Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141 results about "Two-stroke diesel engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A two-stroke diesel engine is a Diesel engine that works in two strokes. It was invented by Hugo Güldner [de] in 1899. All diesel engines use compression ignition, a process by which fuel is injected after the air is compressed in the combustion chamber, thereby causing the fuel to self-ignite. By contrast, gasoline engines utilize the Otto cycle, or, more recently, the Atkinson cycle, in which fuel and air are mixed before entering the combustion chamber and then ignited by a spark plug.

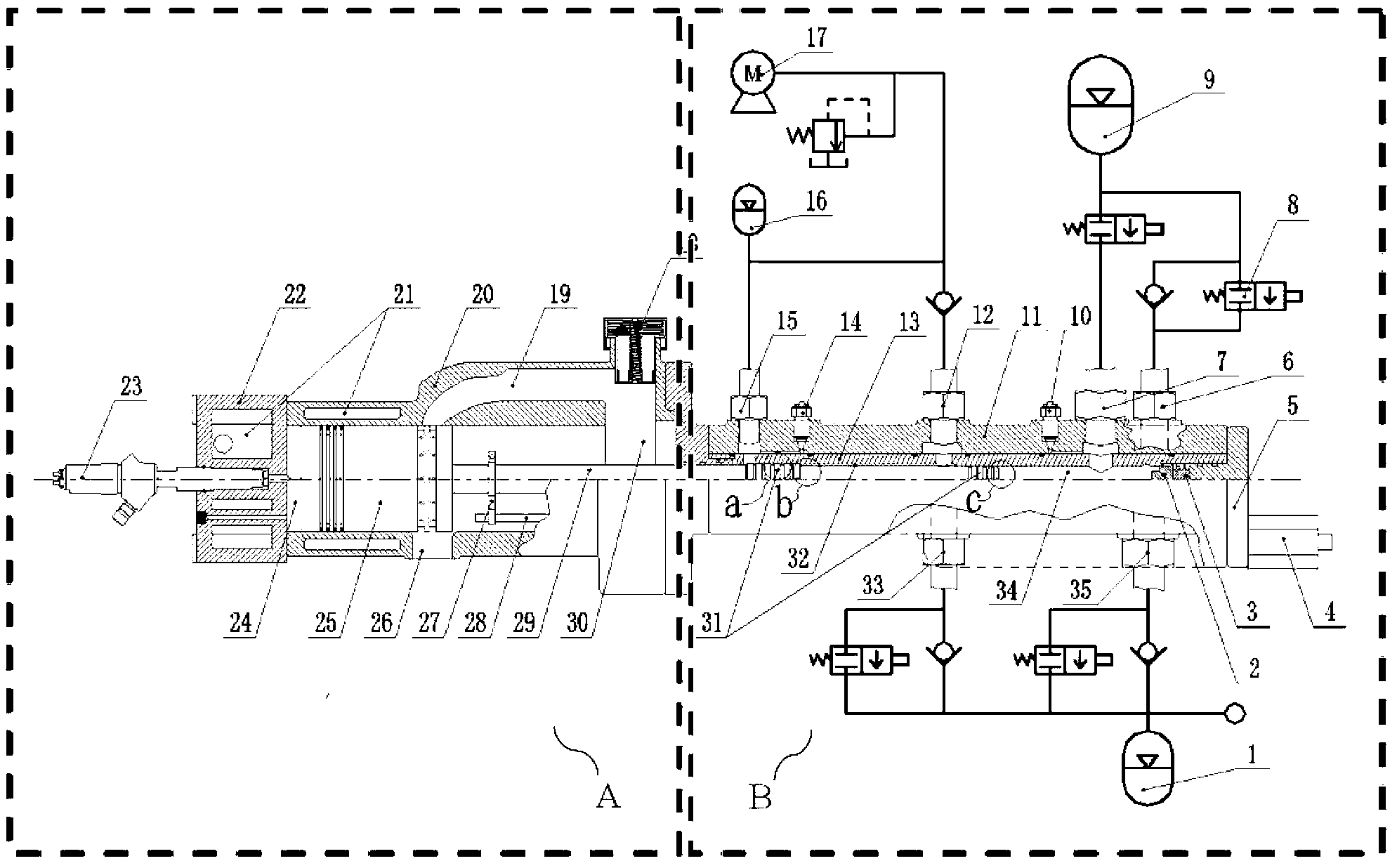

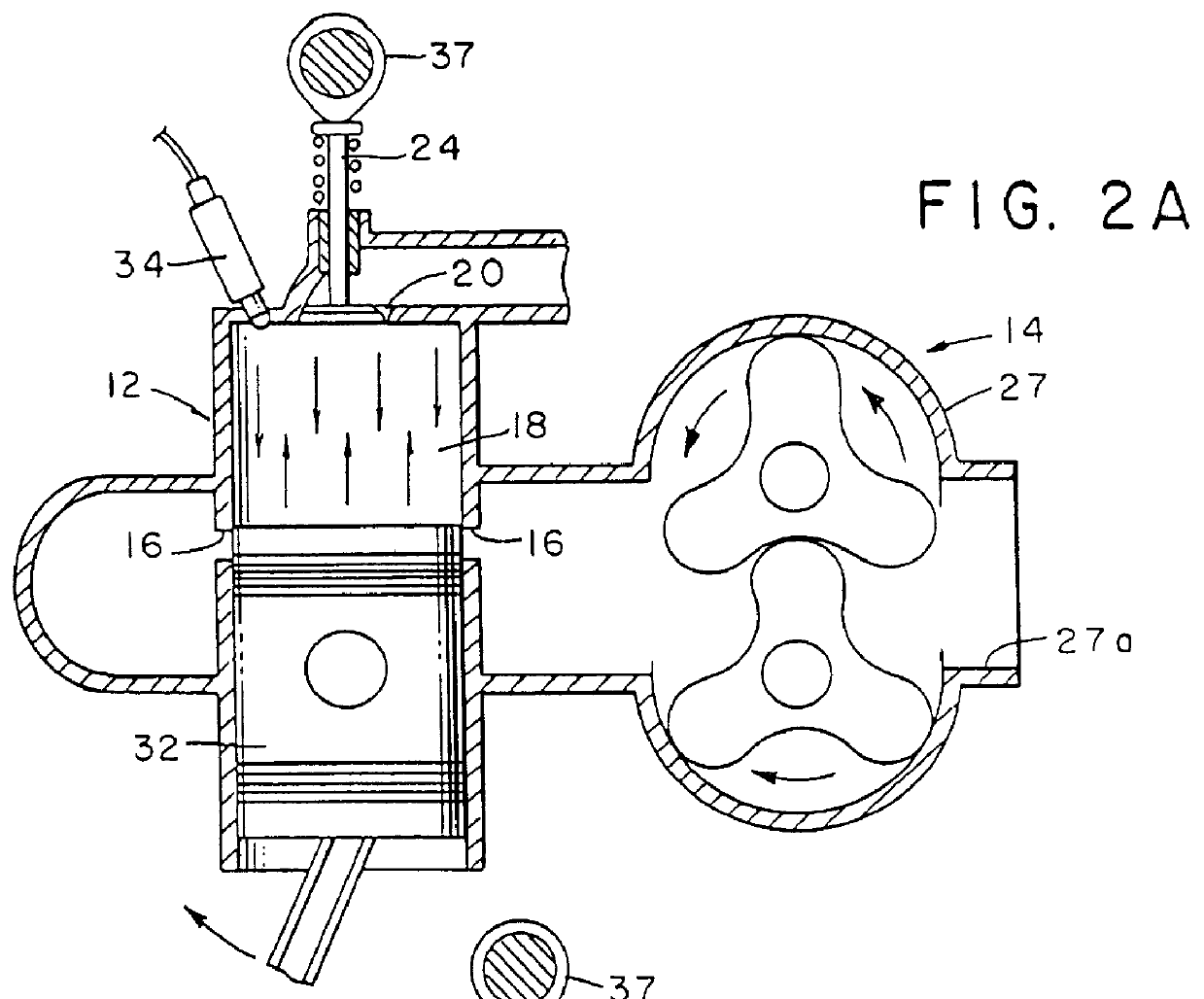

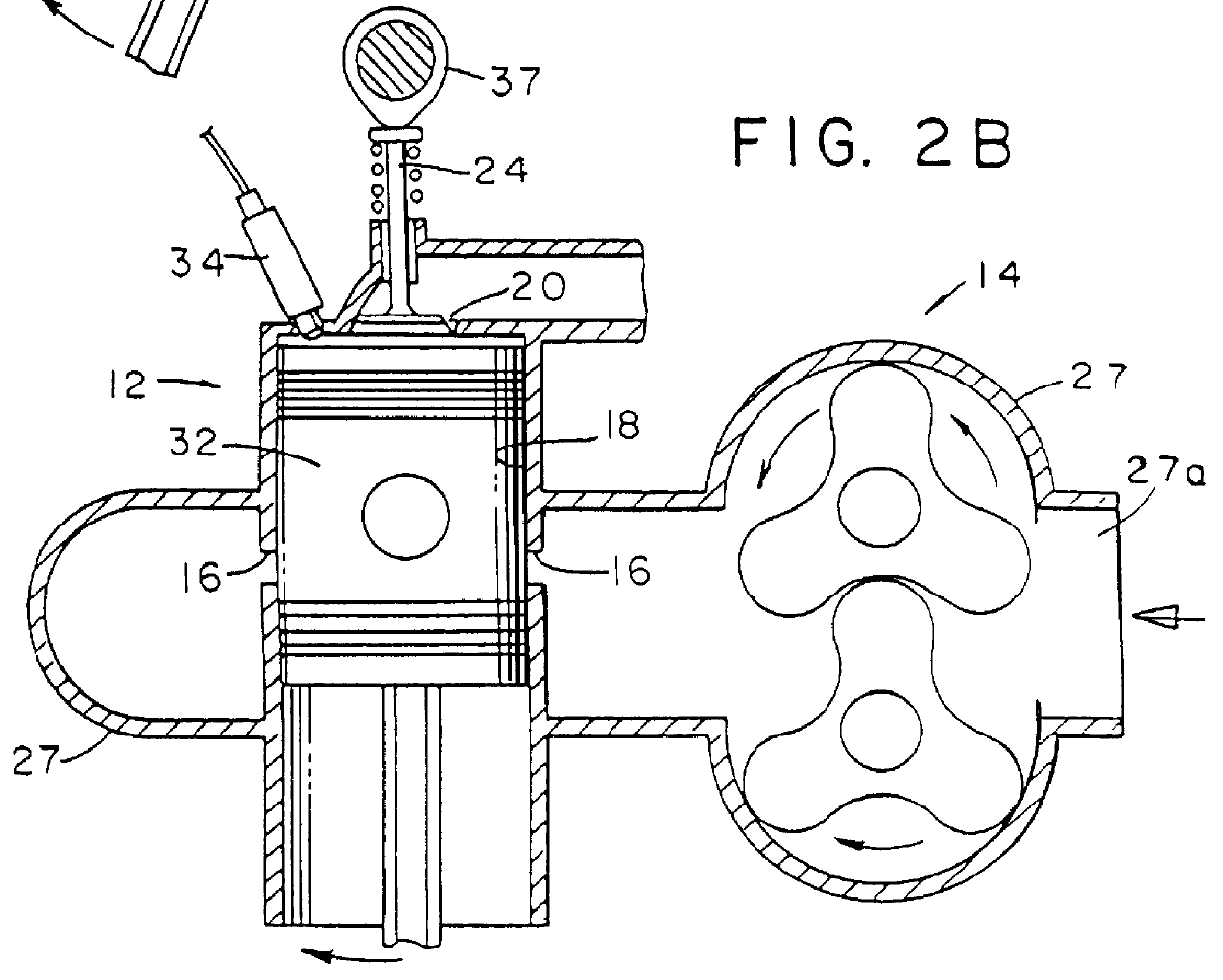

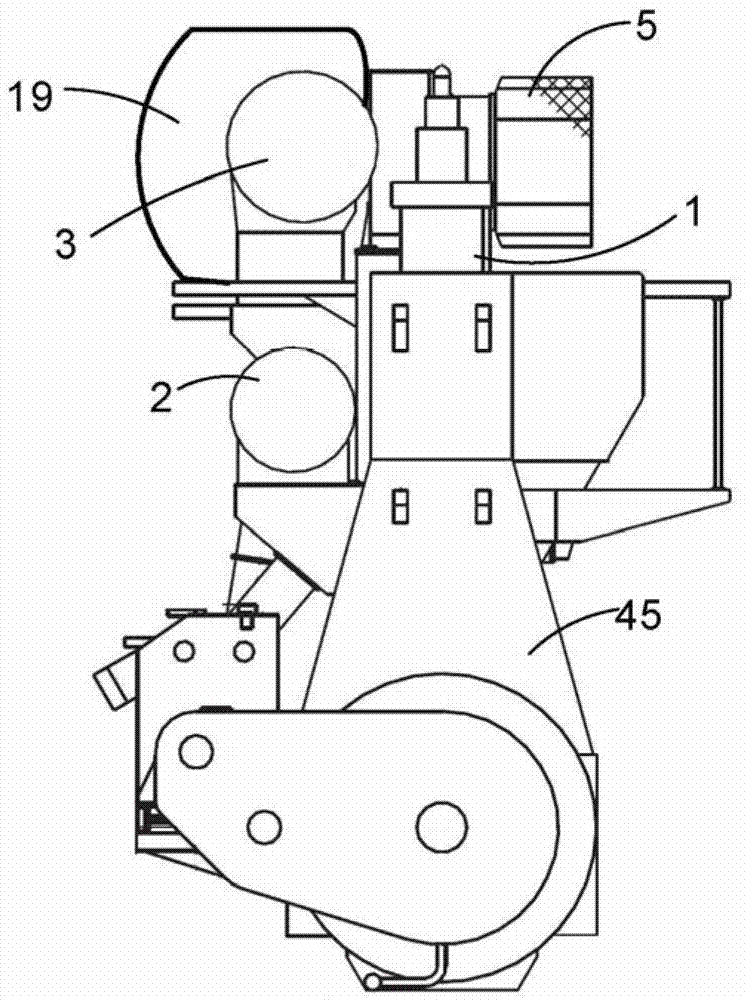

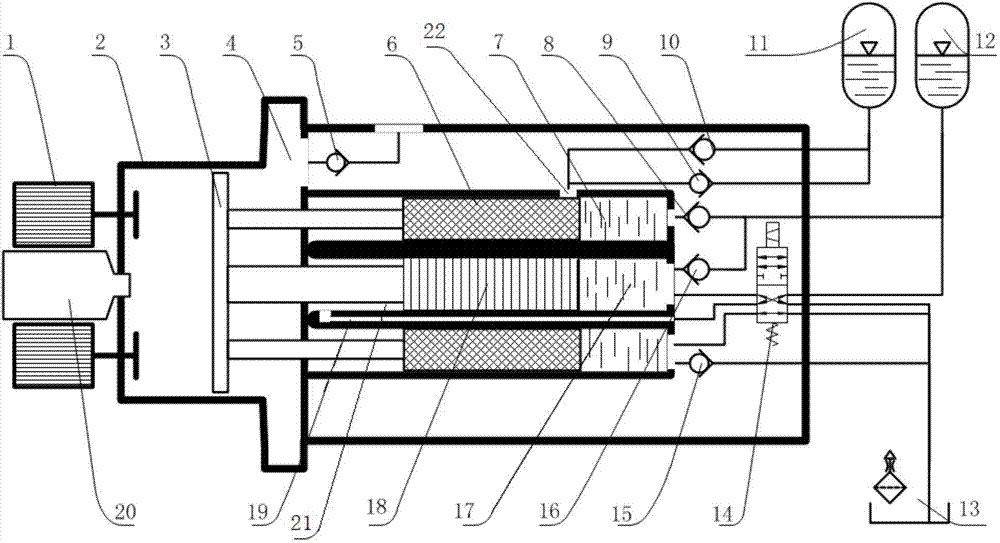

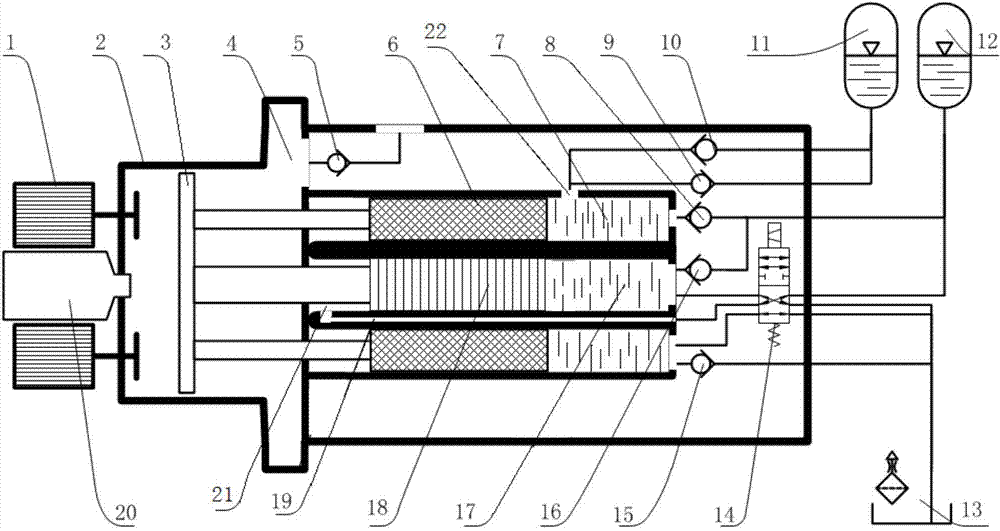

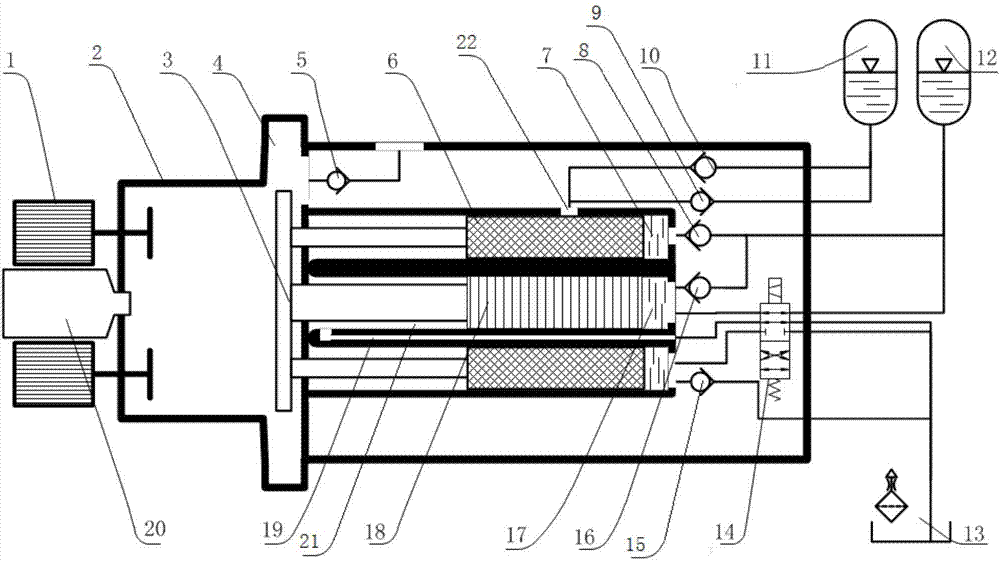

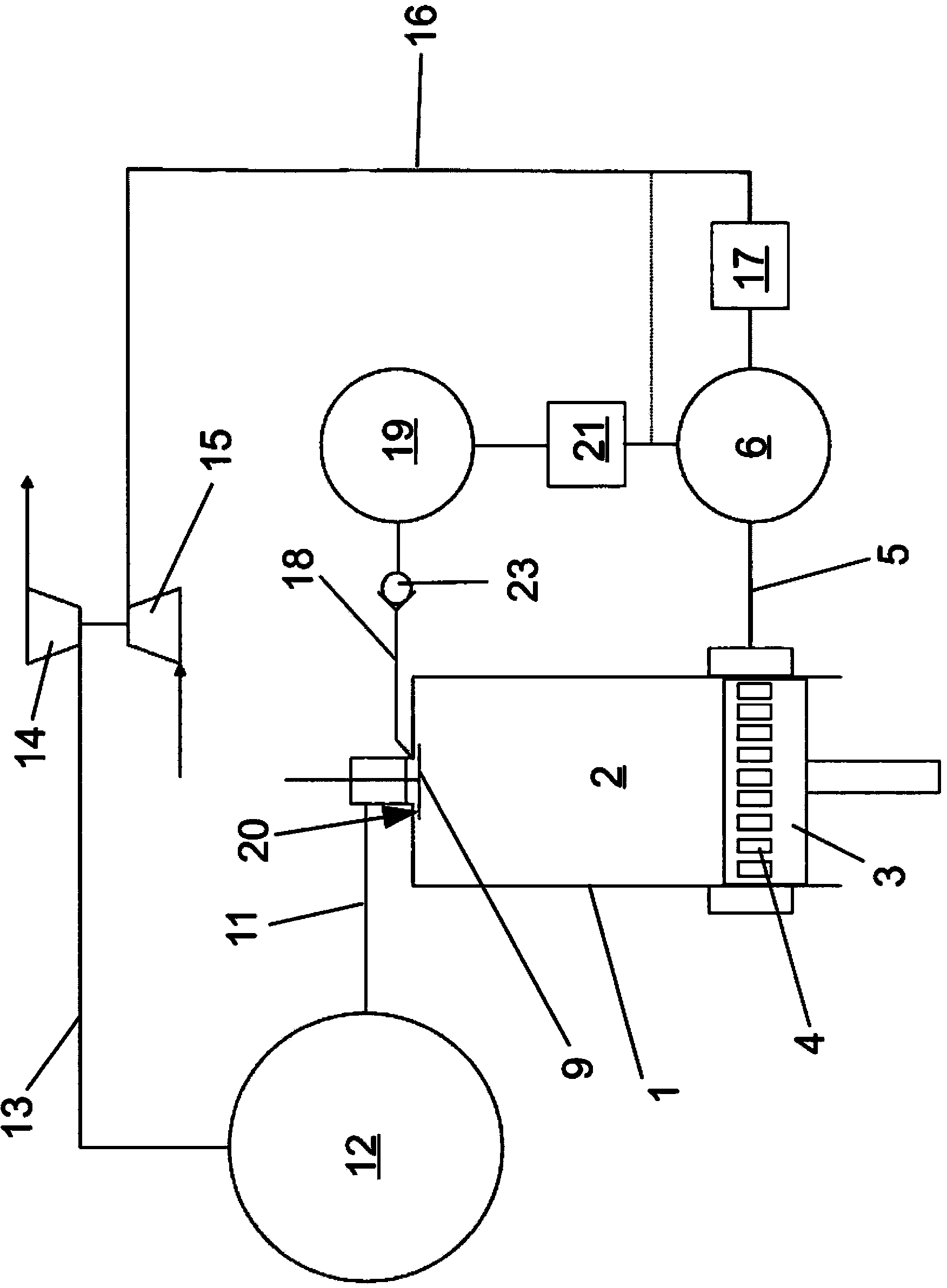

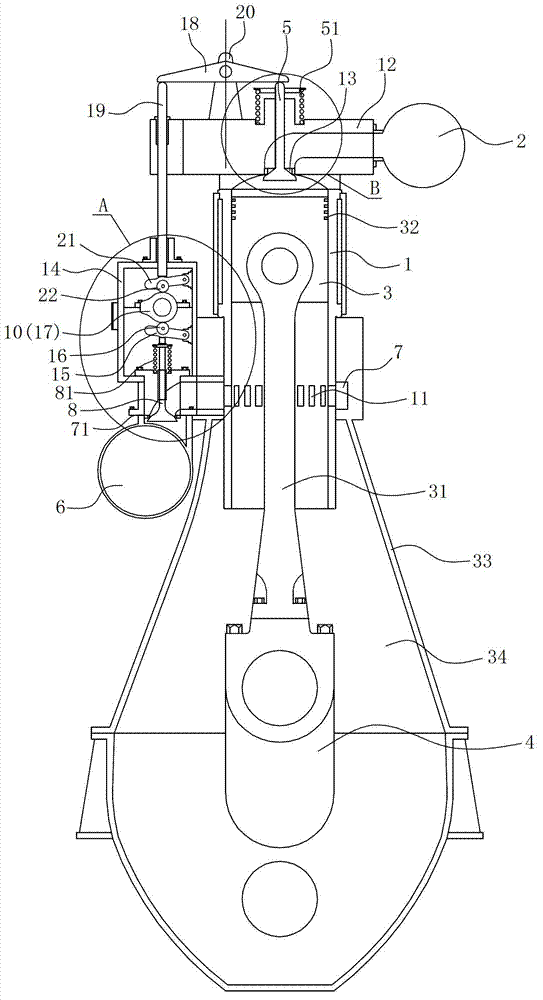

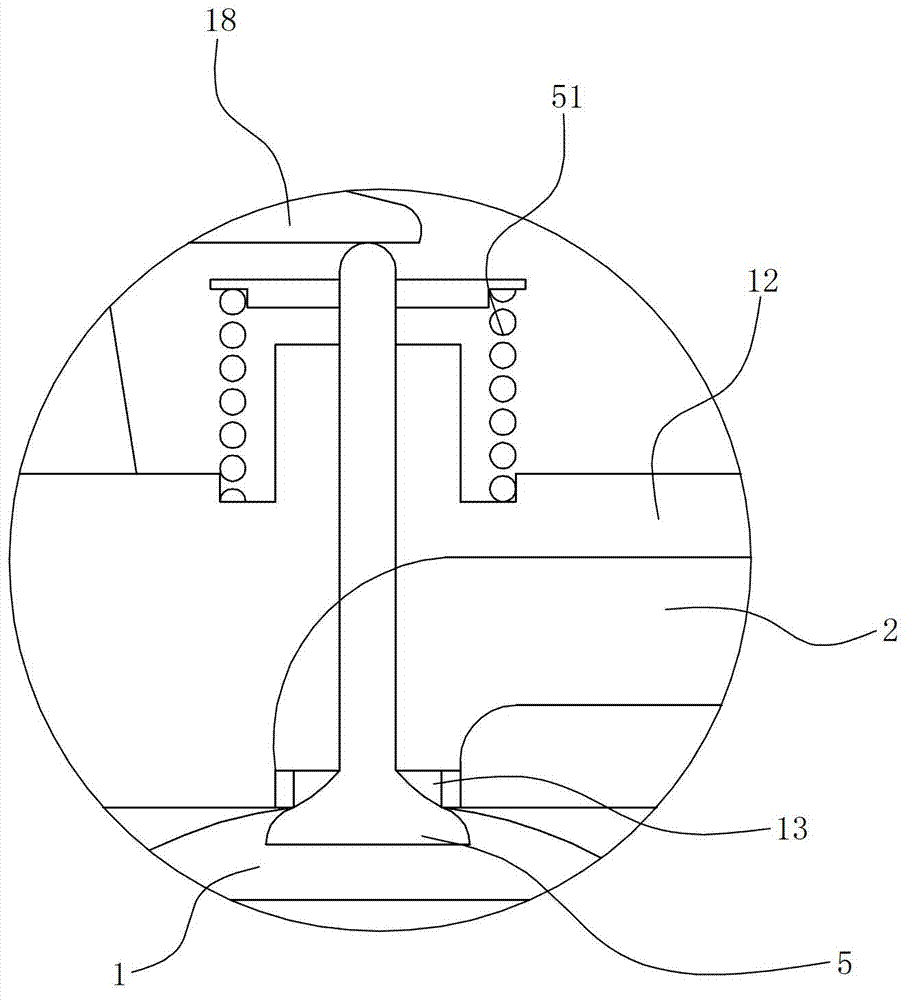

Return flow scavenging type hydraulic free piston diesel engine

InactiveCN102705076AOmit the crankshaftReduce intermediate conversion linksInternal combustion piston enginesFree piston enginesHydraulic motorHydraulic pump

The invention discloses a return flow scavenging type hydraulic free piston diesel engine, which comprises a single-cylinder two-stroke diesel engine without a crankshaft connecting rod and a valve distribution mechanism, and a hydraulic system provided with a linear hydraulic pump and a hydraulic motor, wherein a piston in the single-cylinder two-stroke diesel engine is connected with a plunger in the hydraulic system, and a space in the linear hydraulic pump in the hydraulic system is divided into a high-pressure cavity and a low-pressure cavity; the piston in the single-cylinder two-stroke diesel engine can drive the linear hydraulic pump to output high-pressure oil in an expansion travel, and the high-pressure oil is output to the hydraulic motor from a pipe joint C; the piston is pushed back to an upper dead center from a lower dead center by the low-pressure oil end, so that a compression travel of the piston is completed. According to the invention, a crankshaft in the conventional internal combustion engine is omitted, and a middle conversion step of power output is reduced, so that the heat efficiency is about 5% higher than that of the conventional internal combustion engine, the diesel engine can be operated at a variable compression ratio, the best heat efficiency of a full operation work condition is ensured, and the fuel economy is improved.

Owner:JILIN UNIV

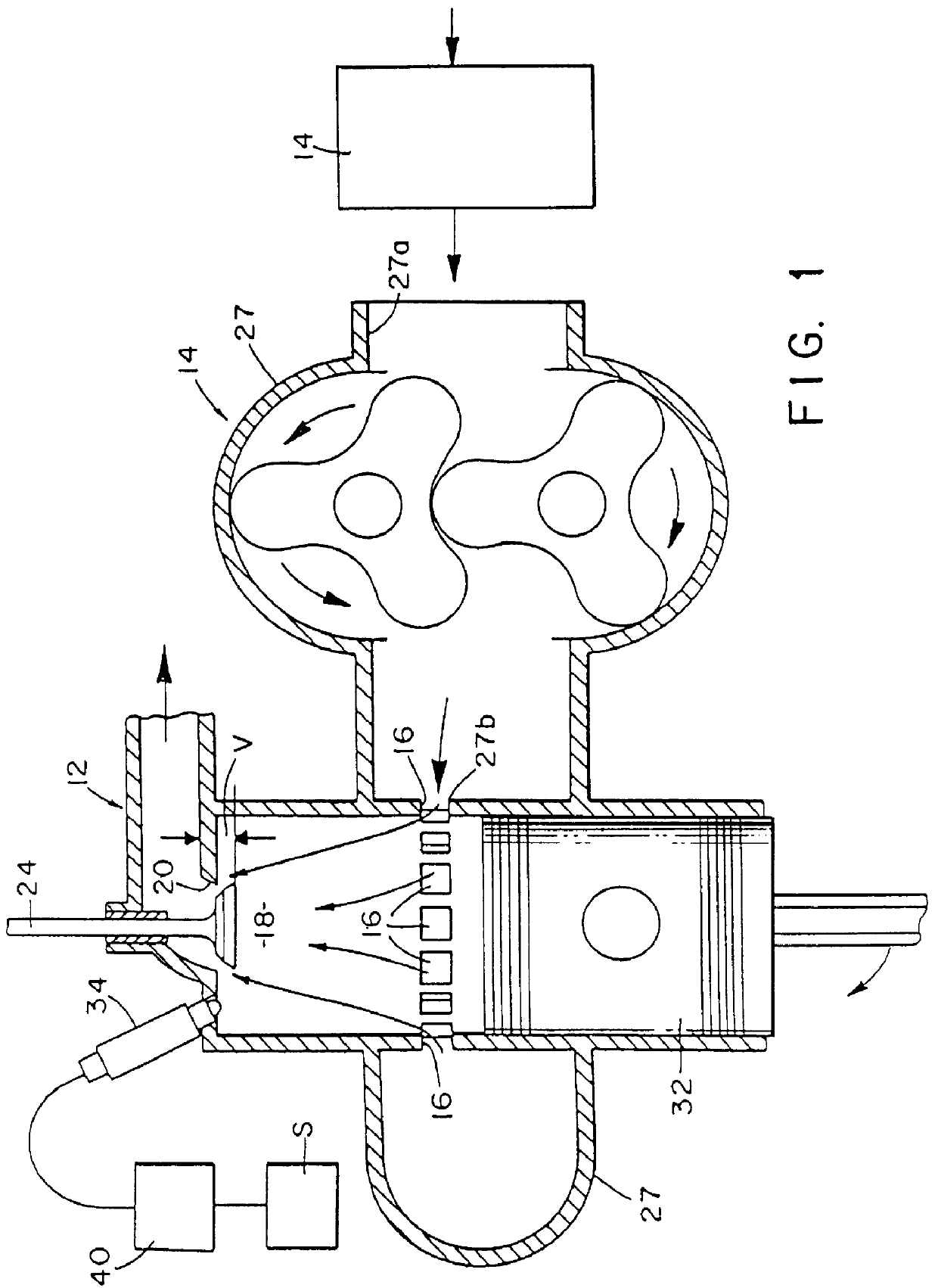

Low emission power plant and method of making same

InactiveUS6101989AReduce the amount of solutionLower than normal exhaust valve liftNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesCombustion chamber

A low emission power generating apparatus which comprises a modified two-stroke diesel engine component and a modified turbocharger component which has a relatively low aspect ratio. The diesel engine component is a modification of a conventional two-stroke diesel engine design and includes an exhaust valve cam of unique design that has a cam profile which results in a later than-normal exhaust valve opening and an earlier-than-normal valve closing so that the time during which the exhaust valve remains open is shorter than normal, thereby causing a substantially greater volume of residual gases to remain in the combustion chamber following the scavenge stroke. This increase in the volume of the residual exhaust gases within the chamber leads to an increase in compression temperature and effectively increases the compression ratio and consequently the compression pressure. Because of the heat absorption capacity of these residual exhaust gases, the exhaust gases remaining in the chamber following the scavenge stroke tend to absorb combustion heat and thereby effectively reduce the peak combustion temperature. This reduction in peak combustion temperature advantageously results in the lower than normal formation of nitrogen oxide (NOx) and, therefore, allows advancement of the injection timing, while still maintaining the NOx emissions coming from the engine lower than those legislatively mandated. Advantageously, the advance in injection timing, which increases NOx emissions, by definition has the effect of also reducing particulate matter emissions. Thus, by increasing the volume of residual exhaust gases within the cylinder, substantial particulate matter emission reductions can be achieved, while at the same time maintaining NOx emissions well below mandated limits. The modified turbocharger component provides an additional charge of oxygen-rich air into the combustion chamber which effectively increases the compression pressure, which, in turn, leads to an earlier start of combustion because of the combustible mixture reaching its auto-ignition temperature at an earlier point in the cycle. This phenomenon leads to more thorough combustion of the fuel and also generally leads to higher exhaust temperatures. Higher exhaust temperatures, in turn, lead to a greater oxidation rate of the soluble organic fraction thus lowering the level of emission from the engine of undesirable particulate matter.

Owner:CLEAN CAM TECH SYST

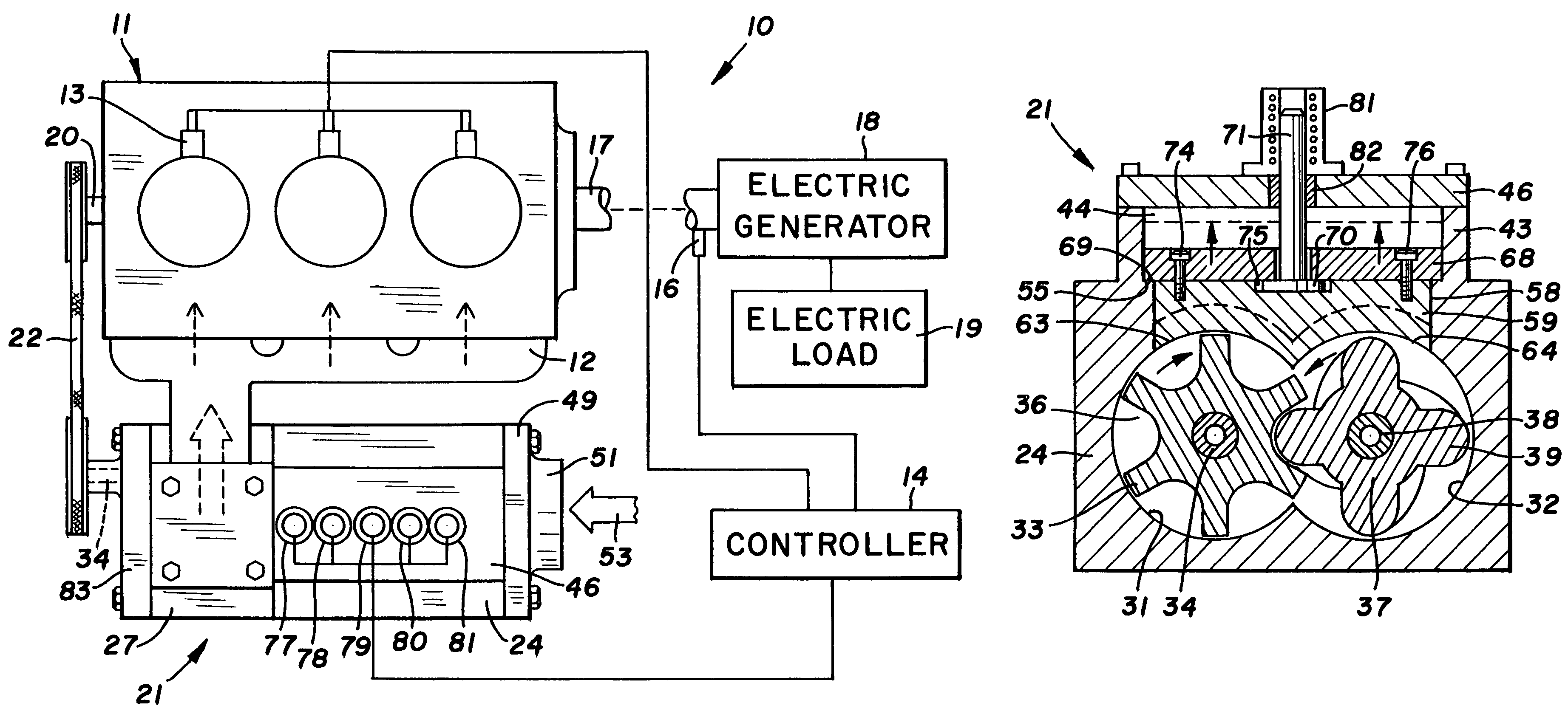

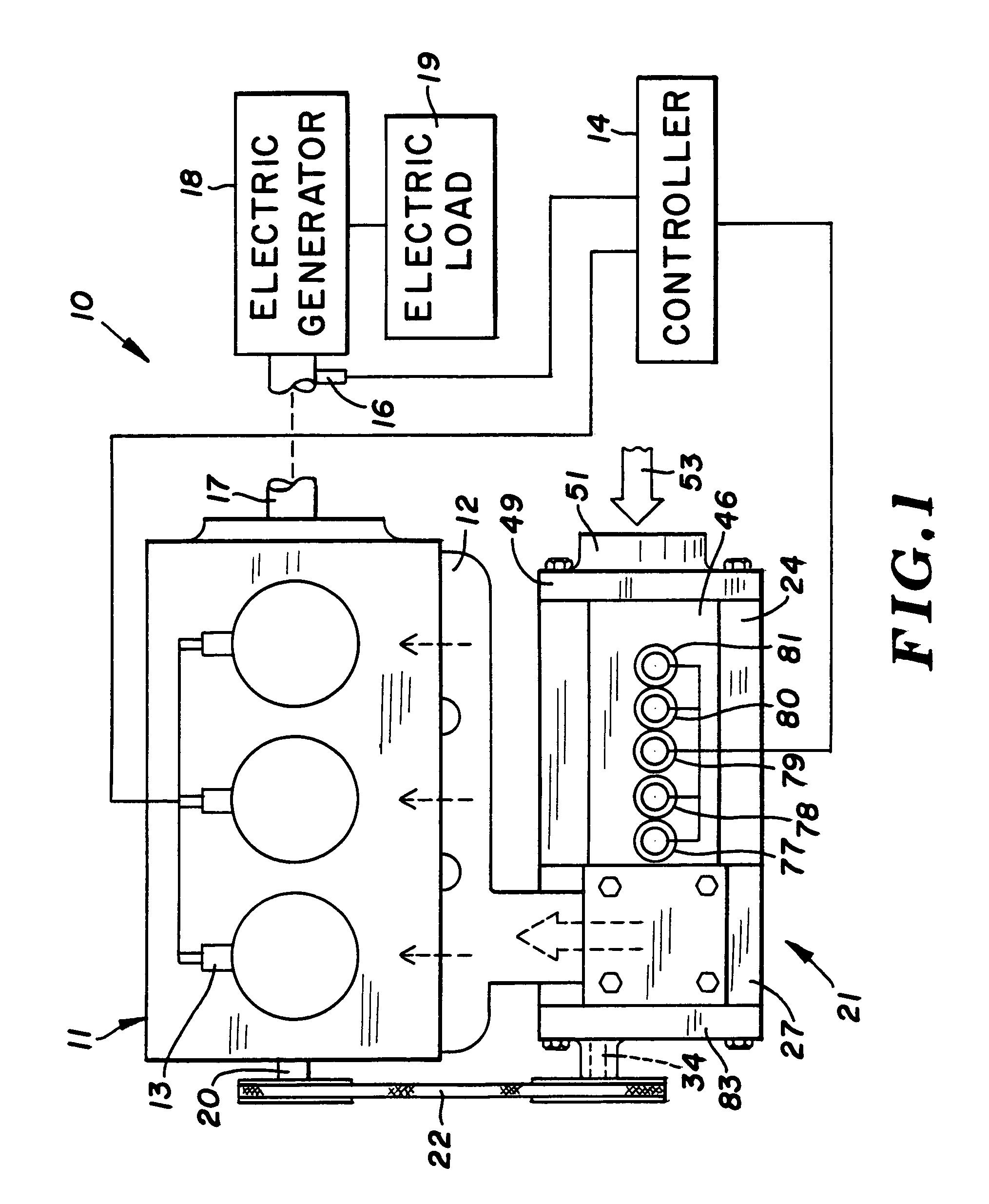

Diesel engine and supercharger

InactiveUS7726285B1Facilitate cold startingLow parasitic lossRotary/oscillating piston combinations for elastic fluidsElectrical controlTwo-stroke diesel engineDiesel engine

A four stroke diesel engine combined with a supercharger is operable to supply varying amounts of air to the engine responsive to the load on the engine. The supercharger has a pair of rotors driven by the engine operable to move air to the engine. Gates associated with the rotors control the amount of air and pressure of the air moved by the rotors to the diesel engine.

Owner:HANSEN ENGINE

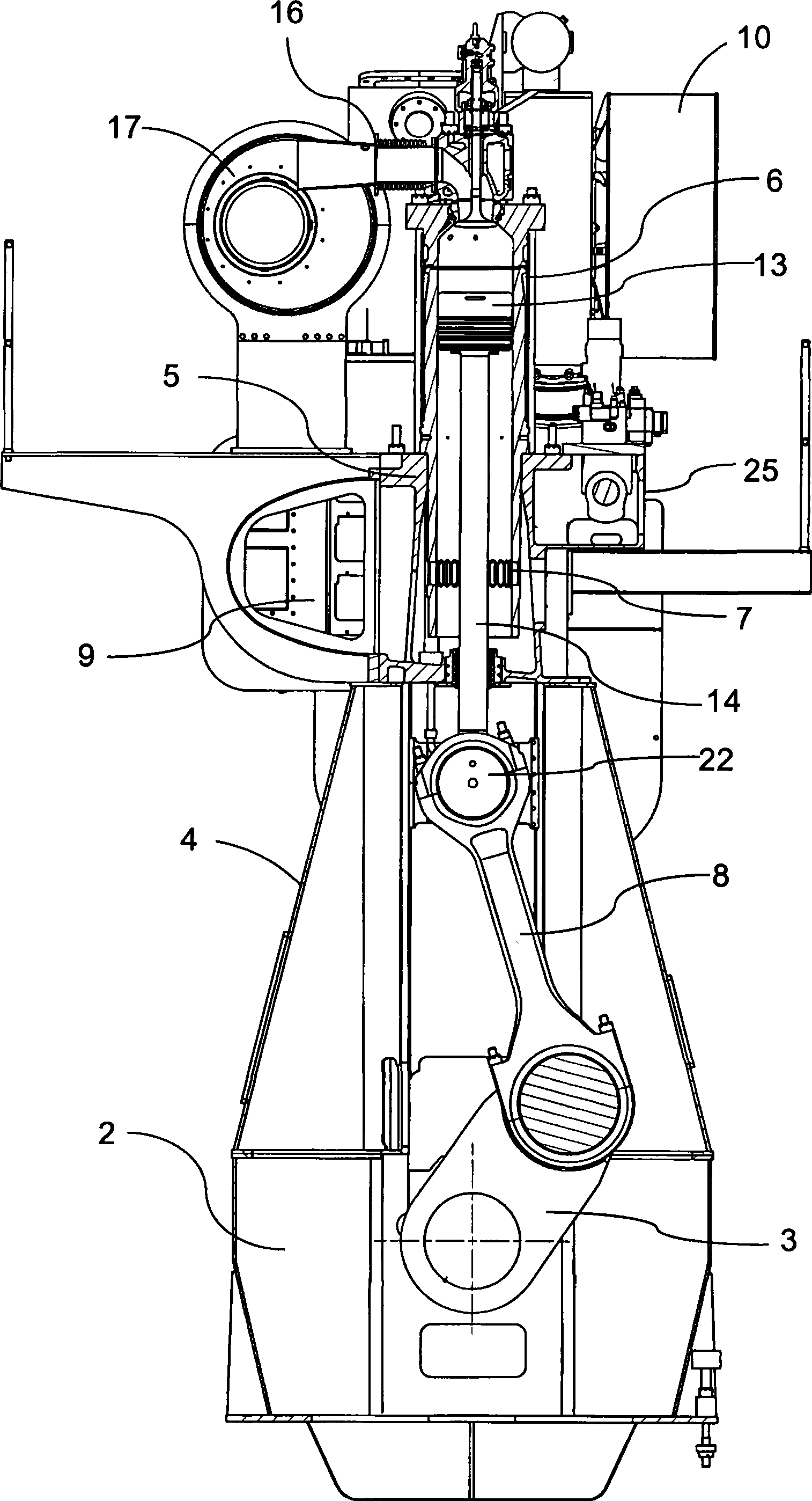

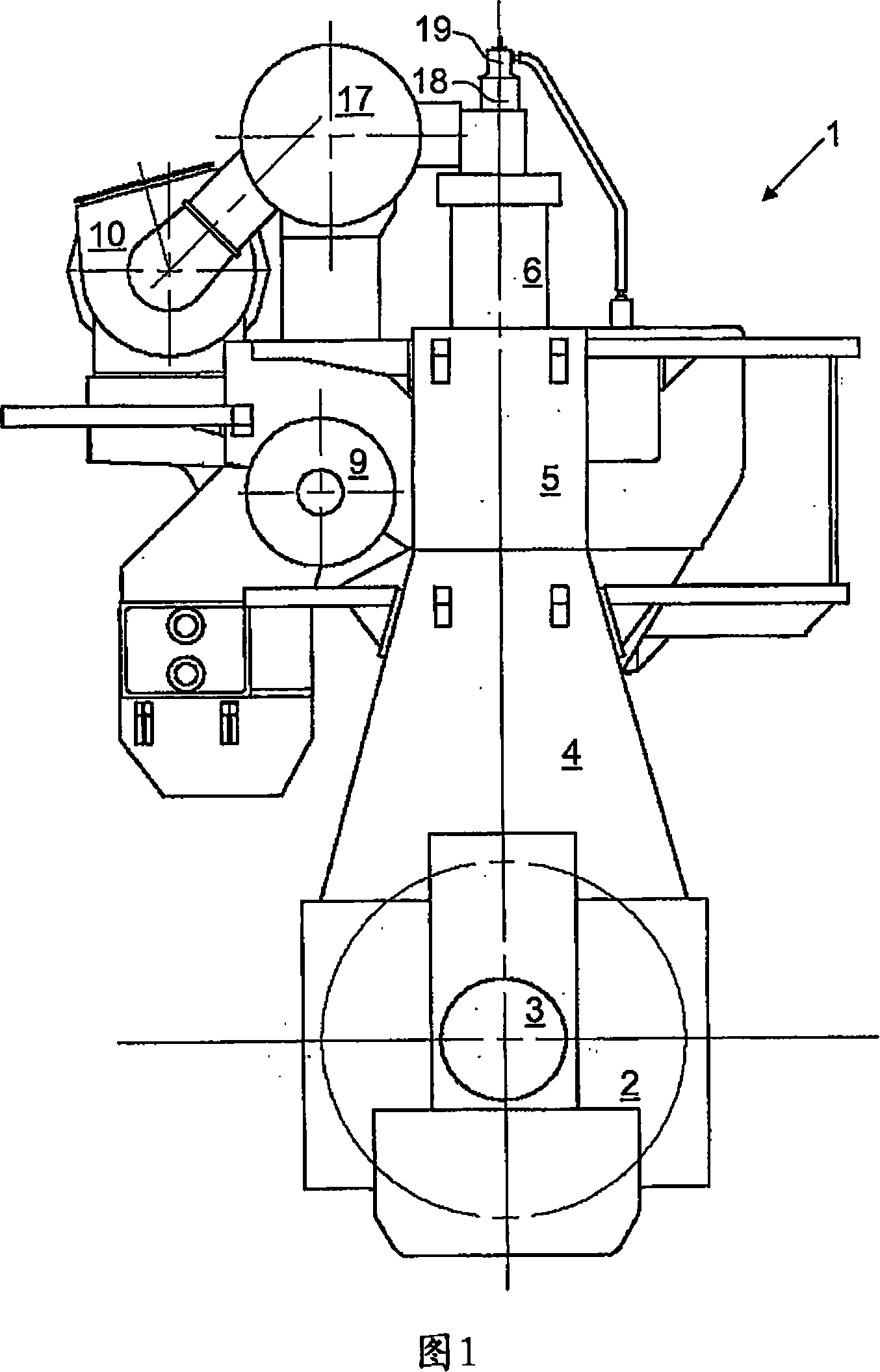

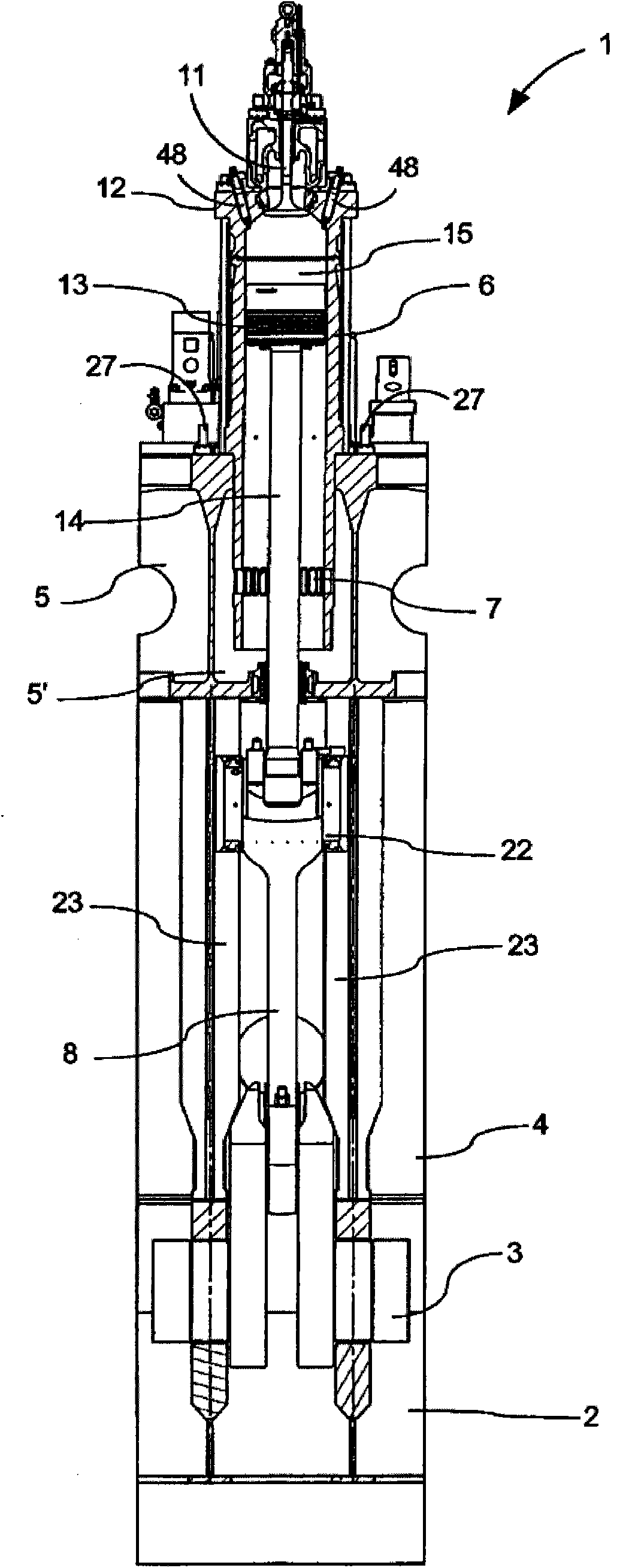

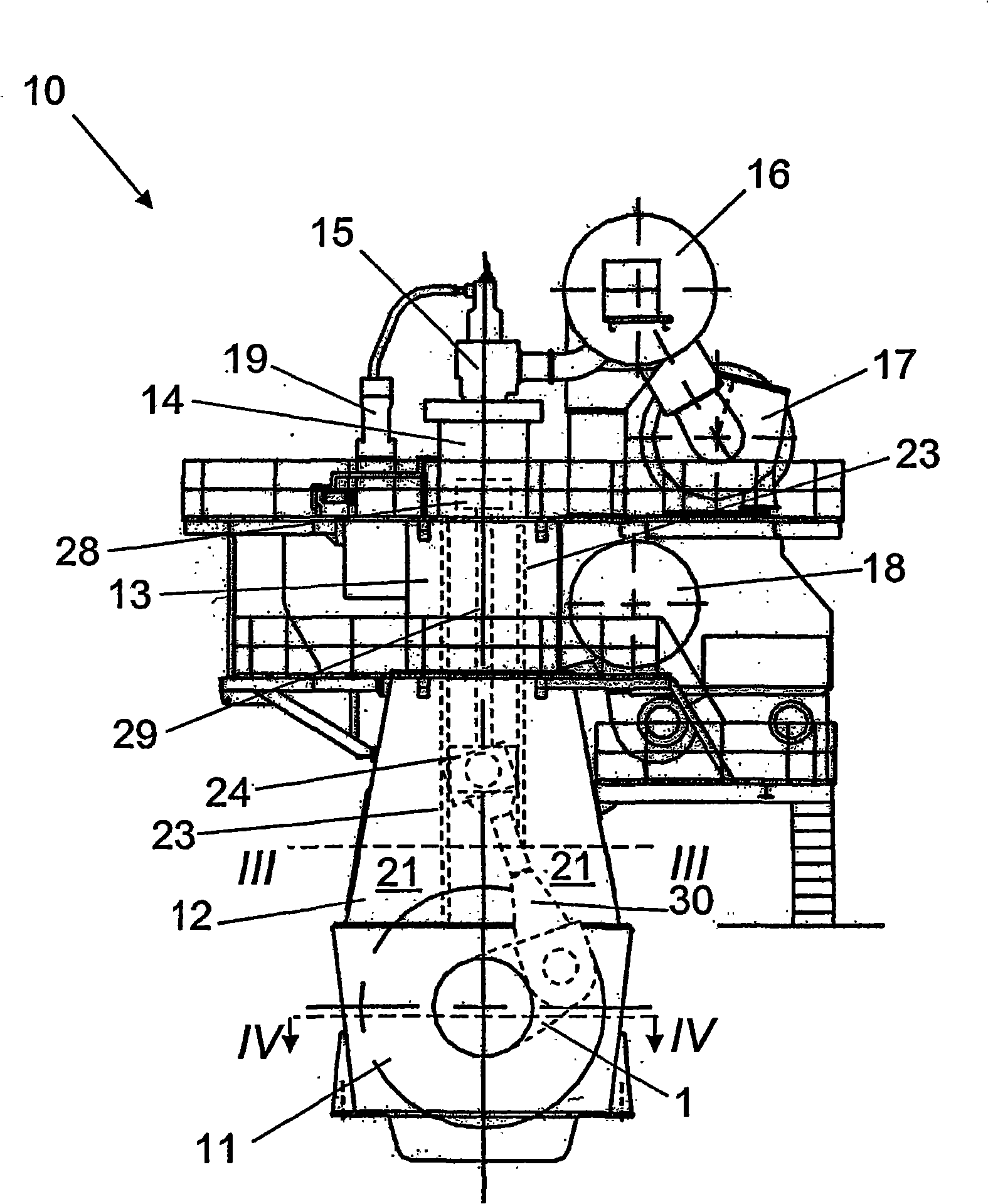

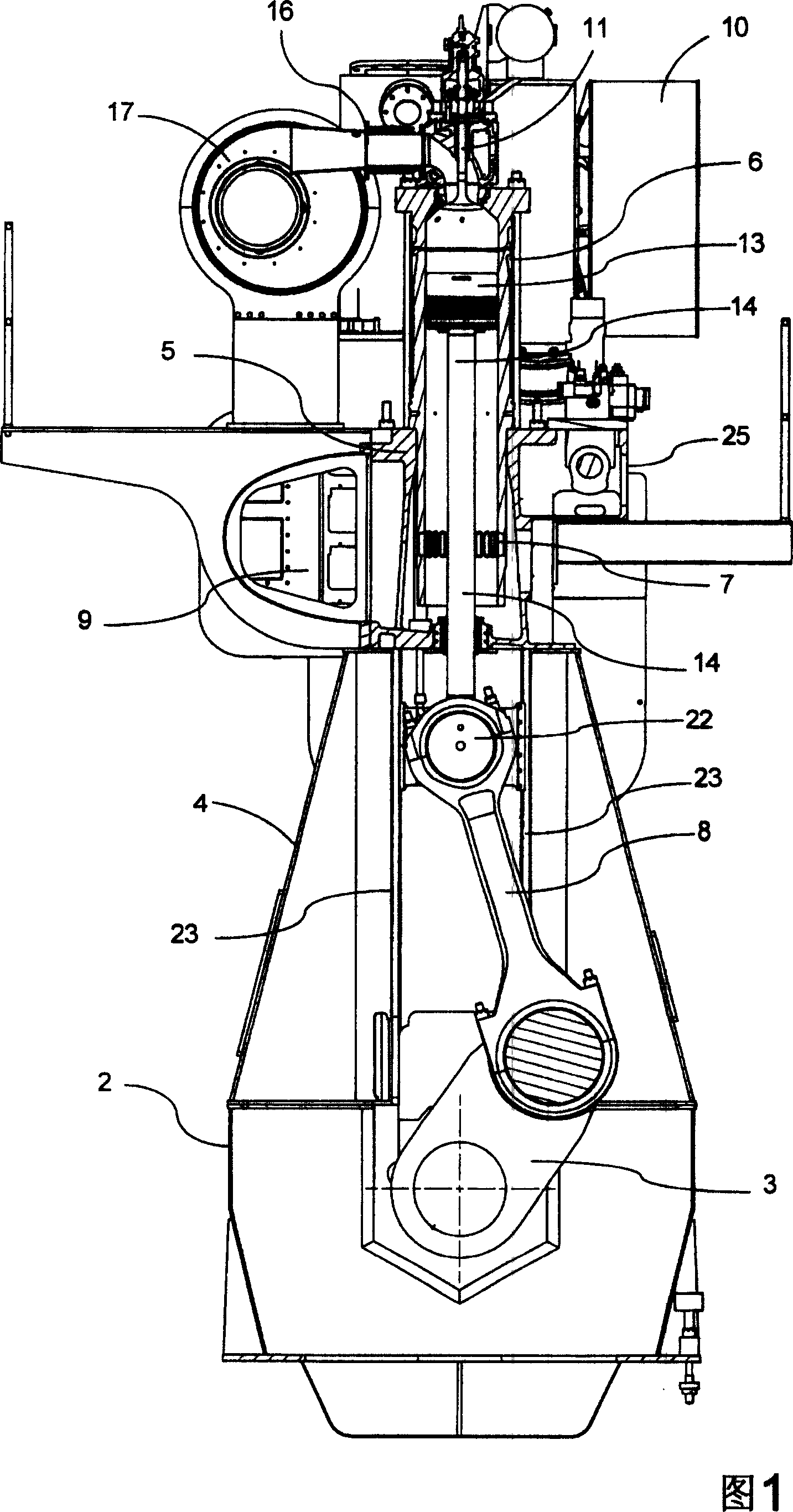

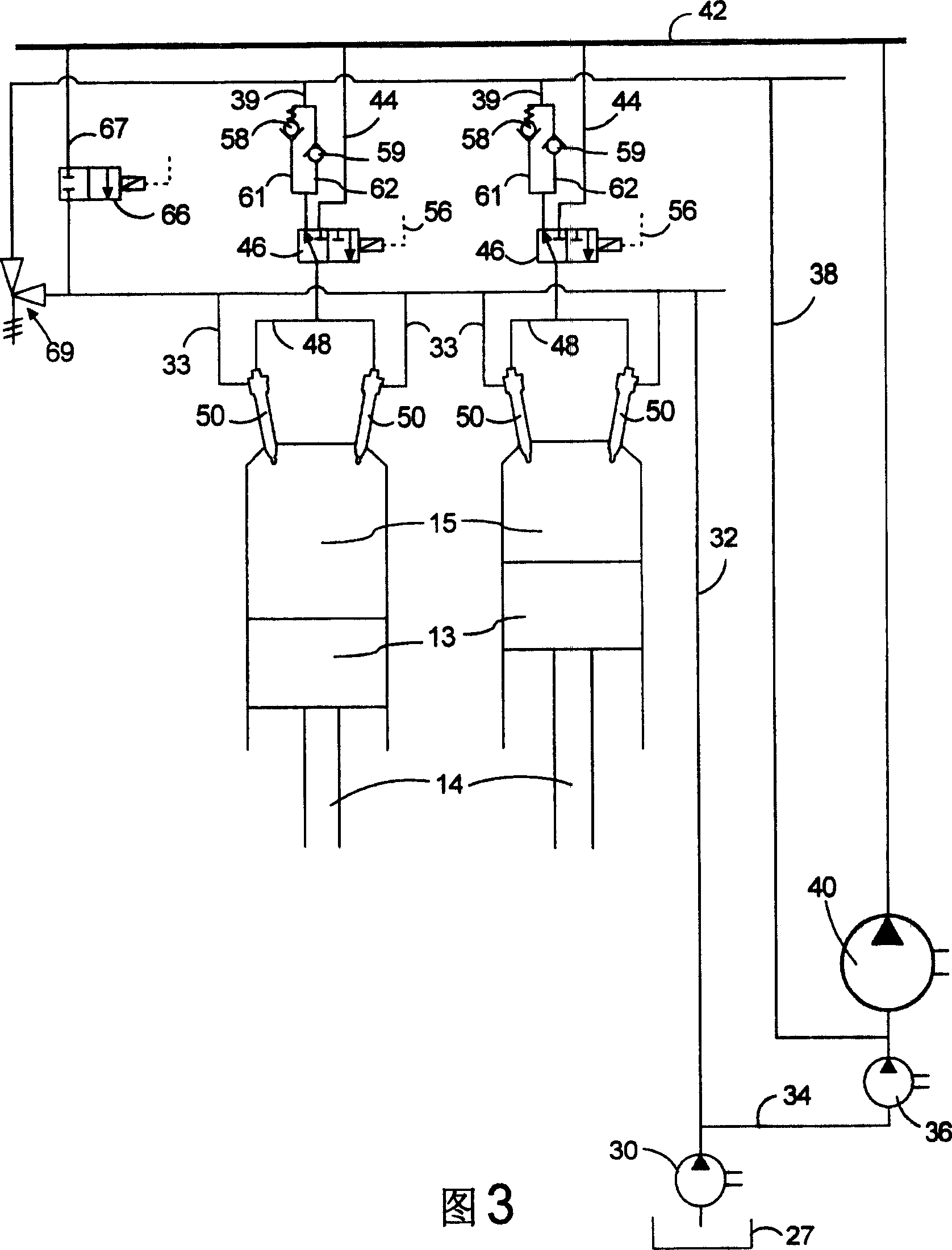

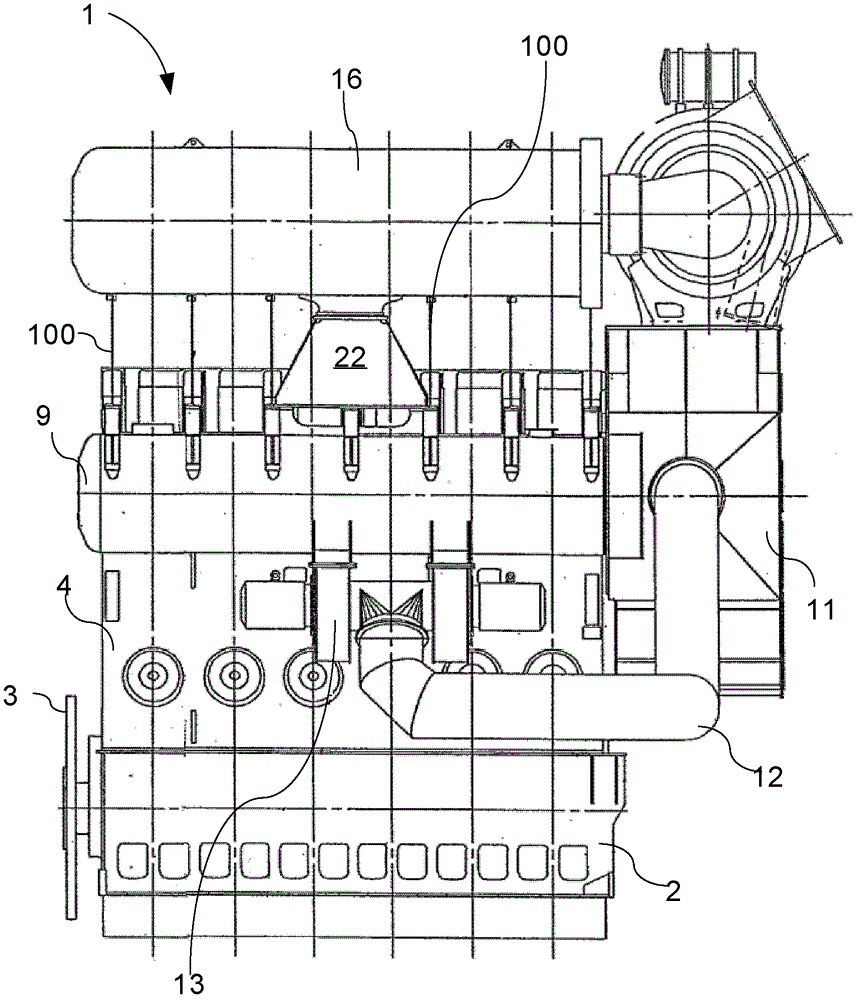

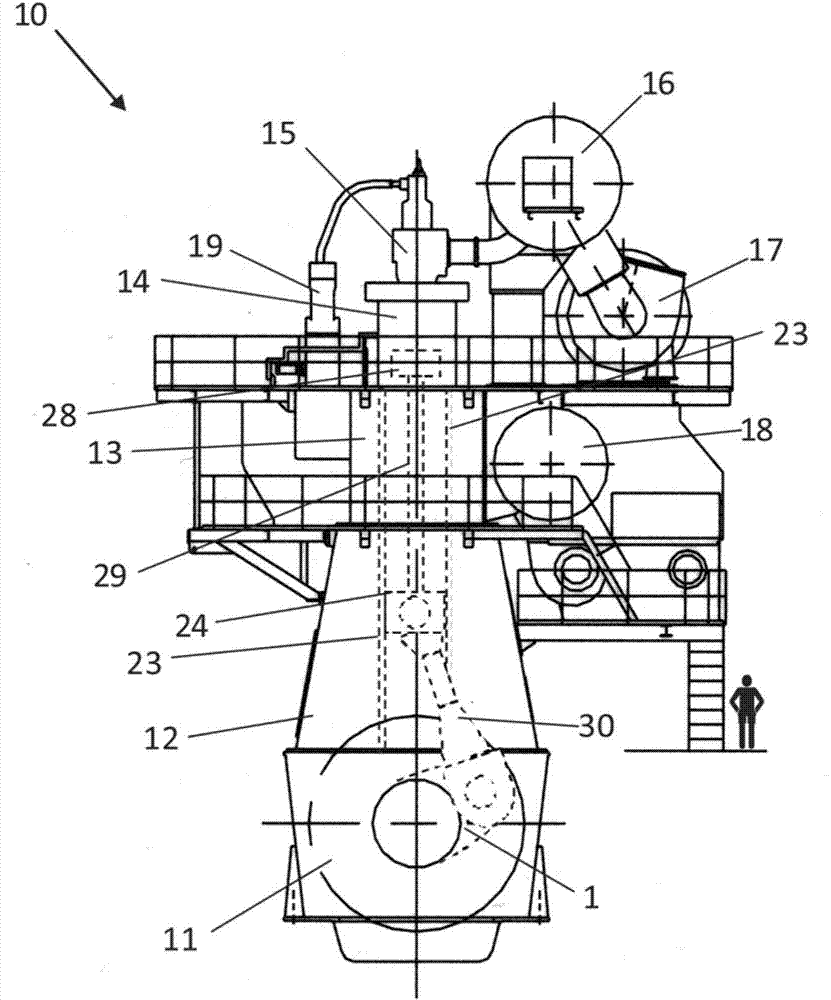

Crosshead type large-sized uniflow type two-stroke diesel motor

ActiveCN101415936ALow costReduce hydraulic power requirementsCasingsInternal combustion piston enginesExhaust valveHydraulic pump

A large uniflow two-stroke diesel engine of the crosshead type with a plurality of cylinders with at least one exhaust valve (11) per cylinder and one or more fuel injectors (23) per cylinder. The fuel injection is performed under the influence of a source of high-pressure fluid. Potential energy is accumulated by compression in a volume (67) of the high-pressure fluid. Electro-hydraulic valves (39) control the fuel injection that is primarily driven by energy accumulated in the volume (67) of high pressure. The engine has a camshaft (28) for actuation of the exhaust valves (11). Hydraulic piston pumps (37) are driven by the cams (29) on the camshaft. Hydraulic actuators (21) move the exhaust valves (11) in the opening direction with hydraulic fluid received via conduits from the hydraulic piston pumps (37) .

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

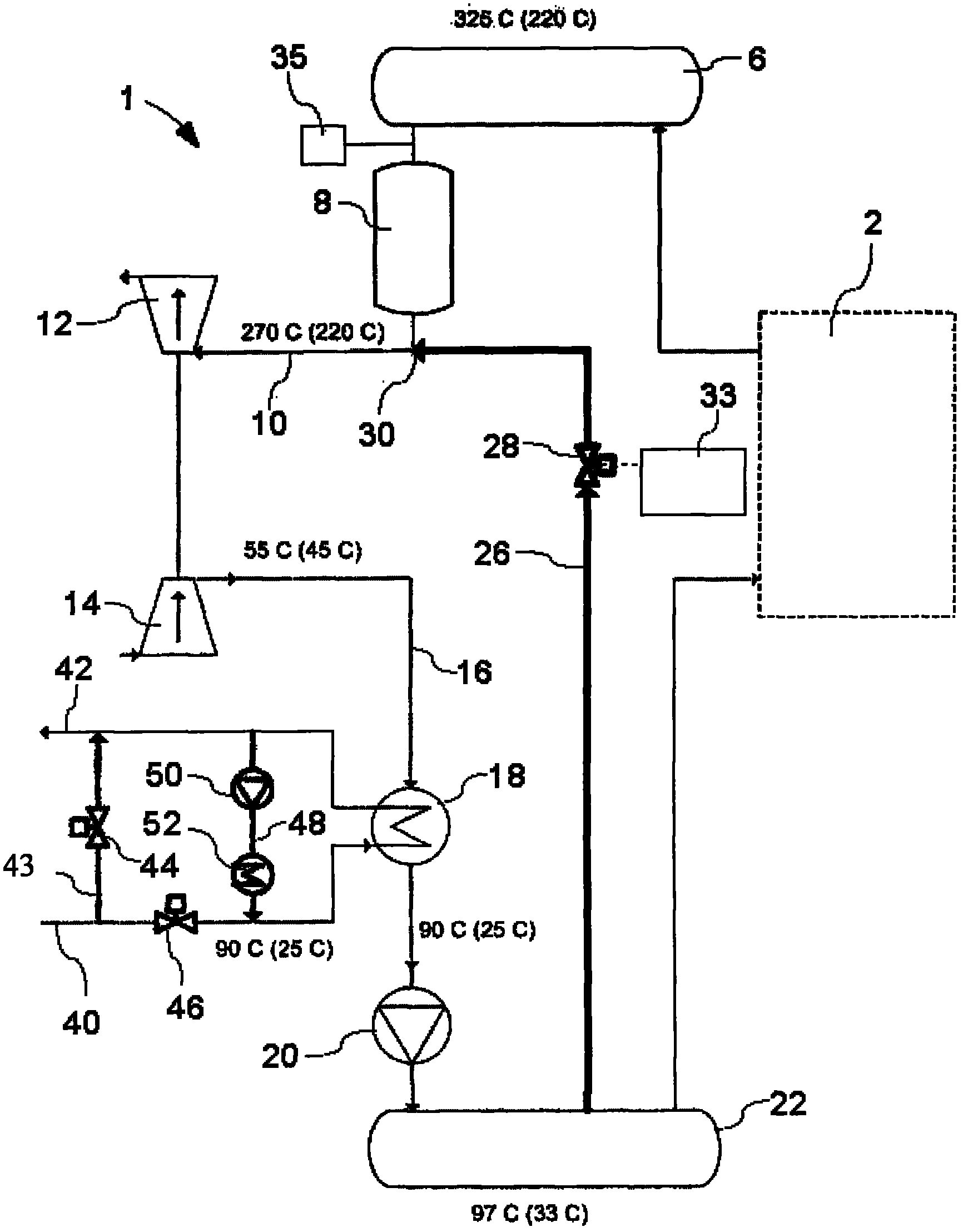

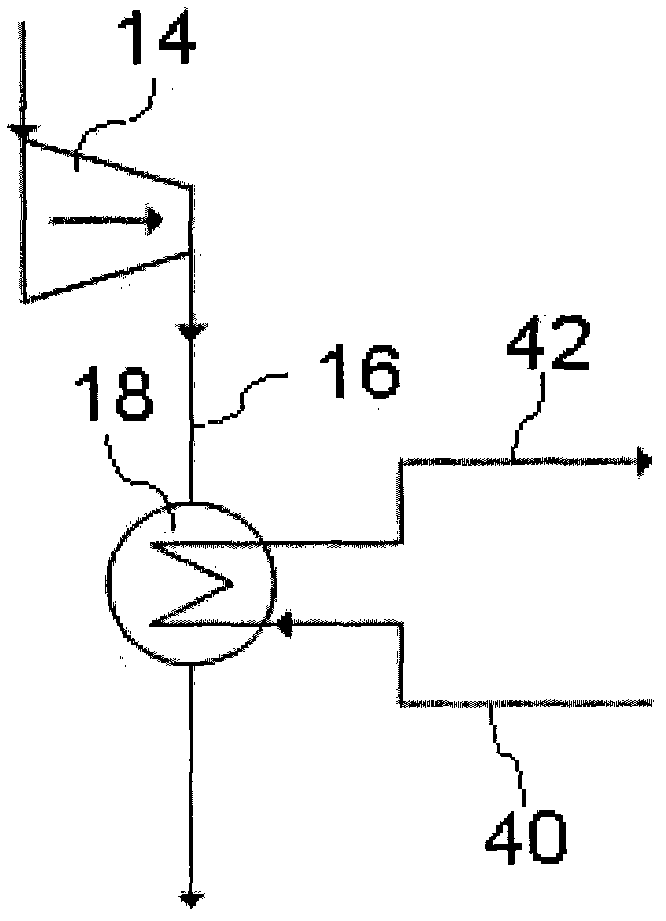

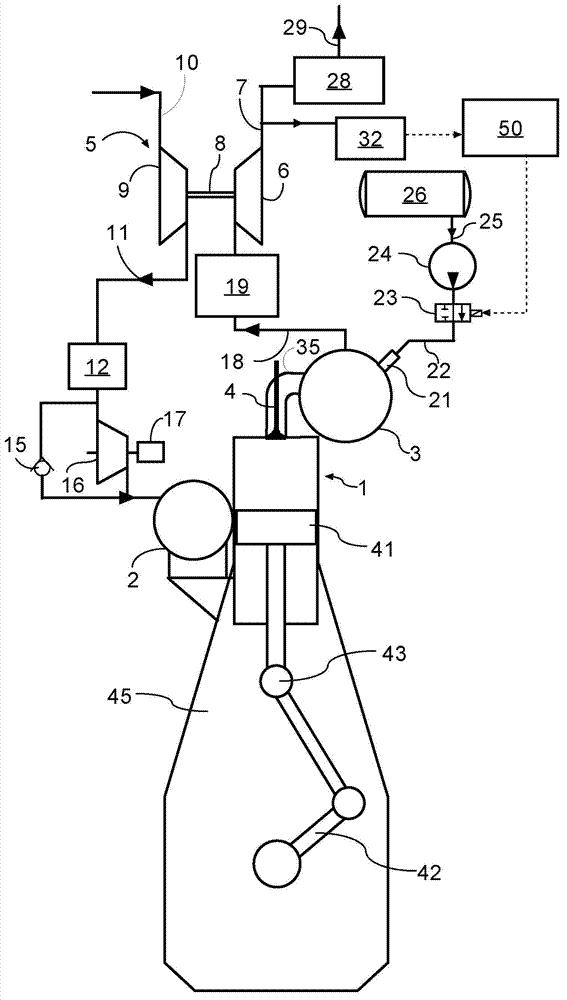

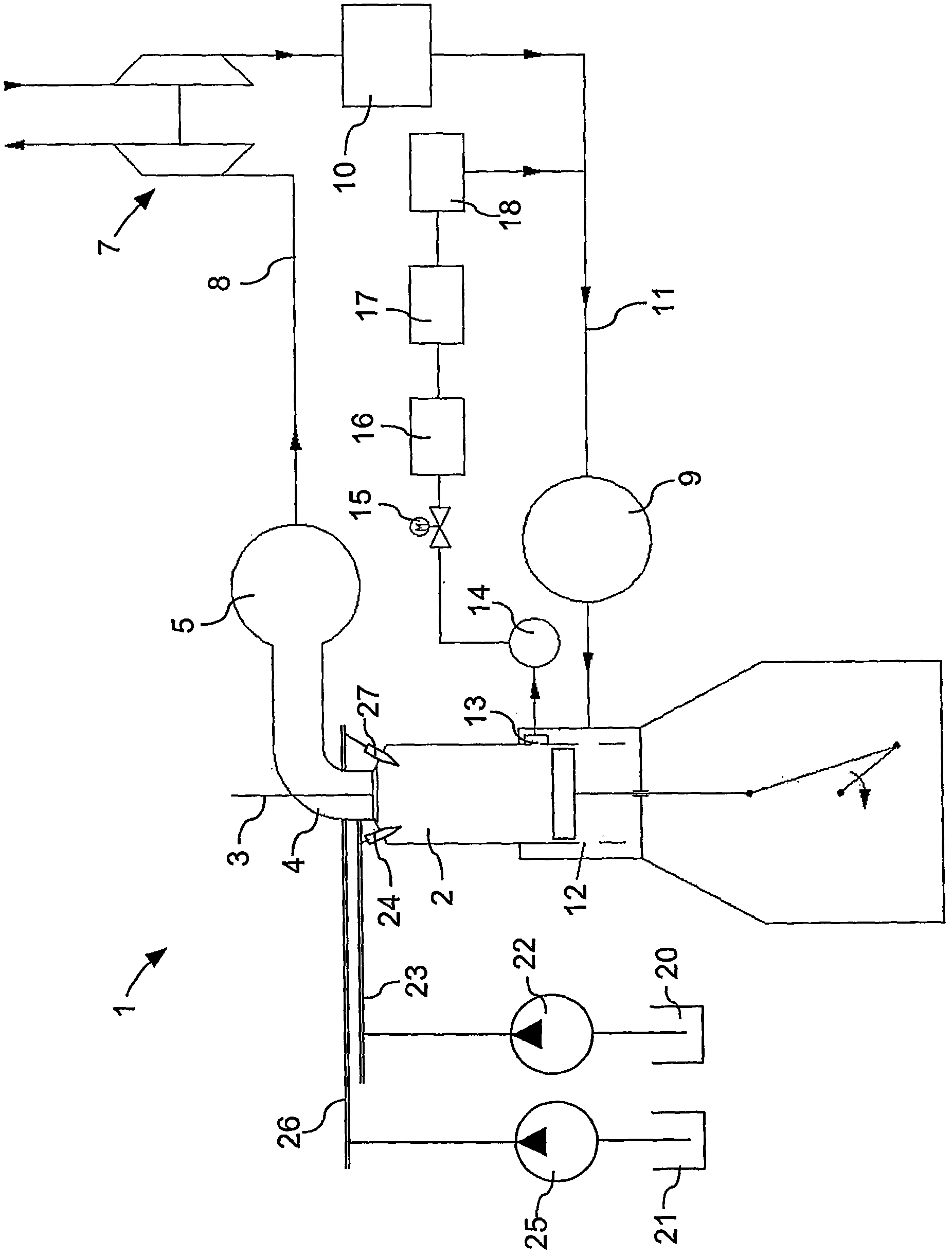

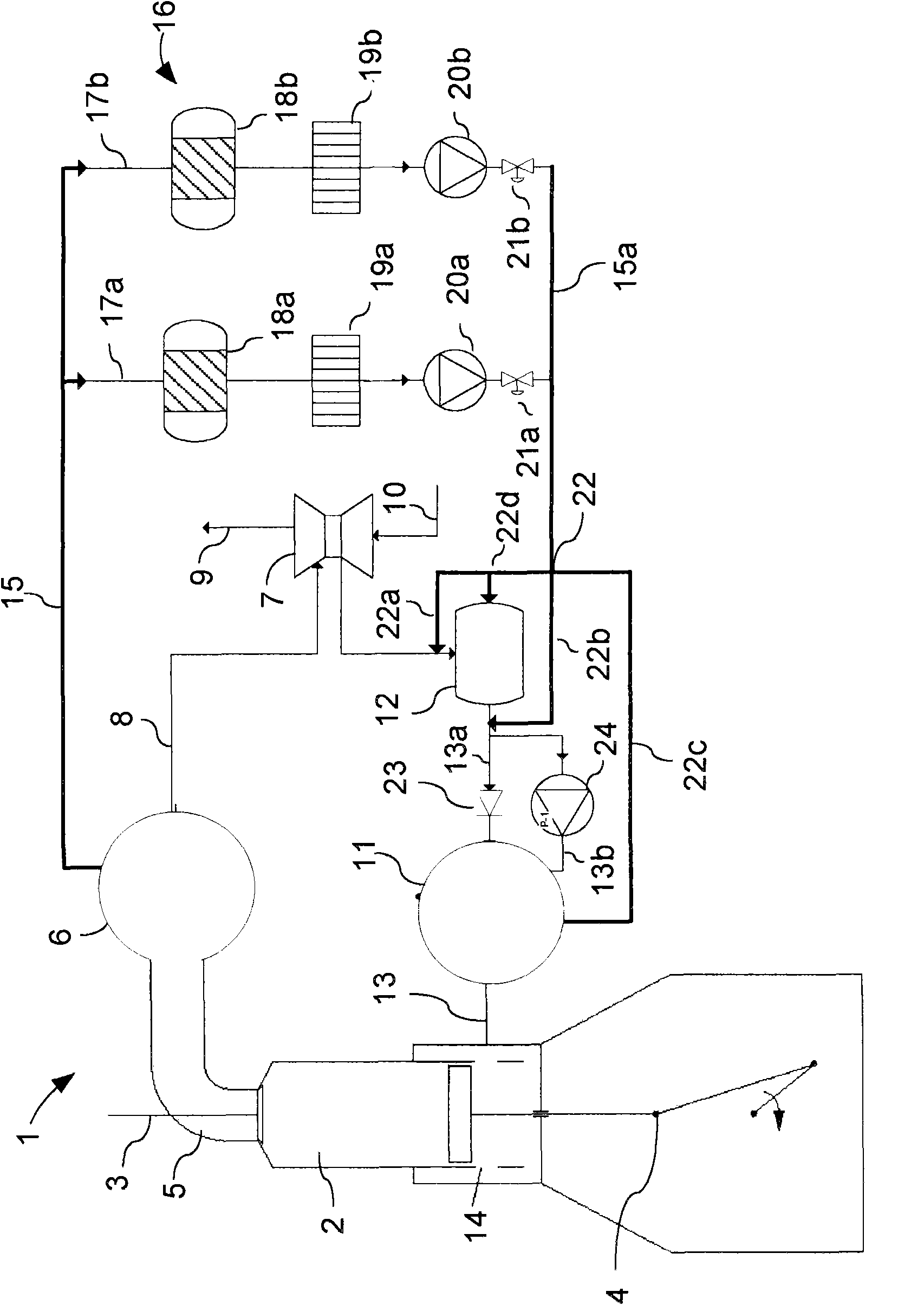

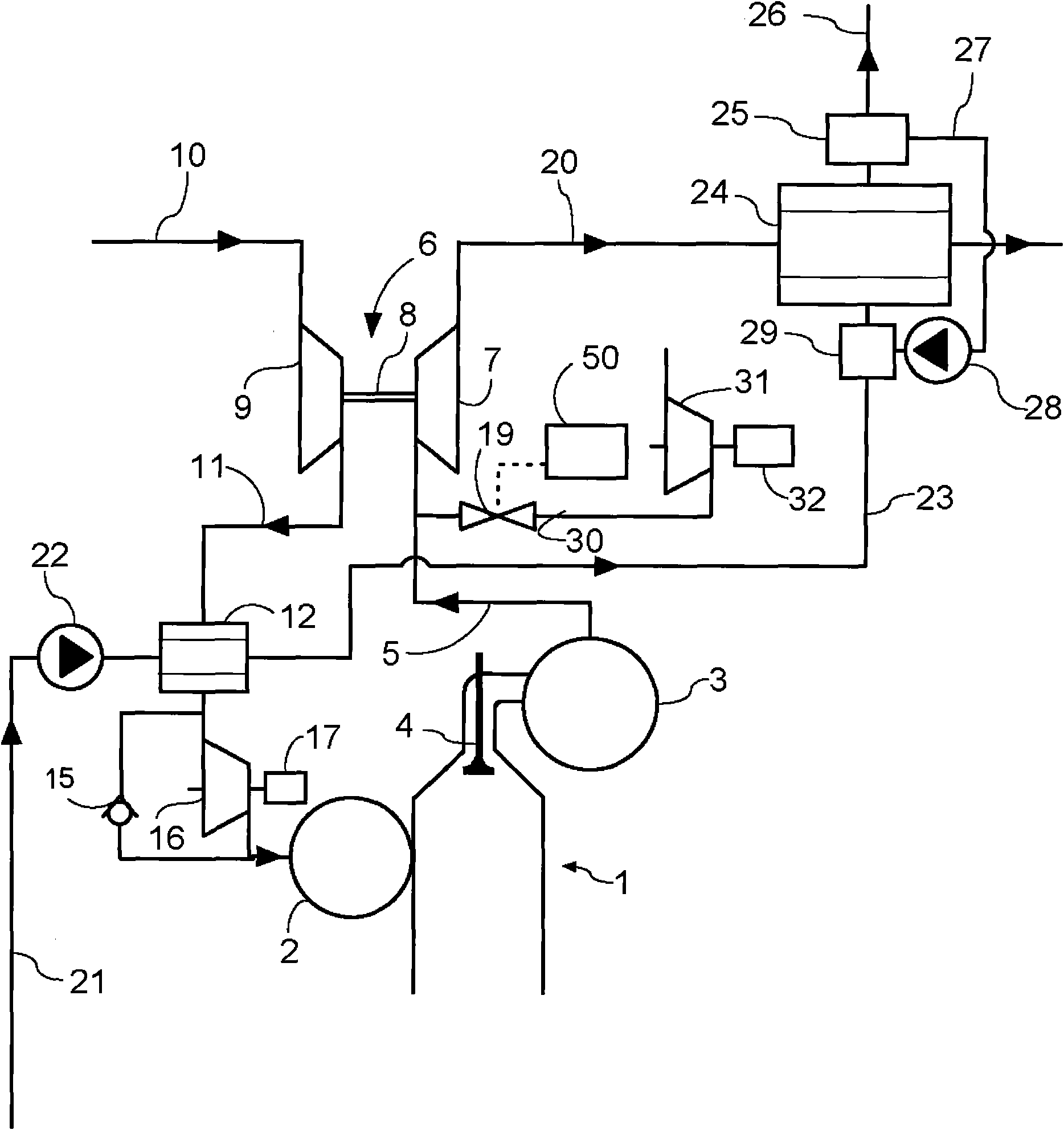

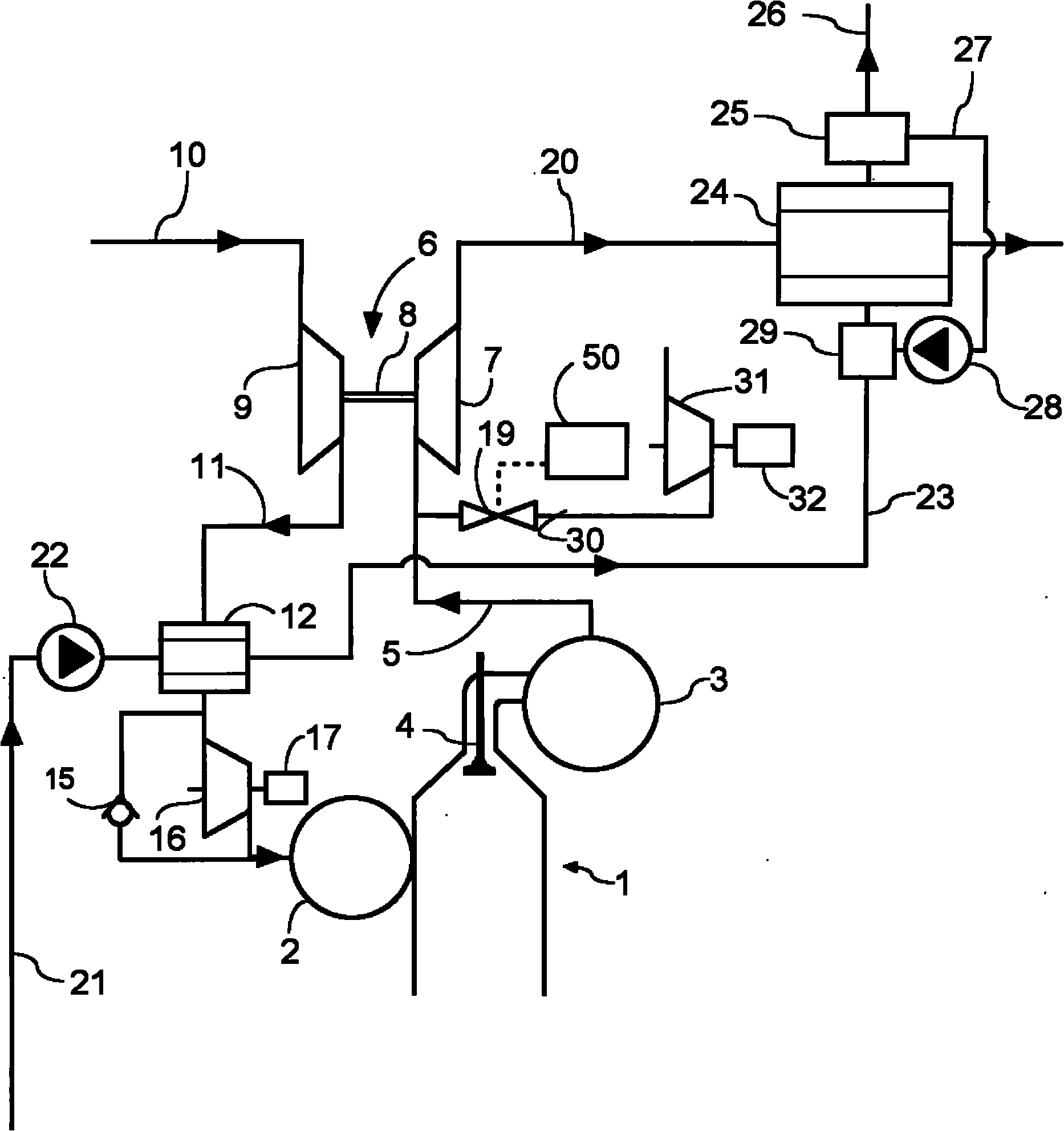

Large two-stroke diesel engine with exhaust gas recirculation system

ActiveCN102140978AExhaust purificationExtended service lifeNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringExhaust gas recirculation

The invention relates to a large two-stroke diesel engine with a exhaust gas recirculation system. In particular, the invention relates to a large crosshead turbocharged two-stroke diesel engine, which comprises a plurality of cylinders, each of which is connected to an exhaust gas receiver, and an exhaust gas recirculation flow channel for supplying a part of the exhaust gas to a scavenging air flow, and also comprises a wet scrubber, a cooler, a device for removing condensed water, and a blower in the exhaust gas recirculation flow channel. The invention also relates to a method for the exhaust gas recirculation in the large crosshead turbocharged two-stroke diesel engine, wherein the engine comprises a plurality of cylinders, each of which is connected to an exhaust gas receiver.

Owner:曼恩柴油机涡轮公司,曼恩柴油机涡轮德国公司子公司

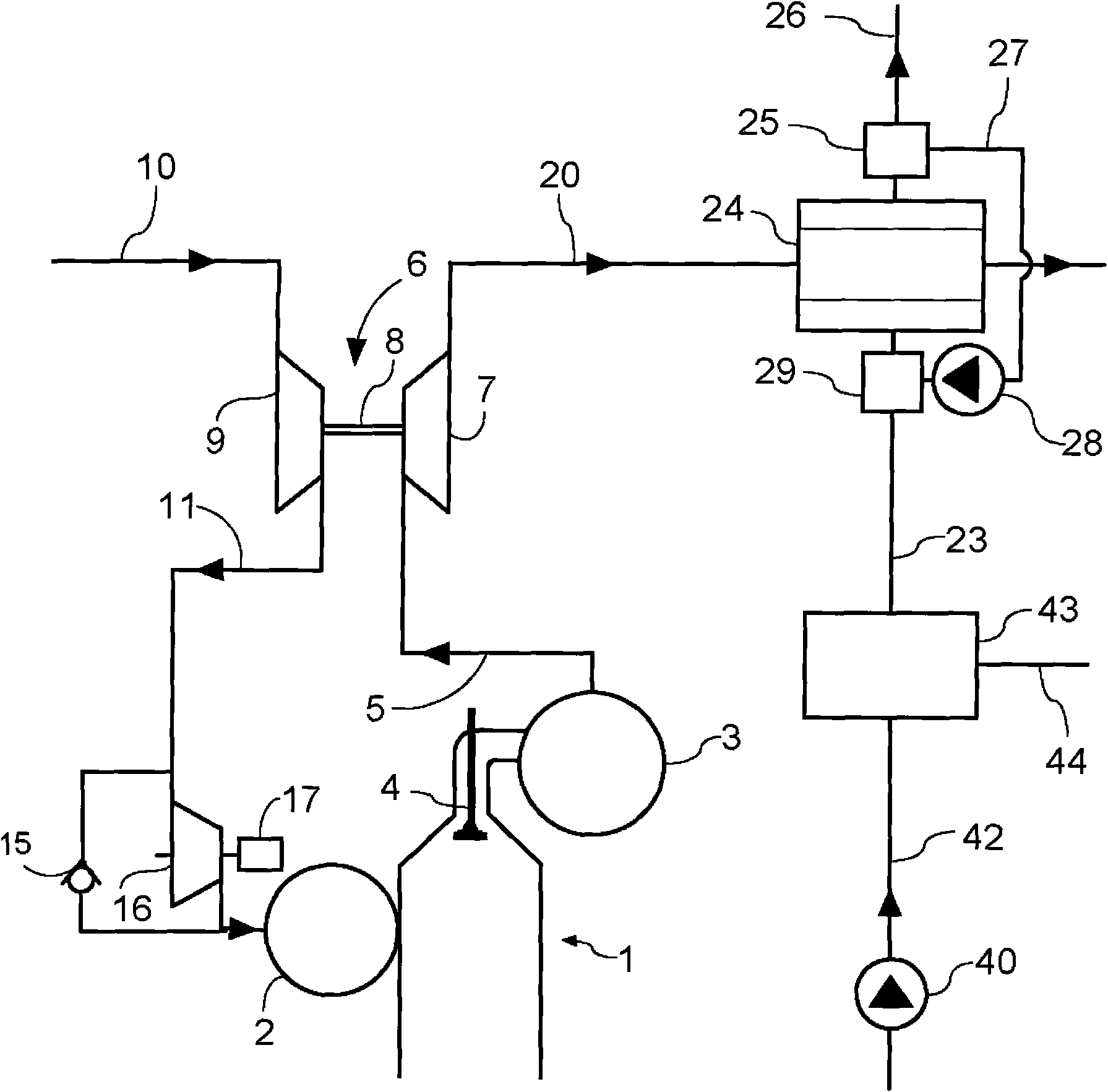

Large-sized two-stroke diesel engine having exhaust gas purifying system

ActiveCN102242670AReduce or disable coolingElectrical controlInternal combustion piston enginesTurbochargerLow load

The invention relates to a crosshead type large-sized turbocharging two-stroke internal combustion engine, which comprises a plurality of cylinders. Each cylinder is connected to an exhaust gas receiver. A selective catalytic reduction reactor is arranged on the downstream of the exhaust gas receiver. The outlet of the selective catalytic reduction reactor is connected to a turbine of a turbocharger through an exhaust pipe. The turbine drives a compressor of the turbocharger. The compressor sends scavenging air through a scavenging air path to a scavenging air receiver which is connected to the plural cylinders. An auxiliary blower on the scavenging air path assists the compressor in a low-load condition. A controllable bypass pipeline extends from the scavenging air receiver to the exhaust pipe. In a low engine load condition, controlled scavenging air flow is guided from the scavenging air receiver to an exhaust pipe part located on the downstream of the selective catalytic reduction reactor and the upstream of the turbine of the turbocharger. The above-mentioned measure makes the temperature of the exhaust gas entering the selective catalytic reduction reactor increased.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

A large turbocharged two-stroke diesel engine with exhaust gas purification

ActiveCN103161548AInternal combustion piston enginesExhaust apparatusTurbochargerExhaust gas recirculation

The invention provides a large two-stroke diesel engine with a cross head, wherein the engine comprises: a plurality of inline cylinders (1), a turbocharger (5) and an SCR reactor (19). The SCR reactor (19) is arranged on upstream of the turbocharger and downstream of an exhaust gas receiver (3). The exhaust gas receiver (3) is connected to each cylinder (3) by relative exhaust pipes, and an outlet (33) is arranged on the exhaust gas receiver (3). A reducing agent is introduced into the exhaust gas receiver at an approximate upstream position at the outlet (33) of the exhaust gas receiver (3).

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

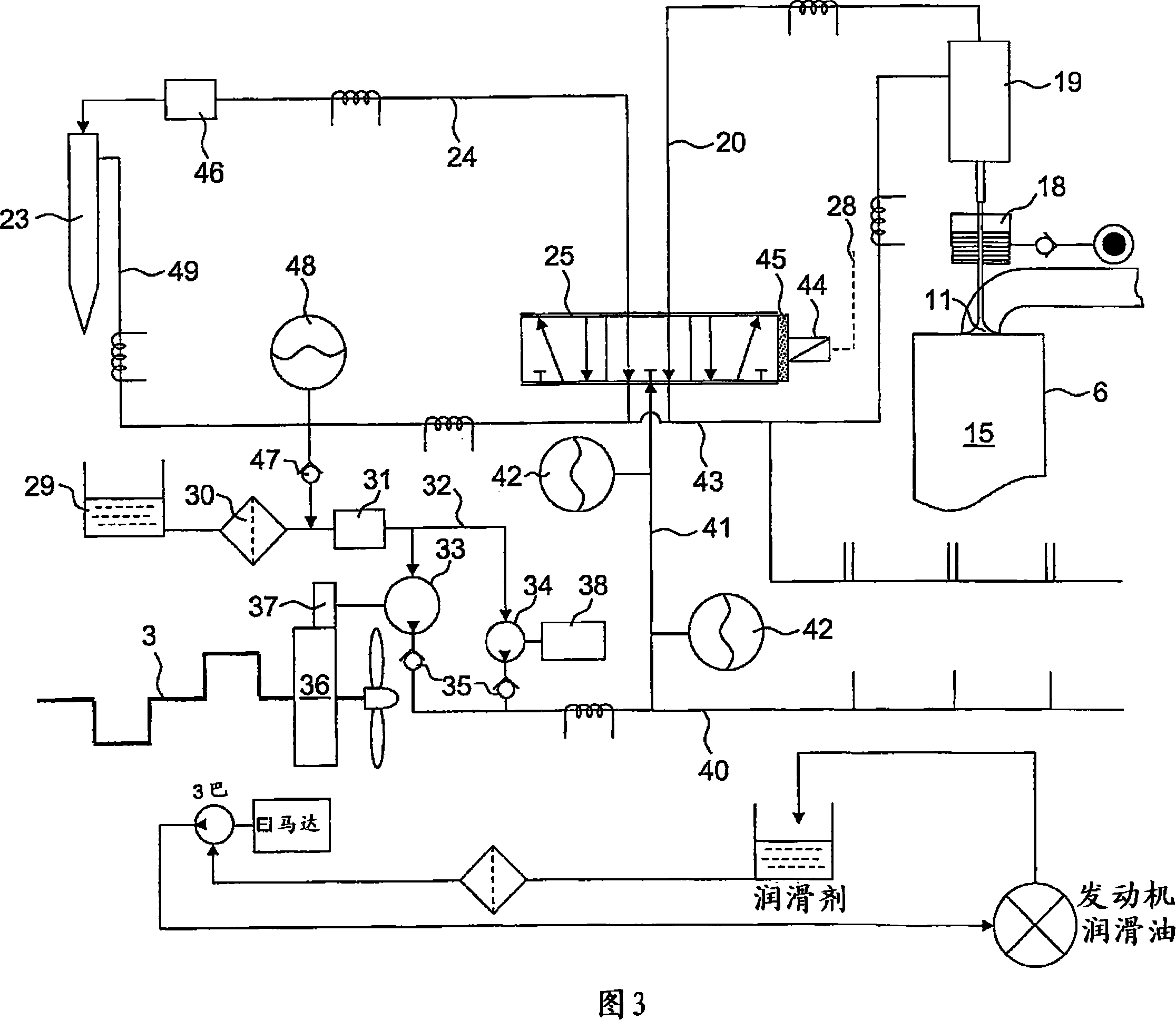

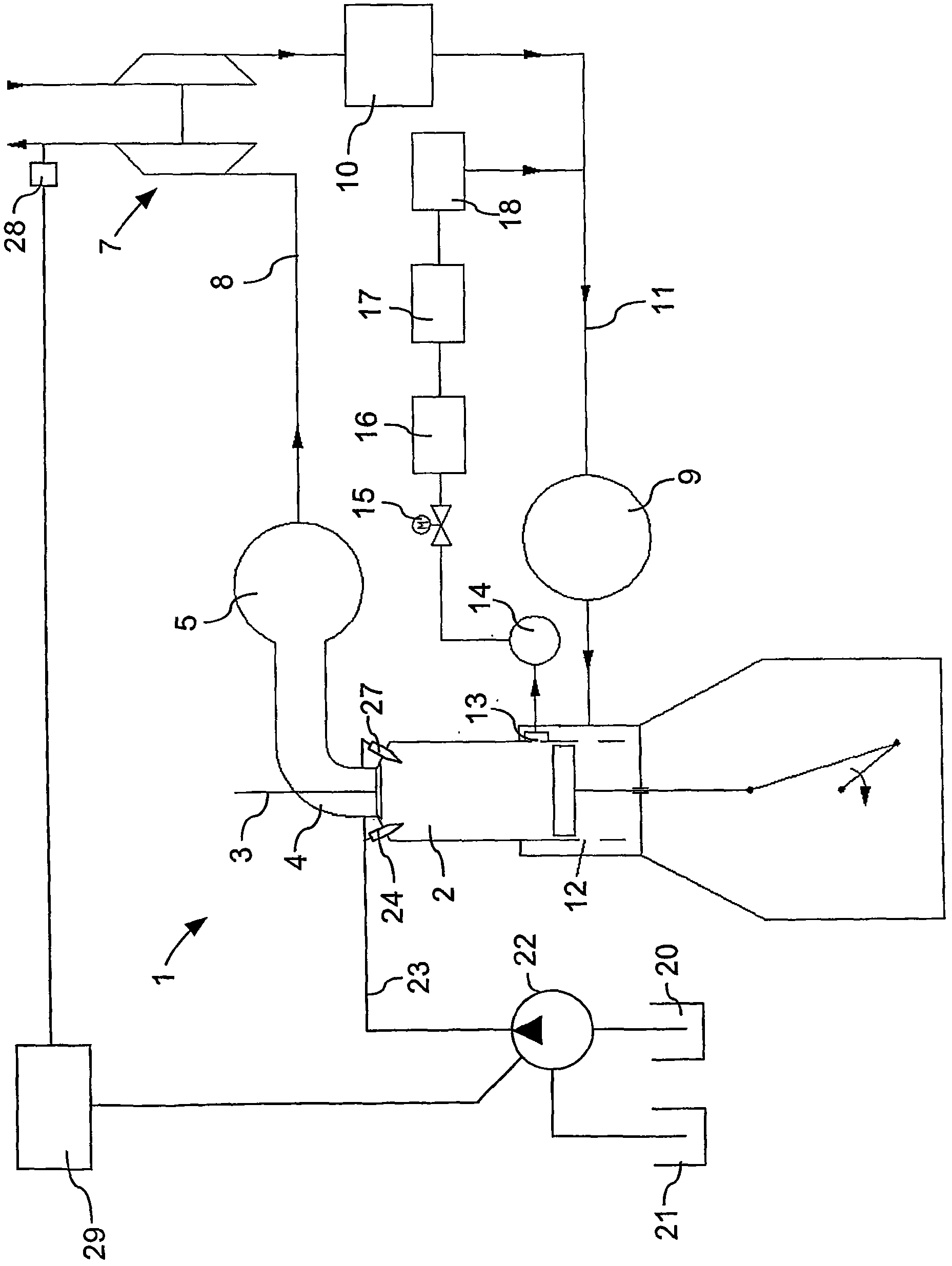

Vessel two-stroke diesel engine exhaust gas recirculation system and control method

InactiveCN104405542ASave spaceReduce volumeNon-fuel substance addition to fuelInternal combustion piston enginesGas compressorExhaust gas recirculation

The invention provides a vessel two-stroke diesel engine exhaust gas recirculation system and a control method. A work mode is a non-EGR (exhaust gas recirculation) mode and an EGR mode; when the vessel sails in a non-exhaust control region, the diesel engine works under the non-EGR mode, the exhaust gas exhausted from an exhaust manifold drives turbines to apply work so as to drive a gas compressor to compress air; the pressurized fresh air is cooled and dehumidified and then enters into the engine from a scavenging air receiver to participate in burning; when the vessel sails in an exhaust control region, the diesel engine works under the EGR mode, part of waste gas is led from the exhaust manifold and then flows to a one-way stop valve , then the waste gas is cooled and washed, so that the temperature is reduced, and the particles and SOx are removed; then, the exhaust gas is pressurized by an EGR fan and humidified by a drop catcher to mix with fresh air from the gas compressor in the scavenging air receiver, and then enters into an air cylinder to participate in burning; the NOx generation and exhaust amount of the engine are reduced, the Tier III standard related to NOx exhaust of IMO (International Meteorological Organization) can be satisfied.

Owner:HARBIN ENG UNIV

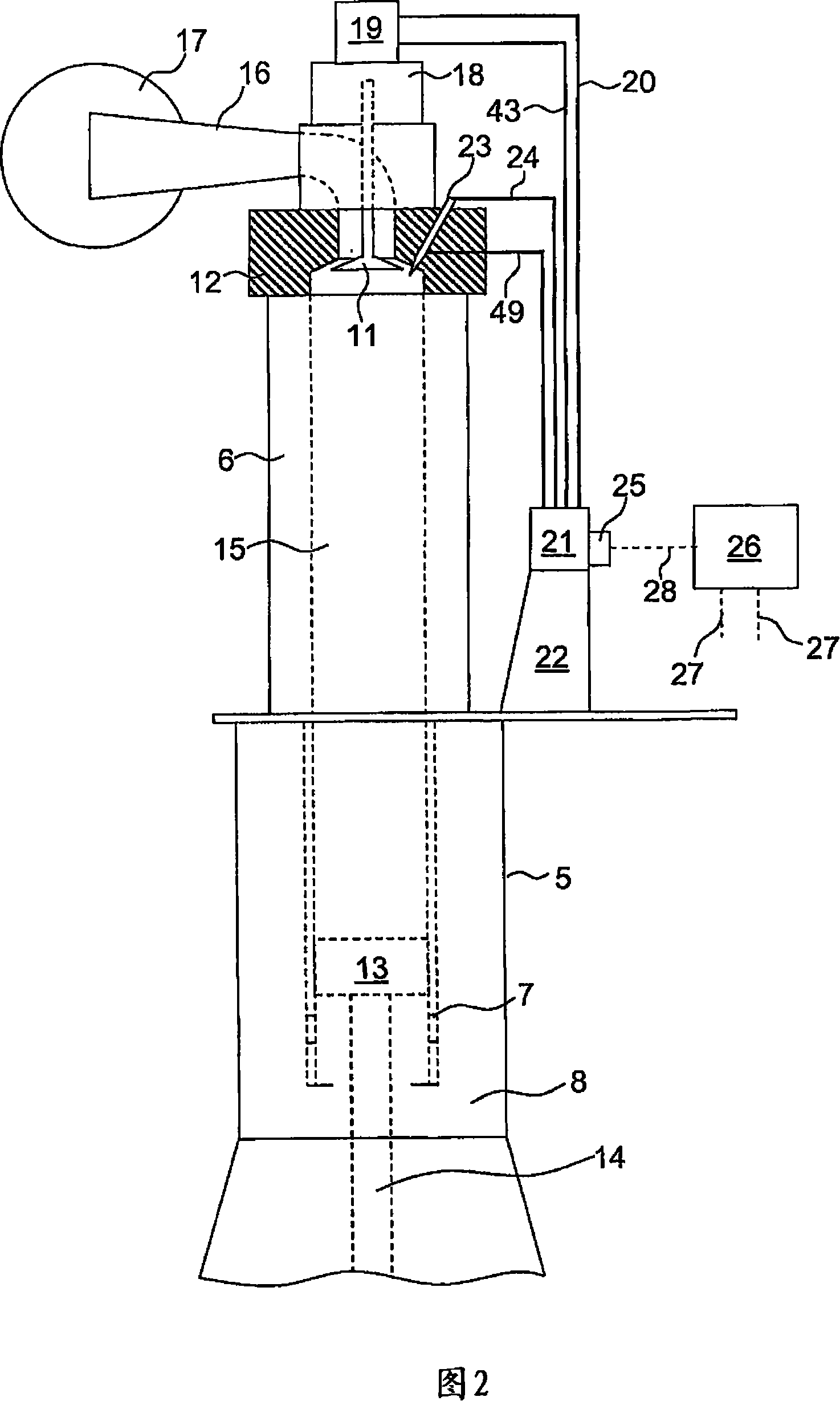

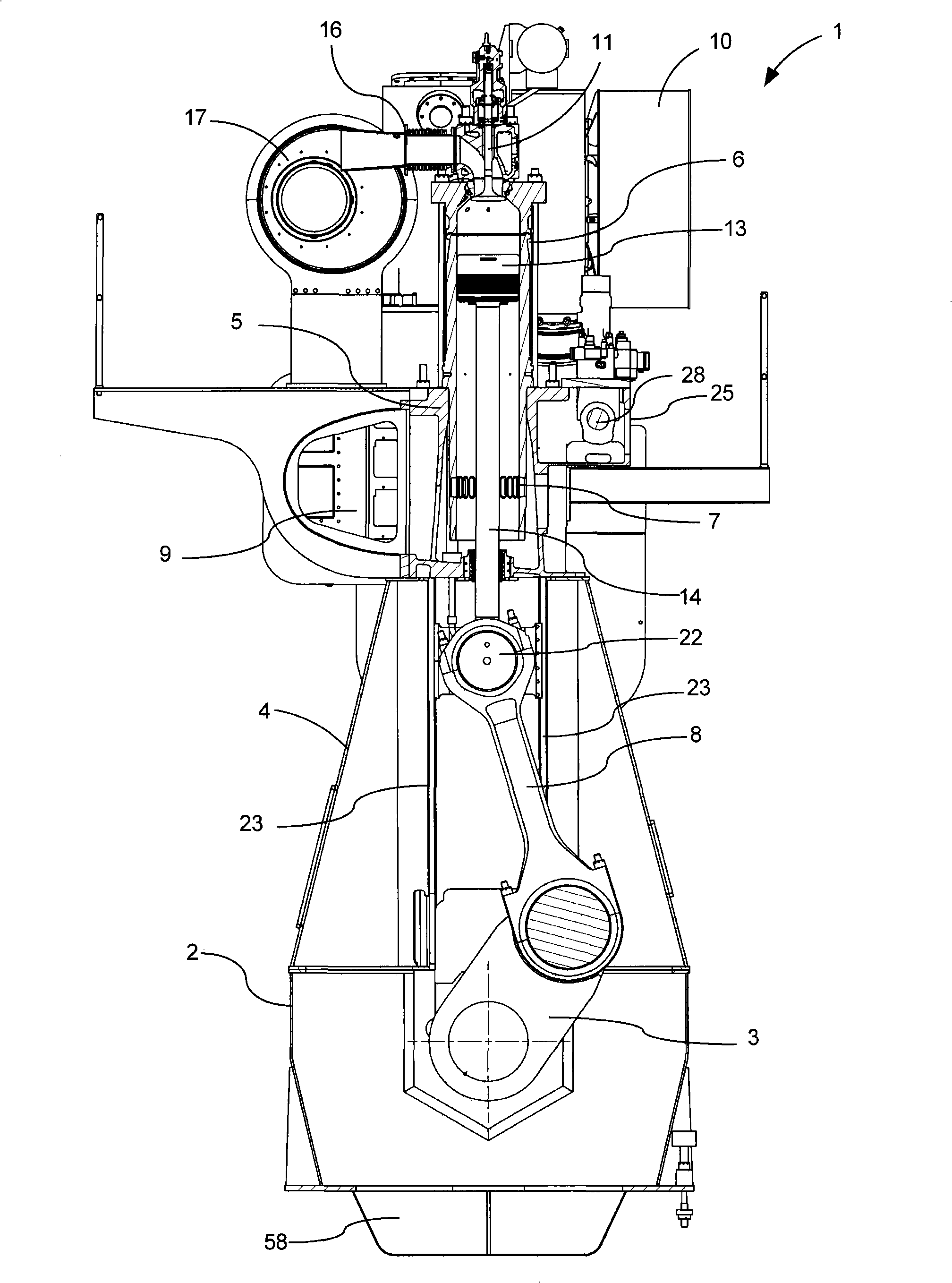

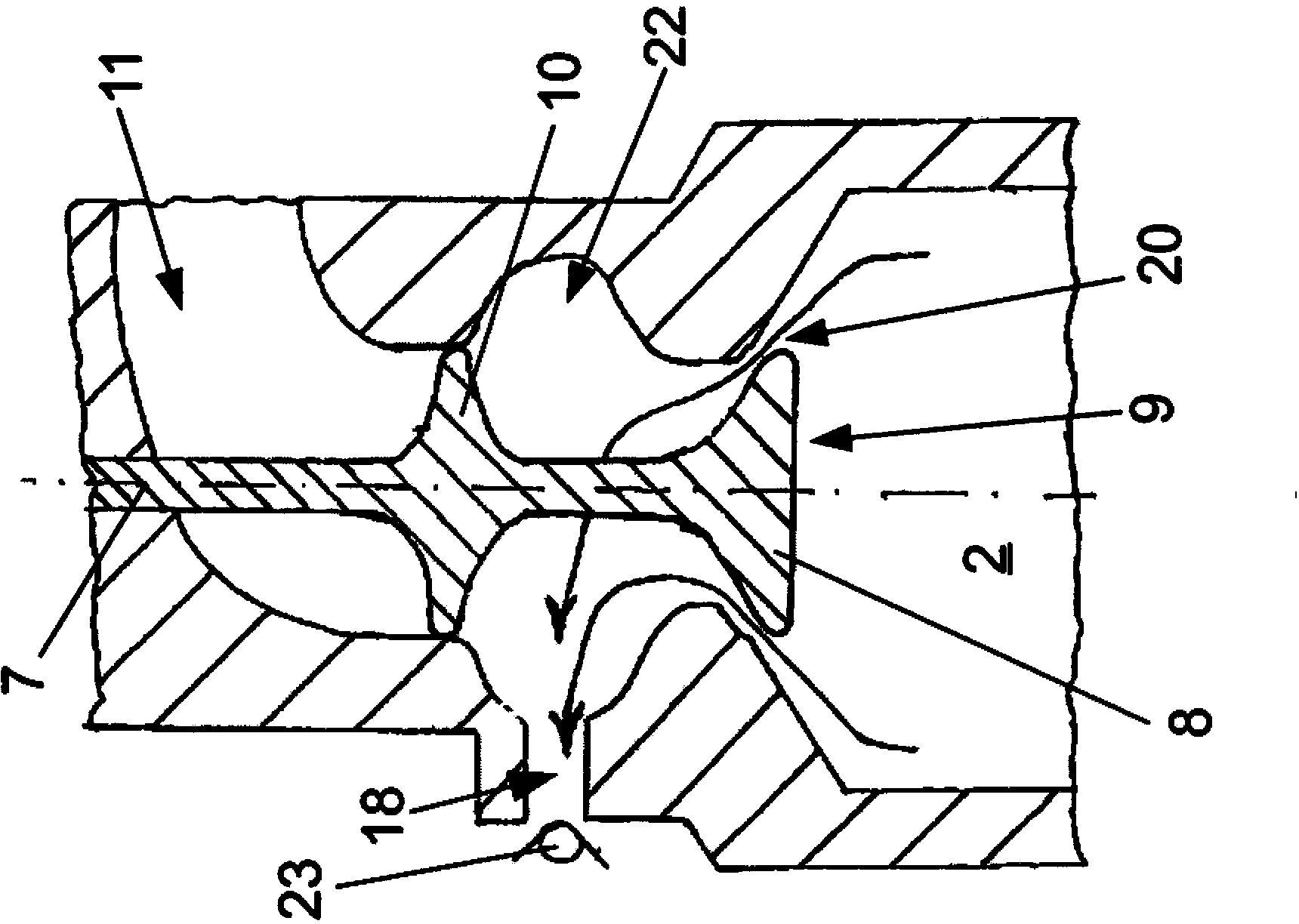

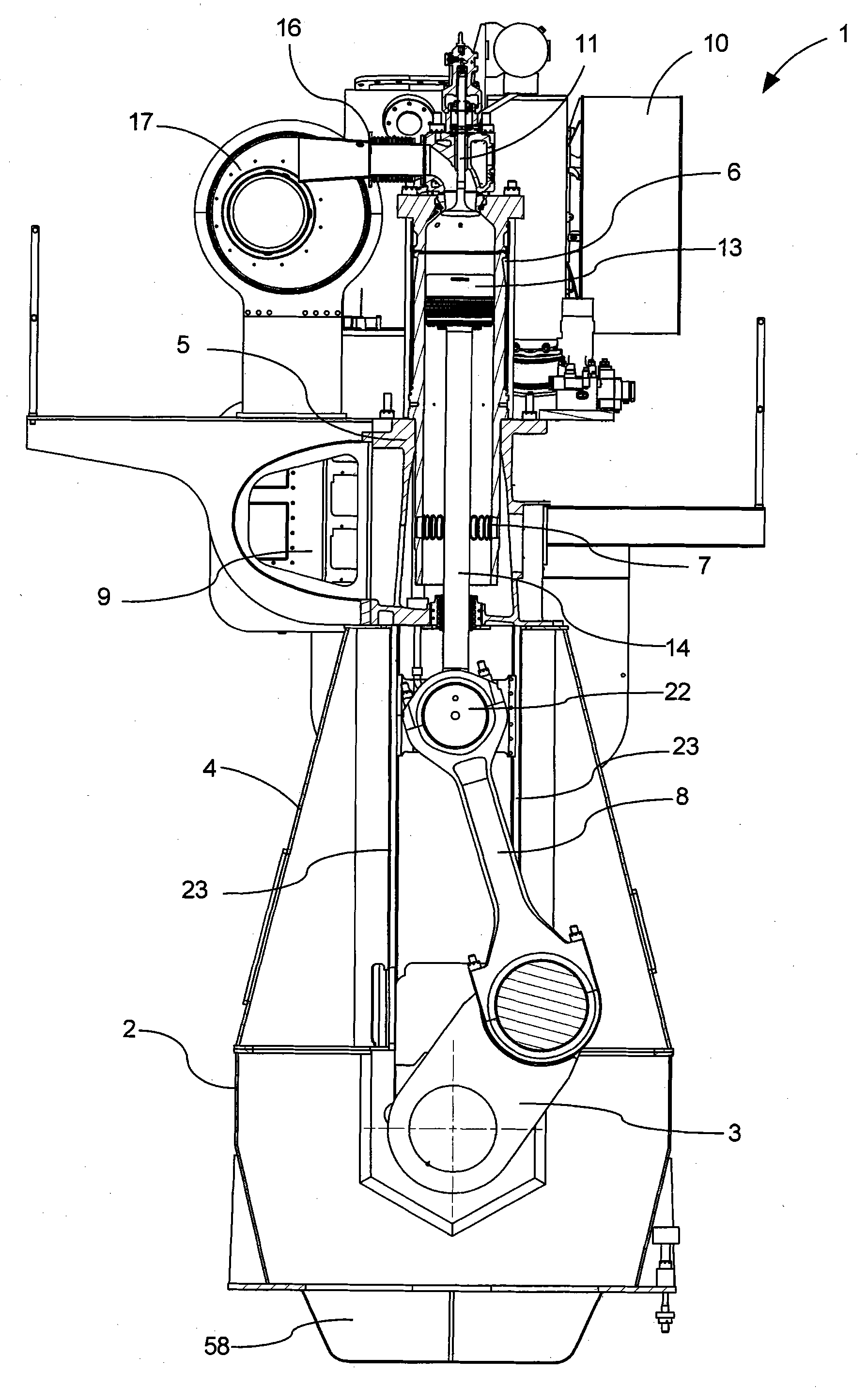

Macrotype double ram stroke diesel engine with hydraulic actuating exhaust valve

InactiveCN101111665AReduce the numberObvious purposeFuel injection apparatusMachines/enginesExhaust valveFuel oil

The present invention relates to a large two-stroke diesel engine (1) of the cross-head type in which the exhaust valves (11) are hydraulically actuated by providing hydraulic actuators (19) associated with each of the exhaust valves (11) with high pressure hydraulic fluid. Fuel oil or heavy fuel oil can be used as hydraulic fluid. The invention also relates to a control valve (25) for use in such an engine (1) , to a hydraulic system for such an engine (1) and to an hydraulic actuator (19) for such an engine (1).

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

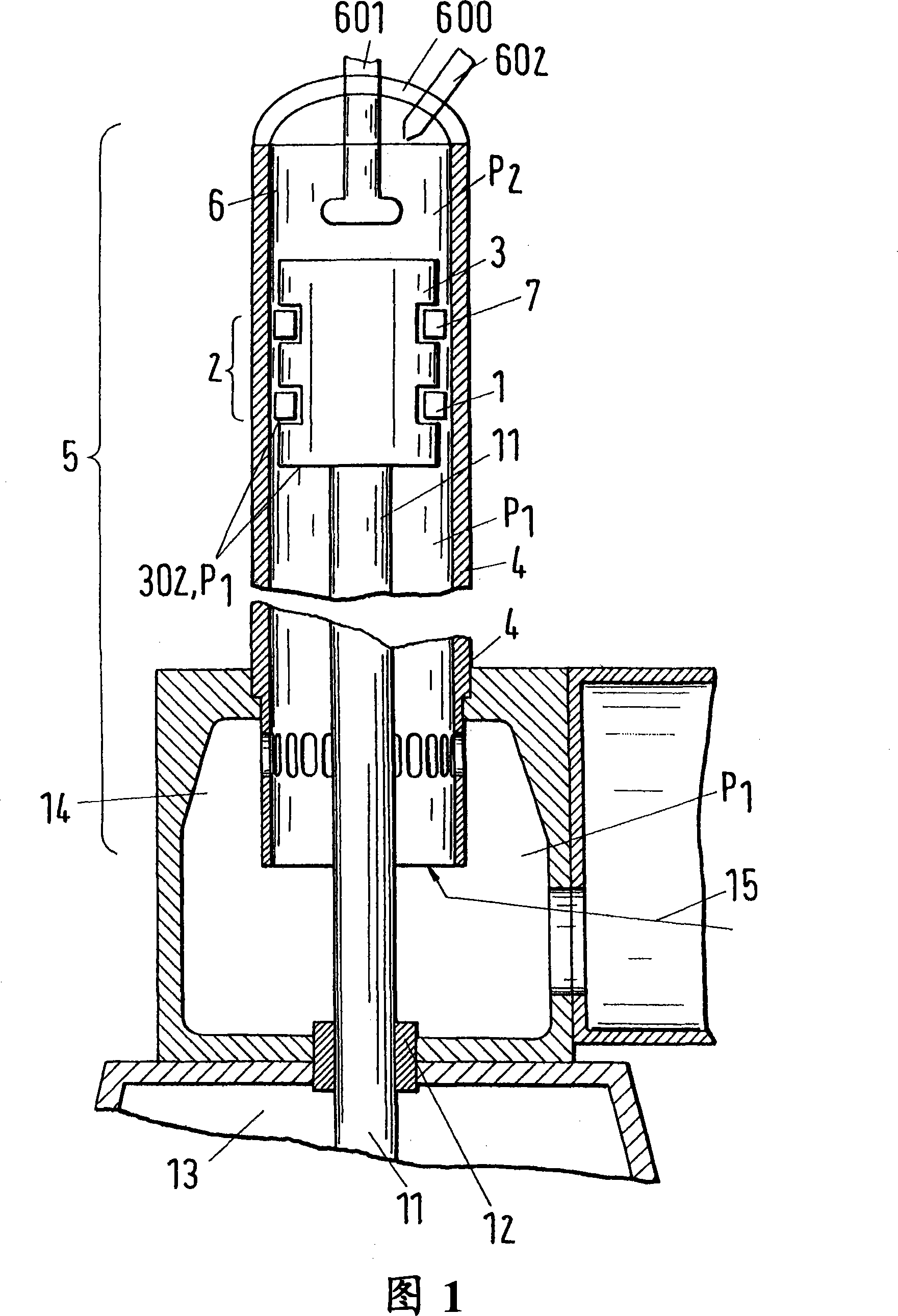

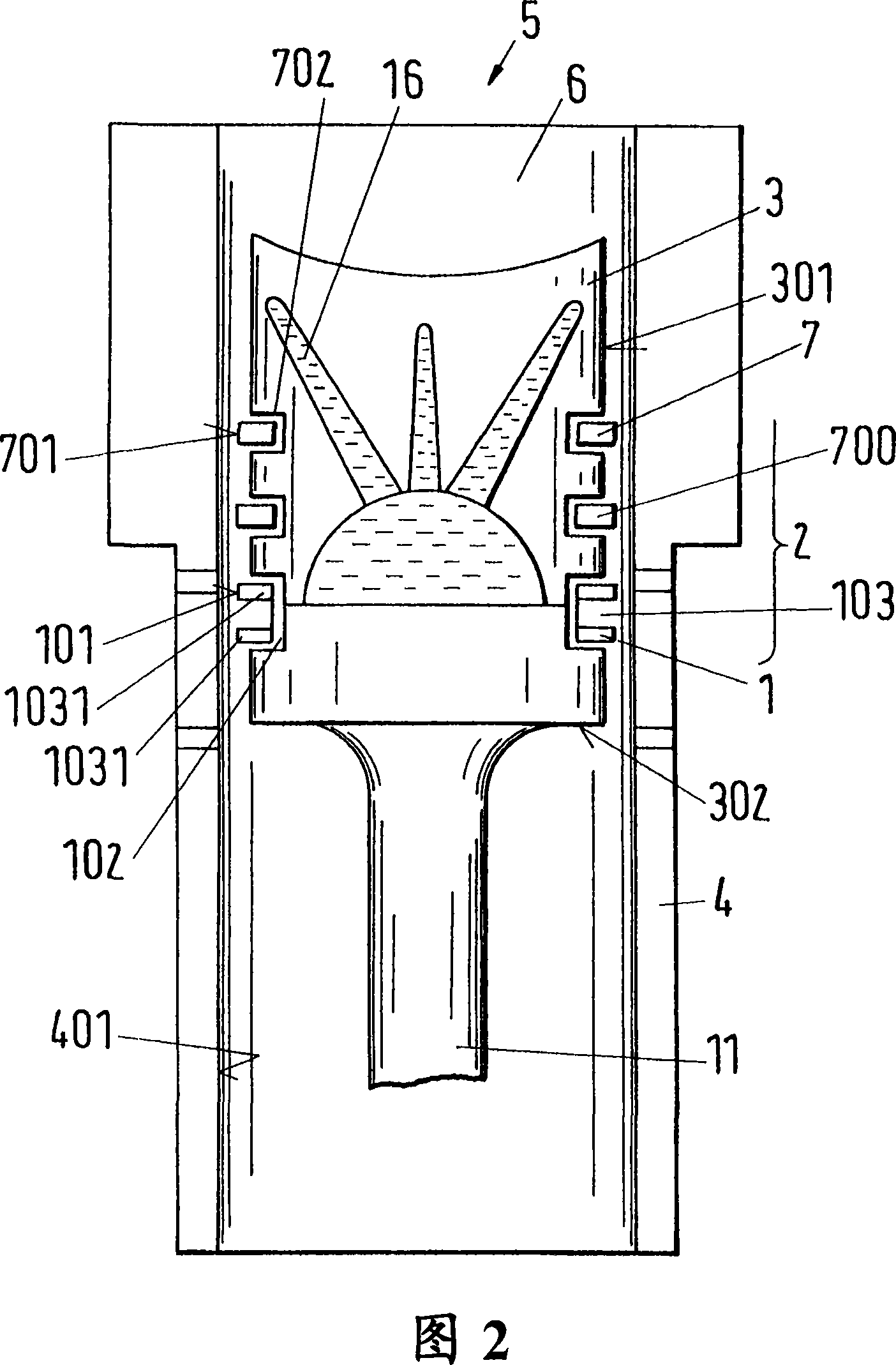

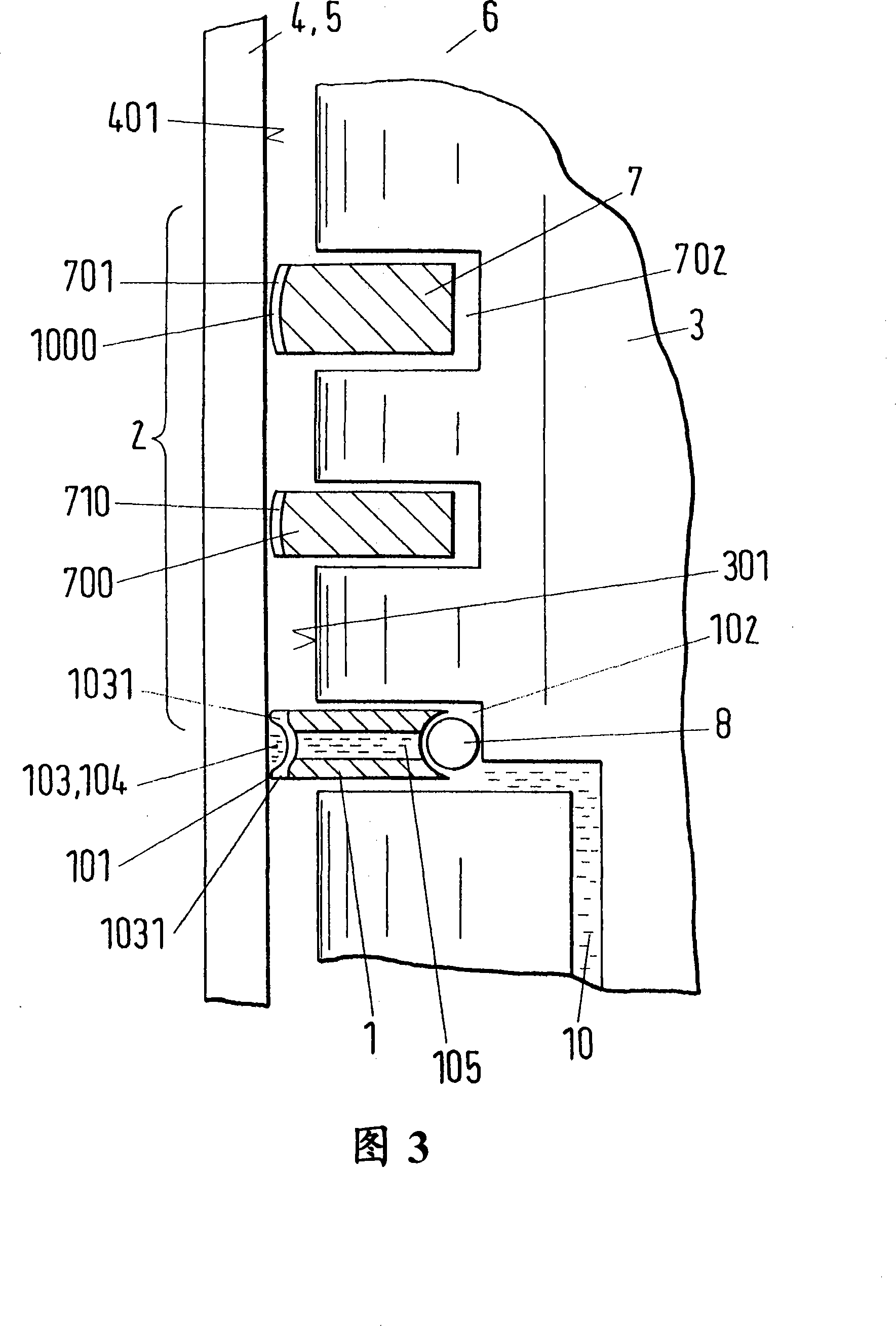

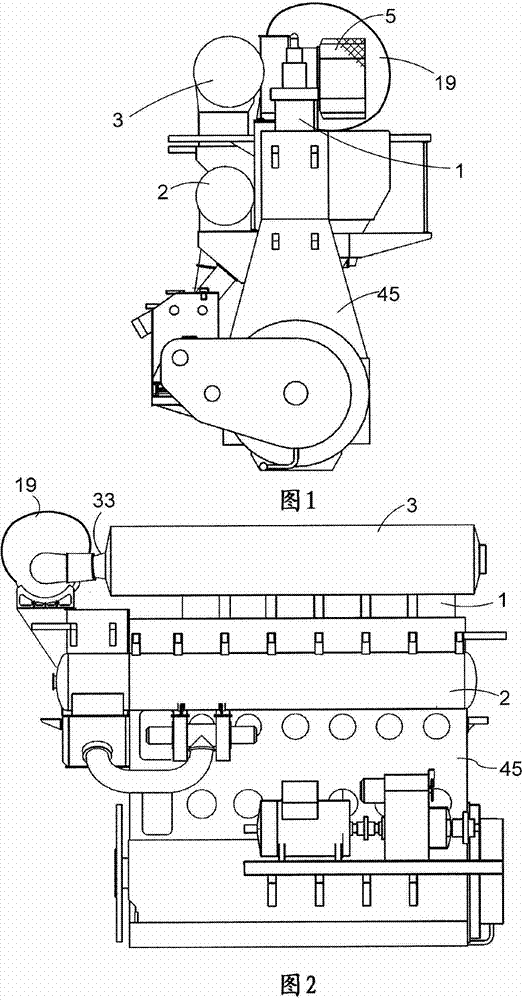

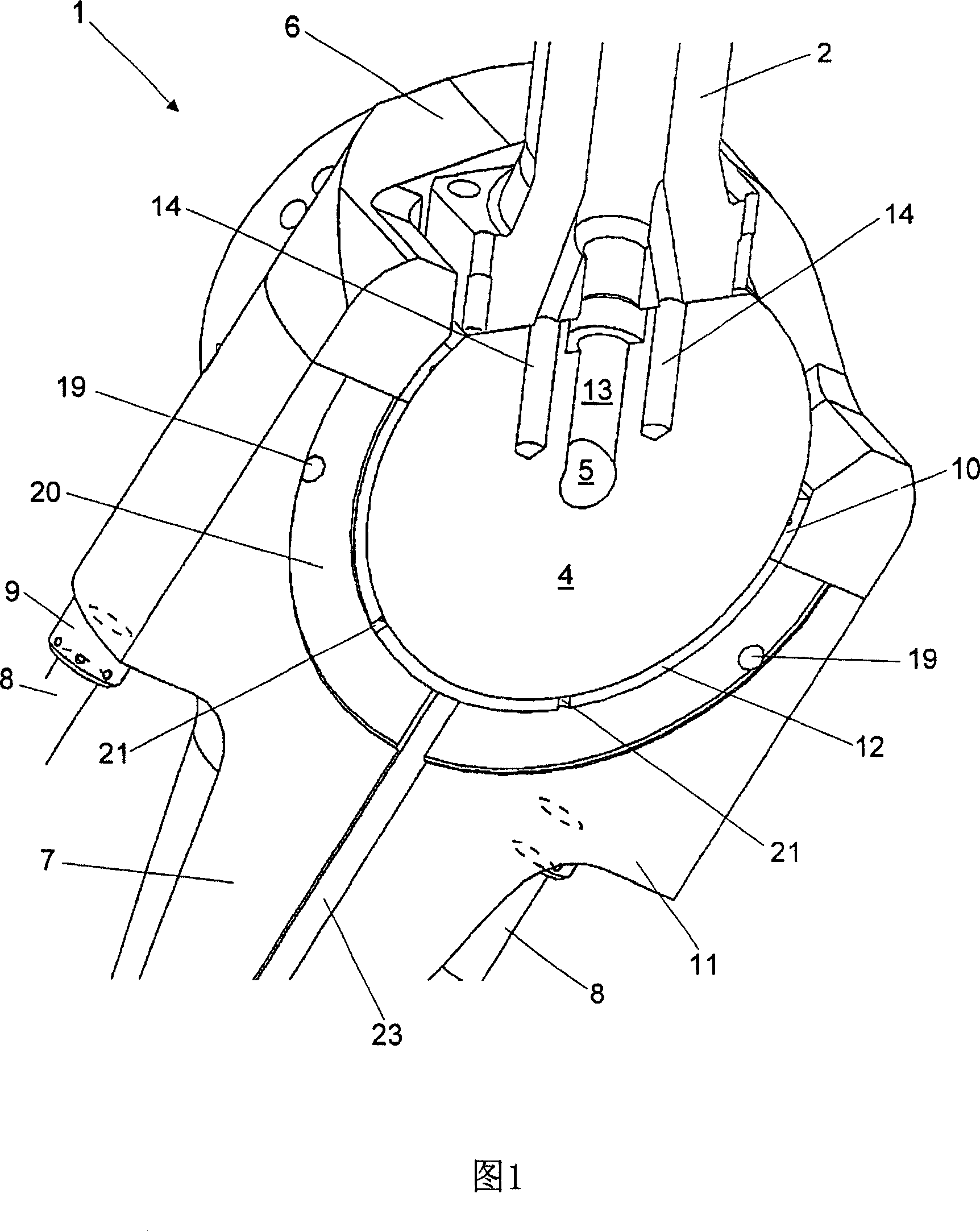

Piston with oil collector ring

The invention relates to a piston (3) with an oil collecting ring. The piston is used in a large two-stroke Diesel machine. The oil collecting ring (1) is used to form a piston ring group (2). The piston is arranged in a The installed state can move back and forth along the cylinder wall (4) of the cylinder (5) of a large two-stroke Diesel engine. The piston ring group (2) includes a ring located at the combustion chamber (6) closest to the cylinder (5). The first piston ring (7) of the first running surface (701) and the oil collecting ring (1) with the collecting ring running surface (101), and the first piston ring (7) is arranged in the first piston ring groove (702 ) and the oil collecting ring (1) is arranged in the collecting ring groove (102) of the piston (3), so that in the operating state, the first running surface (701) of the first piston ring (7) and the collecting ring The ring running surface (101) is in frictional contact with the cylinder running surface (401) of the cylinder wall (4). According to the invention, the piston (3) has lubricating oil holes in the area of the collecting ring groove (102) and / or in the collecting ring groove (102), and the piston (3) is designed such that lubricating oil can escape from the piston (3) through the lubricating oil holes. ) is applied internally to the cylinder running surface.

Owner:WAERTSILAE SCHWEIZ AG

A Large Turbocharged Two-Stroke Diesel Engine With Exhaust- Or Combustion Gas Recirculation And Method For Reducing Nox And Soot Emissions

ActiveCN102341589AIncrease injection pressureAvoid formingElectrical controlNon-fuel substance addition to fuelExhaust gas recirculationTwo-stroke diesel engine

A large two-stroke turbocharged diesel engine of the crosshead type provided with an exhaust gas recirculation system and with a fuel injection system that can, selectively add water to the fuel flow to thereby increase the mass flow through the injection nozzles under particular operating conditions, e.g. at high exhaust gas recirculation rates. The increased mass flow through the injection nozzles improves the entrainment of the fresh charge into the high-speed of the fuel spray and thereby increases the fuel / air mixing and brings the combustion towards the lean side and hence counteracts soot formation.

Owner:MAN ENERGY SOLUTIONS FILIAL AF MAN ENERGY SOLUTIONS SE TYSKLAND

Waste gas pollutant combined removal device for two-stroke diesel engine

ActiveCN104121072AAvoid wear and tearIncrease motivationNon-fuel substance addition to fuelInternal combustion piston enginesCombustionWater vapor

The invention provides a waste gas pollutant combined removal device for a two-stroke diesel engine. The waste gas pollutant combined removal device comprises a waste gas washing device and a recirculation waste gas flow control device, the waste gas washing device comprises a washer, a washing solution storage box, a circulation pump, a SOx absorbing agent supply device and a fresh waste supply device, and the recirculation waste gas flow control device comprises a flow regulating valve, a recirculating draught fan and a one-way control valve. According to the waste gas pollutant combined removal device, waste gas of the two-stroke diesel engine is washed, the SOx content and the particle content in the waste gas are reduced, part of low-temperature clean waste gas is recirculated, the NOx generation amount of the engine is reduced, and combined desulfurization and denitration of waste gas pollutants of the ship diesel engine is achieved. According to the waste gas pollutant combined removal device, part of washed waste gas is recirculated, the combustion condition in a cylinder is improved to a large extent,by CO2 and vapor contained in the low-temperature clean waste gas and the NOx generation amount and the final discharge amount of the engine are reduced.

Owner:HARBIN ENG UNIV

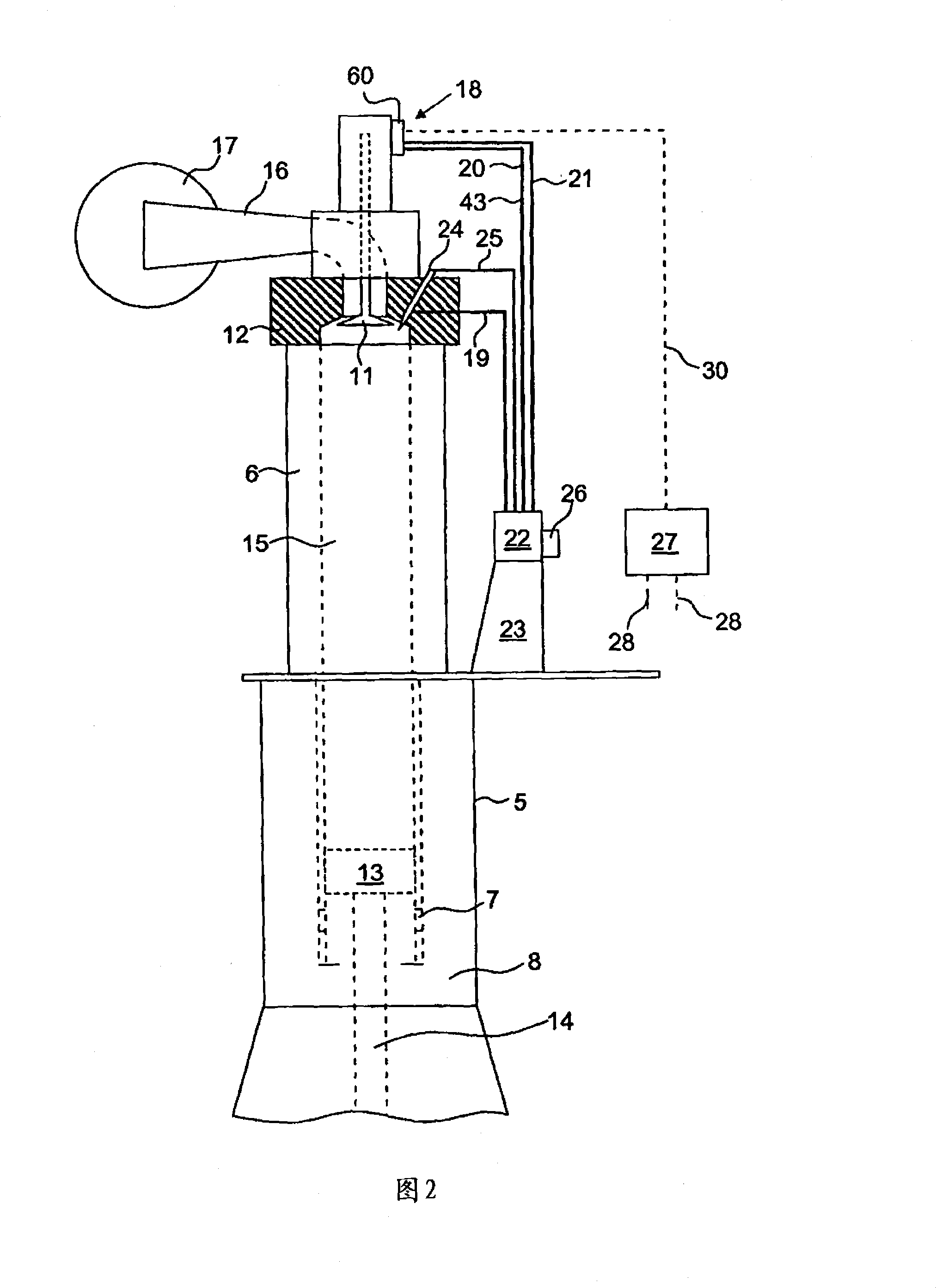

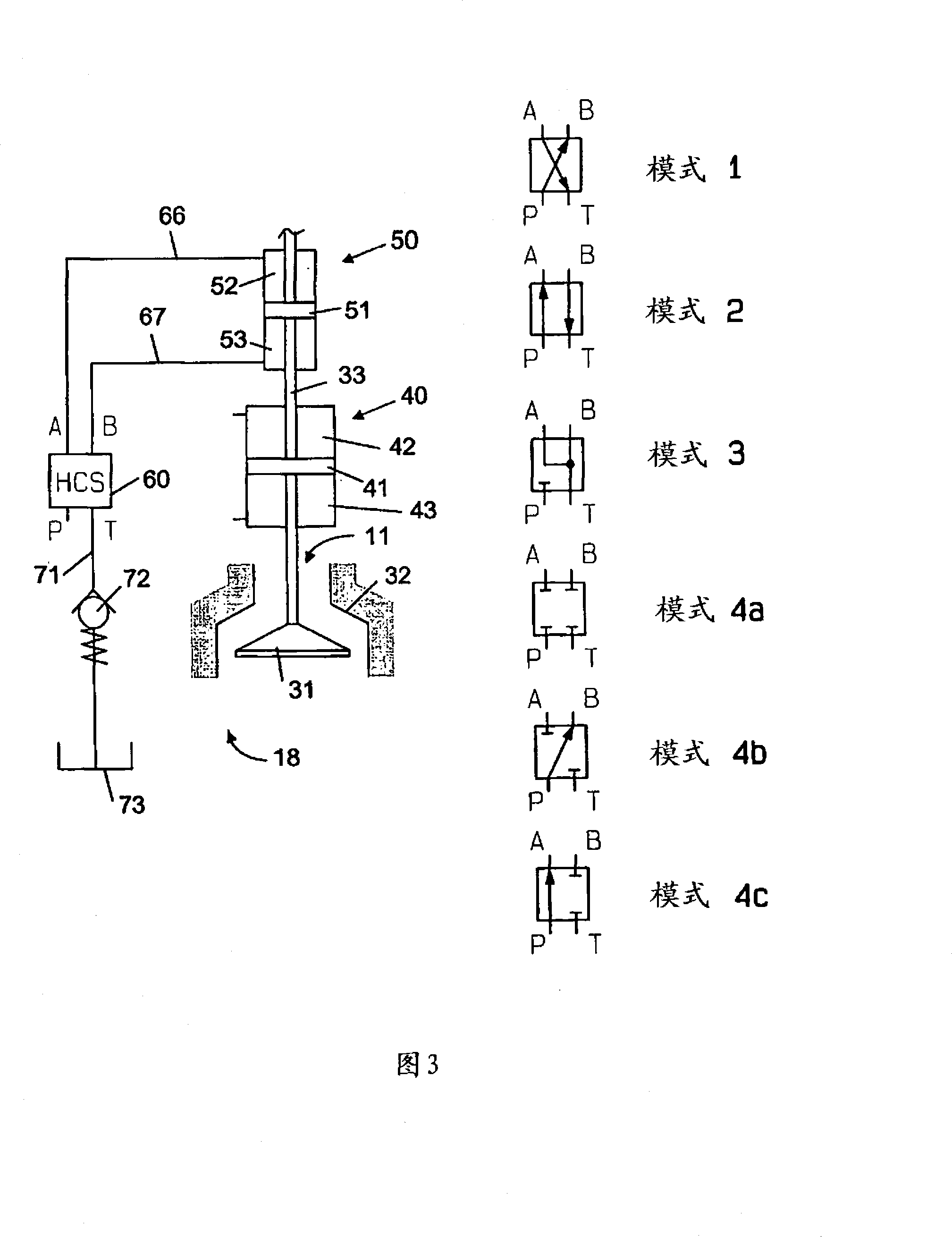

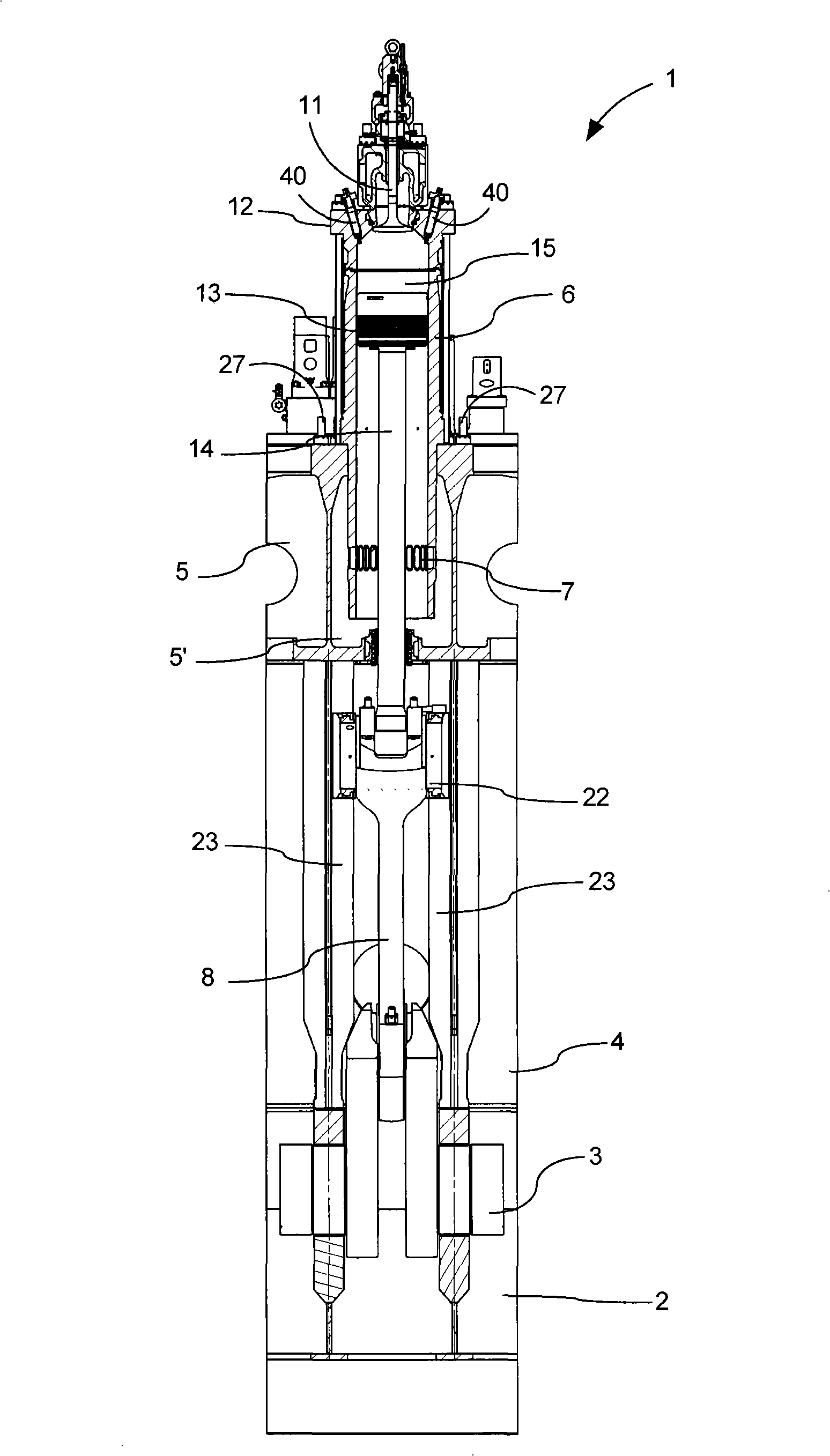

Exhaust valve assembly for a large two-stroke diesel engine

InactiveCN101160457ALess hydraulic energyEasy to useCasingsCombustion enginesExhaust valveFuel efficiency

The present invention relates to an exhaust valve assembly (18) for a large two-stroke diesel engine (1). The assembly (18) includes an exhaust valve (11) that is movable in opposite directions between a closed position and a open position. A double acting spring assembly (40) is operably connected to the exhaust valve (11) and forms a mass-spring system together with the exhaust valve (11) and the mass of any other parts moving in unison with the exhaust valve (11). The double acting spring assembly (40) stores energy during translation of the exhaust valve (11) back and forth between the closed and open position for subsequent propulsion of the exhaust valve (11) in an opposite direction. Hydraulic means (50) hold the exhaust valve (11) on command from a controller (27) in the closed or in the open position.

Owner:MAN B & W DIESEL AS

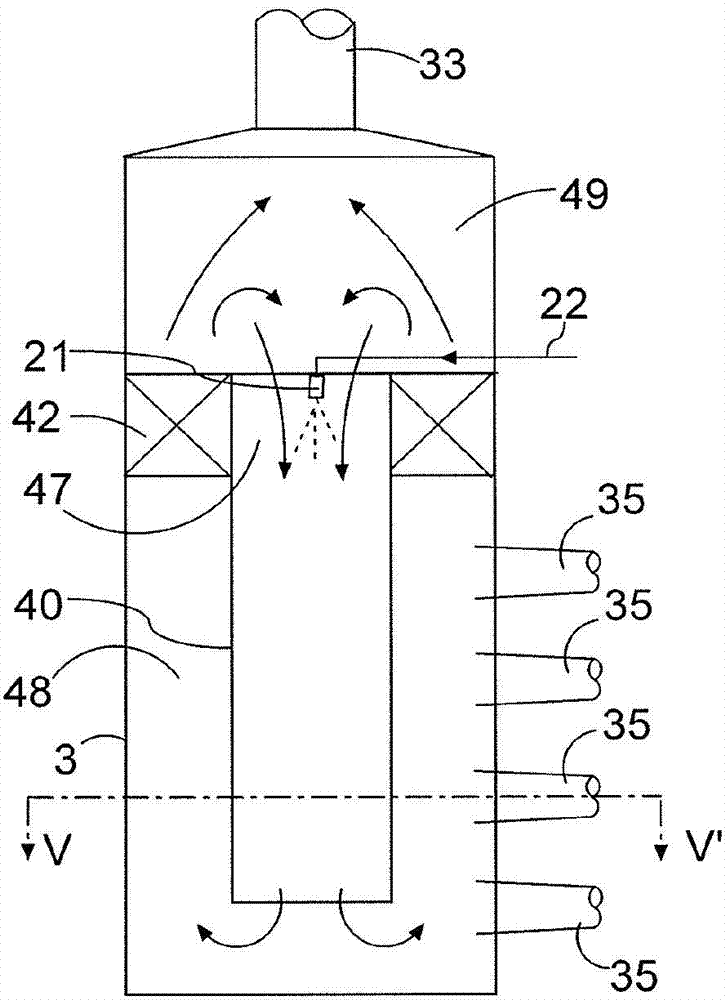

A large turbocharged two-stroke diesel engine with exhaust gas purification

A large turbocharged two-stroke diesel engine with crossheads, said engine having a plurality of cylinders (1) in line, a turbocharger (5) and an SCR reactor (19) upstream of the turbocharger and downstream of an exhaust gas receiver (3) . The exhaust gas receiver (3) is connected to the individual cylinders (1) via respective exhaust ducts (35) that introduce the exhaust gas tangentially and cause a swirl in the exhaust gas inside the exhaust gas receiver (3) . The exhaust gas receiver (3) is provided with an outlet (33) . A unit (42) with plurality of vanes (43) around a central axial duct (47) divides the exhausts gas receiver (3) in a mixing section (48) downstream of the unit and an outlet section (49) upstream of the unit (42) The swirling exhaust gas passes along the vanes (43) on its way from the inixing section (48) to the outlet section (49) and the vanes (43) cause the exhaust gas to lose its swirl and gain pressure. The pressure gain causes a portion of the exhaust gas in the outlet section (49) to flow back to the mixing section (48) via said central duct (47) . The reductant is introduced in the flow in said central duct 47) . A large turbocharged two-stroke diesel engine with an exhaust gas receiver (3) with tangential inlets (35) and a tangential outlet (39) is also disclosed It is suggested that Fig. 4 is published with the abstract.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

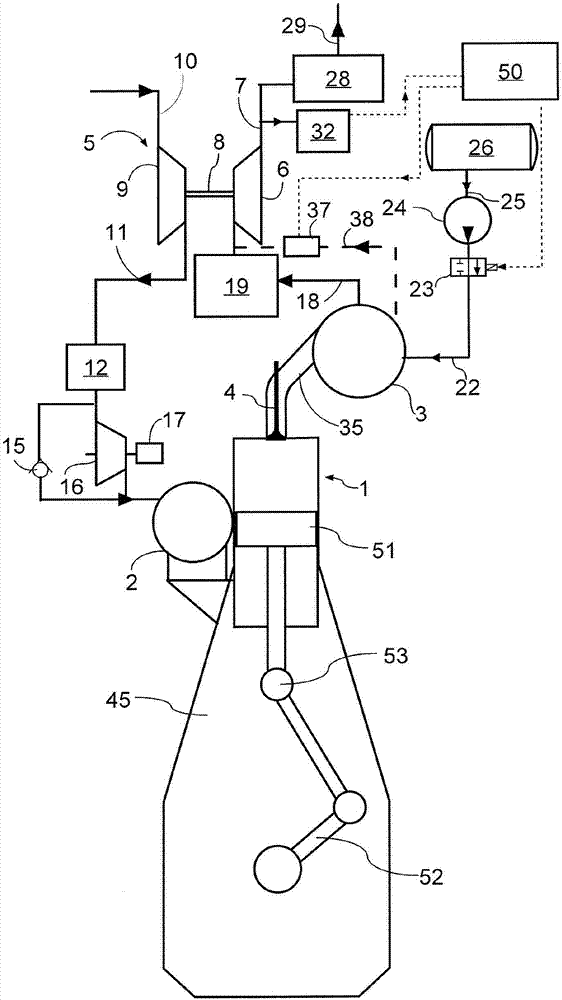

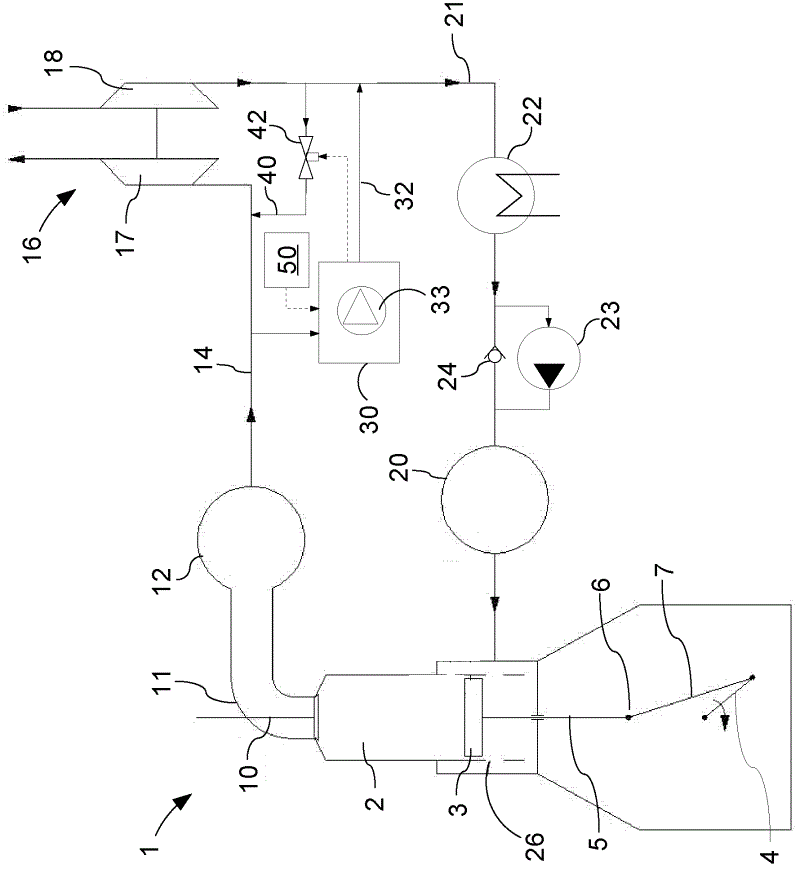

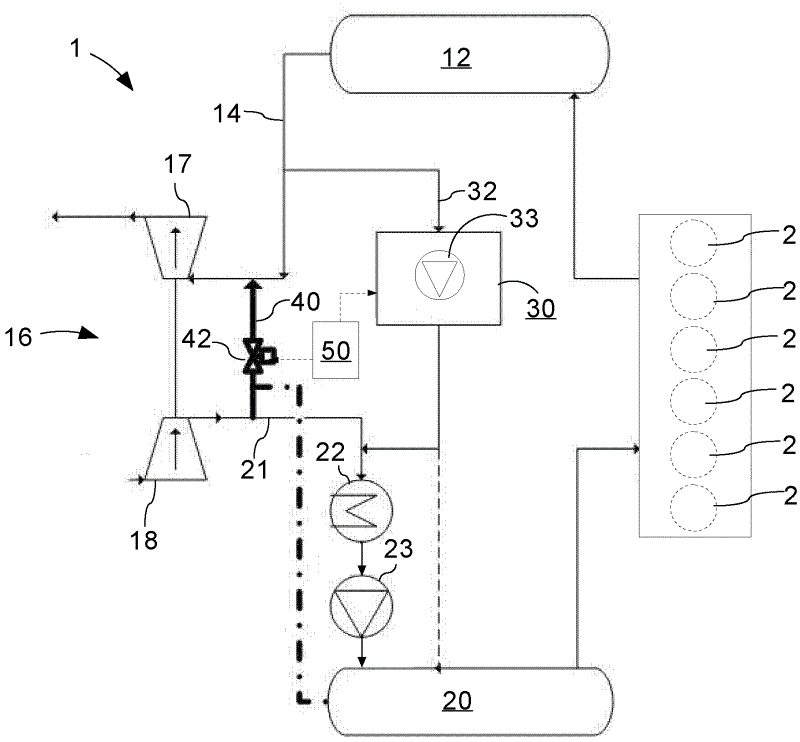

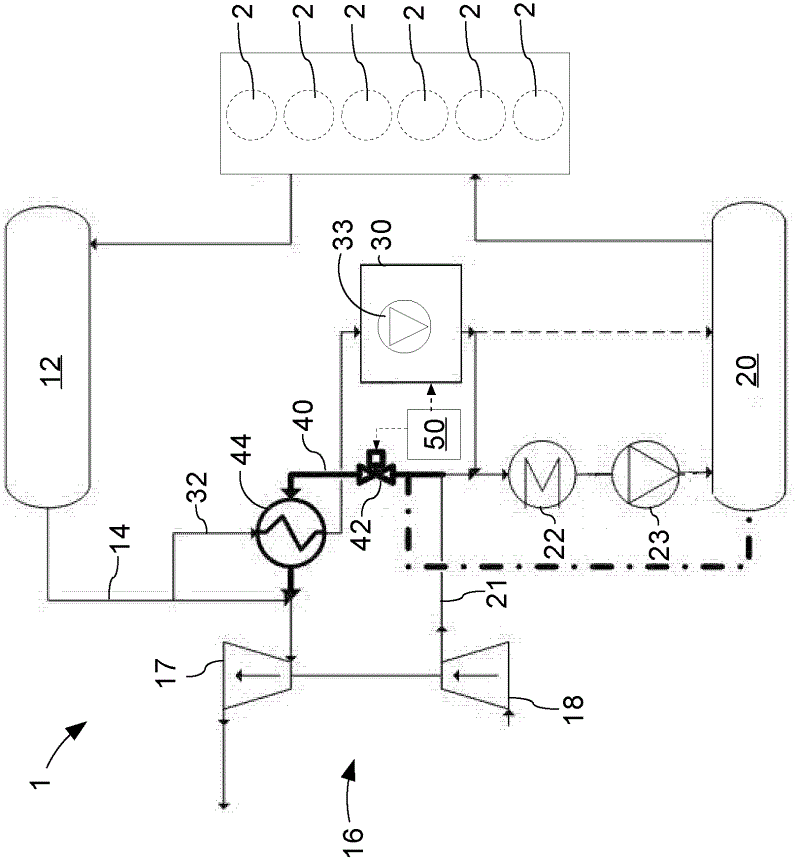

Large turbocharged two-stroke diesel engine with exhaust gas recirculation

ActiveCN102619615AReduce lossesHope to eliminateInternal combustion piston enginesEngine operationsTurbochargerOperation mode

The invention relates to a large turbocharged two stroke diesel engine (1) of the crosshead type that is provided with an exhaust gas recirculation system (30,32) that can be activated or deactivated or can be operated with variable exhaust gas recirculation rates. In order to ensure proper matching of the turbocharger (16) , and in particular the compressor (18) of the turbocharger (16) in all operating conditions, a cylinder bypass flow path (40) that includes a controllable valve (42) enables matching the turbocharger 16 to the engine (1) in operation modes with or without exhaust gas recirculation.

Owner:MAN ENERGY SOLUTIONS FILIAL AF MAN ENERGY SOLUTIONS SE TYSKLAND

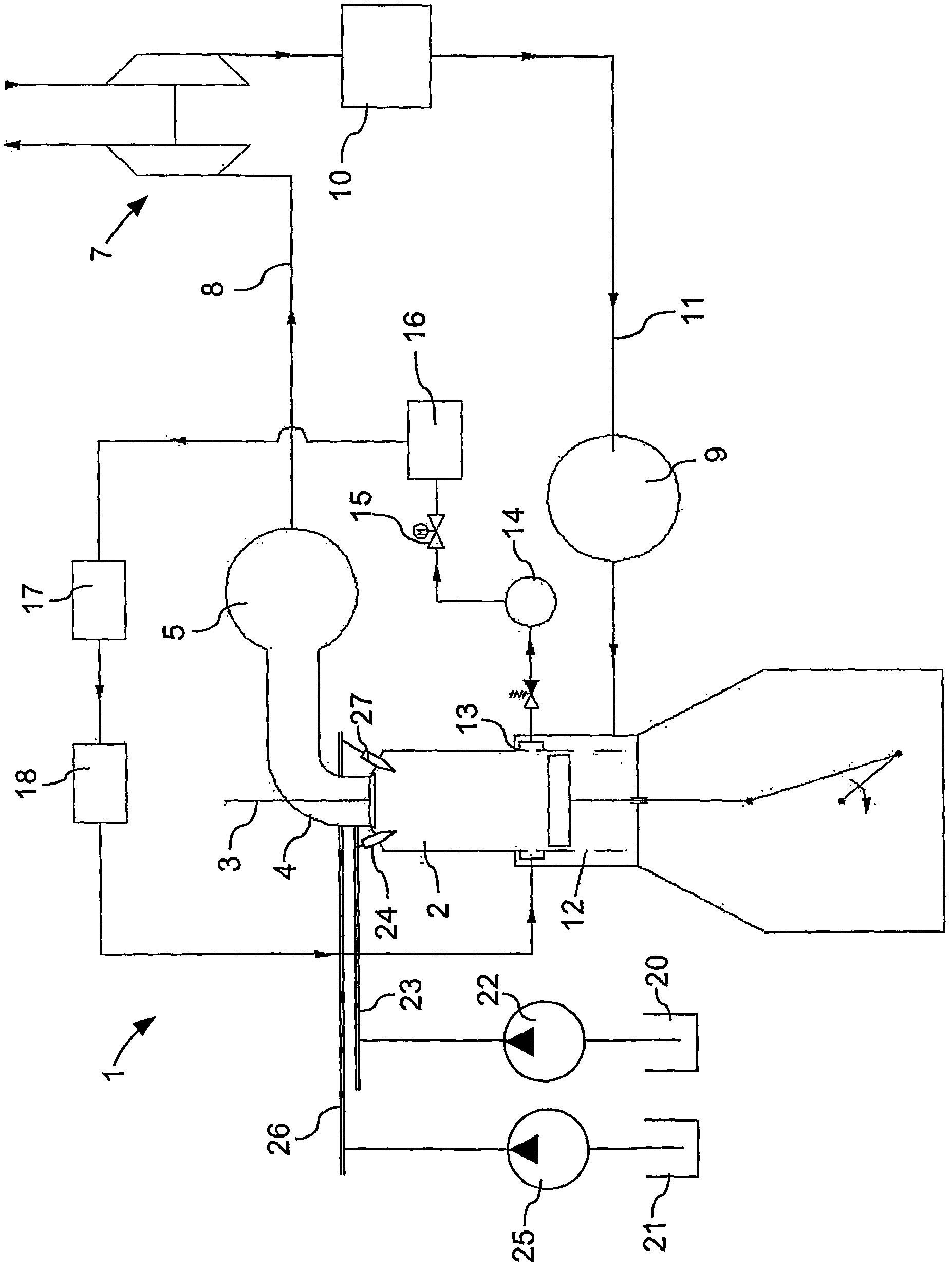

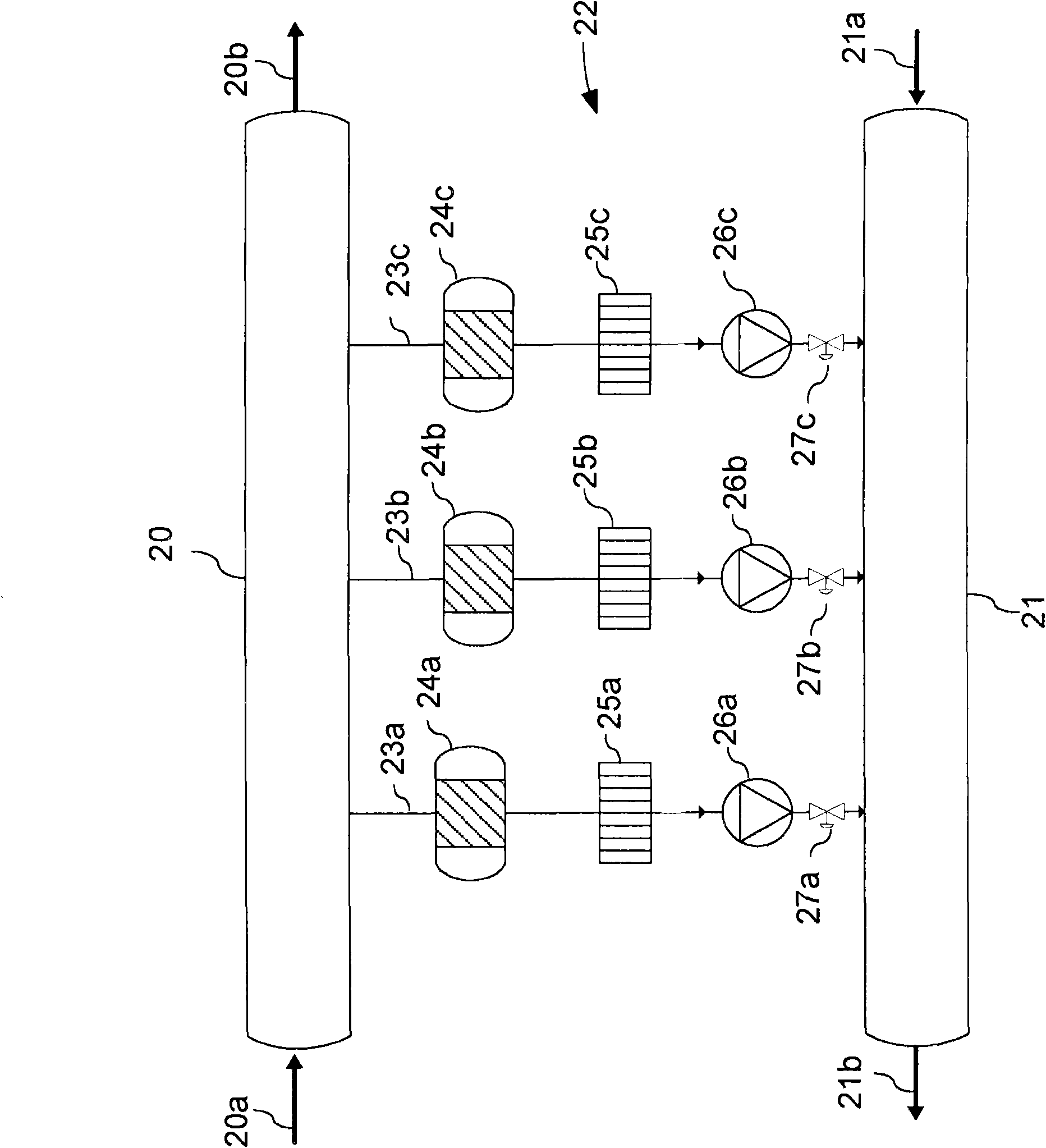

Large two-stroke diesel engine with exhaust gas recirculation control system

ActiveCN102140977AOperating economyEasy to operateNon-fuel substance addition to fuelCombustion enginesControl systemExhaust gas recirculation

The invention relates to a large two-stroke diesel engine with a exhaust gas recirculation control system. In particular, the invention relates to a large crosshead turbocharged two-stroke combustion engine, which comprises: a plurality of cylinders, each of which is connected to an exhaust gas receiver; and an exhaust gas recirculation flow channel for recirculating at least a part of the exhaust gas to a scavenging air channel. At least a part of the exhaust gas recirculation flow channel comprises at least two parallel links, wherein each link forms a flow channel, and each link comprises at least one device for processing or controlling the recirculated exhaust gas. The invention also relates to a method for controlling the exhaust gas recirculation system in the large crosshead turbocharged two-stroke diesel engine.

Owner:MAN ENERGY SOLUTIONS FILIAL AF MAN ENERGY SOLUTIONS SE TYSKLAND

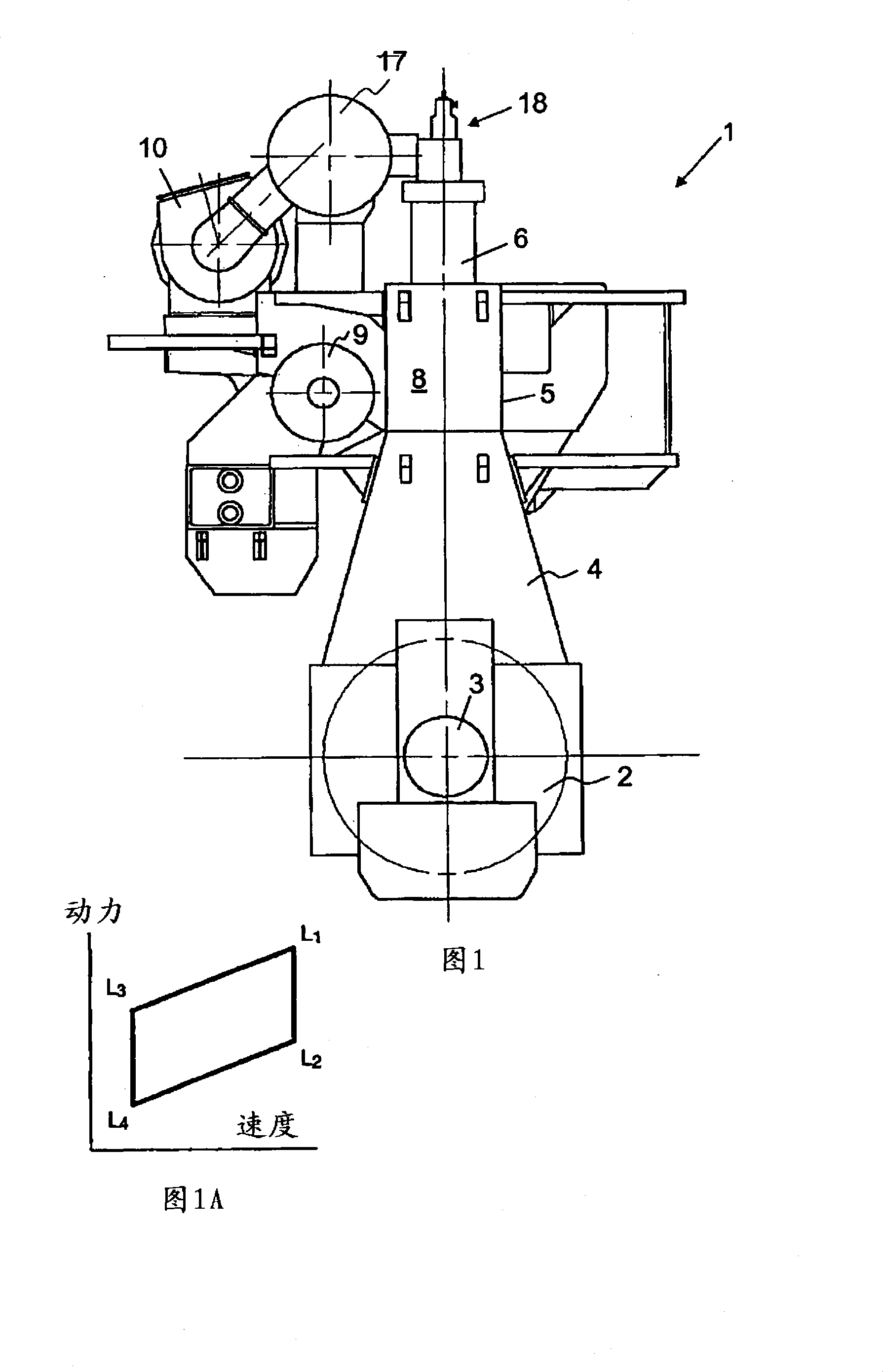

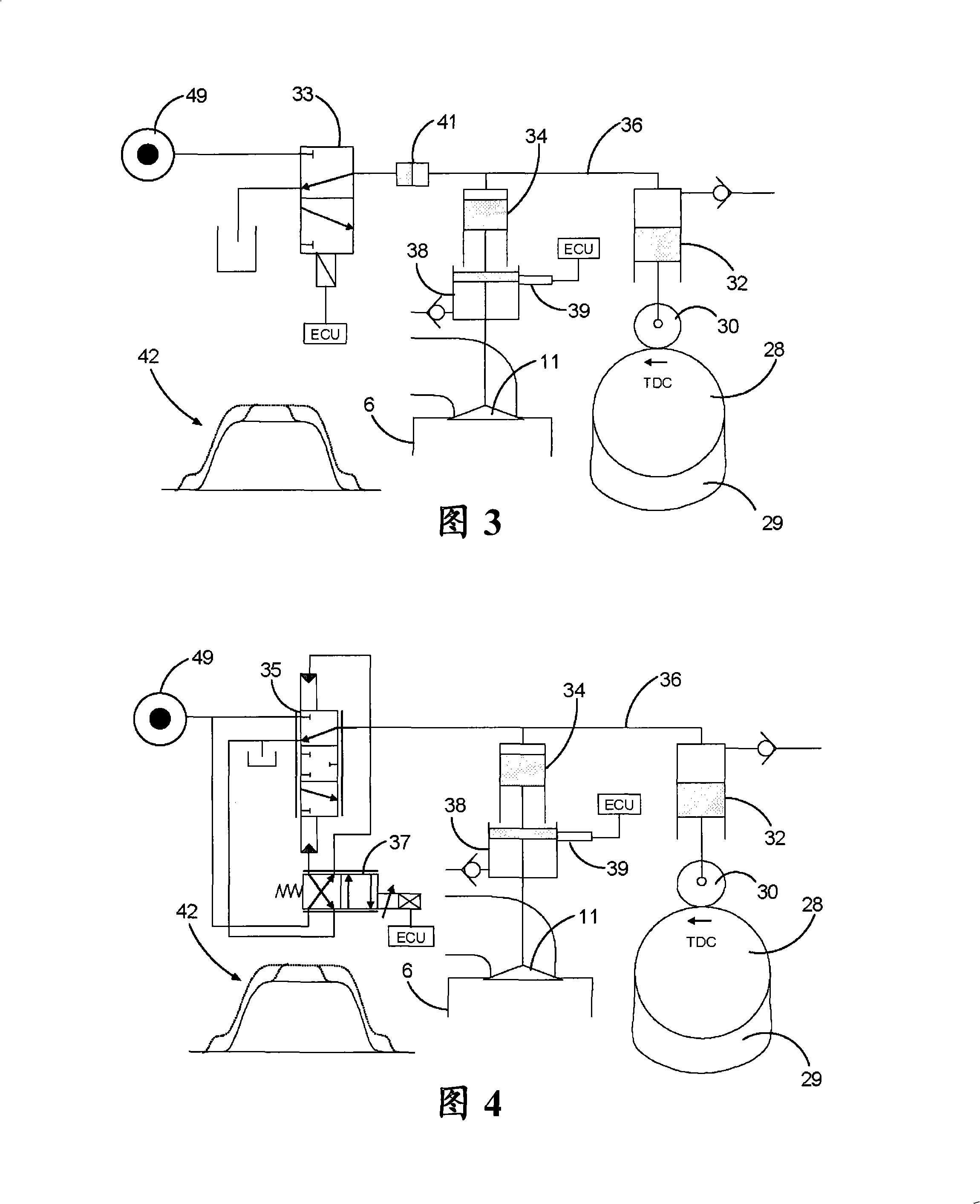

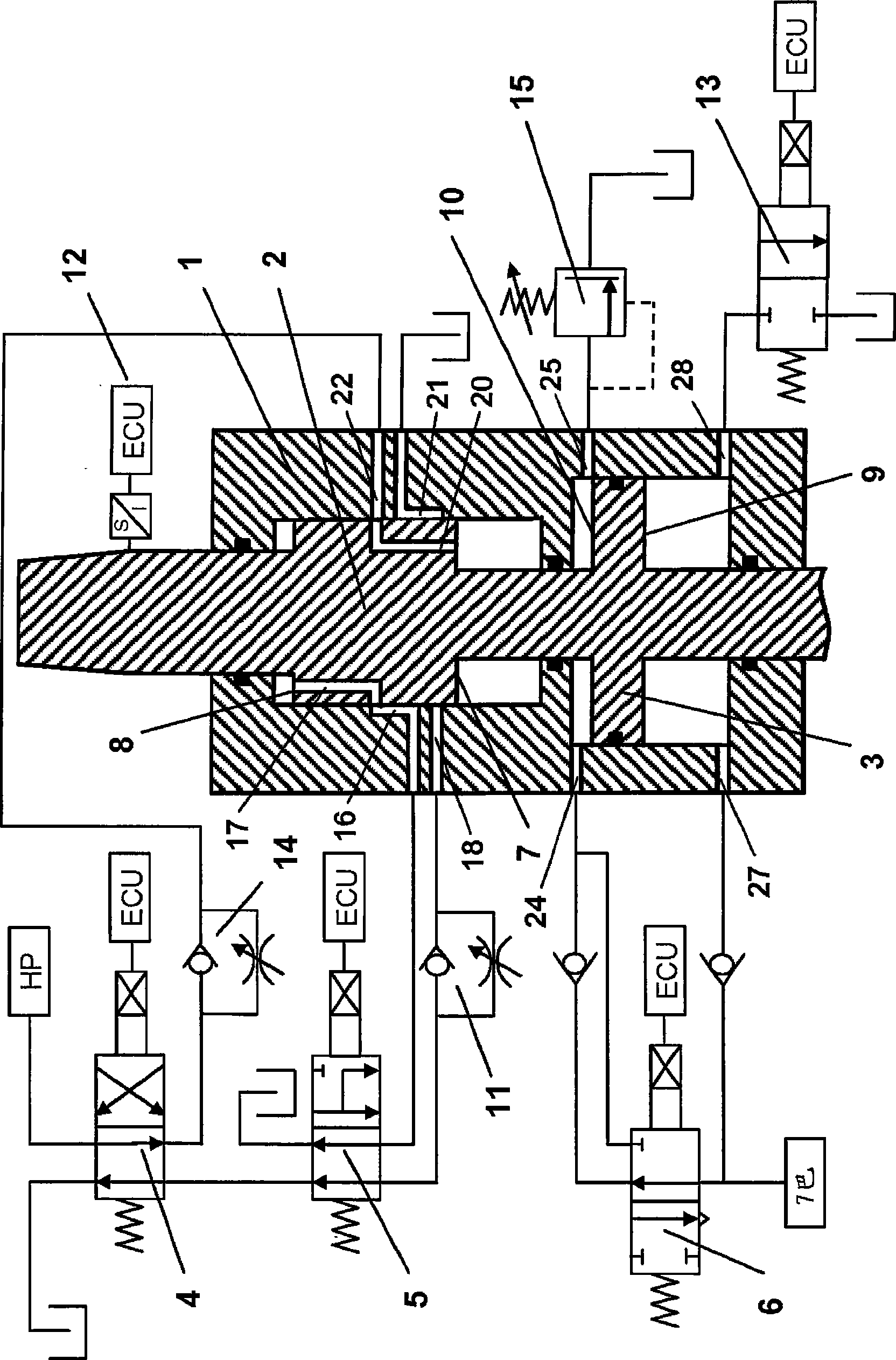

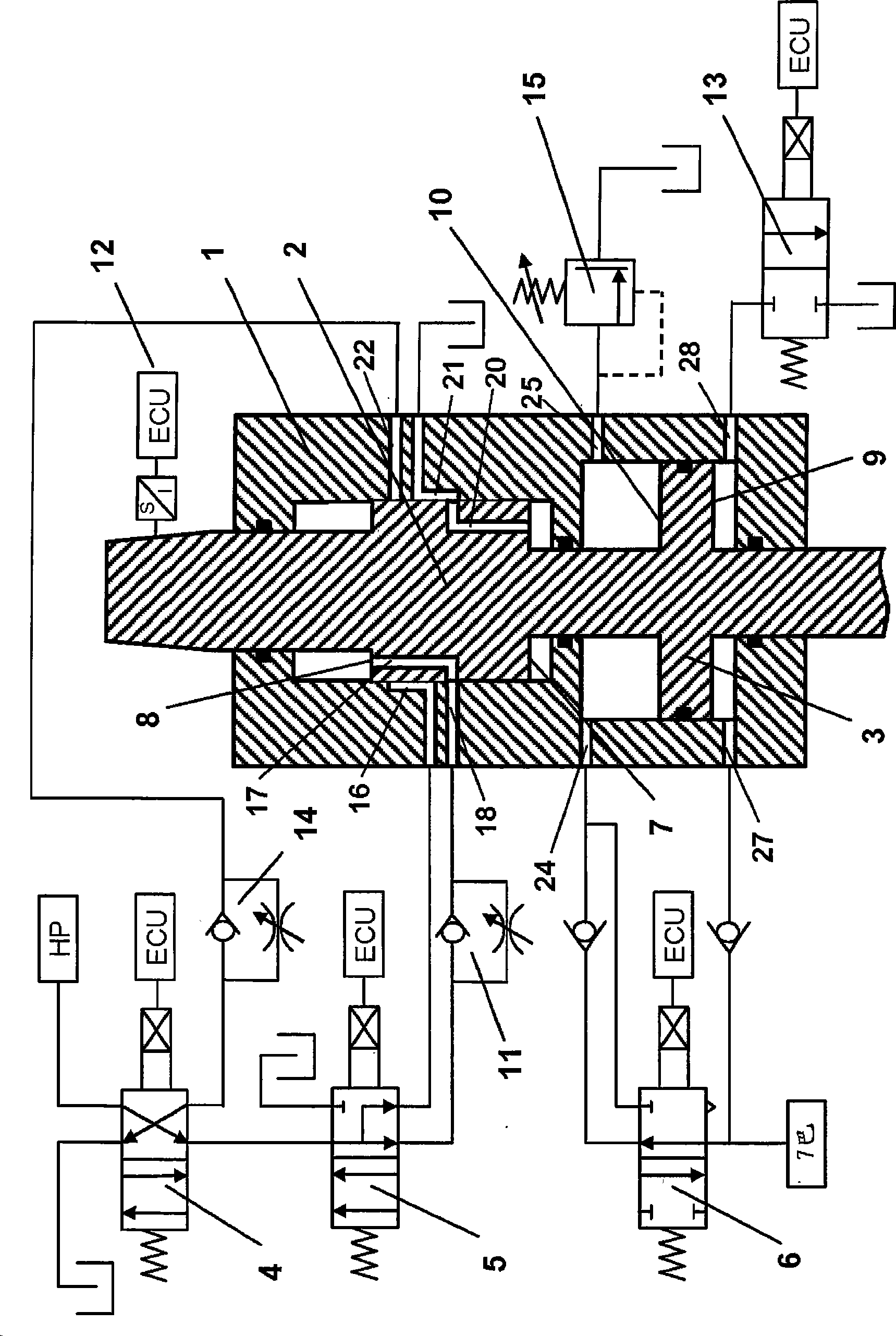

Cam driven exhaust valve actuating system for large two-stroke diesel engine

A large two-stroke diesel engine with an exhaust valve actuating system comprises a cam shaft and a hydraulic push pole. The hydraulic push pole comprises a piston pump driven by the cam shaft; the cam shaft is coupled to the hydraulic exhaust valve actuator moving the relevant exhaust valve via the pipeline. A device can adds a certain quantity of hydraulic fluid to the hydraulic push pole in the controllable way before the effective working time of the cam shaft, so that the exhaust valve is opened before the limited time point of the cam profile. The device also removes a certain quantity of hydraulic fluid from the hydraulic push pole in the controllable way after the effective working time of the cam shaft, so that the exhaust valve is closed after the limited time point of the cam profile. The extra little air exchanging valve is arranged with the actuating system; the actuating system is operated independent to the cam shaft for controlling the recoil and compressing pressure of the cylinder.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

Self-priming hydraulic free-piston linear engine

ActiveCN104763525AImprove efficiencyImprove reliabilityFree piston enginesInternal combustion engineHigh pressure

The invention discloses a self-priming hydraulic free-piston linear engine. Pressure difference produced by a piston moving at high speed can be utilized to suck oil into a pump cavity, an independent oil supply pump can be omitted, accordingly energy loss is reduced, and the efficiency of the engine is improved. The linear engine comprises an internal combustion engine portion and a hydraulic portion, wherein the internal combustion engine portion applies a working principle of a two-stroke diesel engine and adopts a uniflow scavenging mode. The hydraulic portion provides energy for a compression stroke and meanwhile stores energy produced by an acting stroke in energy accumulators. The self-priming hydraulic free-piston linear engine comprises an air cylinder body, a piston module, a scavenging chamber, a low-pressure energy accumulator, a high-pressure energy accumulator, a pressure oil tank, a pneumatic control valve and an oil sprayer. The piston module comprises an air cylinder piston, a pump piston and a compression piston which are fixedly connected together. The piston module performs circulating reciprocating linear motion, and the pump piston suck low-pressure oil through a low-pressure oil way in the compression stroke. In an expansion stroke, the compression piston converts the low-pressure oil into high-pressure oil to complete power output.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

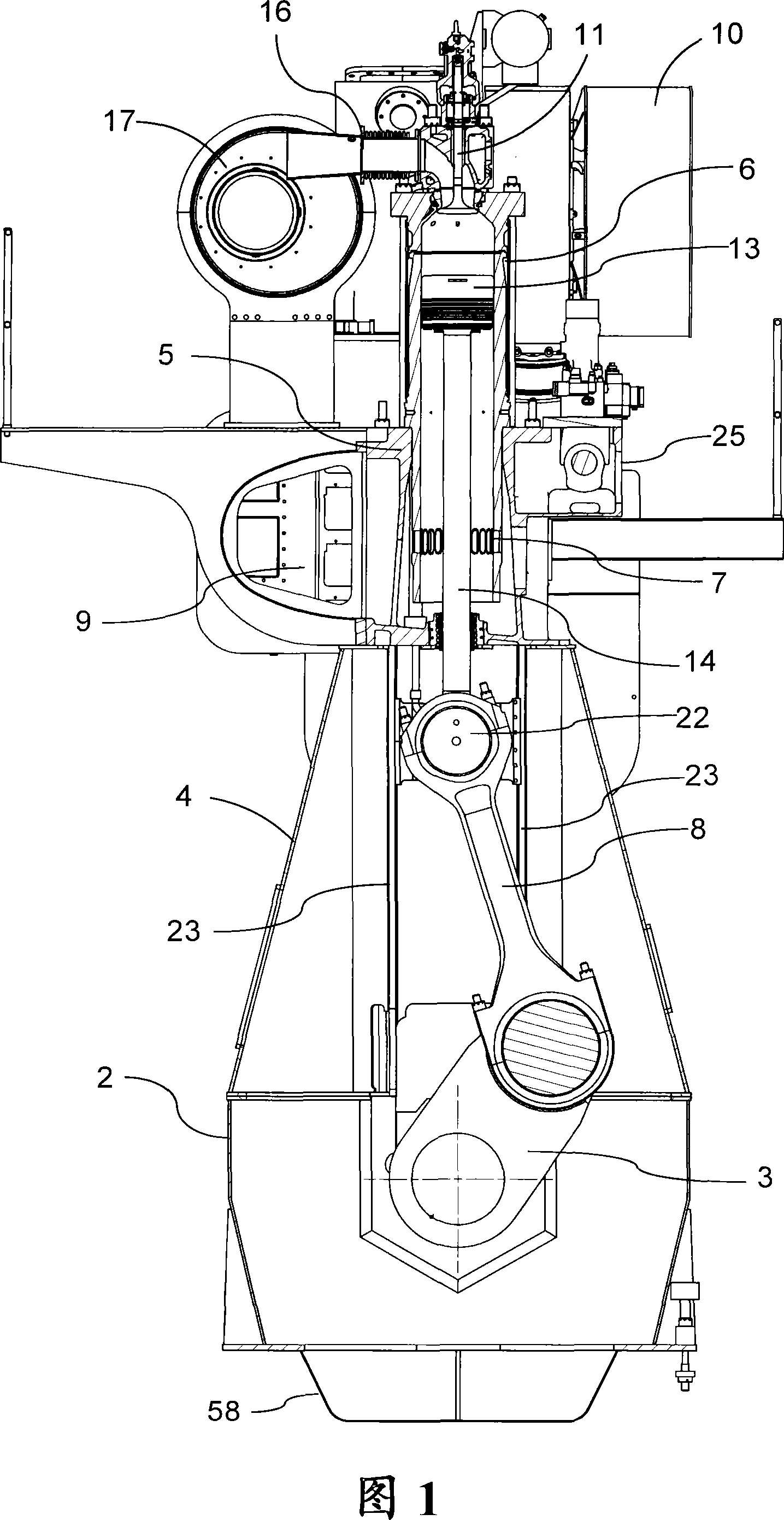

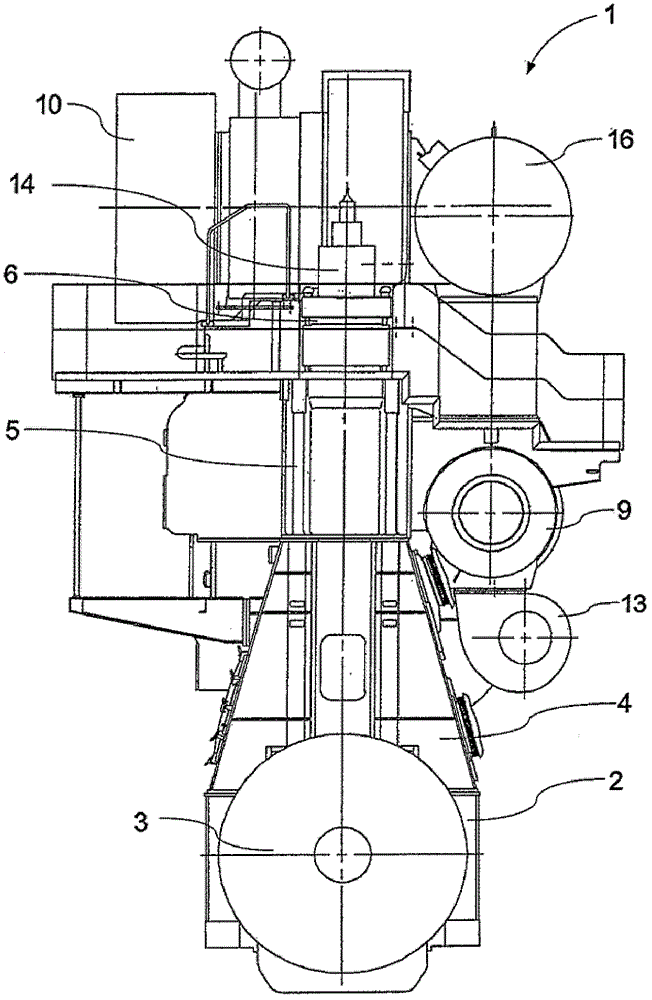

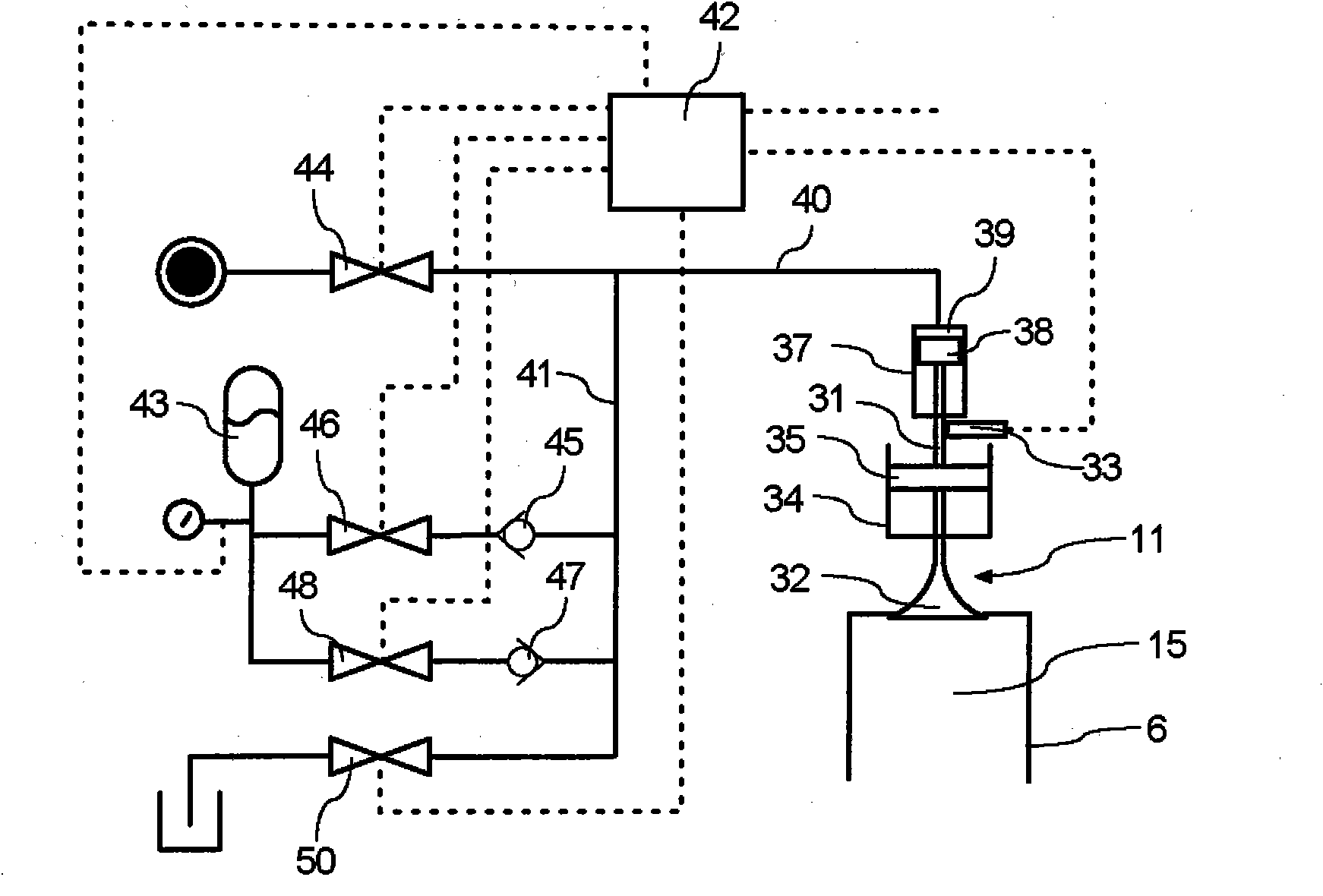

Cam driven exhaust valve actuation system for large two stroke diesel engine

InactiveCN102112708AEfficient productionTurn on stroke increaseValve drivesMachines/enginesExhaust valveAir spring

A large two-stroke diesel engine (1) with an exhaust valve actuating system including a camshaft (28) and hydraulic pushrods that include a piston pump (32) driven by the camshaft coupled via conduit (36) to a hydraulic exhaust valve actuator (34) for moving the exhaust valve (11) concerned. The camshaft is provided with an exhaust cam (29) for each cylinder, and the exhaust cam is profiled with an increased lift (30) exceeding the lift required for opening the exhaust valve. A portion of the additional volume of hydraulic fluid generated by the increased lift of the hydraulic piston pumps is diverted from the hydraulic push rod and delivered to a consumer of pressurized hydraulic fluid that is associated with the engine. The other portion of the additional volume of hydraulic fluid results in additional exhaust valve lift. The energy stored in the air spring (33) urging the exhaust valve to close is returned to the camshaft during the return stroke of the exhaust valve.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

Exhaust valve actuator for large-scale two-stroke diesel engine

The invention relates to an exhaust valve actuator for large-scaled two-stroke diesel motor that is able to move between a closed position and an open position along opposite directions. The actuator includes a bidirectional hydraulic piston including a hydraulic closed chamber and a hydraulic open chamber. The bidirectional spring component is connected to the bidirectional piston and forms a mass spring system with the mandrel of exhaust valve actuator and any other mass of the component that accordantly moves therewith. The bidirectional spring component stores energy when the exhaust valve actuator reciprocally moves between the closed position and the open position so as to push the exhaust valve actuator along the opposite direction. An open / closed hydraulic valve alternatively connects the hydraulic closed chamber to a high pressure source and connects a hydraulic open chamber to an oil cylinder, or on the contrary. When the exhaust valve actuator is in an open position and when an electronically controlled hydraulic valve connects the hydraulic open chamber to a high pressure hydraulic fluid source, the closing force of the bidirectional spring and the opening force of the hydraulic open chamber are balanceable.

Owner:曼柴油机和涡轮公司,德国曼柴油机和涡轮欧洲股份公司的联营公司

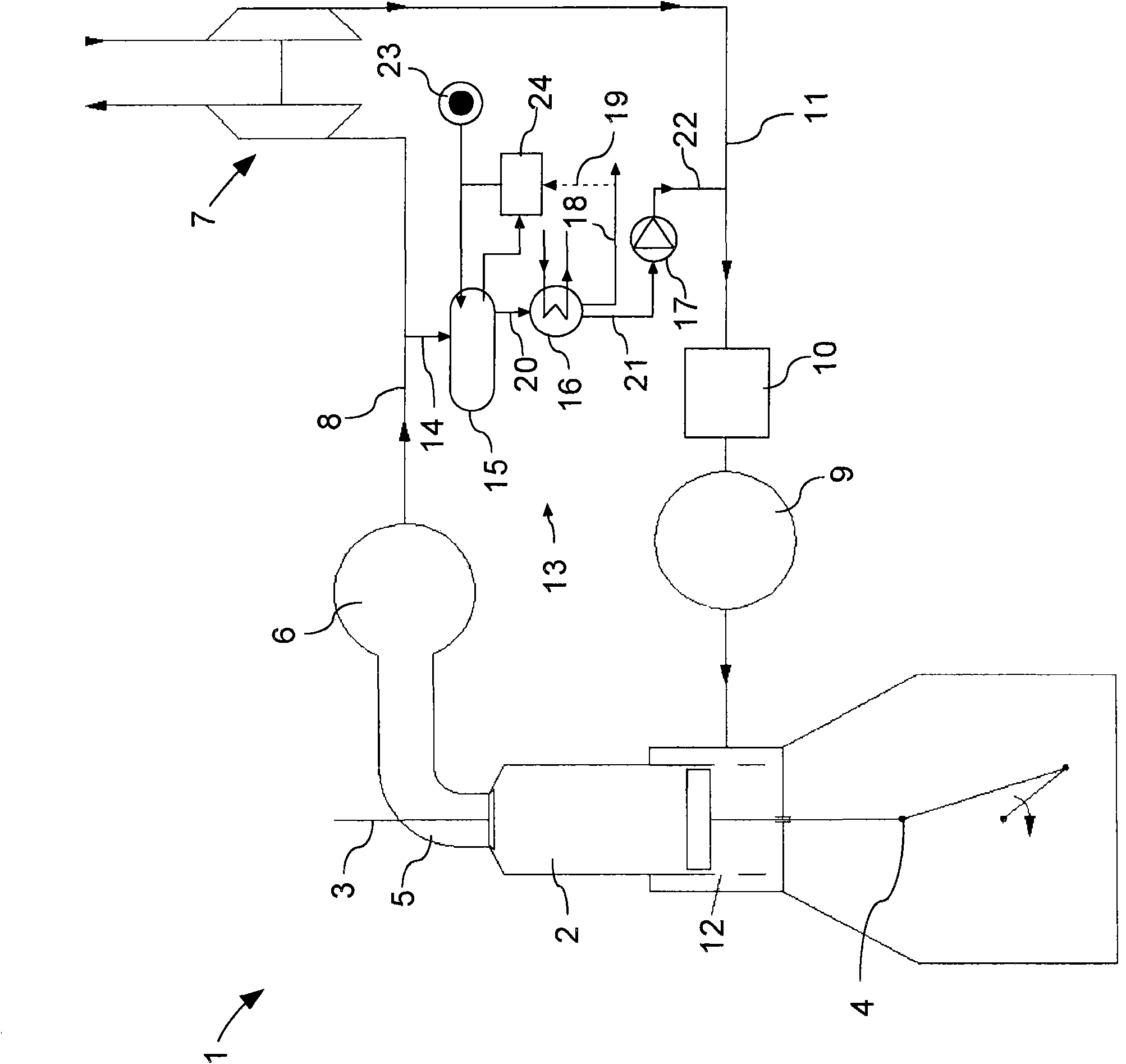

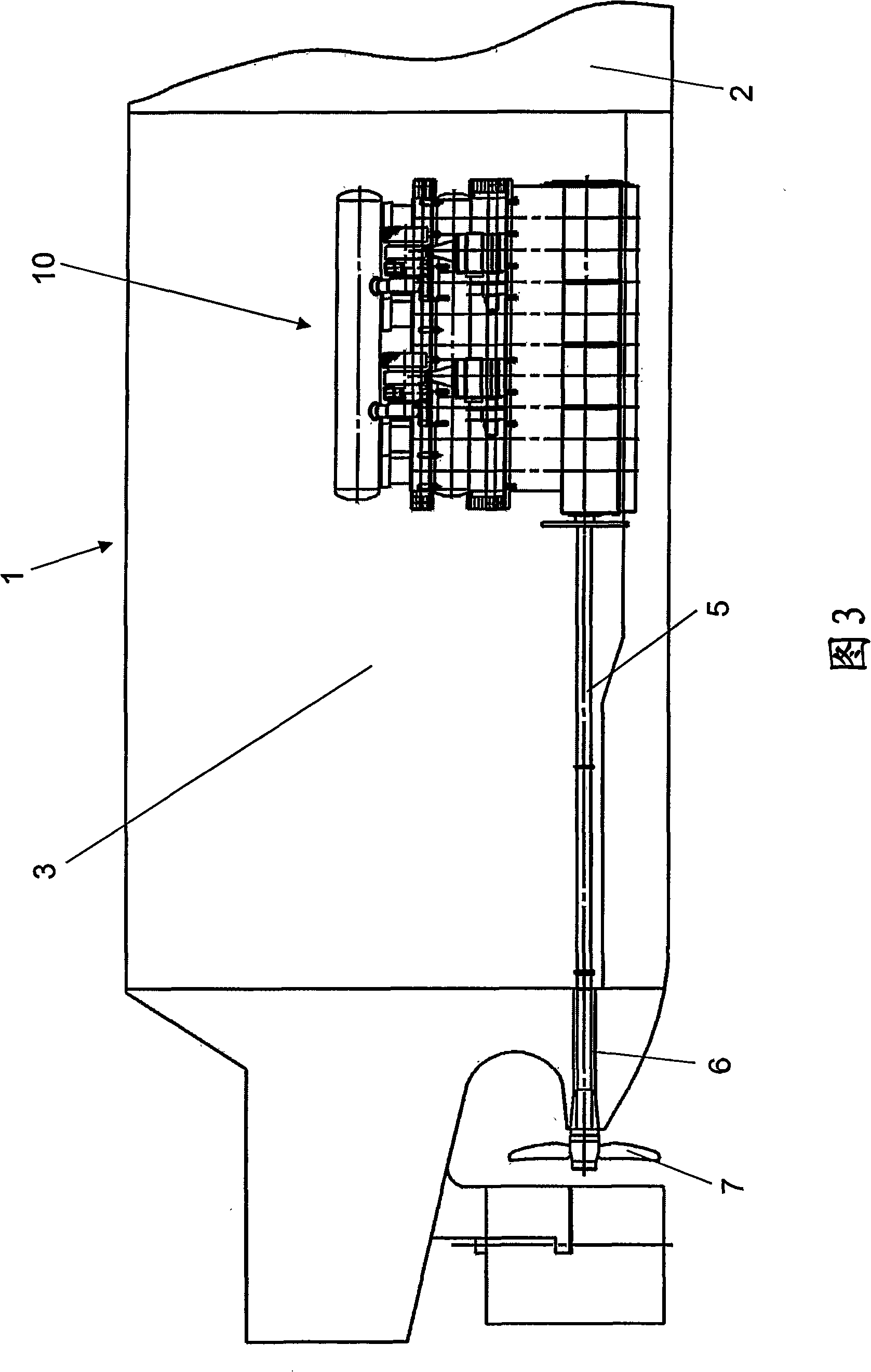

Propulsion system of ship

ActiveCN101283171AInternal combustion piston enginesPower plants being motor-drivenPropellerHigh pressure

A propulsion system for large ocean going vessels. The system includes a large turbo charged multi-cylinder two-stroke diesel engine of the crosshead type coupled to the propeller shaft as a main prime mover and one or more substantially smaller diesel engines coupled to generators as secondary prime movers. The main engine requires electric, hydraulic and pneumatic power in order to be able to startup and operate. The main engine requires heat and small hydraulic power during short stops, and hydraulic power, pneumatic and electrical power during startup. Hydraulic power is provided by one or more high-pressure pumps or pumping stations that are driven by power takeoff from the crankshaft of the large two-stroke diesel engine, by electric motors or by auxiliary diesel engines.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

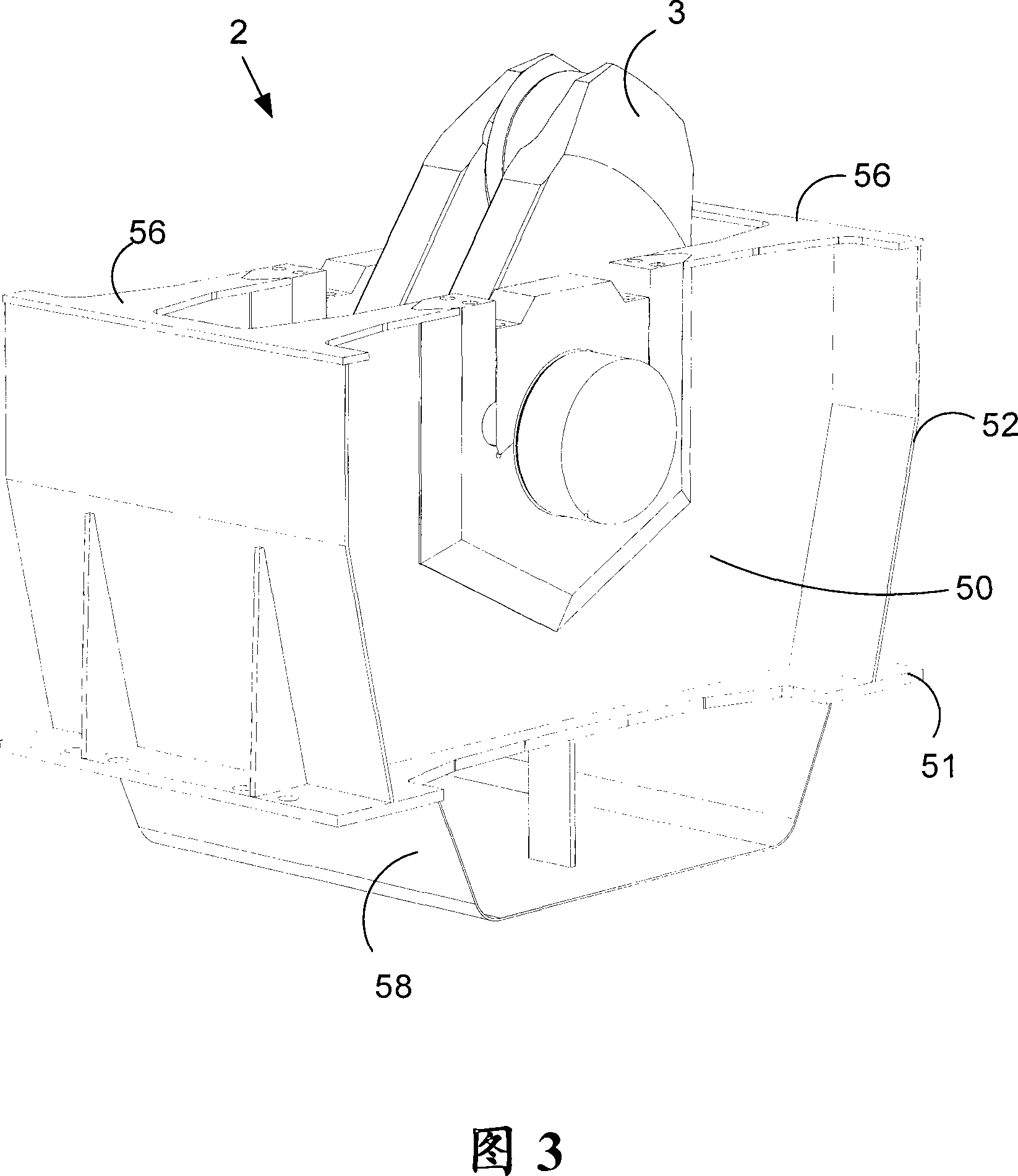

Main bearing support for a large two-stroke diesel engine

InactiveCN101171415AAvoid expensiveReduce transfer timeCasingsMachine framesEngineeringTwo-stroke diesel engine

A large two-stroke diesel engine of the crosshead type with a bedplate, a frame box mounted on the bedplate and a cylinder frame mounted on the frame box. The bedplate comprises welded cross girders with the main bearings for the crankshaft. The cross girders include a main bearing support made from a rolled steel slab or plate with an arc shaped support surface machined therein. The slab or plate is welded to the webplates to form a cross girder.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

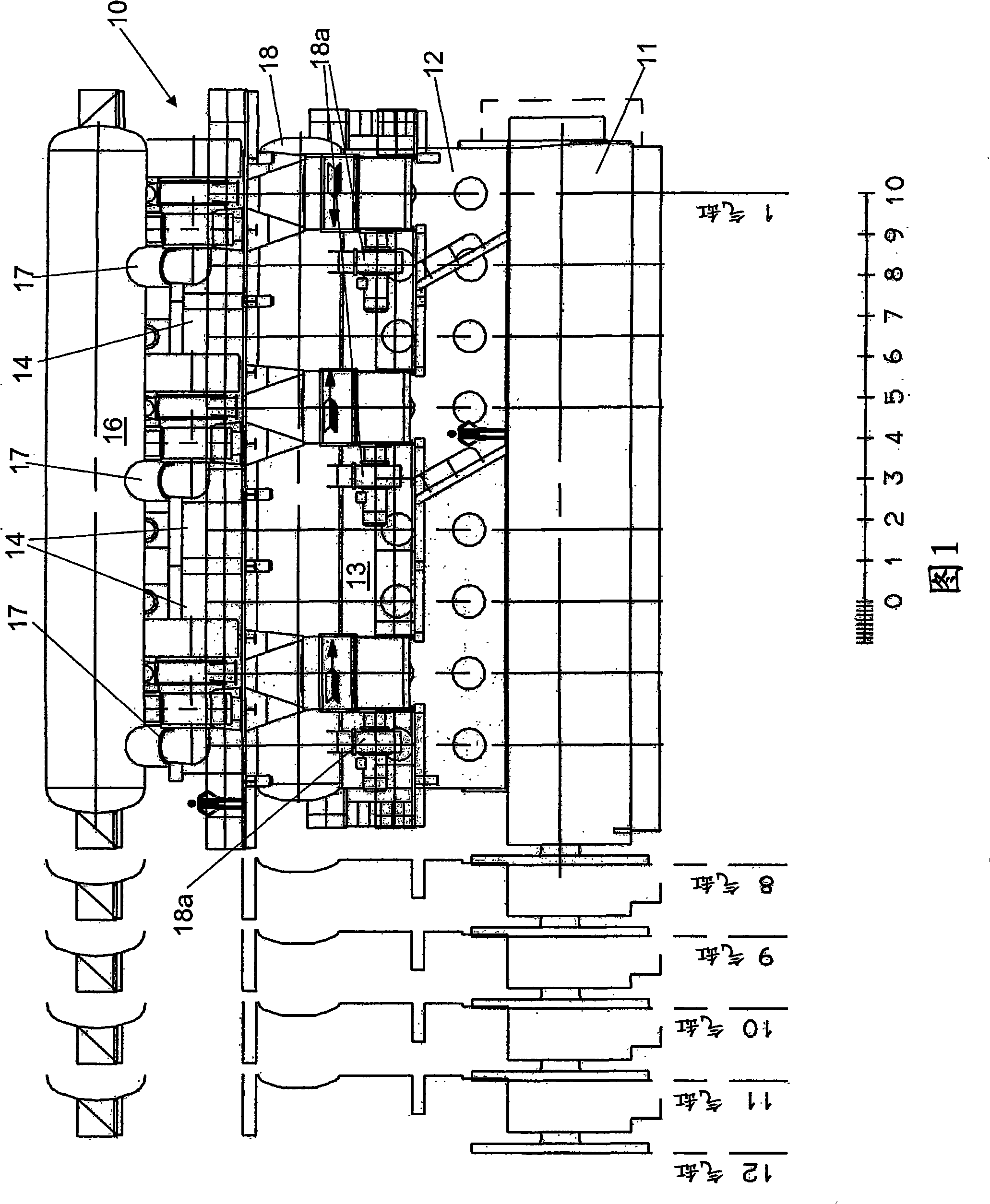

Internal combustion engine, exhaust valve and cylinder head therefor, and production, operation and use of an internal combustion engine

ActiveCN103370523ASimple structureEase of retrofittingNon-fuel substance addition to fuelInternal combustion piston enginesExhaust valveCylinder head

The invention relates to an internal combustion engine, in particular a large two-stroke diesel engine, comprising at least one combustion chamber (2) delimited by a cylinder (1) and a piston (3) interacting with a crankshaft, said combustion chamber comprising at least one combustion gas outlet (20; 120; 320; 420), which is formed between a valve disk (8; 108; 308) of an exhaust valve (9; 109; 309) and an associated disk seat, and at least one charge air inlet (4). The exhaust valve (9; 109; 309) can be actuated between an open position and a closed position. The combustion gas outlet (20; 120; 320; 420) is connected to at least one outlet channel (11) and to at least one combustion gas draw-off duct (18; 118a, 118b; 318, 318a; 418, 418a), for example in order to recirculate part of the combustion gas generated during combustion to the charge air inlet (4). The invention further relates to an exhaust valve (9; 109; 309) and to a cylinder head for such an internal combustion engine. The invention is characterized by a throttle device (10; 110; 310) which is fastened to the exhaust valve (9; 109; 309) or integrally molded as part of the exhaust valve (9; 109; 309) and by means of which the combustion gas is drawn off in a predetermined way. The invention further relates to a method for producing an internal combustion engine, to a method for operating an internal combustion engine, and to a use for an internal combustion engine.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

Large two-stroke diesel engine with exhaust gas scrubber

The present invention provides a large two-stroke diesel engine with an exhaust gas scrubber, wherein the water with high salinity is pumped to the exhaust gas scrubber for generating spray. The exhaust gas passes through the spray for reducing the content of SO2. The engine is also provided with a scavenging humidifying unit which is operated by sea water and / or a fresh water generator that converts sea water to fresh water. The high salinity waste water of the scavenging humidifying unit and / or the fresh water generator is used for the exhaust gas scrubber. Compared with the common sea water, the high salinity of the waste water increases the efficiency of the scrubber. Therefore, a considerably large pumping workload required for keeping the operation of scrubber can be remarkably reduced.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

Common rail fuel injection system with fuel circulation for a large two-stroke diesel engine

InactiveCN101070788ASimple structureEasy maintenanceInternal combustion piston enginesFuel injection apparatusCylinder headCommon rail

The invention provides a large two-stroke diesel engine with a common fuel injection system. A fuel injection of a large two-stroke diesel engine includes a low pressure conduit, an intermediate pressure conduit, a high pressure common fuel rail. The control valves control the flow from the common fuel rail to the fuel injection valve. The fuel valve comprises a entry connected with control valve through injection conduit, and a exit connected with the low pressure conduit. The control valve connects the injection conduit with common rail when the fuel injection starts, and connects the injection conduit with low pressure conduit or intermediate pressure conduit when the fuel injection ends. The invention furthermore comprises valve gear for connecting the intermediate pressure conduit with injection conduit directly or by control valve, and for fuel cycle during outofoperation of engine.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

Crosshead bearing for large two-stroke diesel engine

A positively dimensioned crosshead bearing (1) having a crosshead journal (4) with an axial bore (5) receiving system oil via a flexible connection. The system oil is distributed to the piston, the bearing surface of the crosshead and the crankpin bearing. At least two axial lubrication grooves (22) are disposed in the lower bearing surface. The bearing surface between the at least two axial lubrication grooves (22) is not interrupted nor distorted.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

Two-stroke diesel engine

ActiveCN102777248AReduce resistanceBurn fullyInternal combustion piston enginesOutput powerExhaust valveInlet channel

The invention relates to a two-stroke diesel engine. The two-stroke diesel engine comprises a cylinder sleeve, an exhaust pipe and a piston and is characterized in that a gas inlet pipe is arranged outside the cylinder sleeve, fresh air with certain pressure exists in the gas inlet pipe, the gas inlet pipe is communicated with a gas inlet on the cylinder sleeve through a gas inlet channel, and a gas inlet valve opening on the gas inlet channel is provided with a gas inlet valve which can open and close the gas inlet valve opening; an exhaust valve is opened and waste gas is exhausted before the piston moves down to a position at which a piston ring is close to the upper edge of the gas inlet; the gas inlet valve is opened, pressing of the fresh air is conducted and the waste gas is discharged further, when the piston continues to move down to the gas inlet and the piston is communicated with the inner cavity of the cylinder sleeve on the upper portion of the piston; and before the piston moves up and the piston ring is close to the upper edge of the gas inlet, the exhaust valve is closed firstly and the gas inlet valve is closed later. The gas inlet valve which is arranged at a position of the gas inlet channel is provided with the gas inlet opening. Even though the piston is far away from the gas inlet during the moving process, no fresh air leaks into a machine cavity on the lower portion through the gas inlet, the piston is not required to be lengthened and can moves a position which is far away from the gas inlet, and the stroke of the piston is increased greatly.

Owner:浙江洋普重机有限公司

A large two-stroke diesel engine and a supporting plate structure for connection between an engine main structure and an exhaust gas receiver

The structure has an upright plate (100) whose upper and lower ends are attached to an exhaust-gas receiver (16) and a main portion (1) respectively. A pair of steel plate arranged in upright plate, is extended toward the exhaust-gas receiver. A spacer is arranged between steel plates formed in the upright plate. The predetermined interval is formed between steel plate and spacer.

Owner:MAN ENERGY SOLUTIONS FILIAL AF MAN ENERGY SOLUTIONS SE TYSKLAND

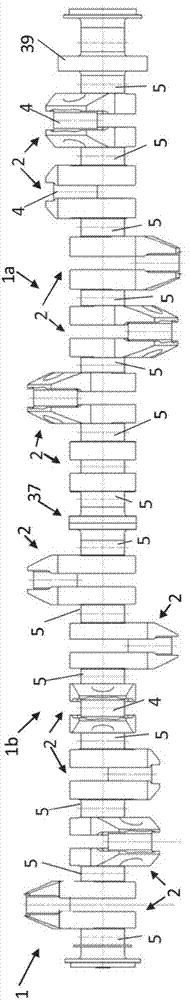

Crankshaft, bearing assembly and large multi-cylinder two-stroke diesel engine

ActiveCN103807282ARelieve stressWell mixedRotary bearingsCrankshaftsReciprocating motionTwo-stroke diesel engine

A crankshaft (1) for a reciprocating piston engine (10) or compressor. The crankshaft (1) has a plurality of throws (2) that are interconnected by main journals. The main journals (5) have a main journal bearing surface with a given width (W) between the two axial ends of (42,43) of said main journal bearing surface (40). At least one receding area (45) is provided in the main journal bearing surface (40) of at least one of the main journals (5). The at least one receding area (45) adjoins one of the two axial ends (42,43) and the receding area (45) has a depth (y) that generally decreases in the axial direction away from the one of the two axial ends (42,43) that the receding area (45) adjoins. A bearing assembly with a plurality of main bearings (62,80,86,87) and a crankshaft (1) as above. A large multi-cylinder two-stroke diesel engine of the crosshead type or a large compressor of the crosshead type with a crankshaft as above or with or a bearing assembly as above.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

Large two-stroke diesel engine with electronically controlled exhaust valve actuation system

A large two-stroke diesel engine with an electronically controlled exhaust valve actuation system includes for each cylinder an exhaust valve with a valve stem and a valve disc, an air spring operably connected to the valve stem and urging the exhaust valve towards the closed position, a hydraulic actuator operably connected to the exhaust valve, an electronically controlled hydraulic system thatselectively connects the hydraulic actuator to a source of high pressure hydraulic fluid for a first short period at the start of the opening stroke of the exhaust valve, and an intermediate pressurehydraulic accumulator for a period immediately following the first short period until the exhaust valve has reached it open position, the intermediate pressure hydraulic accumulator from the start ofthe closing stroke of the exhaust valve until the start of a last short period at the end of the closing stroke of the exhaust valve, and to tank during the last short period of the closing stroke ofthe exhaust valve.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com