Common rail fuel injection system with fuel circulation for a large two-stroke diesel engine

A fuel injection system and fuel injection technology, applied in the direction of fuel injection devices, charging systems, mechanical equipment, etc., can solve the problems of no degassing effect, increased engine maintenance complexity, increased device complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

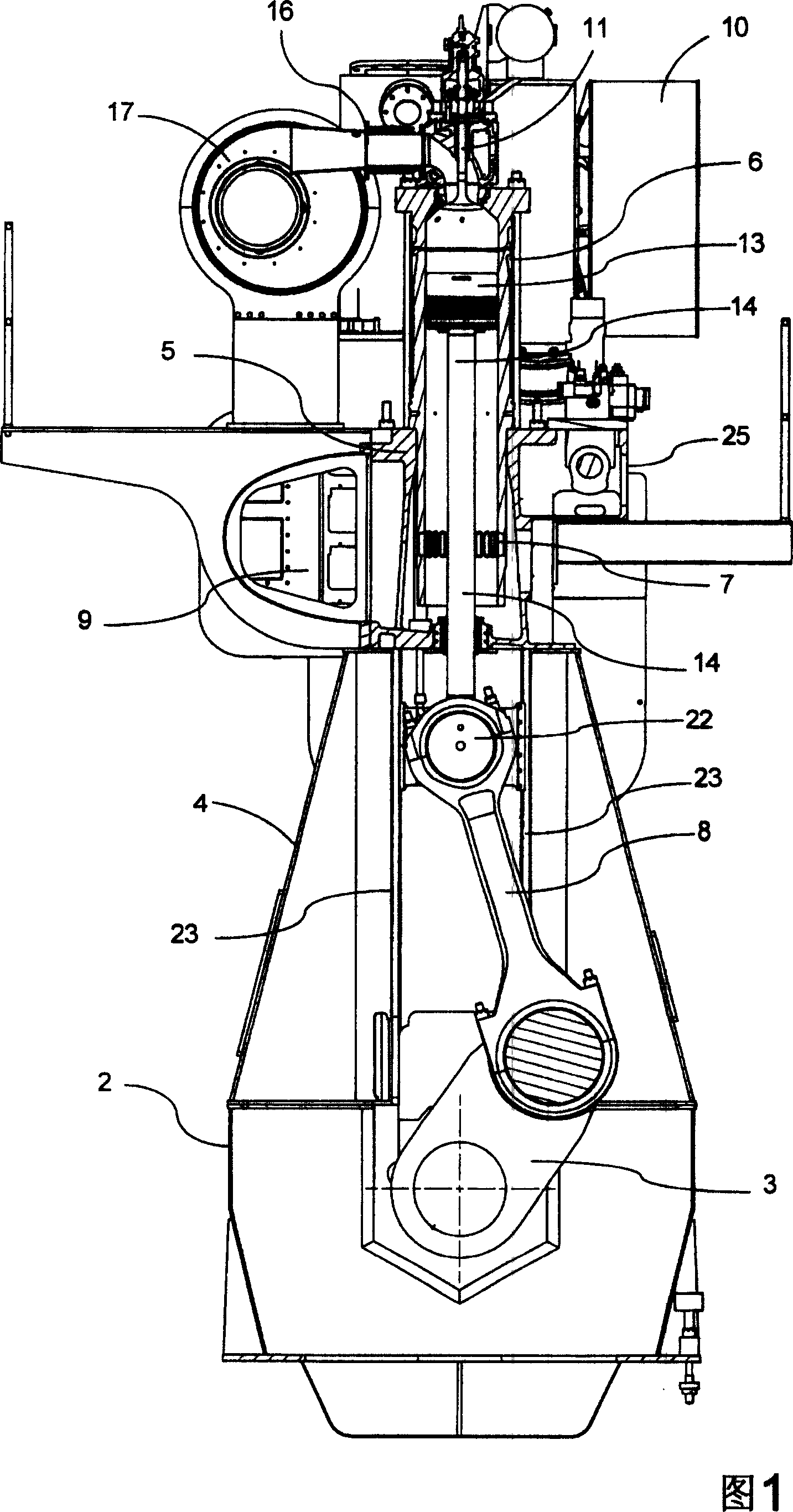

[0023] 1 and 2 respectively show a sectional view and a longitudinal sectional view (for a single cylinder) of an engine 1 according to a preferred embodiment of the invention. The engine 1 is a one-way flow, low-speed, two-stroke, crosshead crosshead diesel engine, which can be used as a propulsion system of a ship or a prime mover in a power plant. These engines typically have 3 to 14 cylinders arranged in series. Engine 1 is formed by a base plate 2 with main bearings for crankshaft 3 .

[0024] Crankshaft 3 is of the semi-compound type. The semi-composite type is made of a forged or cast steel crank that is connected to the main journal by a shrink fit.

[0025] The bottom plate 2 can be integrated or divided into several parts of appropriate size according to the convenience of manufacture. The base plate includes side walls and welded cross girders with bearing seats. Cross beams are also referred to as "transverse beams" in the prior art. An oil pan 58 is welded to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com