Internal combustion engine, exhaust valve and cylinder head therefor, and production, operation and use of an internal combustion engine

A technology of internal combustion engine and exhaust valve, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve problems such as consumption, achieve the effect of simple structure and avoid power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

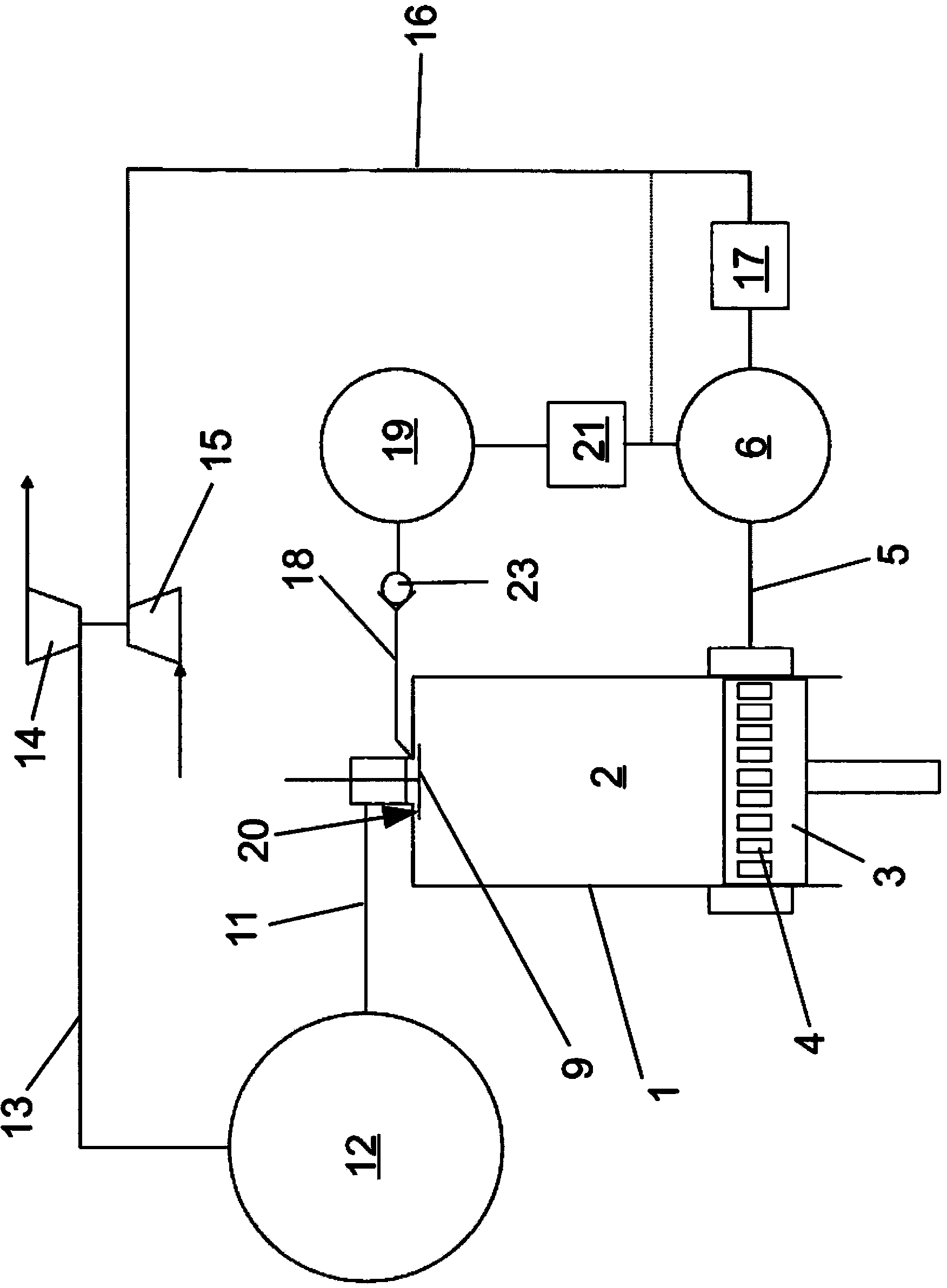

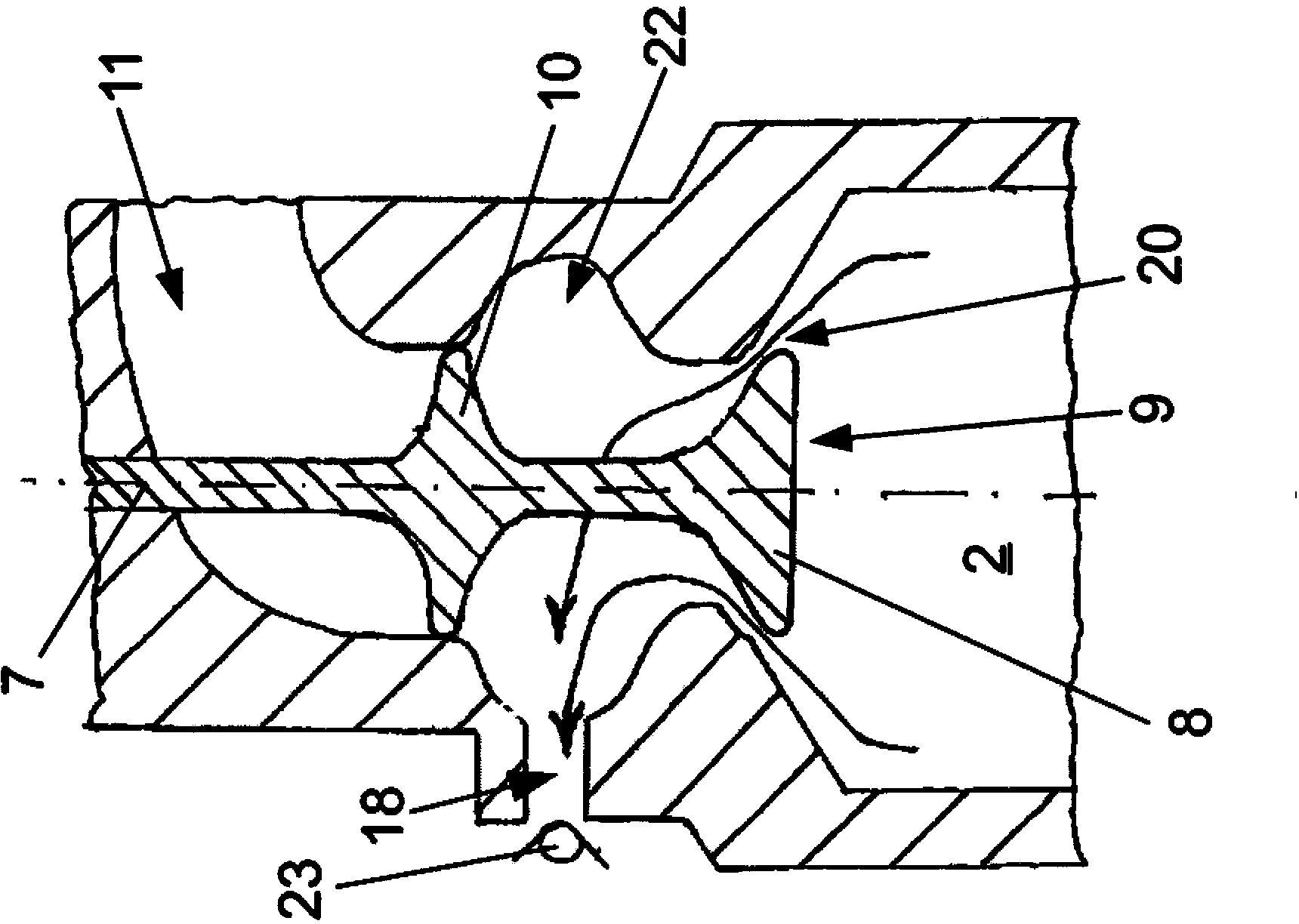

[0049] The main field of application of the invention is two-stroke large diesel engines, as they are used, for example, as ship drives. The basic structure and mode of operation of such arrangements are known per se. In this case, a part of the exhaust gas is often returned, that is to say recirculated into the working chamber 2 for the reduction of NO x emissions. In order to simplify the control and ensure precise metering, this so-called recirculation gas should be the purest possible combustion gas, that is to say not exhaust gas diluted with purge gas.

[0050] figure 1 For example, an internal combustion engine with combustion gas recirculation can be seen, which is developed according to an embodiment of the invention. However, the invention is not limited to the presence of recirculation figure 1 The structure shown purely by way of example. It is also possible to use different exhaust valves and cylinder heads constructed in accordance with the invention, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com