Combustion experimental facility capable of realizing continuousness and stability of liquid level

An experimental device and stable technology, which can be applied in the direction of removing certain components, such as weighing, etc., can solve problems such as undiscovered, and achieve the effects of simple and easy operation of the device, high precision, and flexible and convenient adjustment system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

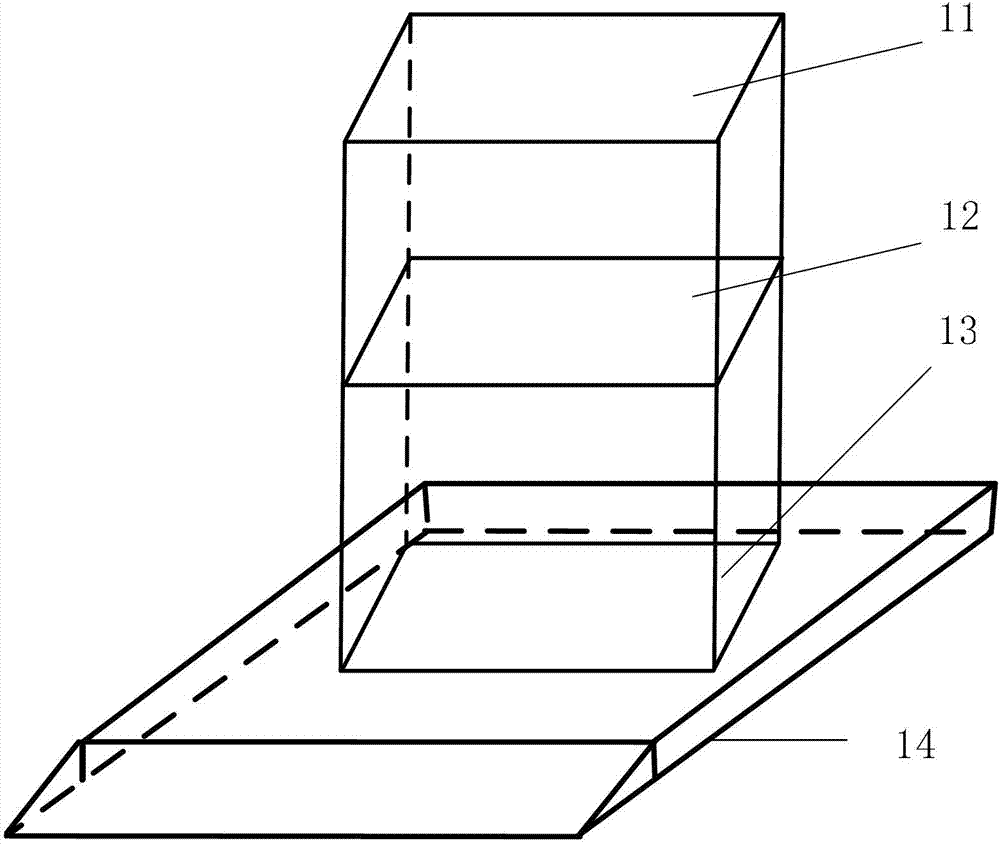

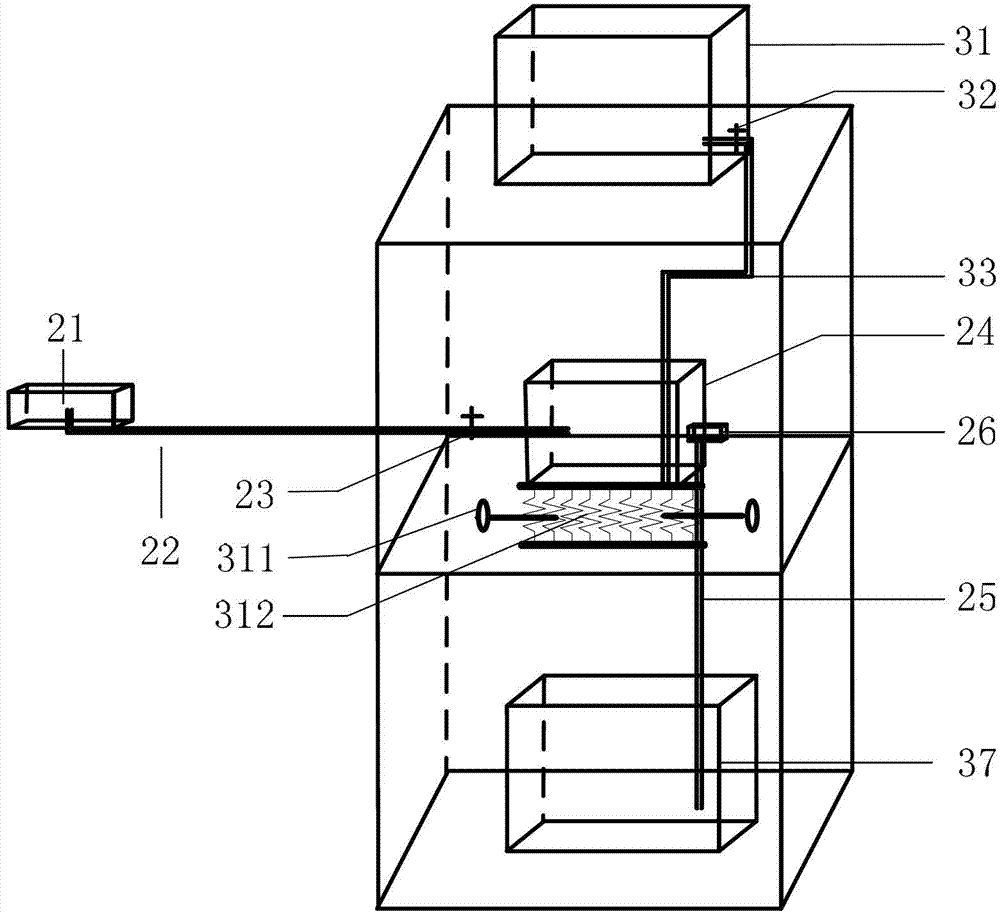

[0020] See figure 1 , the maximum capacity of the experimental balance 14 is 34kg, and the accuracy is 0.1g. The weighing platform transmits the received pressure change to the data acquisition module and inputs it into the computer. After conversion, the output quality changes with time. The signal of the data acquisition time The interval is 1s. The system structure is composed of three layers of support surfaces, 11 is the top fuel storage tank support plate, 12 is the fuel supply tank support plate, and 13 is the bottom fuel storage tank support plate, and the top fuel storage tank 31 and the fuel supply tank are respectively placed from top to bottom. 24 and underlying fuel storage pool 37. The structural support frame is welded by 20mm×20mm stainless square steel, and the overall size is 40cm×40cm×100cm.

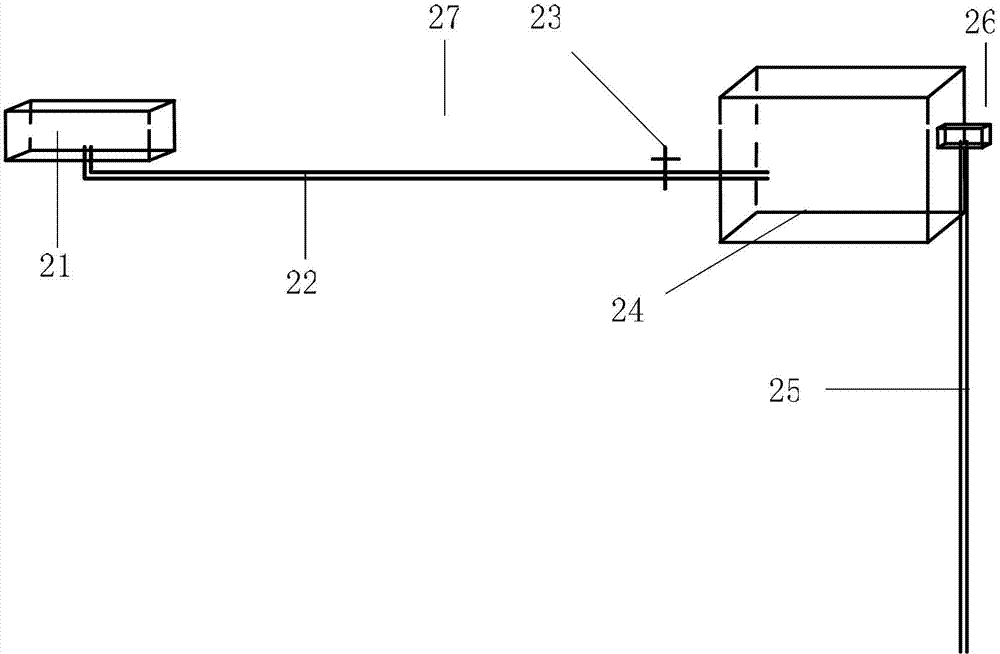

[0021] See figure 2 , The fuel supply system is a simple connector device. The fuel supply pool 24 and the combustion pool 21 are connected by pipelines. Consider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com