Precise chemical reagents preparation instrument

A chemical reagent and sophisticated technology, applied in the field of precision chemical reagent preparation equipment, can solve the problems of inaccuracy, inflexibility, and heavy labor, and achieve the effect of simple preparation of reagents and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

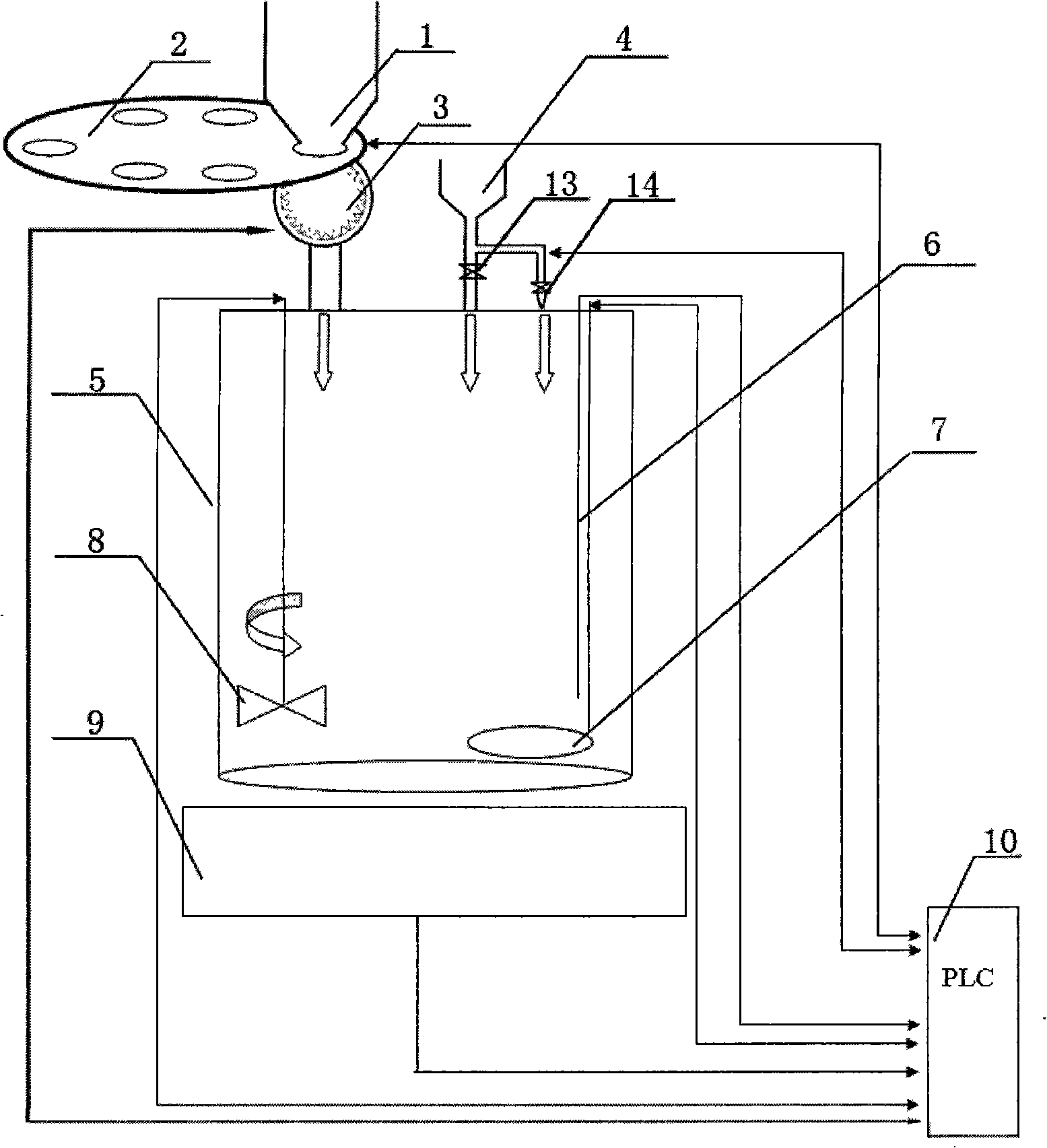

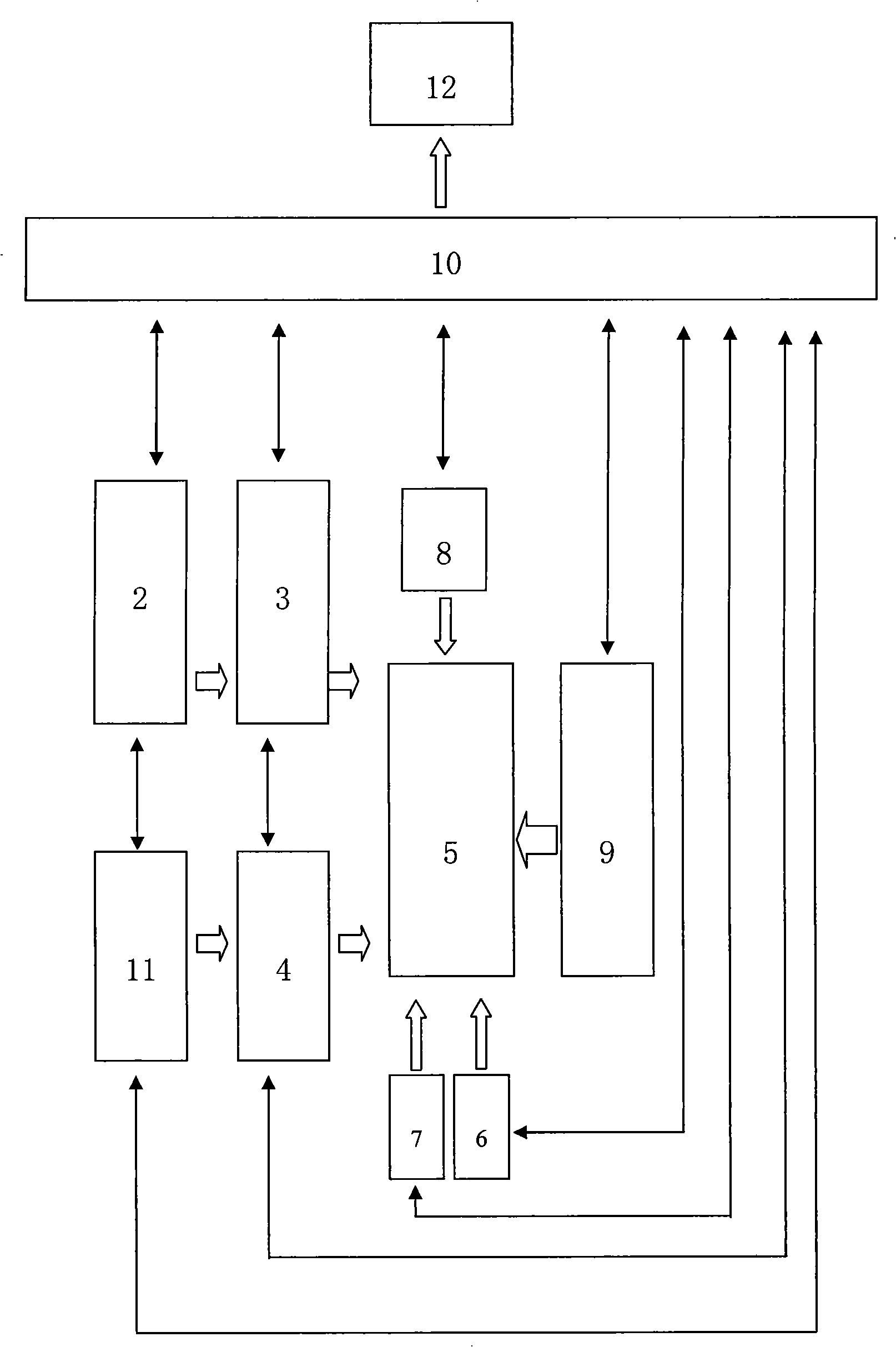

[0026] like figure 1 , 2 shown. Query the characteristics of reagents and preparation precautions through PLC10, and perform calculations and settings. Several solid raw materials can be added at the same time through the switching of the material selection device 2, and can be added accurately through the large amount of feeding rotary wheel and the micro-feeding rotary wheel of the solid feeding device 3. Under the action of the stirring device 8, it is fully stirred. If it is necessary to heat up, you can also Heating is performed under the action of the heating device 7, and when the temperature needs to be measured, the temperature sensor 6 and the programming controller PLC10 can be used for measurement, control and output, including display, and then the printer 12 prints out the result. Solid-solid preparation can be realized accurately and conveniently.

Embodiment 2

[0028] like figure 1 , 2 Shown: through the programming controller PLC10 query reagent characteristics, and preparation precautions, calculation and setting. PLC10 controls several kinds of solid raw materials can be added at the same time by switching the material selection device 2, and controls the solid feeding device 3 to add accurately, and accurately weighs the quality of the solid materials through the precision balance 9, and the data information is automatically imported into the programming controller PLC10. Set the target concentration, accurately calculate the required solvent quality through the programming controller PLC10, add liquid through the liquid feeder 4, the large flow port of the fast flow solenoid valve, and automatically switch to the small flow port to achieve accurate addition when the liquid is close to the target amount. Under the action of the stirring device 8, fully stir, if the temperature needs to be raised, it can also be heated under the ...

Embodiment 3

[0030] like figure 1 , 2 Shown: Query the characteristics of the reagents and preparation precautions through the programming controller PLC10. Through the switching of the liquid material selection device, more than two kinds of liquids can be added simultaneously or successively. The liquid feeder 4 can accurately add the liquid material, and the precision balance 9 can accurately weigh the quality of the liquid material, and the data information is automatically imported into the program controller of the program control device. PLC10, according to the set target concentration, accurately calculate the required solvent quality through the programming controller PLC10, add liquid solvent through the liquid feeder 4 and the fast flow solenoid valve 13, and automatically switch to the precision flow solenoid when the liquid is close to the target amount The valve 14 is added slowly, under the action of the stirring device 8, fully stirred, if the temperature needs to be raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com