Pulse vector high-pressure burner

A burner and pulse technology, applied in the direction of burner, lighting and heating equipment, etc., can solve the problems of complex structure and high operating cost, and achieve the effect of high thermal efficiency, low cost and stable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

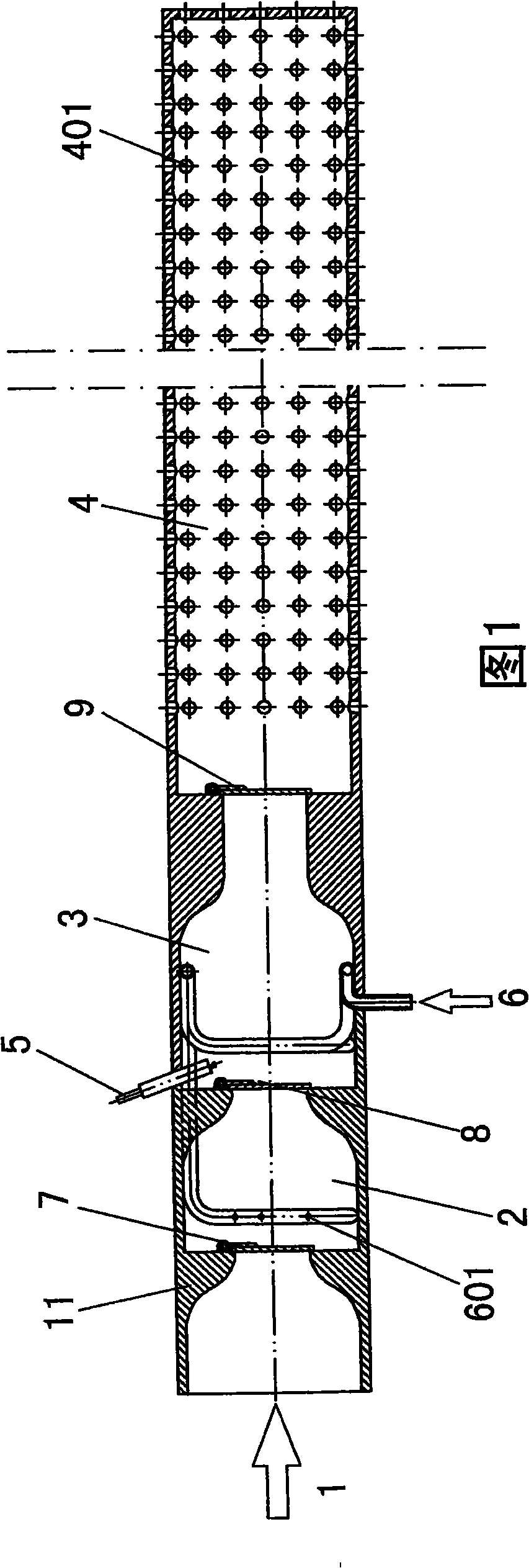

Embodiment 1

[0033] The structure of the device for automatically generating pulsed supply of oil and gas by utilizing gas and oil pressure changes is as follows: the fuel oil inlet pipe 6 leads into the inner chamber of the combustion chamber 3 and the oil-gas mixing chamber 2, and the fuel oil inlet pipe 6 has a plurality of An oil mist spray hole 601, the oil-gas mixing chamber 2, the combustion chamber 3, and the flame injection pipe 4 have a combined housing 11 connected to each other, and between the oil-gas mixing chamber 2 and the high-pressure air, there is only a direction toward the flame injection pipe 4. The No. 1 check valve 7 that can't get in and out is provided between the combustion chamber 3 and the oil-gas mixing chamber 2, and the No. 2 check valve 8 that can only go out in the direction of the flame injection pipe 4 is provided between the combustion chamber 3 and the flame injection A No. 3 check valve 9 is provided between the pipes 4 toward the direction of the flam...

Embodiment 2

[0043]Please refer to Fig. 2, the structure of the device for automatically generating pulsed supply of oil and gas by using gas and oil pressure changes is as follows: the fuel oil inlet pipe 6 leads into the inner cavity of the combustion chamber 3 and the oil-gas mixing chamber 2, and the fuel oil inlet pipe 6 There are a plurality of oil mist spray holes 601 on the pipe wall. The oil-gas mixing chamber 2, the combustion chamber 3 and the flame injection pipe 4 have a combined housing 11 connected to each other. A slide valve 12 with a hole in the center is arranged in the oil-gas mixing chamber 2. , the slide valve 12 touches at least two guide rods 13, and the extended end of the guide rods 13 protruding from the air compression chamber 16 is set with a return spring 14, and the spring 14 is limited by the counterweight 15 at the end of the guide rod 13 , between the pressurized air 1 and the air compression chamber 16, there is a No. 1 one-way valve 7 that can only go in ...

Embodiment 3

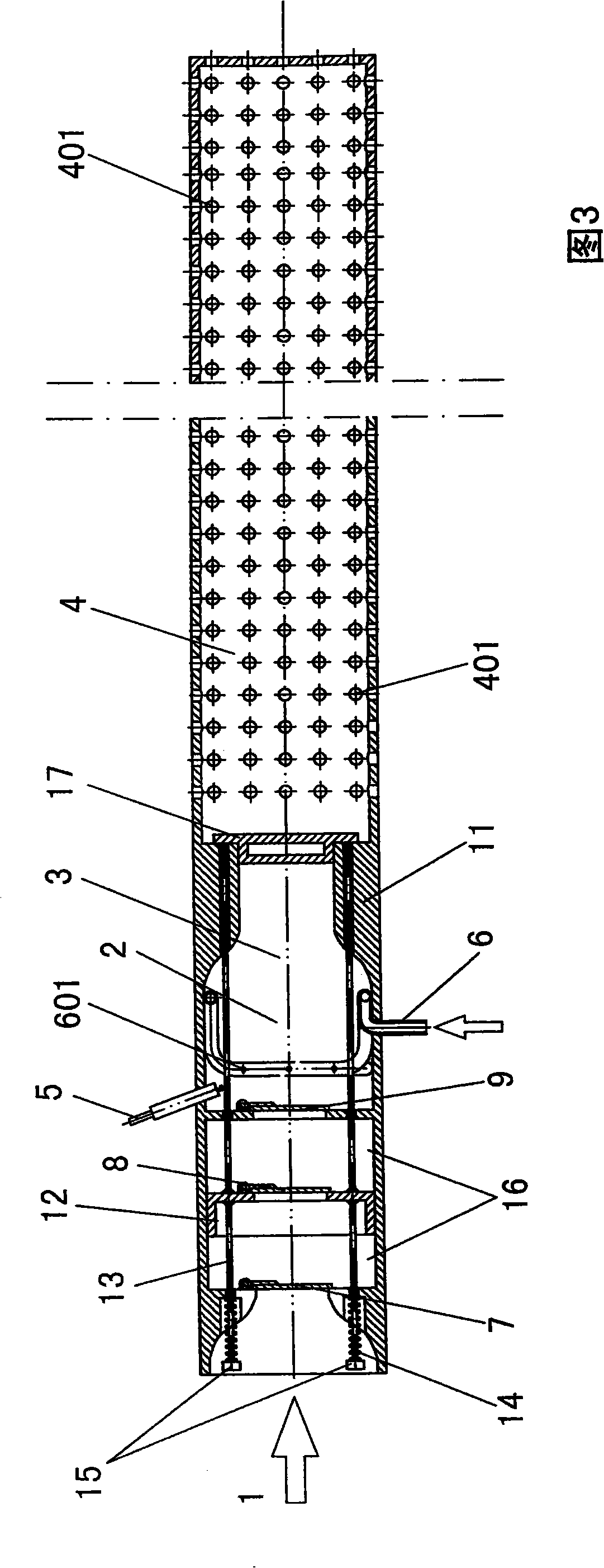

[0057] Please refer to Fig. 3, the structure of the device for automatically generating pulse supply of oil and gas by using gas and oil pressure changes is as follows: the fuel oil inlet pipe 6 leads into the inner cavity of the combustion chamber 3 and the oil-gas mixing chamber 2, and the fuel oil inlet pipe 6 There are a plurality of oil mist spray holes 601 on the pipe wall, the oil-gas mixing chamber 2, the combustion chamber 3, and the flame injection pipe 4 have a combined housing 11 connected to each other, and a slide valve with a hole in the center is arranged in the air compression chamber 16 12. There is a normally closed valve cover 17 in the pipe hole between the combustion chamber 3 and the flame injection pipe 4. The valve cover 17 is connected to at least two guide rods 13, and the guide rods 13 pass through the slide valve 12. The guide rods Fixed on the slide valve 12, the extended end of the guide rod protruding from the combination housing 11 is set with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com