Graded low-nitrogen gas combustor based on rotational flow

A gas burner and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as unfavorable gas and air fully mixed combustion, NOx emissions that do not meet environmental protection requirements, incomplete combustion, etc. The effect of avoiding flashback or misfire conditions, increasing flame propagation speed, and stabilizing combustion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

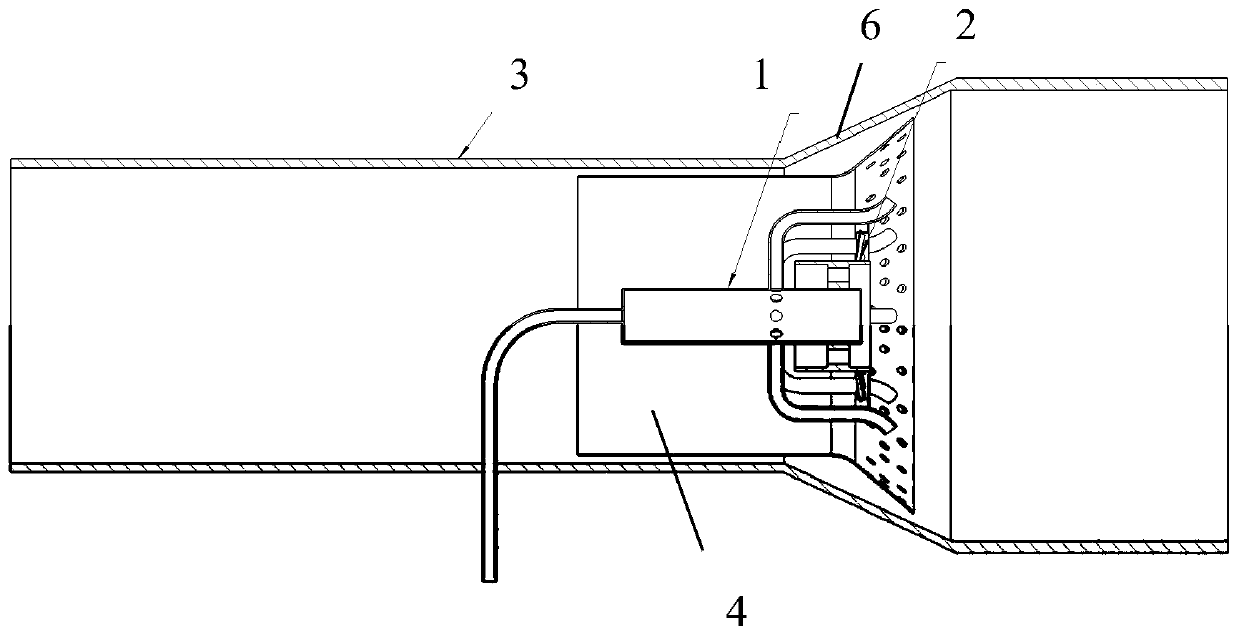

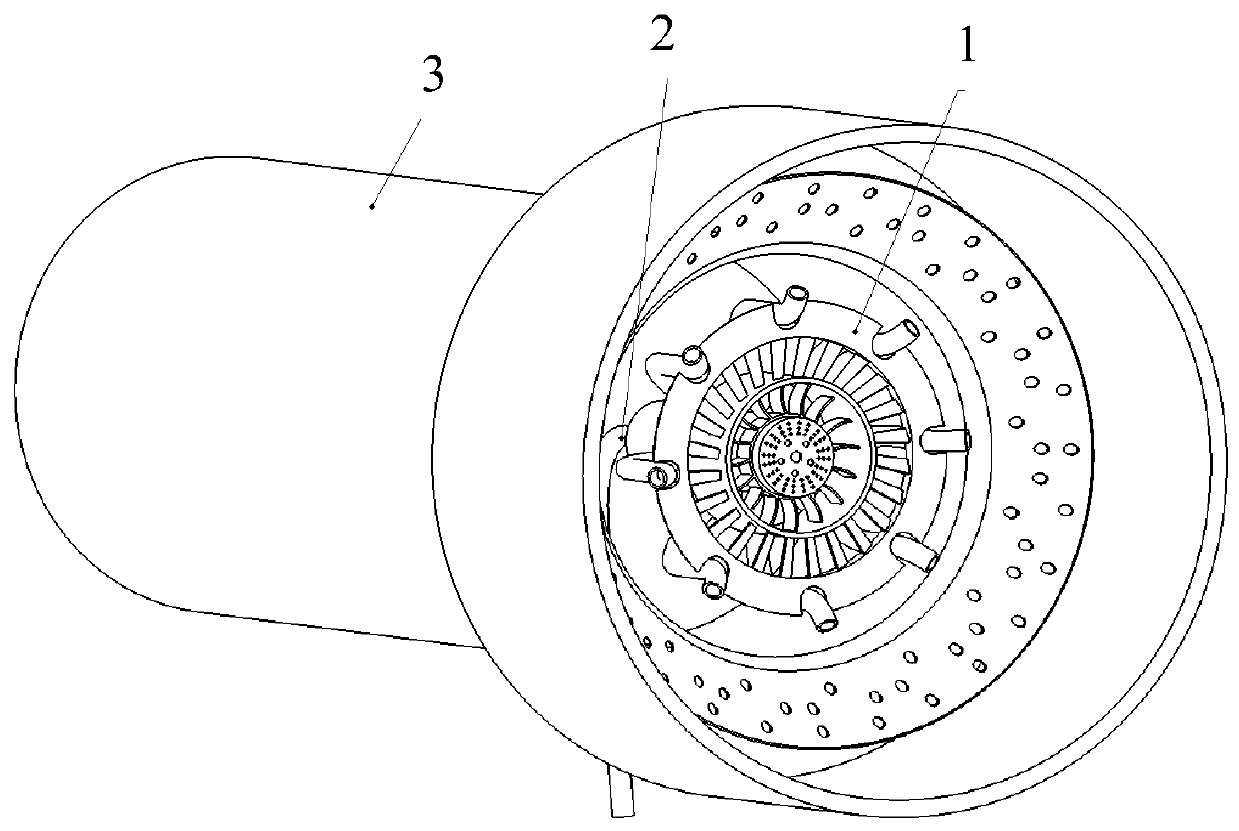

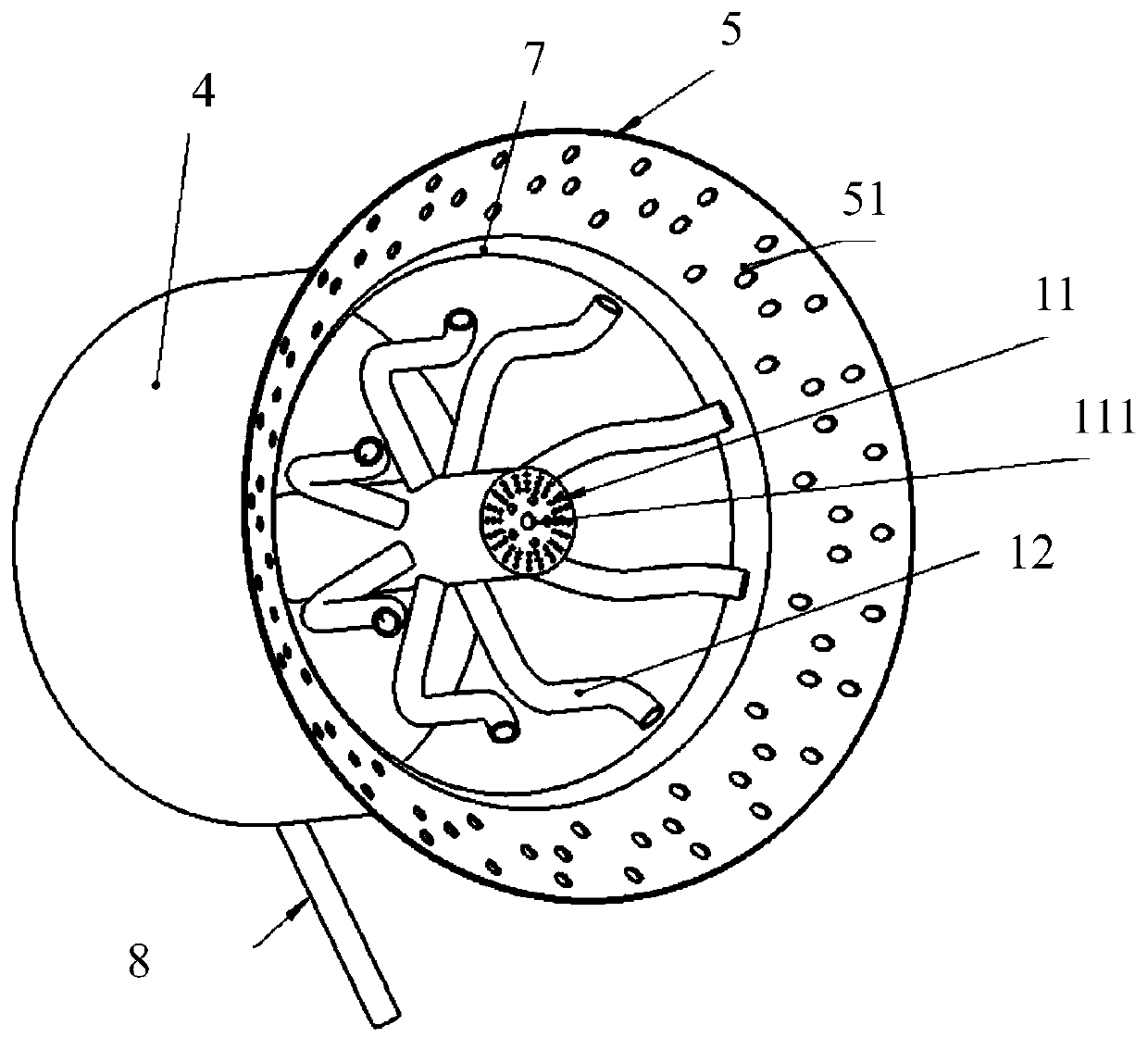

[0028] A swirl-based staged low-nitrogen gas burner, reference Figures 1 to 5 , including burner cylinder 3, connecting cylinder 6, and burner hood 9 arranged in sequence; the diameter of the burner cylinder 3 is smaller than the burner hood 9, and the connecting cylinder 6 is formed from the The diameter of the burner barrel 3 to the burner head cover 9 gradually expands; the end of the burner barrel 3 to the connecting barrel 6 is provided with a gas injection device 1; the gas injection device 1 includes Main gas nozzle 11 and auxiliary gas nozzle 12; said auxiliary gas nozzle 12 is symmetrically distributed with the length direction of said main gas nozzle 11 as the central axis and communicated with said main gas nozzle 11; said Between the main gas nozzle 11 and the auxiliary gas nozzle 12, there is also a swirling flame stabilizing dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com