Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Combustion state is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

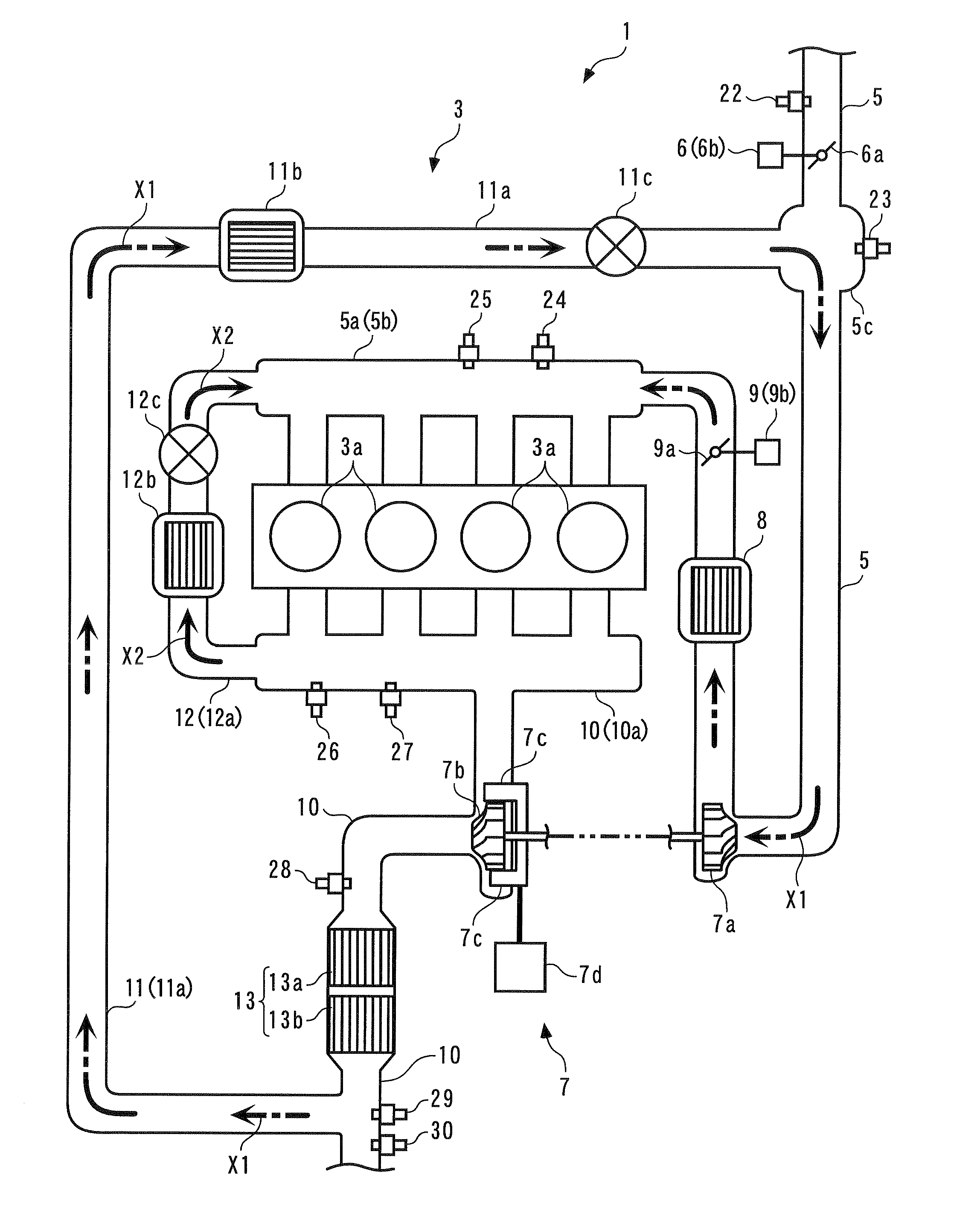

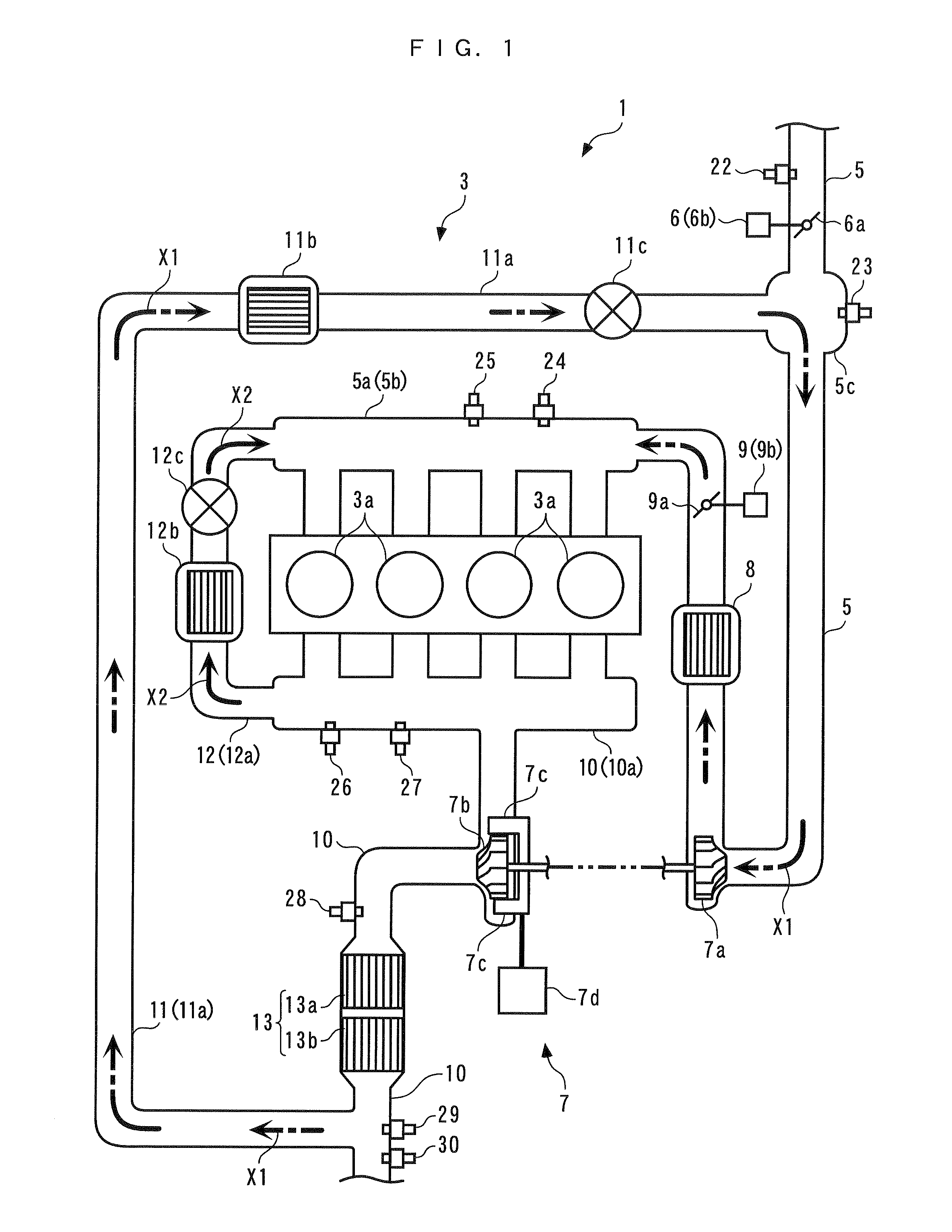

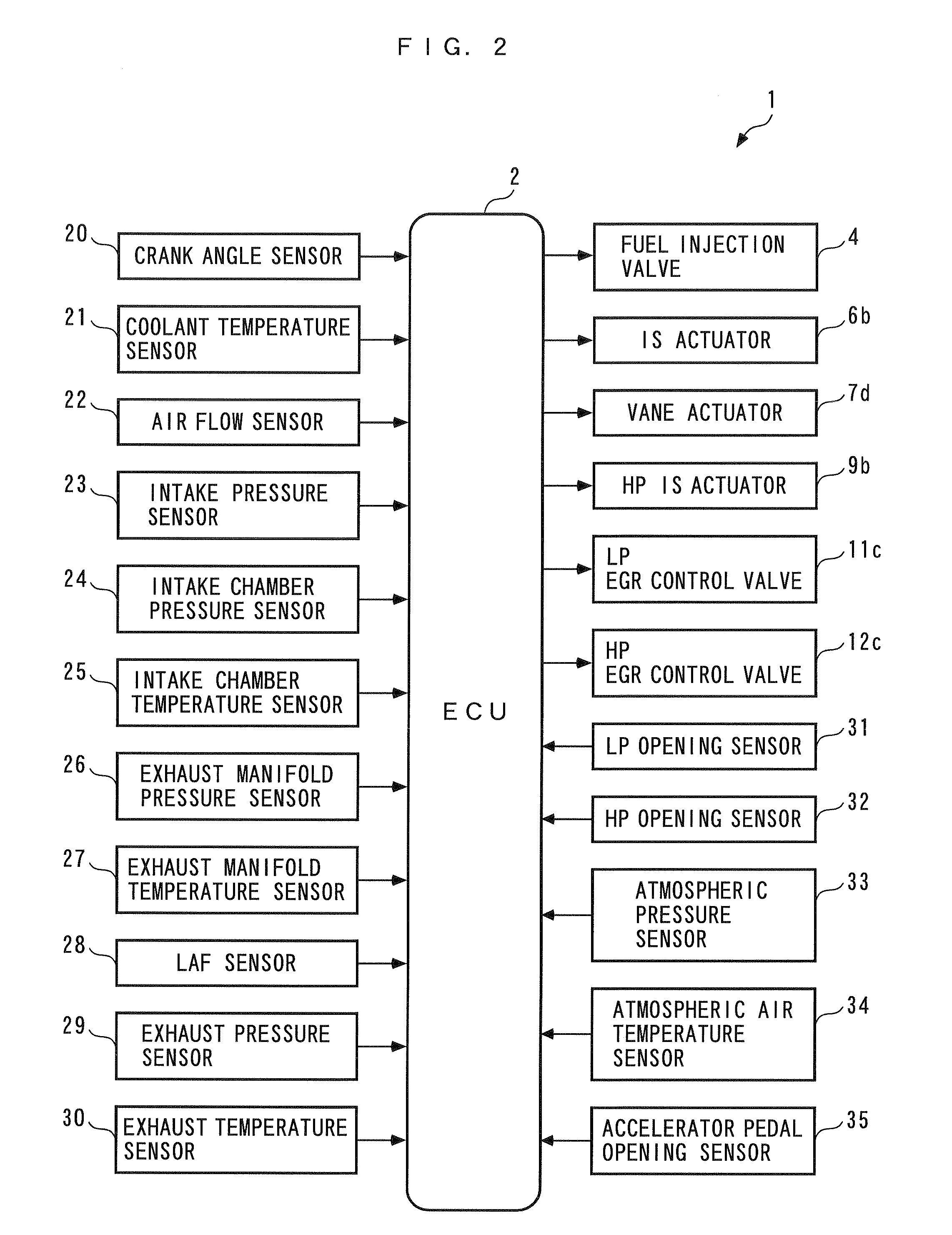

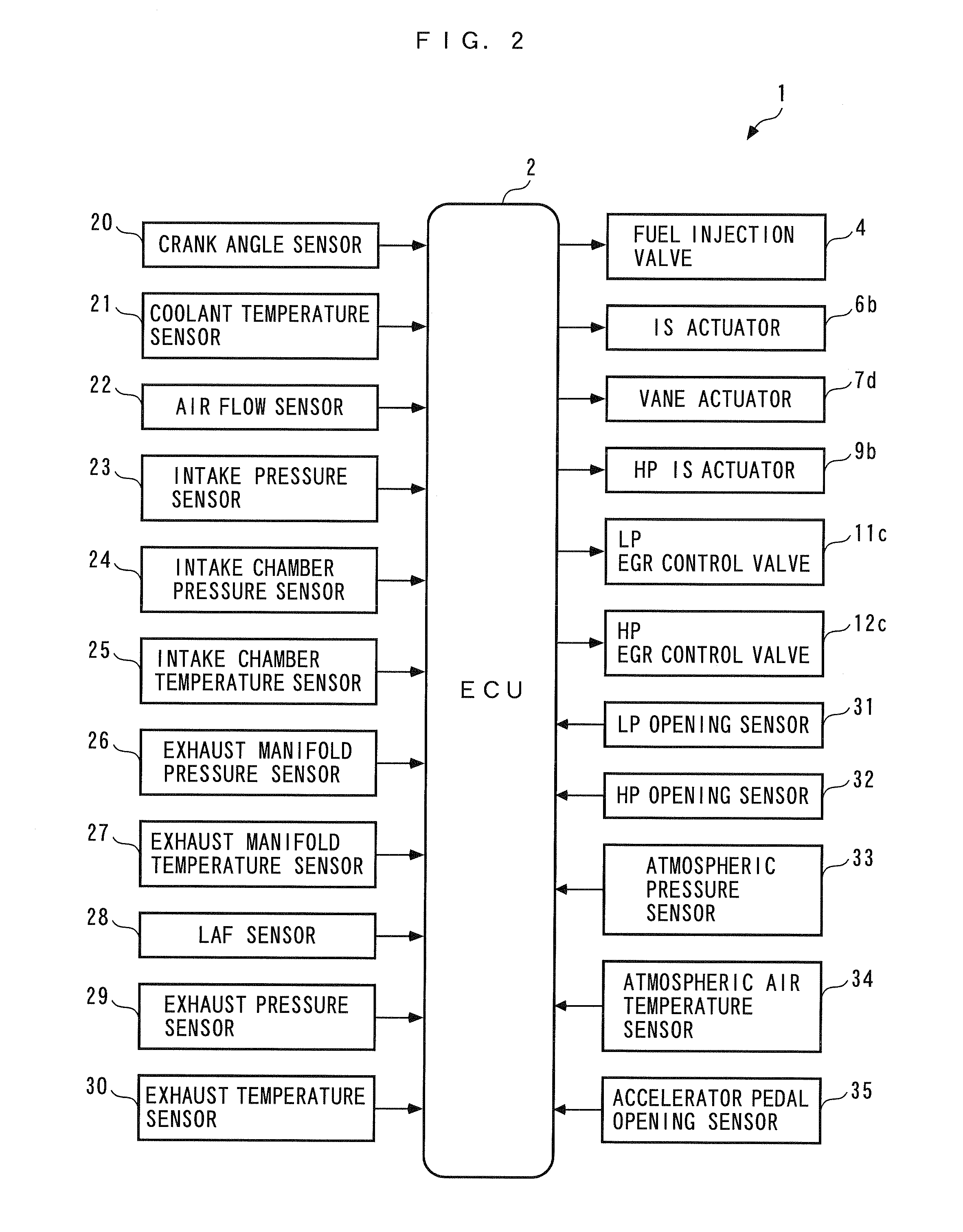

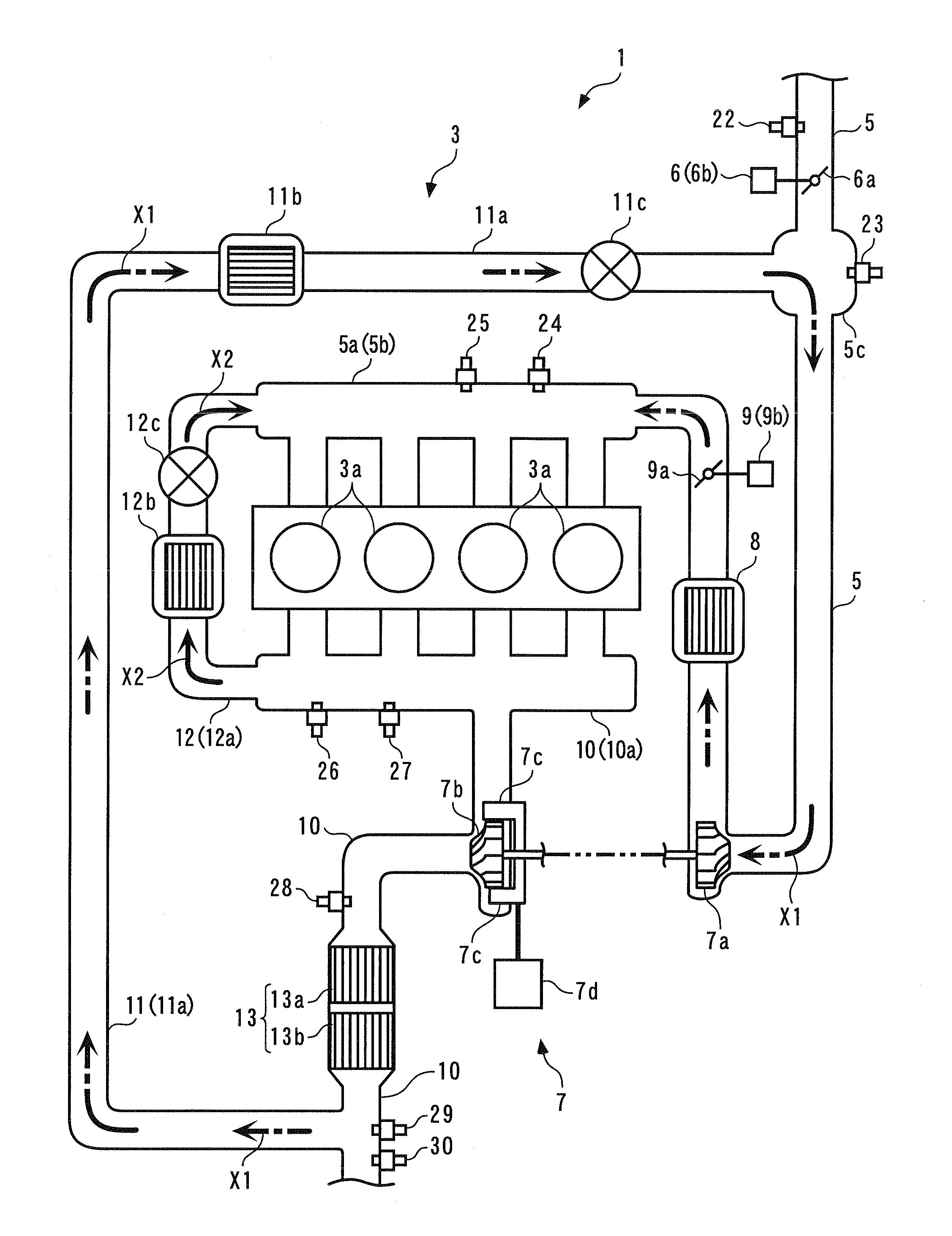

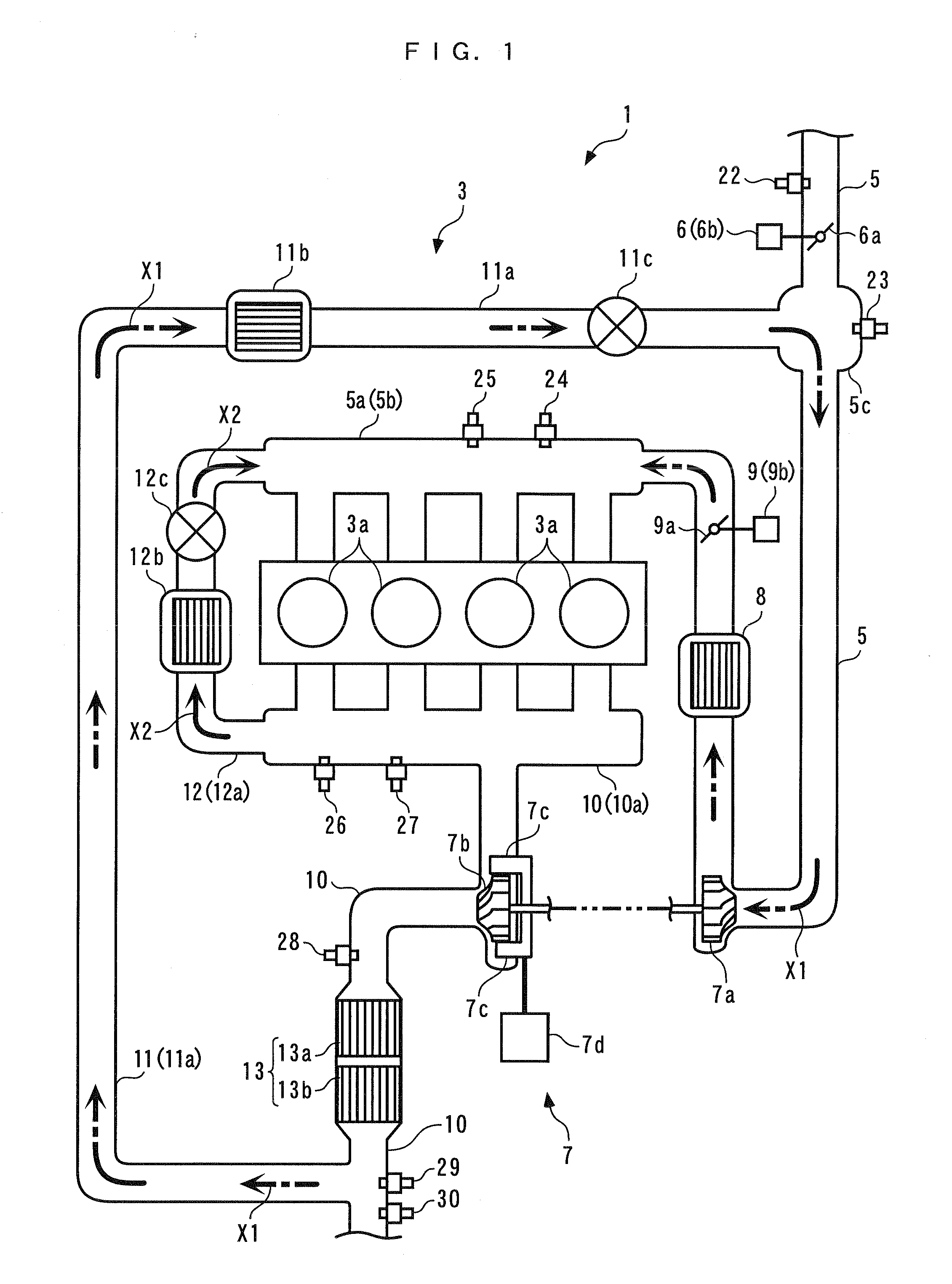

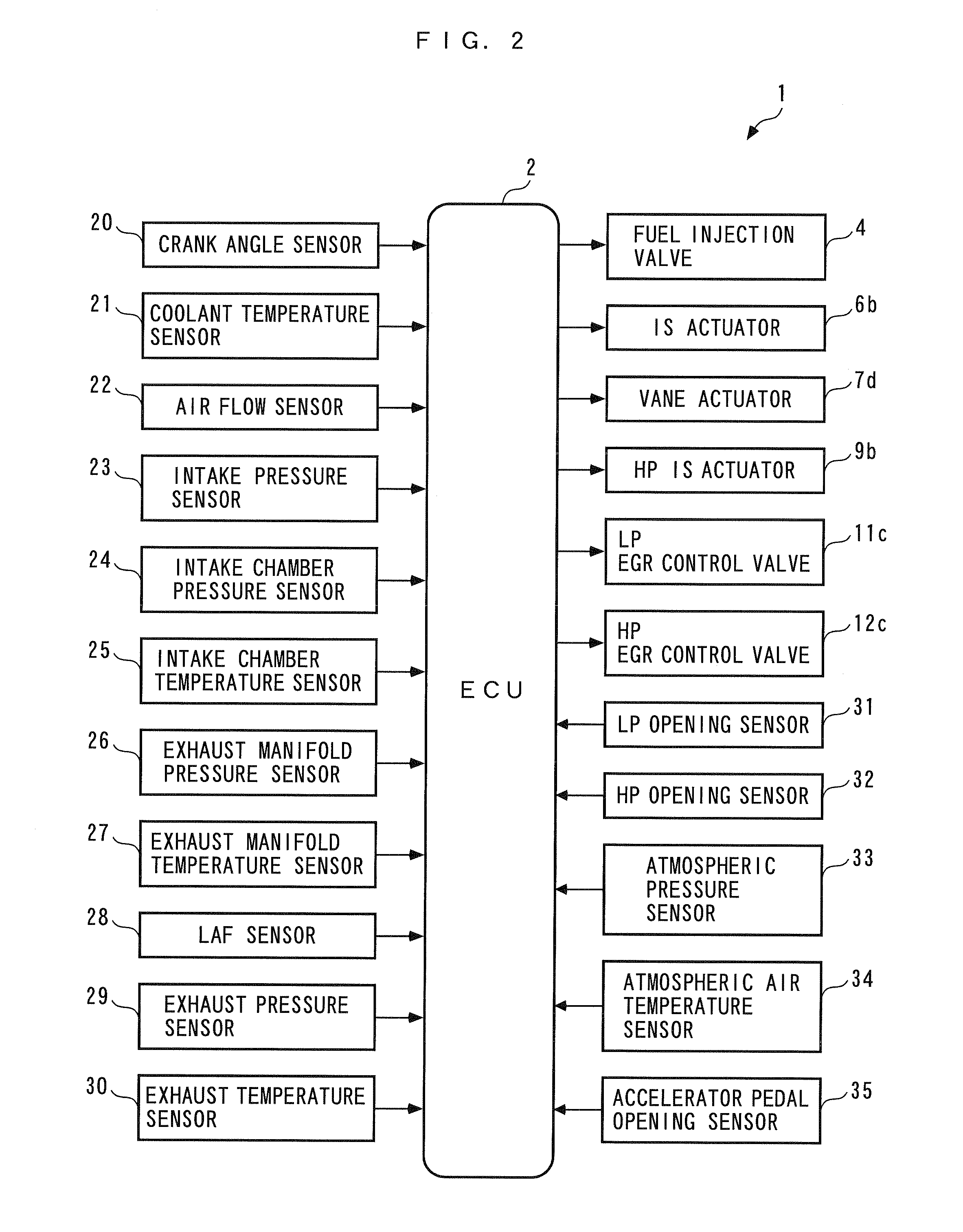

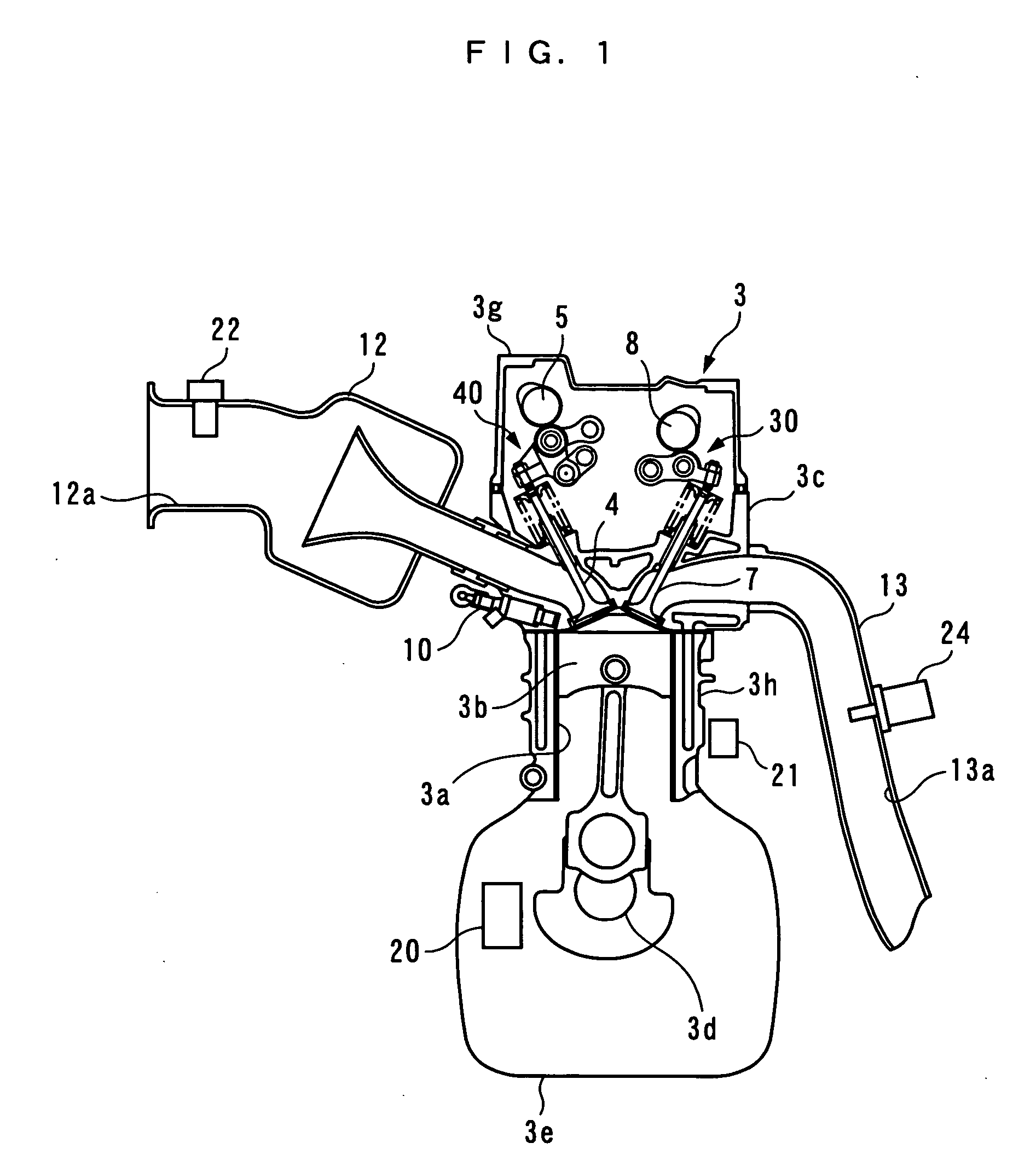

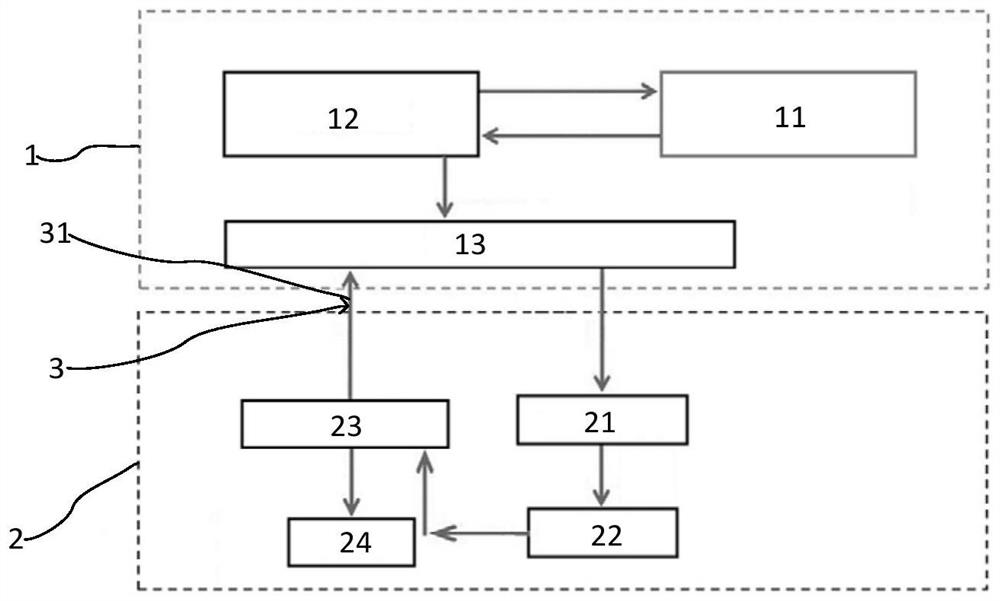

Egr control apparatus for internal combustion engine

ActiveUS20110308503A1Stable combustion stateReduce exhaust emissionsElectrical controlInternal combustion piston enginesHigh pressureExternal combustion engine

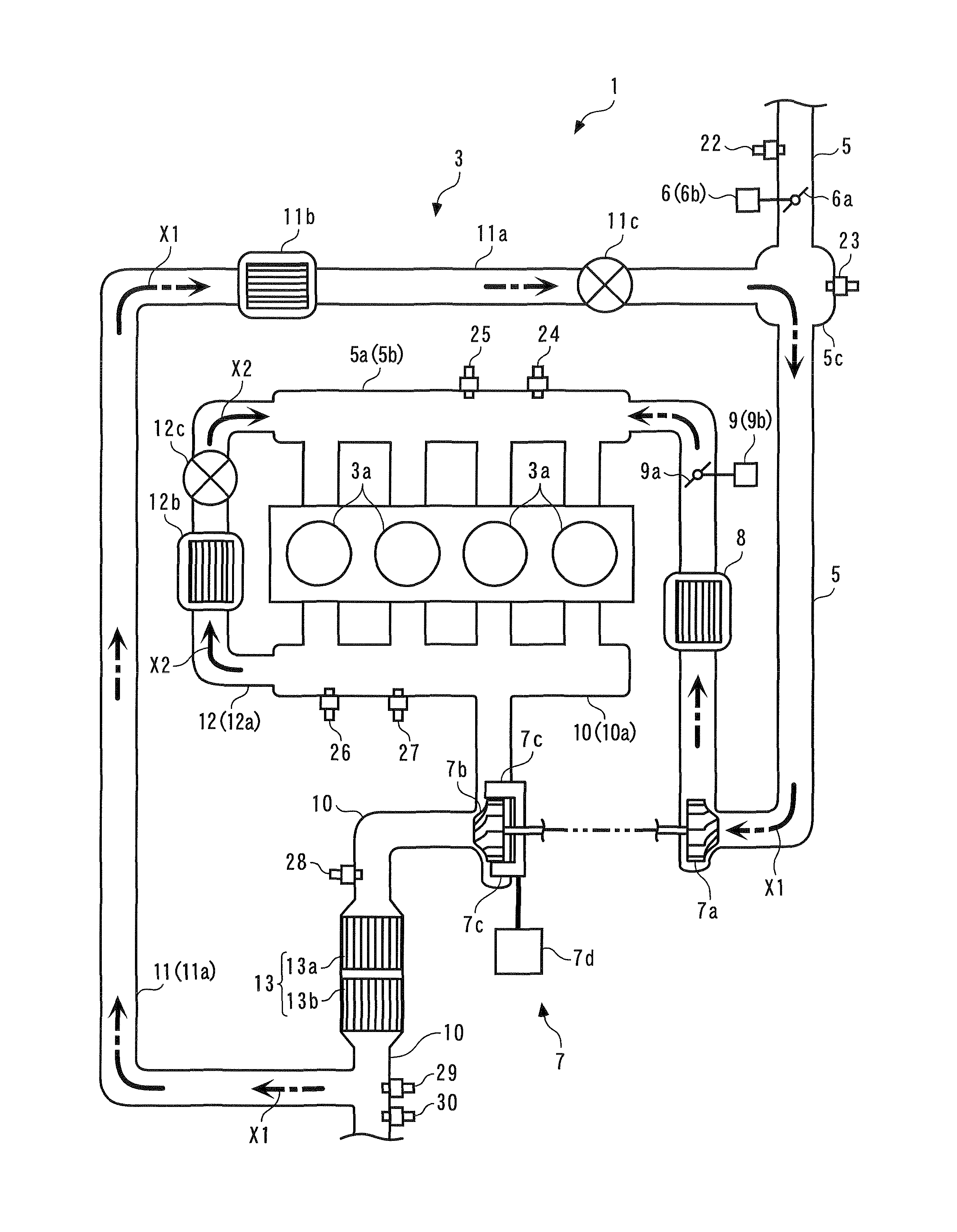

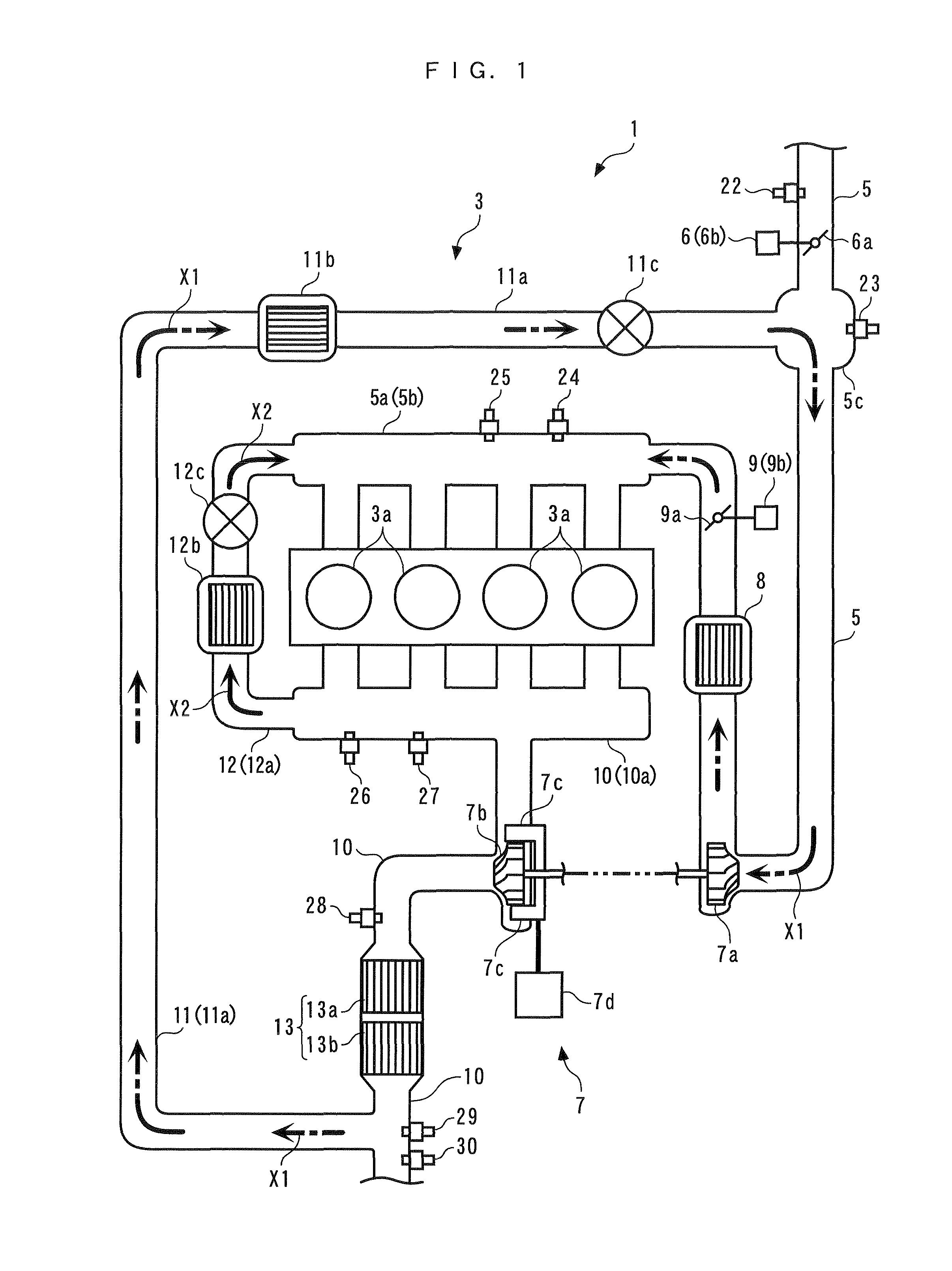

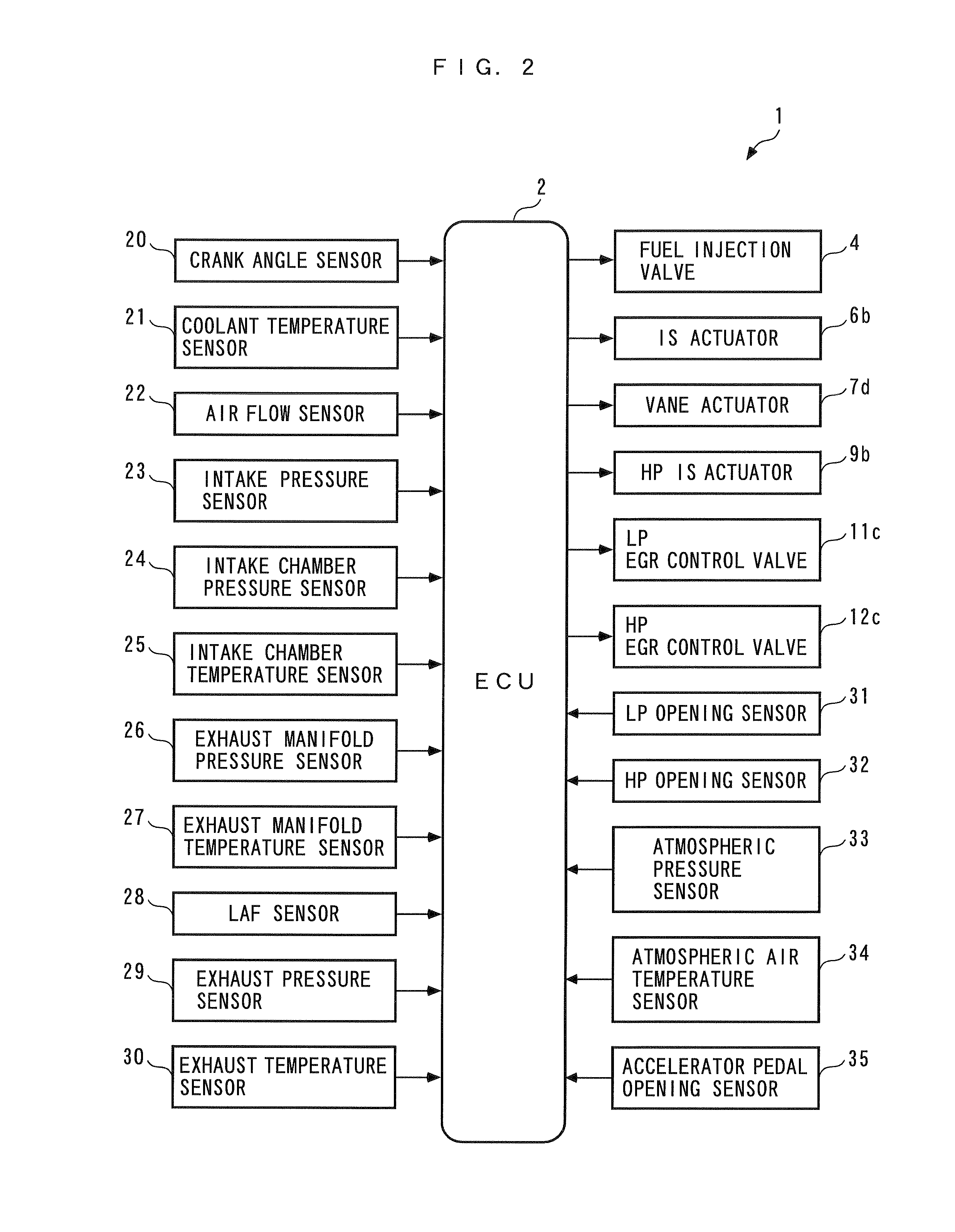

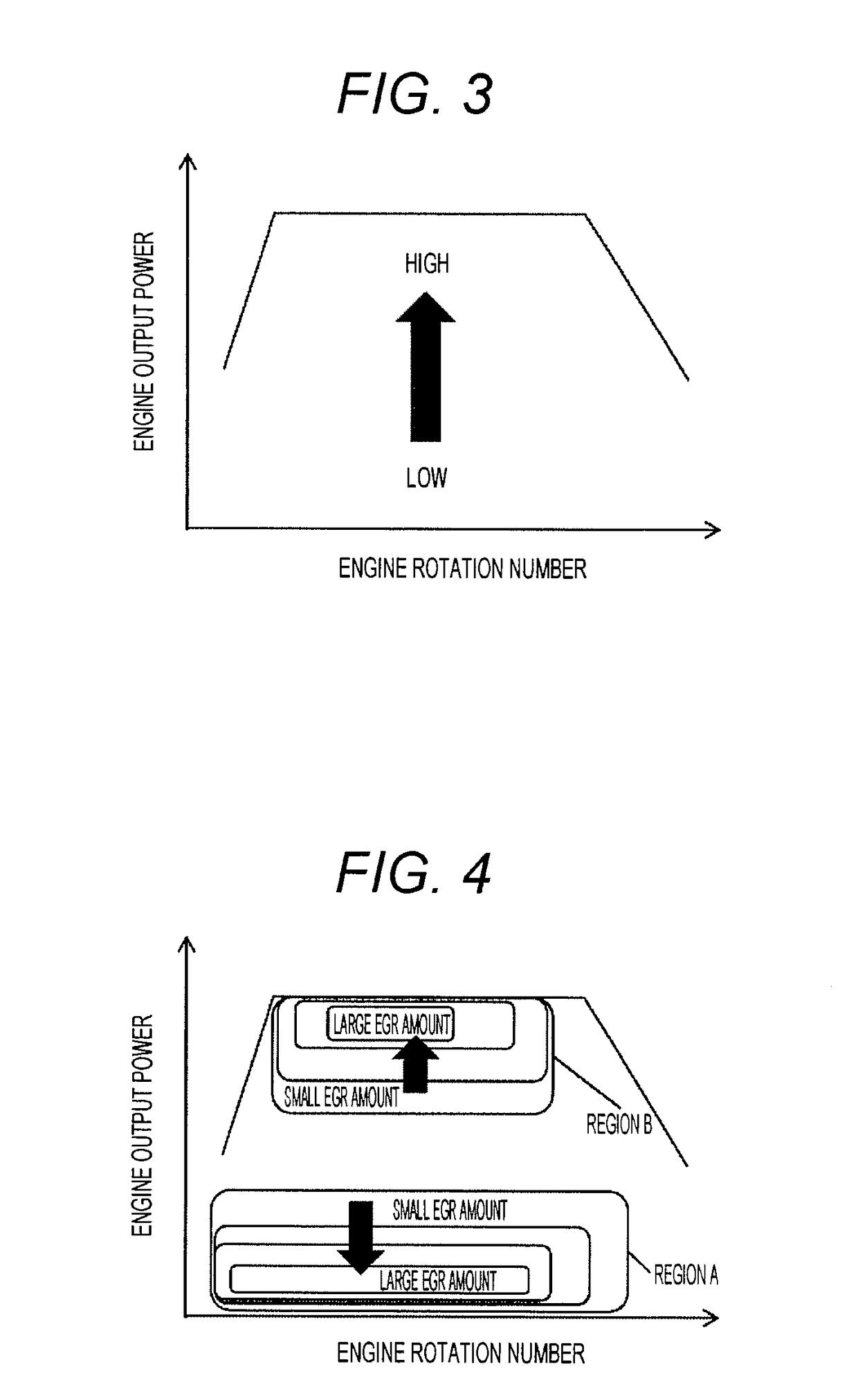

An EGR control apparatus for an internal combustion engine, which is capable of properly controlling an inert gas amount of two types of EGR gas supplied to cylinders of the engine via two paths different from each other, thereby making it possible to ensure a stable combustion state, reduced exhaust emissions, and improve operability. The EGR control apparatus includes low-pressure and high-pressure EGR devices, and an ECU. The ECU controls the low-pressure and high-pressure EGR gas amounts according to engine speed and demanded torque, and when a combination of engine speed and demanded torque is in a predetermined region, the low-pressure and high-pressure EGR gas amounts are controlled such that inert gas in low-pressure EGR gas exceeds in amount inert gas in high-pressure EGR gas, and the former more exceeds the latter as engine speed is higher or demanded torque is larger.

Owner:HONDA MOTOR CO LTD

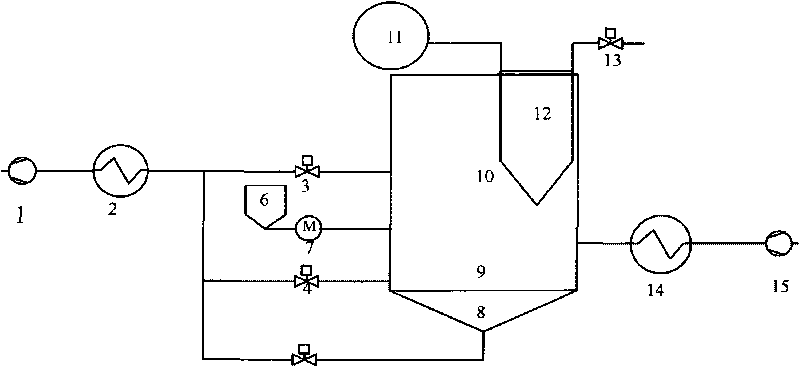

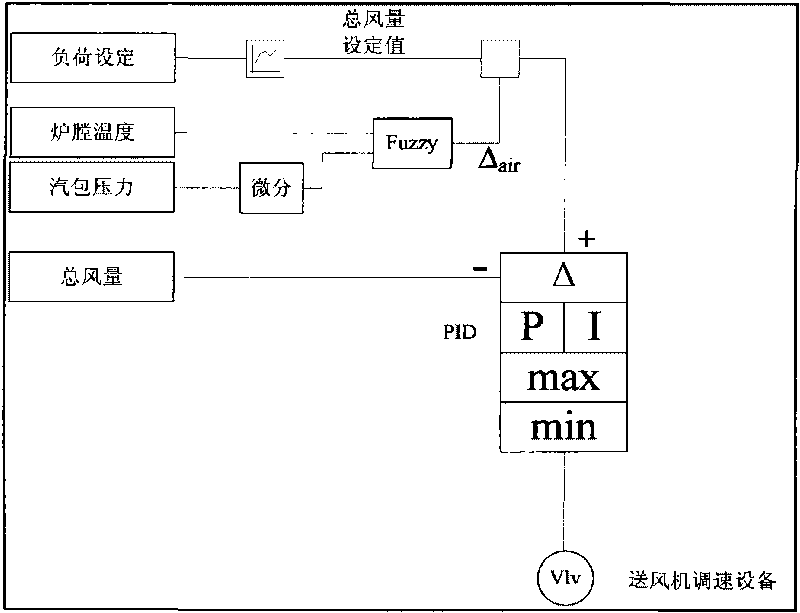

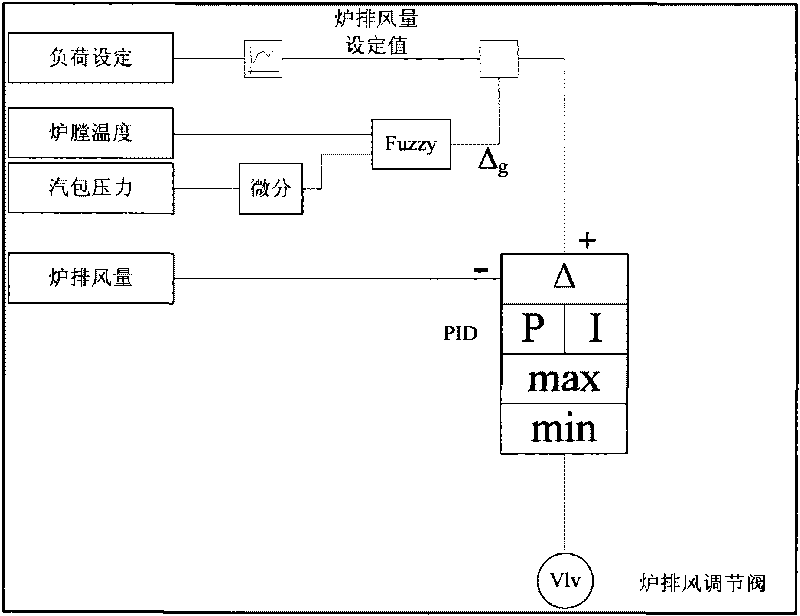

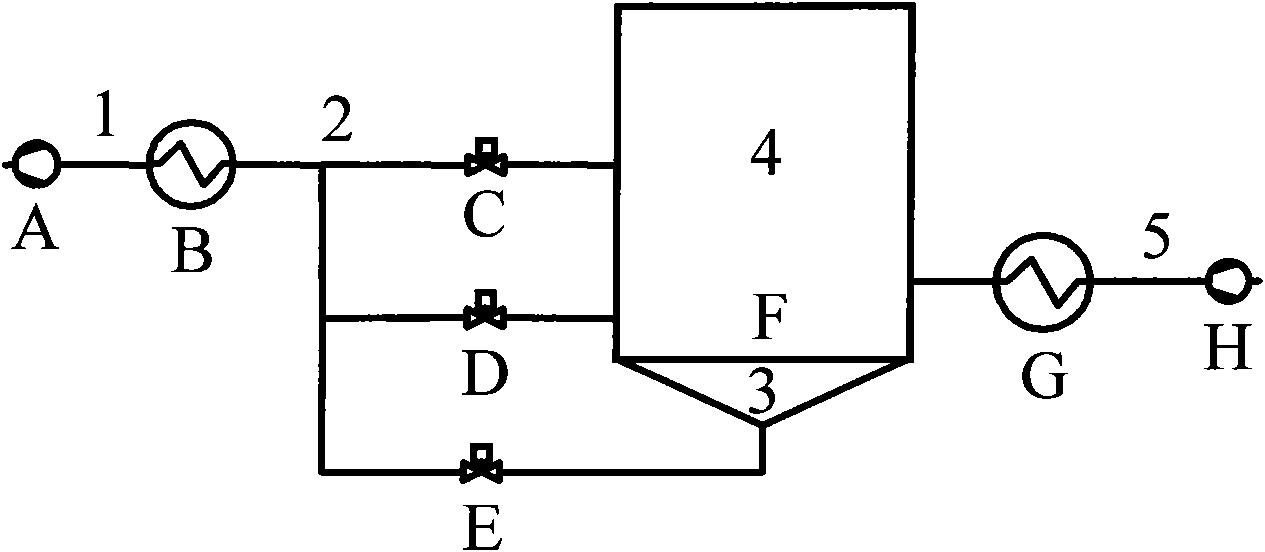

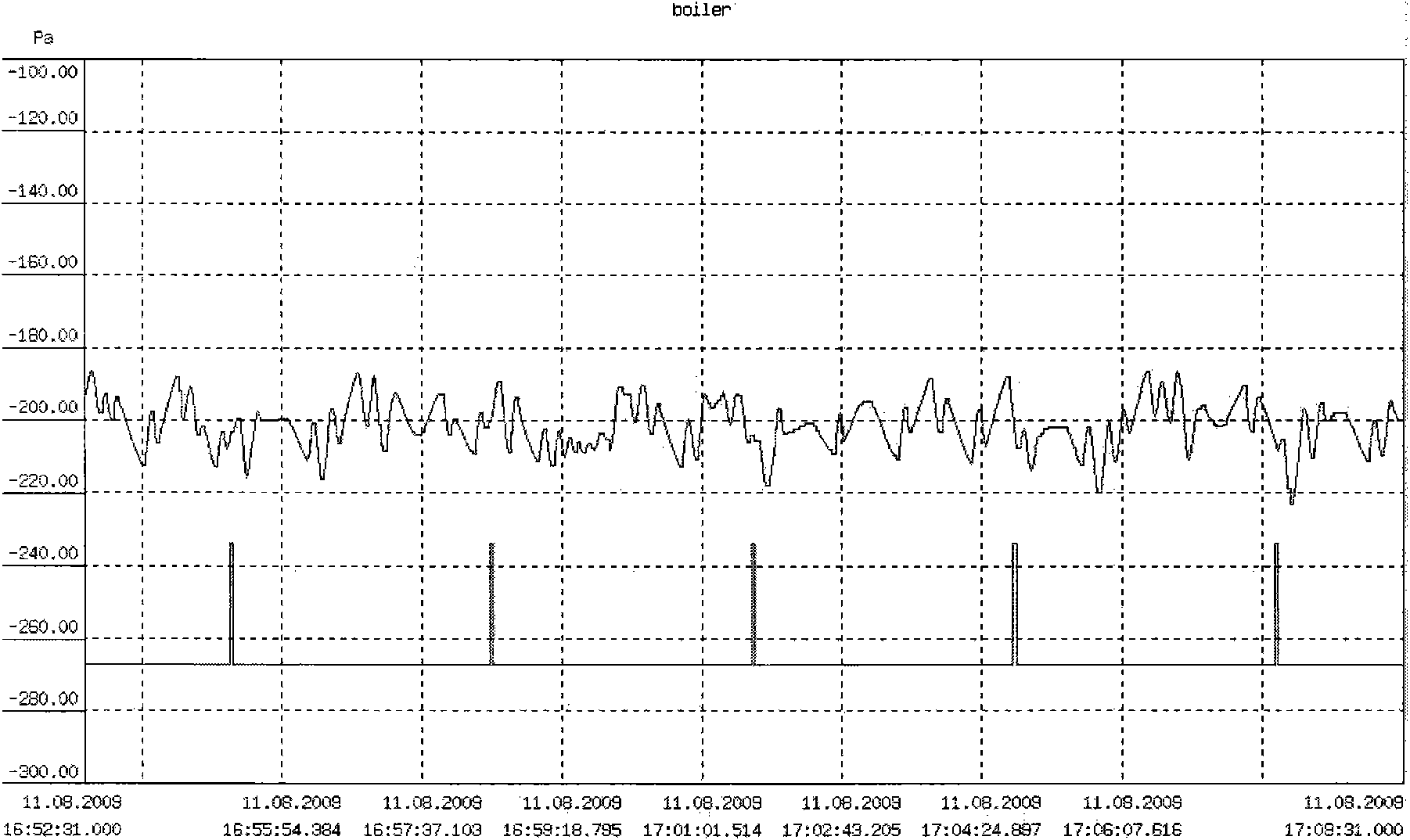

Method for controlling load of biomass vibration grate boiler

InactiveCN101725999AEvenly loadedCombustion state is stableCombustion regulationAir volumeFuzzy control system

The invention carries out intensive model analytical research on influence of biomass fuel characteristic changes on boiler load, analyzes the principle that the load fluctuates along with changes of moisture and calorific values of the fuel, provides a measure for stabilizing the boiler load to ensure stable fuel supply quantity, properly increases total air quantity and grate air quantity, increases grate vibration frequency, air temperature and the like, and carries out fuzzy control on the total air quantity and the grate air quantity by using a fuzzy control principle so as to achieve the aim of quickly regulating the temperature of the hearth and stabilizing the boiler load.

Owner:CHINA ELECTRIC POWER RES INST +1

Egr control apparatus for internal combustion engine

ActiveUS20110313634A1Limit amount of gasCombustion state is stableAnalogue computers for vehiclesElectrical controlCombustionInternal combustion engine

An EGR control apparatus for an internal combustion engine, which is capable of accurately controlling an inert gas amount and an inert gas ratio of two types of EGR gas supplied to cylinders of the engine via two paths different from each other, thereby making it possible to ensure a stable combustion state and reduced exhaust emissions. The EGR control apparatus includes a low-pressure EGR device, a high-pressure EGR device, and an ECU. The ECU calculates a target low-pressure opening, calculates an estimated value of an in-cylinder low-pressure inert gas flow rate, which is the estimated value of an inert gas amount included in low-pressure EGR gas supplied to the cylinders via an intake passage, calculates a target high-pressure opening using the estimated value, and controls low-pressure and high-pressure EGR control valves, using the target low-pressure opening and the target high-pressure opening.

Owner:HONDA MOTOR CO LTD

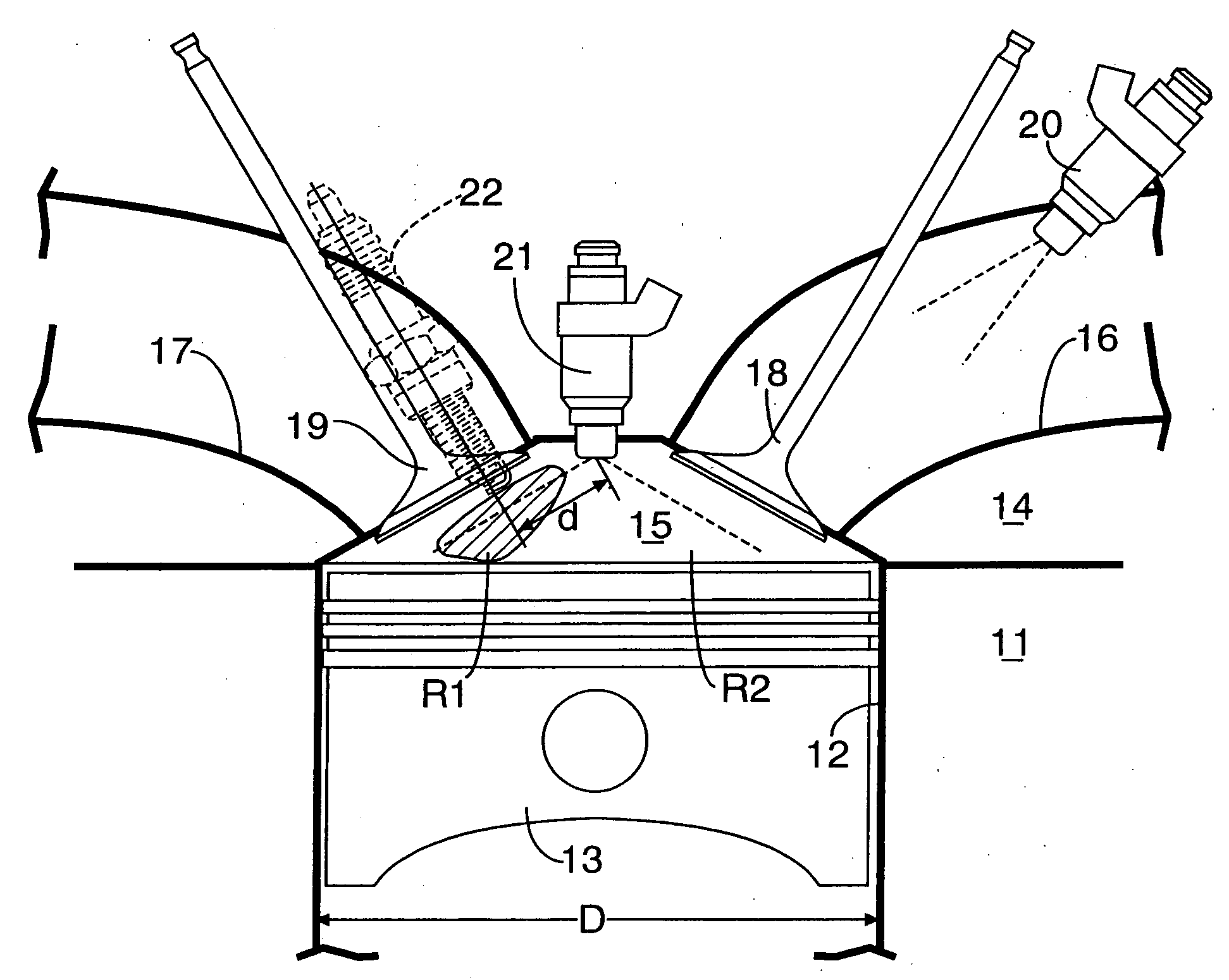

Internal combustion engine and fuel injection method in internal combustion engine

InactiveUS20080210198A1Consumption amount can be reducedReduce the amount requiredElectrical controlInternal combustion piston enginesInjectorSpark-ignition engine

An air-fuel ratio of an air-fuel mixture produced by fuel injected from a first injector into an intake port (or into a combustion chamber) is set in a range of 28 to 38. Therefore, when the temperature and pressure rise with a first combustion started by spark-ignition around a spark plug to the fuel injected from a second injector into the combustion chamber, the timing of starting a second compressive hypergolic ignition is optimized to provide a stable combustion state free of knocking and misfire.

Owner:HONDA MOTOR CO LTD

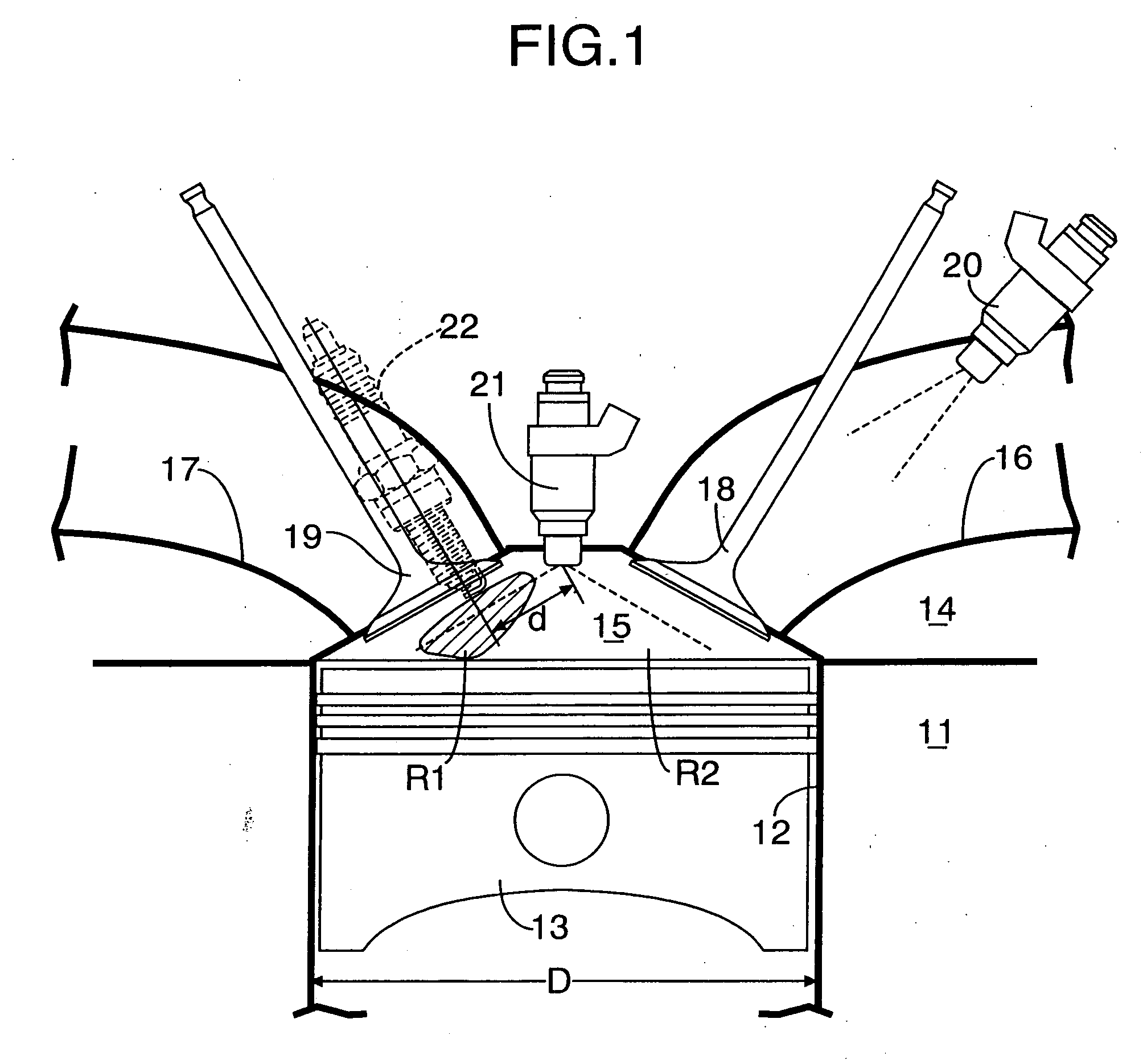

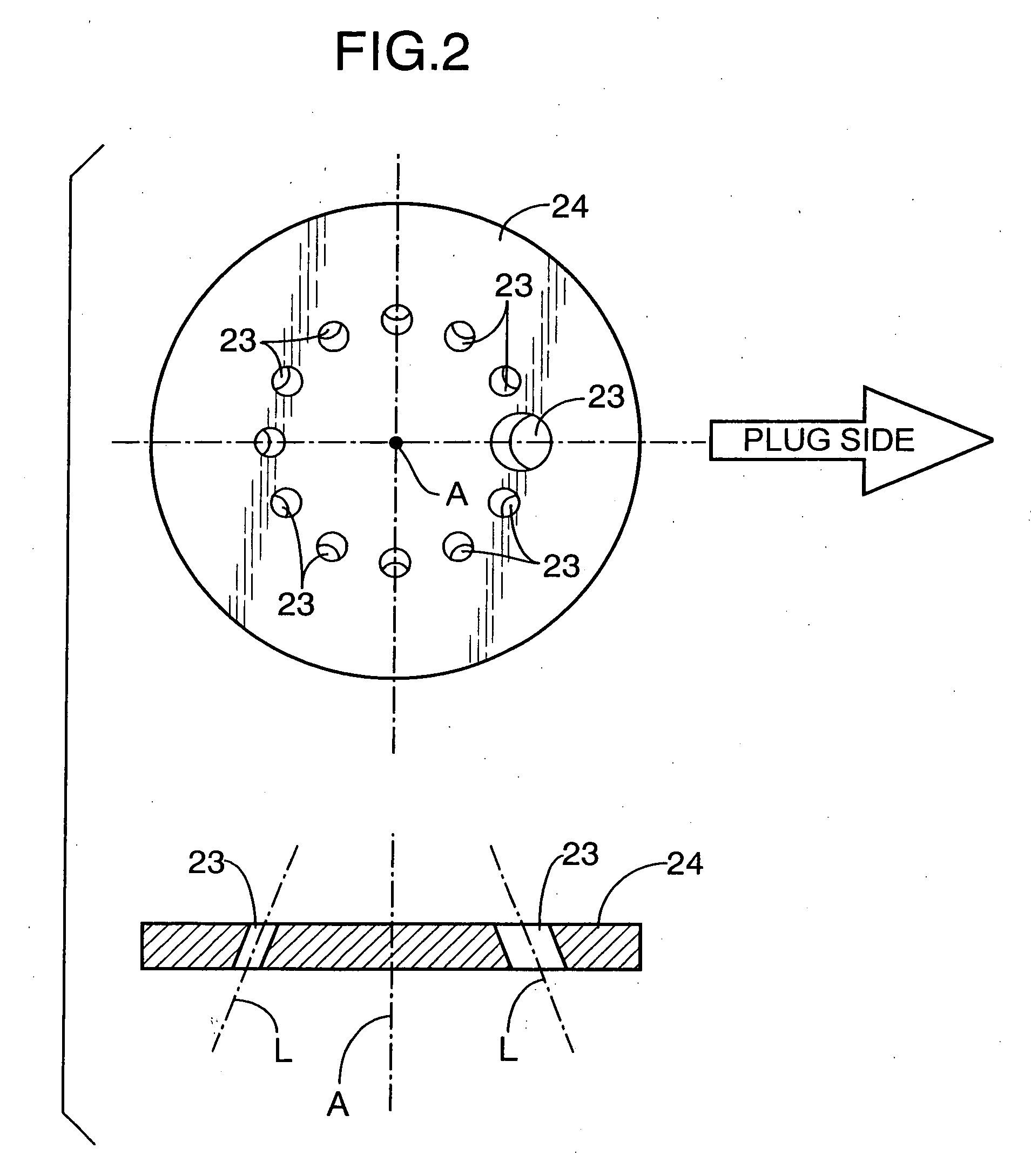

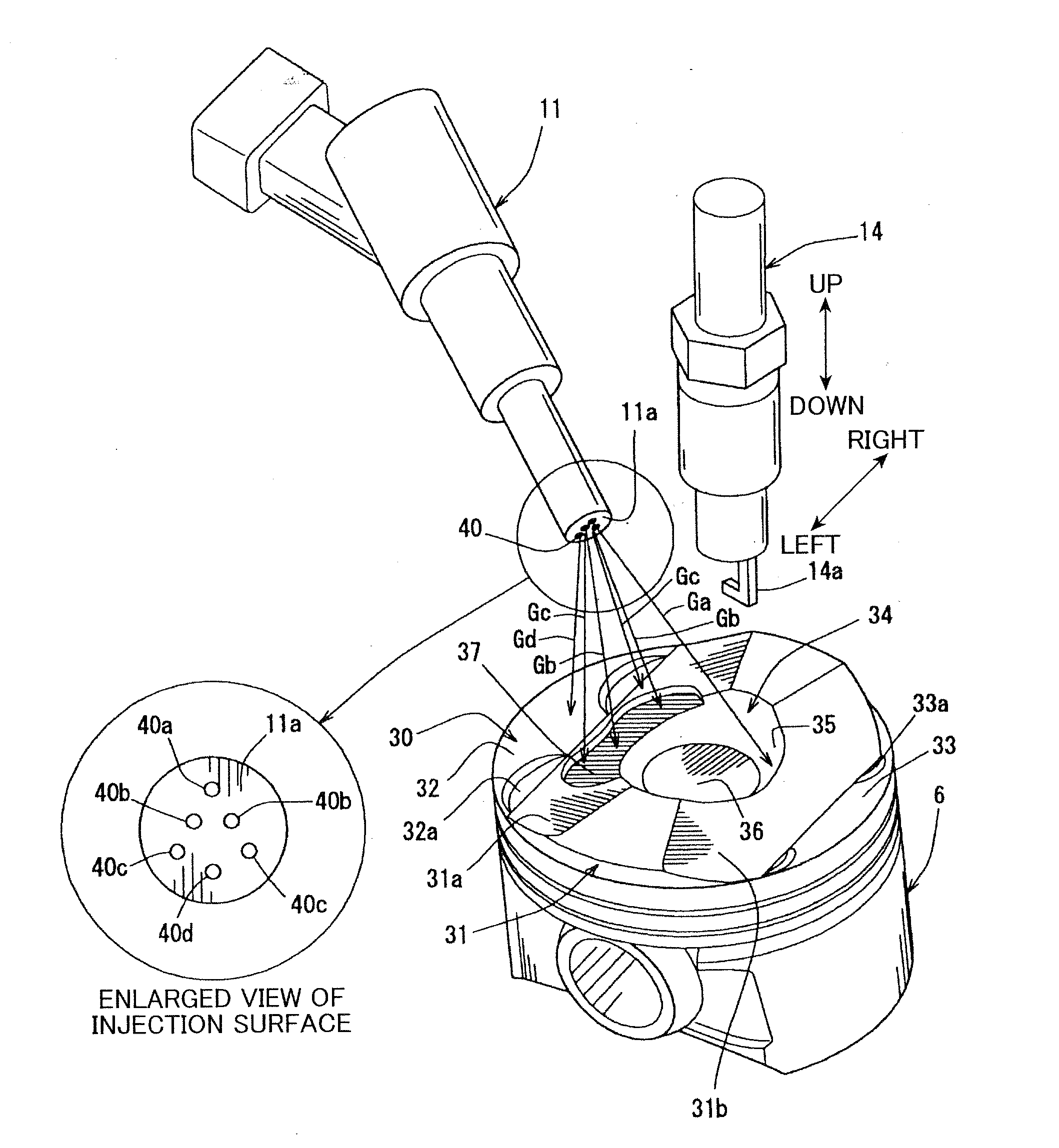

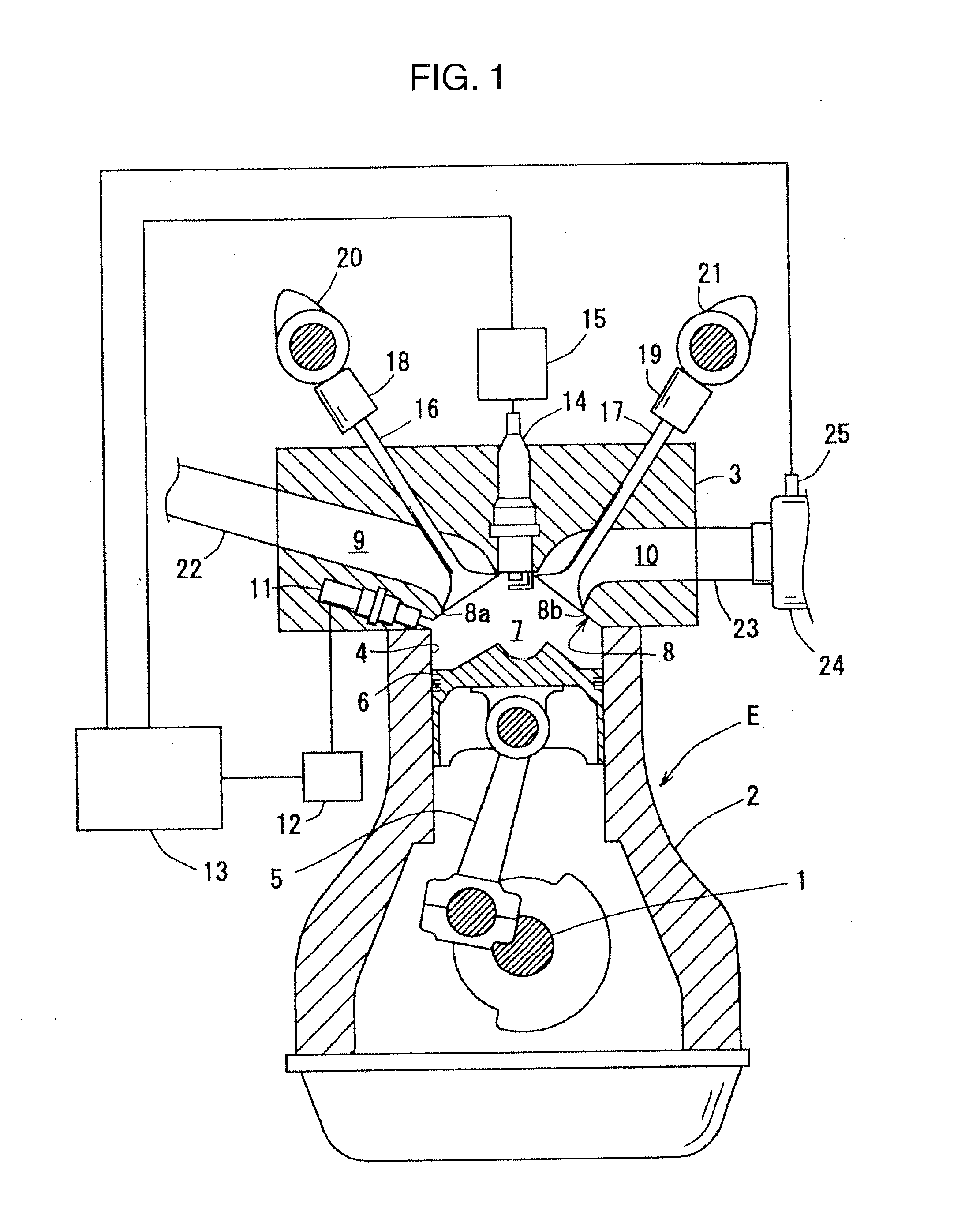

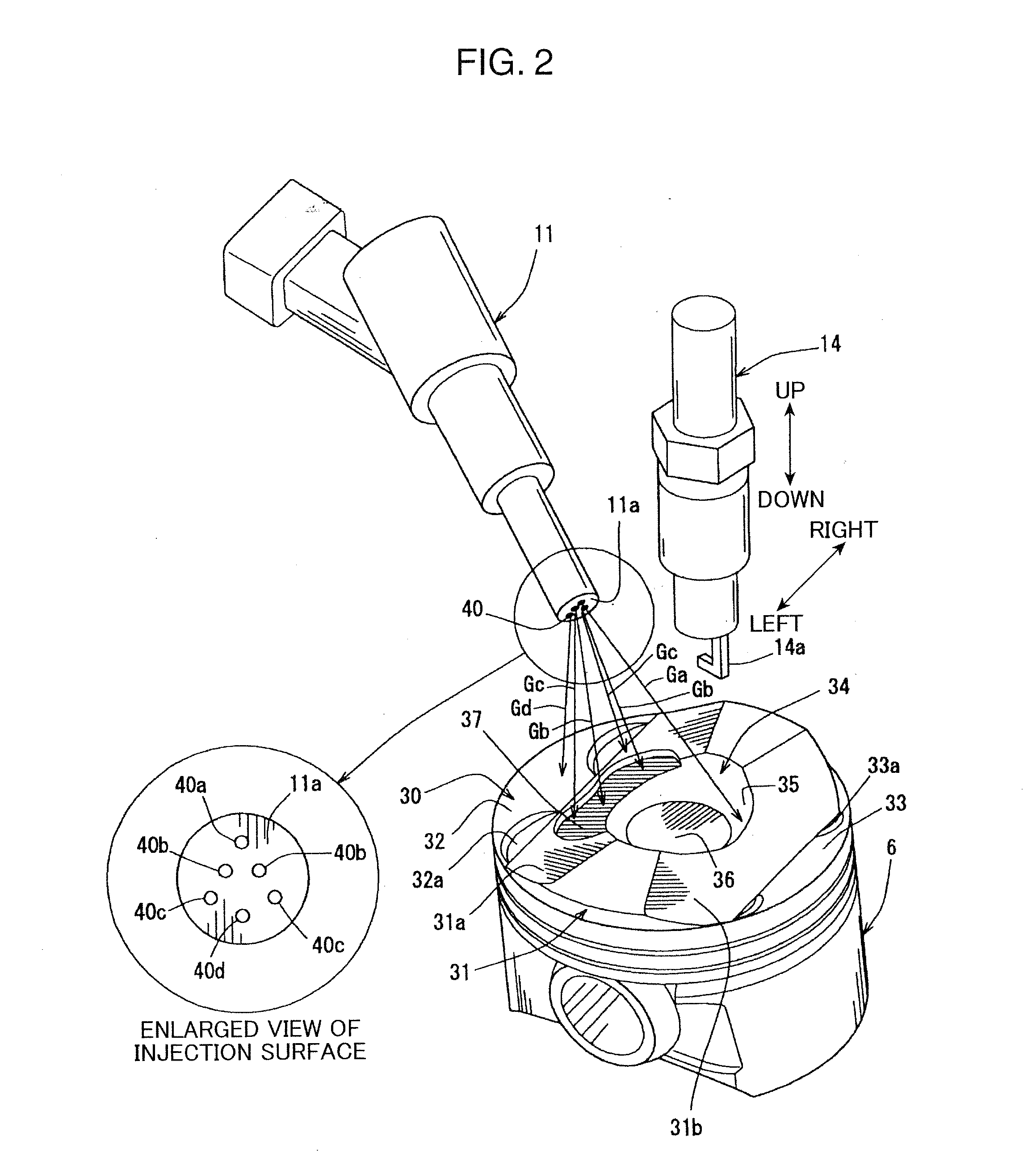

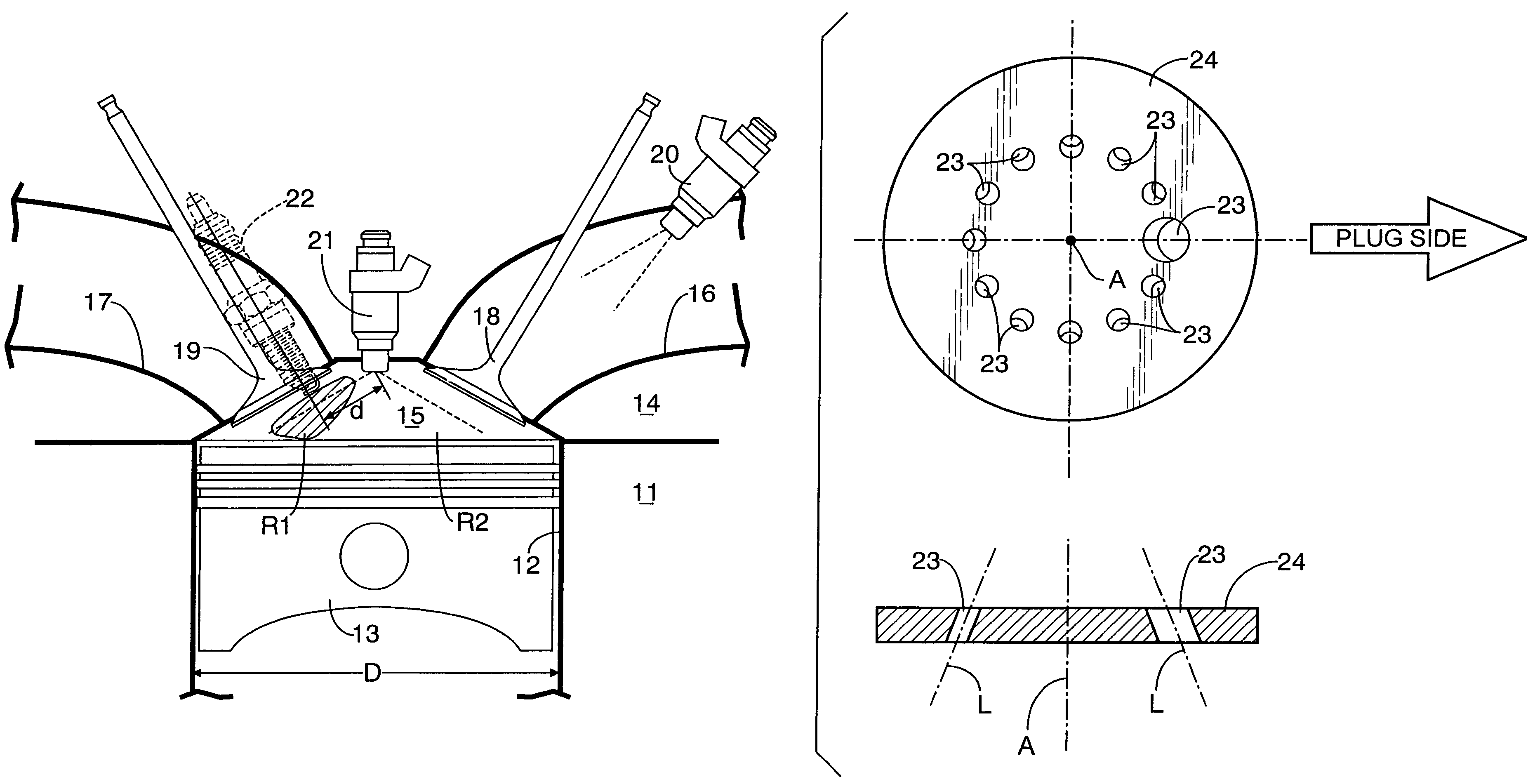

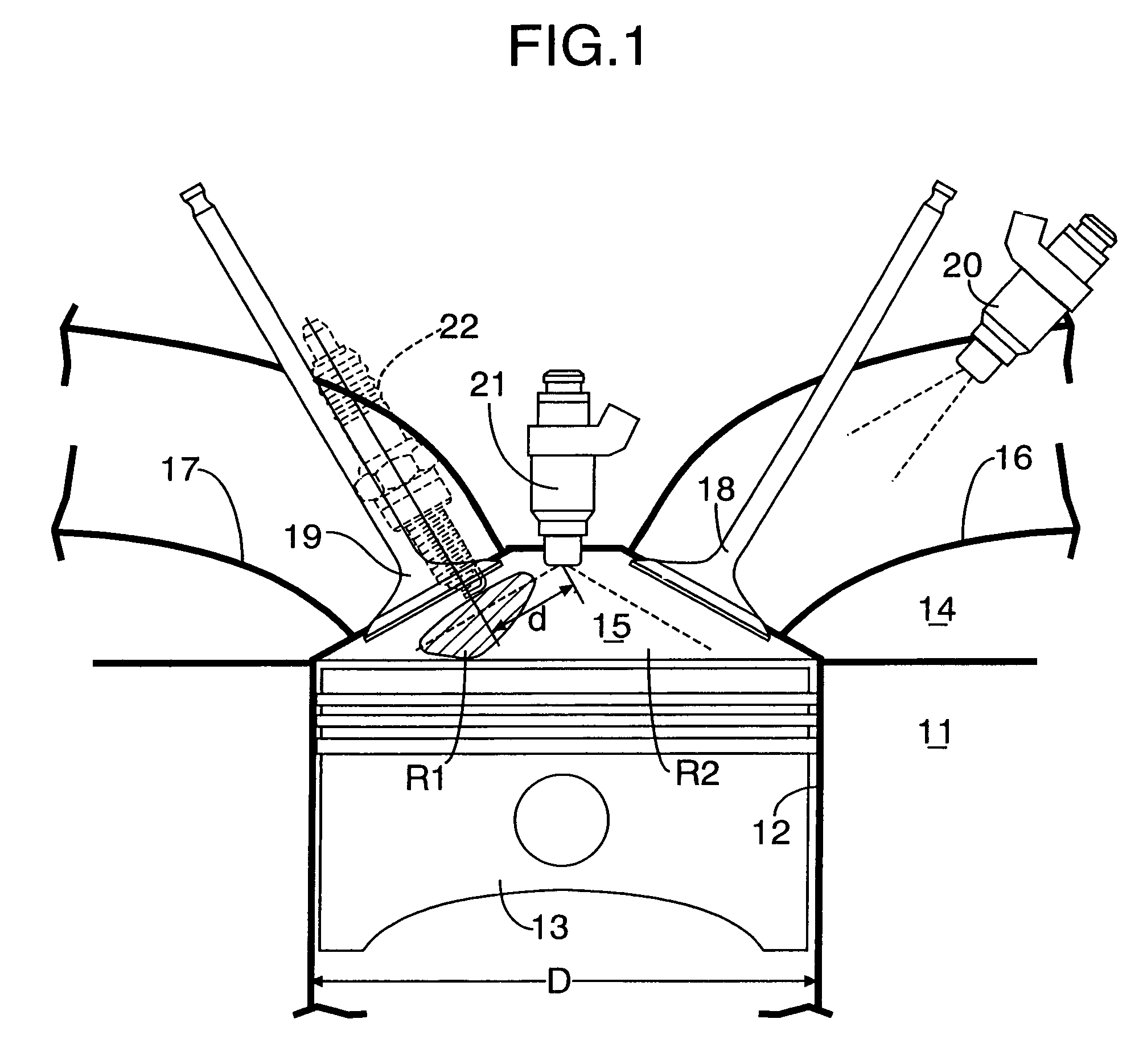

Direct-injection spark-ignition engine

ActiveUS20100175660A1Promoting catalyst activationImprove combustion efficiencyAnalogue computers for vehiclesInternal combustion piston enginesPenetration forceEngineering

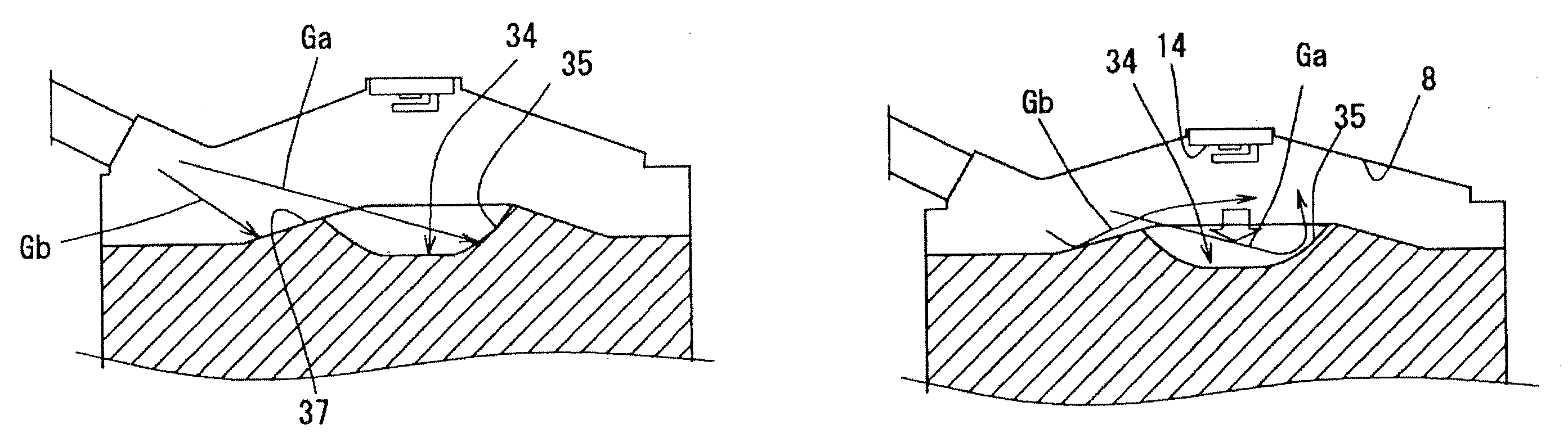

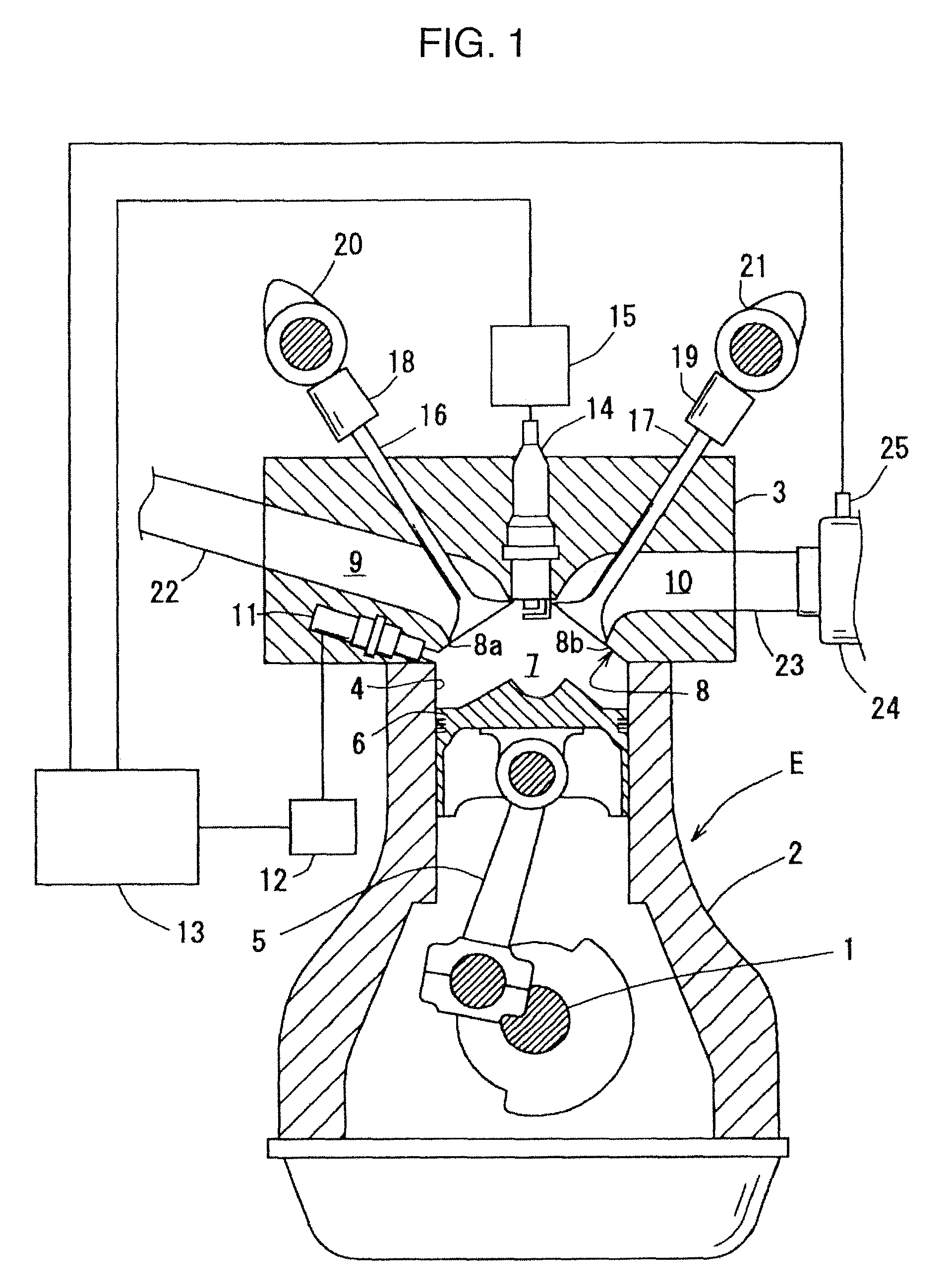

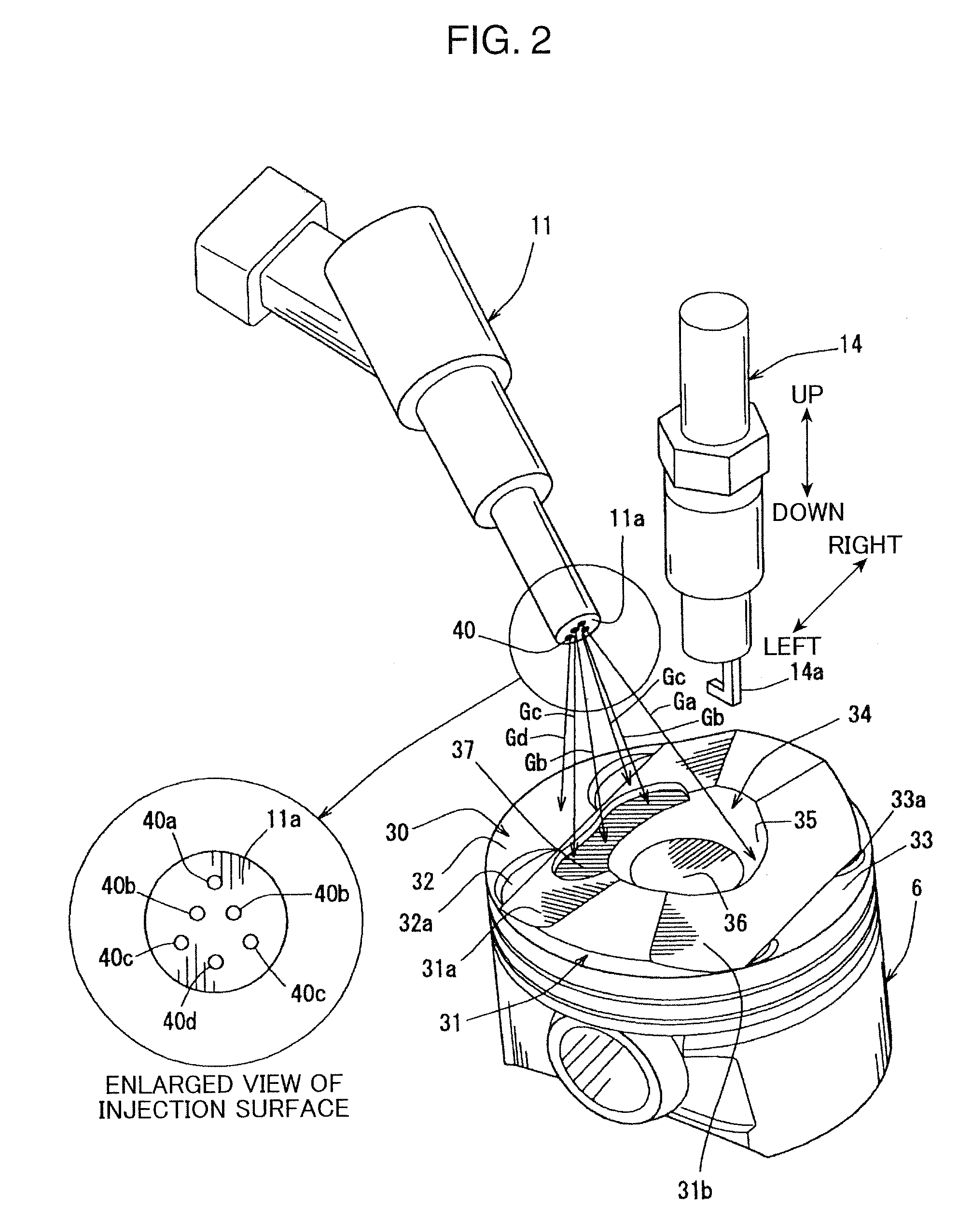

Disclosed is a direct-injection spark-ignition engine designed to promote catalyst activation during cold engine operation. A fuel injection timing for a fuel injection period in an compression stroke (second fuel injection period F2) is set to allow a first fuel spray Ga injected from a first spray hole 40a to enter a cavity 34 in a piston crown surface 30, and allow a second fuel spray Gb to impinge against a region of the piston crown surface 30 located closer to an injector than the cavity 34, so as to cause the second fuel spray Gb having a lowered penetration force due to the impingement to be pulled toward the cavity 34 by a negative pressure generated in the cavity 34 as a result of passing of the first fuel spray Ga therethrough. The direct-injection spark-ignition engine can maximally hold an injected fuel spray around a spark plug to reliably stabilize a combustion state in a combustion mode for promoting catalyst activation during cold engine operation, while enhancing combustion efficiency in a homogenous combustion mode during normal engine operation.

Owner:MAZDA MOTOR CORP

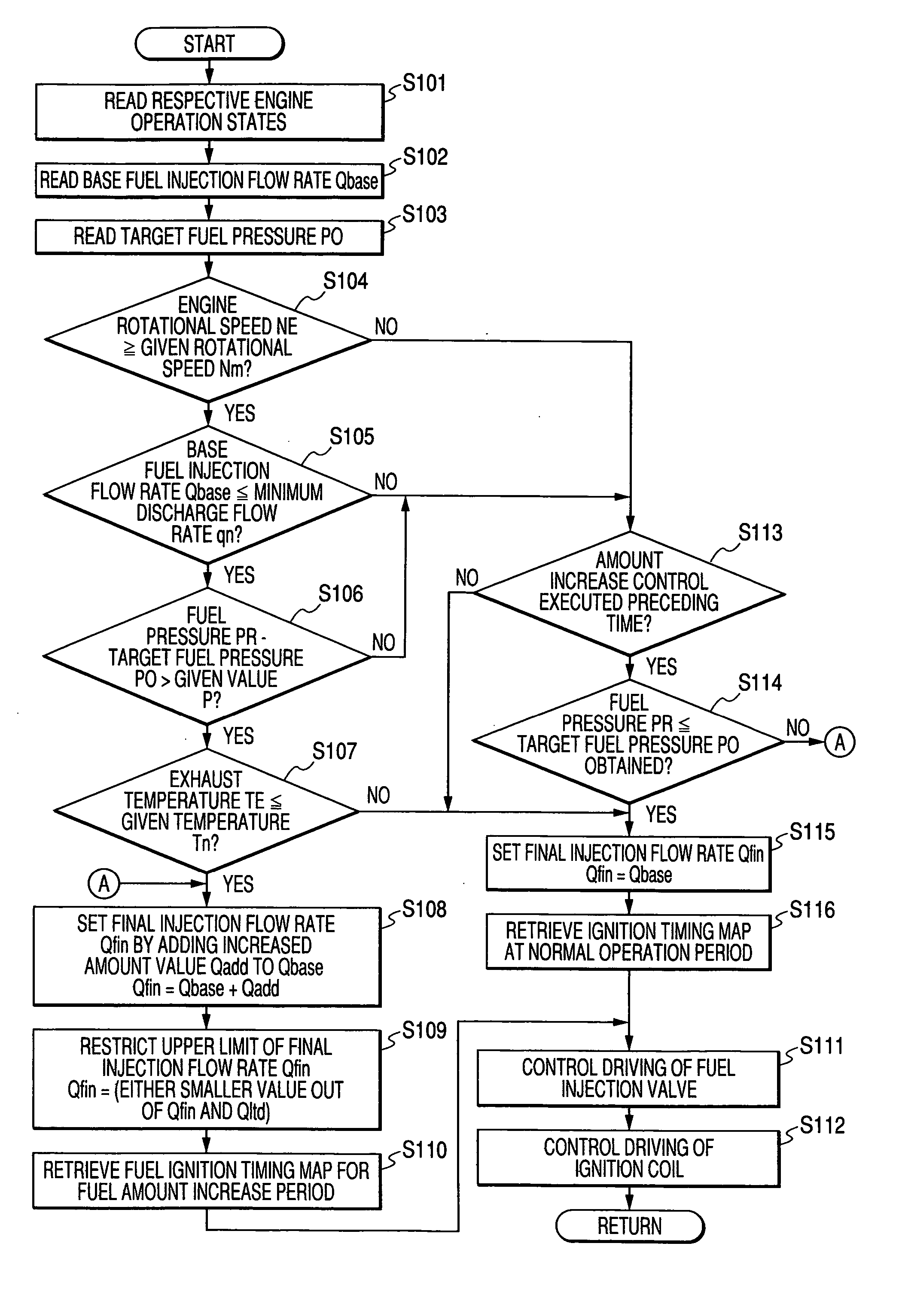

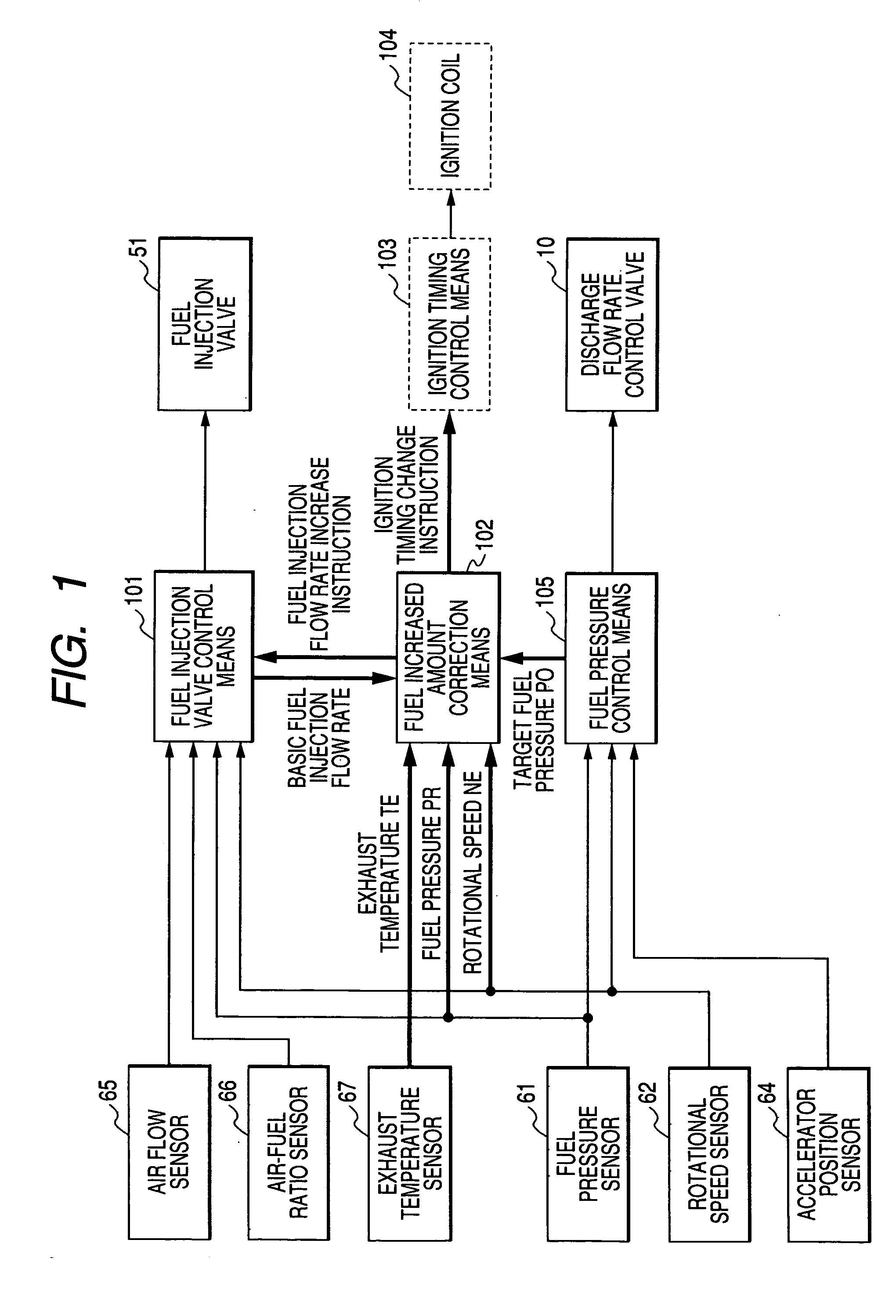

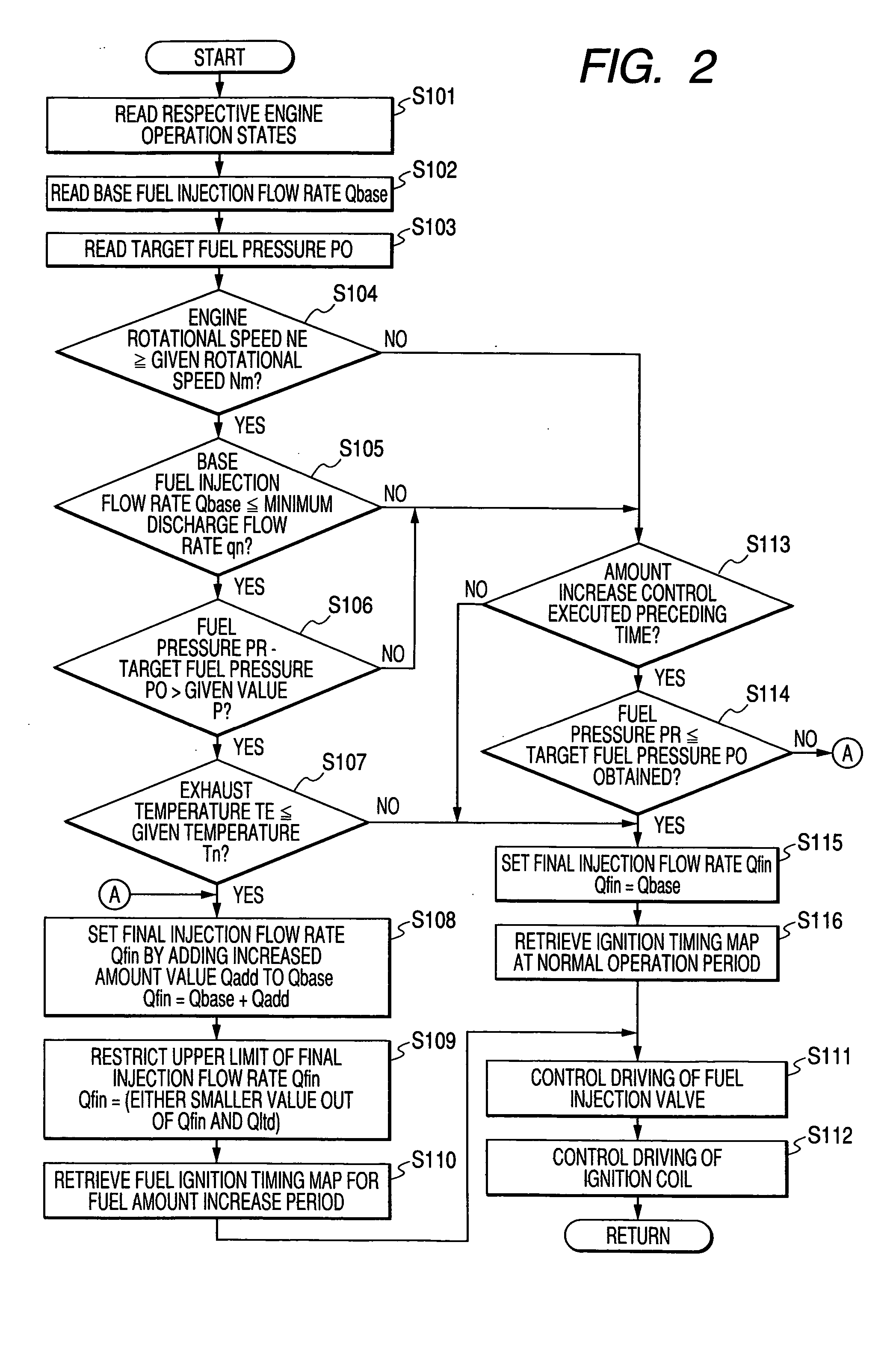

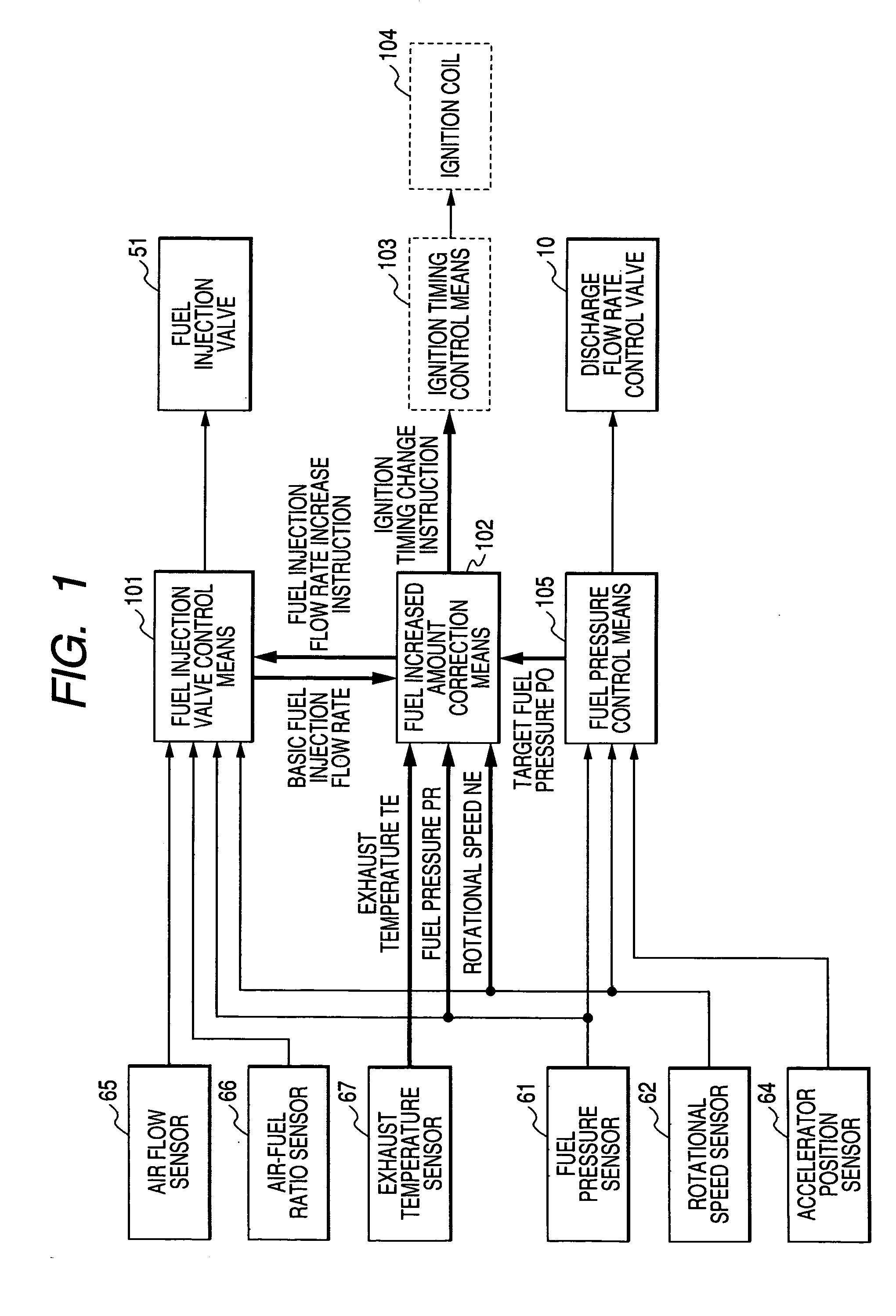

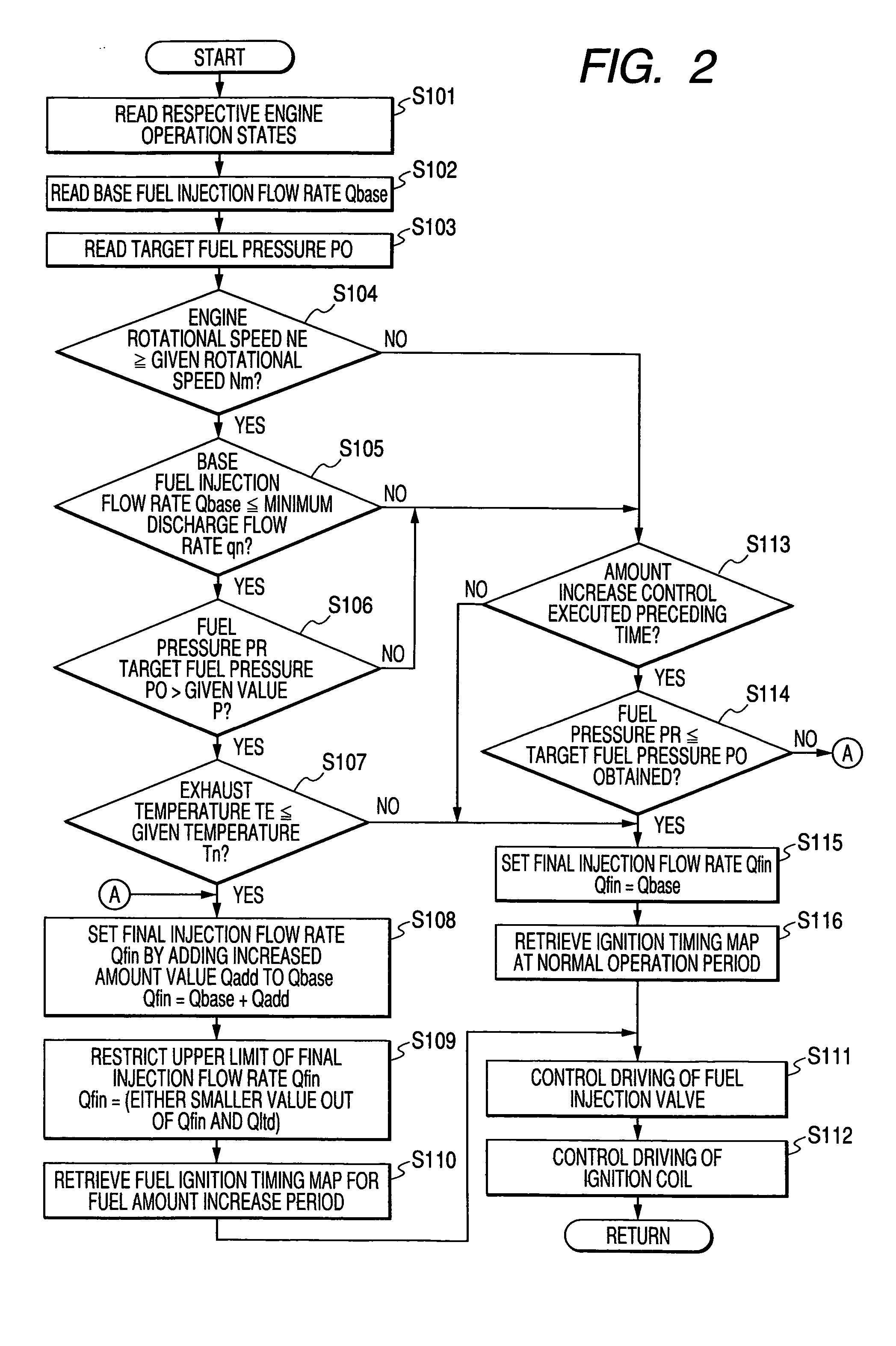

Fuel injection control device of internal combustion engine

InactiveUS20050252200A1Prevent the deterioration of an exhaust gasPreventing excessive elevationElectrical controlExhaust apparatusHigh pressureControl valves

A fuel injection control device of an internal combustion engine includes fuel injection valve control means which calculates a basic fuel injection flow rate which becomes a target air-fuel ratio corresponding to an engine operation state and performs a driving control of the fuel injection valve, a fuel pressure sensor which detects a fuel pressure in the inside of the pressure storage chamber, a discharge amount control valve for controlling a fuel amount supplied to the pressure storage chamber from the high-pressure pump, and fuel pressure control means which controls the discharge amount control valve such that the fuel pressures in the inside of the pressure storage chamber agrees with a preset target fuel pressure, wherein the fuel injection control device includes fuel increase correction means which increases the basic fuel injection flow rate in a state that a rotational speed of the engine falls in a given preset rotational speed region where the minimum discharge flow rate of the high-pressure pump is expected to exceed zero and the fuel pressure in the inside of the pressure storage chamber is higher than the target fuel pressure.

Owner:MITSUBISHI ELECTRIC CORP

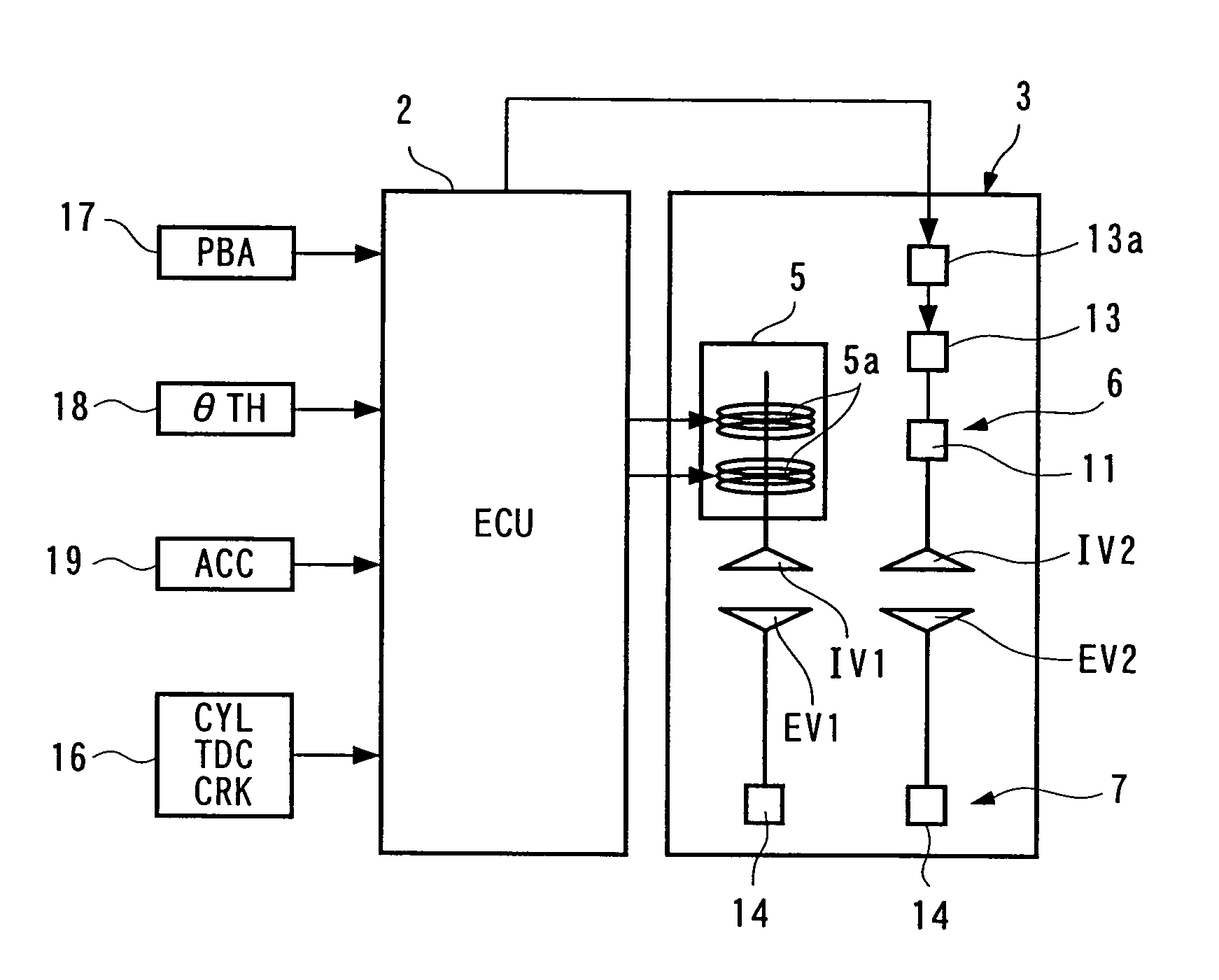

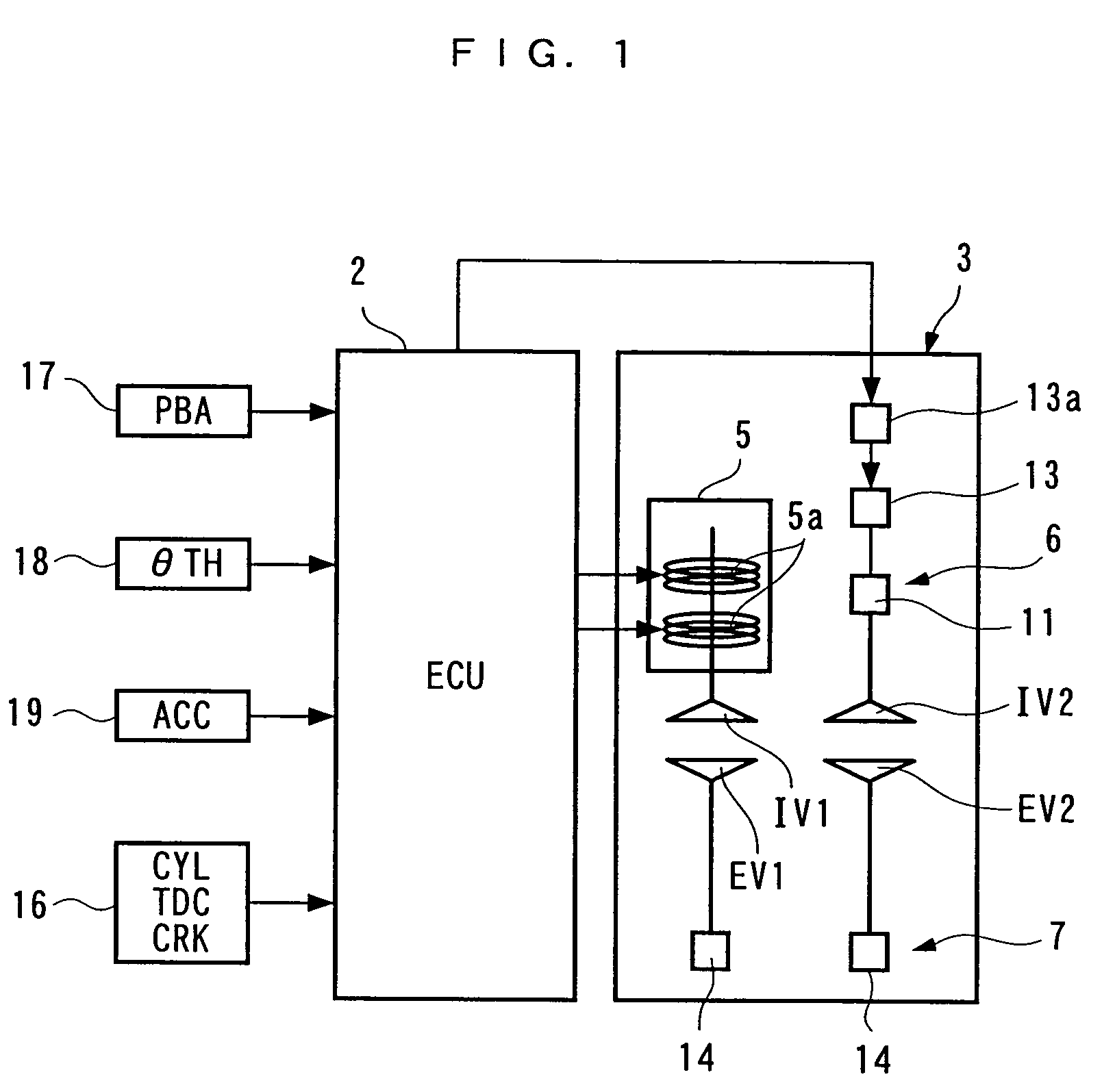

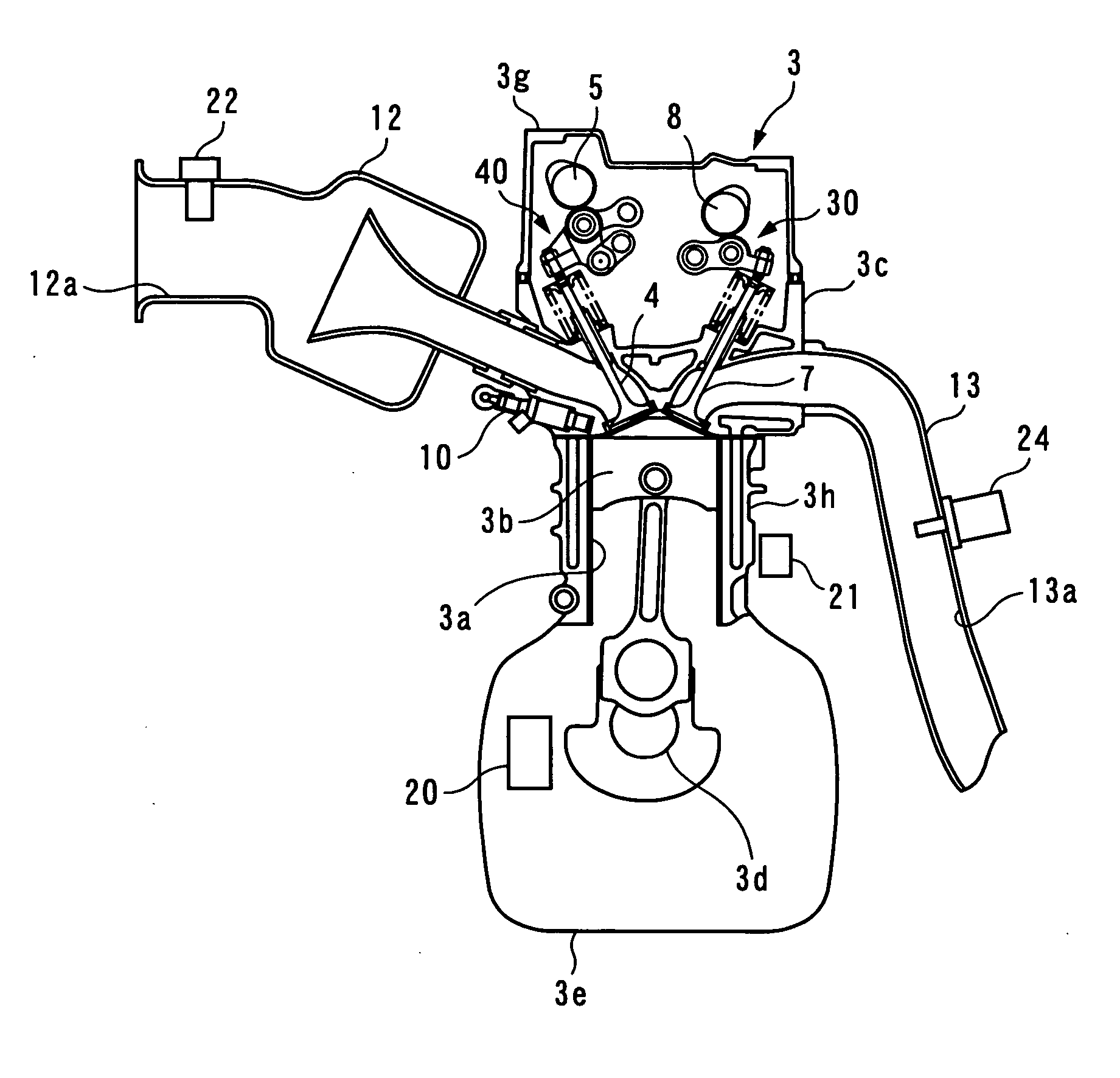

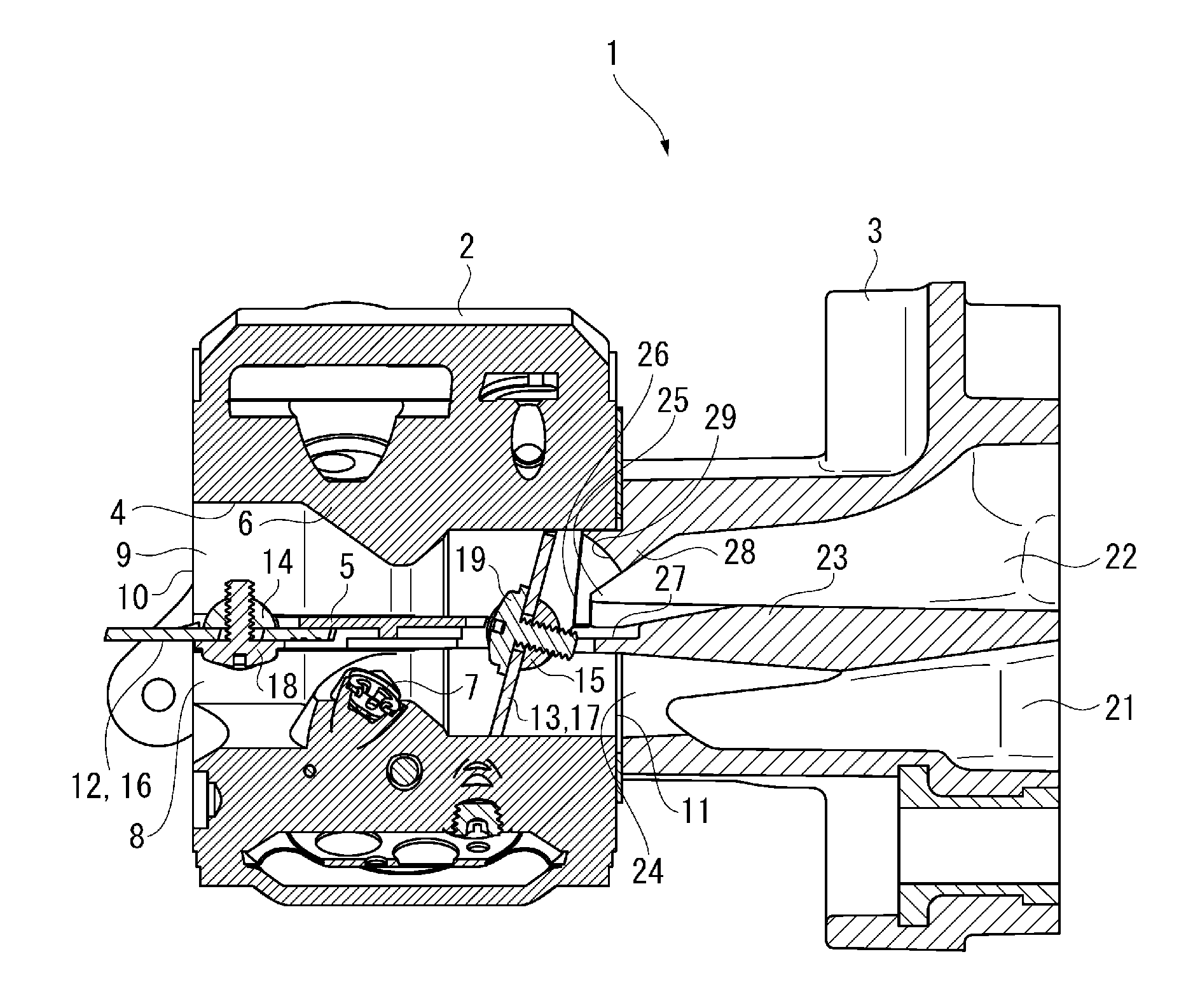

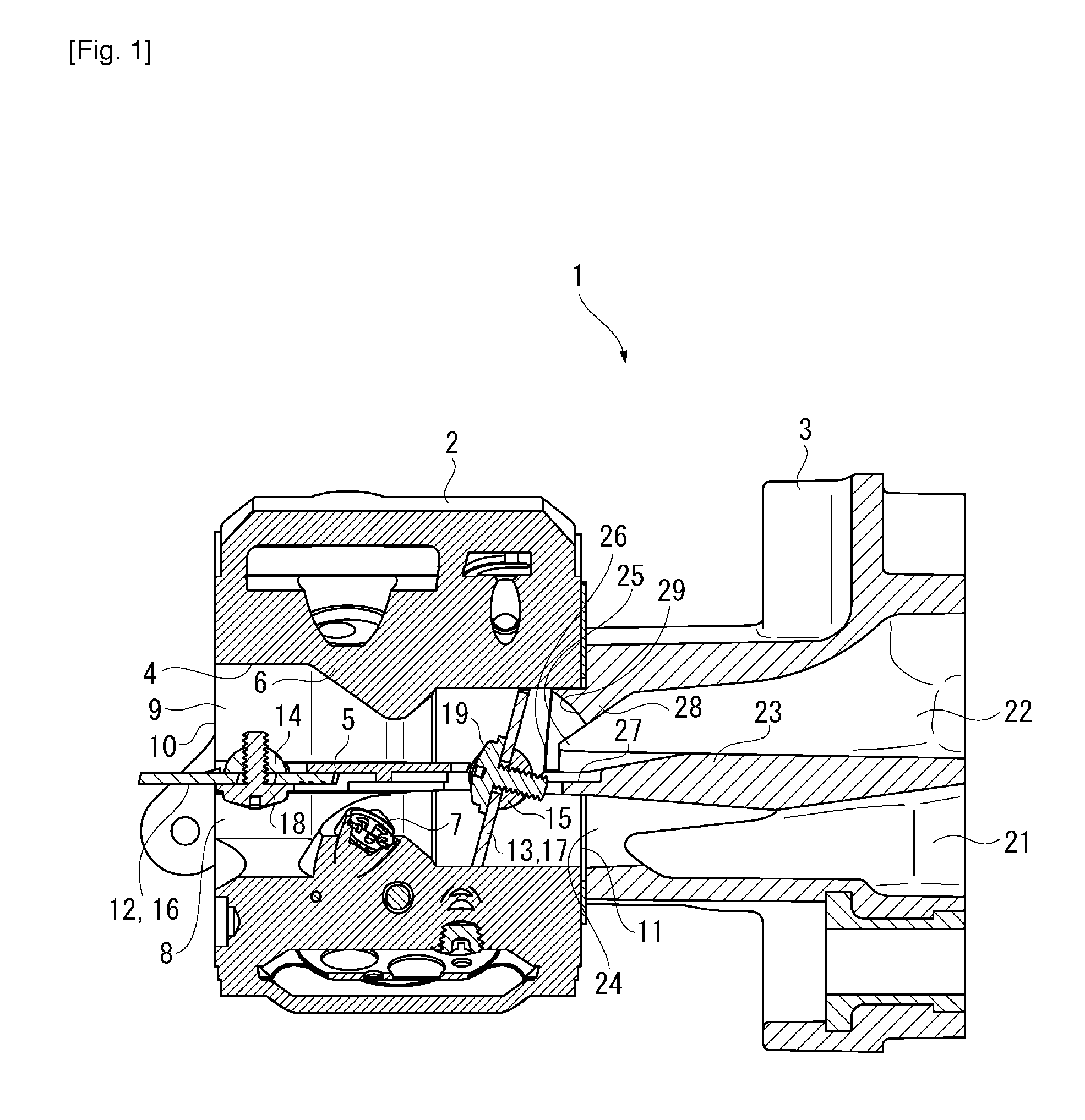

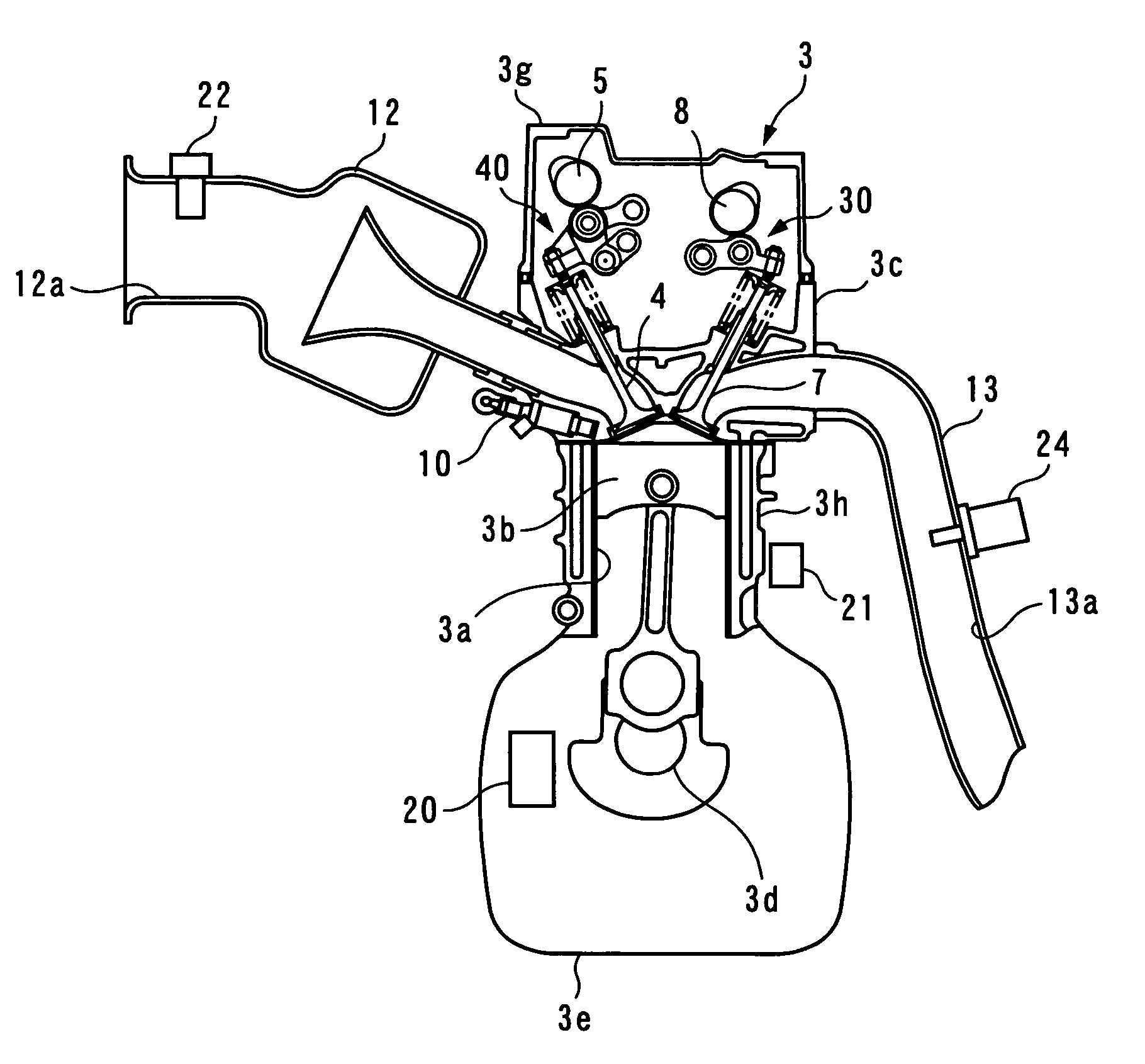

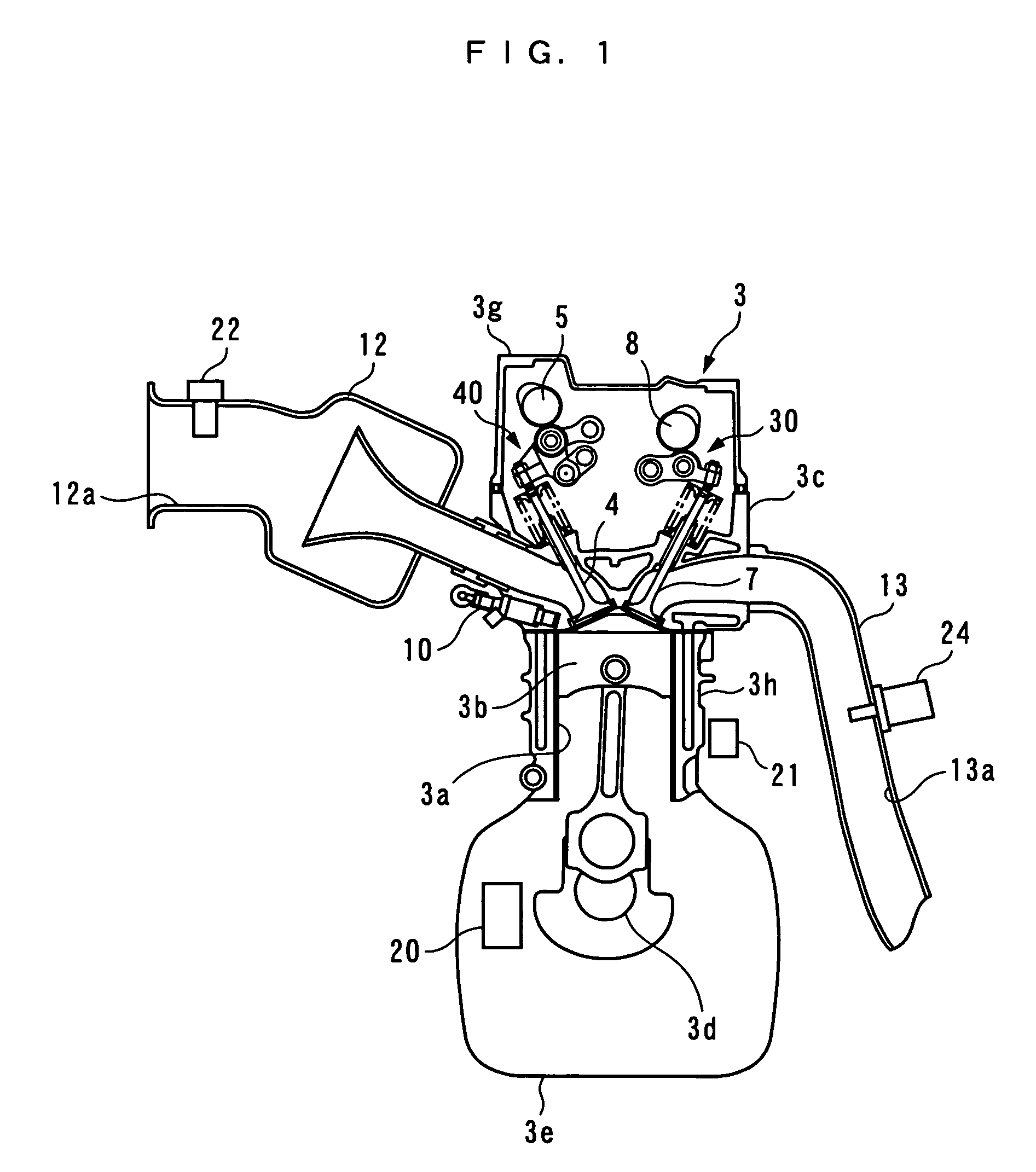

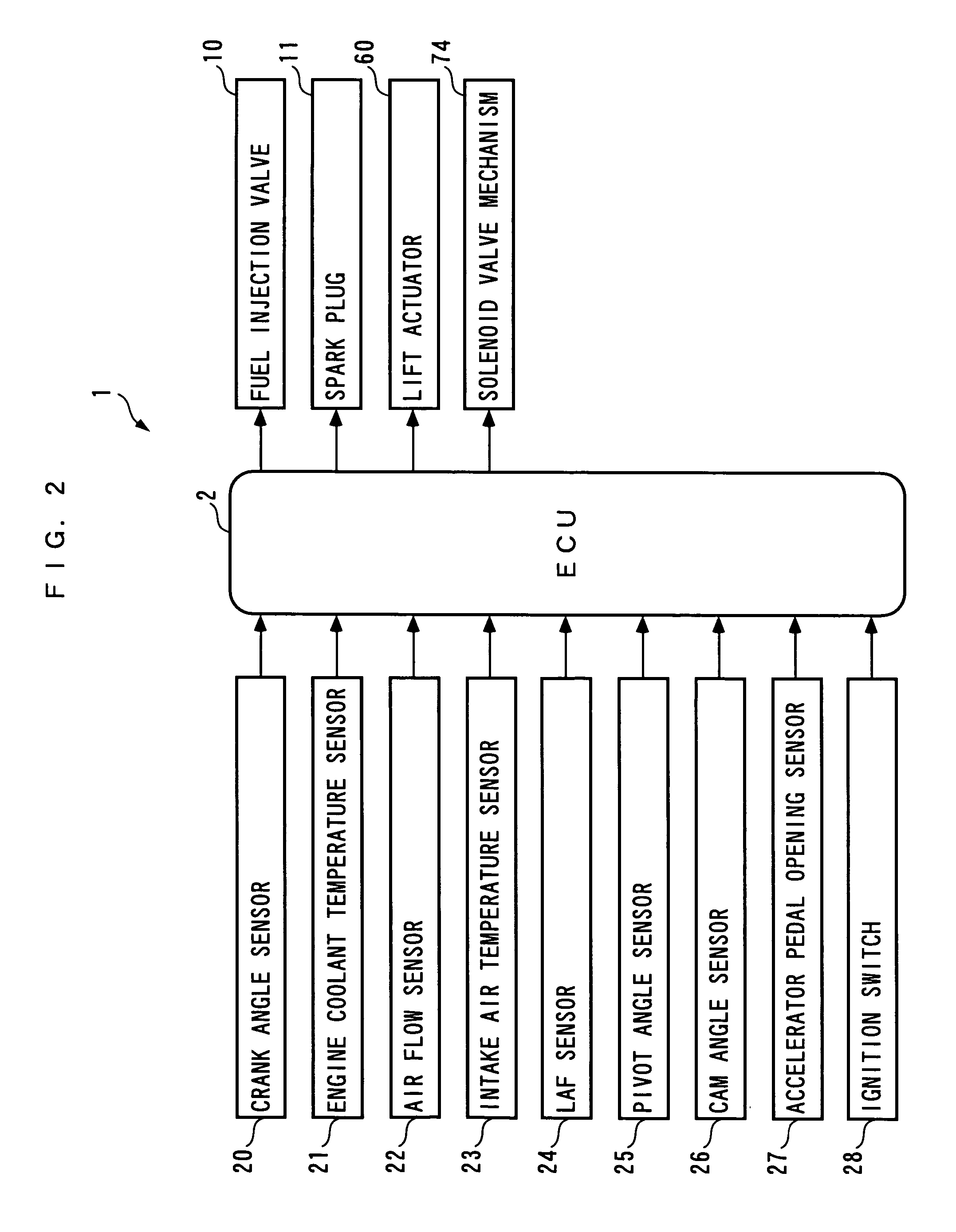

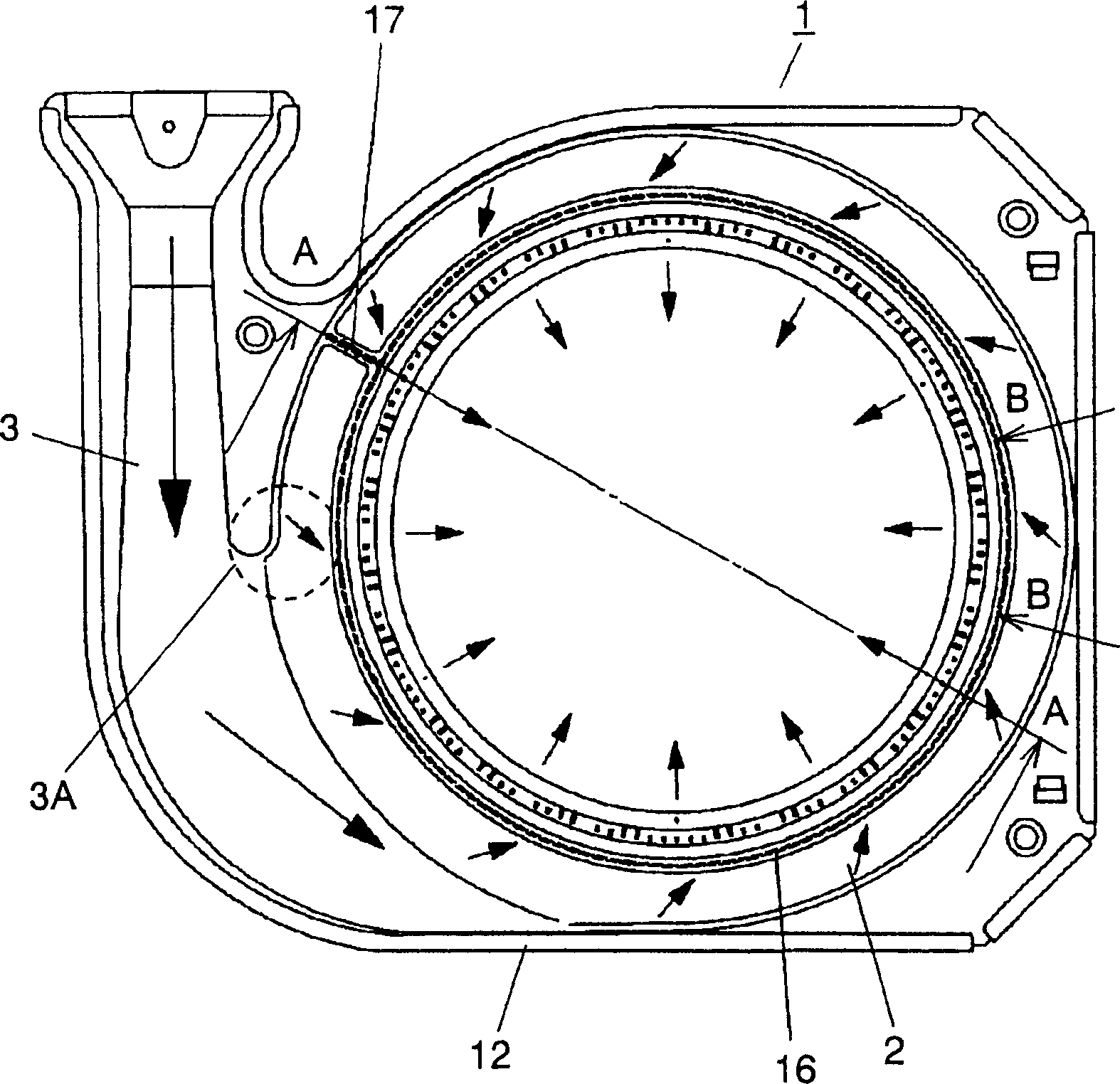

Valve operation controller

InactiveUS7051687B2Eliminate fuel stagnationImprove efficiencyOperating means/releasing devices for valvesElectrical controlCombustion chamberExhaust valve

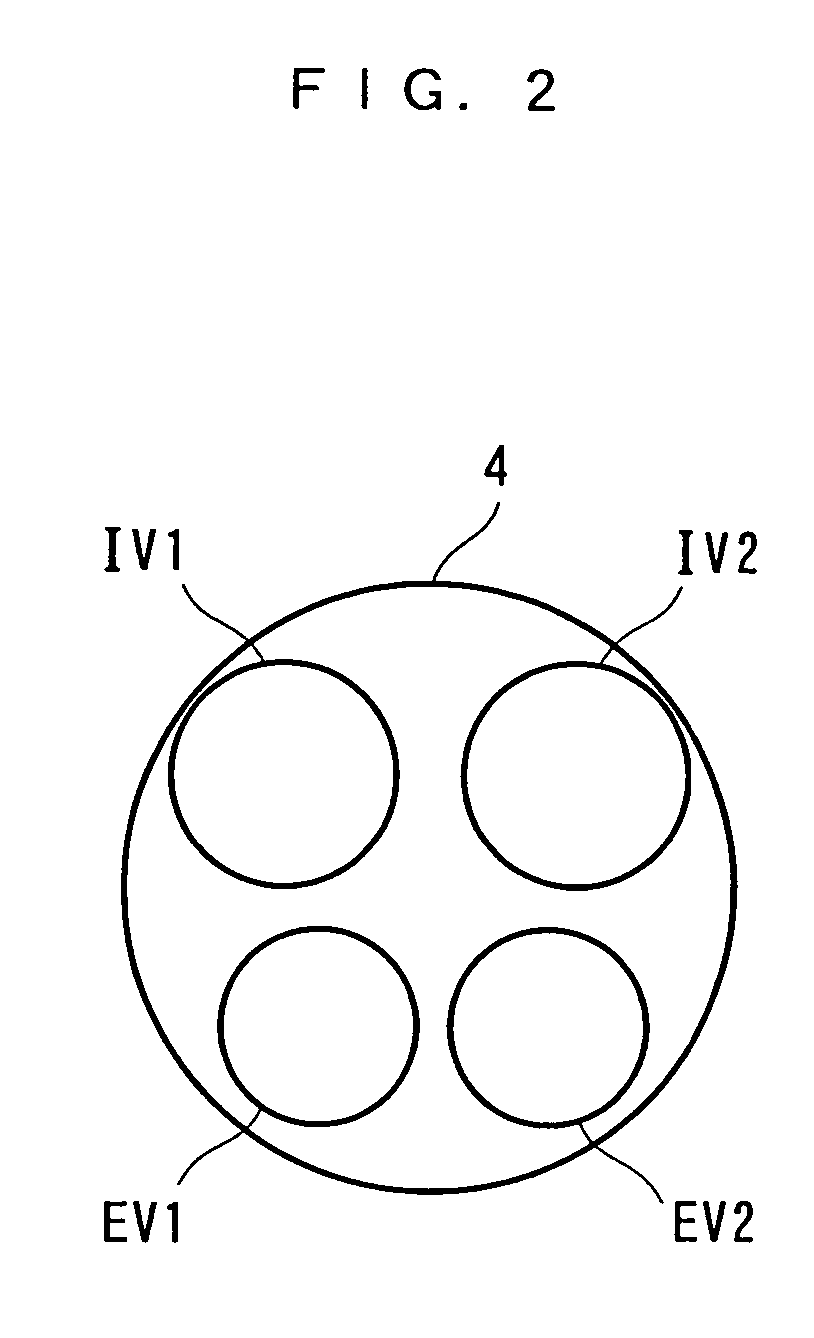

A valve operation controller for an internal combustion engine is provided for optimally setting a valve opening timing and a valve closing timing for an intake valve in accordance with an operating state of the internal combustion engine to improve the fuel efficiency and power of the internal combustion engine, eliminate fuel stagnation in the intake valve and sticking of the intake valve with its valve seat, and reduce the cost and weight. The valve operation controller controls open / close operations of exhaust valves (EV1, EV2) and first and second intake valves (IV1, IV2) arranged in one cylinder (4). An electromagnetic valve operating mechanism (5) electromagnetically opens / closes the first intake valve (IV1). A cam type valve operating mechanism (6) opens / closes the second intake valve (IV2) with an intake cam (11) arranged on a cam shaft (10) driven in synchronism with rotation of the internal combustion engine (3). The cam type valve operating mechanism (6) can generate a cylinder flowage within a combustion chamber of the cylinder (4). An ECU (2) controls operations of the electromagnetic valve operating mechanism (5) and the cam type valve operating mechanism (6).

Owner:HONDA MOTOR CO LTD

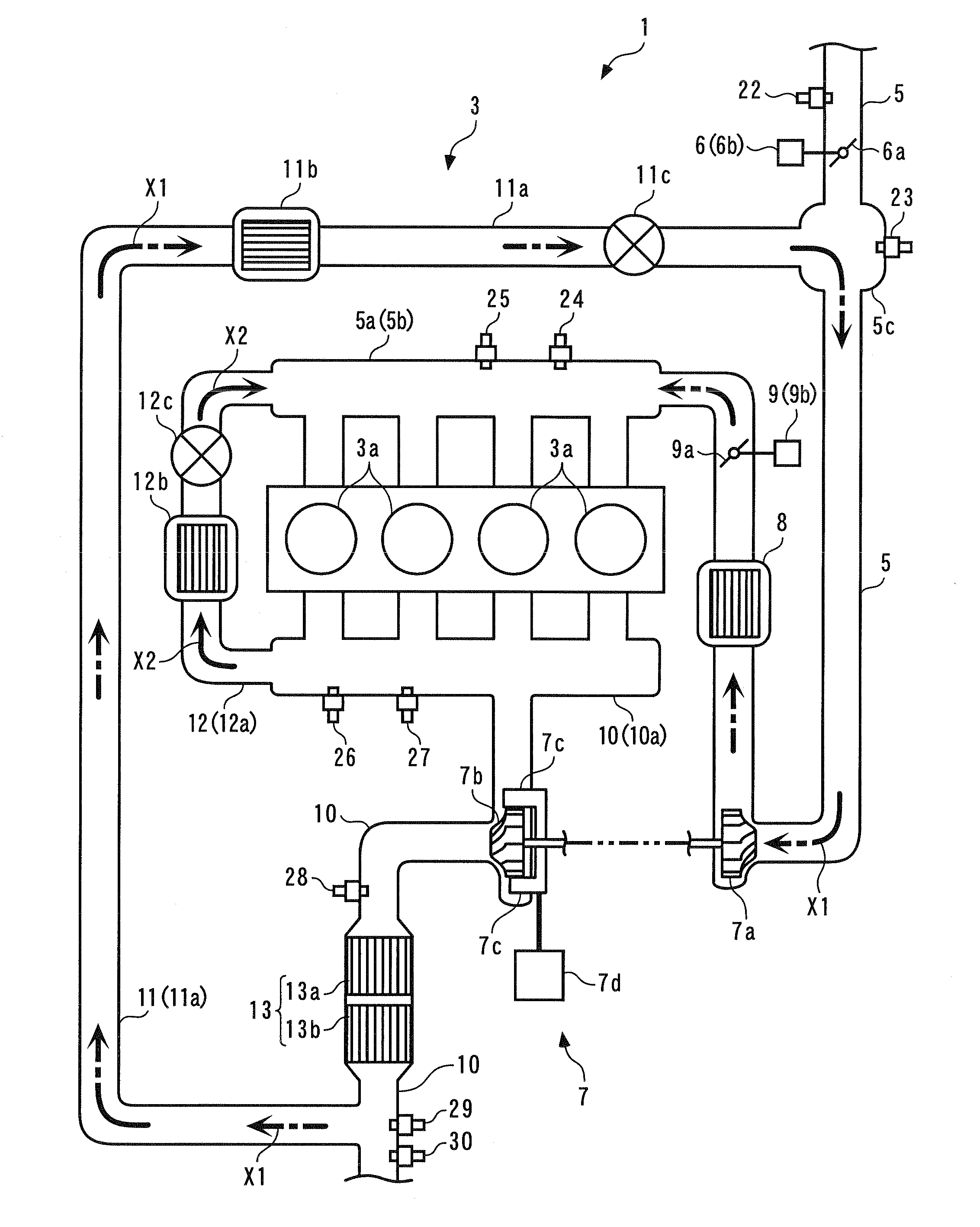

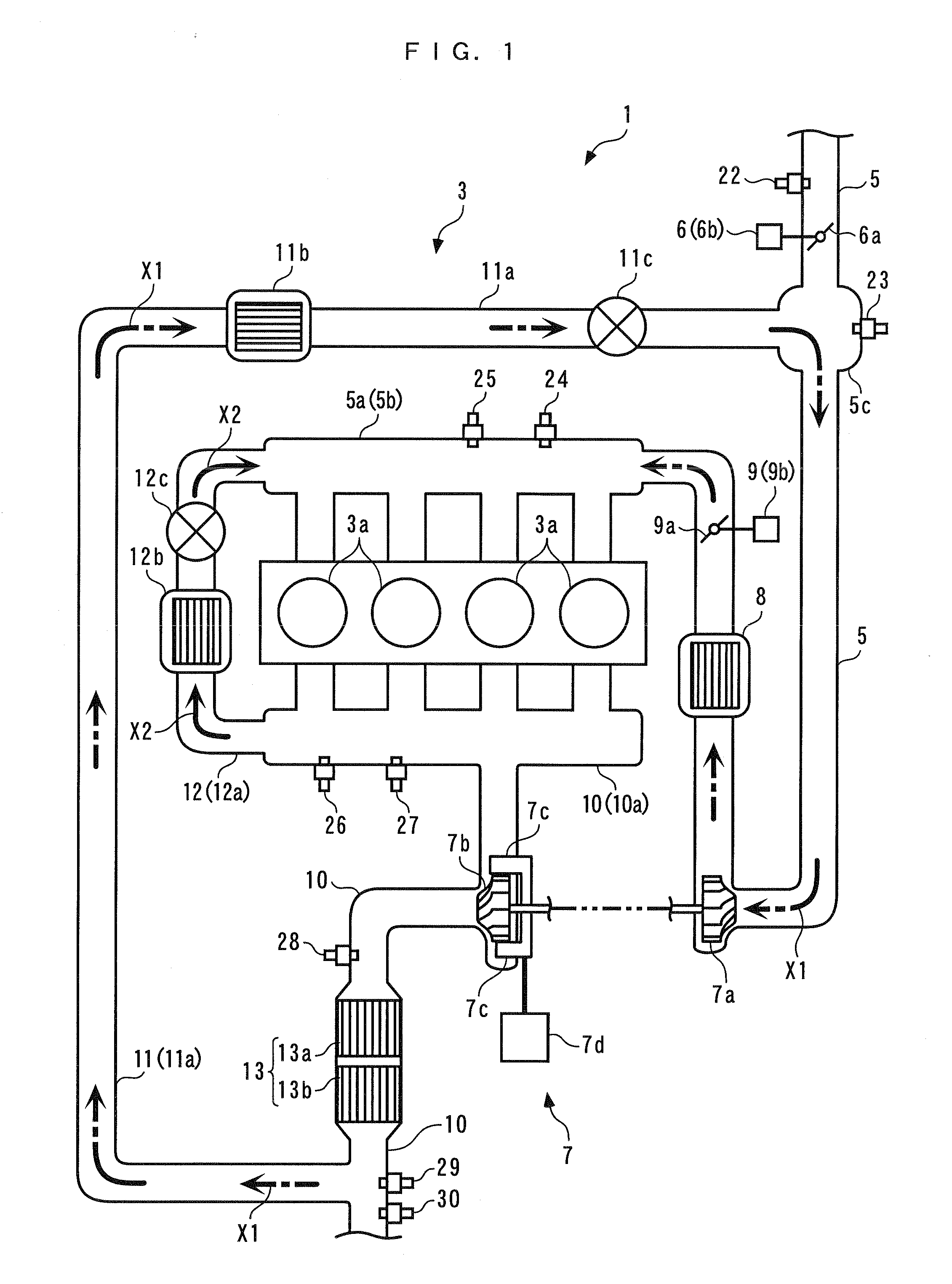

EGR control apparatus for internal combustion engine

ActiveUS8794219B2Combustion state is stableReduce exhaust emissionsElectrical controlInternal combustion piston enginesCombustionInternal combustion engine

An EGR control apparatus for an internal combustion engine, which is capable of properly controlling an inert gas amount of two types of EGR gas supplied to cylinders of the engine via two paths different from each other, thereby making it possible to ensure a stable combustion state, reduced exhaust emissions, and improve operability. The EGR control apparatus includes low-pressure and high-pressure EGR devices, and an ECU. The ECU controls the low-pressure and high-pressure EGR gas amounts according to engine speed and demanded torque, and when a combination of engine speed and demanded torque is in a predetermined region, the low-pressure and high-pressure EGR gas amounts are controlled such that inert gas in low-pressure EGR gas exceeds in amount inert gas in high-pressure EGR gas, and the former more exceeds the latter as engine speed is higher or demanded torque is larger.

Owner:HONDA MOTOR CO LTD

EGR control apparatus for internal combustion engine

ActiveUS8646271B2Limit amount of gasCombustion state is stableAnalogue computers for vehiclesElectrical controlCombustionExternal combustion engine

An EGR control apparatus for an internal combustion engine, which is capable of accurately controlling an inert gas amount and an inert gas ratio of two types of EGR gas supplied to cylinders of the engine via two paths different from each other, thereby making it possible to ensure a stable combustion state and reduced exhaust emissions. The EGR control apparatus includes a low-pressure EGR device, a high-pressure EGR device, and an ECU. The ECU calculates a target low-pressure opening, calculates an estimated value of an in-cylinder low-pressure inert gas flow rate, which is the estimated value of an inert gas amount included in low-pressure EGR gas supplied to the cylinders via an intake passage, calculates a target high-pressure opening using the estimated value, and controls low-pressure and high-pressure EGR control valves, using the target low-pressure opening and the target high-pressure opening.

Owner:HONDA MOTOR CO LTD

Fuel injection control device of internal combustion engine

InactiveUS7143576B2Prevent the deterioration of an exhaust gasPreventing excessive elevationElectrical controlExhaust apparatusHigh pressureControl valves

A fuel injection control device of an internal combustion engine includes fuel injection valve control means which calculates a basic fuel injection flow rate which becomes a target air-fuel ratio corresponding to an engine operation state and performs a driving control of the fuel injection valve, a fuel pressure sensor which detects a fuel pressure in the inside of the pressure storage chamber, a discharge amount control valve for controlling a fuel amount supplied to the pressure storage chamber from the high-pressure pump, and fuel pressure control means which controls the discharge amount control valve such that the fuel pressures in the inside of the pressure storage chamber agrees with a preset target fuel pressure, wherein the fuel injection control device includes fuel increase correction means which increases the basic fuel injection flow rate in a state that a rotational speed of the engine falls in a given preset rotational speed region where the minimum discharge flow rate of the high-pressure pump is expected to exceed zero and the fuel pressure in the inside of the pressure storage chamber is higher than the target fuel pressure.

Owner:MITSUBISHI ELECTRIC CORP

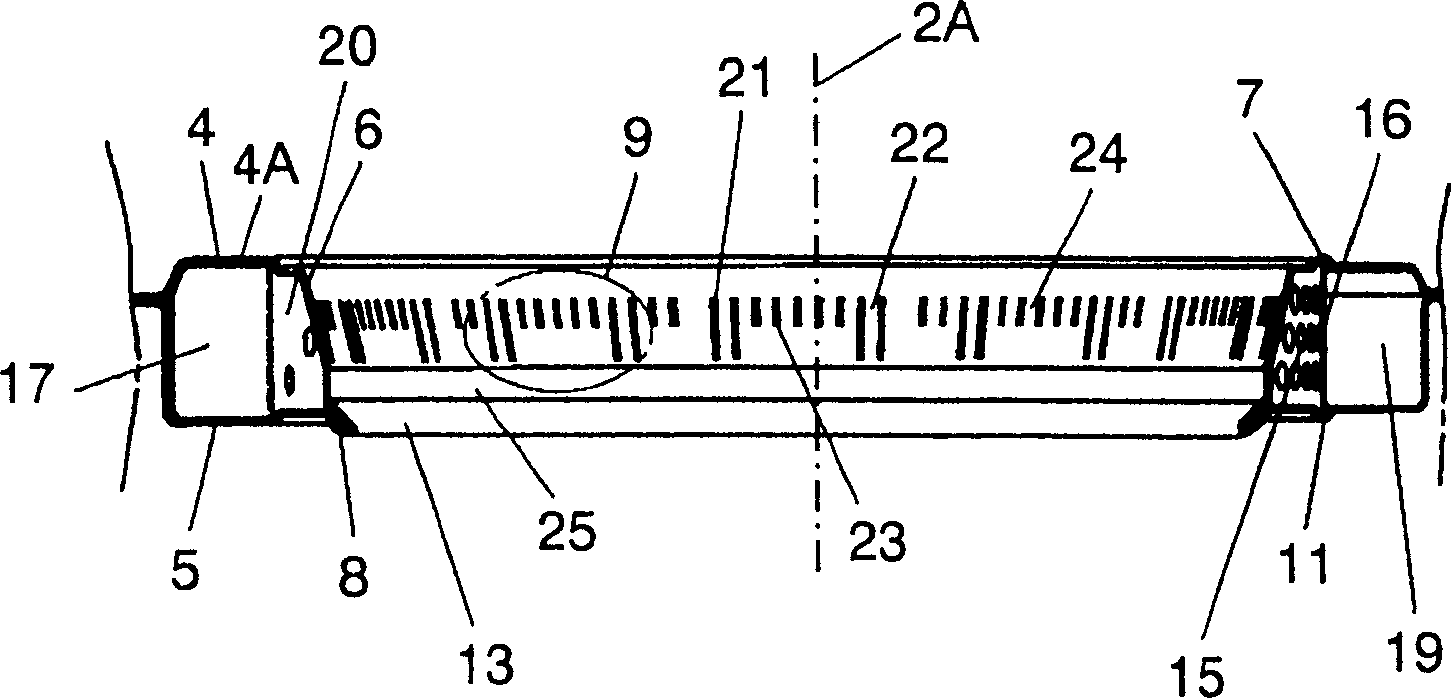

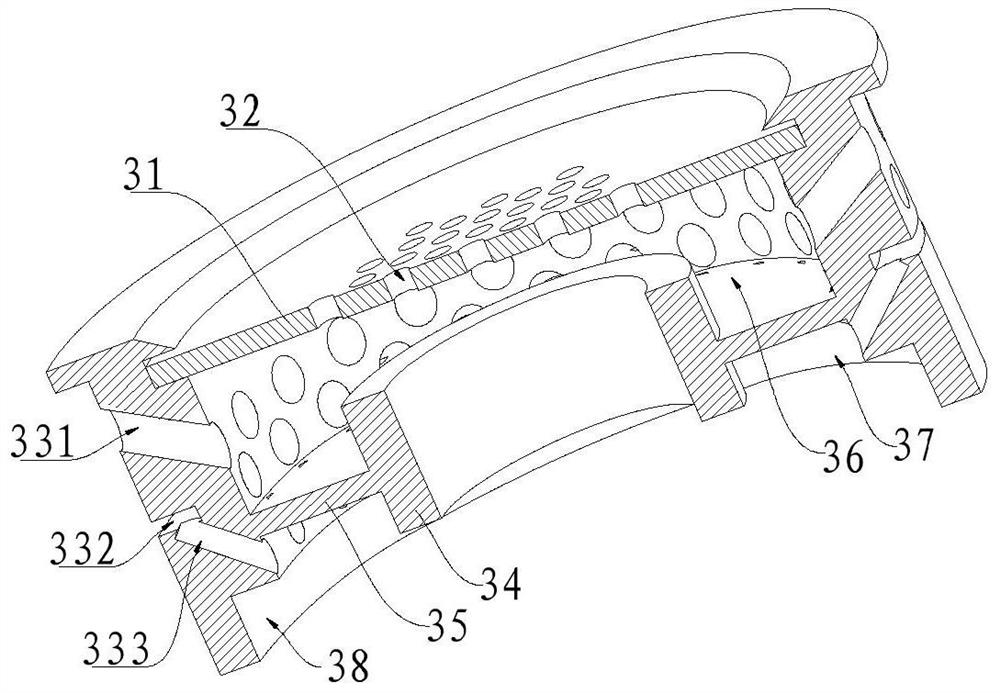

Gas generator propellant grain

ActiveCN103267453AReasonable layoutCompact structureSelf-propelled projectilesCartridge ammunitionGas generatorMissile

Provided is a gas generator propellant grain. Gas generator propellant is filled in a supporting barrel, more than one combustion-supporting hole is formed in a position, corresponding to the gas generator propellant, of the circumferential surface of the supporting barrel, an axial through hole is formed in the gas generator propellant, a position, making contact with the supporting barrel, of the side face of the gas generator propellant is provided with a lining, and combustion-limiting layers are installed on two end faces of the gas generator propellant. The gas generator propellant grain starts to burn simultaneously from the axial through hole and the combustion-supporting holes in the side face of the supporting barrel, the combustion face tends to increase, and produced gas flows to an exhaust hole of a gas generator through the inner axial through hole and the surface of the supporting barrel. The gas generator propellant grain used for guided missile ejection power devices has the advantages that the gas is produced rapidly, the combustion temperature is low, the gas producing quantity is gradually increased over time, and the change rule is controllable.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

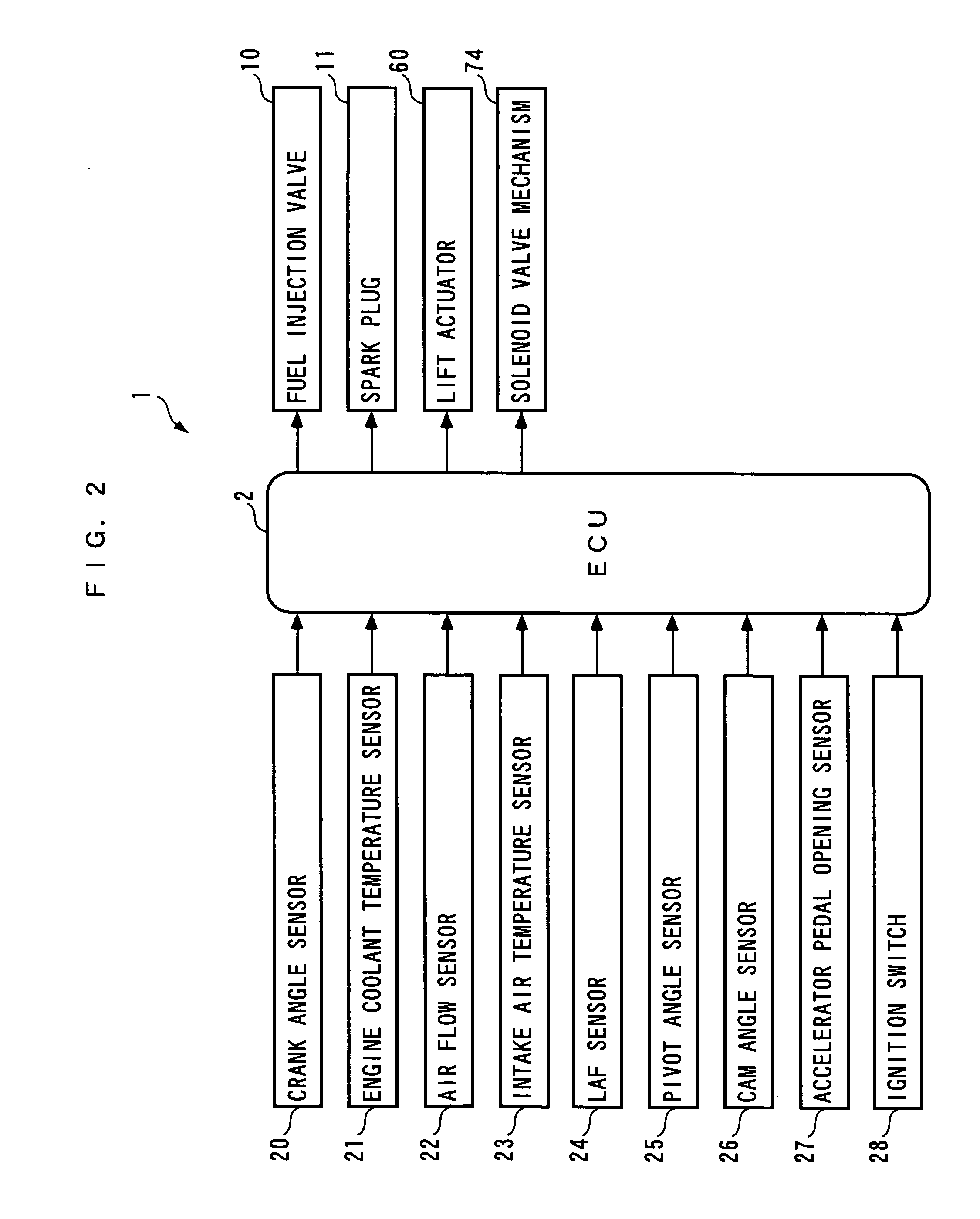

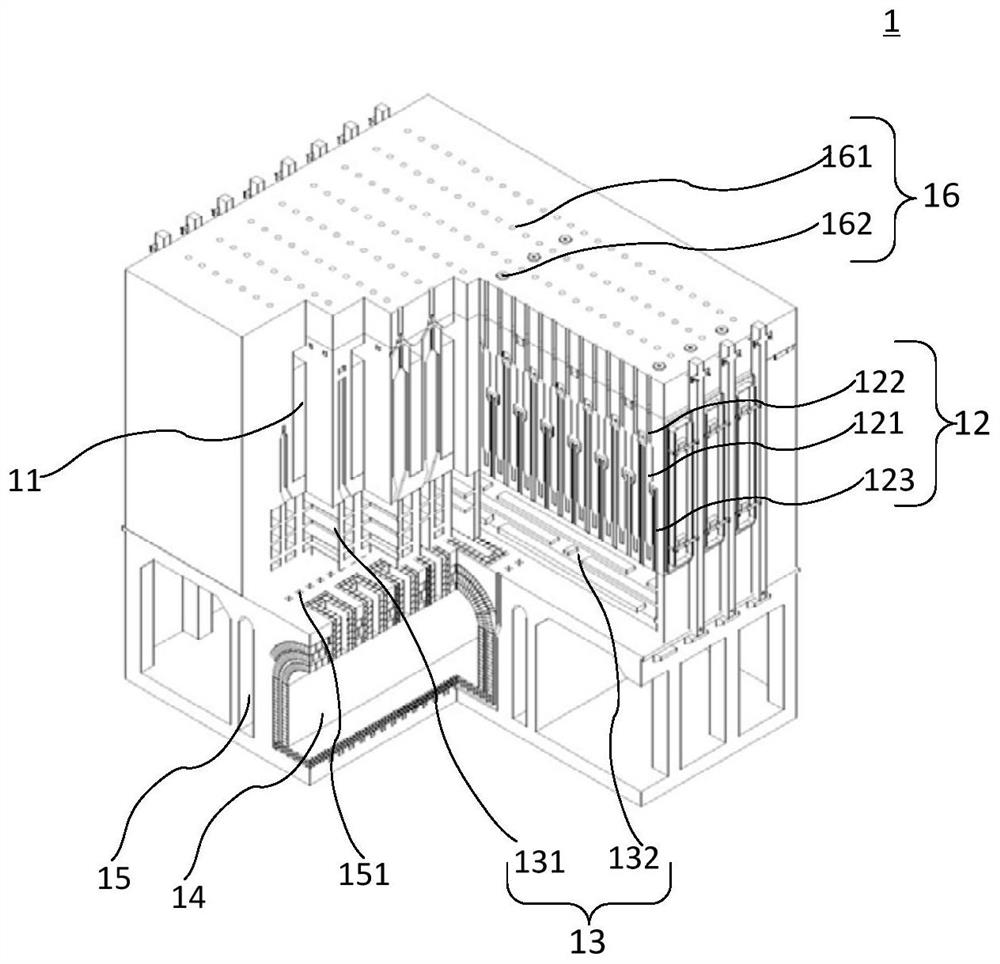

Control System For Internal Combustion Engine

InactiveUS20070208486A1Improve accuracyGreat reductionAnalogue computers for vehiclesValve arrangementsControl systemCam

A control system for an internal combustion engine, which is capable of properly performing air-fuel ratio control and ignition timing control according to an actual amount of intake air, even when reliability of the results of detection of the operating condition of a variable intake mechanism is low. The control system 1 for controlling air-fuel ratio and ignition timing includes an ECU 2. The ECU 2 calculates a target air-fuel ratio KCMD (step 22), calculates an air-fuel ratio correction coefficient KSTR for performing feedback control of an air-fuel ratio (steps 2 to 7), calculates a statistically processed value KAF_LS of an air-fuel ratio index value (step 82), calculates a corrected valve lift Liftin_comp and a corrected cam phase Cain_comp according to the statistically processed value KAF_LS (steps 81 to 92), and determines a fuel injection amount TOUT according to the corrected valve lift Liftin_comp, the corrected cam phase Cain_comp, and the air-fuel ratio correction coefficient KSTR.

Owner:HONDA MOTOR CO LTD

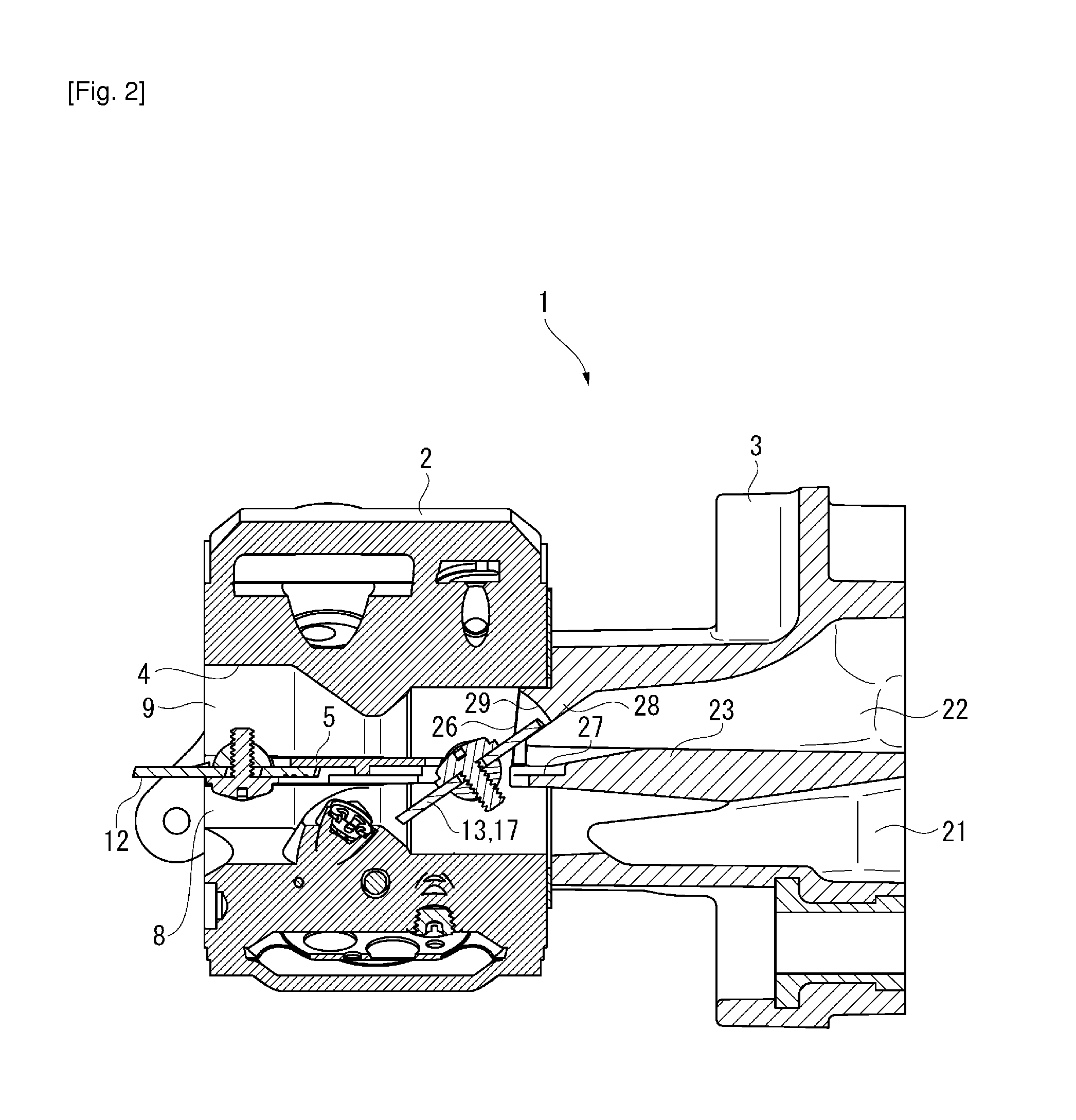

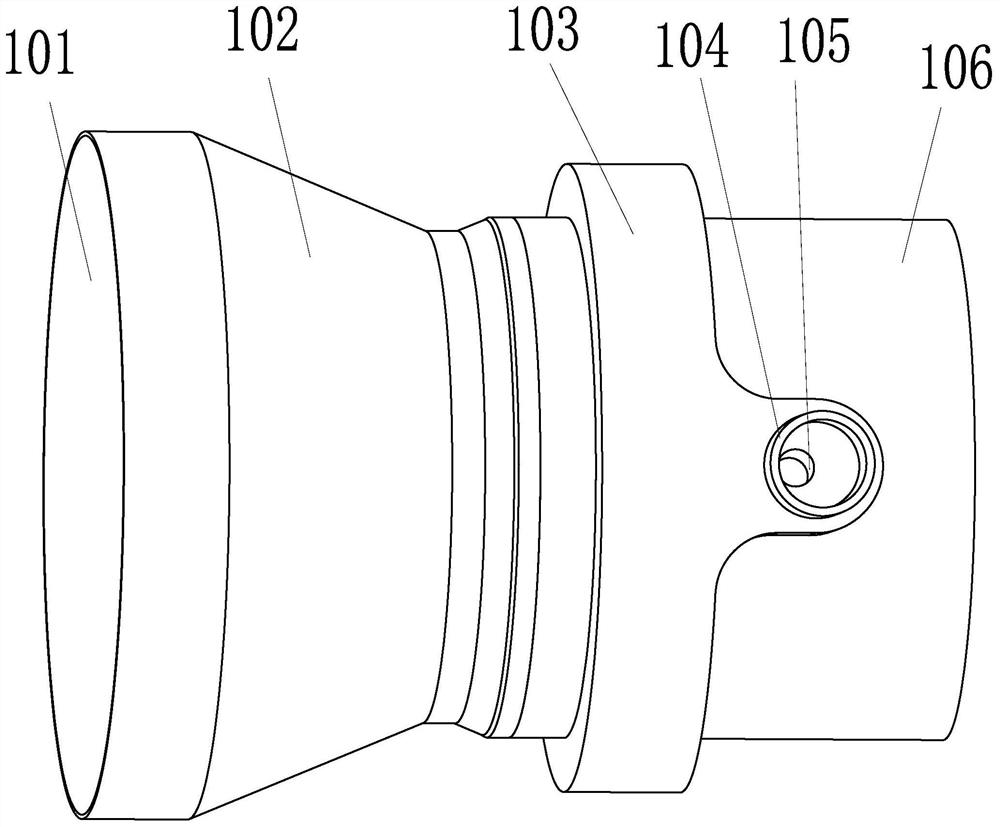

Air supply device of stratified scavenging two-cycle engine

ActiveUS20130228152A1Smoothly and evenly controlledCombustion state is stableEngine controllersMachines/enginesEngineeringCarburetor

An air supply device (1) of a stratified scavenging two-cycle engine includes: a mixture passage (40) that penetrates a carburetor (2) and an insulator (3), the mixture passage being provided by a carburetor-side mixture passage (8) and an insulator-side mixture passage (21); a air passage (41) that is provided by a carburetor-side air passage (9) and an insulator-side air passage (22); a throttle valve (13) provided in a single bore (4) of the carburetor (2), the throttle valve(13) being provided by a butterfly valve that rotates in conjunction with a throttle operation; and a flow rate regulator (28) provided inside the air passage (41), the flow-rate regulator (28) bulging inward in the air passage (41). At least a part of a periphery of a valve body (17) of the throttle valve is close to the flow-rate regulator (28) until the valve body (17) is rotated from an initial position corresponding to an idling speed at a predetermined rotation angle.

Owner:HUSQVARNA ZENOAH

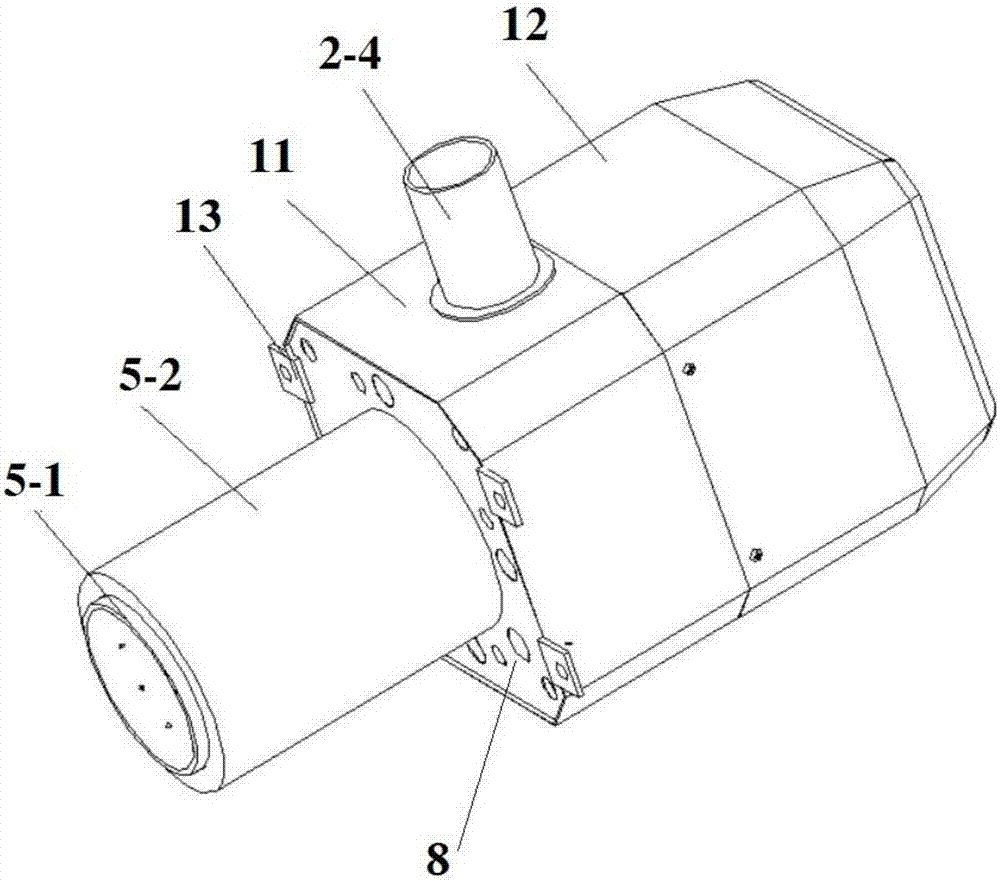

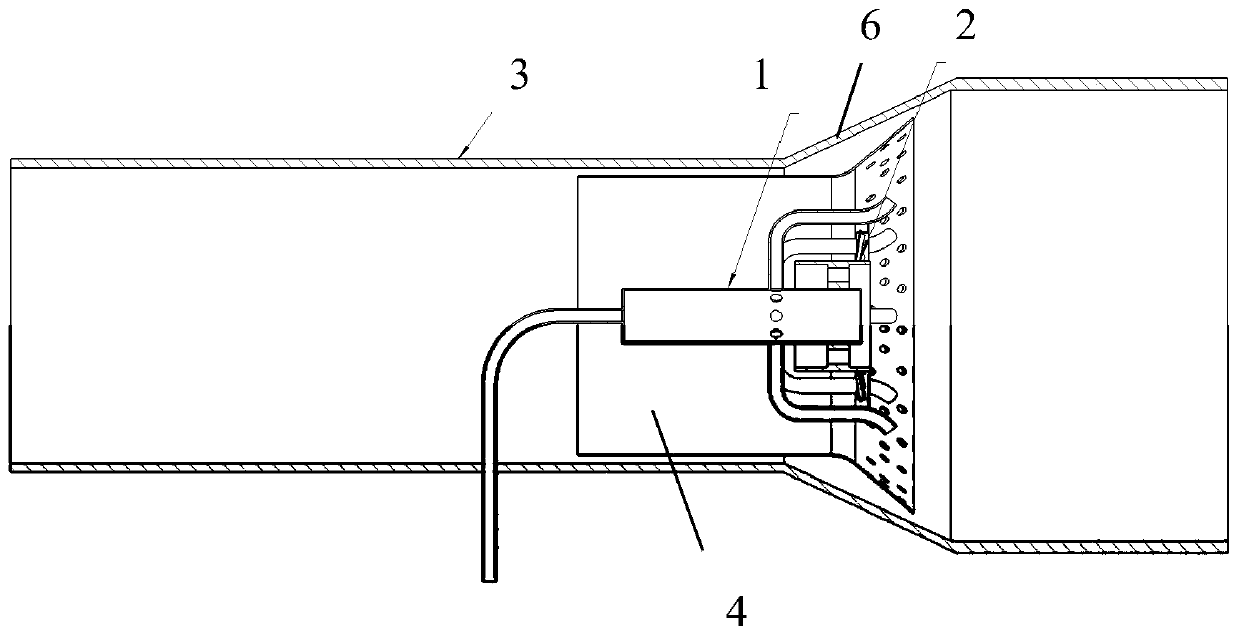

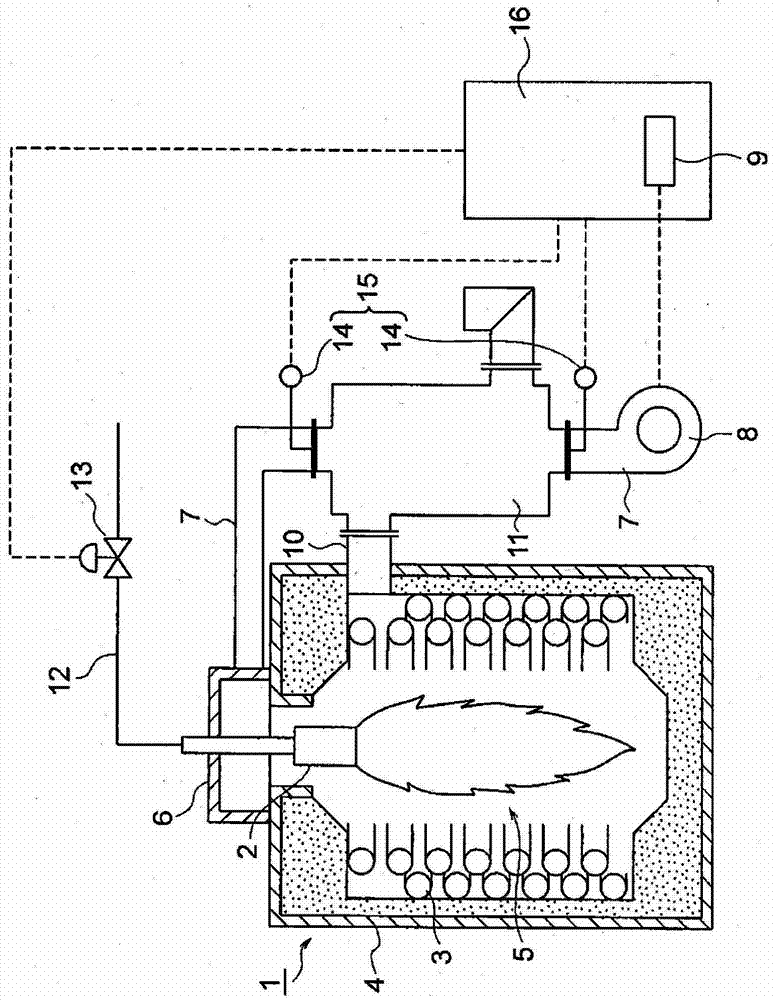

Sectionalized biomass combustion device

PendingCN106918040AReduce lossesHigh thermal efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

The invention provides a sectionalized biomass combustion device. The sectionalized biomass combustion device comprises a rack. A feeding device, an air supply device, a combustion chamber and an igniter are arranged on the rack. The feeding device communicates with the combustion chamber. An ignition port is formed in the combustion chamber. The air supply device is used for blowing air into an air chamber. The air chamber communicates with the feeding device and the combustion chamber. A flow disturbing plate is arranged in the combustion chamber. The sectionalized biomass combustion device has the beneficial effects that flow disturbing plates with different sizes can be adopted to change the primary tangent air direction according to the power of a combustion machine and the diameter of a combustion cylinder, so that slight reversal combustion is formed, sectionalized combustion is formed by properly increasing the combustion temperature of the rear section of the combustion cylinder, the rear section is a thermal decomposition section, and the front section is a high-temperature gasification section; and by widening the combustion temperature adjustment range, high-temperature biomass raw materials can be combusted and decomposed, and the adaptability of the device is improved, so that fuel is combusted sufficiently, the loss caused by insufficient combustion is reduced, and the heat efficiency is greatly improved.

Owner:XIAN SENWAS AGRI SCI & TECH

Direct-injection spark-ignition engine

ActiveUS8151762B2Combustion state is stablePromote activationAnalogue computers for vehiclesInternal combustion piston enginesPenetration forceEngineering

Disclosed is a direct-injection spark-ignition engine designed to promote catalyst activation during cold engine operation. A fuel injection timing for a fuel injection period in an compression stroke (second fuel injection period F2) is set to allow a first fuel spray Ga injected from a first spray hole 40a to enter a cavity 34 in a piston crown surface 30, and allow a second fuel spray Gb to impinge against a region of the piston crown surface 30 located closer to an injector than the cavity 34, so as to cause the second fuel spray Gb having a lowered penetration force due to the impingement to be pulled toward the cavity 34 by a negative pressure generated in the cavity 34 as a result of passing of the first fuel spray Ga therethrough. The direct-injection spark-ignition engine can maximally hold an injected fuel spray around a spark plug to reliably stabilize a combustion state in a combustion mode for promoting catalyst activation during cold engine operation, while enhancing combustion efficiency in a homogenous combustion mode during normal engine operation.

Owner:MAZDA MOTOR CORP

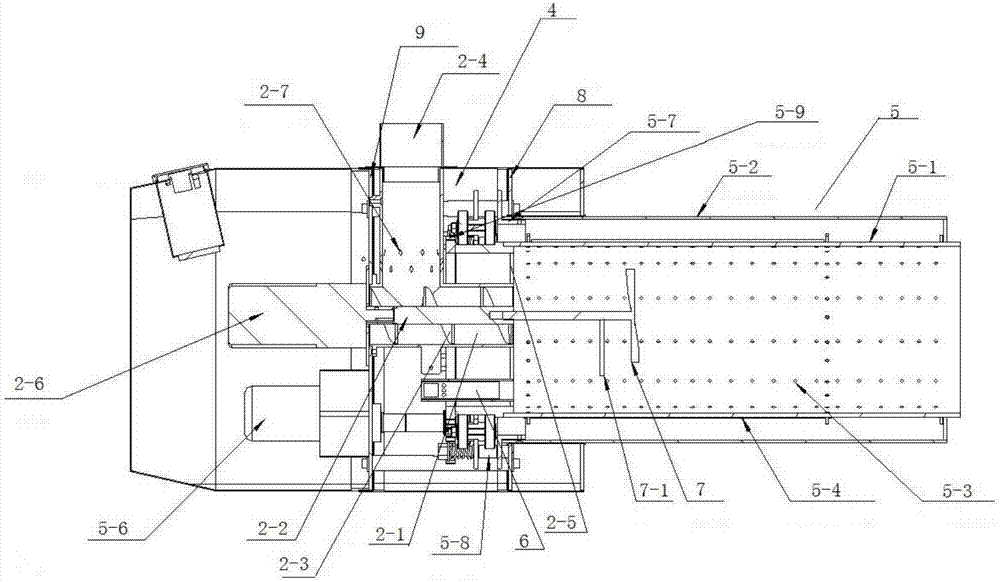

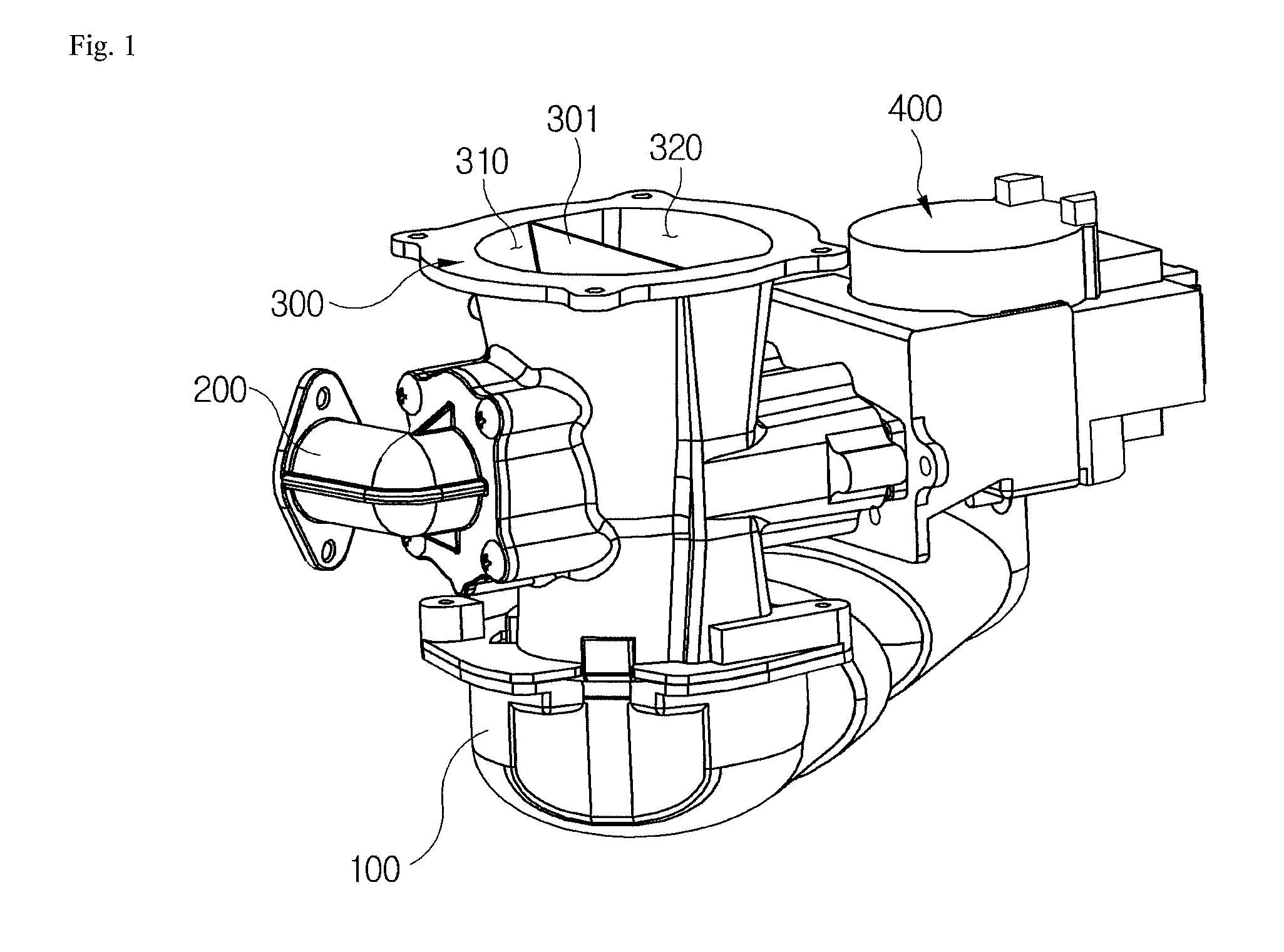

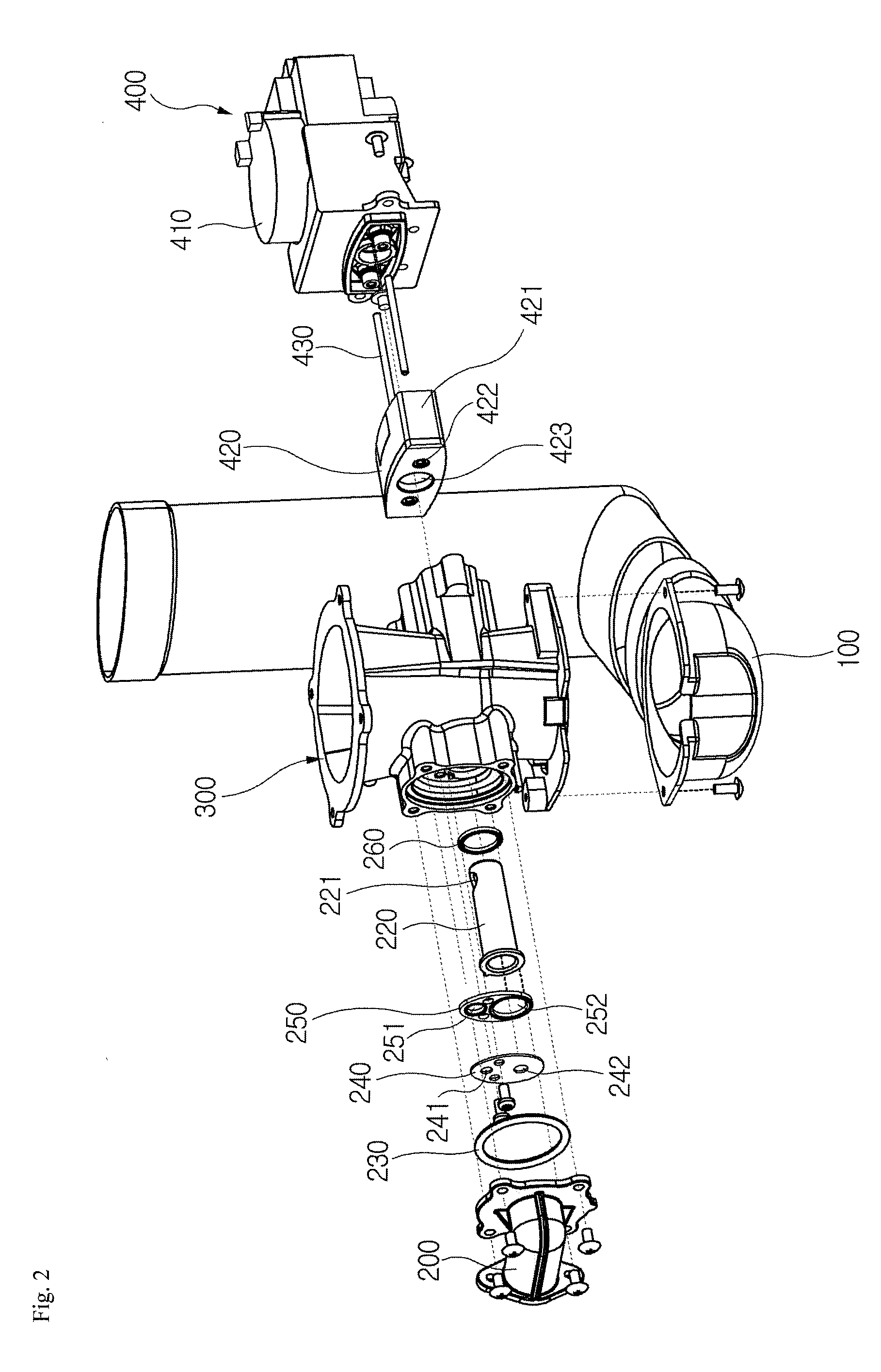

Combustion device for improving turndown ratio

ActiveUS20150086931A1Combustion state is stableImprove combustion efficiencyCombustion using gaseous and pulverulent fuelFuel supply regulationCombustorProcess engineering

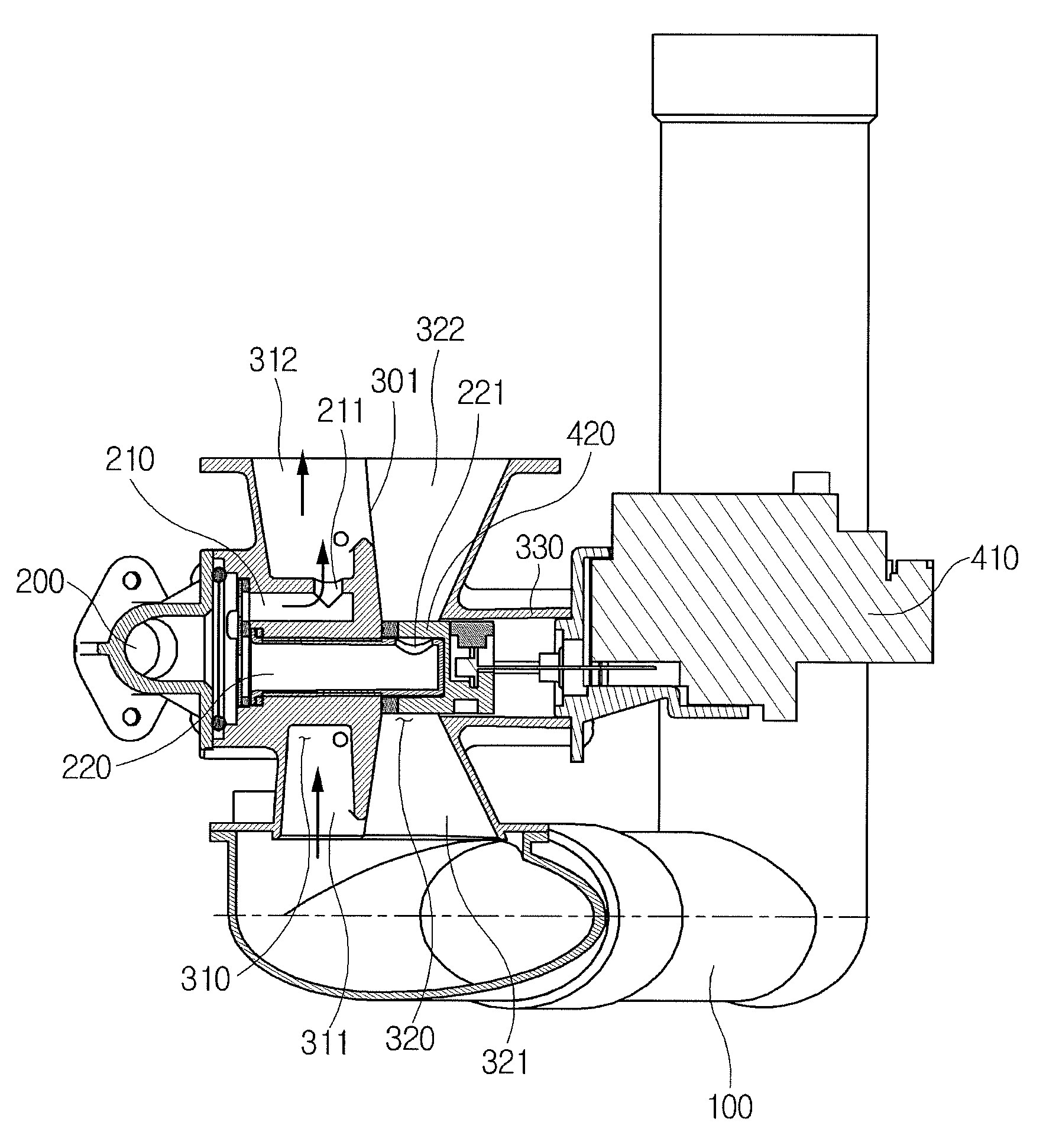

The purpose of the present invention is to provide a combustion device for improving a turndown ratio, which is capable of stably implementing a combusted state in a low-output load region by improving a turndown ratio of a burner. To this end, the present invention provides the combustion device having a premixing chamber (300) which is connected to an air supply tube (100) and a gas supply tube (200), and which has a space for premixing air and gas provided therein, wherein the space for premixing the air and gas supplied from the air supply tube (100) and the gas supply tube (200) is divided into multiple stages of a venturi structure in the premixing chamber (300), and the discharging direction of the gas discharged inside the premixing chamber (300) through the gas supply tube (200) is formed in parallel to the flow direction of the gas supplied inside the premixing chamber (300) through the air supply tube (100).

Owner:KYUNGDONG NAVIEN

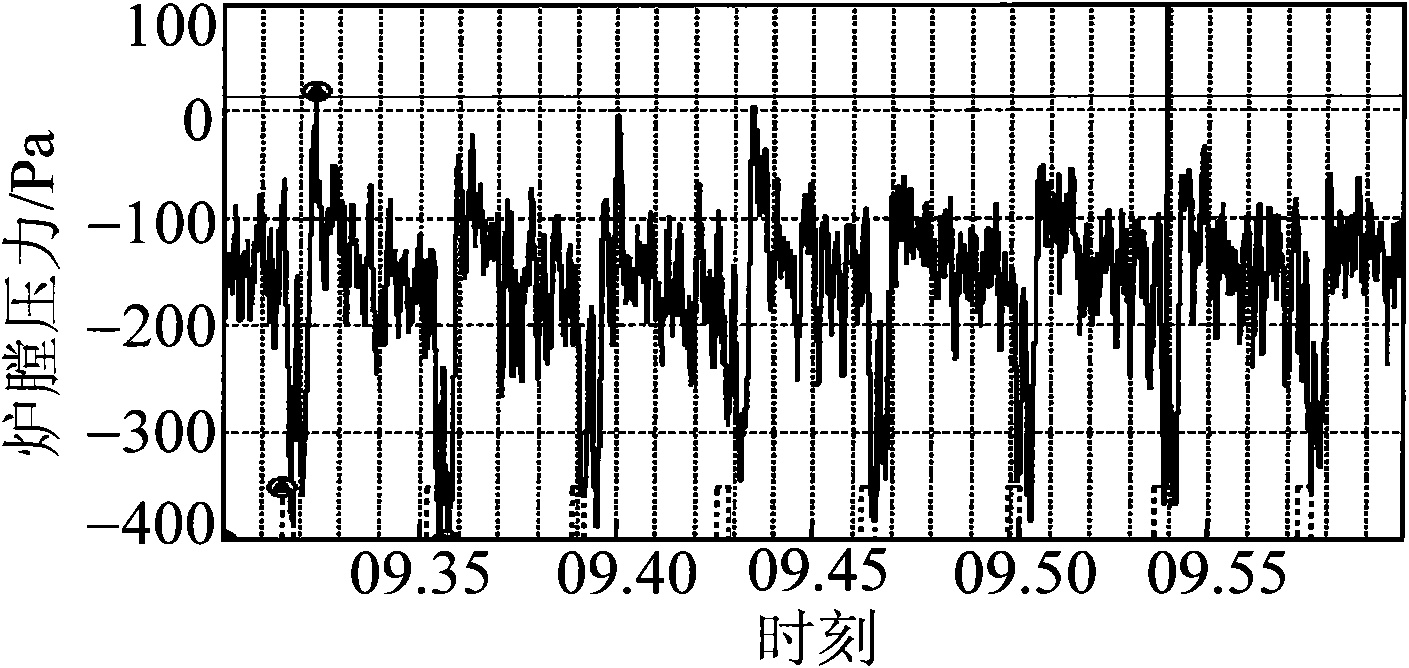

Hearth pressure control method of vibrating grate boiler

InactiveCN101660766AImprove efficiencyCombustion state is stableCombustion regulationCombustionAir volume

The invention relates to a hearth pressure control method of a vibrating grate boiler, which is an assistant adjusting method aiming at grate vibrating on the basis of an original hearth pressure control system, and can judge the hearth pressure change according to the influence of the grate vibrating on the flow of all the parts of an air and flue system, reduce grate air flow in due time and increase secondary air flow through advanced adjustment of all the executing mechanisms of the air and flue system, and provide guarantee for the safe combustion of the fuel while realizing the stable control of the hearth pressure. The method well solves the problems of raising, oscillating and the like of the hearth pressure along with the grate vibrating, improves the efficiency of the control system, improves the control effect, and is beneficial to the stabilization of the boiler burning state, and the improvement of the economical and safe operation level of the boiler.

Owner:CHINA ELECTRIC POWER RES INST +1

Control system for internal combustion engine

InactiveUS7440836B2Great reductionCombustion state is stableAnalogue computers for vehiclesValve arrangementsControl systemExternal combustion engine

A control system for an internal combustion engine, which is capable of properly performing air-fuel ratio control and ignition timing control according to an actual amount of intake air, even when reliability of the results of detection of the operating condition of a variable intake mechanism is low. The control system for controlling air-fuel ratio and ignition timing includes an ECU. The ECU calculates a target air-fuel ratio, calculates an air-fuel ratio correction coefficient, calculates a statistically processed value of an air-fuel ratio index value, calculates a corrected valve lift and a corrected cam phase, and determines a fuel injection amount according to the corrected valve lift, the corrected cam phase, and the air-fuel ratio correction coefficient.

Owner:HONDA MOTOR CO LTD

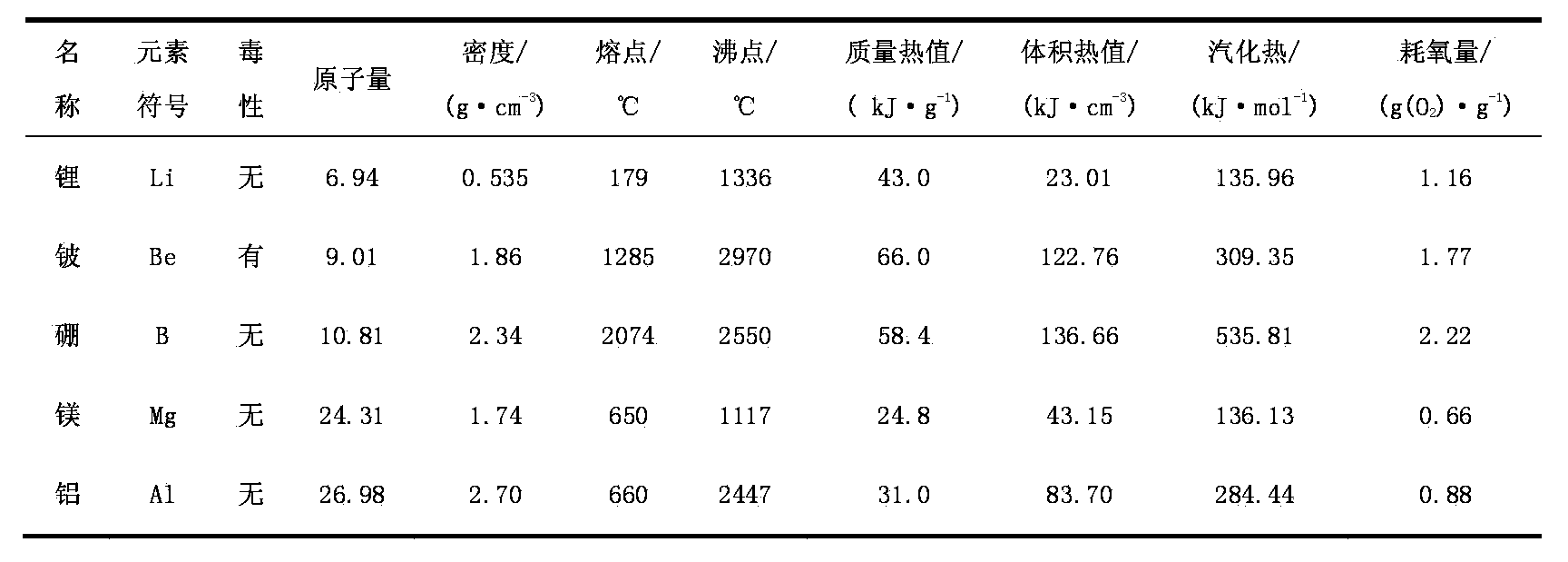

Nanometer bismuth oxide-coated modified boron fuel and preparation methods thereof

The invention discloses a nanometer bismuth oxide-coated modified boron fuel and two kinds of preparation methods thereof. The modified boron fuel comprises the components, in percentage by mass: 30-60 of superfine boron powder, and 70-40 of nanometer bismuth oxide. The first preparation method comprises the steps of metering raw materials, preparing a raw material solution, adding the boron powder, preparing a precursor and calcinating; and the second preparation method comprises the steps of metering raw materials, preparing the precursor and calcinating. The nanometer bismuth oxide-coated modified boron fuel has low ignition temperature, releases a large amount of heat, has high combustion efficiency, and has a stable combustion state when be added in an explosive formula.

Owner:NANJING UNIV OF SCI & TECH

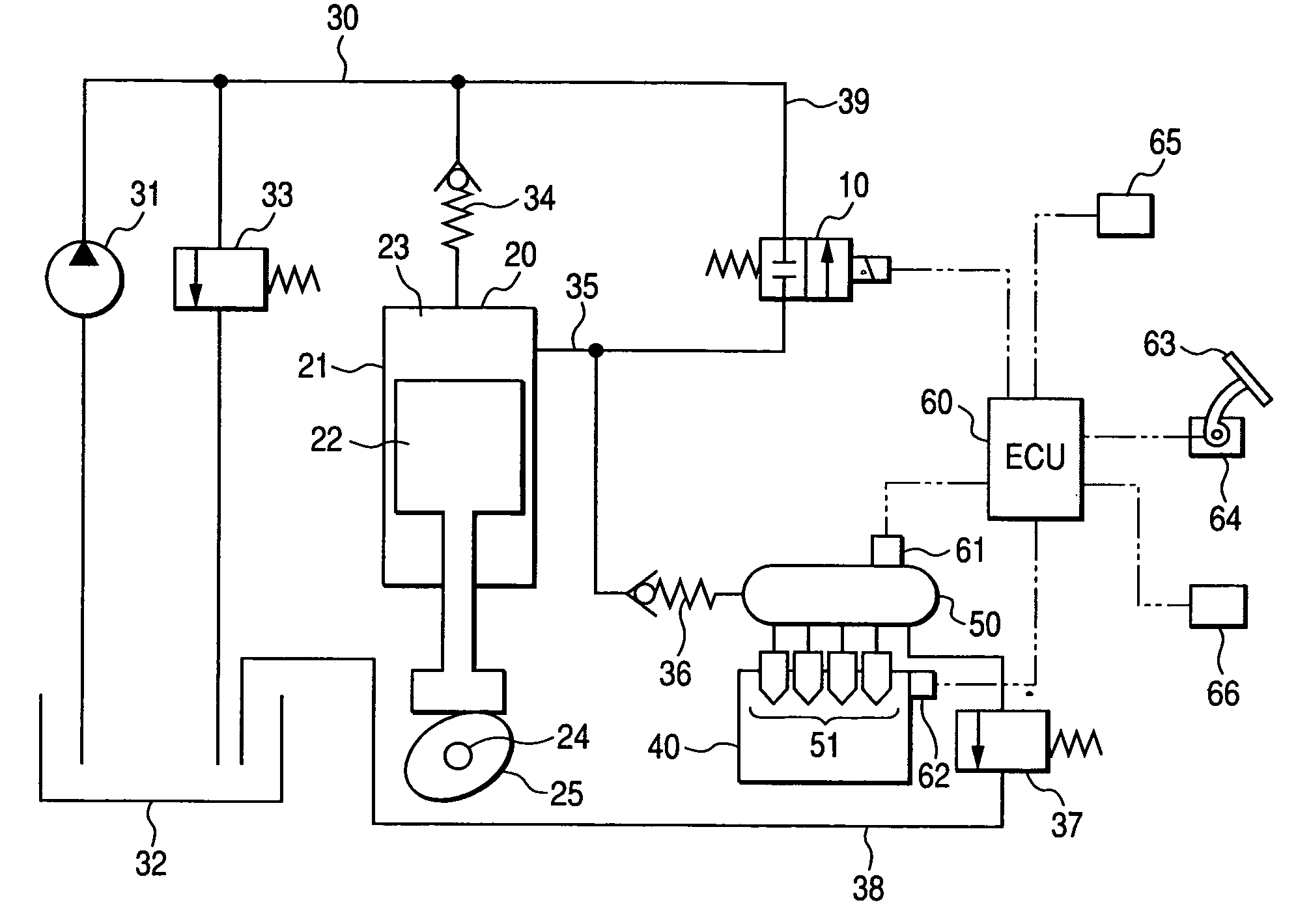

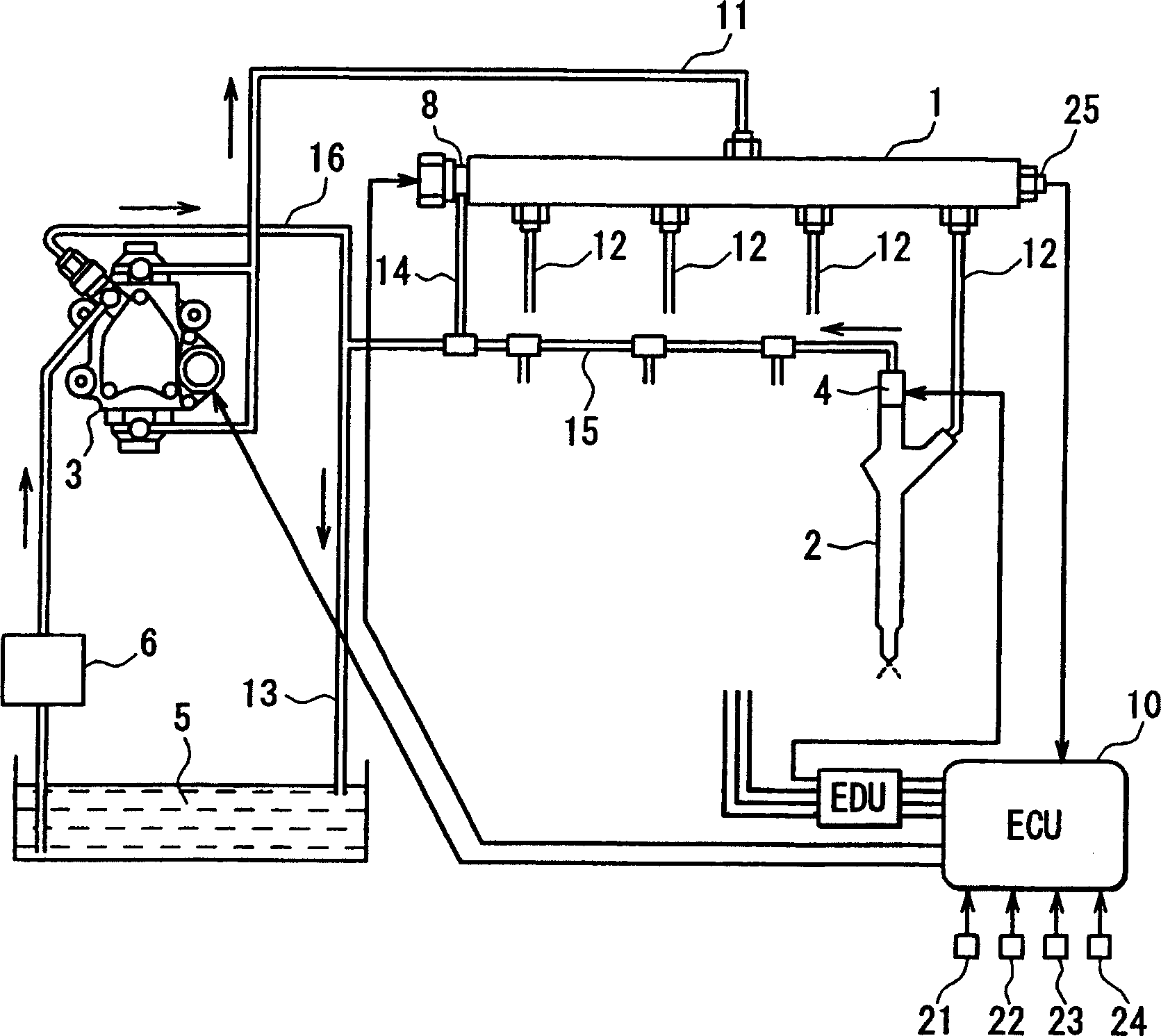

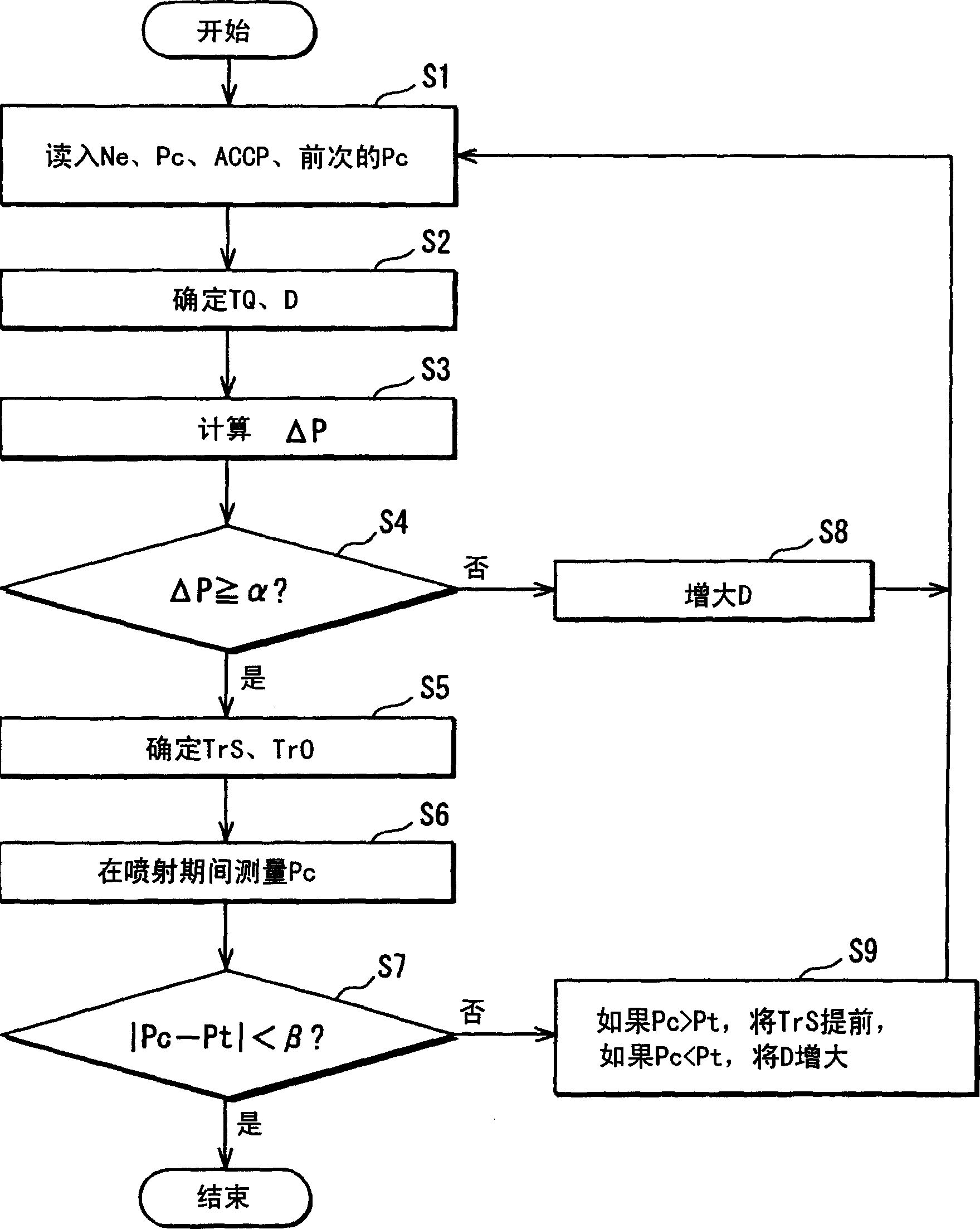

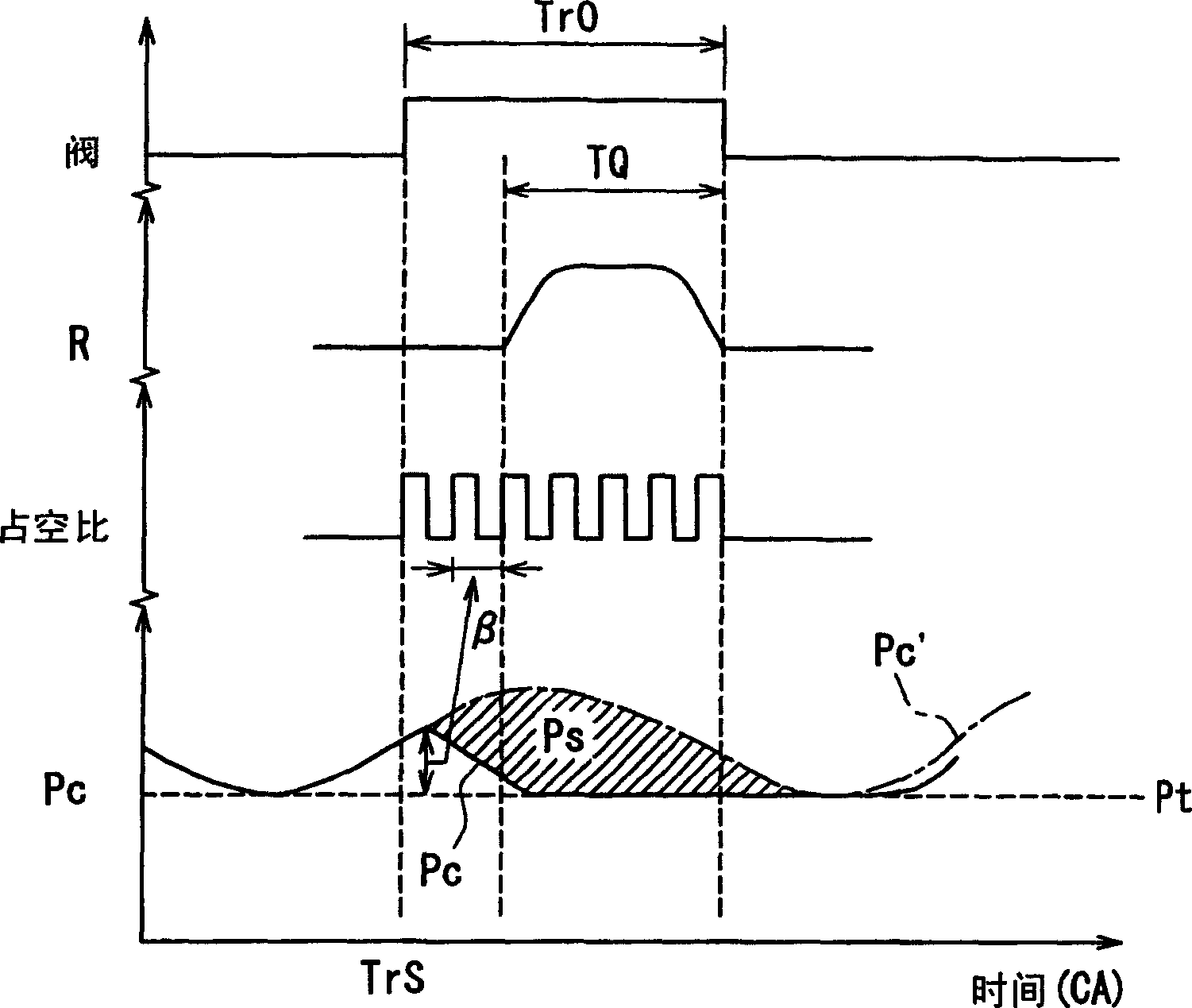

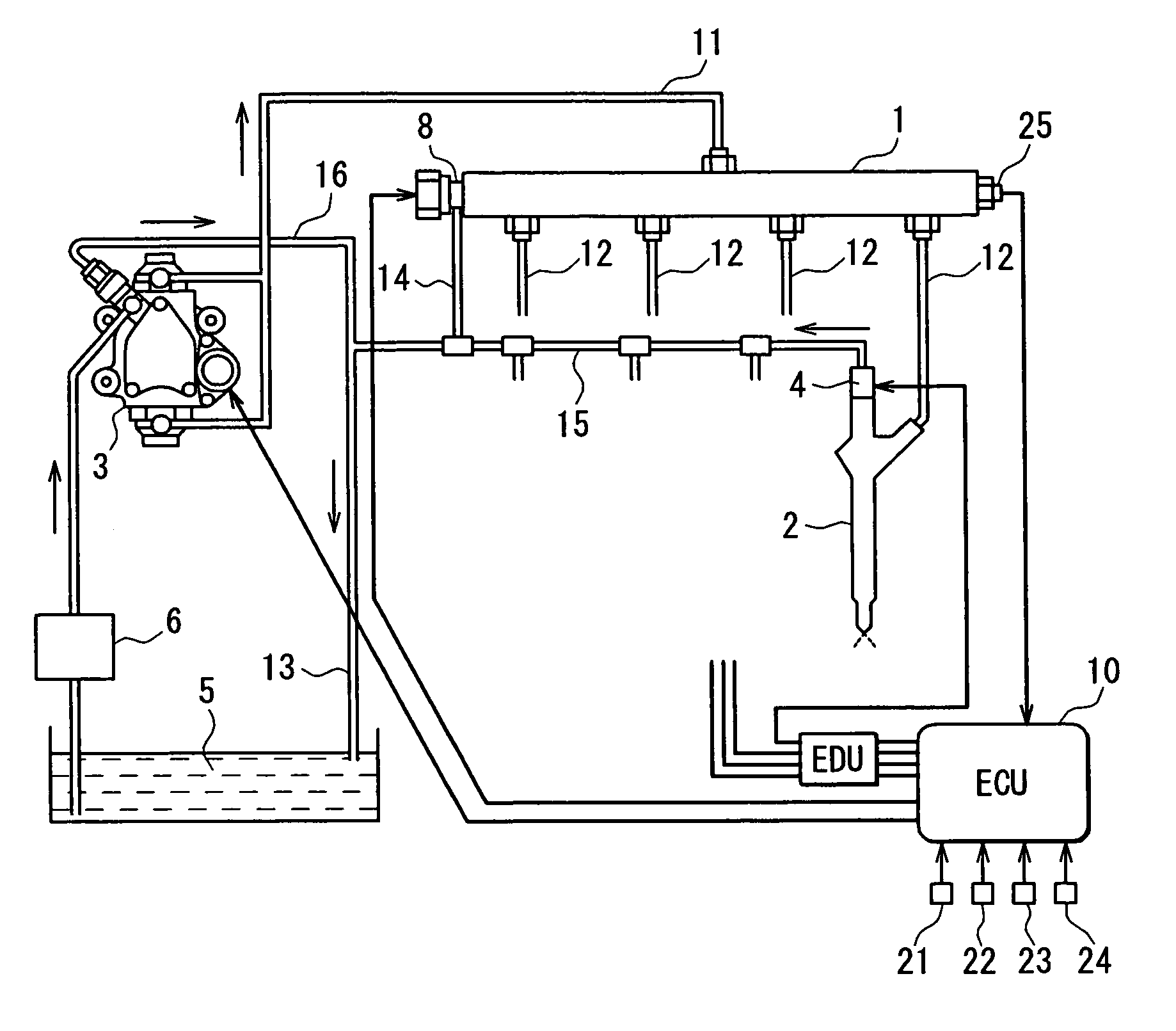

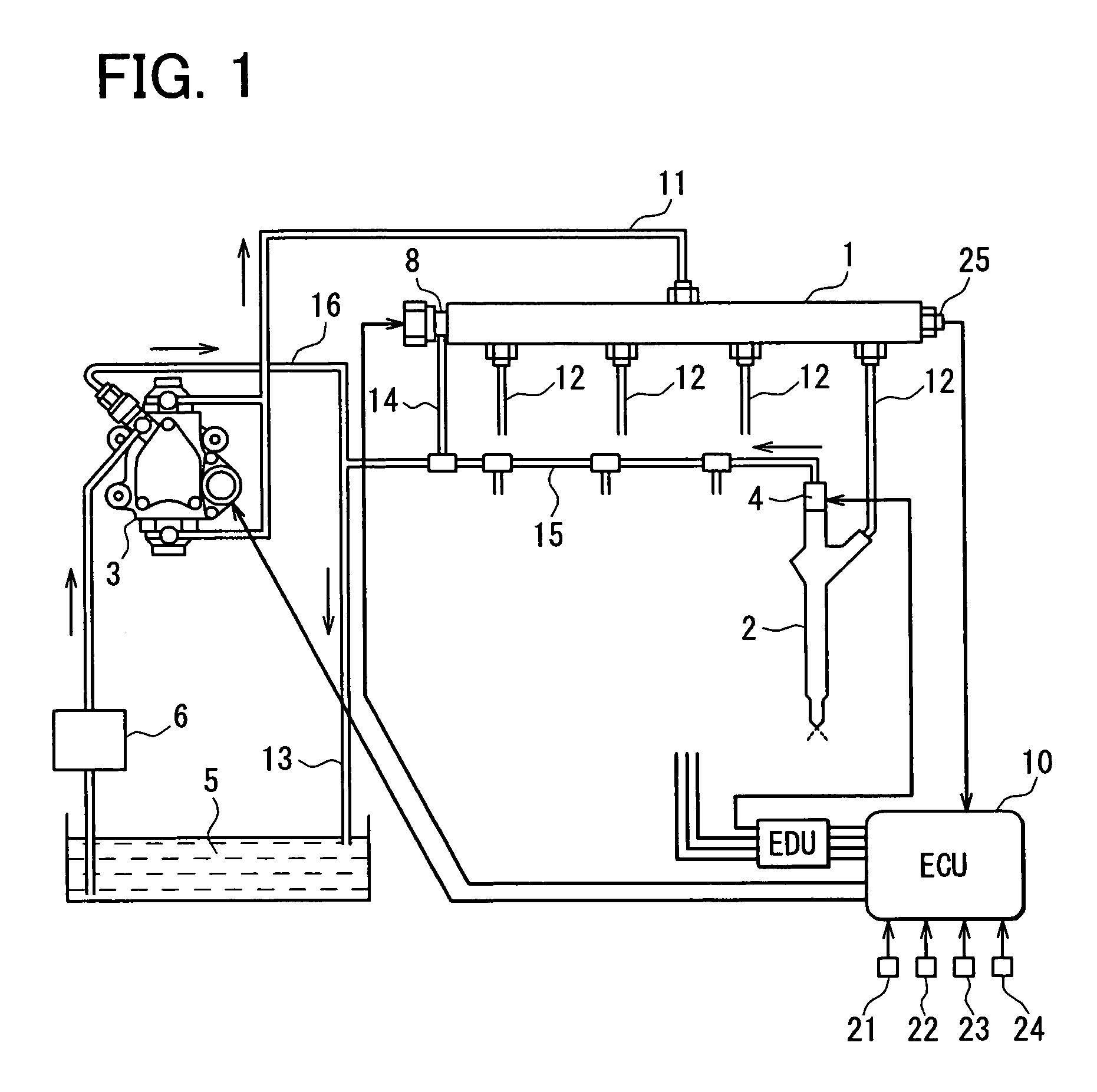

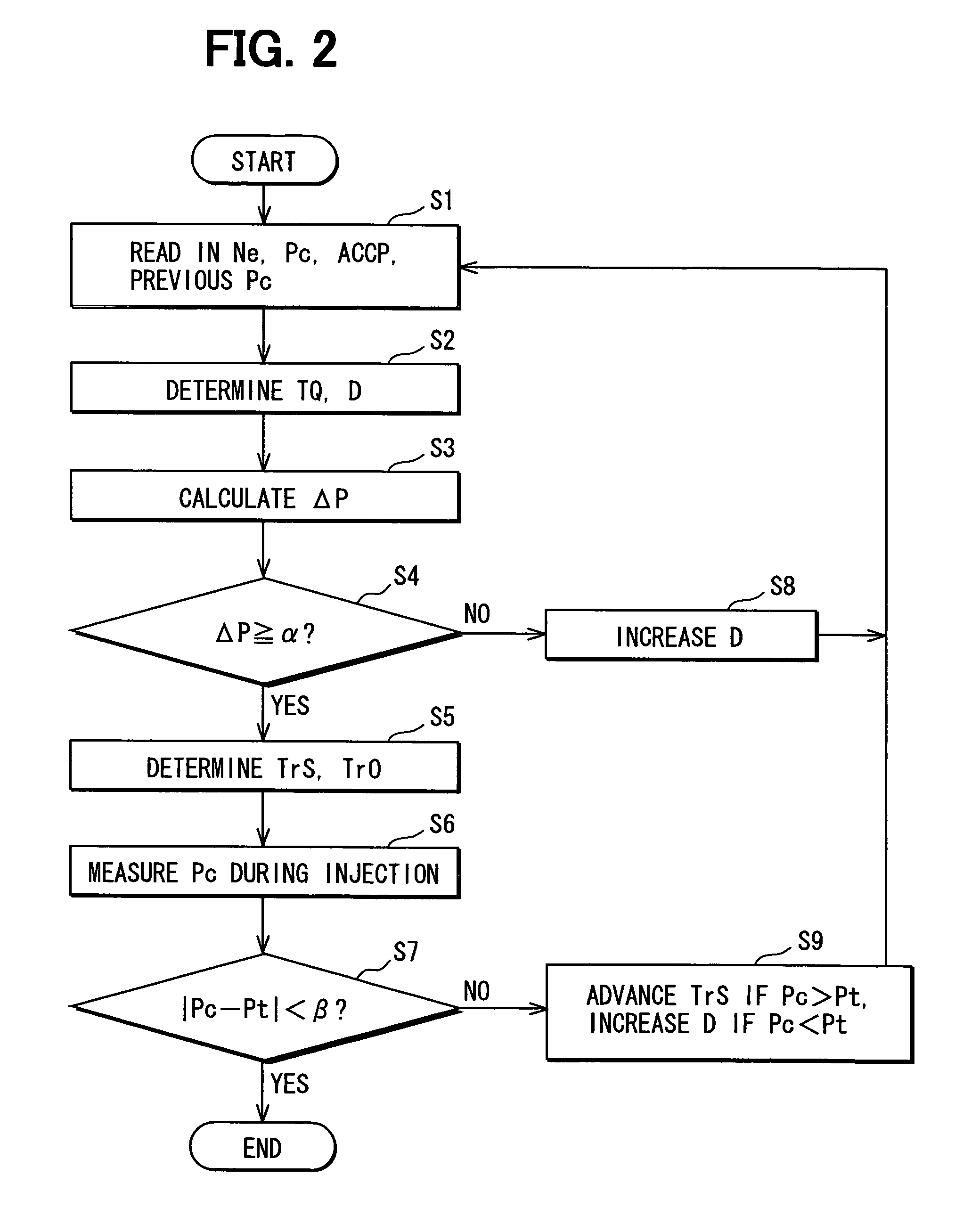

Pressure accumulation fuel injection controller

InactiveCN1900505AImprove injection volume accuracyCombustion state is stableElectrical controlFuel injection apparatusInjection pressureCommon rail

A pressure pattern estimation device of a fuel injection controller of an engine estimates a pressure transition of fuel in a common rail. A surplus pressure range calculation device of the fuel injection controller calculates a surplus pressure range in which pressure pattern data provided by the pressure pattern estimation device exceeds a target common rail pressure. The fuel injection controller releases the common rail pressure to a lower-pressure side by operating a pressure reduction valve of the common rail to eliminate the surplus pressure range calculated by the surplus pressure range calculation device. Thus, the common rail pressure (injection pressure) during an injection period is smoothed.

Owner:DENSO CORP

Coke oven system and method for operating same

PendingCN114437740AImprove uniformityImprove securityCombustible gas coke oven heatingDistillation gas withdrawalCombustion chamberCarbonization

The embodiment of the invention provides a coke oven system and an operation method thereof, the coke oven system comprises a coke oven, a waste heat recovery system and a flue gas remelting system, and the coke oven comprises a carbonization chamber, a combustion chamber, a heat exchange chamber, a flue and a flue gas balance channel. Waste heat of flue gas generated by the coke oven is recovered through the waste heat recovery system, and part of low-temperature flue gas subjected to waste heat recovery is introduced into the second air channel through the flue gas balance channel by utilizing the flue gas remelting system, so that the content of oxygen in combustion-supporting air can be reduced, and when the generation amount of raw coke oven gas in the carbonization chamber is increased, the content of oxygen in the combustion-supporting air is reduced. According to the invention, less oxygen and raw gas can be combusted, so that the phenomenon that the local temperature of the coke oven body is too high is avoided, the combustion state in the vertical flue of the coke oven is stabilized, the heating uniformity of the coke oven is improved, and the safety and stability of a coke oven system are further improved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

Pressure accumulation fuel injection controller

ActiveUS7201148B2Improve accuracyCombustion state is stableElectrical controlLow pressure fuel injectionCommon railPressure reduction

A pressure pattern estimation device of a fuel injection controller of an engine estimates a pressure transition of fuel in a common rail. A surplus pressure range calculation device of the fuel injection controller calculates a surplus pressure range in which pressure pattern data provided by the pressure pattern estimation device exceeds a target common rail pressure. The fuel injection controller releases the common rail pressure to a lower-pressure side by operating a pressure reduction valve of the common rail to eliminate the surplus pressure range calculated by the surplus pressure range calculation device. Thus, the common rail pressure (injection pressure) during an injection period is smoothed.

Owner:DENSO CORP

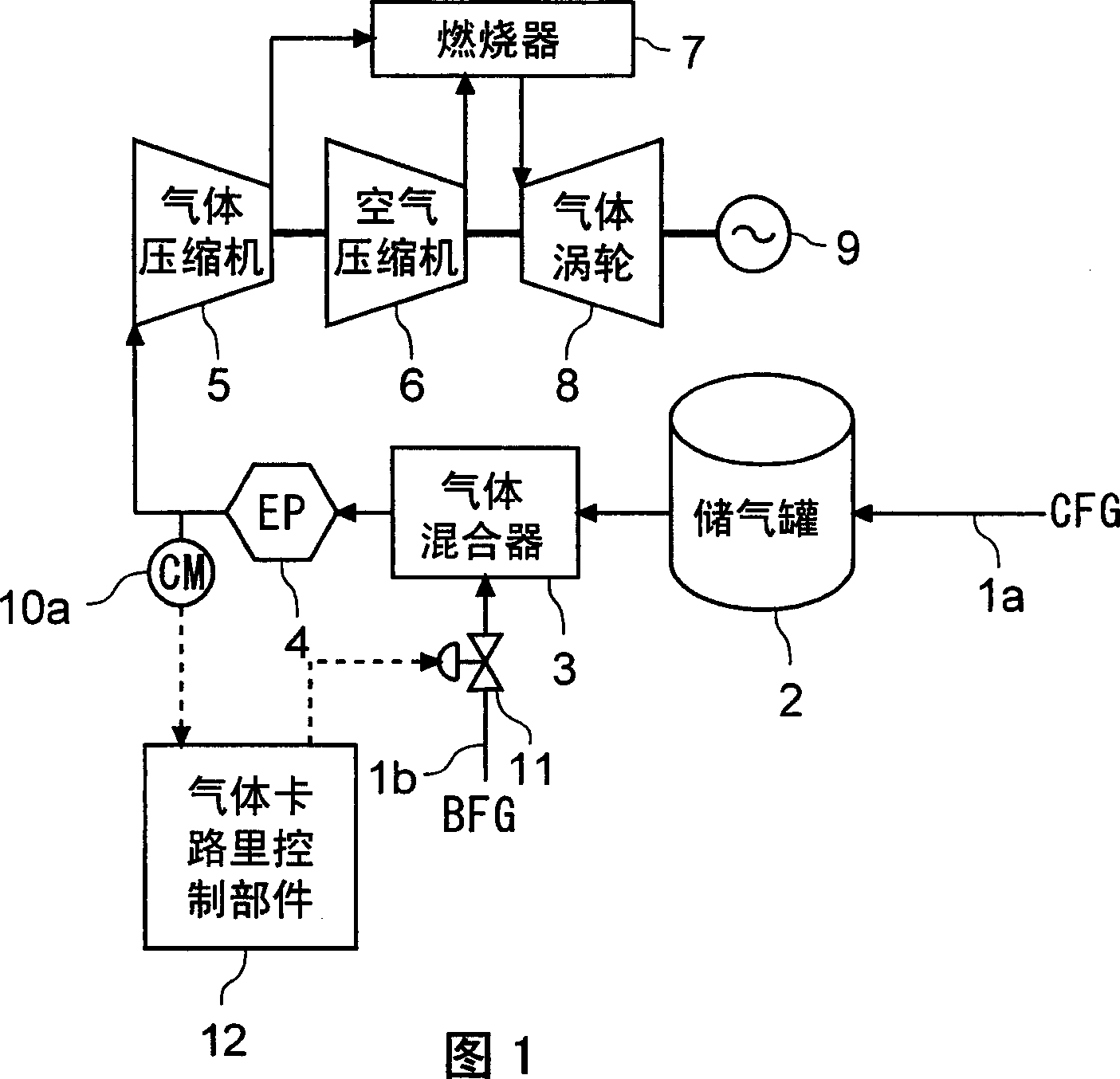

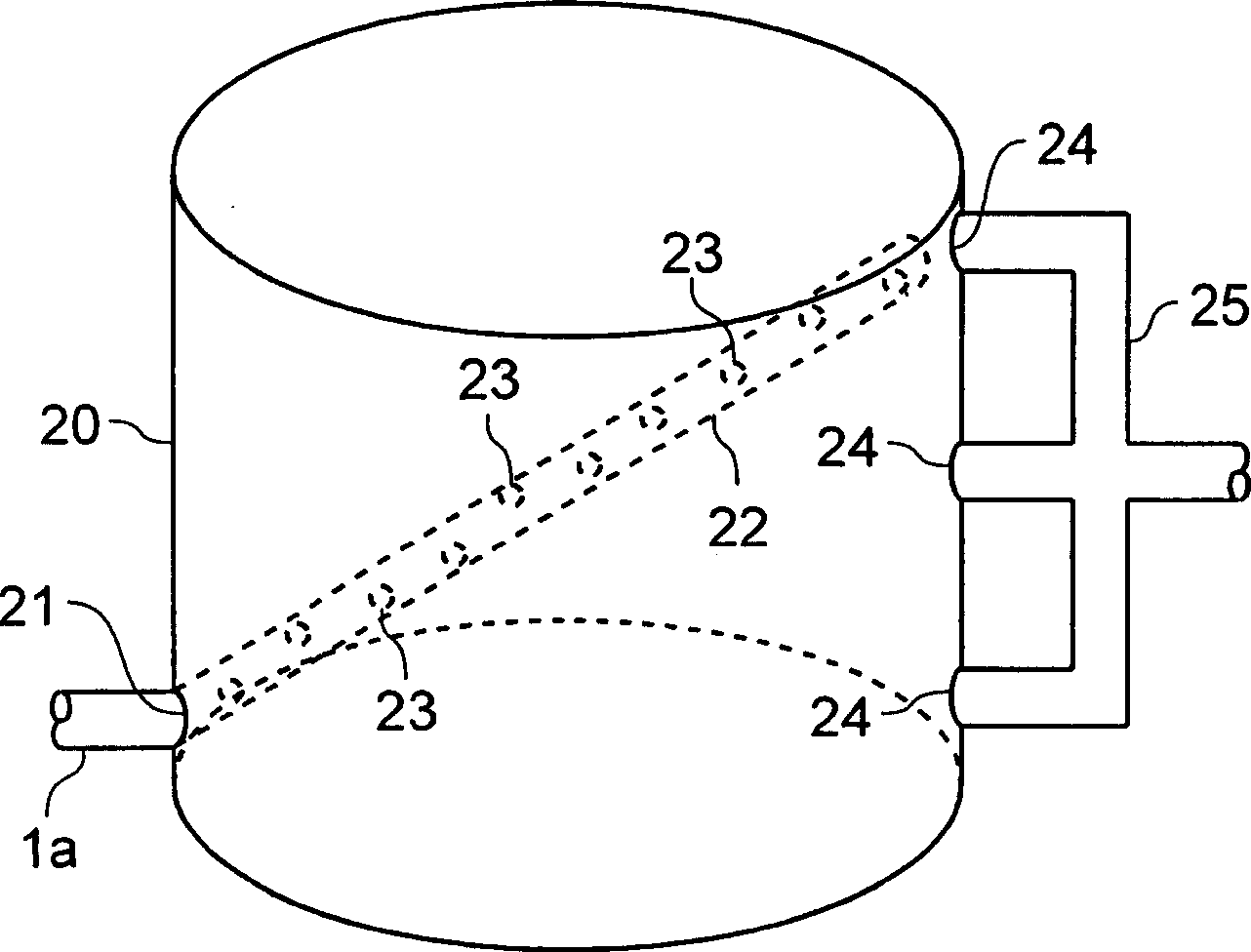

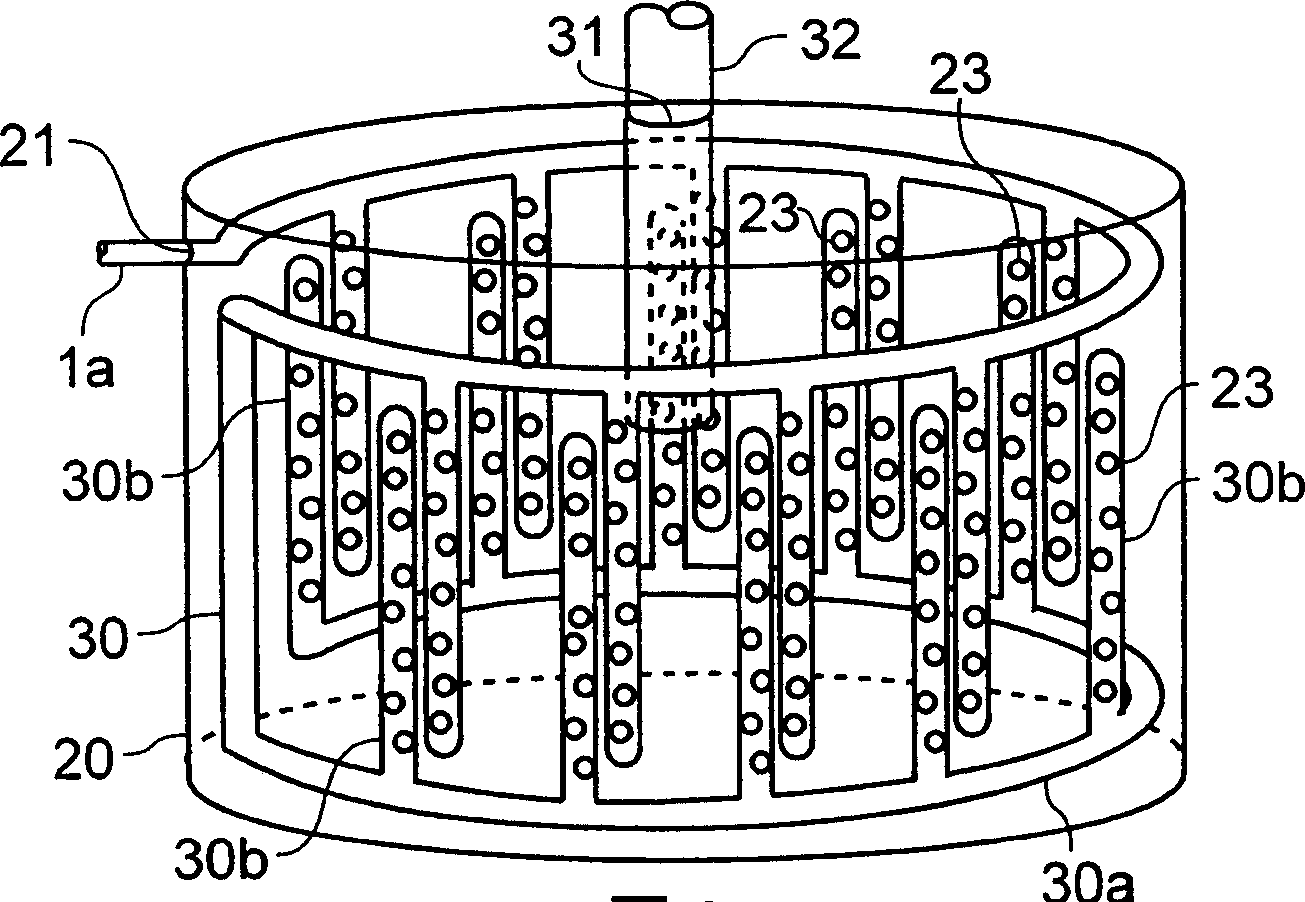

Fuel gas calorie control equipment and gas turbine system

InactiveCN1828029ASmall fluctuationReduce volatilityGas turbine plantsTurbine/propulsion fuel controlEngineeringProcess engineering

The CFG is mixed with BFG by providing different delayed time when it is supplied into air reservoir (2), and thus the fluctuation ratio of CFG calorie is inhibited. The air current rate of BFG is controlled by feedback control according to gas calorie of mixed gas, and so the gas calorie of mixed gas is controlled.

Owner:MITSUBISHI HEAVY IND LTD

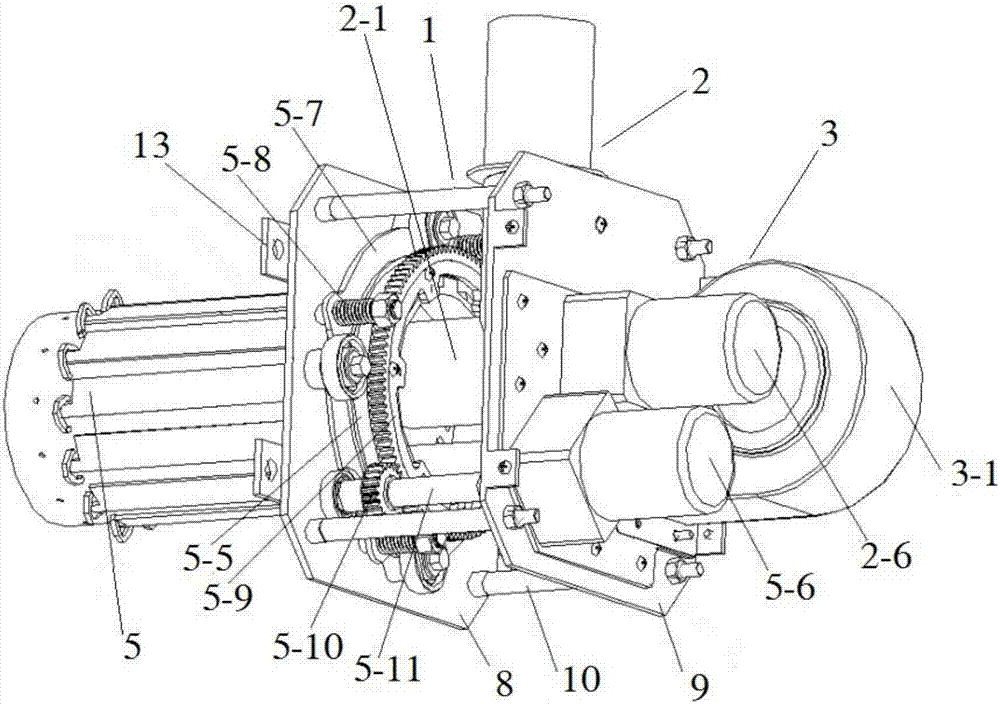

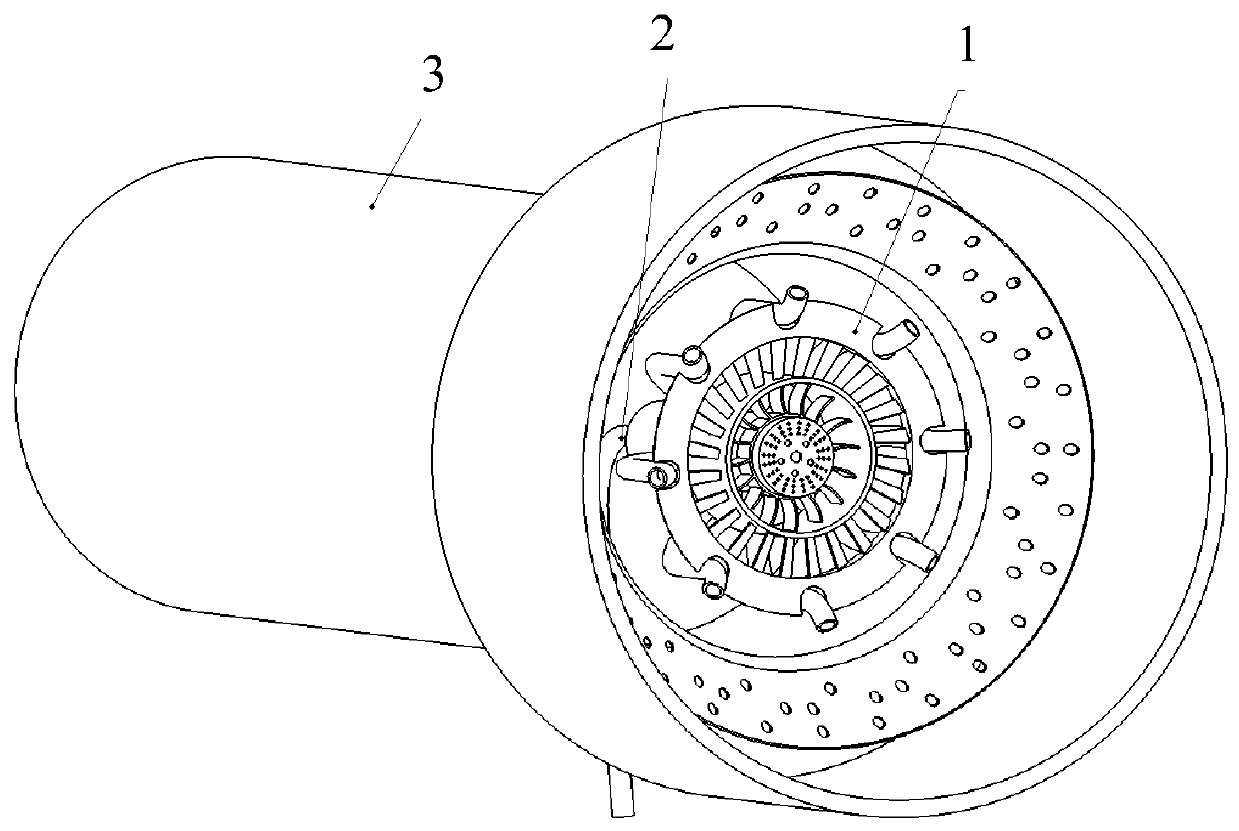

Graded low-nitrogen gas combustor based on rotational flow

The invention provides a graded low-nitrogen gas combustor based on rotational flow. The graded low-nitrogen gas combustor comprises a combustor barrel body, a connecting barrel body and a combustor hood which are sequentially arranged, the diameter of the combustor barrel body is smaller than that of the combustor hood, the diameter of the connecting barrel body is gradually increased in the direction from the combustor barrel body to the combustor hood, a rotational flow flame stabilizing disc is further arranged between a main fuel gas spray pipe and an auxiliary fuel gas spray pipe, the rotational flow flame stabilizing disc comprises a first cylinder and a second cylinder which are coaxially arranged, the first cylinder is arranged inside the second cylinder, a first rotational flow blade is arranged between the first cylinder and the second cylinder, a flame stabilizing disc end part is further arranged in the circumferential direction of the second cylinder, a second rotationalflow blade is arranged between the second cylinder and the flame stabilizing disc end part, and the distance between the first rotational flow blade and the combustor barrel body in the central axis direction is smaller than the distance between the second rotational flow blade and the combustor barrel body in the central axis direction. By means of the technical scheme, the mixing degree of gas can be enhanced, and therefore the key performance of a combustor is improved.

Owner:HUAQIAO UNIVERSITY

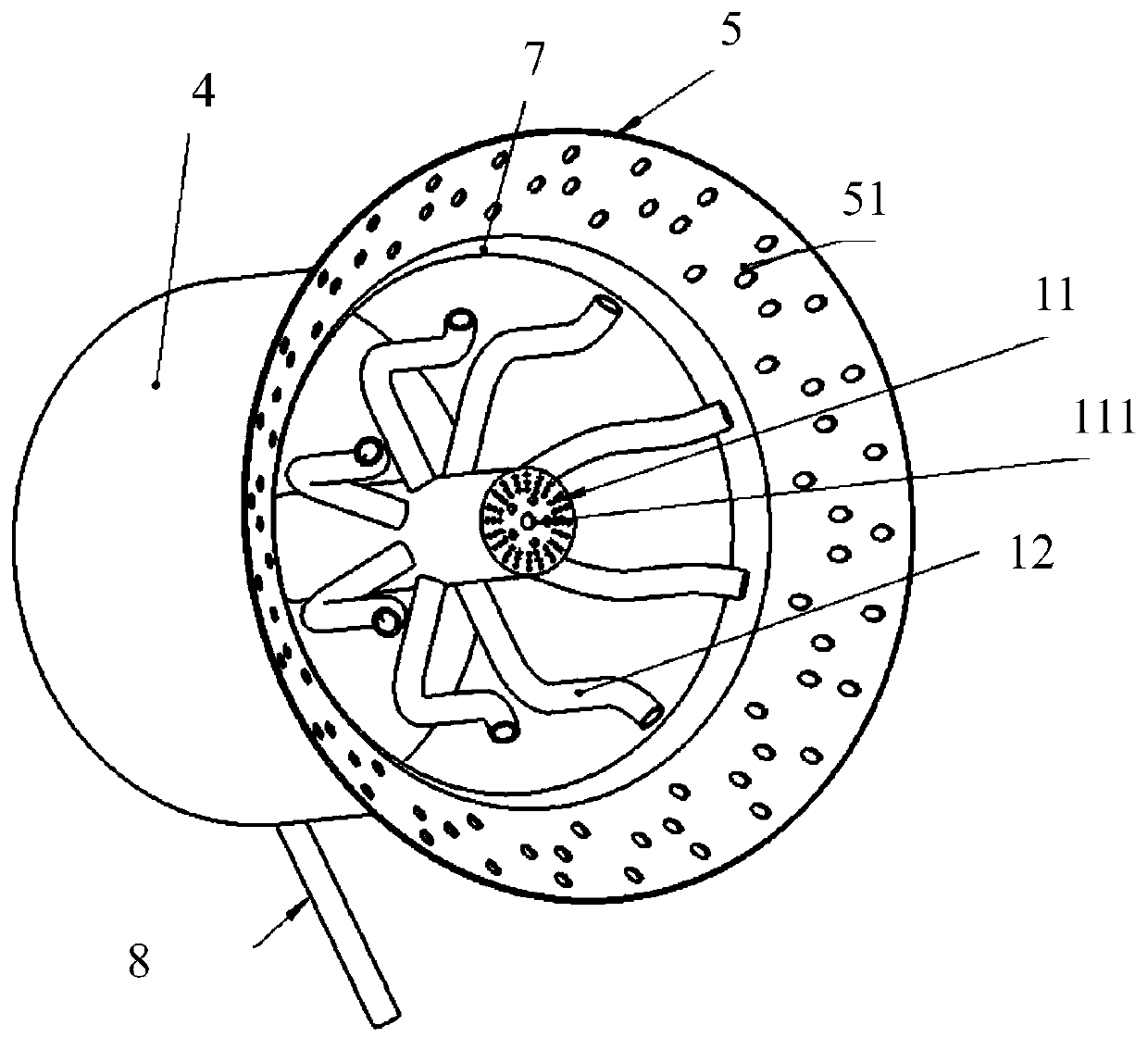

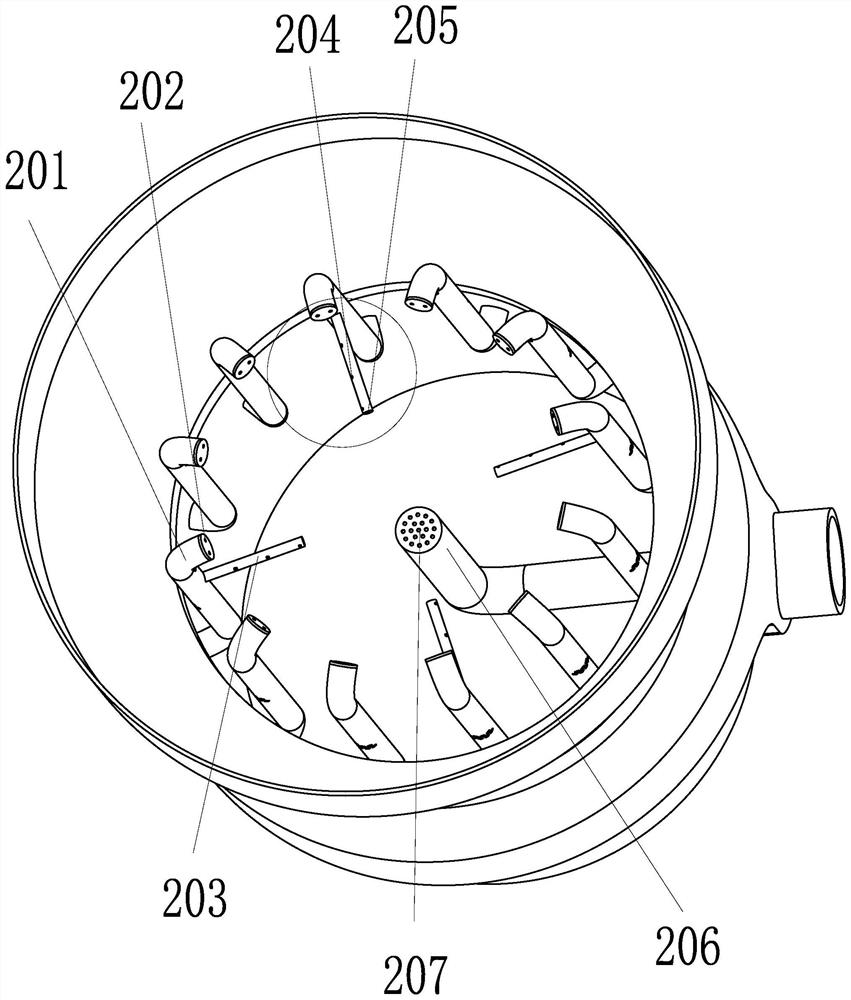

Combustor based on multi-zone combustion

PendingCN112361335AImprove mix qualityImprove combustion efficiencyGaseous fuel burnerThermodynamicsCombustor

The invention provides a combustor based on multi-zone combustion. The combustor comprises a combustor barrel body, a fuel gas injection system and a flame stabilizing disc, wherein, the fuel gas injection system and the flame stabilizing disc are arranged in the combustor barrel body; the fuel gas injection system comprises a central fuel gas pipe and a plurality of annular fuel gas spray pipes which are rotationally and symmetrically arranged by taking the central fuel gas pipe as the center; a plurality of central fuel gas through holes are formed in the tail end of a central fuel gas spraypipe; the fuel gas injection system further comprises a plurality of fuel gas branch pipes which are rotationally and symmetrically arranged by taking the central fuel gas pipe as the center, and oneends of the fuel gas branch pipes are in communication with the annular fuel gas spray pipes; first flow distribution through holes are formed in the fuel gas branch pipes in the radial direction ofthe combustor barrel body, and second flow distribution through holes are formed in the tail ends, away from the annular fuel gas spray pipes, of the fuel gas branch pipes; and annular fuel gas through holes are formed in the tail ends of the annular fuel gas spray pipes. By applying the technical scheme, the combustion efficiency can be improved, and the combustor can be heated uniformly.

Owner:HUAQIAO UNIVERSITY

Burner and gas range using the same

InactiveCN1590844AInhibition of refluxSteady attractionDomestic stoves or rangesGaseous fuel burnerEngineeringMechanical engineering

A combustor comprises a mixing tube for leading in the premixed gas and an annular tube which is communicated with the mixing tube and is arranged with a plurality of flame openings at the inner circumferential surface. The inner side of the annular tube is arranged with a rectifier which allows the passing of the premixed gas and homogenizes the flame distribution at the flame opening, and / or an obstructing body which restrains the backward flow of the premixed gas from the annular tube to the communicating part between the mixing tube and the annular tube.

Owner:PANASONIC CORP

Control device for internal combustion engine

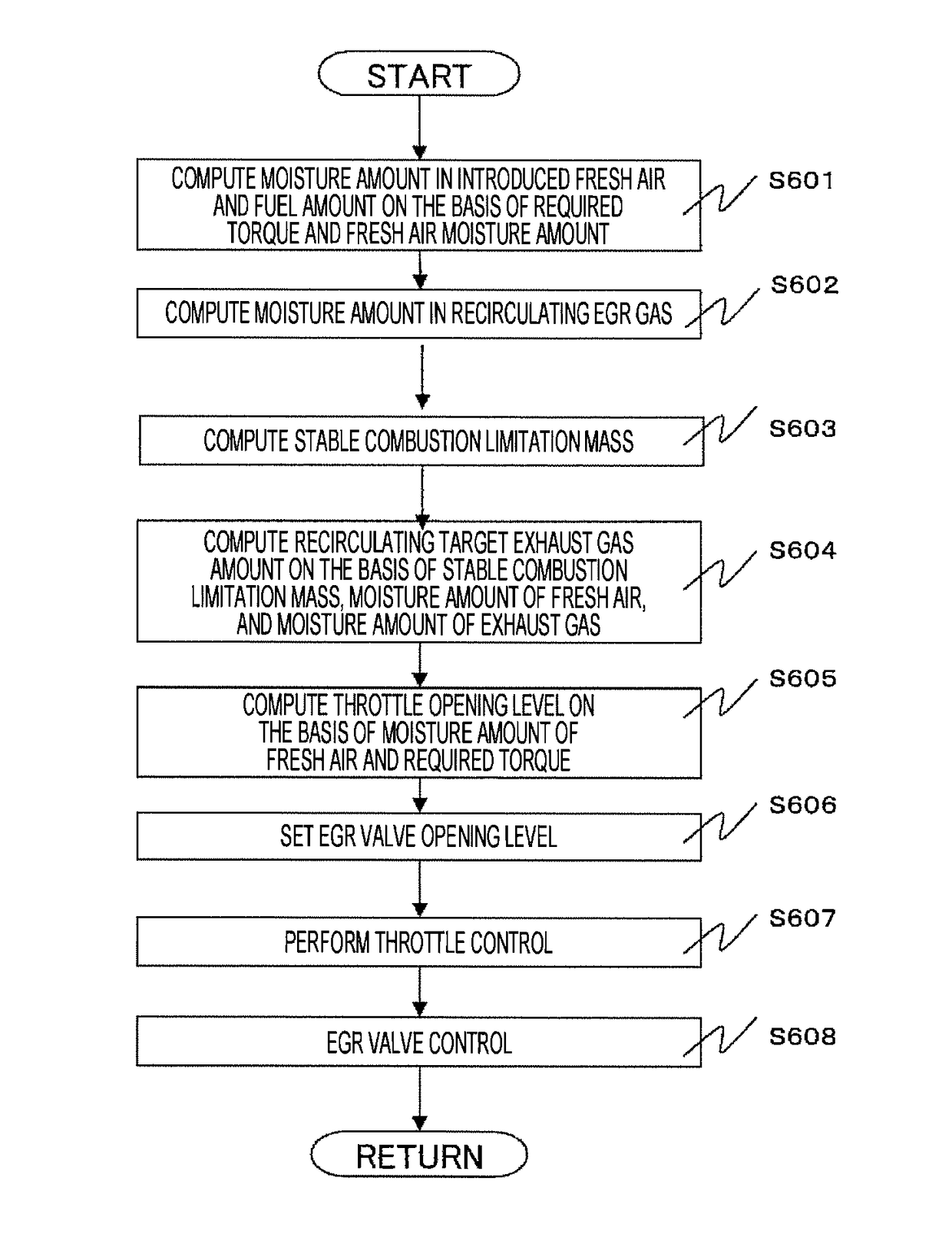

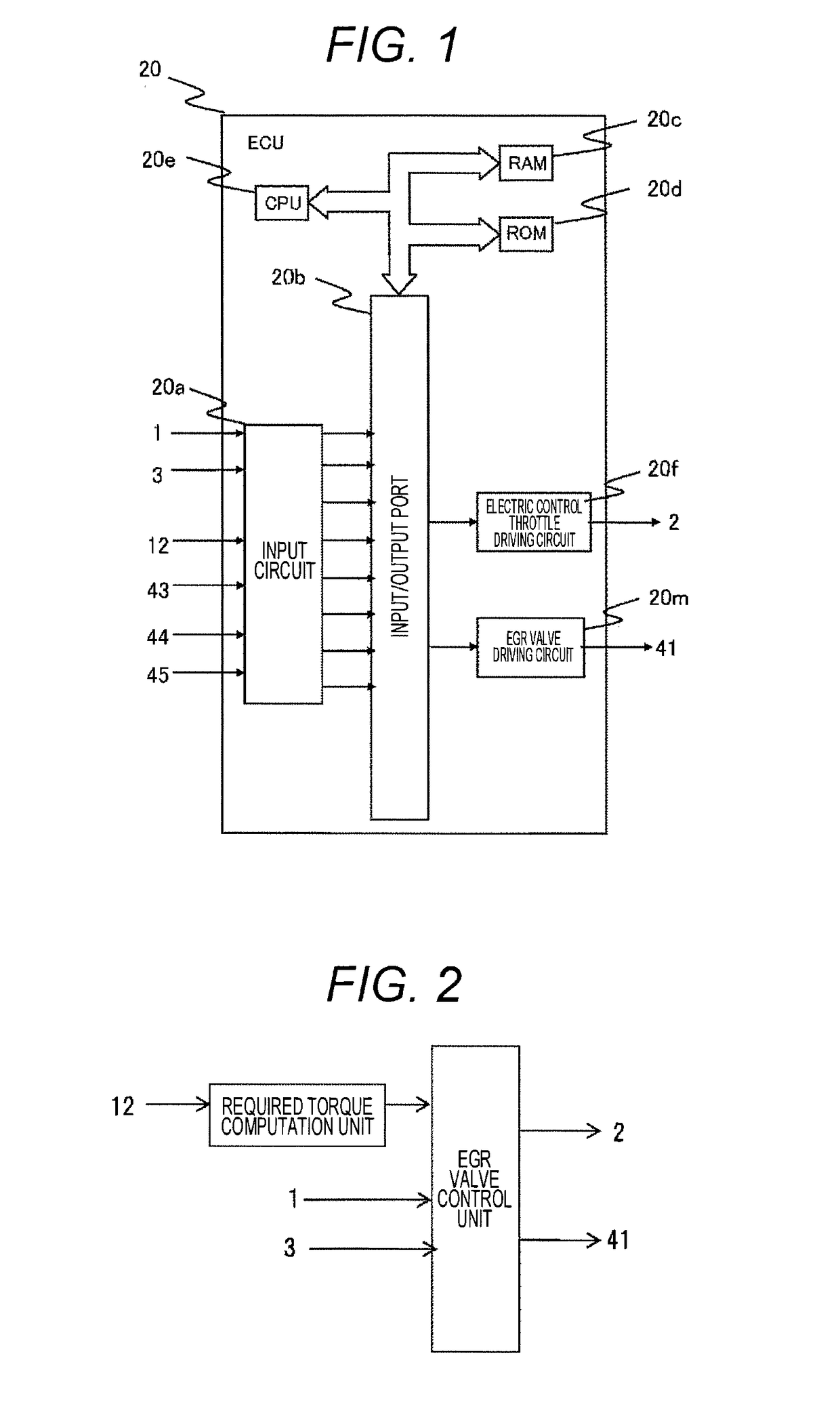

ActiveUS20170268442A1Stabilize combustion stateCombustion state is stableElectrical controlInternal combustion piston enginesExhaust gasEngineering

The objective of the present invention is to provide a control device for an internal combustion engine that is able to provide a more stable combustion state by suitably setting the amount of recirculated exhaust gas. The present invention is an internal combustion engine control device equipped with air cylinders and an EGR mechanism that returns exhaust gas emitted from the air cylinders to the intake side of the air cylinders, and is characterized by being equipped with an EGR control unit that controls the EGR flow volume of the EGR mechanism, and a humidity detection means that directly or indirectly detects the humidity of outside air supplied to the air cylinders, with the EGR control unit calculating the moisture amount in the outside air and the moisture amount in the recirculated exhaust gas, and controlling the EGR mechanism on the basis of: a stable combustion limit air cylinder mass, which is set in accordance with the combustion state in the air cylinders; the mass of the air introduced into the air cylinders; the mass of the fuel; and the moisture amounts.

Owner:HITACHI ASTEMO LTD

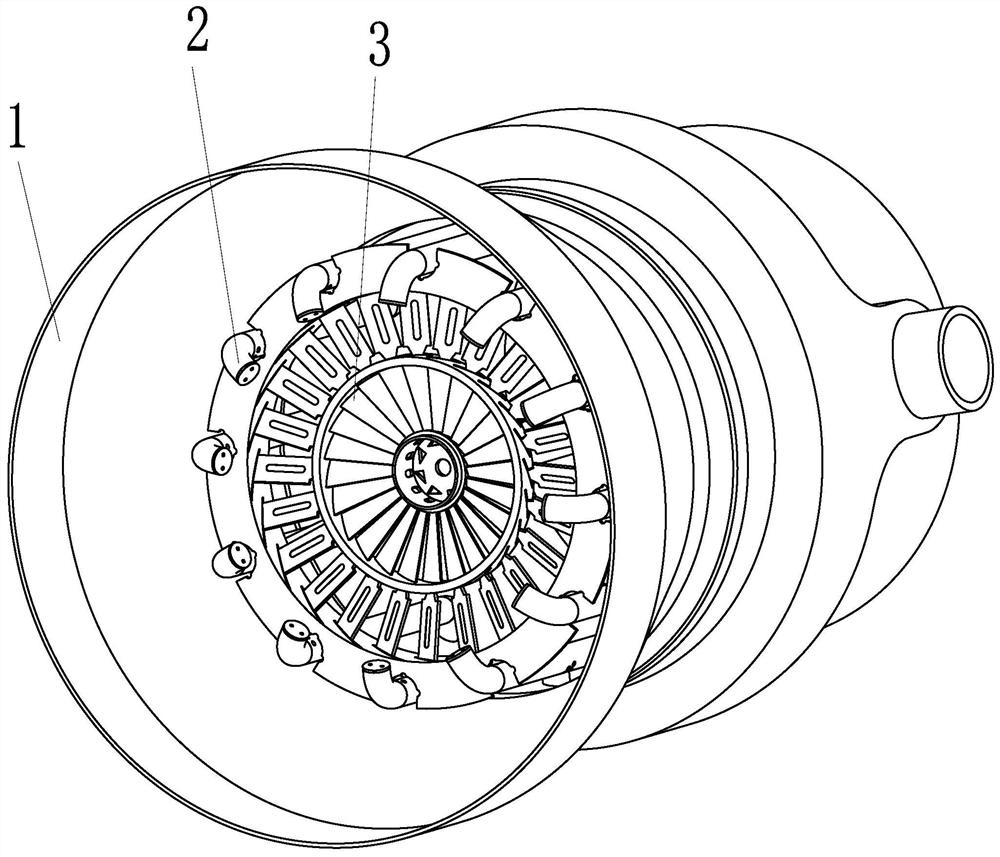

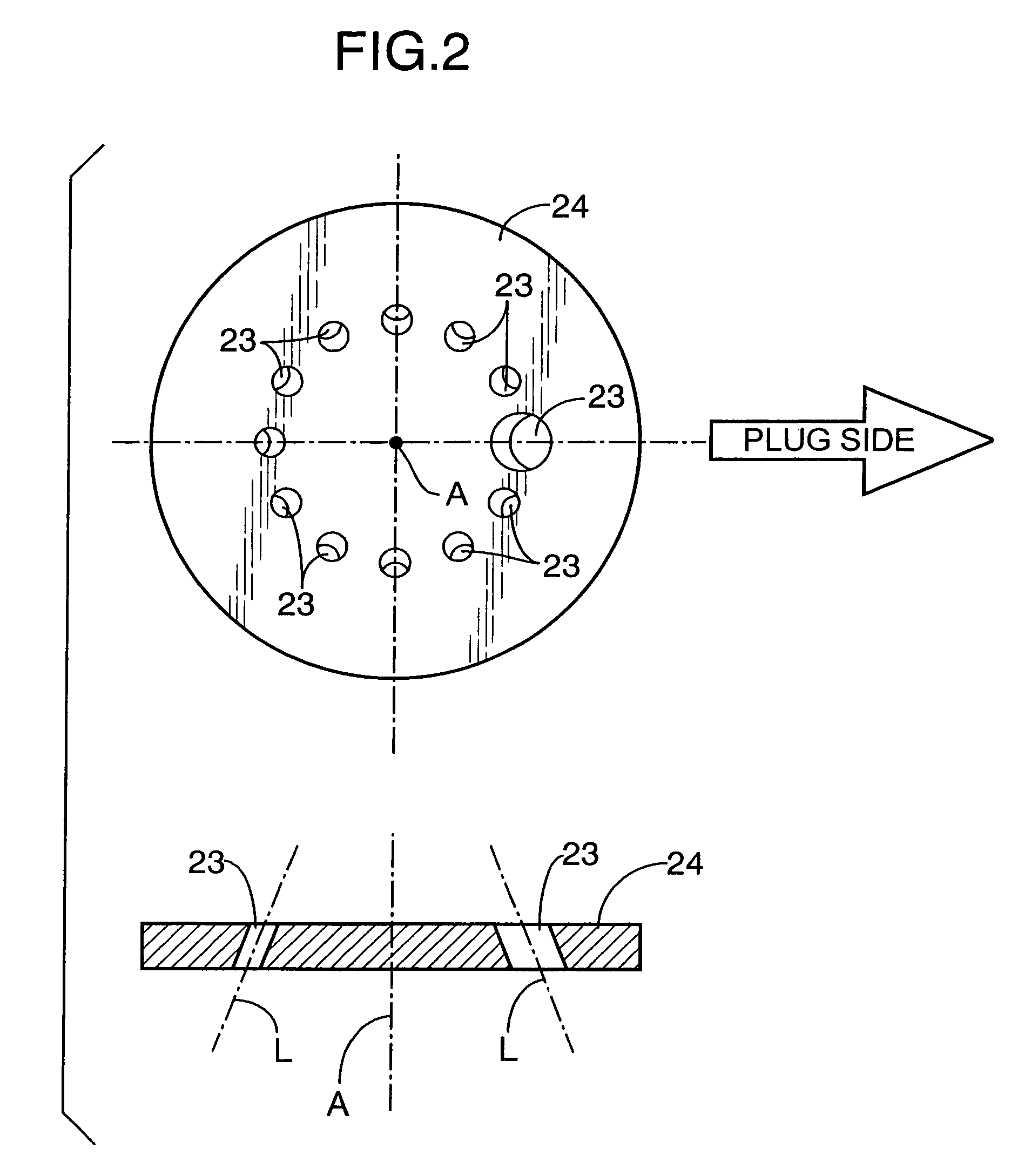

Inner ring fire cover, combustor and gas stove

PendingCN111750350ACombustion state is stableDomestic stoves or rangesStoves/ranges topsPhysicsEngineering

The invention discloses an inner ring fire cover, a combustor and a gas stove. The inner ring fire cover comprises a top cover, an outer ring wall, an inner ring wall and a connecting plate, wherein the top cover is disposed on the outer ring wall; the inner ring wall is disposed inside the outer ring wall, and a central cavity is formed in the middle of the inner ring wall; and the connecting plate is disposed between the outer ring wall and the inner ring wall, the top cover, the outer ring wall and the connecting plate enclose a first inner ring gas cavity in communication with the centralcavity, first inner ring fire holes communicating with the first inner ring gas cavity are formed in the top cover at intervals in the circumferential direction, second inner ring fire holes communicating with the first inner ring gas cavity are formed in the outer ring wall, a second inner ring gas cavity is formed by enclosing the outer ring wall, the connecting plate and the inner ring wall, and flame stabilizing holes communicating with the second inner ring gas cavity are formed in the outer ring wall at intervals in the circumferential direction. According to the inner ring fire cover,,the gas load of the first inner ring fire holes can be reduced, so that the inner ring fire cover can maintain the stable combustion state in an extremely small fire state.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG

Internal combustion engine and fuel injection method in internal combustion engine

InactiveUS7536994B2Reduce the amount requiredCombustion state is stableElectrical controlInternal combustion piston enginesCombustion chamberEngineering

An air-fuel ratio of an air-fuel mixture produced by fuel injected from a first injector into an intake port (or into a combustion chamber) is set in a range of 28 to 38. Therefore, when the temperature and pressure rise with a first combustion started by spark-ignition around a spark plug to the fuel injected from a second injector into the combustion chamber, the timing of starting a second compressive hypergolic ignition is optimized to provide a stable combustion state free of knocking and misfire.

Owner:HONDA MOTOR CO LTD

Heat medium boiler

InactiveCN103782101ACombustion state is stableImprove combustion performanceFuel supply regulationIndirect carbon-dioxide mitigationCombustorRecuperator

A heat medium boiler (1) is provided with a recuperator (11) which preheats combustion air by causing the combustion air and gas discharged from the boiler to exchange heat with each other. The heat medium boiler (1) is provided with a fuel gas supply line (12) which supplies gas fuel to a burner (2), an inverter (9) which changes the rotational speed of an air blower (8), a fuel gas flow rate adjustment valve (13), a control means (16) which controls the fuel gas flow rate adjustment valve (13), and a pressure difference detection means (15) which detects a pressure difference across the recuperator (11). The control means (16) calculates the amount of combustion air on the basis of the detected pressure difference and controls the fuel gas flow rate adjustment valve (13) according to the calculated amount of combustion air. When a change in the combustion air exceeds a predetermined range, the control means (16) adjusts the frequency of the inverter (9) and controls the fuel gas flow rate adjustment valve (13) according to the amount of combustion air.

Owner:MIURA COMPANY LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com