Exhaust valve assembly for a large two-stroke diesel engine

A diesel engine, stroke technology, applied in combustion engines, mechanical equipment, engine components, etc., can solve problems such as waste, and achieve the effect of simplified complexity and low construction height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

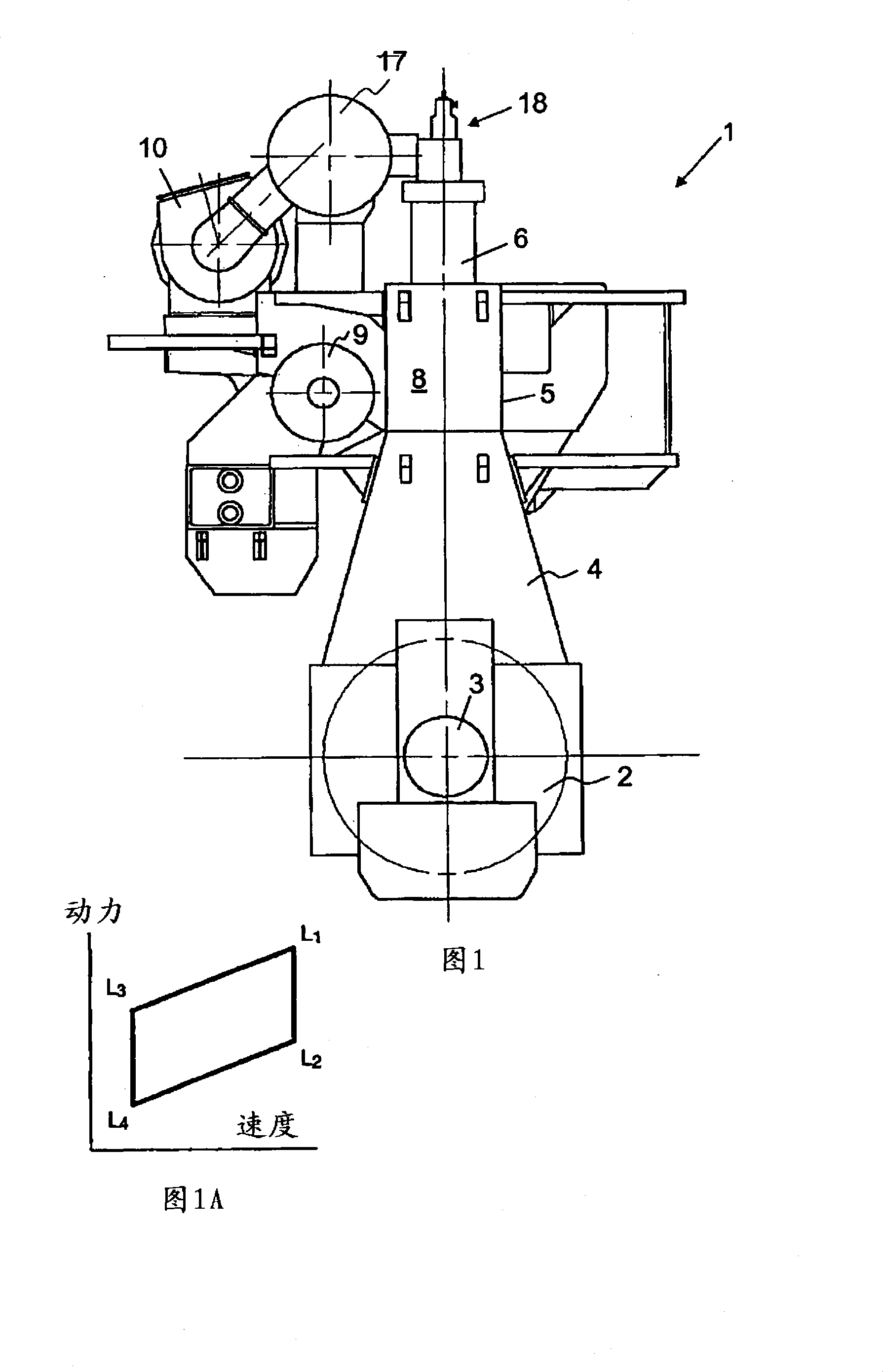

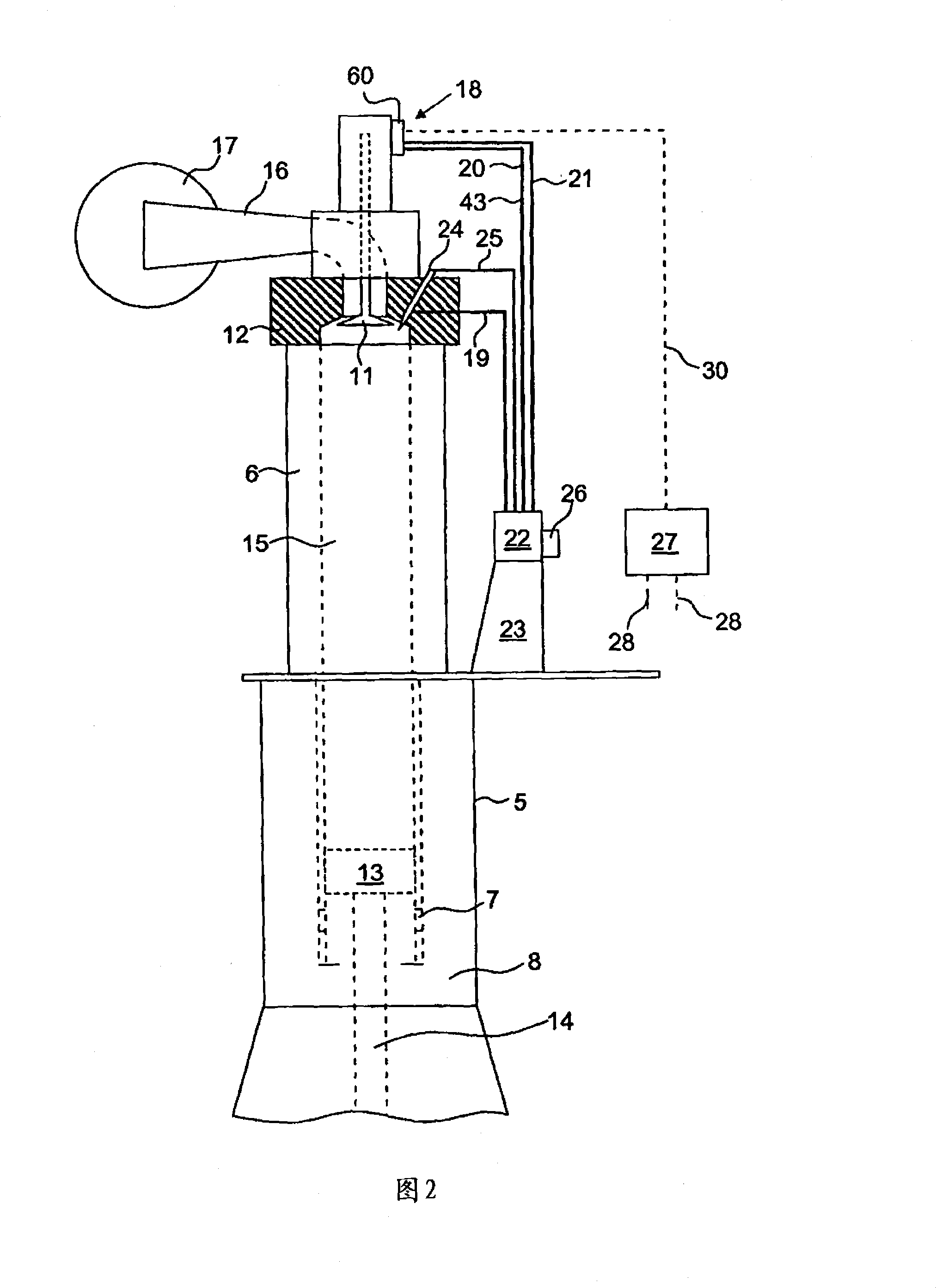

[0065] Figure 1 shows an engine 1 according to the invention. The engine is a low speed two stroke crosshead type diesel engine which may be a propulsion engine on a ship or a prime mover in a power plant. These engines typically have 6 to 12 in-line cylinders. The engine is built upwards from a base plate 2 with main bearings for the crankshaft 3 . The base plate is divided into sections of suitable size according to the available manufacturing equipment. An A-shaped crankcase frame 4 of welded design is mounted on the base plate. The cylinder block 5 is installed on top of the crankcase frame 4 . Tension bolts (not shown) connect the base plate to the cylinder block and hold the structure together. The cylinder 6 is supported by the cylinder block 5 . An exhaust valve assembly 18 is mounted on top of each cylinder 6 . The cylinder block 5 also carries an exhaust gas collector 17 , a turbocharger 10 and a scavenging gas collector 9 .

[0066] Figure 1A shows a layout f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com