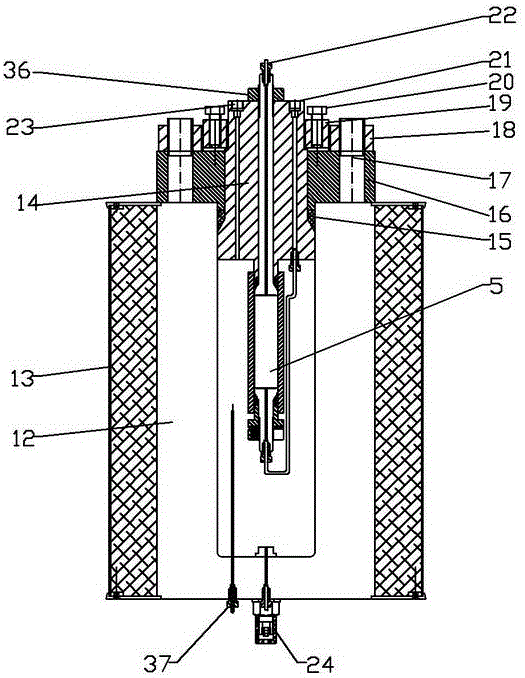

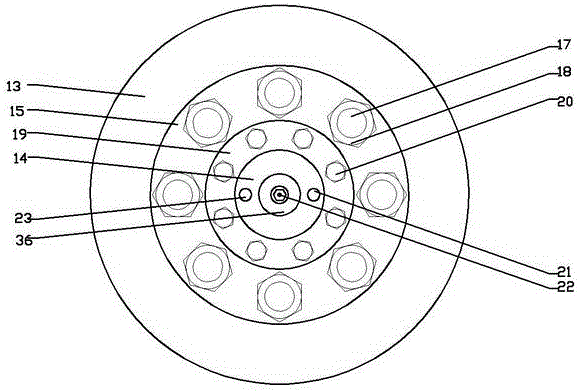

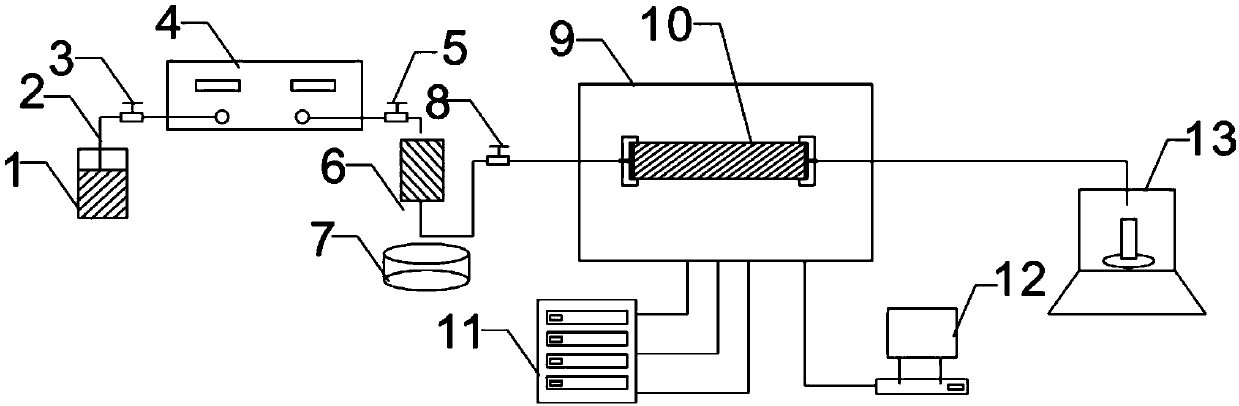

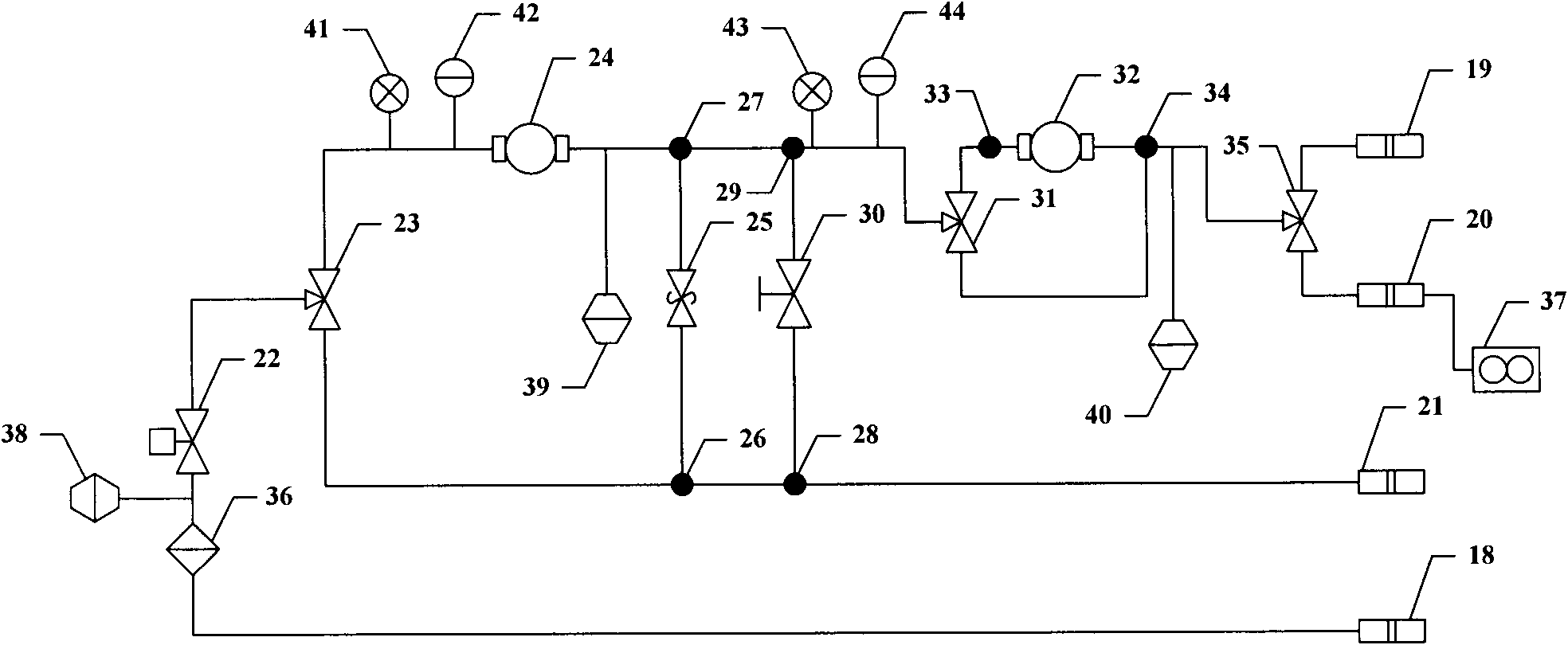

Device for testing permeability under high temperature and high pressure

The invention discloses a device for testing permeability under high temperature and high pressure. The device can achieve test of the permeability of a rock sample under conditions of 50-500 DEG C and 0.2-100.0 Mpa. The device comprises a fluid source, a fluid supercharging device, a preheater, a high temperature high pressure reactor, a high temperature high pressure core holding unit, a transfusion pipeline, a confining press pump, a cooler, a backpressure control system, a precision balance and a data collection system. According to the device, real-time measurement on the permeability of the core under the conditions of high temperature and high pressure can be achieved, the device can be further used for simulating a transfusion process of the liquid in the rock in place under the ground, simulation study of underground in-situ exploiting such as underground hot gas exploiting, superheated steam exploiting and near / super critical fluid exploiting can be conducted, and new mentality and feasible testing programs can be provided for exploiting underground hot dry rock and thickened oil and in situ exploiting unconventional oil and gas resources such as oil sand and oil shale.

Owner:JILIN UNIV

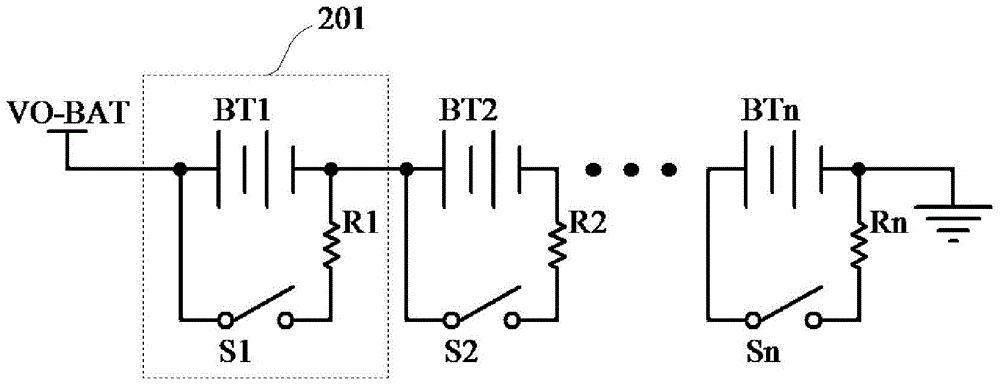

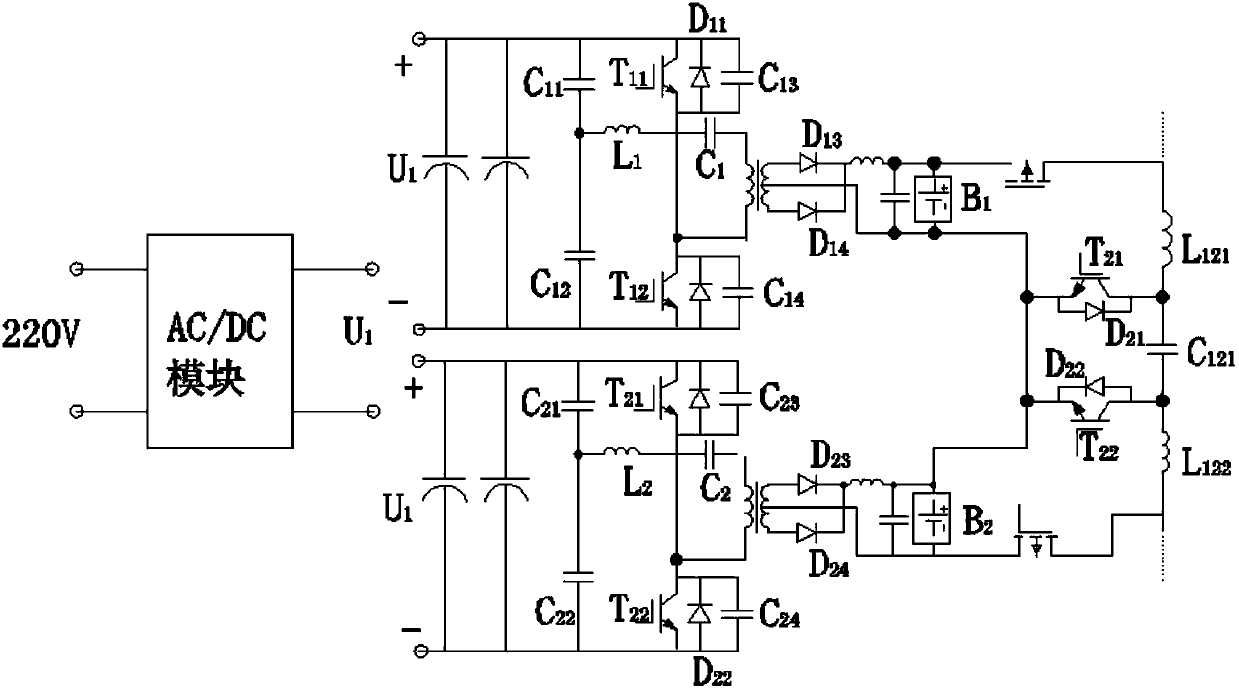

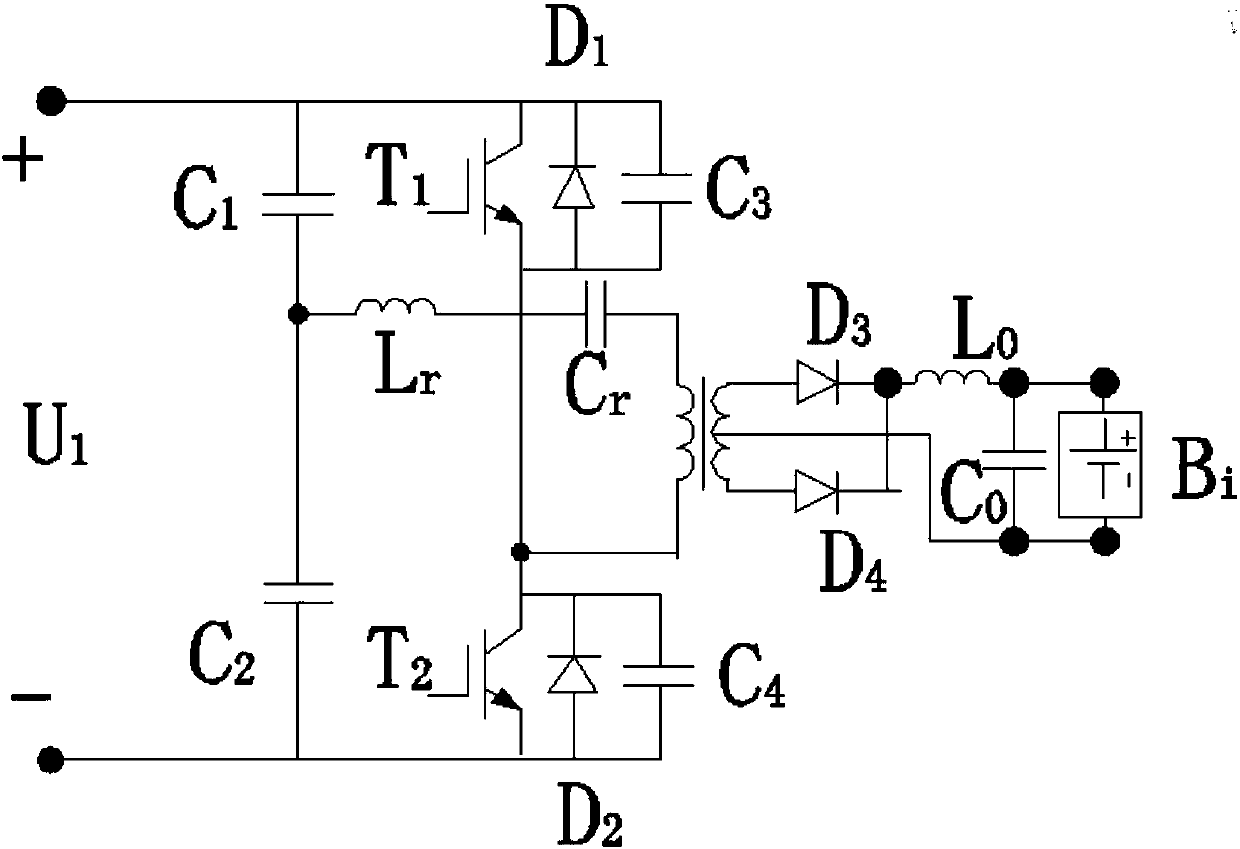

A series battery equalization circuit

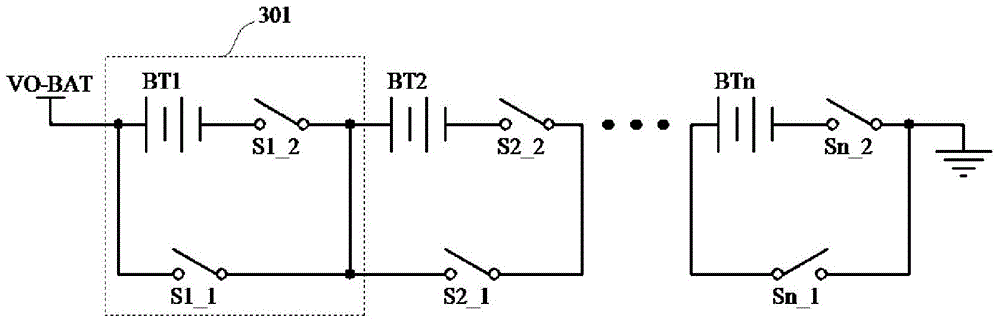

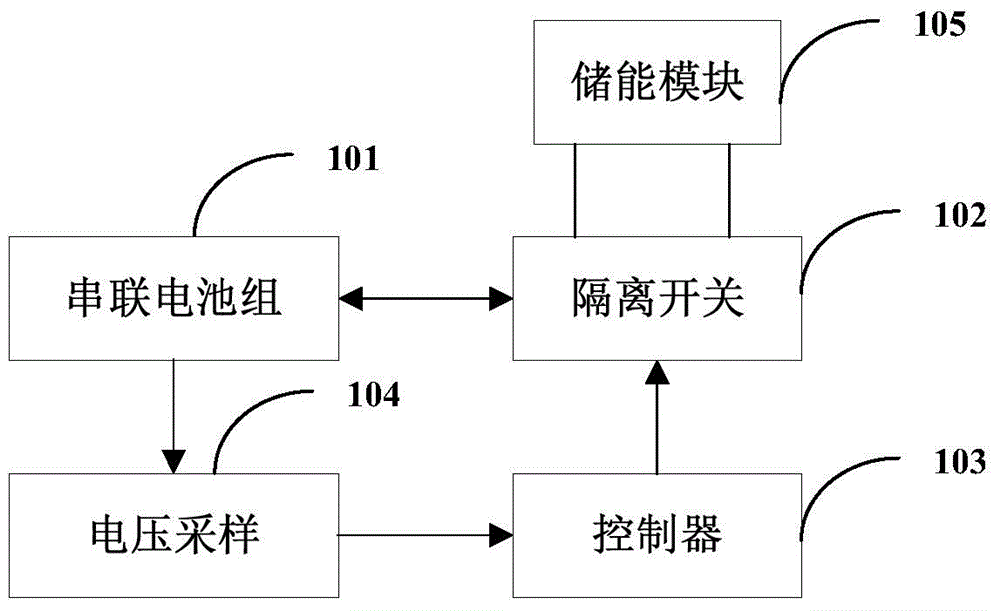

InactiveCN104935051ASolve the "barrel effect"Normal full chargeBatteries circuit arrangementsElectric powerCapacitanceControl signal

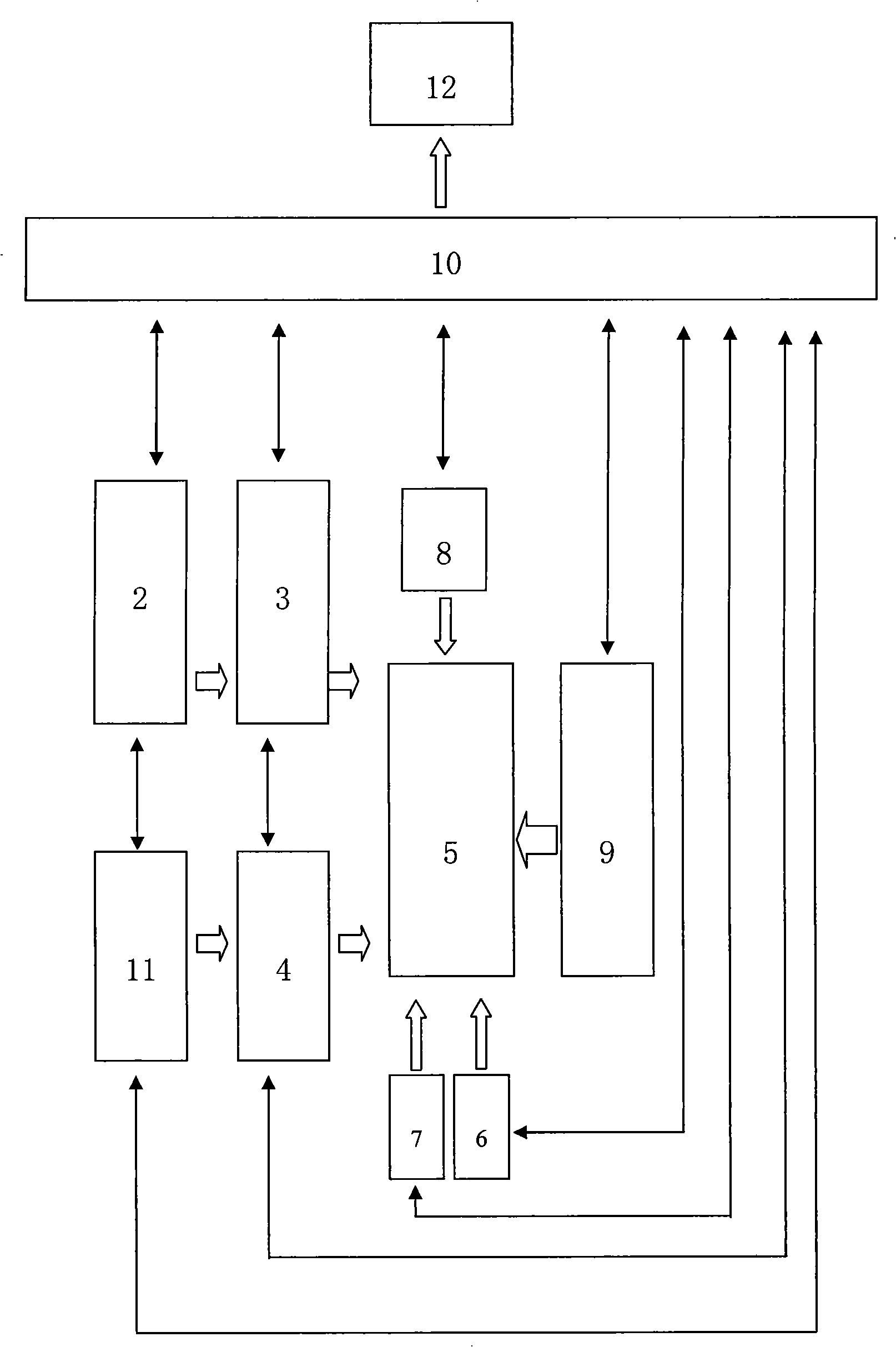

The invention provides a series battery equalization circuit belonging to the field of electric power and electronic techniques. The circuit comprises a voltage sampling module, a controller, a disconnecting switch module and an energy storage module. A voltage acquisition input terminal of the voltage sampling module is connected to a series battery. A voltage acquisition output terminal of the voltage sampling module is connected to a voltage input terminal of a controller. A control signal output terminal of the controller is connected to a control terminal of the disconnecting switch module. A voltage input terminal of the disconnecting switch module is connected to the series battery. A first voltage output terminal and a second voltage output terminal of the disconnecting switch module are respectively connected to the two terminals of the energy storage module. According to the invention, high-precision balancing between voltages of batteries in the series battery can be realized to enable normal fully-charging and fully-discharging of the whole series battery. Transferring efficiency and equalization efficiency of electric quantities between the batteries can be raised. In addition, equalization can be realized in charging, discharging and static states by the series battery equalization circuit of the invention. The equalization of the batteries can be realized just by a capacitor. The cost for the equalization circuit is reduced.

Owner:EDAN INSTR

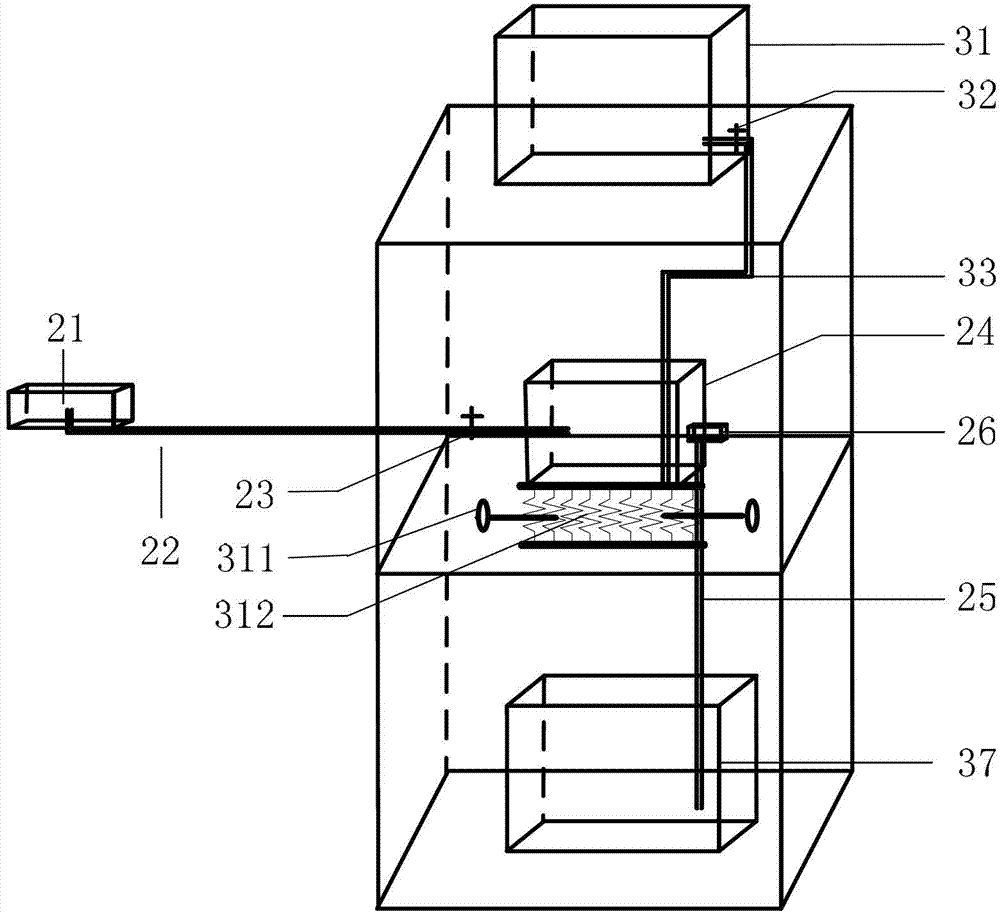

Combustion experimental facility capable of realizing continuousness and stability of liquid level

InactiveCN102879292AHigh precisionFlexible and convenient adjustment systemWeighing by removing componentCombustionEngineering

The invention provides a combustion experimental facility capable of realizing continuousness and stability of liquid level. A main body of the experimental facility consists of a fuel supply system, an overflow system and a weighing system, wherein the fuel supply system comprises a top fuel storage pond and a supplied fuel pond which are connected with each other via a stainless steel hose; a valve on the stainless steel hose can control the rate of oil which flows into the supplied fuel pond from the top fuel storage pond; the overflow system comprises the supplied fuel pond and a bottom fuel storage pond which are connected with each other through a stainless steel hose; and the weighing system comprises a balance and a system frame. The experimental facility keeps fire combustion liquid level of a combustion pond stable, the liquid level of the combustion pond can be controlled by adjusting the height of the supplied fuel pond, an adjusting system is flexible and convenient, and accuracy is high. Moreover, experimental combustion rate can be measured by the high-precision balance.

Owner:UNIV OF SCI & TECH OF CHINA

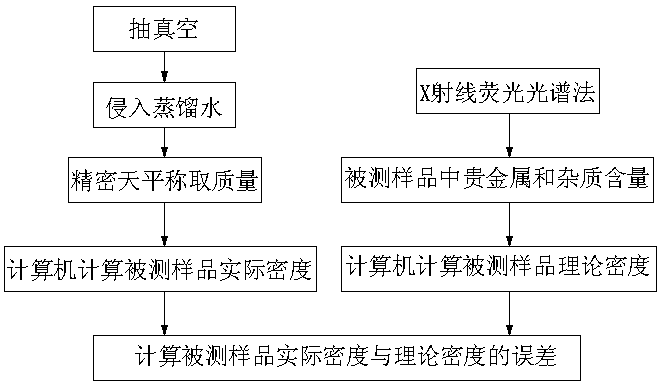

Rapid detection method for noble metal

InactiveCN103267708AOvercome limitationsSolve shapeMaterial analysis using wave/particle radiationMaterial analysis by measuring buoyant forcesFluorescenceDistilled water

The invention discloses a rapid detection method for noble metal. The rapid detection method comprises the following steps of: 1) weighing the mass of a sample to be detected by a precision balance and vacuumizing the sample to be detected; 2) immersing the sample to be detected in distilled water and weighing the mass of the immersed sample by using the precision balance; 3) calculating the actual density of the sample to be detected; 4) detecting the content of the noble metal and impurity elements in the sample to be detected by utilizing an X fluorescence spectrograph and calculating the theoretical density of the sample to be detected; and 5) calculating an error between the actual density and the theoretical density of the sample to be detected, wherein if the error is in a range of 0.5%, testing data of the sample to be detected is accurate. The method disclosed by the invention can detect a plurality of samples to be detected at the same time and can analyze the reliability of detection results of the plurality of samples to be detected from a plurality of angles, so that a final detection conclusion is obtained and the accuracy of detection data is guaranteed; and the data can be rapidly obtained and an effective manner is provided for the development of the mass detection work.

Owner:CHONGQING ACAD OF METROLOGY & QUALITY INST

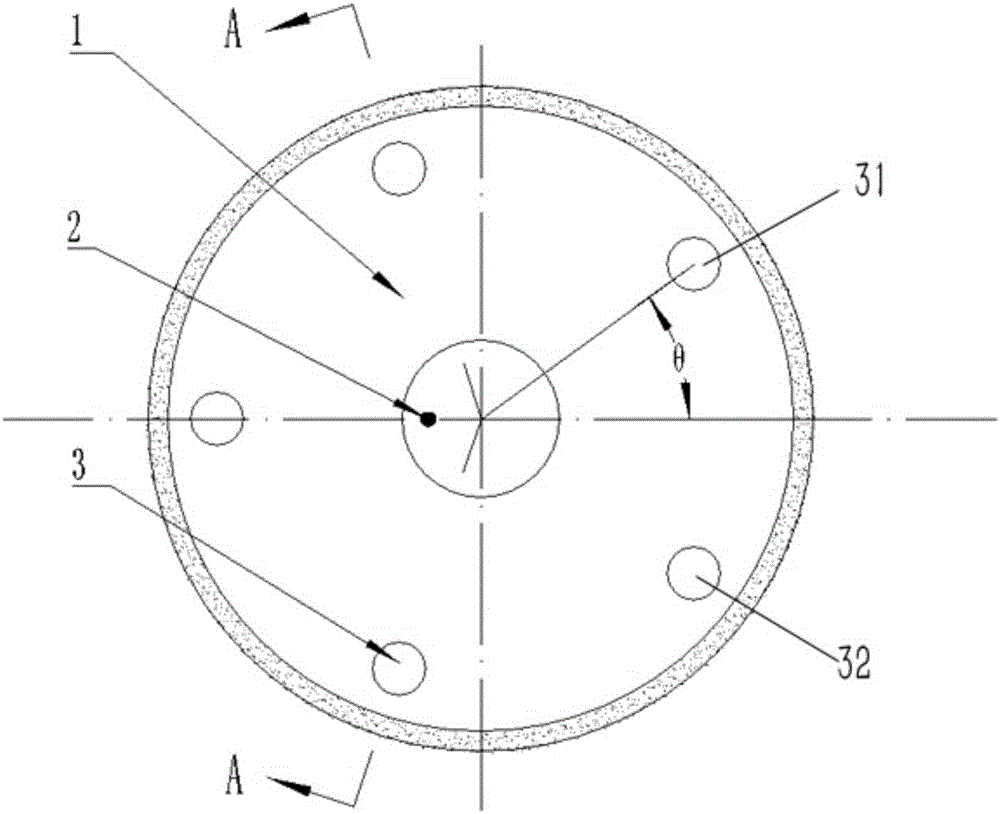

Precise balancing correcting method for super-hard abrasive grinding wheel

InactiveCN106153258AHigh balance precisionQuick and easy balance correctionStatic/dynamic balance measurementBalancing machineEngineering

The invention discloses a precise balancing correcting method for a super-hard abrasive grinding wheel. The method comprises the following steps: 1) drilling 3-6 uniformly distributed balancing holes on a same circumference of a base end face of the grinding wheel and arranging plugs; 2) testing unbalance amount of the grinding wheel on a balancing machine, thereby acquiring an initial gravity center position of the grinding wheel and unbalance torque of the grinding wheel; 3) establishing an X axis above the initial gravity center and circle center on the end face of the grinding wheel, symmetrically arranging the light point and initial gravity center of the grinding wheel about the center of the X axis, and confirming two balancing holes in the light point area of the grinding wheel, on the two sides of the X axis and closest to the X axis as first and second counterweight holes corrected by the grinding wheel; 4) respectively mounting opposite counterweights in the two counterweight holes. Practically, the mass on the opposite side of the gravity center area on the grinding wheel is greatly increased through the counterweights, so that the gravity center of the whole grinding wheel falls back to the axis position, and meanwhile, the counterweights are subdivided through a precision balance, so that the balance precision is increased.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Magnetic resonance imaging testing device for online imbibition experiment and experiment method

ActiveCN109682850AAccurate measurementImprove accuracyWater resource assessmentAnalysis using nuclear magnetic resonancePorous mediumLow field nuclear magnetic resonance

The invention discloses a magnetic resonance imaging testing device for an online imbibition experiment and an experiment method. The device comprises a constant voltage maintaining system, a porous medium system and a low field magnetic resonance imaging analyzer. The constant voltage maintaining system comprises a constant voltage and constant speed pump, the front end of the constant voltage and constant speed pump is connected with a first water containing device, the rear end of the constant voltage and constant speed pump is arranged above a second water containing device, the bottom ofthe second water containing device is connected with an inlet of the porous medium system, an outlet is connected with a precision balance, the porous medium system is placed into a magnetic field generated by the low field magnetic resonance imaging analyzer, the porous medium system comprises an organic glass tube, a rock core sheet, a steel wire net and a weak magnetism metal sealing piece arearranged at the front end of the organic glass tube, and the rear end of the organic glass tube is provided with a steel wire net and a weak magnetism metal sealing piece; the invention further provides an online imbibition experiment method. The requirement for online imbibition experiment testing is met, the device is simple in structure, easy and convenient to operate and low in nuclear magnetism signal interference, the testing result obtained by the method is accurate, the experiment error is small, and repeated experiments can be performed.

Owner:SOUTHWEST PETROLEUM UNIV

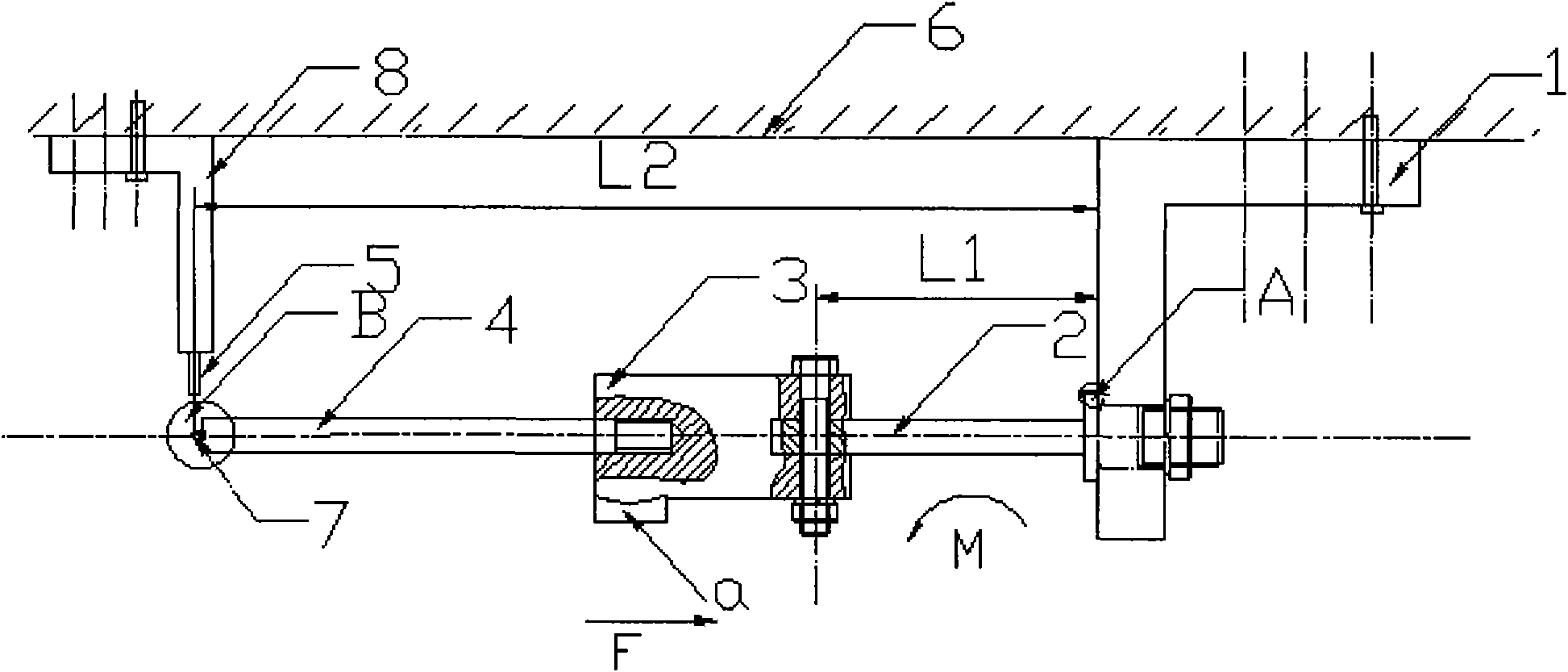

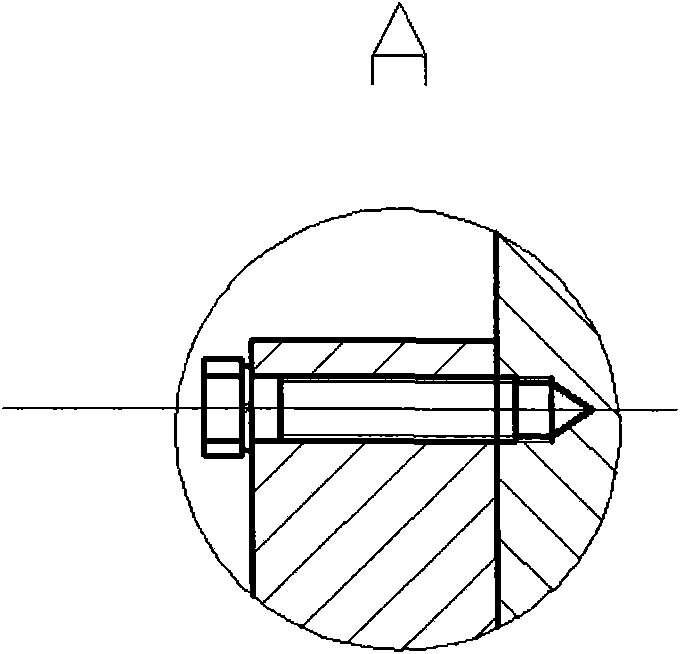

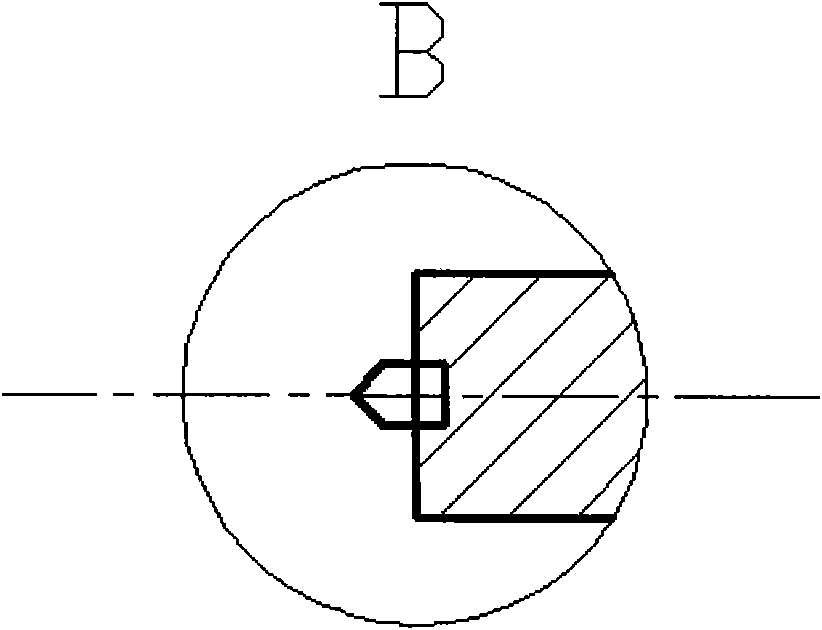

High-precision balance for measuring resistance of water tunnel

The invention discloses a high-precision balance for measuring the resistance of a water tunnel, which comprises a balance bracket, an elastic deformation girder, a rigid connecting bracket, a non-magnetic beam, a magnetic telescopic displacement sensor, a magnetic needle and a sensor-mounting bracket. The resistance-measuring balance bracket and the sensor-mounting bracket are connected with a water tunnel cover plate, an M20 external bolt at the right end of the elastic deformation girder penetrates through a Phi 20 through hole on the balance bracket and fastened and connected by an M20 nut, the rigid connecting bracket and the elastic deformation girder are connected by two M6 bolts, and the magnetic needle is inlaid in a small hole at the left end of the non-magnetic beam in an interference way. The displacement of the small magnetic needle is measured by magnetic telescopic displacement sensor to indirectly measure the resistance of a water tunnel experimental model, and the high-precision balance for measuring the resistance of a water tunnel measures has the advantages of simple structure and high precision and can be widely applied to resistance comparison experiments of water tunnels.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

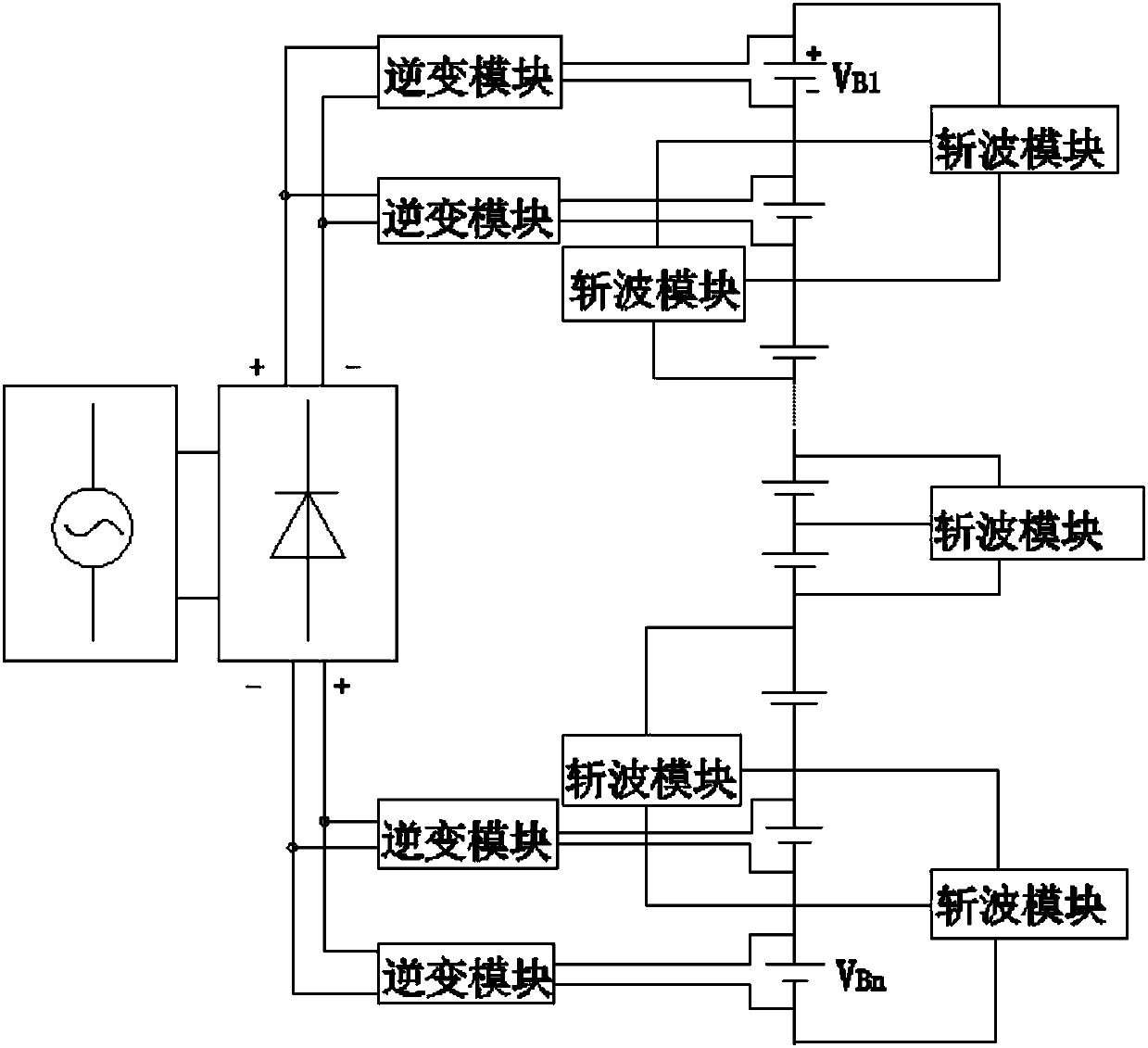

Equalizing charging circuit for battery pack, and control circuit for equalizing charging circuit

PendingCN107658948AImprove equalization performanceReduce power consumptionCharge equalisation circuitElectric powerControl setLow voltage

The invention relates to the technical field of power, and especially relates to an equalizing charging circuit for a battery pack, and a control circuit for an equalizing charging circuit. Based on the above equalizing structure, an inversion module is started for charging a low-voltage battery unit when voltage of the battery unit is too low, and then a chopping module is used for charging the whole body, thereby completing the equalization of key tasks. When the voltage of the battery unit is too high, the chopping module is started at first, and enables the electric quantity of the high-voltage battery unit to be transferred to other low-voltage battery unit, and then the inversion module is used for charging the whole body, thereby achieving the equalizing charging. According to the scheme, the two modules cooperate with each other, thereby reducing the equalizing time, guaranteeing the equalizing precision, avoiding a condition that a single module cannot adapt to various types of imbalance conditions and achieves the equalizing function and effect improvement.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD TAIZHOU POWER SUPPLY BRANCH +1

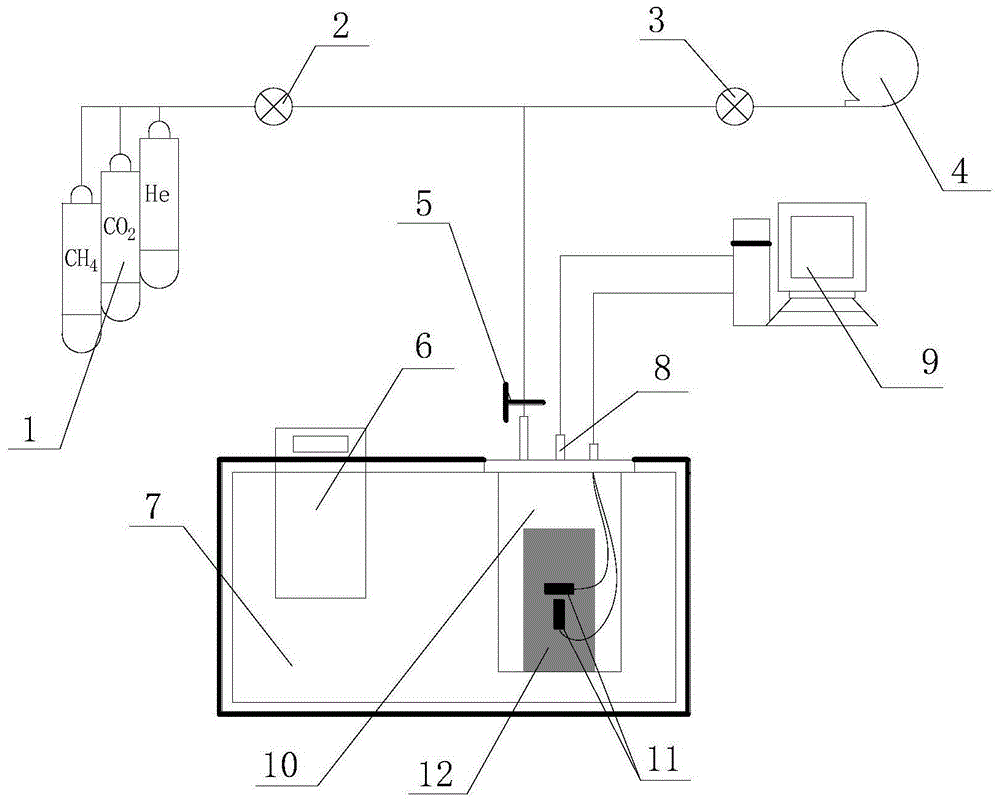

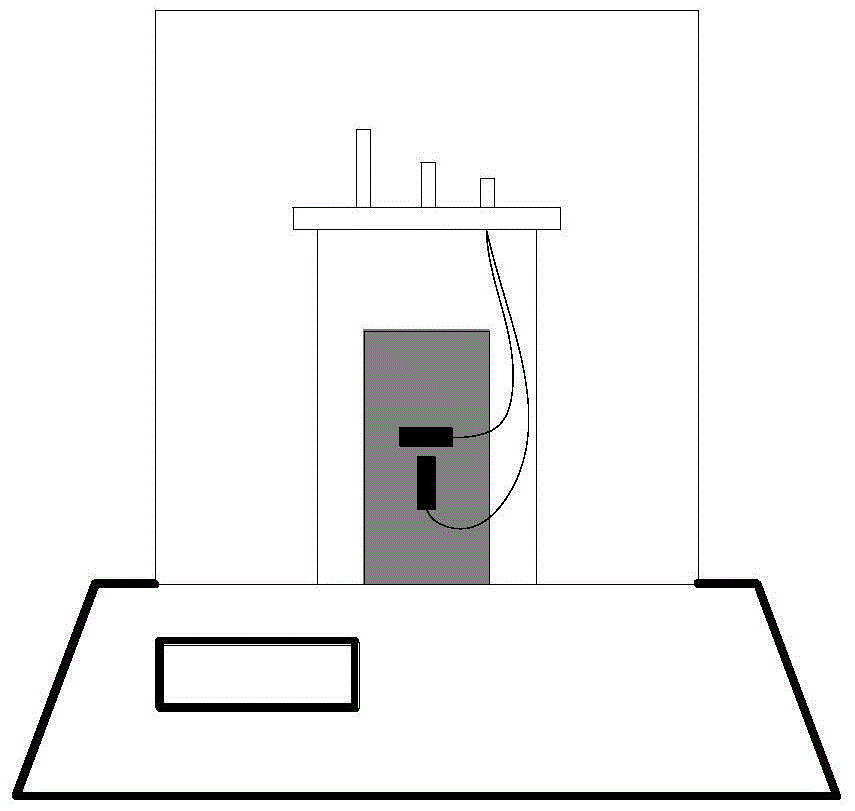

Test method for measuring rock mass constant temperature adsorption and monitoring rock mass strain and instrument

InactiveCN105043920AAvoiding Difficulties in High-Precision CalibrationImprove reliabilityStrength propertiesWeighing by absorbing componentAdsorption equilibriumParticle size measurement

Belonging to testing methods and instruments for rock mass constant temperature and rock mass strain, the invention relates to a test method for measuring rock mass constant temperature adsorption and monitoring rock mass strain and an instrument. According to the test method, rock mass constant temperature adsorption capacity is measured by an indirect gravitational method, at the same time, transverse and longitudinal strain gauges can be pasted to a side of a tested sample, the strain condition of the rock sample is monitored while the rock sample reaches adsorption equilibrium, thus being convenient to analyze the relation between rock mass adsorption and rock mass microscopic stress. A plurality of adsorption tanks are added, also adsorption test is carried out on rock samples in different particle size ranges at the same time, the rock mass sample particle size measurement range is wide, and the particle size test range covers 100micrometer-20mm. The test method calculates the sample adsorbing capacity by high precision balance weighing, which is different from the previous volumetric method for measurement of adsorbing capacity. The method can be used for determining the adsorbing capacity of rock to gas in laboratories, test enterprises and government departments. The test instrument is single, has few joints, enhances the system airtightness, and has the characteristics of simple operation, simple and reliable calculation method, and high accuracy.

Owner:CHINA UNIV OF MINING & TECH

Detection method for non-metal foreign substances in high speed steel powder

InactiveCN102507367AQuality improvementImprove toughnessWeighing by removing componentMaterial analysis by measuring secondary emissionChemical solutionMass ratio

The invention belongs to the field of powder high speed steel, and relates to a detection method for non-metal foreign substances in high speed steel powder. According to the method, the high speed steel powder is taken; a phosphoric acid aqueous solution is added as a chemical corrosive agent, wherein a mass ratio of the high speed steel powder to the phosphoric acid aqueous solution is 1:40; a discontinuous stirring treatment is performed for 2-8 hours at a room temperature; the resulting mixing solution passes through a test sieve to carry out screening for the powder-containing phosphoric acid aqueous solution, and the resulting substances on the sieve (the non-metal foreign substances) are repeatedly washed and dried; quantitative analysis and qualitative analysis of the non-metal foreign substances are performed through a precision balance and a scanning electron microscopy. According to the present invention, the weak acid chemical corrosion method is adopted to dissolve the high speed steel powder matrix in the chemical solution to separate the foreign substances from the high speed steel powder, and finally the quantitative analysis and the qualitative analysis are performed on the non-metal foreign substances; the method has advantages of rapidness and high efficiency, low cost, accurate analysis, and the like, and the quantitative analysis and the qualitative analysis can be performed on the non-metal foreign substances with the method of the present invention.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

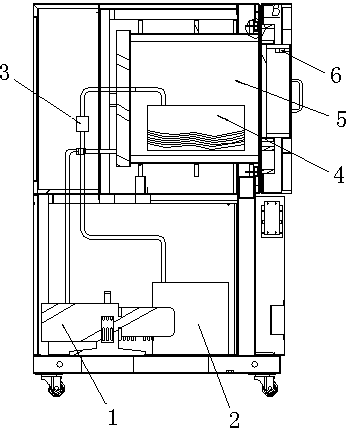

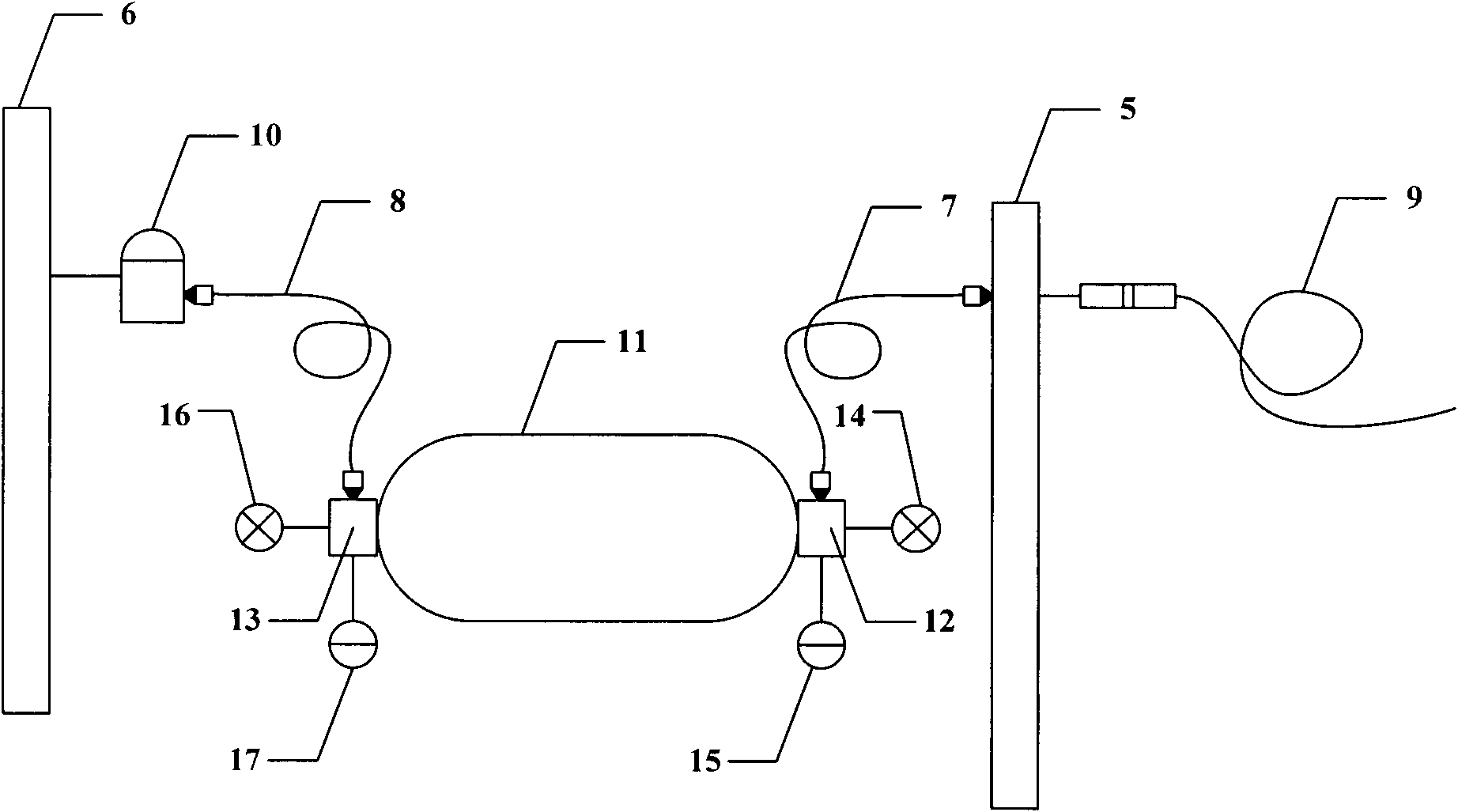

Fuel consumption assessment device for fuel cell vehicle

InactiveCN101975663AGuarantee R&DGuarantee universalInternal-combustion engine testingFuel cellsGas cylinder

The invention discloses a fuel consumption assessment device for a fuel cell vehicle, belonging to the technical field of new energy vehicle performance test and assessment. The fuel consumption assessment device is used for assessing the fuel consumption and economical efficiency of the fuel cell vehicle, and comprises a gas source bottle rack and a pipeline system connected with the gas source bottle rack, wherein the pipeline system is connected with the fuel cell vehicle; the gas source bottle rack comprises a gas bottle bracket, a temperature sensor and a pressure sensor; the gas bottle bracket is used for accommodating gas bottles, and the temperature sensor and the pressure sensor are used for measuring the gas in the gas bottles, and the fuel consumption is calculated based on the measuring results of the temperature sensor and the pressure sensor; the fuel consumption assessment device also comprises a weighing device; and the weighing device comprises a windproof and shockproof tank body, a precision balance and a balance weighing auxiliary device, and is used for carrying out fine measurement on the fuel consumption. The fuel consumption assessment device can realize measuring the fuel consumption of heavy type fuel cell vehicles and assessing the fuel economy of the heavy type fuel cell vehicles.

Owner:清华大学苏州汽车研究院(吴江) +1

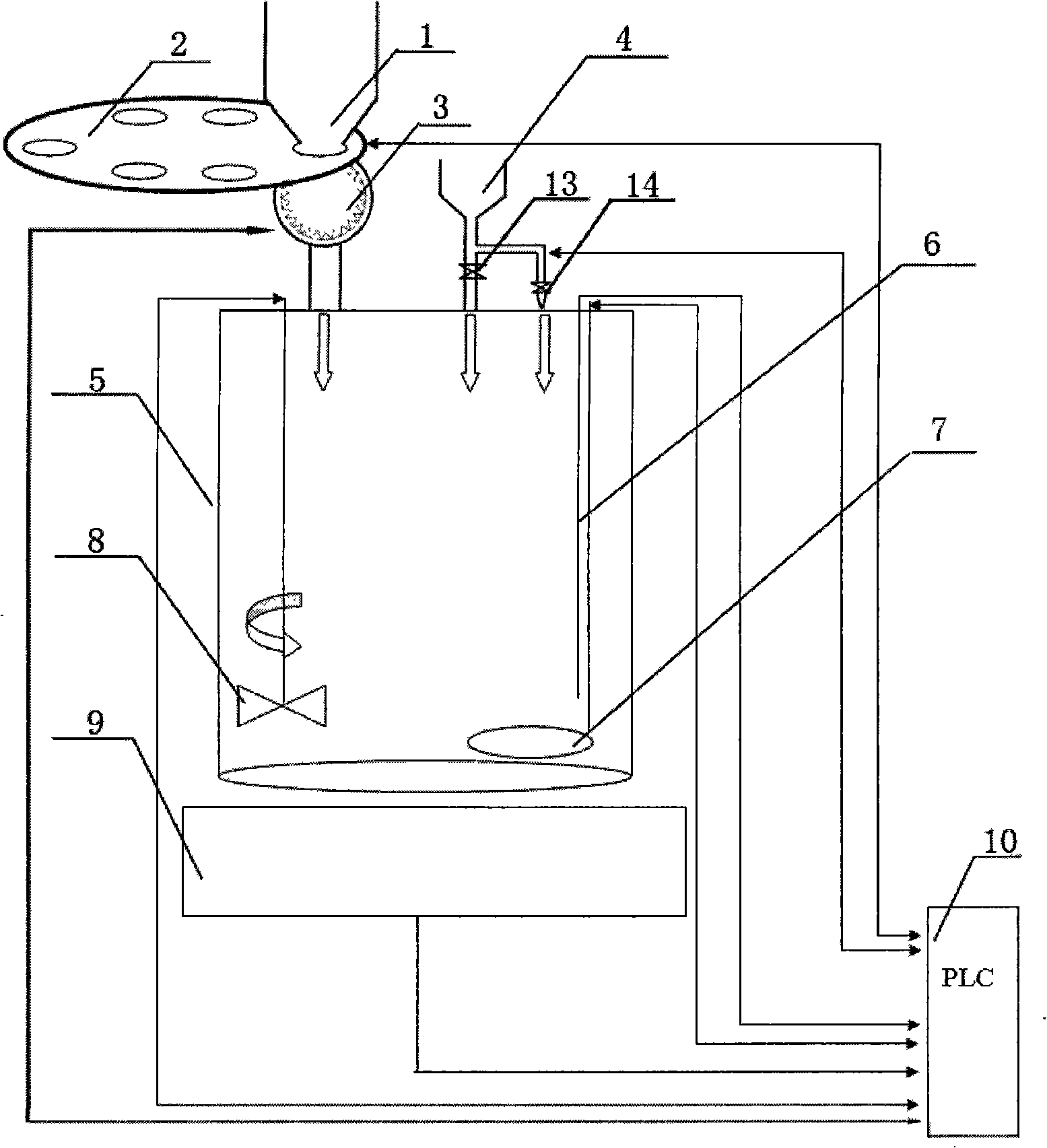

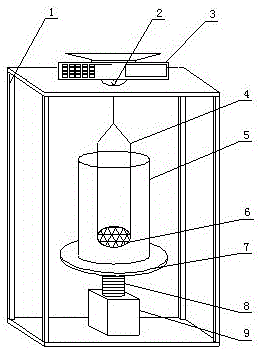

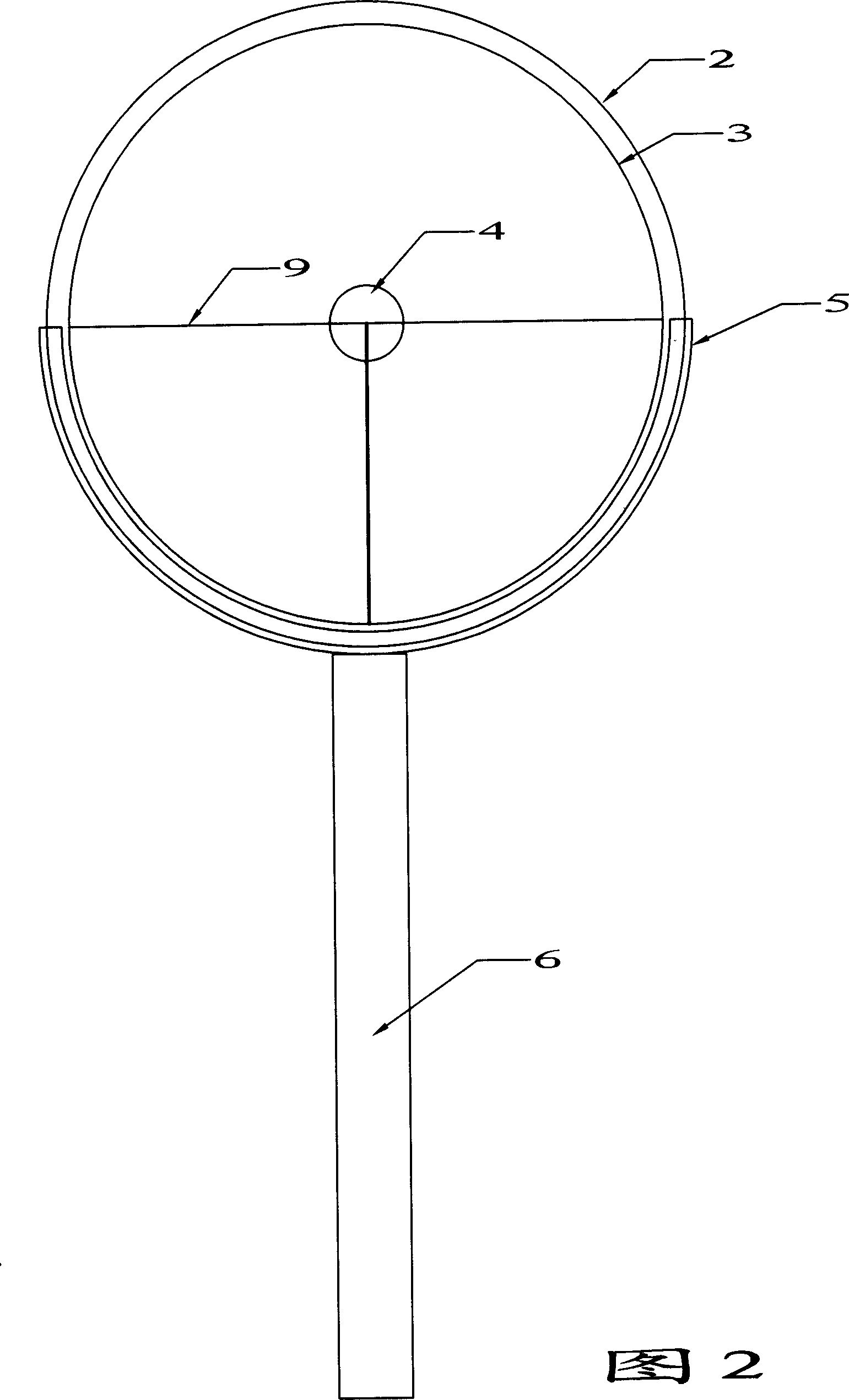

Precise chemical reagents preparation instrument

The invention provides a precise chemical reagent compounding instrument which is applicable to chemicals, chemistries, medicines, foods, beverage, etc. which require solid-solid, solid-liquid and liquid-liquid precise compounding. The compounding instrument is characterized in that the precise chemical reagent compounding instrument comprises a liquid bell and hopper 4, a solid charging device 3 and a material selection device 2 which are arranged at the upper part of a position where a reagent bottle 5 is arranged, a temperature sensor 6 and a mixing device 8 which are arranged in the reagent bottle 5, a heating device 7 which is arranged at the bottom of the reagent bottle 5, a precision balance 9 which is arranged at the external part of the bottom of the reagent bottle 5, a PLC 10 which controls the material selection device 2, the solid charging device 3, the liquid bell and hopper 4, the temperature sensor 6, the heating device 7, the mixing device 8 and the precision balance 9. The compounding instrument of the invention has simple and convenient reagent compounding, realizes that the performance indexes such as temperature and density, etc. are fed back by query, automatic computation and data recording function, can be used in a laboratory for compounding a plurality of reagent and has the functions of recording, automatic conversion and output printing, etc., and has simple, convenient and scientific reagent compounding.

Owner:HENAN POLYTECHNIC UNIV

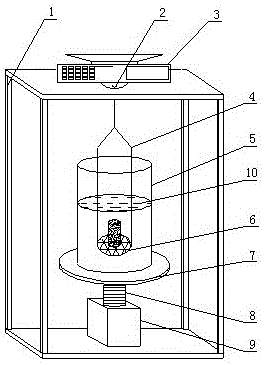

Making method of rock sample with specific water content in unsaturated water state

InactiveCN105910860ASimple methodEasy to operatePreparing sample for investigationDistilled waterWater state

The invention relates to a making method of a rock sample with specific water content in an unsaturated water state. The making method comprises the following steps: 1, making a rock sample with natural water content according to GB / T50266-99 Engineering Rock Test Method Standard; 2, drying the rock sample with natural water content, and recording the mass m1 of the dried rock sample in air; 3, putting the dried rock sample in a beaker (5), adding distilled water (10), and recording to the mass m2 of the dried rock sample in water; 4, obtaining the rock sample with specific water content according with a theoretical value when the mass of the rock sample immersed in water on a precision balance (3) reaches the theoretical mass m3 of the rock sample with specific water content in water; and 5, obtaining the rock sample with specific water content in an unsaturated water state when the practical water content error epsilon of the rock sample with specific water content according with the theoretical value is not greater than 5%, and repeating above steps when the practical water content error epsilon is greater than 5%. The method has the characteristics of simplicity, convenient operation, high efficiency and high precision.

Owner:WUHAN UNIV OF SCI & TECH

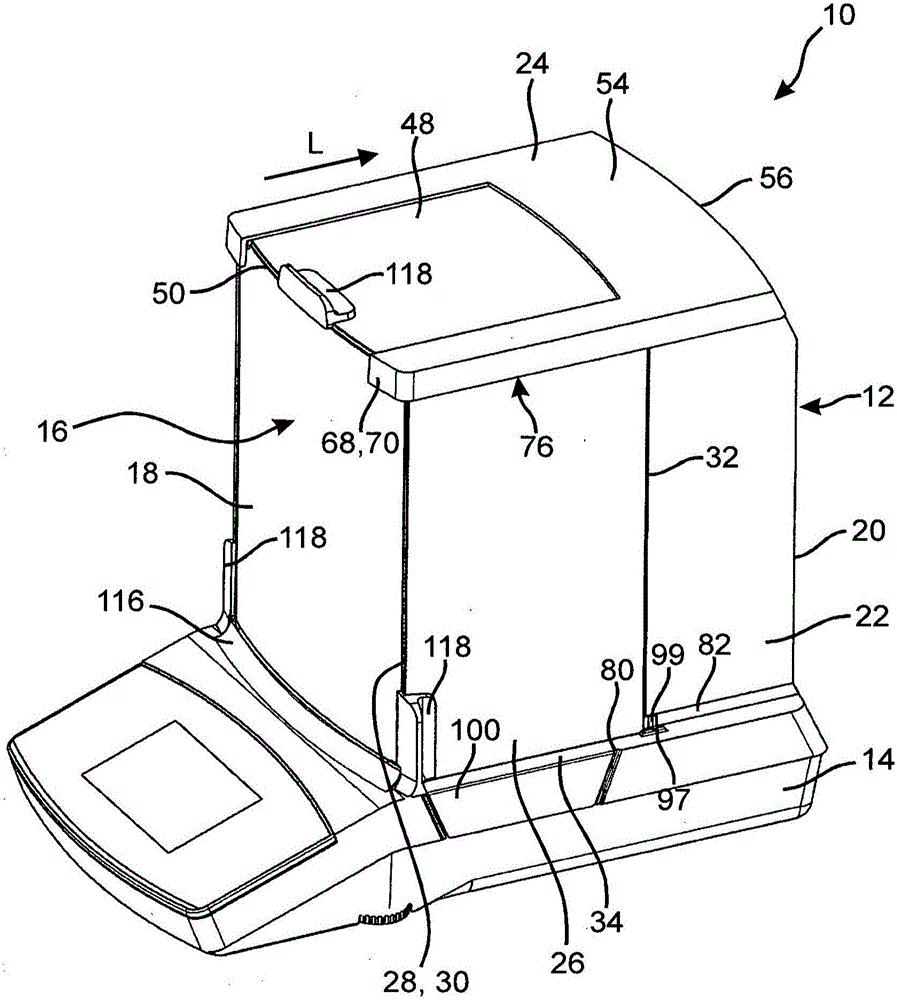

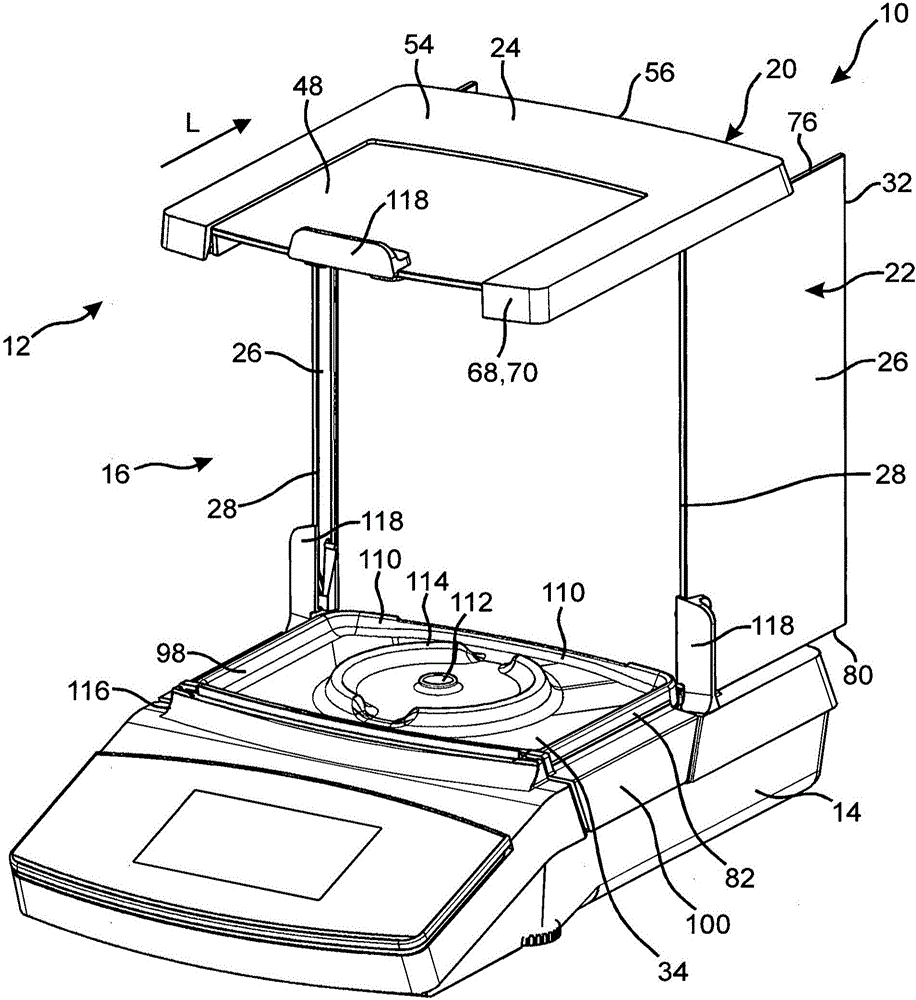

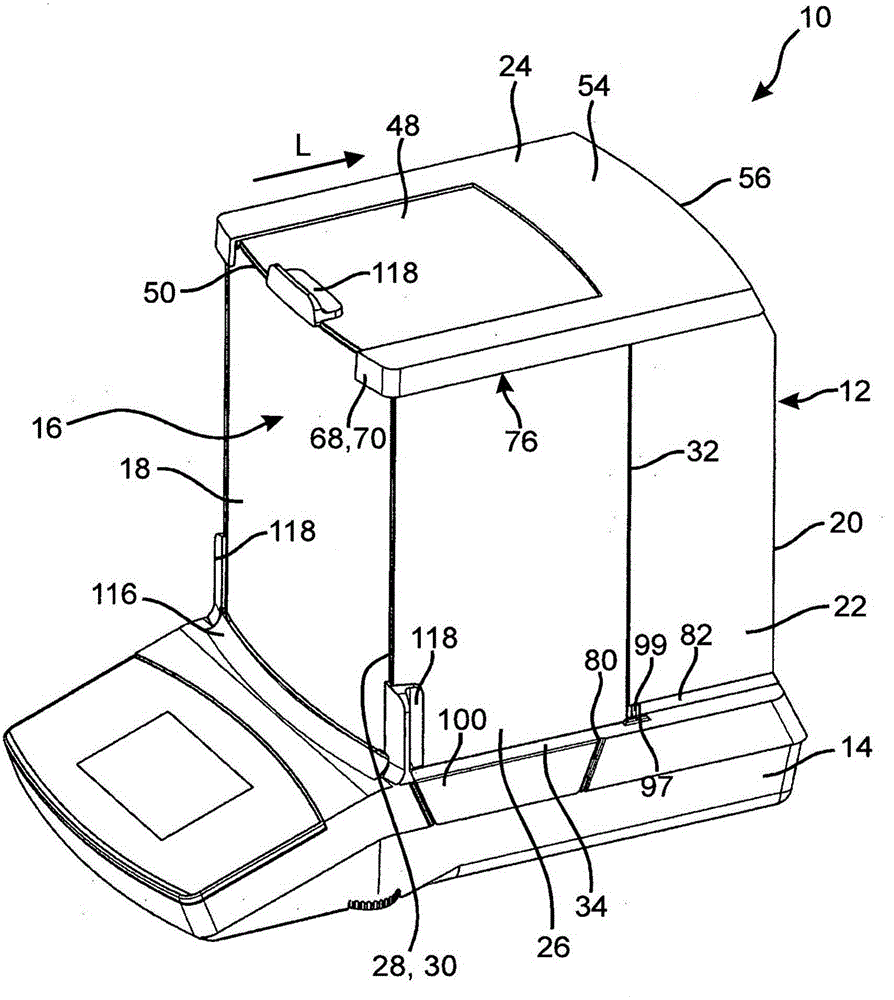

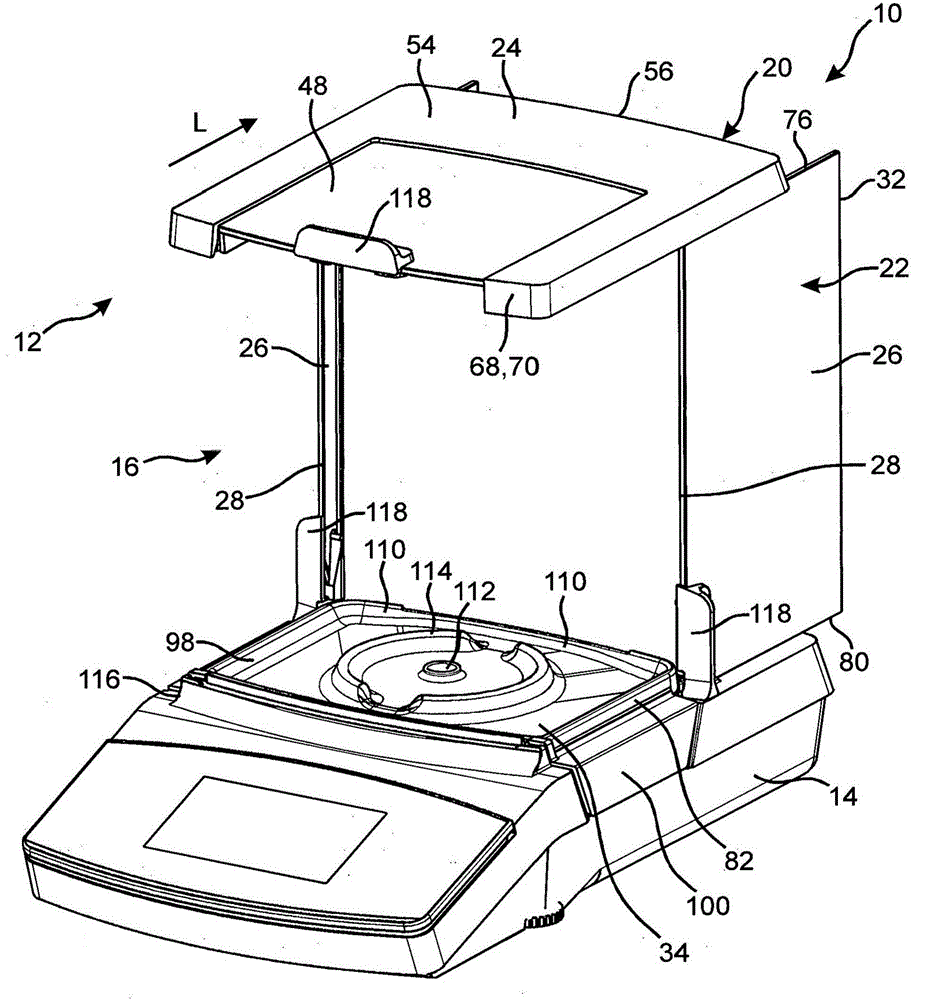

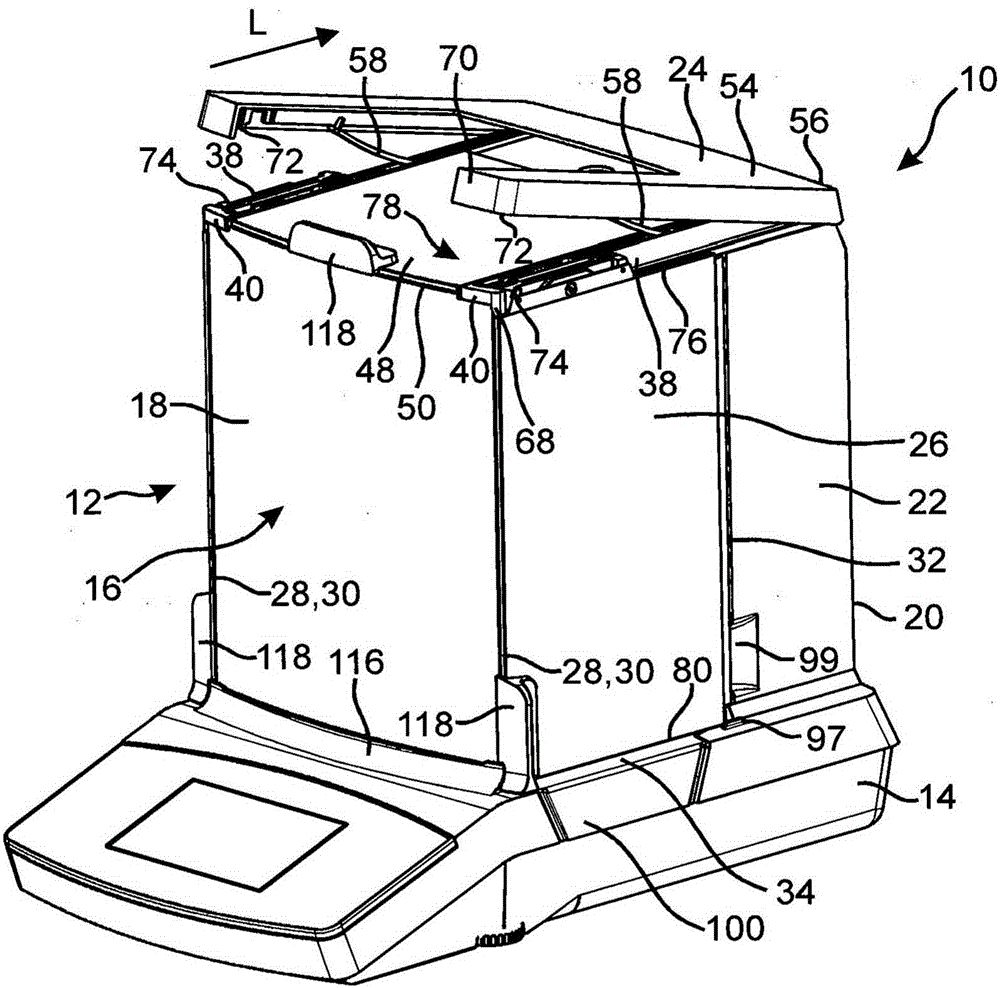

Weighing-chamber base and draught shield for a precision balance, and precision balance

ActiveCN106133486AEasy to disassembleImprove protectionWeighing apparatus detailsEngineeringBiomedical engineering

A weighing-chamber base (34) for a precision balance (10) has a weighing-base portion (98) and two side pieces (100) which are arranged vertically on the weighing-base portion (98), on opposite peripheries (102) of the weighing-base portion (98), and are located outside the draught shield. A draught shield (12) is provided for a precision balance (10), having a weighing-chamber base (34) according to the invention and having at least one side panel (26), which can be displaced between an open position and a closed position, wherein the side pieces (100) of the weighing-chamber base (34) form part of the side walls (22) of the draught shield (12). Also provided is a precision balance (10) having a housing and a weighing-chamber base (34) according to the invention or a draught shield (12) according to the invention, wherein the side pieces (100) of the weighing-chamber base (34) form part of the side walls of the housing.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

Precision balance measuring instrument

InactiveCN1932463AHigh measurement accuracyWide measurement rangeStatic/dynamic balance measurementMeasuring instrumentElectrical polarity

A high precision traverse adjustment for measuring the imbalance quality of the rotating member is provided in the invention. It puts the magnetic canister into the bigger magnetic slot to suspend the magnetic canister by the repulsive force produced by the same polarity. The tested part is rotating with the magnetic canister droved by the cord or connected by the sleeve. So it can get the distribution and the magnitude of the imbalance quality according to the gravity sagged theory. So it can avoid the interface and improve the measuring precision.

Owner:冯昌荣

Preparation method of degradation controllable PLLA (poly-L-lactic acid)/PGA (poly glycolic acid) composite membrane

The invention relates to a preparation method of a degradation time controllable PLLA (poly-L-lactic acid) / PGA (poly glycolic acid) composite membrane. The preparation method includes the steps: weighing PLLA and PGA by a precision balance and uniformly mixing the PLLA and the PGA according to needed degradation time; increasing the temperature to reach 65-70 DEG C and drying mixture for 3-4 hours to perform pre-crystallization; continuing increasing the temperature to reach 110 DEG C and drying the pre-crystallization mixture for 12 hours; extruding the mixture by a double-screw extruder, adding the PLLA and PGA mixture treated in the second step into dichloromethane solution, and completely dissolving the PLLA and PGA mixture; preparing the membrane by a scraper coating machine according to a solvent evaporation method. The preparation method has the advantage that the degradation rate of the composite membrane can be set between that of the PLLA and the PGA.

Owner:TAIYUAN UNIV OF TECH

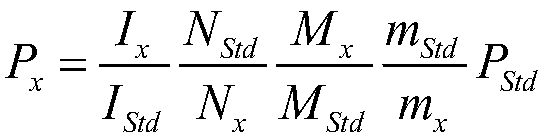

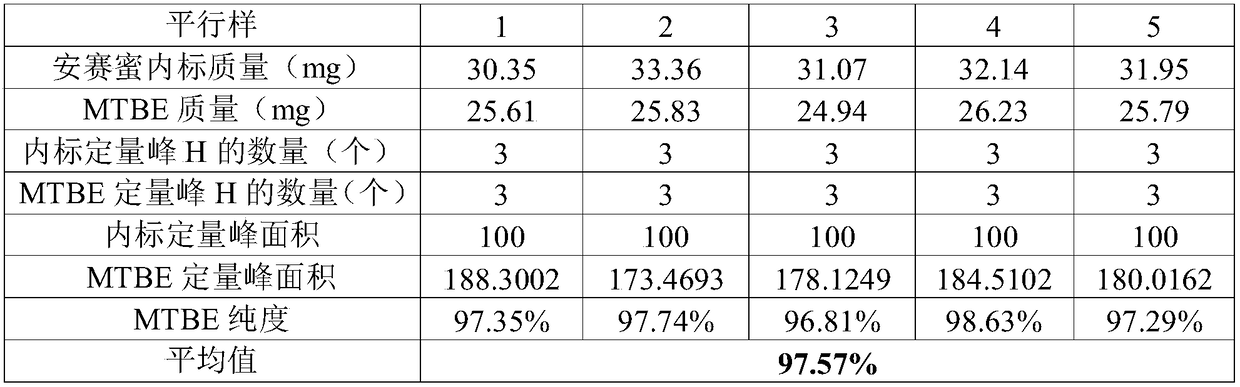

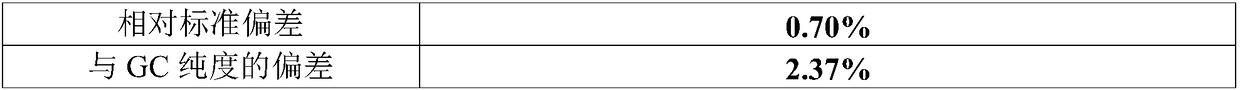

Method for accurately measuring purity of volatile substances by adopting quantitative HNMR

ActiveCN108827998AAccurately Measure PuritySolve the difficulties in the application of quantitative nuclear magnetic resonance technologyAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceHydrogen

The invention discloses a method for accurately measuring the purity of volatile substances by adopting quantitative HNMR (Hydrogen Nuclear Magnetic Resonance). The method comprises the following steps: (1), taking a volatile substance as a to-be-detected target sample; (2), taking high-purity solvent standard substance with metrological traceability as an interior label; (3), accurately weighingthe target sample and the interior label in a sealed sample bottle through an air-tight needle and a high-precision balance, and dissolving in deuterated solvent to prepare solution; and (4), after mixing uniformly, transferring the solution into a sealed nuclear magnetic tube through the air-tight needle to perform HNMR measurement. The method can effectively solve the problem that the measurement result is not accurate due to weighing deviation caused by sample volatilization. The method provided by the invention has the characteristics that the degree of accuracy is high and the result cantrace to the source of SI, and the like, and the method can be applied to scientific researches such as high-accuracy analysis and detection and standard substance valuing.

Owner:NAT INST OF METROLOGY CHINA

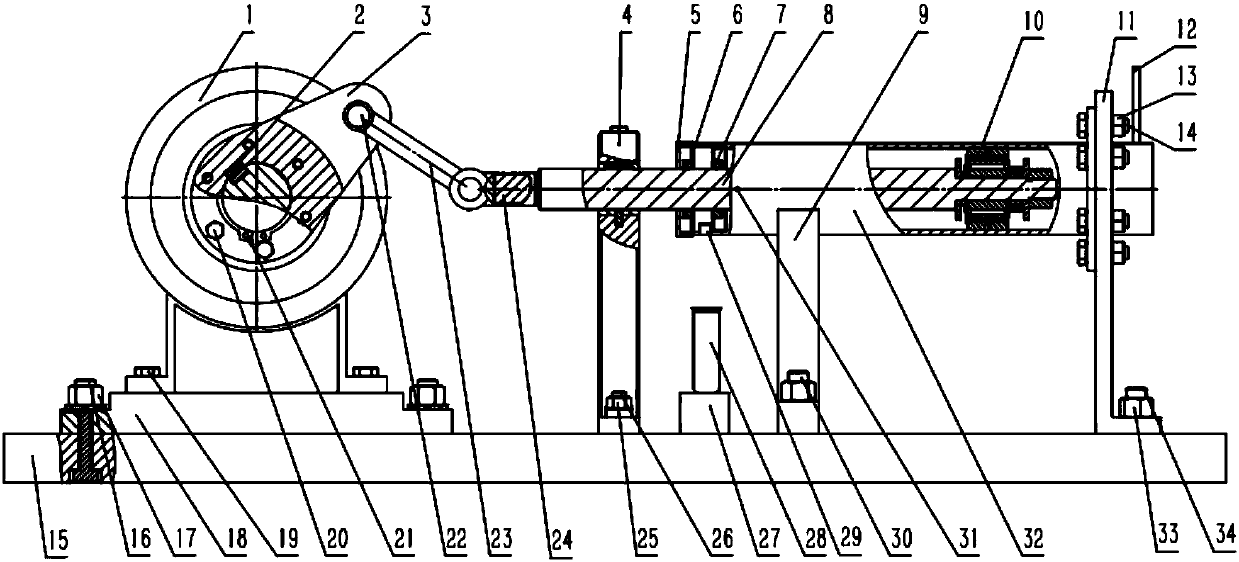

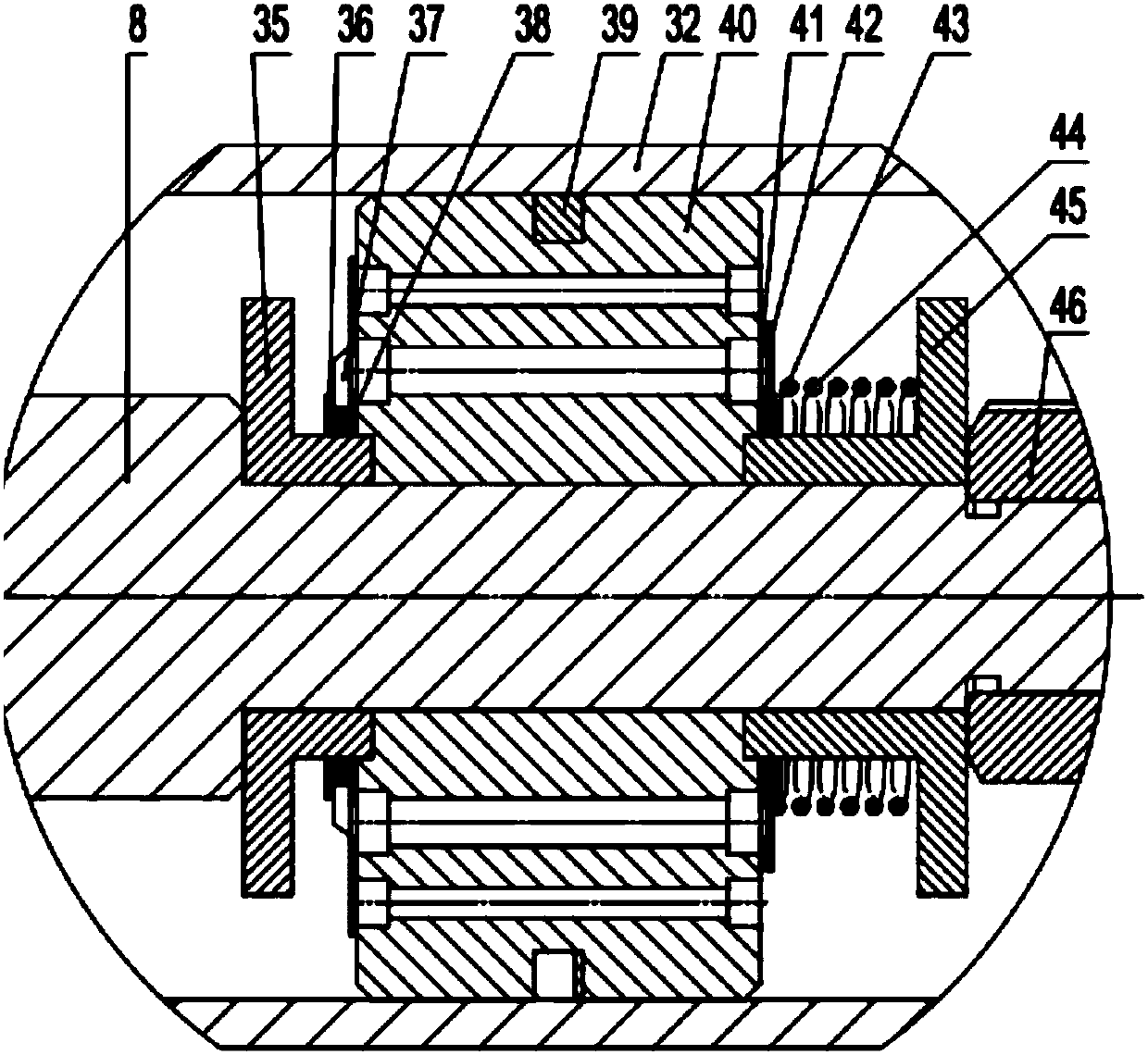

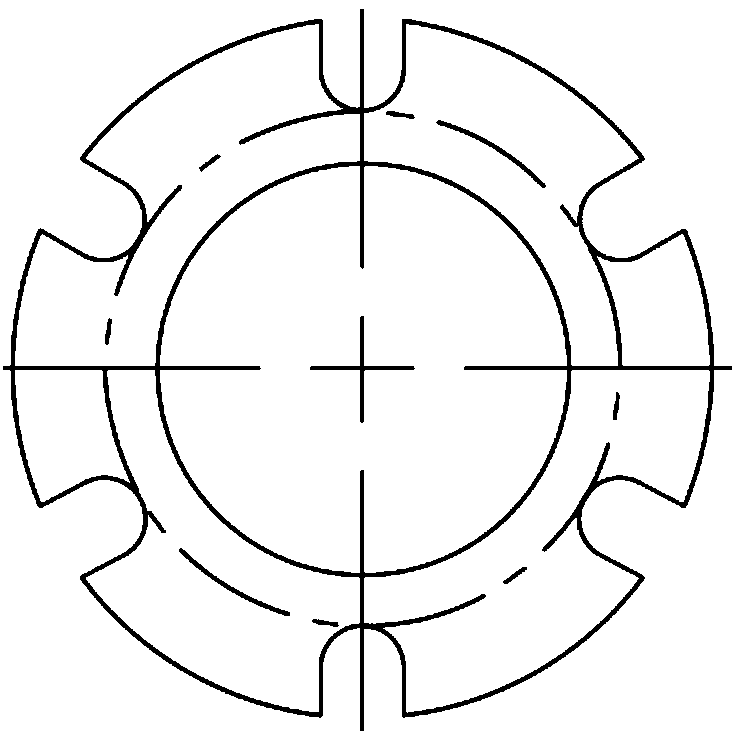

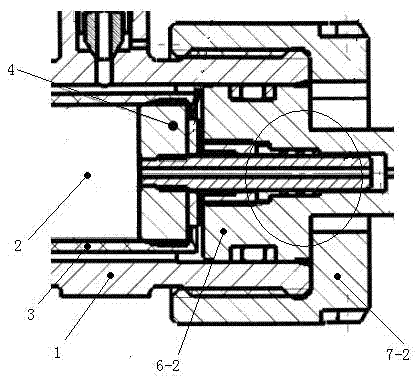

Reciprocating oil seal performance testing testbed

PendingCN107741318ASimulate pressure changesMachine sealing rings testingReciprocating motionEngineering

The invention discloses a reciprocating oil seal performance testing testbed. The reciprocating oil seal performance testing testbed comprises parts like a motor, a crank-link mechanism, a sliding bearing, an end cover, a cylinder barrel, a valve system, an oil seal and an oil supplement chamber, an output shaft of the motor is connected with the crank-link mechanism through key joint, and the crank-link mechanism is connected with a piston rod through an inner thread and an outer thread to drive the piston rod to move; oil leakage holes are formed in the bottom, provided withthe oil seal, ofthe cylinder barrel, a small beaker is put under the oil leakage holes to collect leaked oil, and the leakage amounts in different time periods are weighed through a precise balance scale; a temperature sensor is put in the position, close to the sealing portion, of the oil seal to record the temperature change of a lip portion in the motion process; the right end of the cylinder barrel is connected with the oil supplement chamber, and the oil supplement chamber can collect or supplement oil liquid during the reciprocating motion of the piston rod. By means of the reciprocating oil seal performance testing testbed, the pressure change in a sealing chamber of the reciprocating oil seal can be simulated, the leakage amounts and the temperature change of the oil seal under the conditions of different interference magnitudes, reciprocating speeds, in-oil pressures and friction coefficients are measured, and guidance is provided for manufacturing and using conditions of the oil seal.

Owner:QINGDAO UNIV OF SCI & TECH

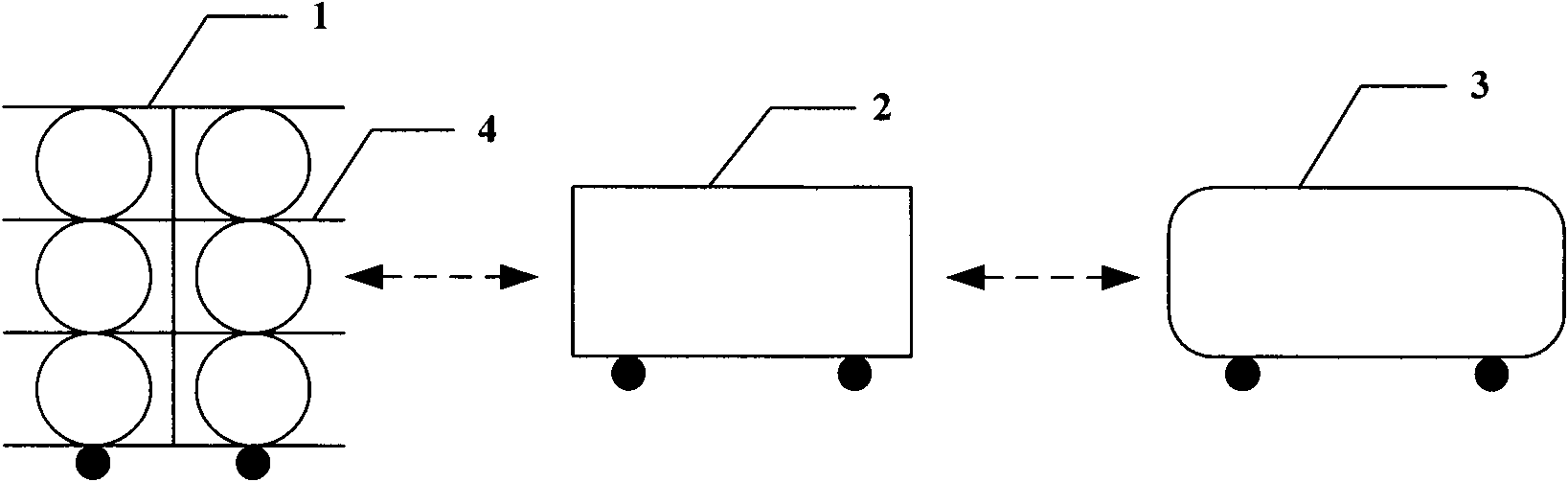

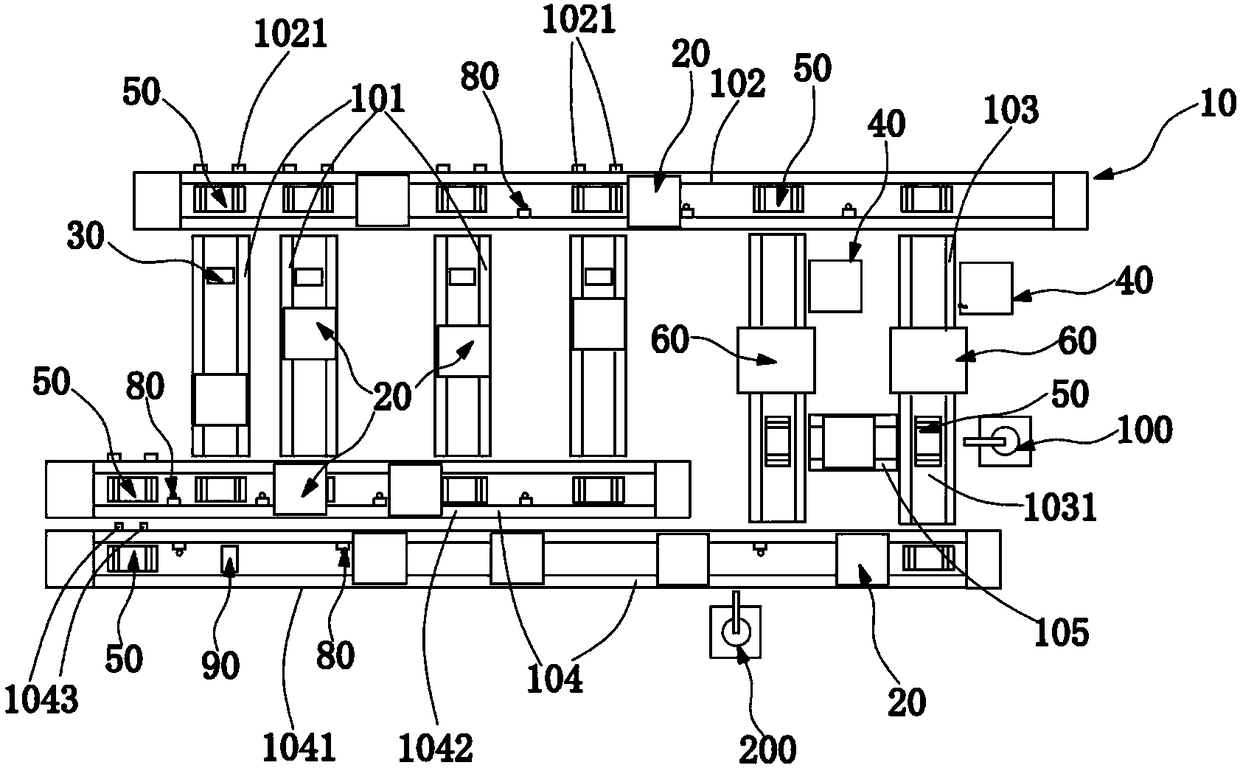

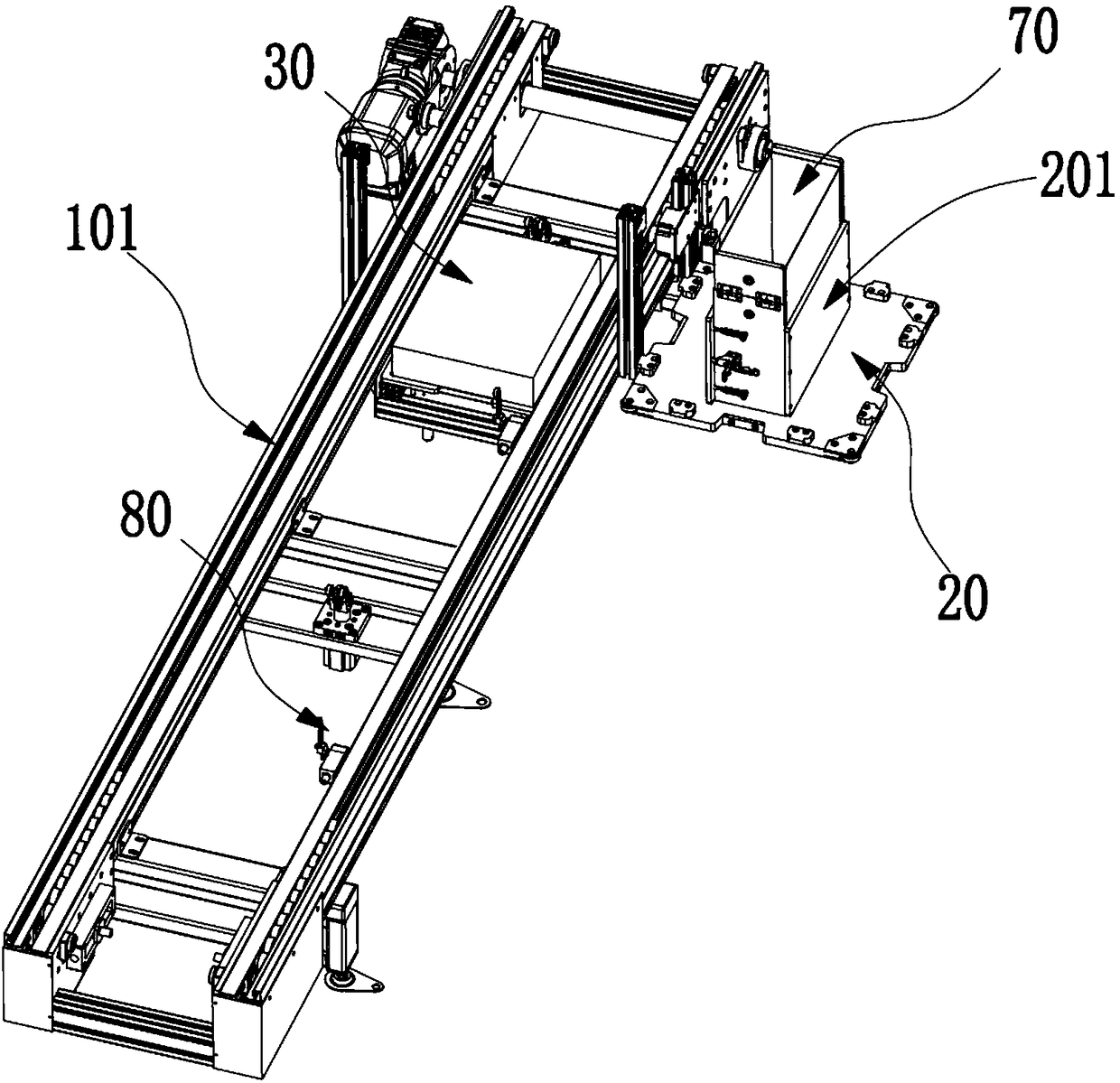

Full-automatic particle secondary balance weight packaging equipment and balance weight packaging method thereof

PendingCN108545220AReduce the risk of contaminationFast weighingPackaging under vacuum/special atmosphereSolid materialEngineeringPrecision balance

The invention discloses full-automatic particle secondary balance weight packaging equipment and a balance weight packaging method thereof. The equipment comprises tool plates capable of containing particles and circularly moving on a circular conveying line, a weighing device capable of obtaining the rough weight of the particles on the tool plates, a two-dimensional code or bar code or RFID tagfor storing rough weight data of the particles on each tool plate and / or rough weight and standard weight difference value, and a precision balance weight station obtaining the rough weight and / or therough weight and standard weight difference value through recognition of the two-dimensional code or bar code or RFID tag and supplementing the rough weight and standard weight difference value through powder. According to the scheme, circular movement of the tool plates is utilized, the weighing device is used for obtaining the rough weight of the particles on the tool plates and storing the rough weight to the two-dimensional code or bar code or RFID tag, rough weight information is obtained through recognition equipment, and accordingly powder can be accurately supplemented for reaching ofthe standard weight; and through two-time weighing and powder supplementing, rapid polycrystalline silicon particle weighing and uniform weight and precision guaranteeing are effectively achieved, and the automation degree is high.

Owner:SUZHOU HONBEST CLEAN TECH CO LTD

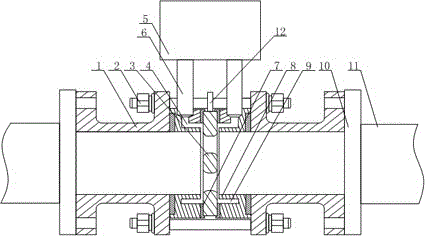

High-precision balancing flowmeter

InactiveCN105973320AReduce complex proceduresReduce work intensityVolume/mass flow by differential pressureSpray nozzleEngineering

The invention discloses a high-precision balancing flowmeter. The high-precision balancing flowmeter comprises connecting pipes, a straight pipe section, a sensor, two packer rings and two pressure measuring pipes, wherein the two connecting pipes are connected through a bolt, the other end of each connecting pipe is connected with the straight pipe section, the packer rings are arranged on the end faces of the two connecting pipes, a pore plate body is arranged between the two packer rings, and multiple nozzles are arranged on the pore plate body; an air duct communicated with the interior of the corresponding connecting pipe is formed in one side of each packer ring, one end of each pressure measuring pipe is communicated with the corresponding air duct, and the other end of each pressure measuring pipe is communicated with the sensor; a buffer groove communicated with the interior of the corresponding connecting pipe is formed in the inner wall of the other side of each packer ring; each nozzle is composed of a shrinkage section with inner diameter decreasing gradually in the flowing direction of fluid, a straight section and an enlargement section with inner diameter increasing gradually in the flowing direction of fluid, wherein the shrinkage section, the straight section and the enlargement section are connected in sequence. The connecting pipes are connected through a flange, the connecting pipes and the straight pipe section are connected through flanges, so that the practicality of the connecting pipes in measurement of different types of sensors is improved greatly, and installation and detachment can be achieved conveniently and quickly.

Owner:CHENGDU GUOGUANG ELECTRONICS INSTR

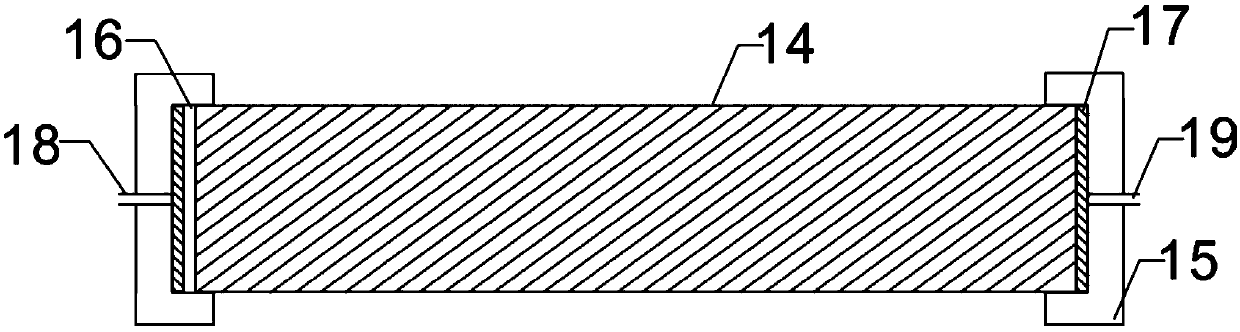

Ultrahigh pressure and high temperature core holder

ActiveCN102778417AAchieve precision weighingReduce quality problemsFlow propertiesEngineeringTitanium alloy

The invention relates to an ultrahigh pressure and high temperature core holder, which comprises a core cabin, and a left seal plug and a right seal plug positioned at two ends of a core cabin cylindrical space and screwed tightly as well as sealed by a left compaction nut and a right compaction nut. The outer ends of the left seal plug and the right seal plug are respectively equipped with a left built-in needle valve and a right built-in needle valve. The inside of the core cabin 1 cylindrical space includes a core, choke plugs and a sleeve. Two sides of the core are respectively equipped with a choke plug. The choke plugs are in close contact with the core, and they are placed in a cylindrical sleeve inside the core cabin together. The outer wall of the core cabin is equipped with an upper built-in needle valve and a lower built-in needle valve. The holder core cabin, the choke plugs, the seal plugs, the compaction nuts, the built-in needle valves and valve accessories all employ a titanium alloy material, and the sleeve adopts polyetheretherketone. The core holder has the characteristics of ultrahigh pressure and high temperature, as well as light mass. With a highest bearable pressure of 200MPa, a highest temperature of 250DEG C, and an overall mass of 2600g, the core holder can realize precise weighing in a precision balance, thus providing a reliable guarantee for core flow experiments under ultrahigh pressure and high temperature conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Copper-based composite material and preparation method thereof

ActiveCN110257664AGood comprehensive performance indexSimple processMaterials preparationNuclear radiation

The invention relates to a copper-based composite material and a preparation method thereof, and belongs to the field of metal and composite materials thereof. The copper-based composite material comprises the following components of, in percentage by weight, 3%-18% of W, 0.5%-5% of B4C, and the balance copper. The preparation method comprises the following steps of firstly, selecting high-purity Cu powder, W powder and B4C powder, and weighing the Cu powder, the W powder and the B4C powder by adopting a high-precision balance, and carrying out vacuum ball milling for 2 h-8 h; secondly, filling the mixed powder into a mold made of heat-resistant steel, and then putting the mold into a vacuum hot-press sintering furnace for hot-pressing sintering forming, wherein the sintering temperature is 950 DEG C-1030 DEG C, the sintering pressure is 50 MPa-60 MPa, the heat and pressure preservation time is 1 h-3 h, and the vacuum degree is 10<-3> Pa; finally, carrying out cooling along with the furnace after the sintering is completed. The copper-based composite material preparation method has the advantage of being simple in process, and the prepared copper-based composite material has good comprehensive performance and can be used in strict working conditions of power receiving, abrasion, corrosion and nuclear radiation interaction, thus having a very wide application prospect and popularization value.

Owner:HENAN UNIV OF SCI & TECH

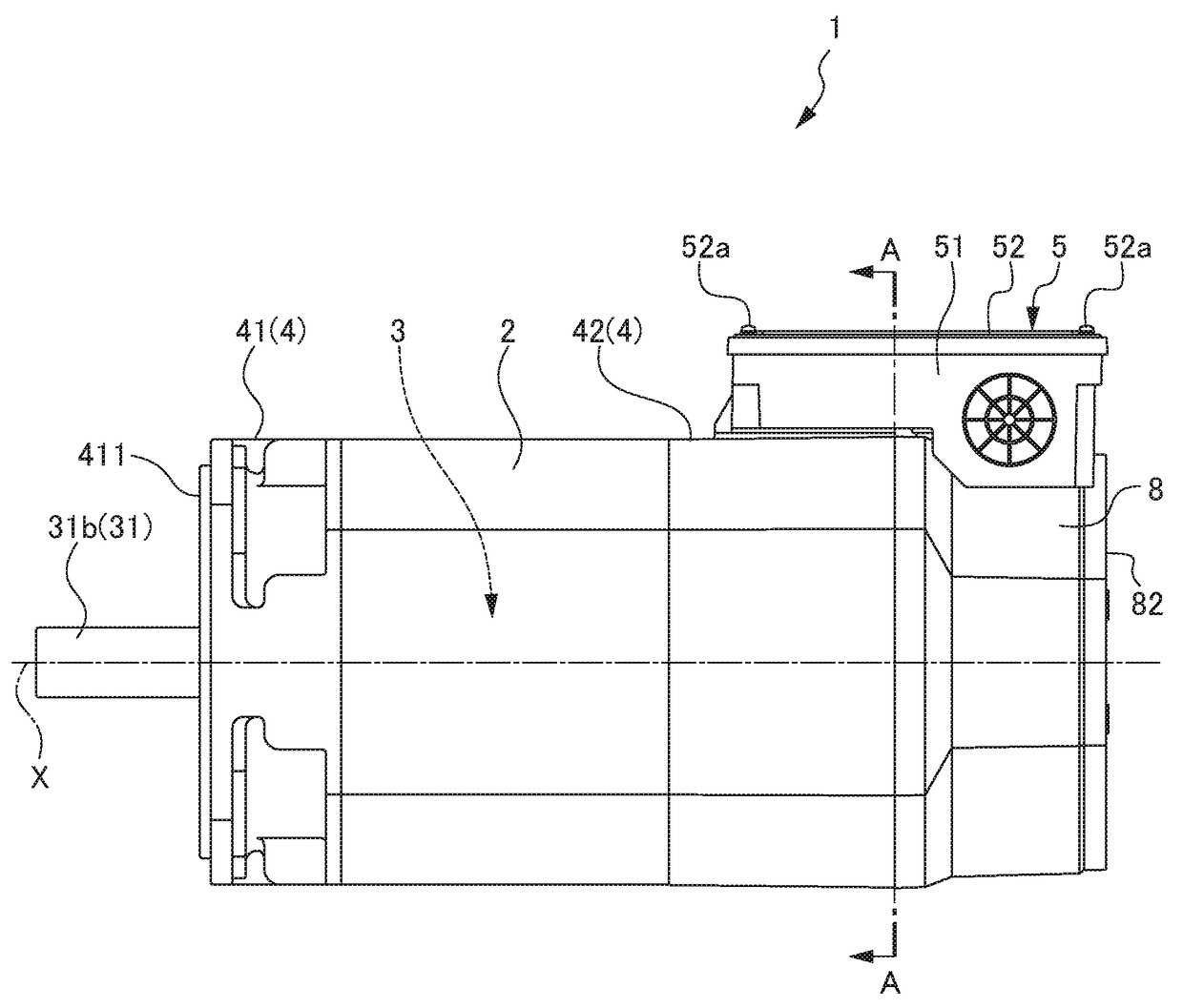

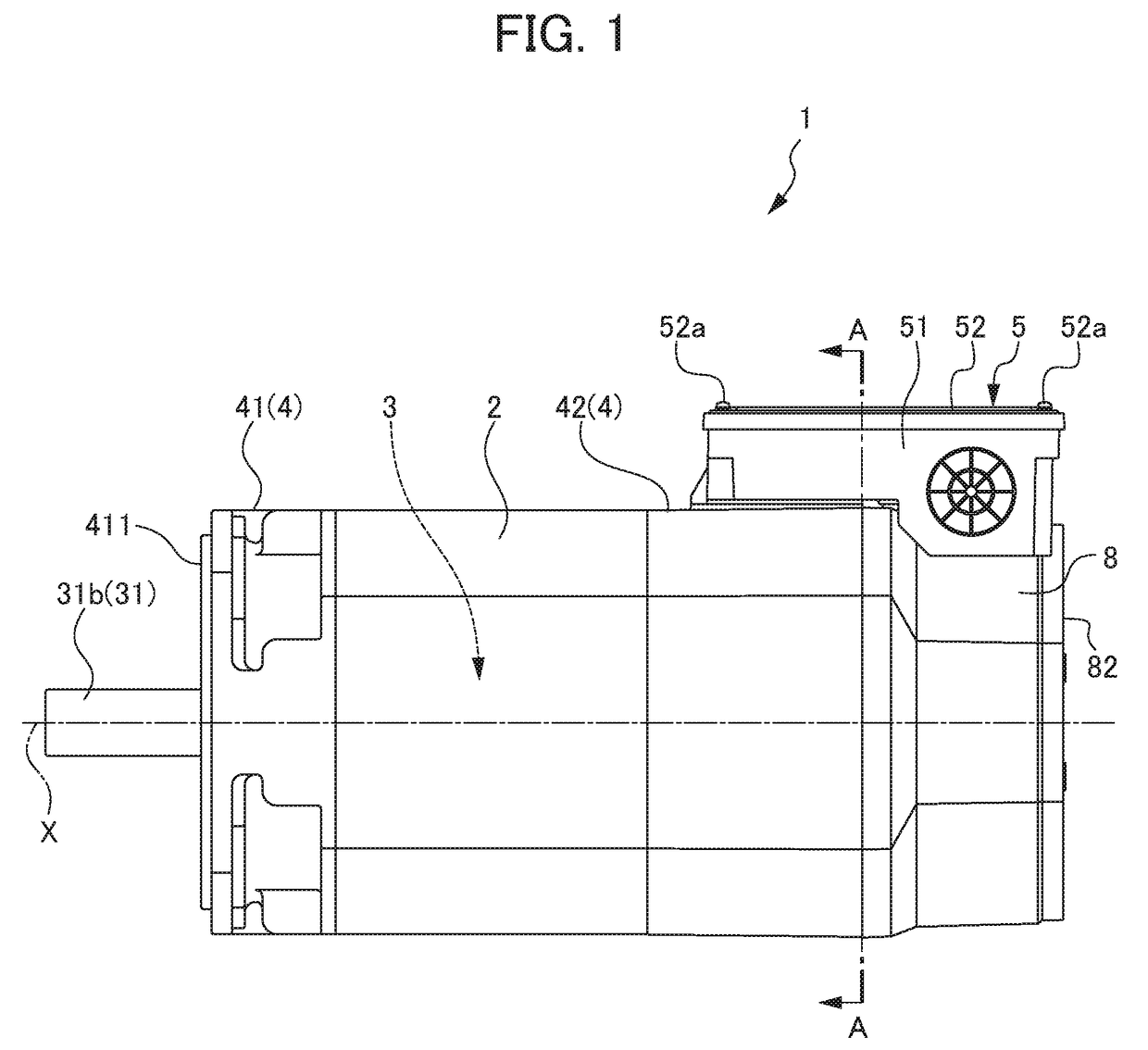

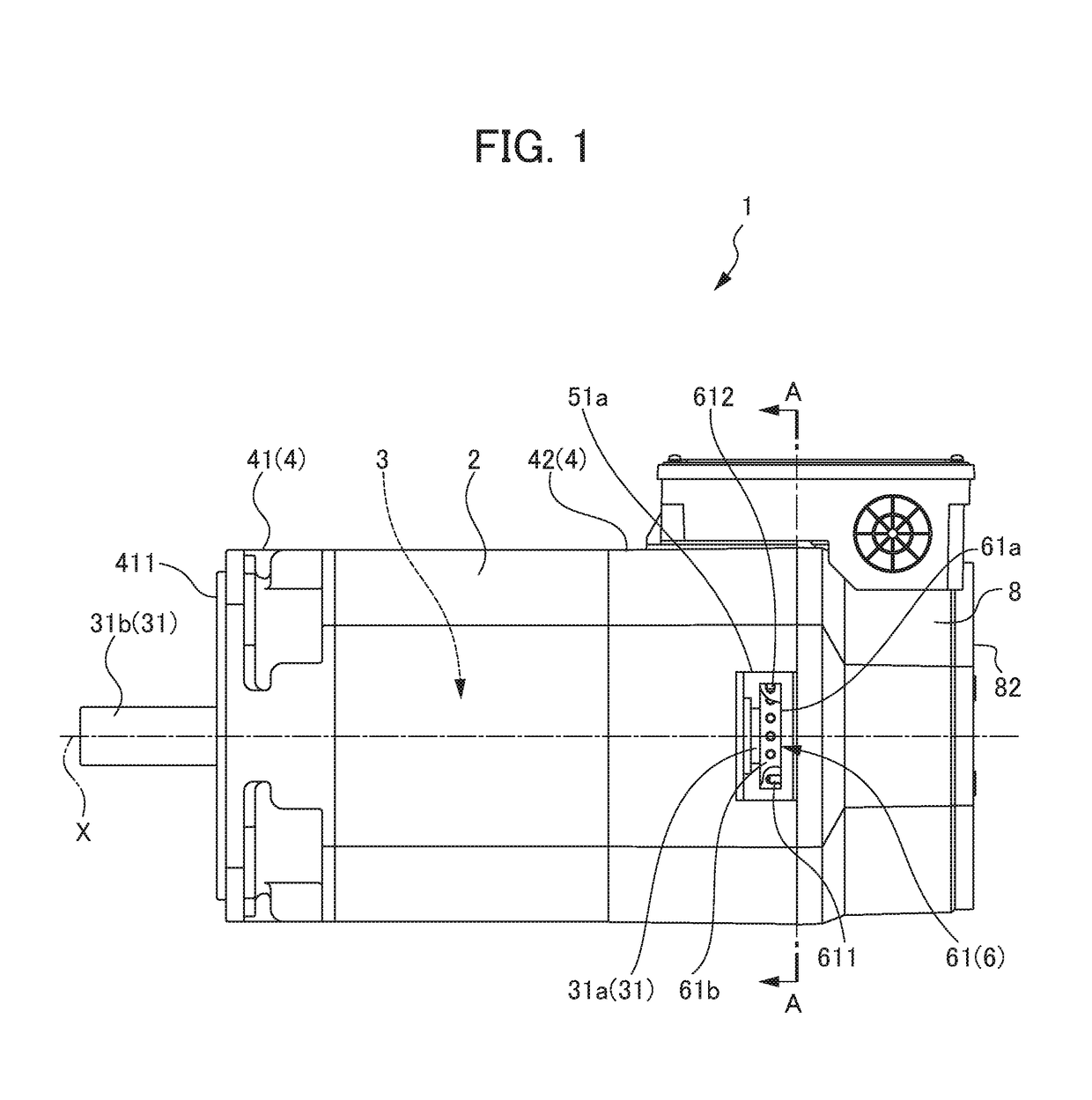

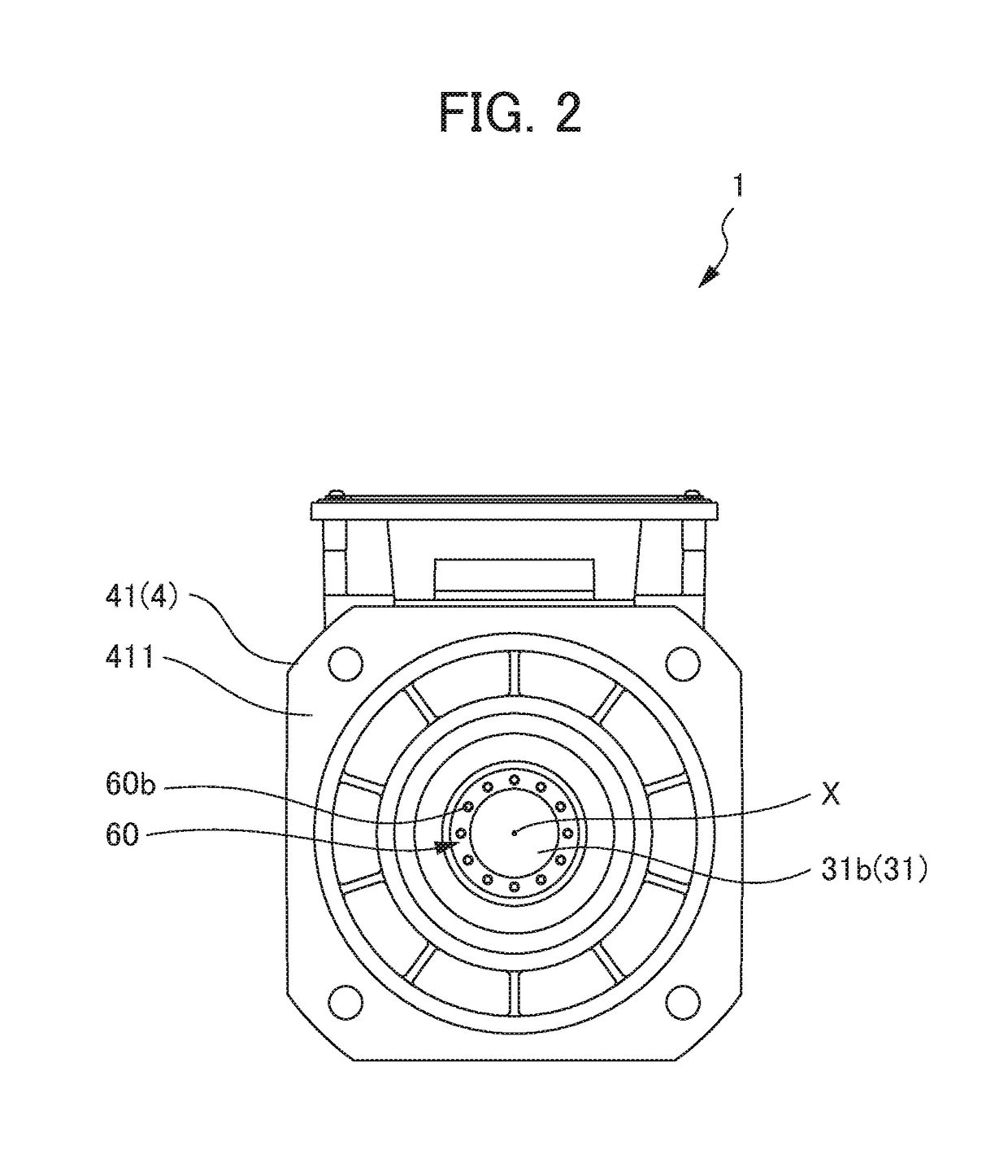

Electric motor and machine tool equipped with the electric motor

ActiveUS20170373572A1Easy and high-precision balance correctionEasy and balanceMechanical energy handlingCentering/balancing rotorsEngineeringMachine tool

To provide an electric motor enabling easy and high-precision balance correction even after operating over a long period, and a machine toll including this electric motor. An electric motor includes: a cylindrical stator; a rotor having a rotary shaft part inserted inside of the stator; a housing installed to both ends in an axial direction of the stator; a terminal box that is mounted to the housing and accommodates a terminal block; an opening provided so as to open within the terminal box through the housing, and disposed to be separated from a ventilation passage formed in the stator; and a first balance correction component that is installed to the rotary shaft part, and corrects balance of the rotor, in which the first balance correction component is exposed within the terminal box from the opening; and a machine tool includes this electric motor.

Owner:FANUC LTD

Sound field enhanced air flow drying and boundary layer measurement integration experiment system

InactiveCN105627964AChange flow fieldAffects the distribution of the airflow fieldWeighing by removing componentDrying gas arrangementsElectrical resistance and conductanceMeasurement device

The invention discloses a sound field enhanced air flow drying and boundary layer measurement integration experiment system comprising a dry air circulation device, a replaceable air flow distribution device, a sound wave generating device, a dried object weight measurement device, and a boundary layer measurement device. The dried object weight is measured by a precision balance disposed on a drying box, and an air circulating fan is communicated with the drying box by an inlet air circulation pipeline and an outlet air circulation pipeline to form a closed loop. The boundary layer measurement device is constituted by a thermistor thermometer C inserted in the air flow pipeline, a pitot tube, and a shifter. The outlet air circulation pipe is provided with a pore plate flowmeter. By adopting the experiment system provided by the invention, the drying rate curve of the dried object can be determined under the constant drying condition, the influences of the flow field and the sound wave on the drying process can be inspected, and the speed boundary layer and the temperature boundary layer can be measured. The experimenter can master the definition and measurement method of the object drying rate, the speed boundary layer, and the temperature boundary layer by using the experiment system.

Owner:SICHUAN UNIV

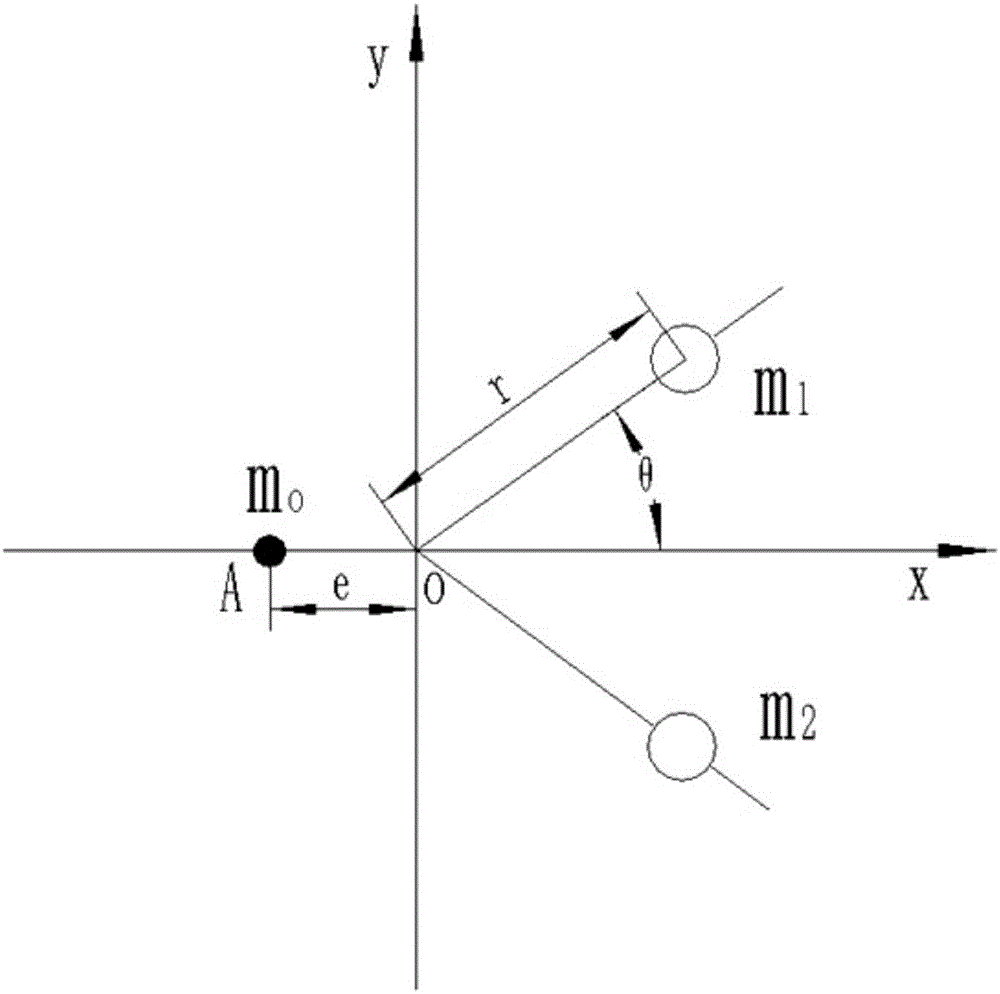

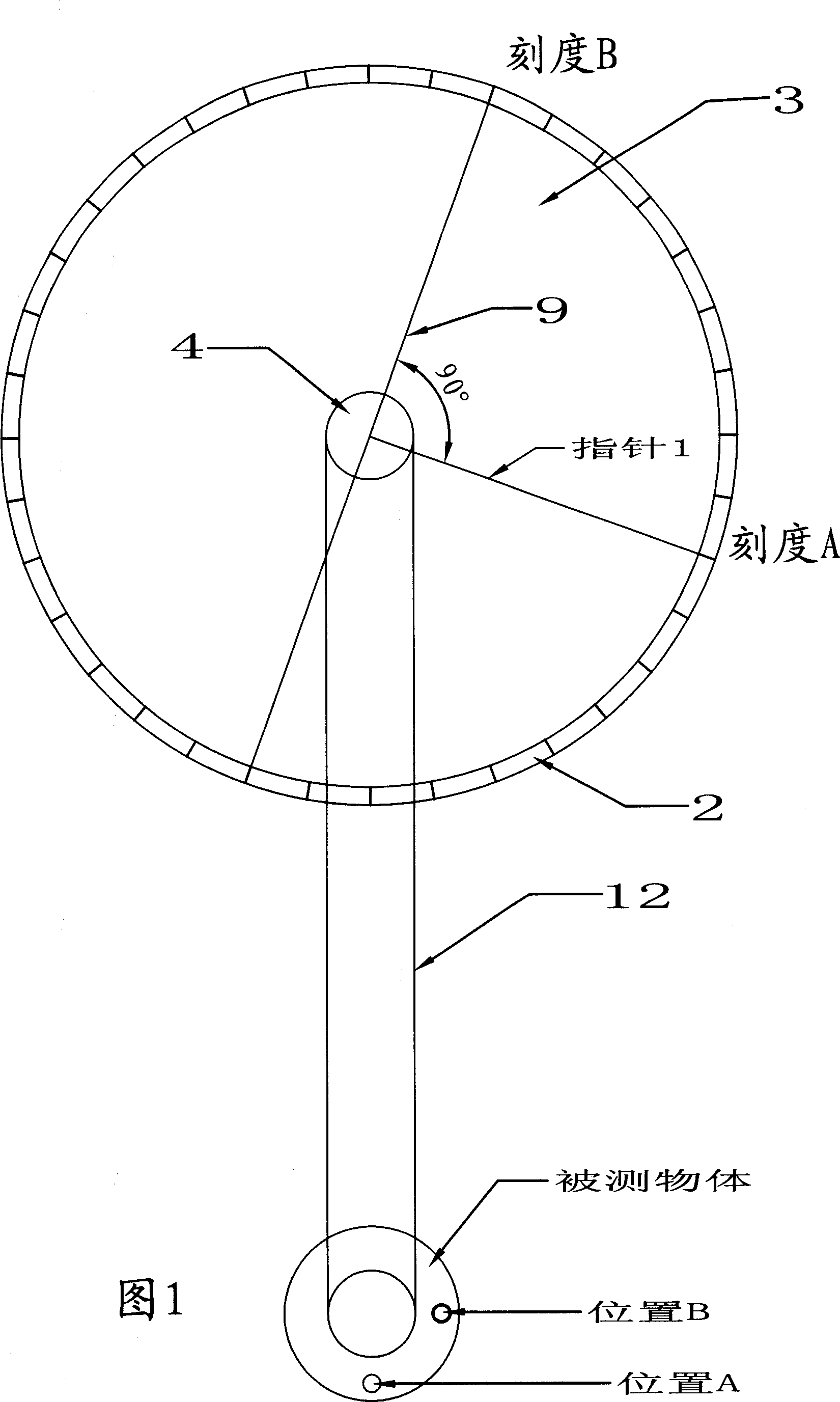

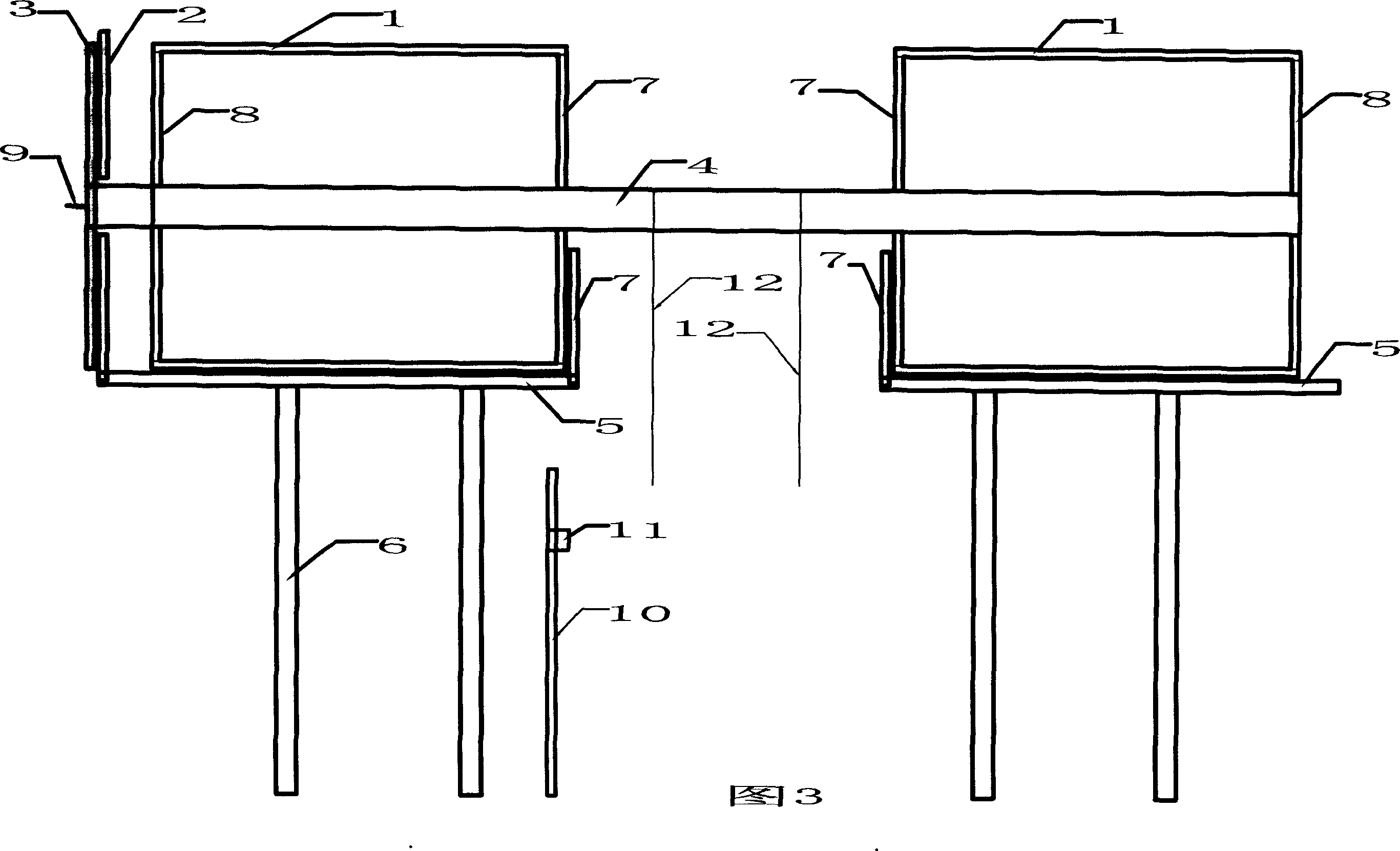

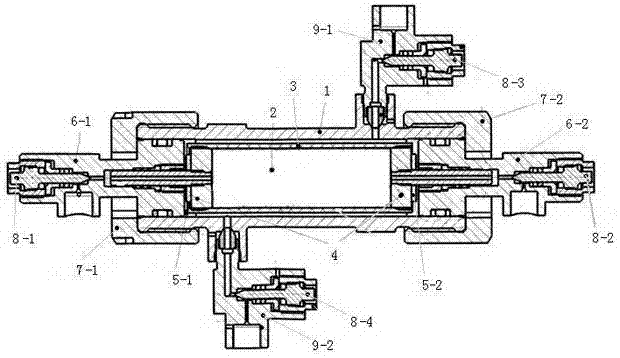

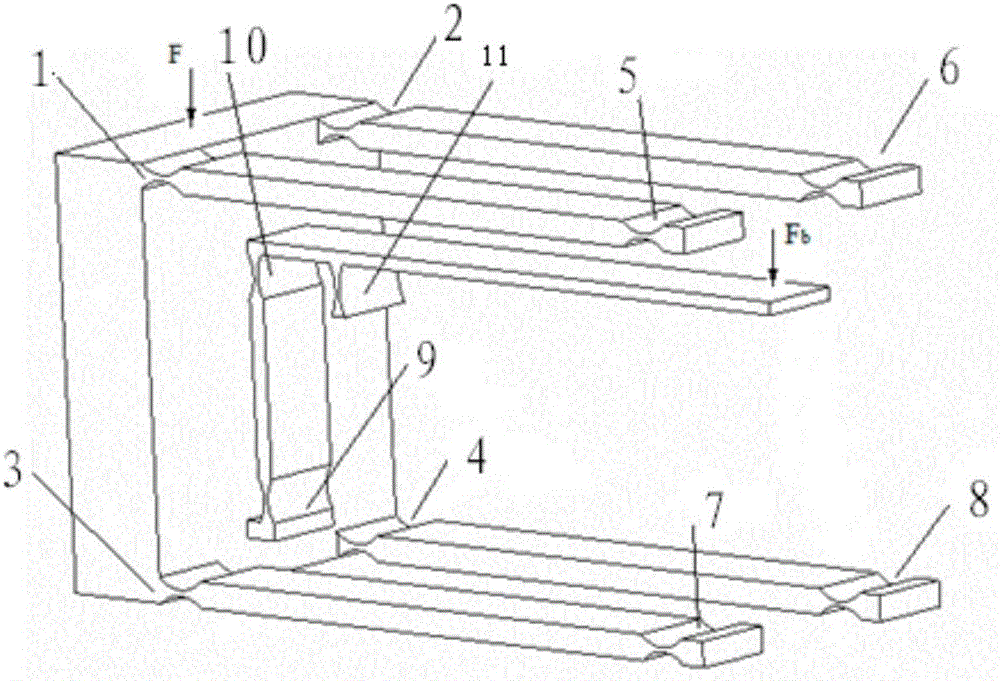

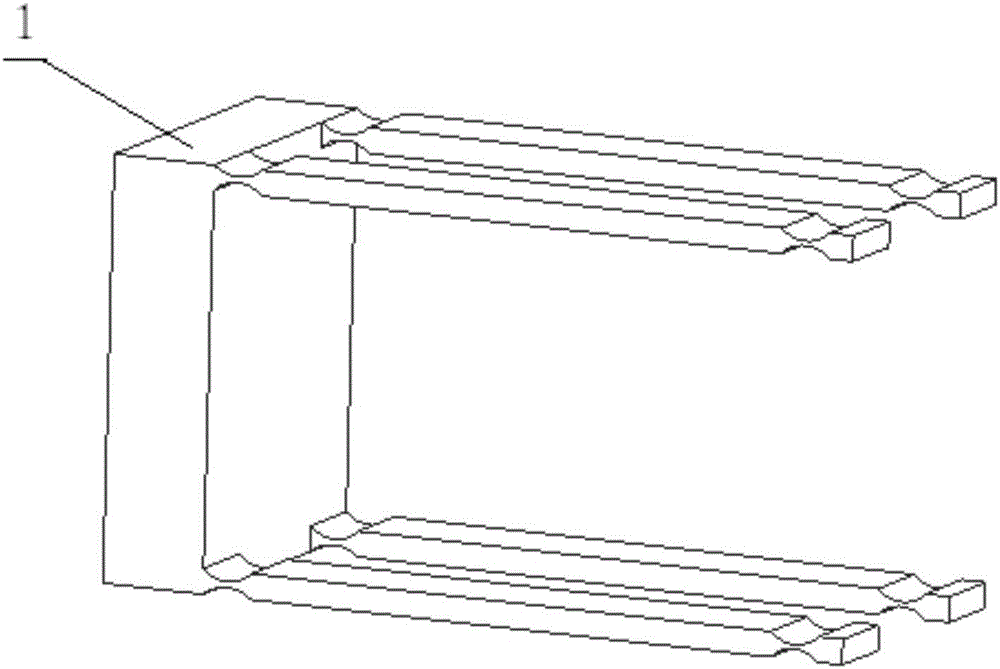

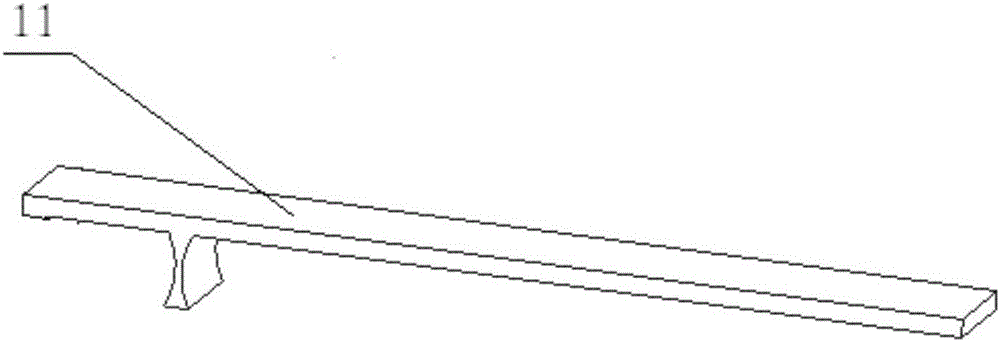

Motion mathematic model of balance-amplification mechanism for precision balance

The invention discloses a motion mathematic model of a balance-amplification mechanism for a precision balance. The motion mathematic model comprises a flexible hinge parallel four-rod mechanism, a lever mechanism, a string draw mechanism and a supporting mechanism, which all form an integral molded rigid body. The flexible hinge parallel four-rod mechanism includes flexible hinges. The lever mechanism includes flexible hinges and rigid bodies at two sides of the hinges. The string draw mechanism includes flexible hinges and corresponding rigid bodes between the hinges. The approximation mathematic model of the motion model, containing parameters such as K1, K2, K3, l, x and y, is shown in the description. To-be-tested force F is forced applied to one end portion of the flexible hinge parallel four-rod mechanism, and D is displacement of the lever mechanism relative to the other end of the flexible hinge parallel four-rod mechanism when the to-be-tested force F generates gravity at the minimum precision quality. The beneficial effects of the invention are that the motion mathematic model of a balance-amplification mechanism is provided for the design of balances that need different precision requirements, a convenient approach is provided for research and development of a precision balance, the research and development time is saved, and the research and development cost is reduced.

Owner:TIANJIN UNIV

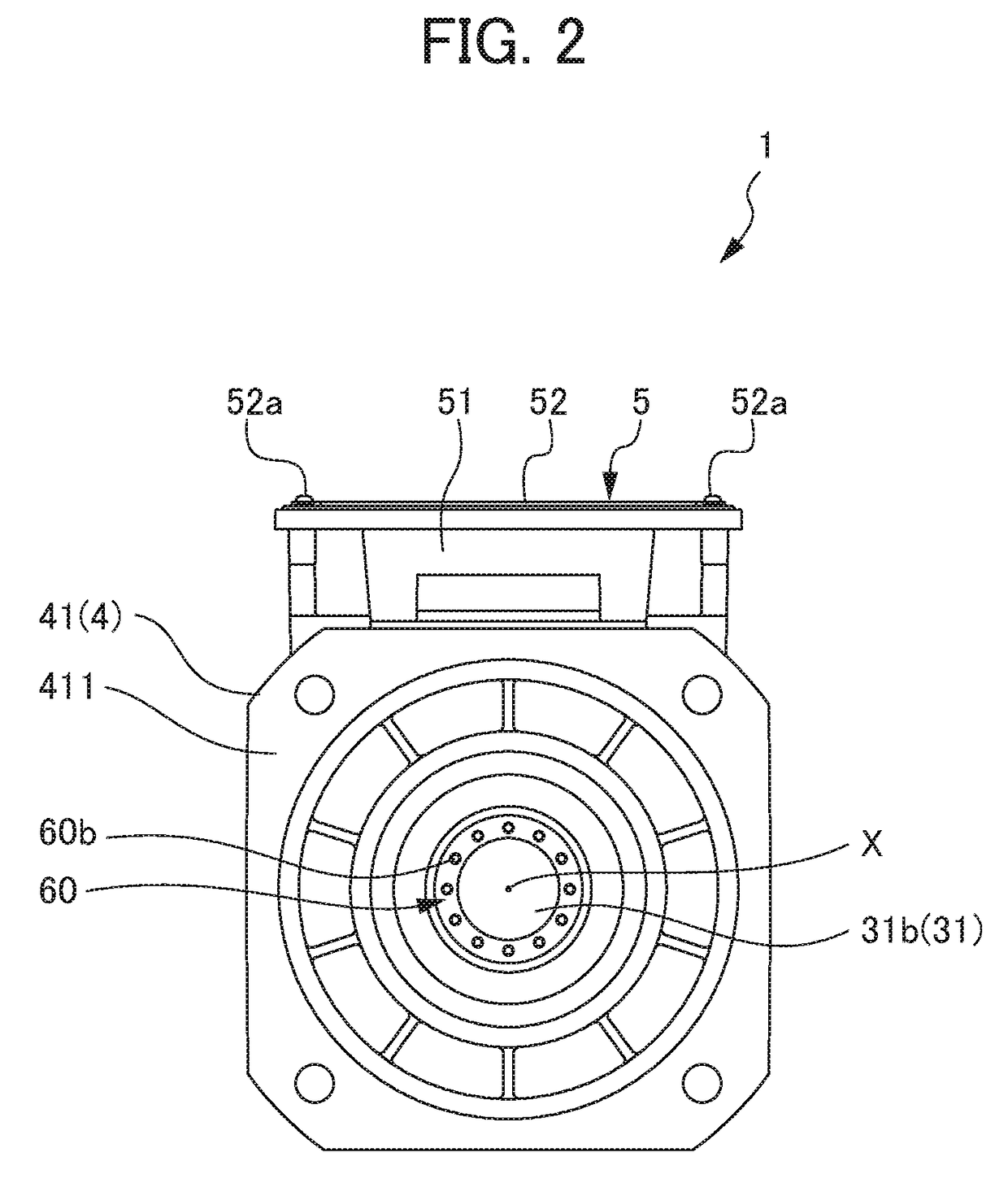

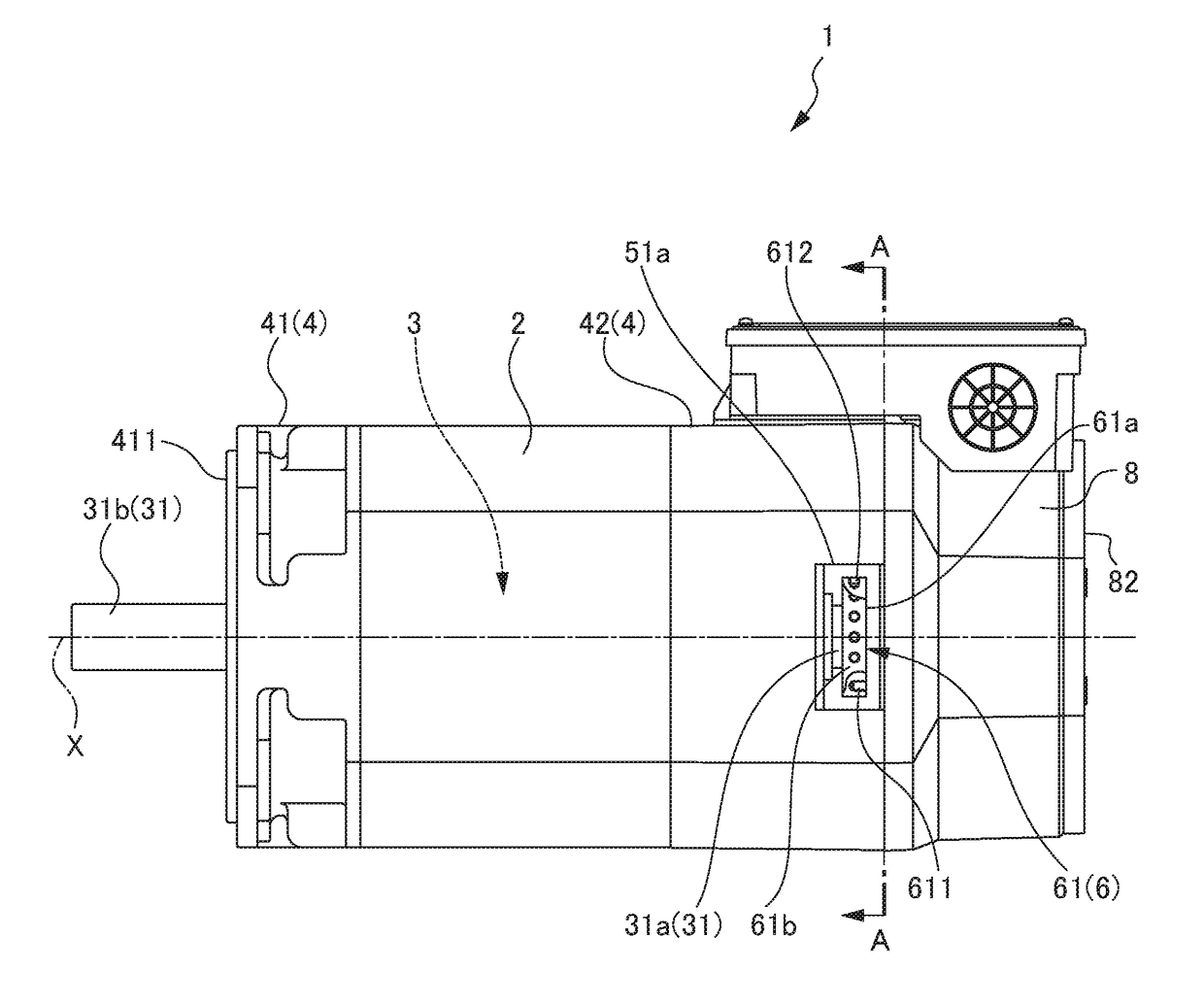

Electric motor having balance structure and machine tool equipped with the electric motor

ActiveUS20170346362A1Easy and high-precision balance correctionAccurate balanceInertia force compensationManufacturing dynamo-electric machinesEngineeringMachine tool

To provide an electric motor enabling easy and high-precision balance correction, and a machine toll including this electric motor. An electric motor (1) includes: a cylindrical stator (2); a rotor (3) having a rotary shaft part (31) inserted inside of the stator (2); a housing (4) installed to both ends in an axial direction of the stator (2); an opening (51a) provided in at least one outer peripheral lateral face of the housing (4), and disposed to be separated from an internal space (S) of the stator and a ventilation passage (9) formed in the stator (2); and a balance correction component (6, 61) that is installed to the rotary shaft part (31), and corrects balance of the rotor (3), in which the balance correction component (61) is exposed to outside from the opening (51a); and a machine tool (10) includes this electric motor (1).

Owner:FANUC LTD

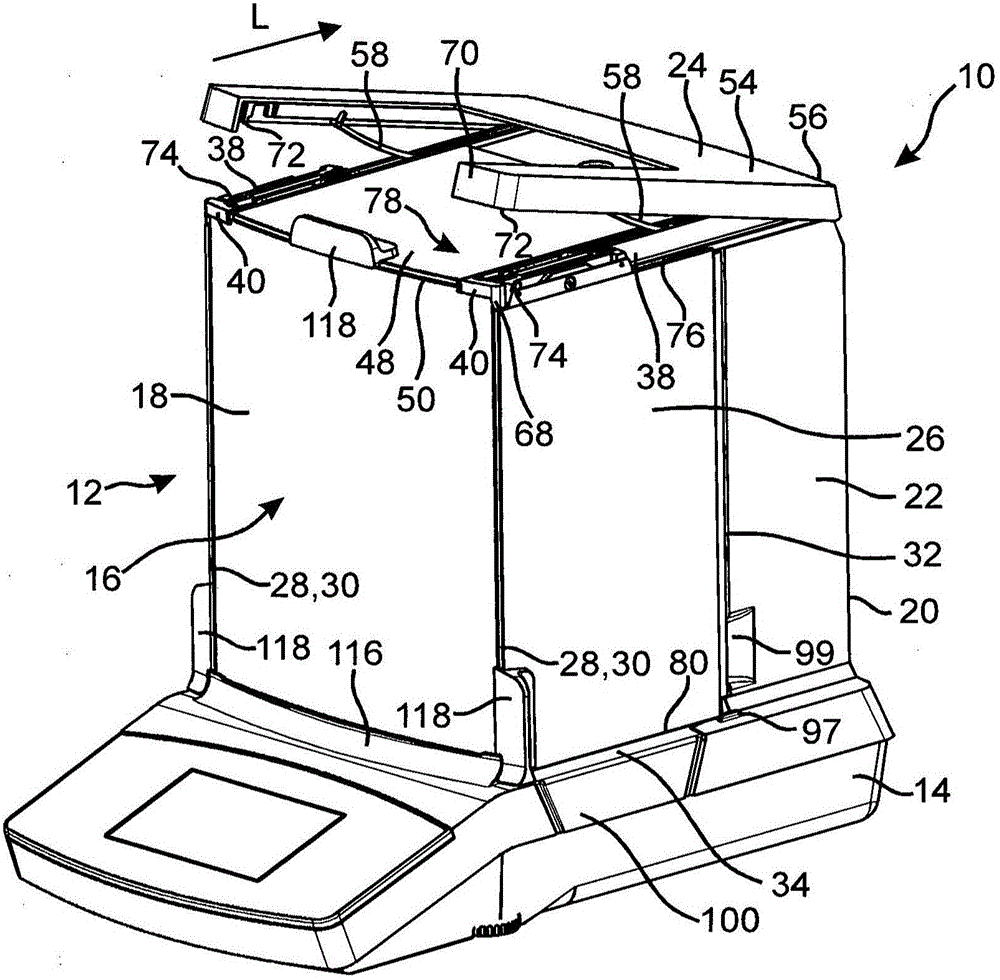

Cover of draught shield of precision balance, and draught shield for precision balance

A cover (24) of a draught shield (12) of a precision balance (10) has a carrier frame (36), on which are provided retaining elements (40) and / or guide rails (38) for a front panel (18) and / or at least one side panel (26) and a covering element (54), which can be pivoted between a retaining position and a release position about a mounting (60) provided along a periphery, wherein the periphery located opposite the mounting (60) has provided on it retaining elements (72, 74) which fix the covering element (54) on the opposite periphery of the carrier frame (36), wherein the retaining elements (72, 74) can be freed by virtue of at least one portion of the covering element (54) being displaced in the direction of the mounting (60). The invention also provides a draught shield (12) for a precision balance (10), having a front panel (18), a rear wall (20), two opposite side panels (26) and a cover (24) according to the invention, wherein the guide rails (38) for the side panels (26) and / or retaining elements (40) for the front panel (18) are provided on the carrier frame (36).

Owner:SARTORIUS LAB INSTR GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com