Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Organic fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The definition of organic fraction of municipal solid waste (OFMSW) varies regionally and nationally; in the United States of America, OFMSW is considered a mixture of food, garden wastes and paper ( Palmisano and Barlaz, 1996 ). In the European Union is considered a mixture of wastes from parks, gardens and kitchens ( Al Seadi et al., 2013 ).

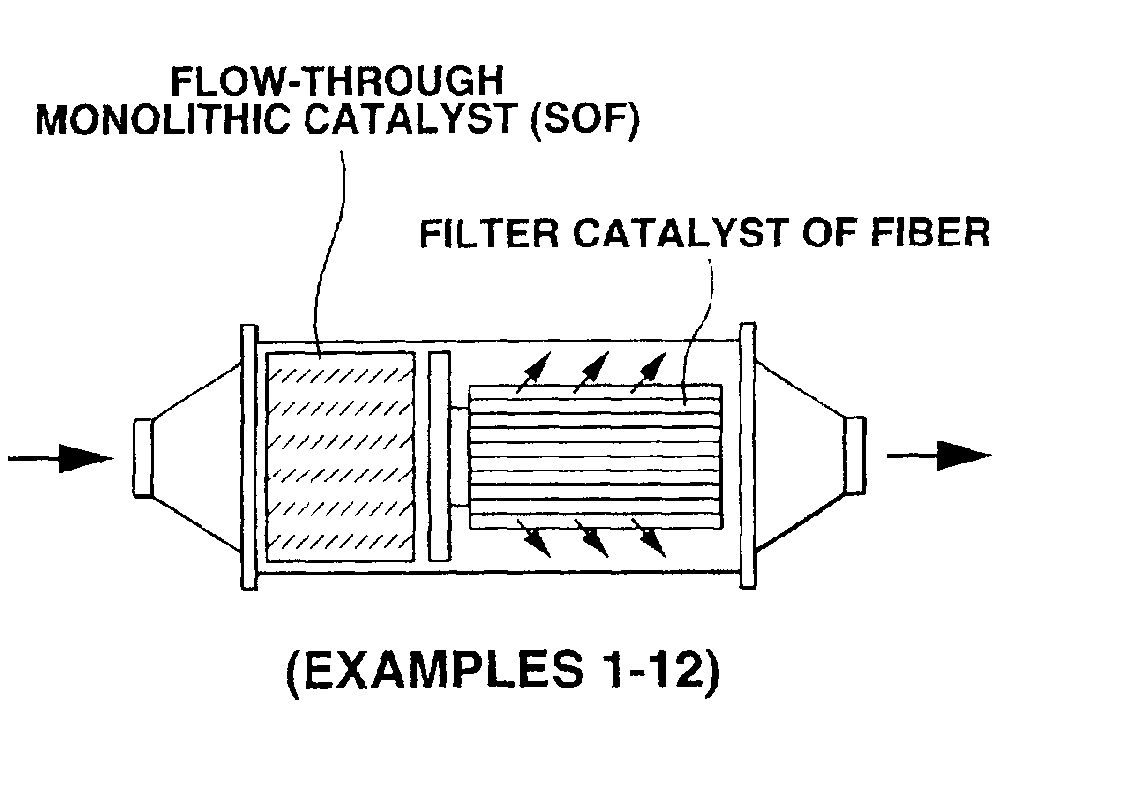

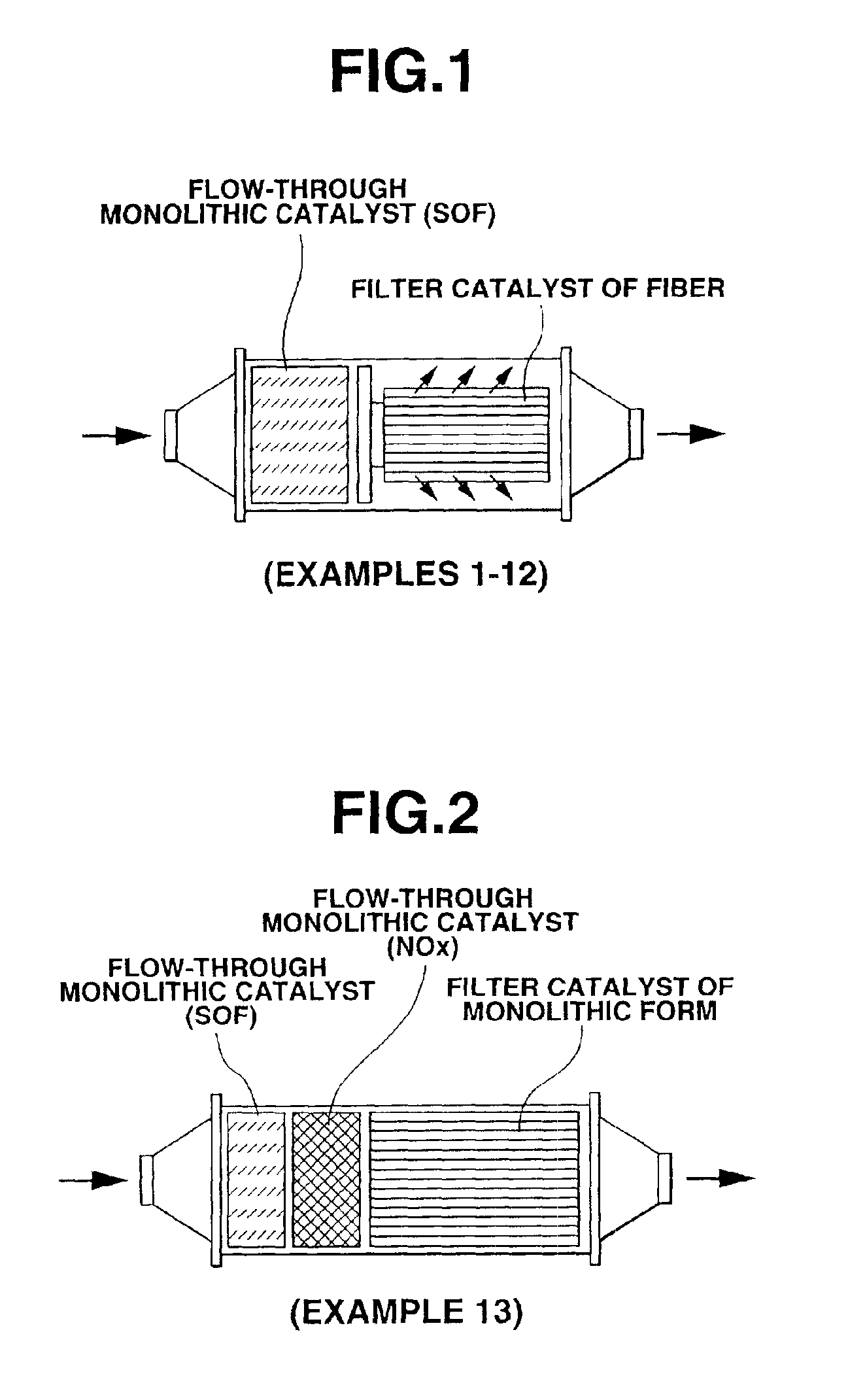

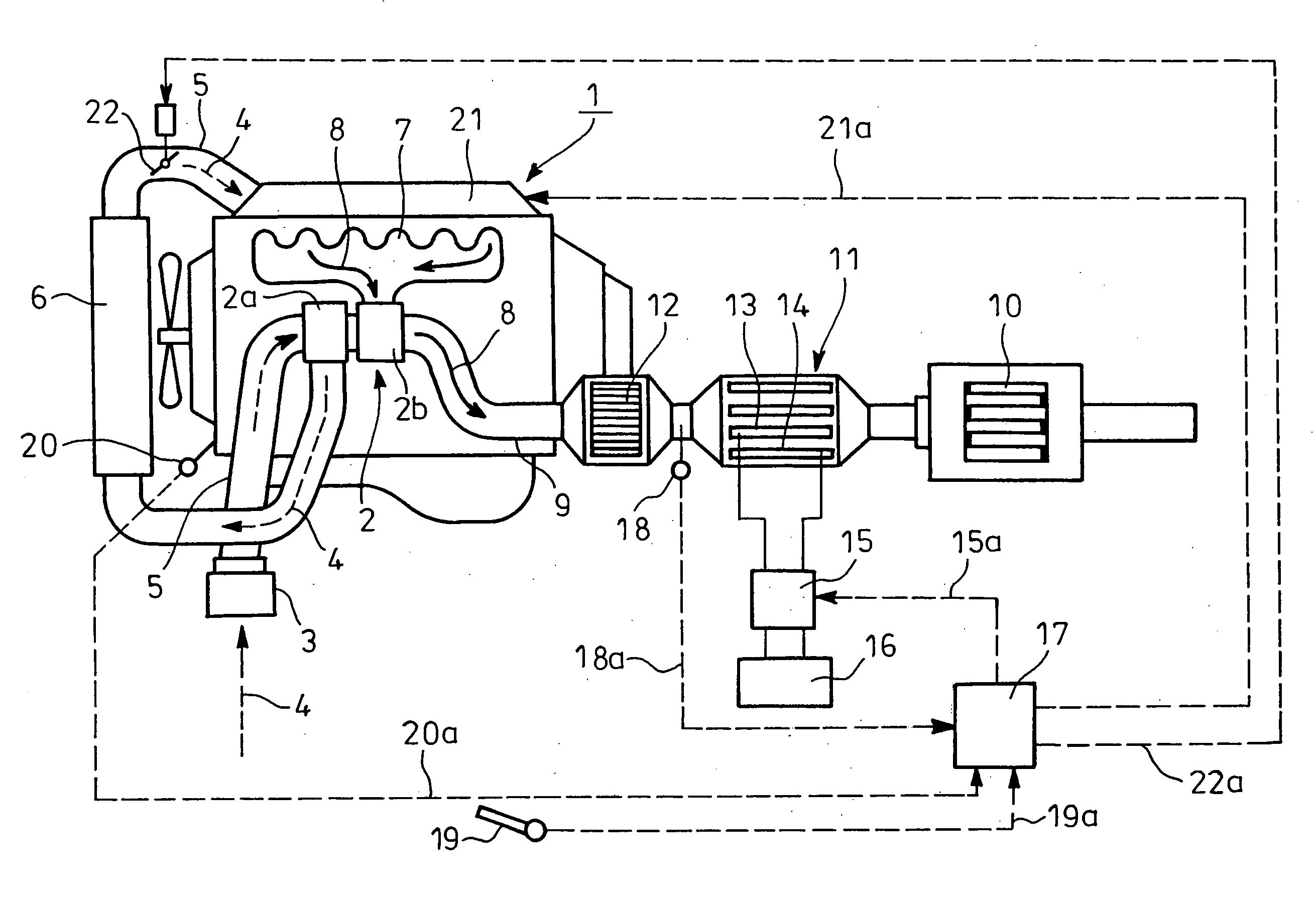

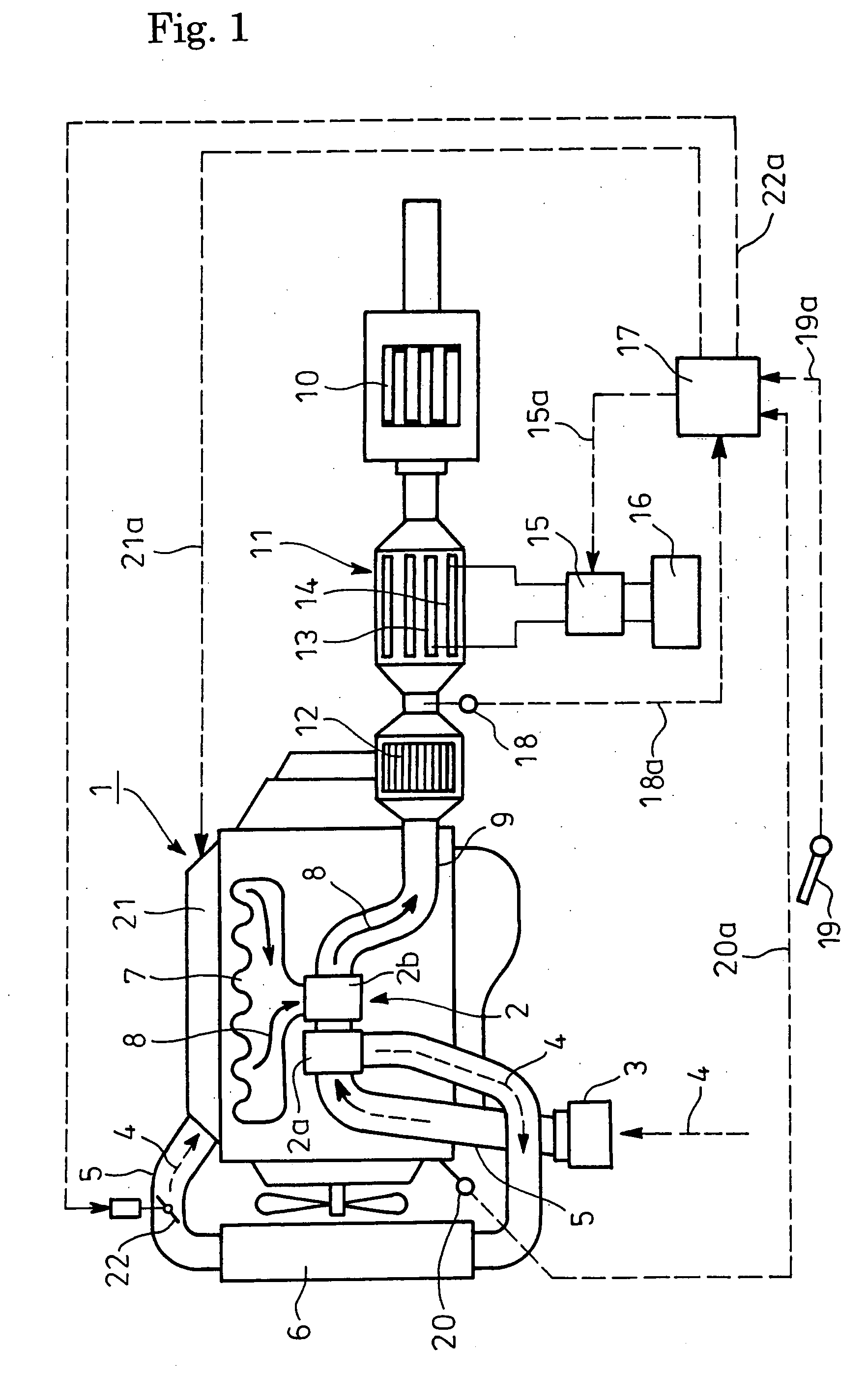

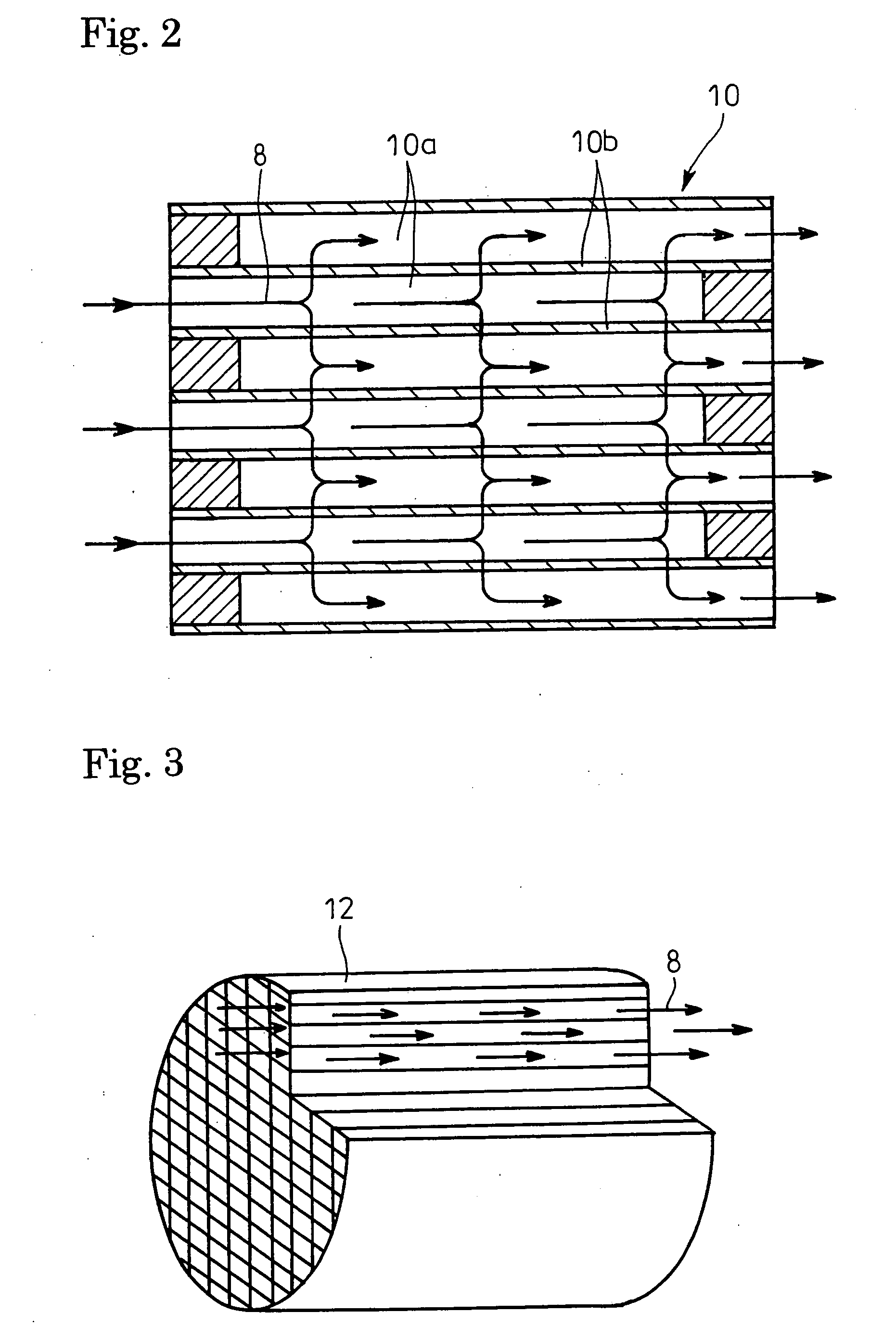

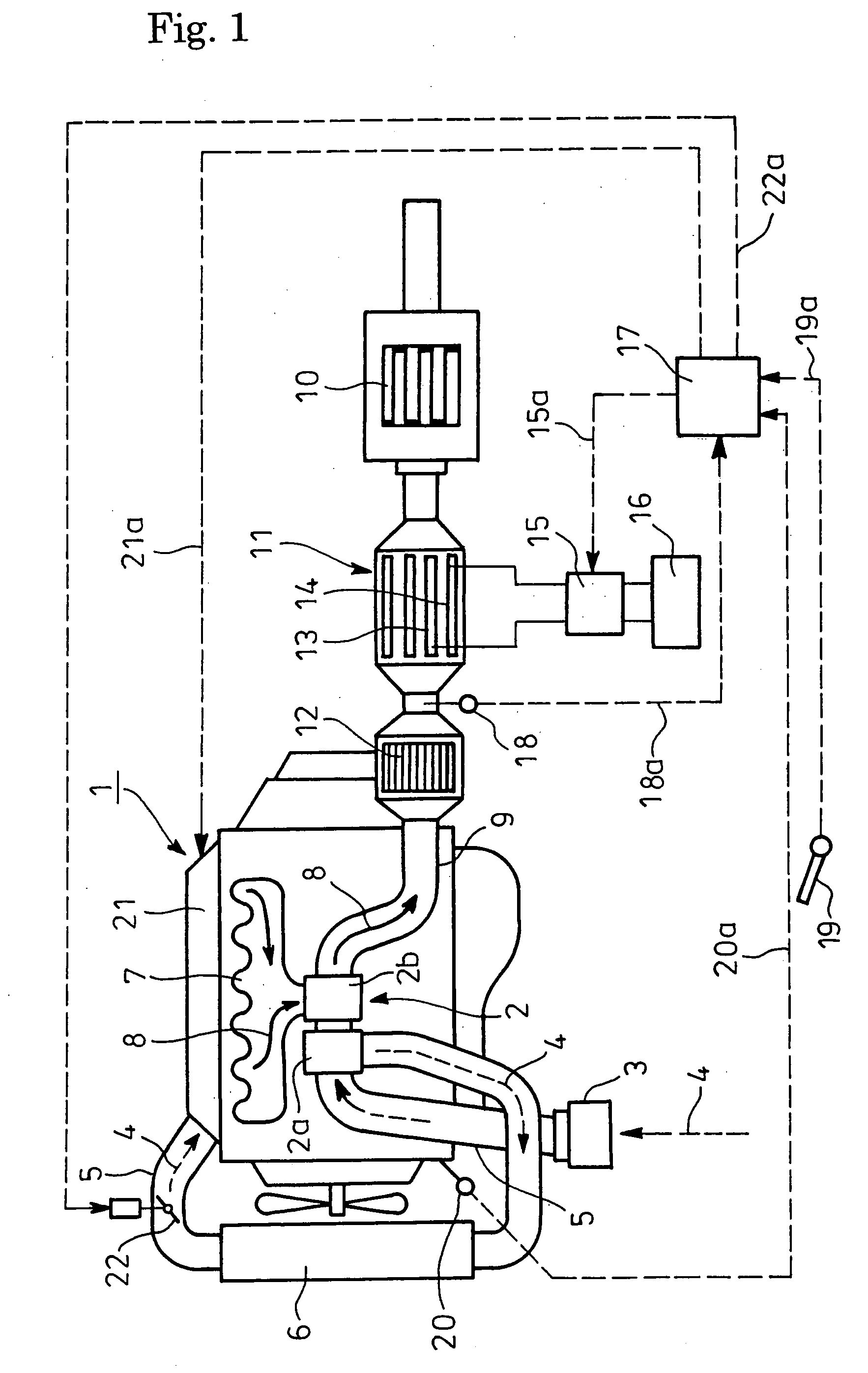

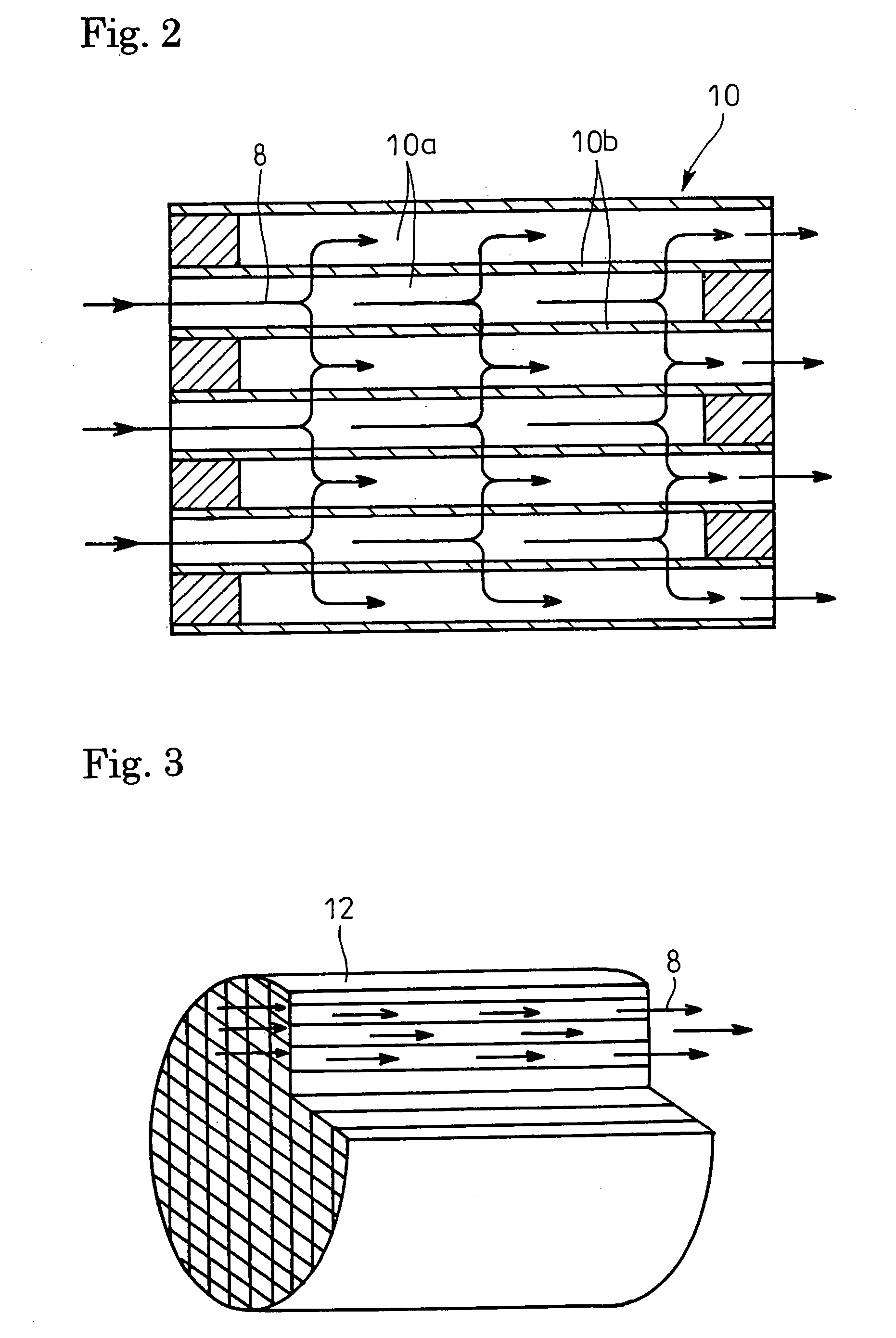

Exhaust gas purifying system and method

InactiveUS20020053202A1Improve efficiencyEasy to useMaterial nanotechnologyCombination devicesOrganic fractionNitrogen monooxide

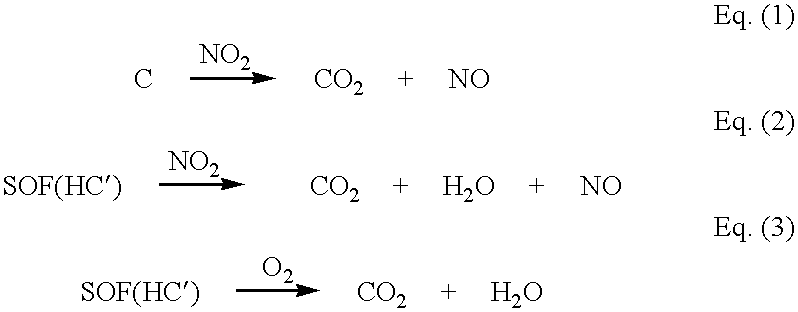

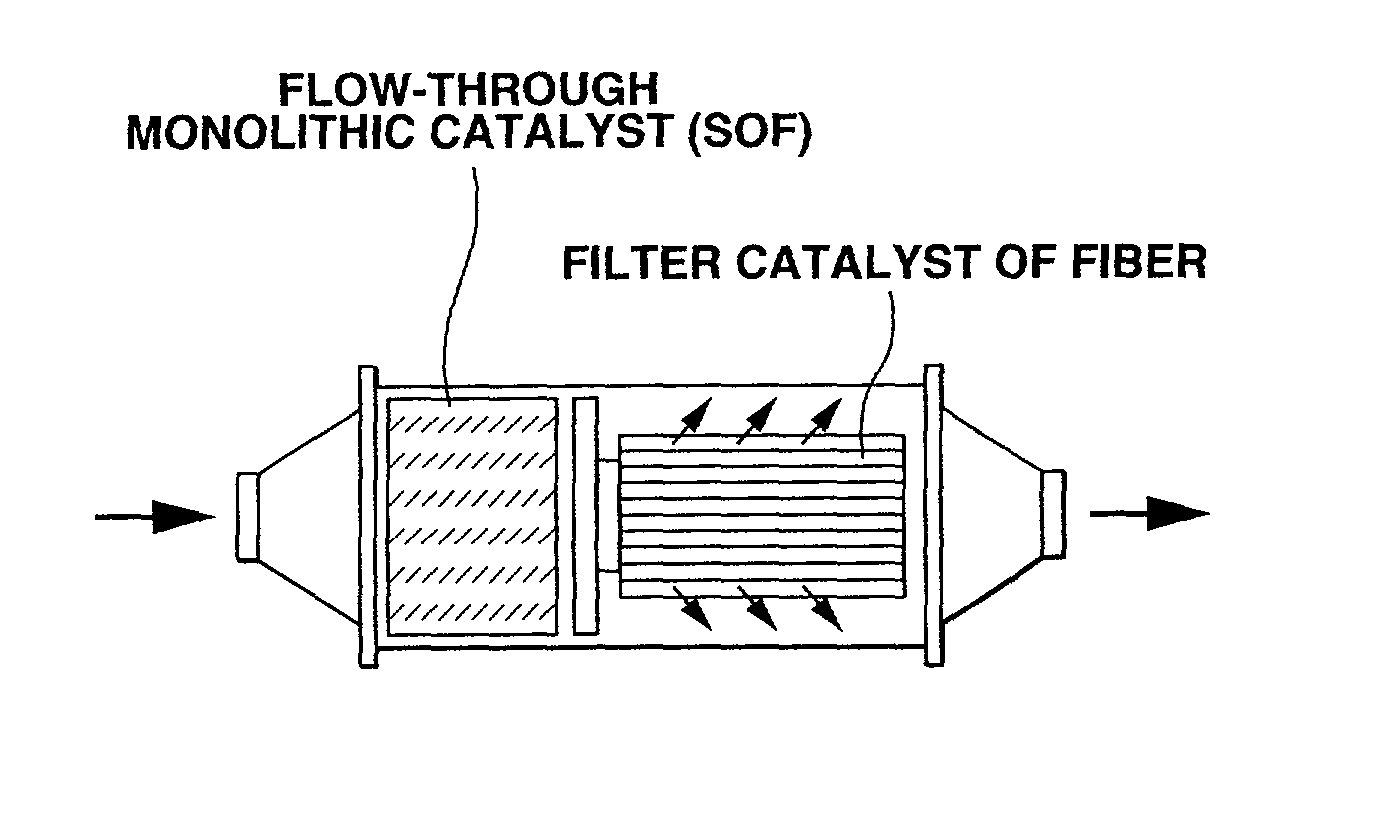

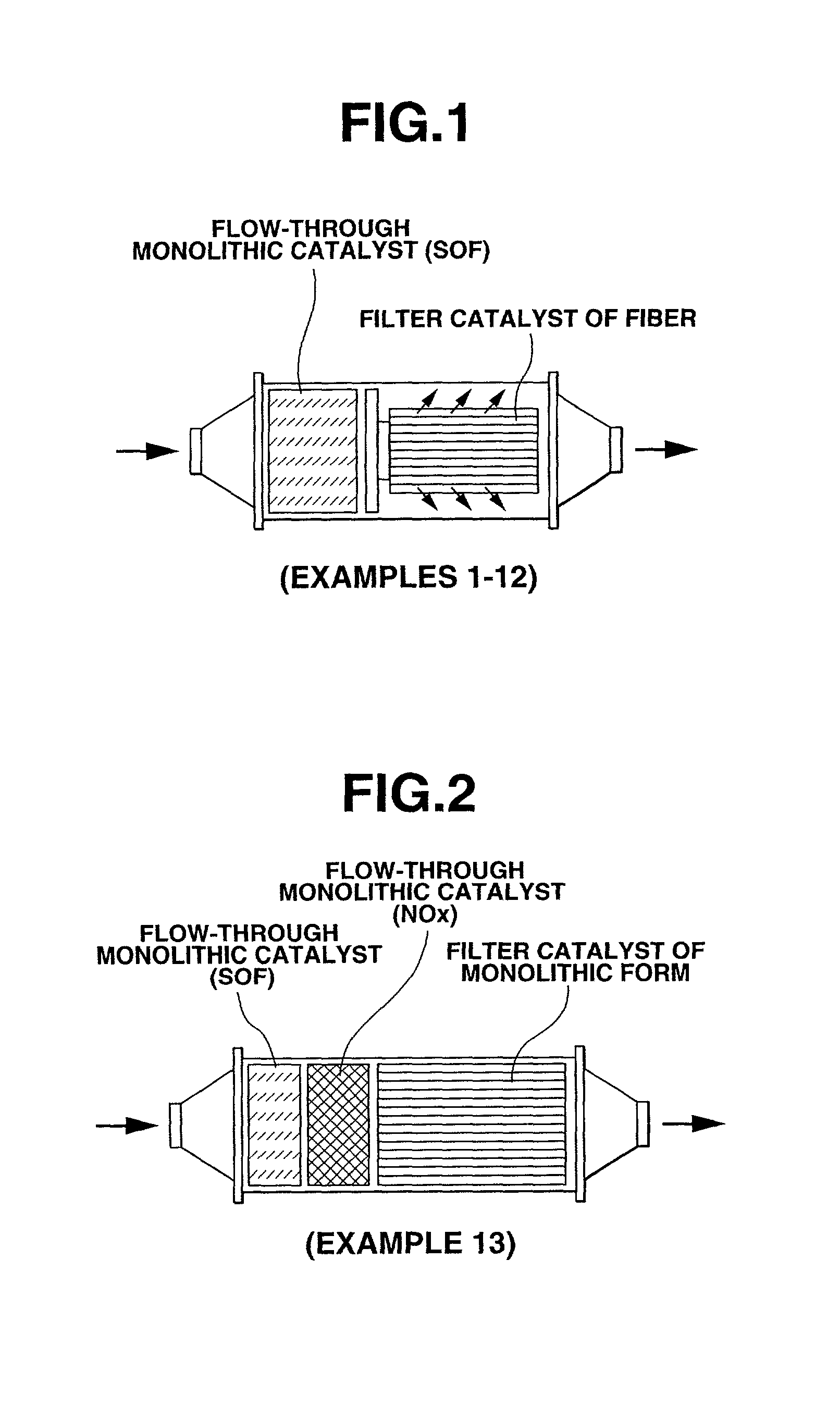

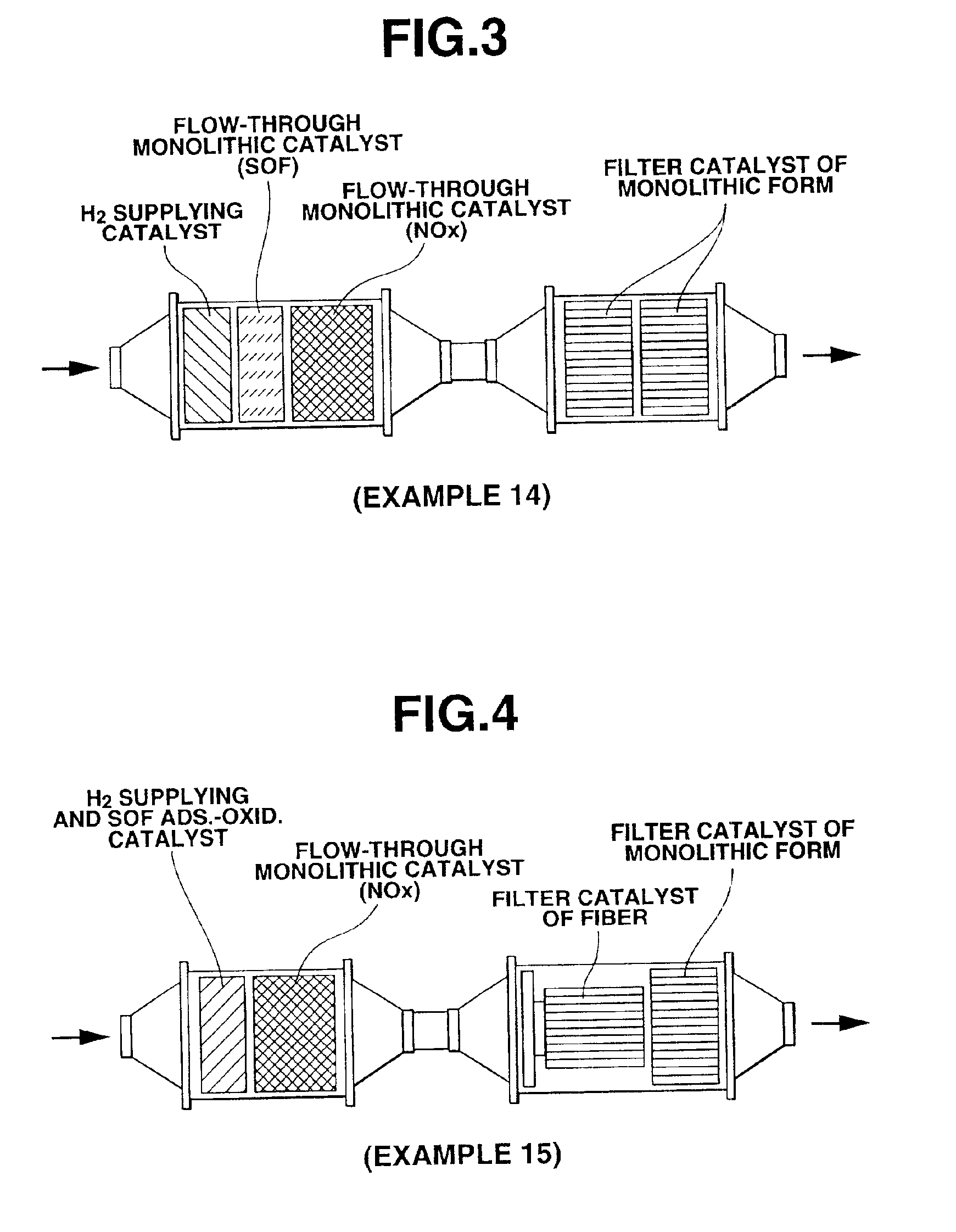

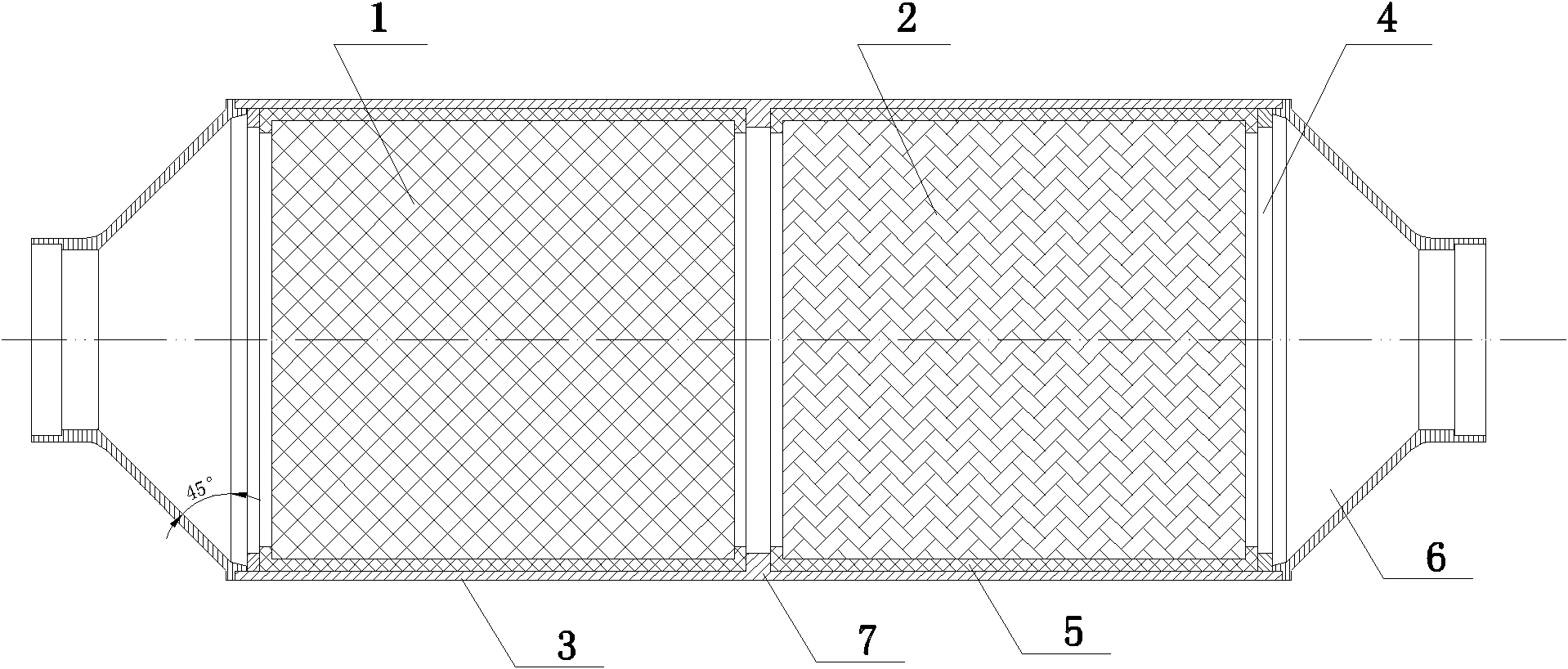

An exhaust gas purifying system for an automotive internal combustion engine. The exhaust gas purifying system comprises a flow-through monolithic catalyst disposed in an exhaust gas passageway through which exhaust gas flows. The monolithic catalyst functions to adsorb and oxidize a soluble organic fraction in exhaust gas, to adsorb nitrogen oxides in exhaust gas in a condition in which a temperature of exhaust gas is not higher than 200° C. and to allow carbon particle in exhaust gas to pass through the monolithic catalyst. Additionally, a filter catalyst is disposed in the exhaust gas passageway downstream of the flow-through monolithic catalyst. The filter catalyst functions to trap the carbon particle and to oxidize hydrocarbons, carbon monoxide and nitrogen monoxide in exhaust gas.

Owner:NISSAN MOTOR CO LTD

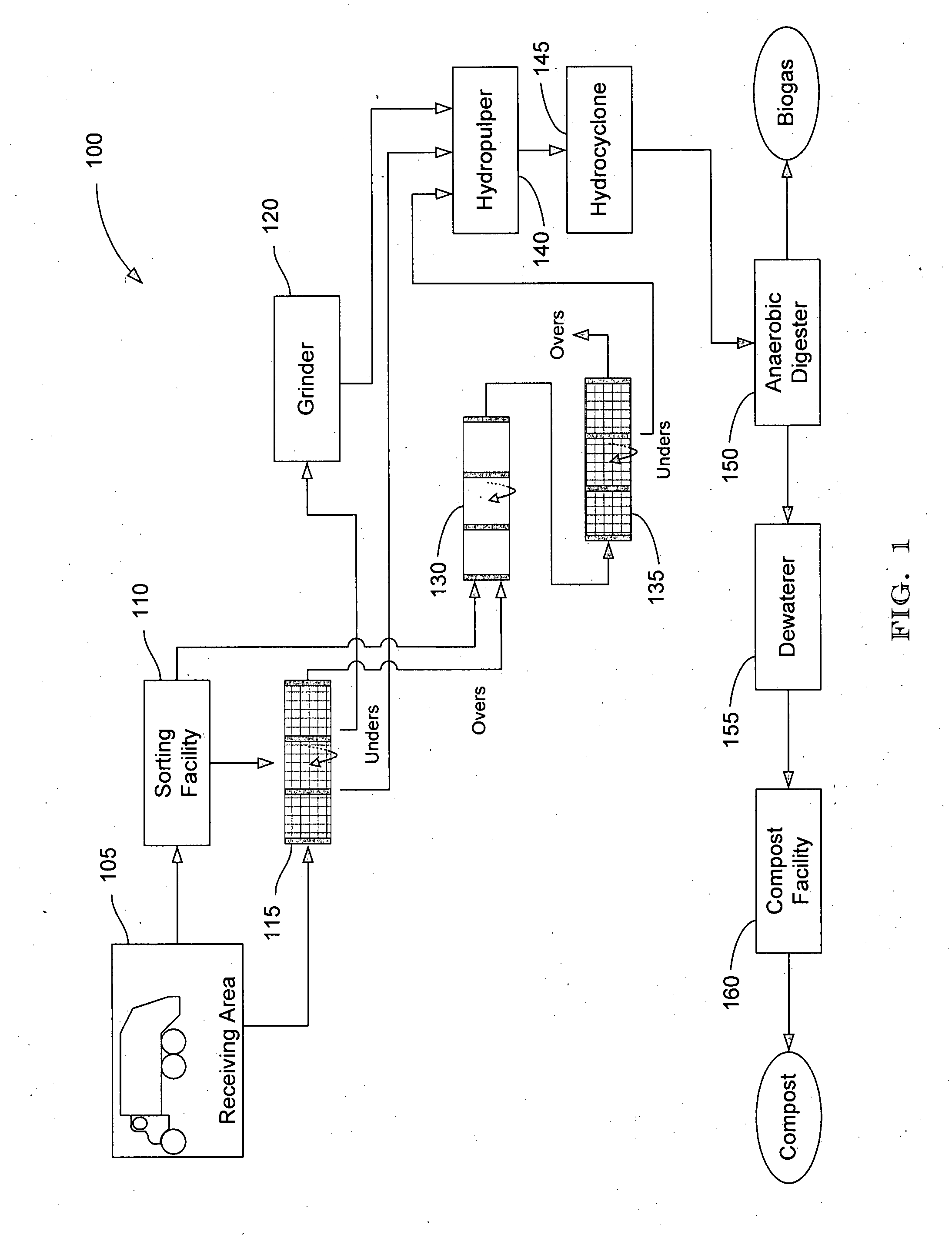

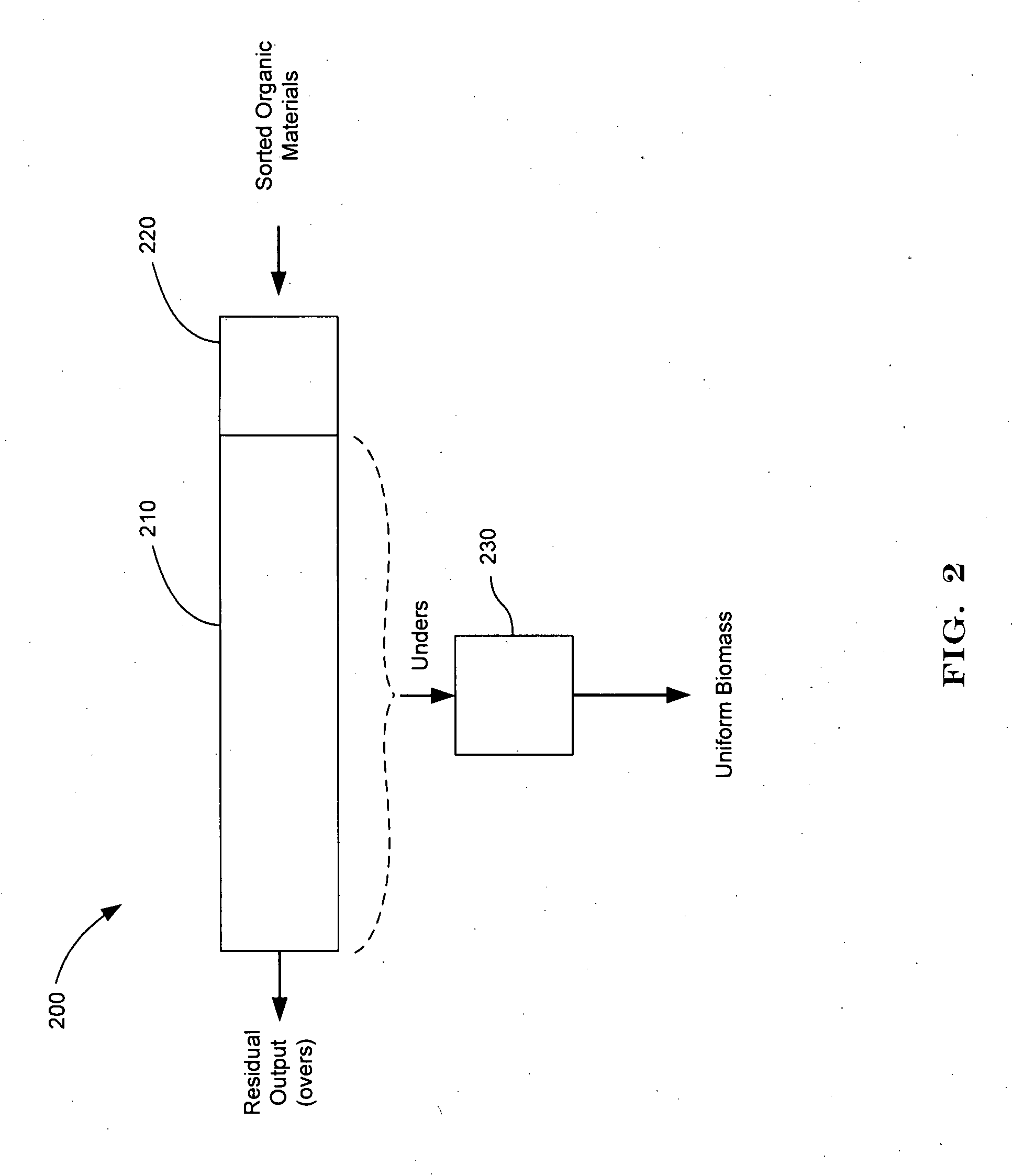

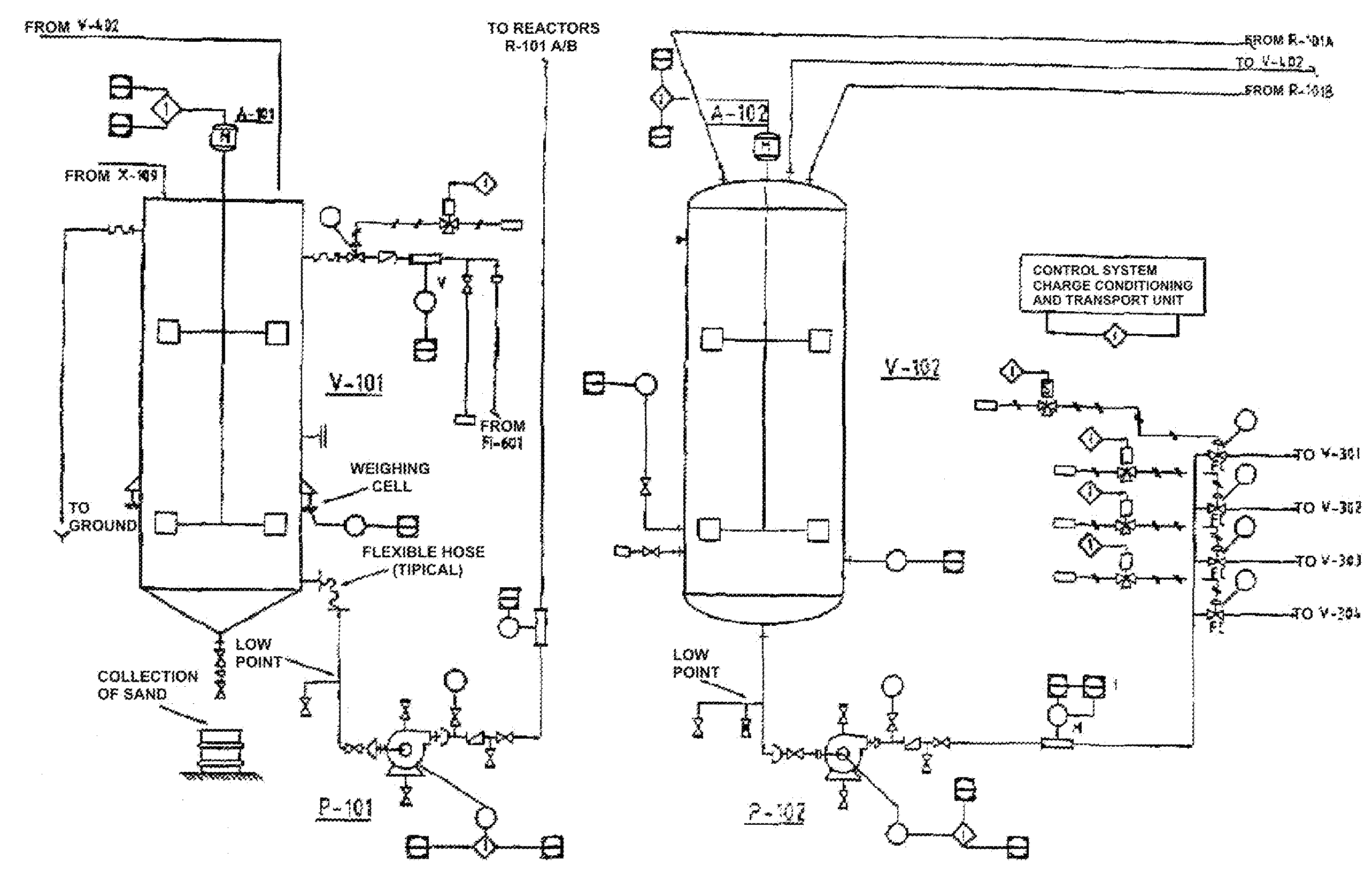

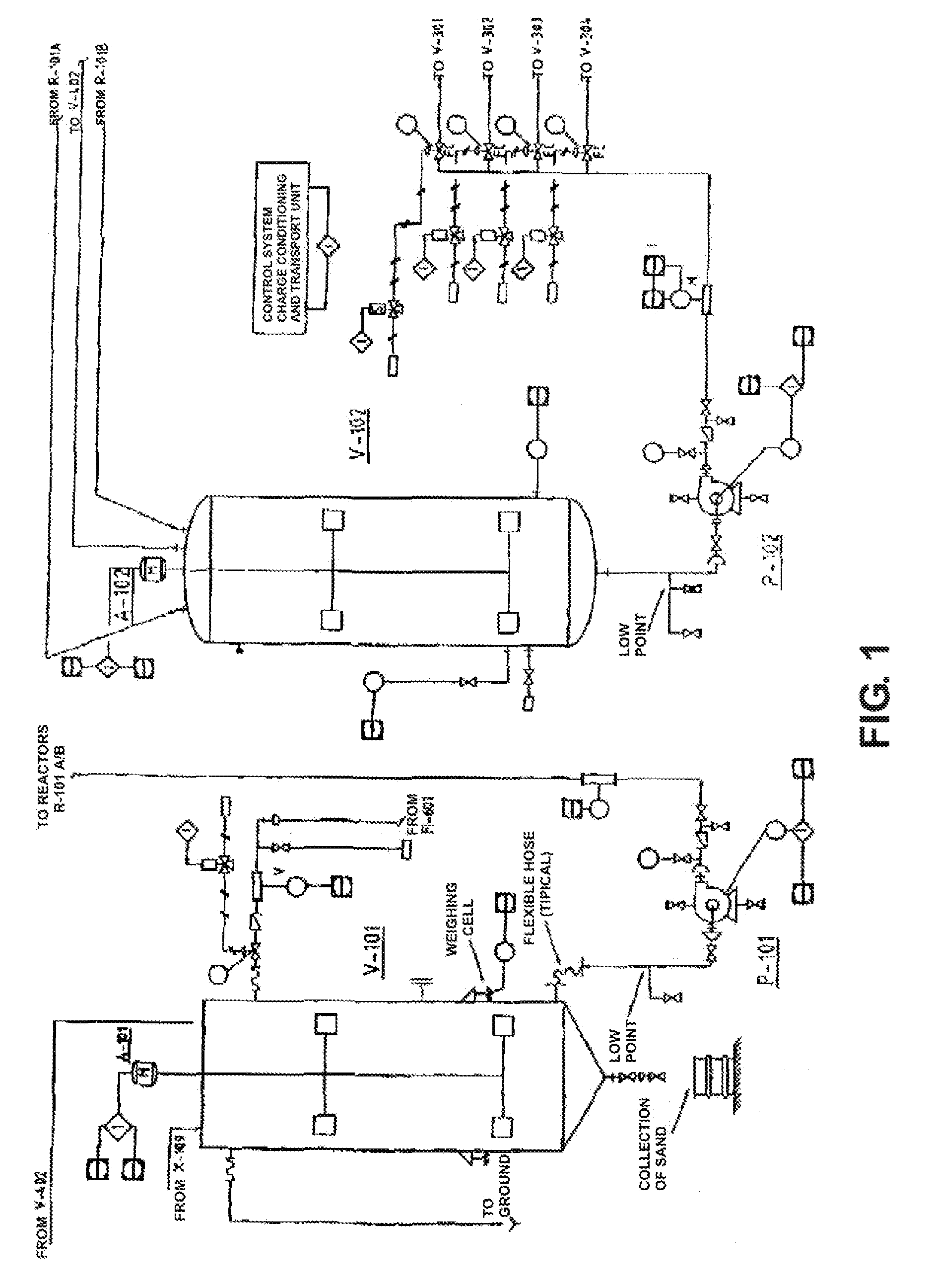

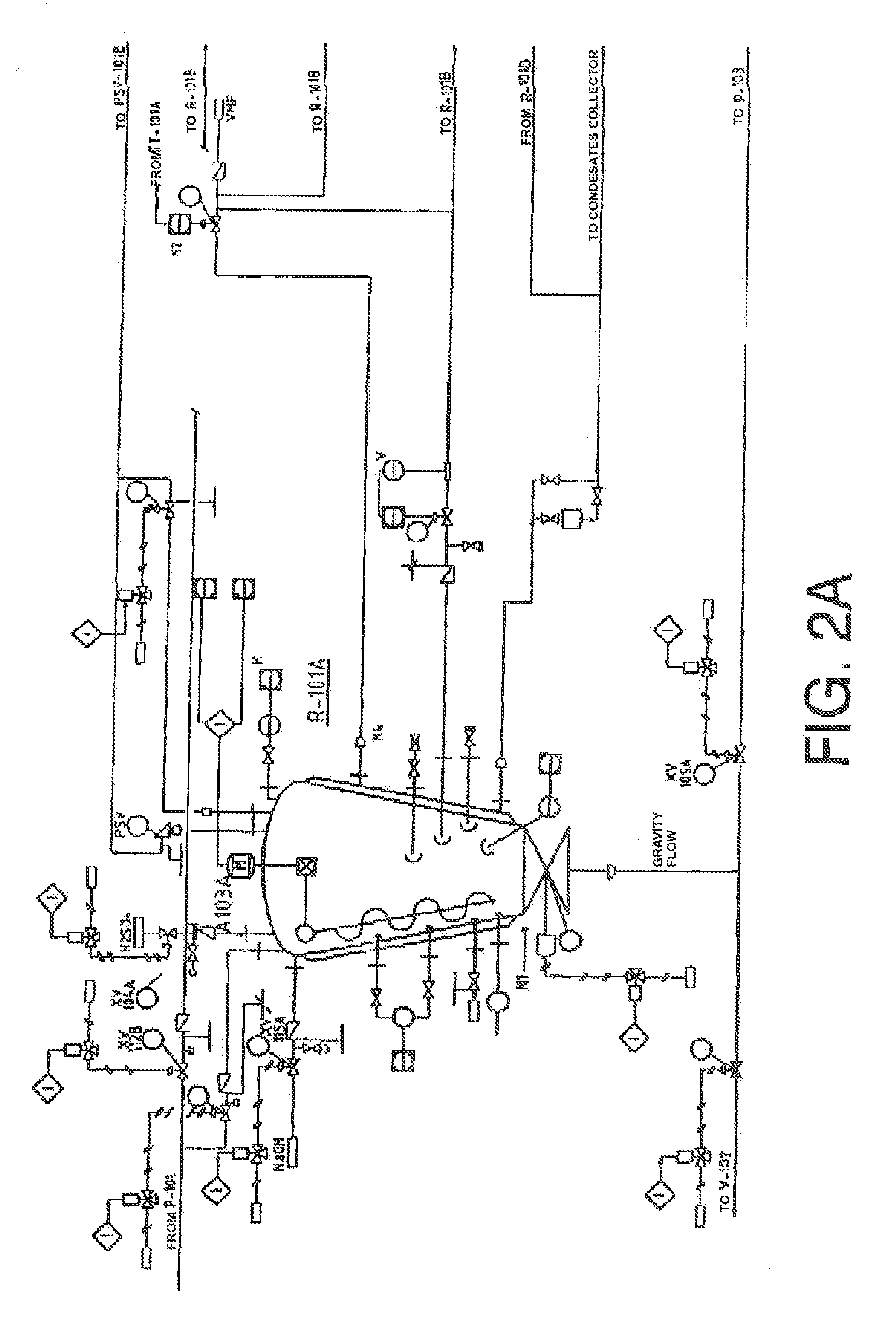

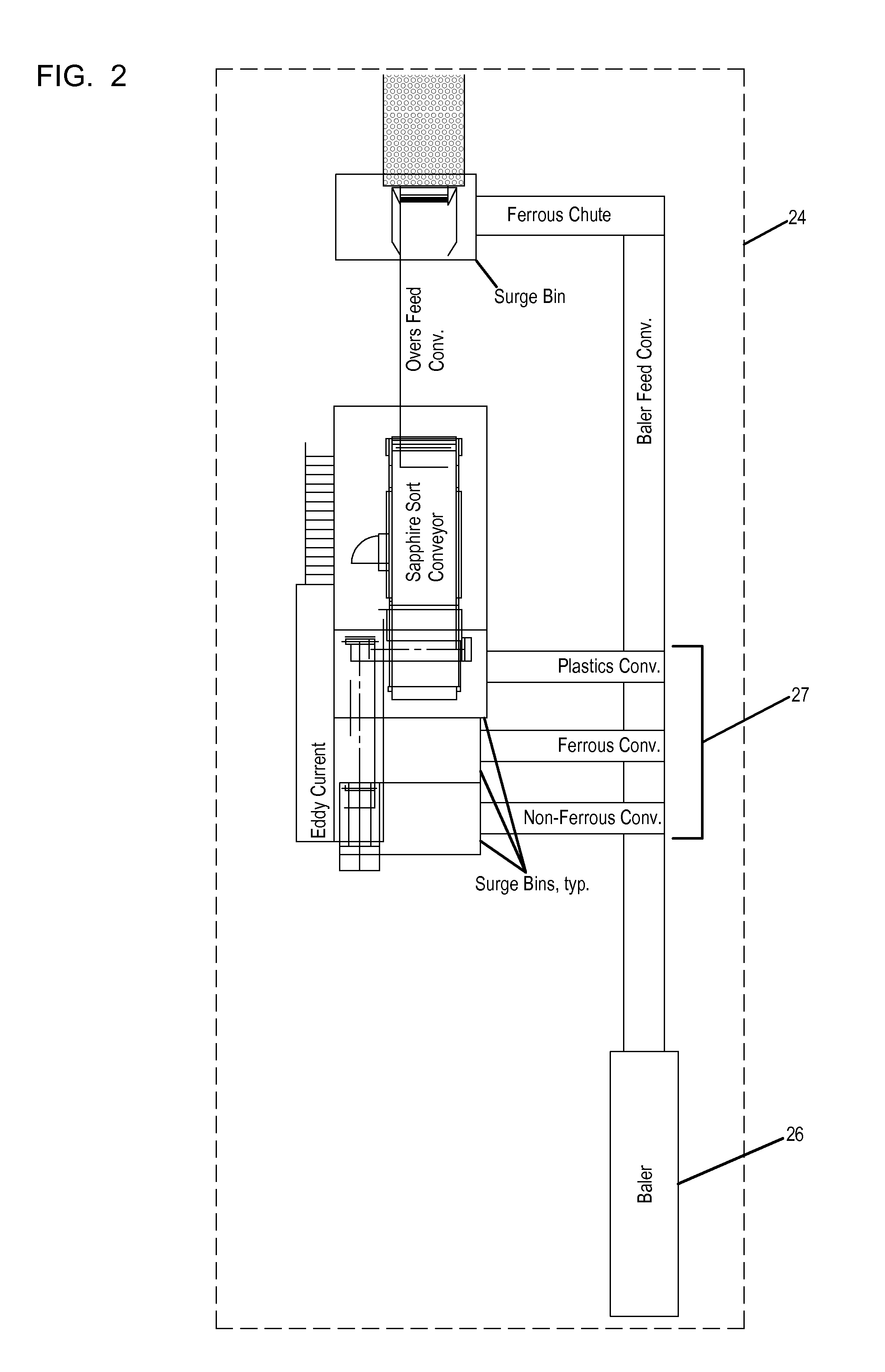

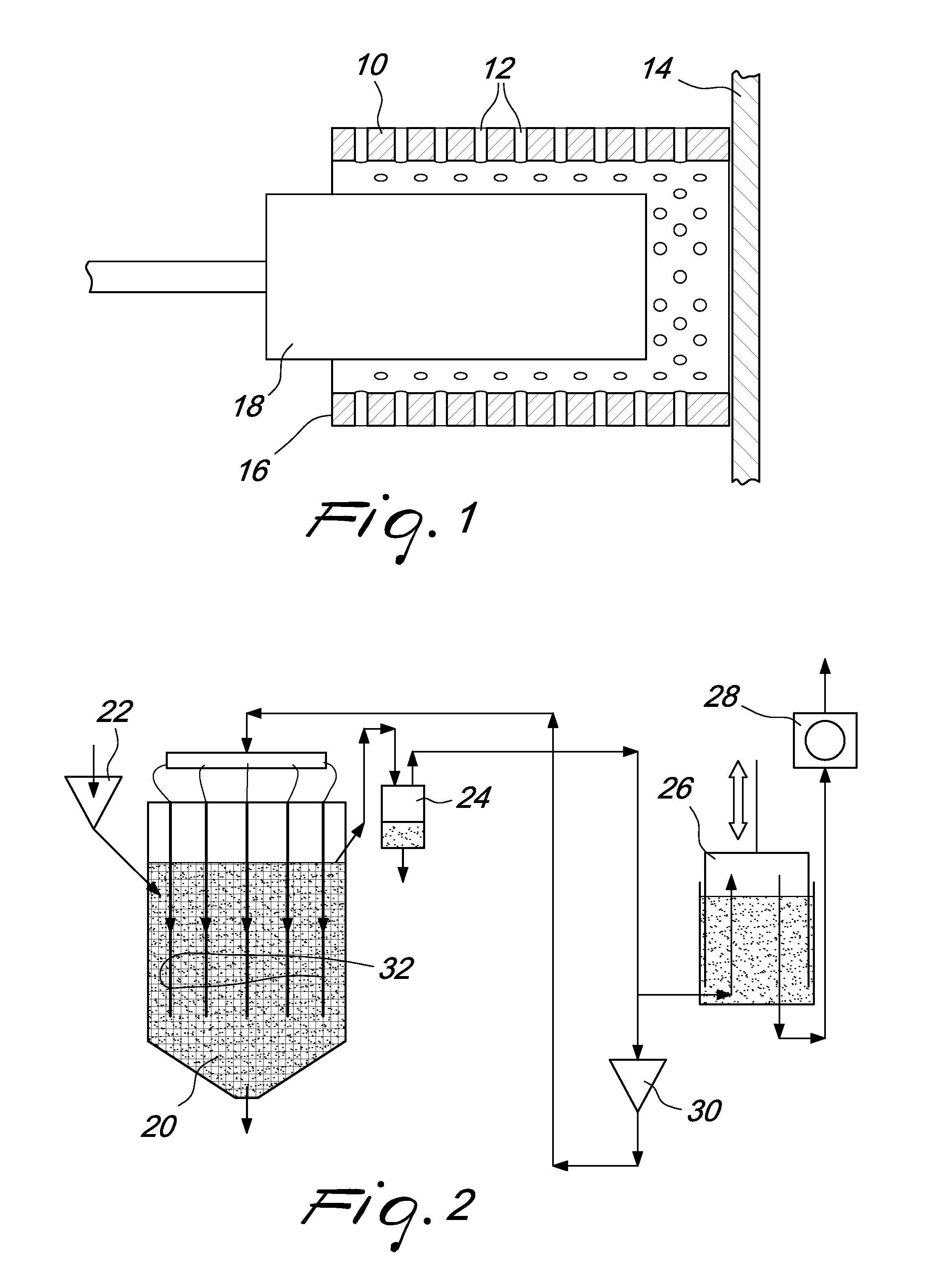

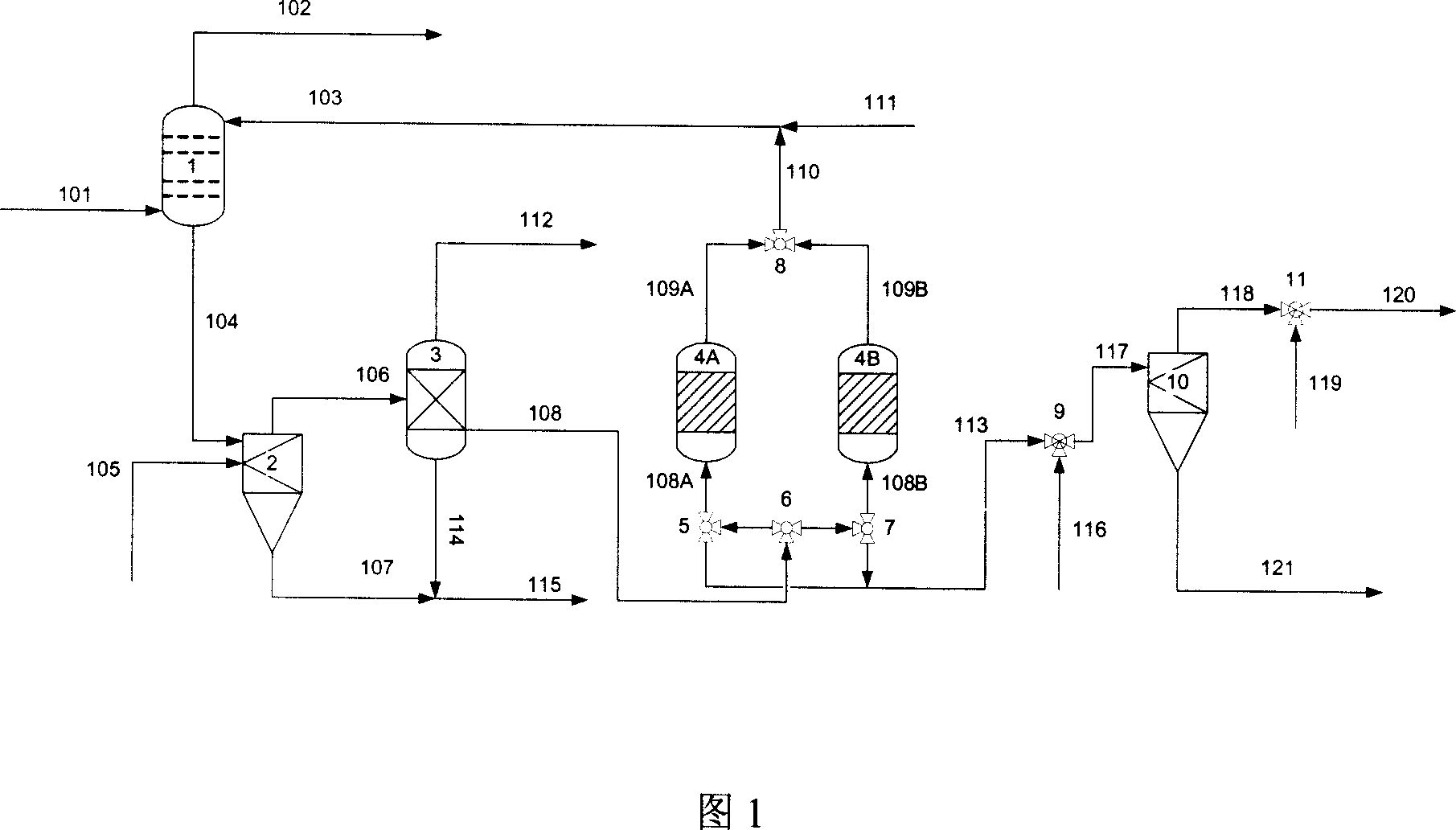

Systems and methods for converting organic waste materials into useful products

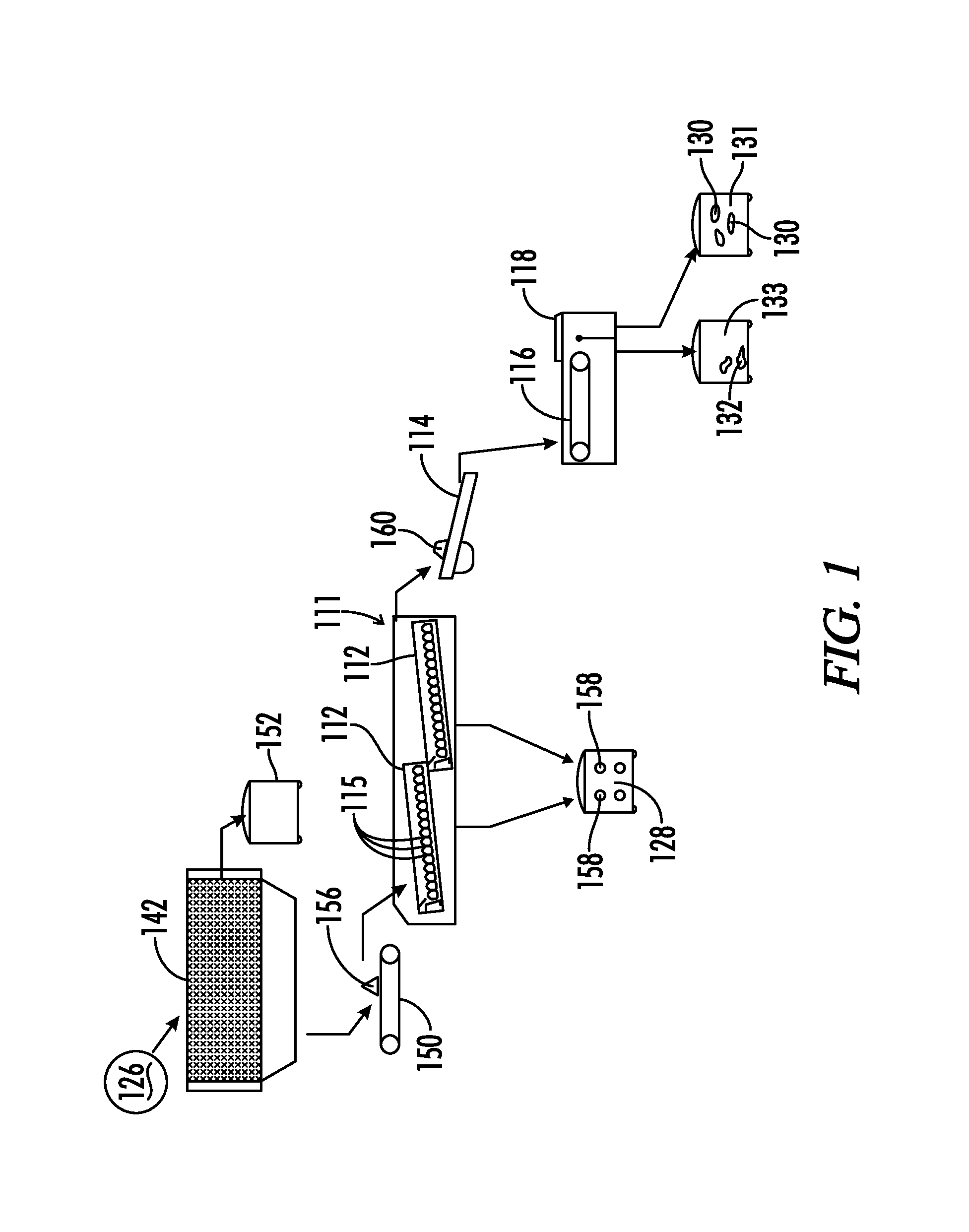

ActiveUS20080020456A1Bioreactor/fermenter combinationsBio-organic fraction processingOrganic fractionProduct system

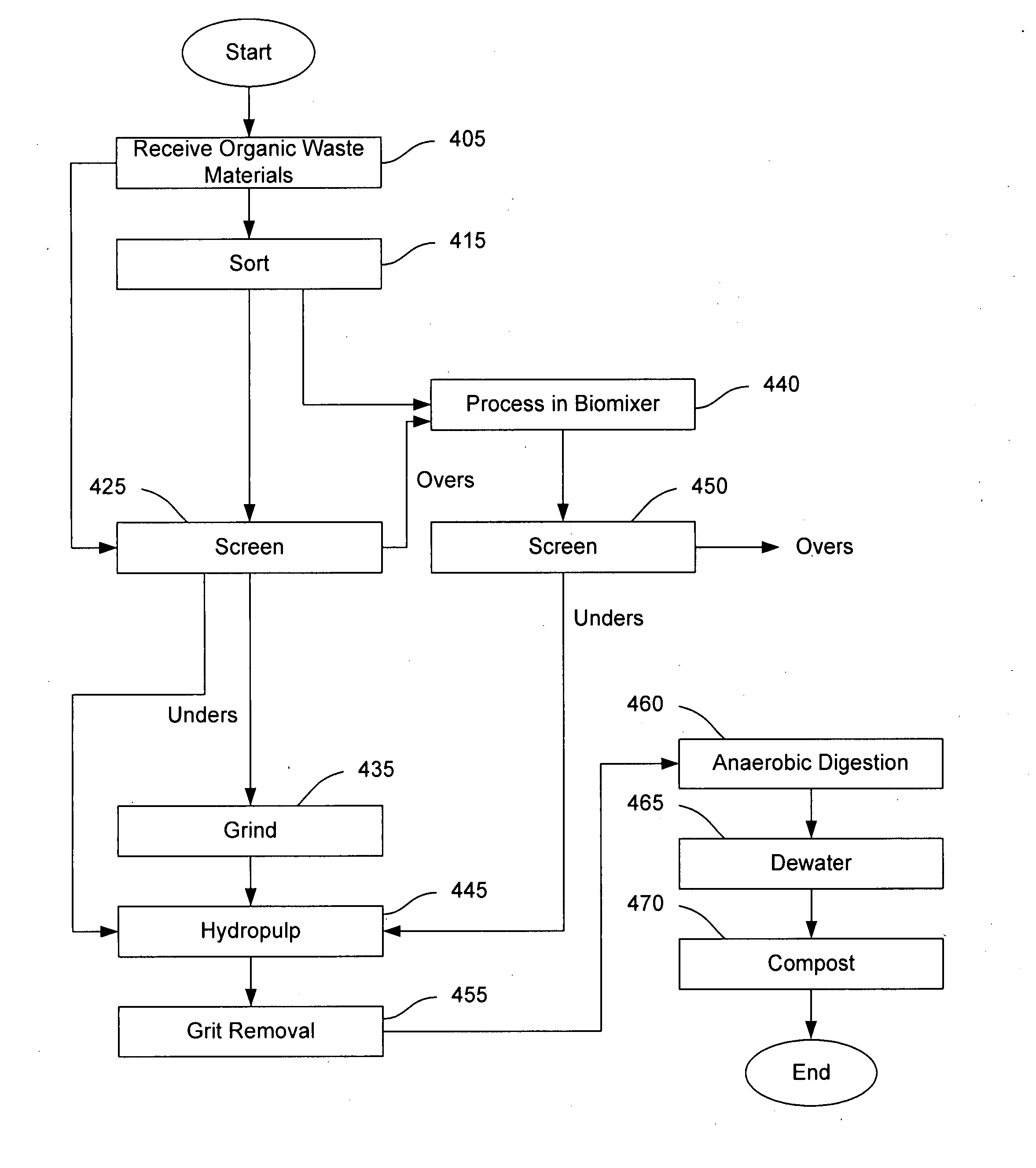

Systems and methods are provided for converting organic waste materials from a municipal waste stream to useful products. Organic waste materials having a wide range of compositions such as, for example, yard waste, food waste, paper, and the organic fraction of municipal solid waste are converted into a uniform biomass that is suitable for conversion to useful products, such as fuels. Through the use of a biomixer and a hydropulper, as well as through sorting and screening, the organic waste materials are progressively reduced in size and cleaned of contamination. The resulting uniform biomass is suitable for anaerobic digestion to produce biogas and a residual solid that is suitable for producing a high quality compost.

Owner:RECOLOGY

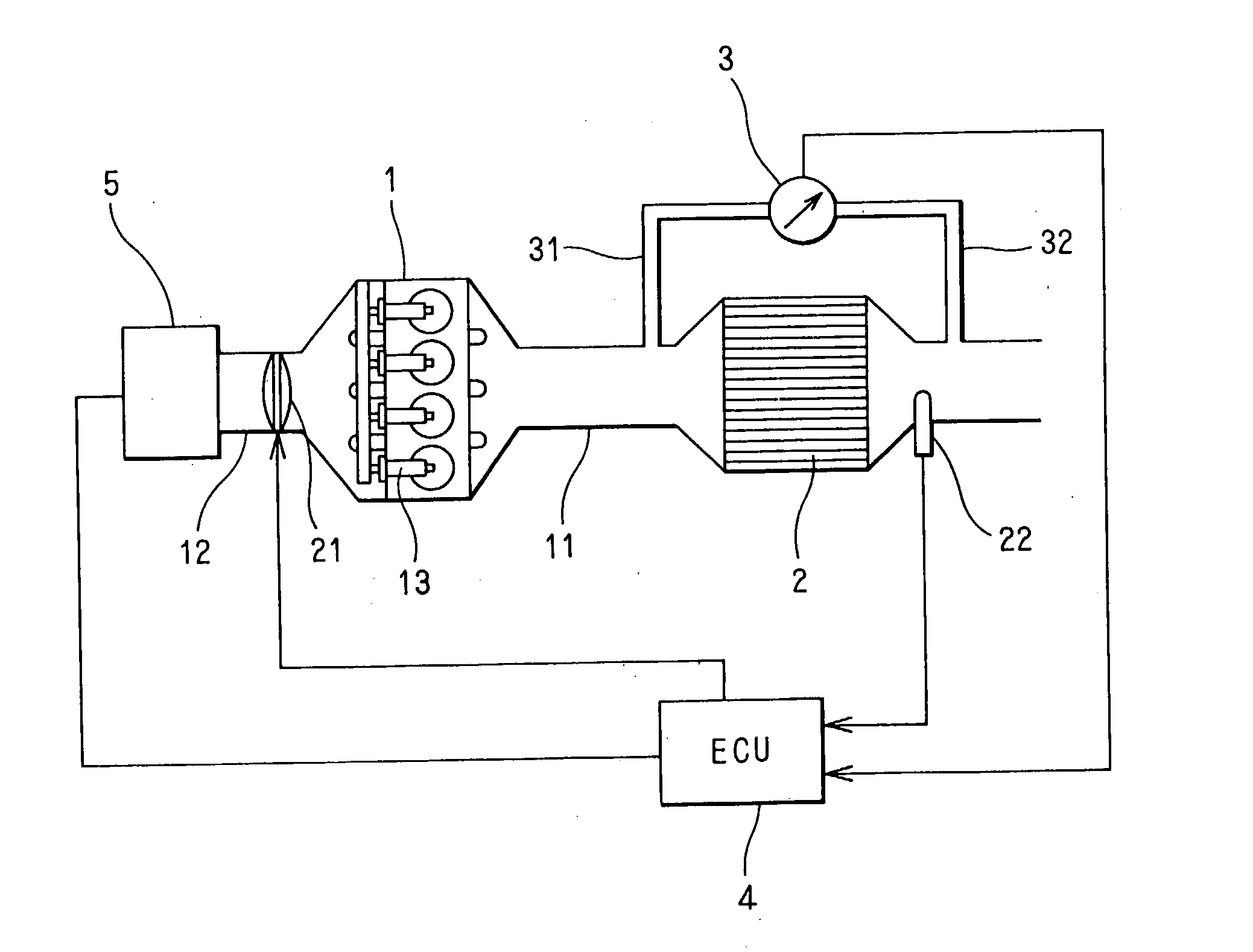

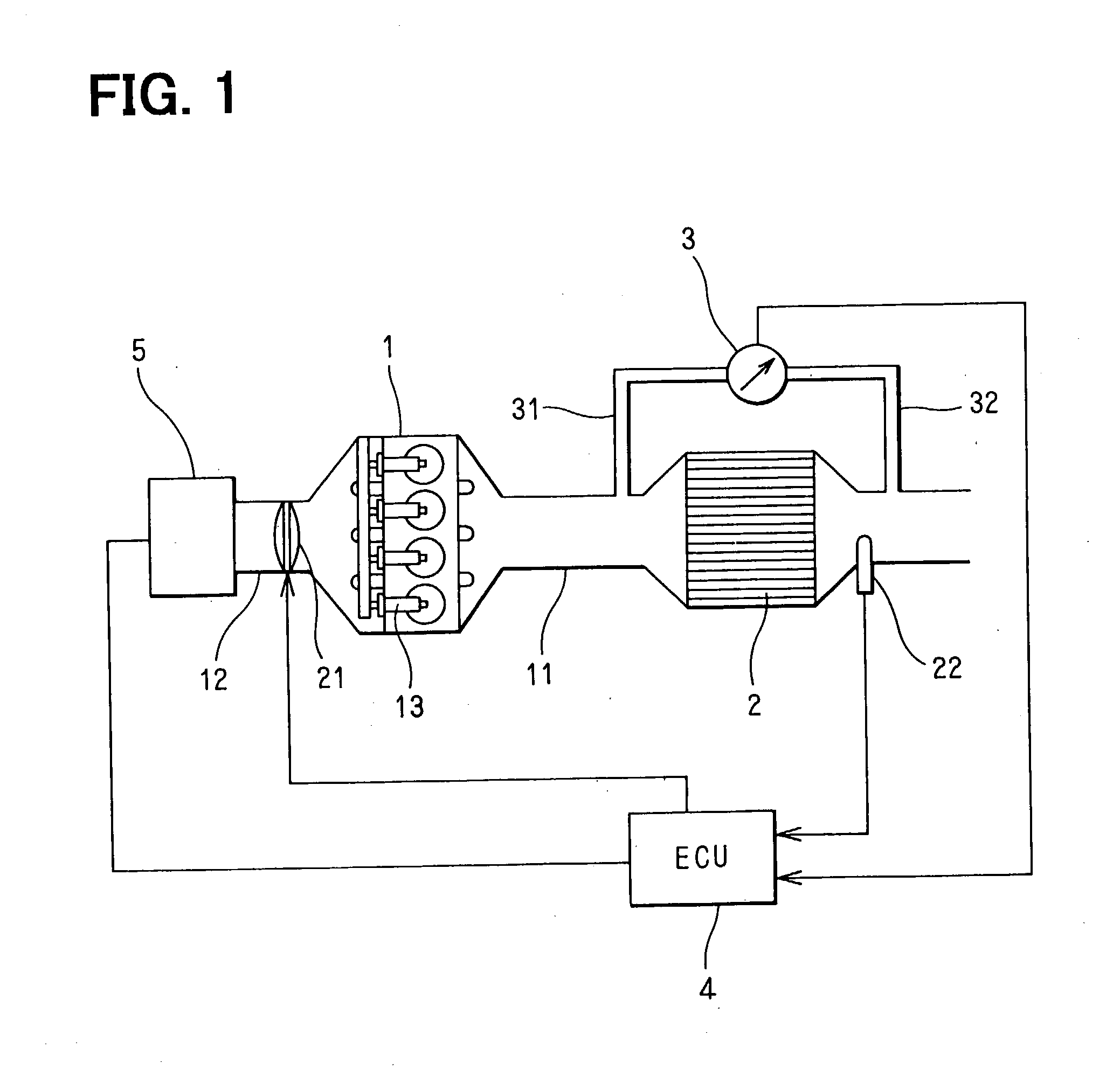

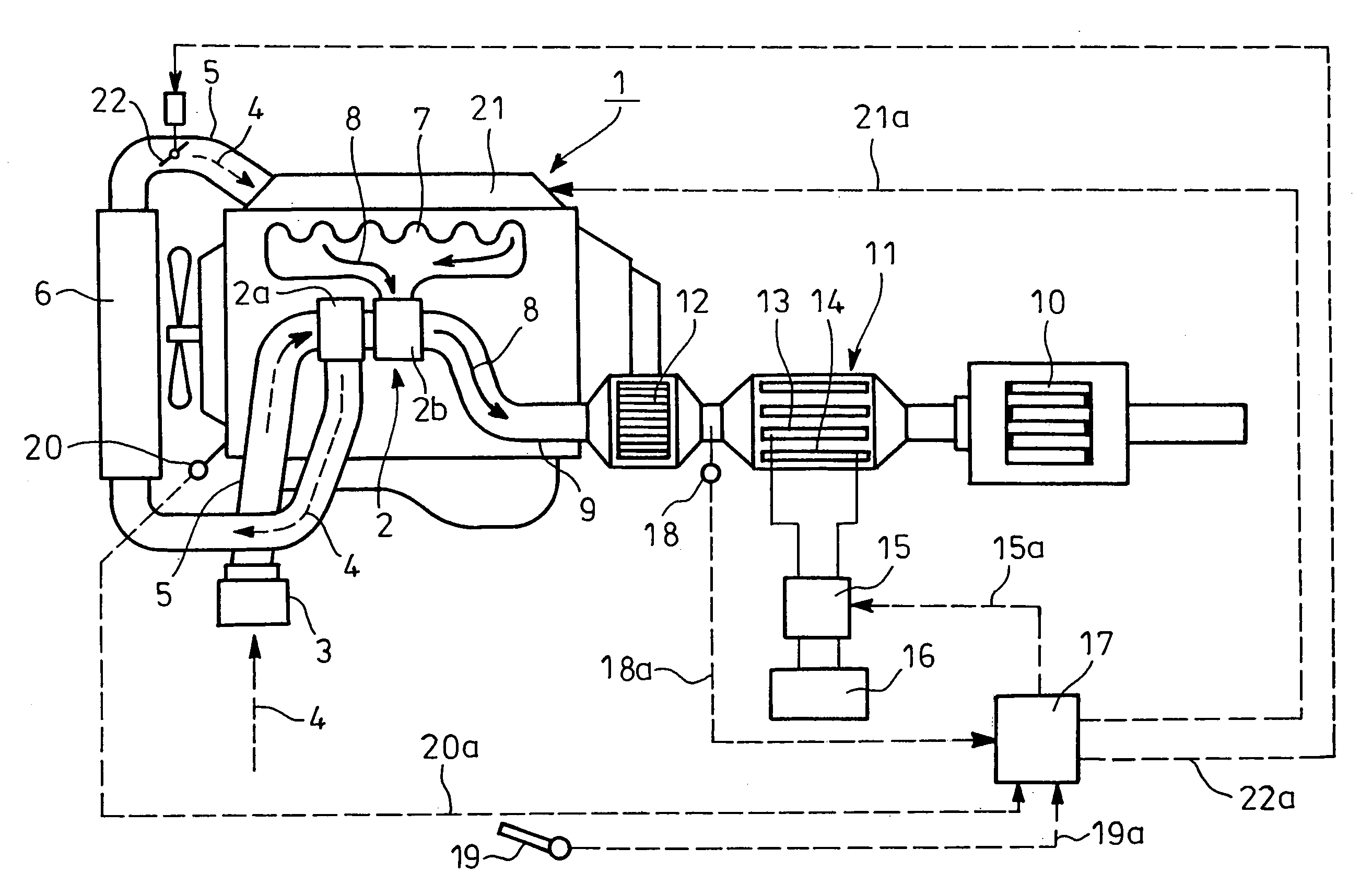

Exhaust gas purifying system and method

InactiveUS6916450B2Overcomes drawbackImprove efficiencyCombination devicesMaterial nanotechnologyOrganic fractionNitrogen monooxide

An exhaust gas purifying system for an automotive internal combustion engine. The exhaust gas purifying system comprises a flow-through monolithic catalyst disposed in an exhaust gas passageway through which exhaust gas flows. The monolithic catalyst functions to adsorb and oxidize a soluble organic fraction in exhaust gas, to adsorb nitrogen oxides in exhaust gas in a condition in which a temperature of exhaust gas is not higher than 200° C. and to allow carbon particle in exhaust gas to pass through the monolithic catalyst. Additionally, a filter catalyst is disposed in the exhaust gas passageway downstream of the flow-through monolithic catalyst. The filter catalyst functions to trap the carbon particle and to oxidize hydrocarbons, carbon monoxide and nitrogen monoxide in exhaust gas.

Owner:NISSAN MOTOR CO LTD

Exhaust gas purification system having particulate filter

Owner:DENSO CORP

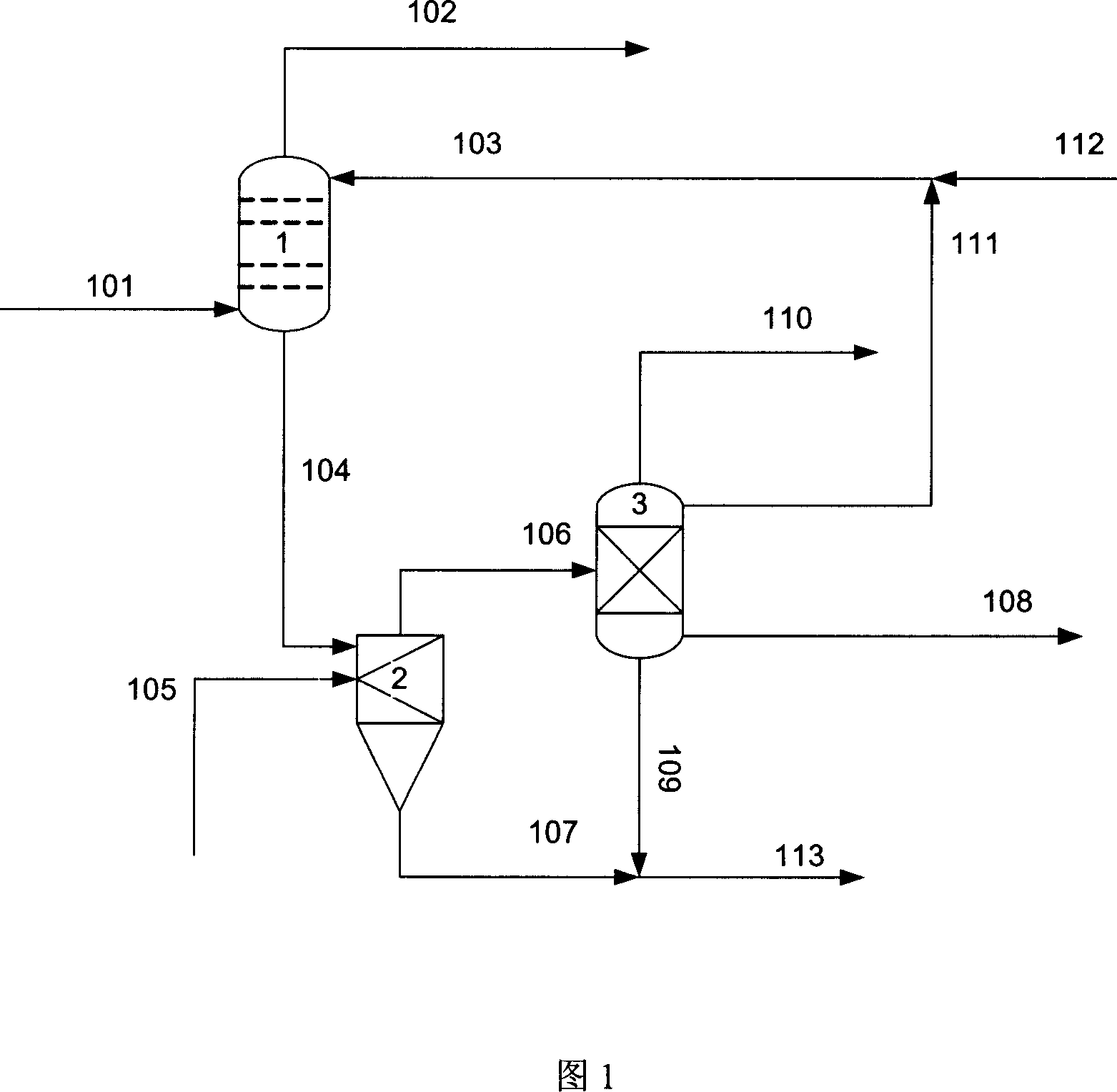

Method for recovering energy from the organic fraction of solid urban waste and associated facility

ActiveUS20100151550A1High organic contentAvoid enteringBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationSlurry

The invention relates to a method for recovering energy from the organic fraction of urban solid waste comprising the following steps: a) the organic fraction is pre treated with mineral acids, preferably sulfuric acid, during which the fraction is heated by an outer thermal jacket with no steam injection or steam explosion, thereby producing a first slurry containing an insoluble solid susceptible to enzymatic attack by cellulases; b) a step comprising enzymatic hydrolysis using cellulases and simultaneous fermentation, using an ethanologenic microorganism, of the first slurry in order to obtain a second slurry containing diluted ethanol; and c) distillation of the second slurry such as to obtain wet ethanol, a recyclable liquid effluent and a solid.

Owner:PERSEO BIOTECHNOLOGY SL +1

Catalytic filter for removing soot particulates from diesel engine exhaust and method of preparing the same

Owner:SK ENERGY CO LTD (KR)

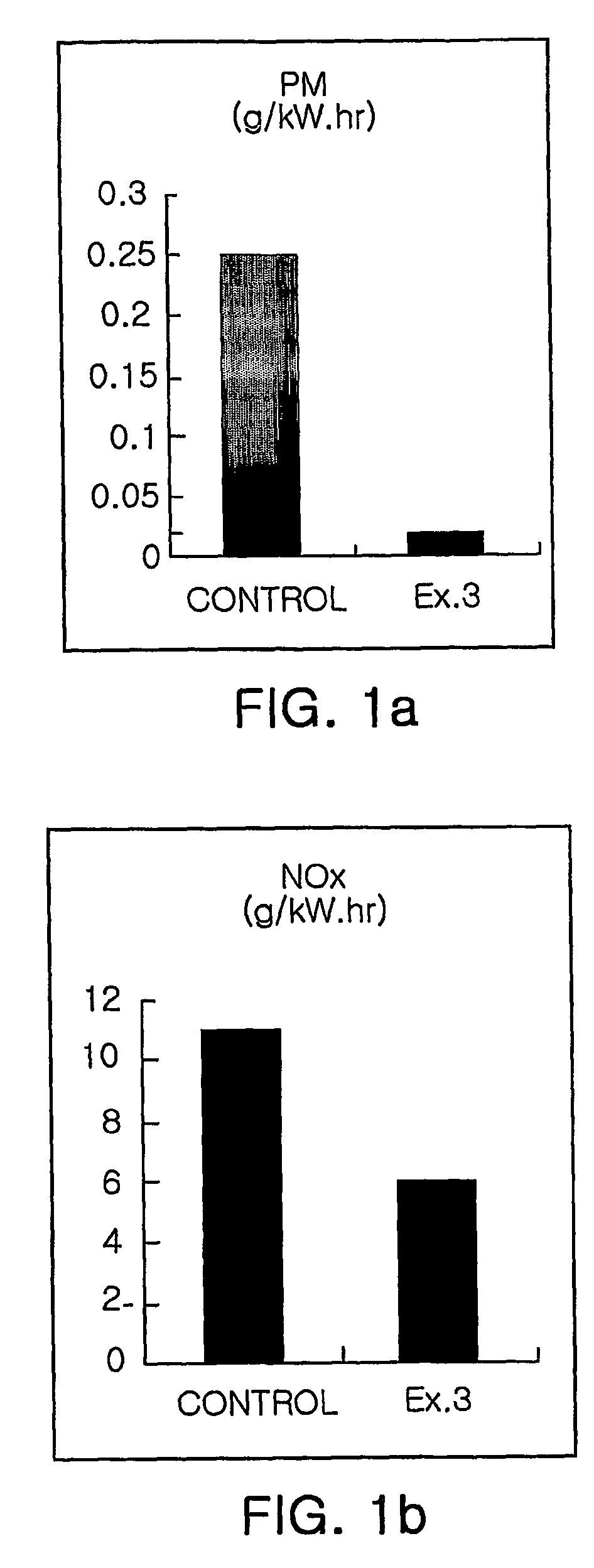

Low emission power plant and method of making same

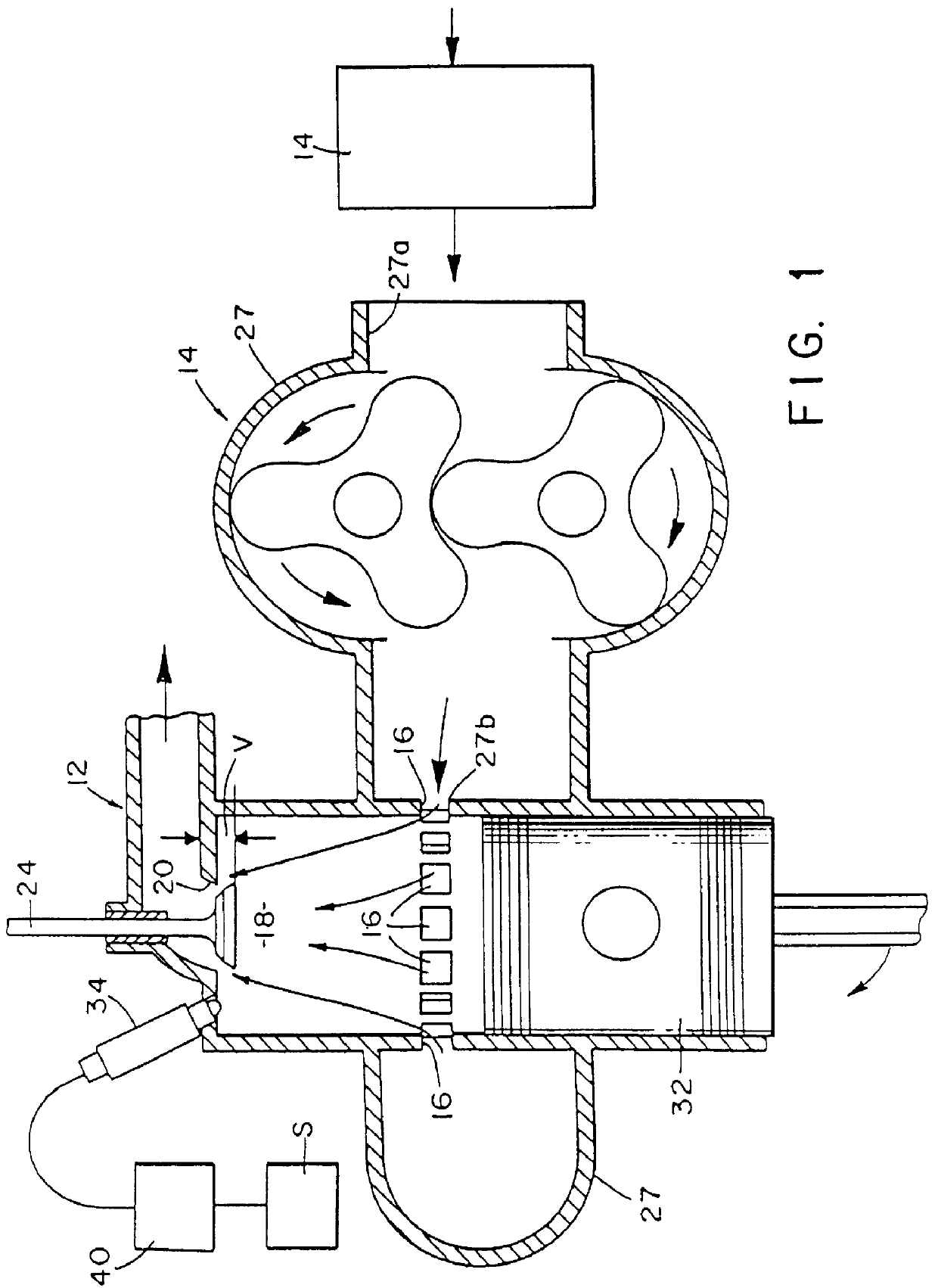

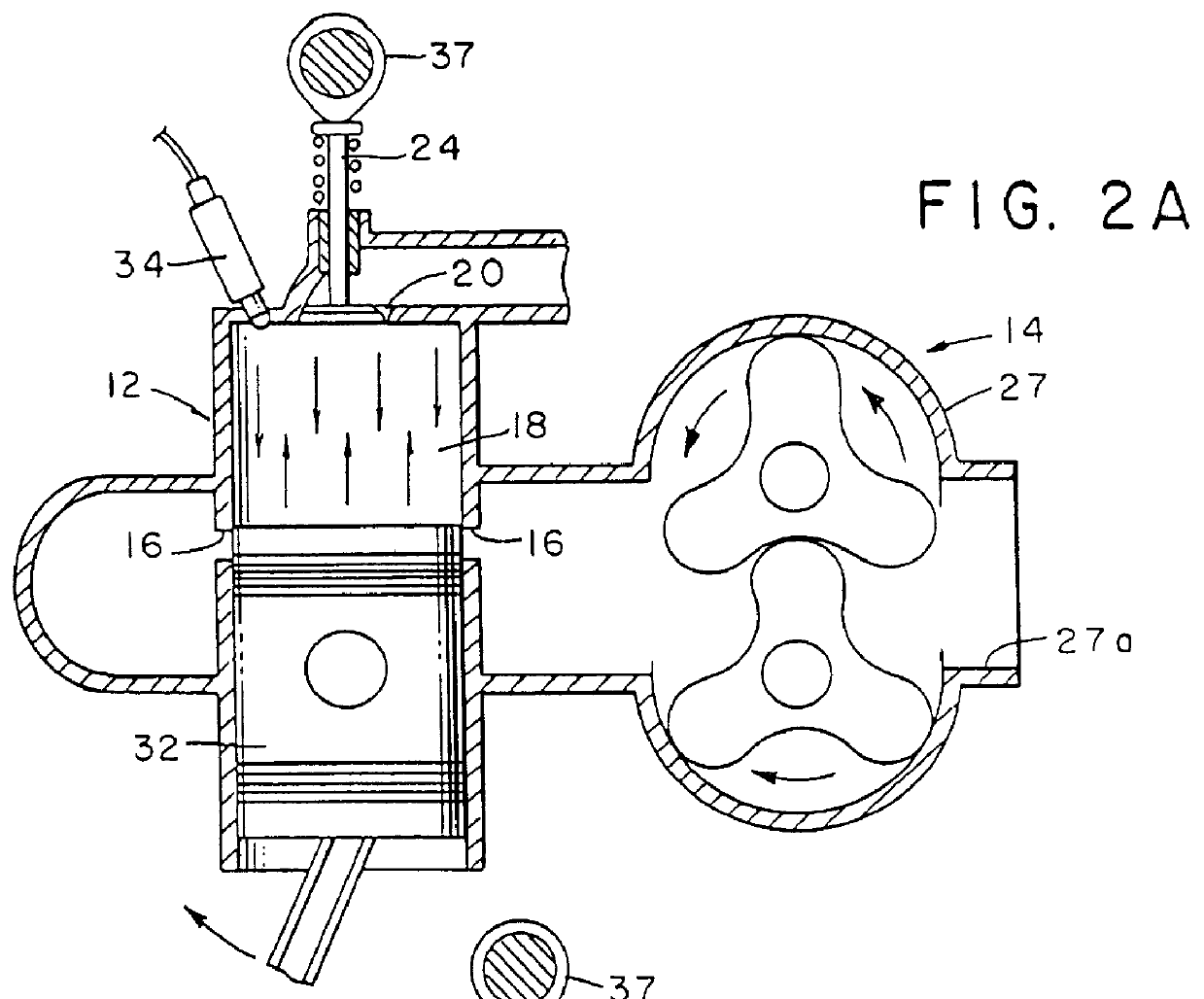

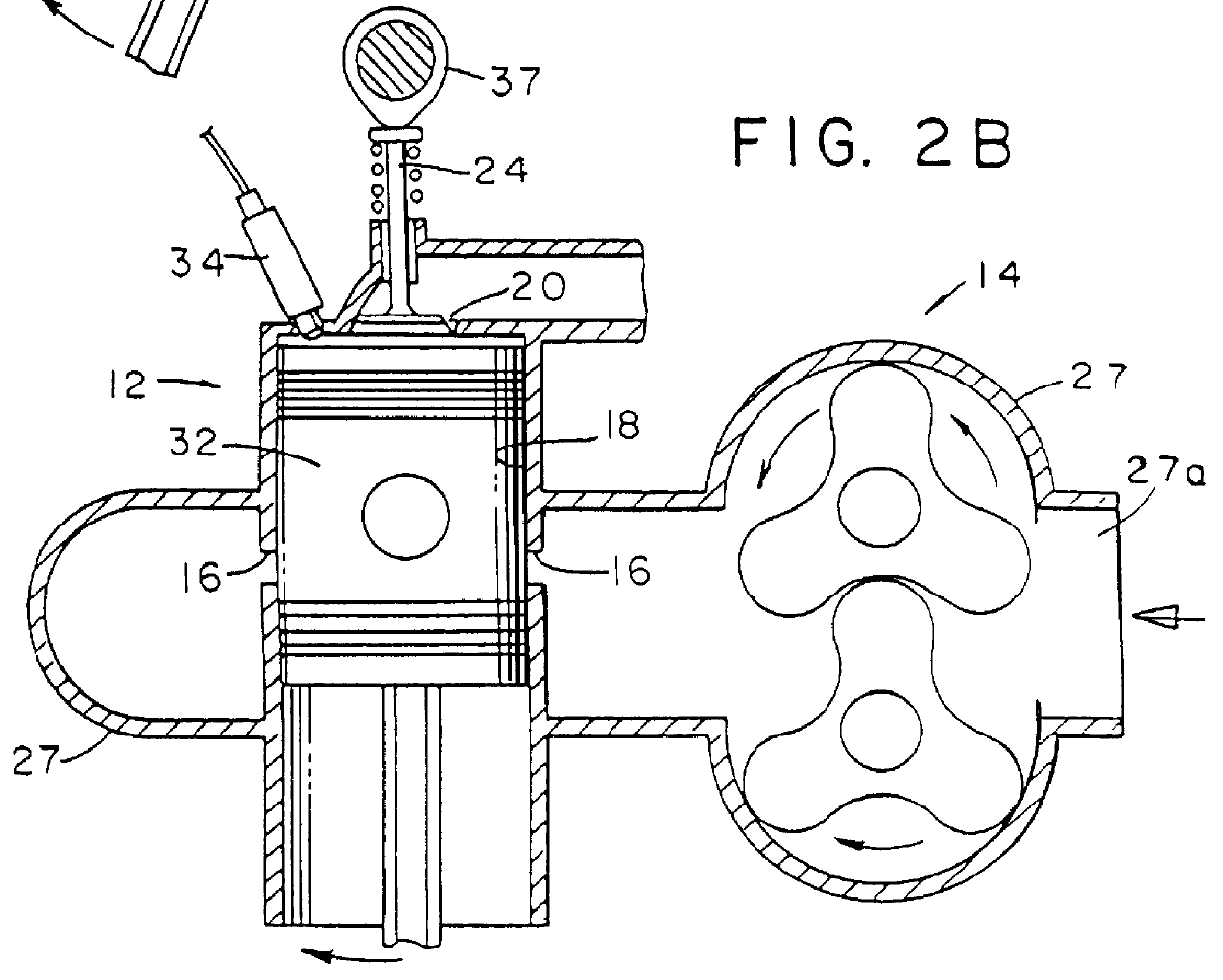

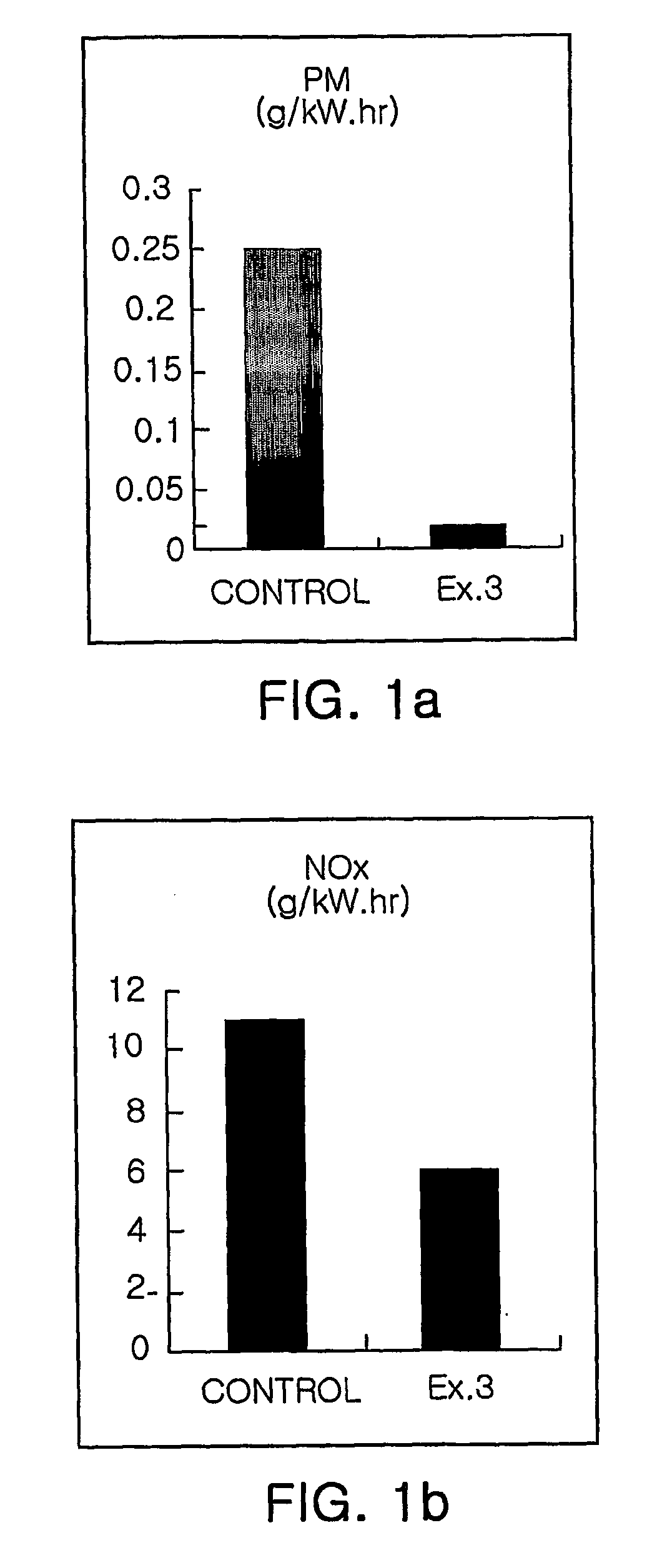

InactiveUS6101989AReduce the amount of solutionLower than normal exhaust valve liftNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesCombustion chamber

A low emission power generating apparatus which comprises a modified two-stroke diesel engine component and a modified turbocharger component which has a relatively low aspect ratio. The diesel engine component is a modification of a conventional two-stroke diesel engine design and includes an exhaust valve cam of unique design that has a cam profile which results in a later than-normal exhaust valve opening and an earlier-than-normal valve closing so that the time during which the exhaust valve remains open is shorter than normal, thereby causing a substantially greater volume of residual gases to remain in the combustion chamber following the scavenge stroke. This increase in the volume of the residual exhaust gases within the chamber leads to an increase in compression temperature and effectively increases the compression ratio and consequently the compression pressure. Because of the heat absorption capacity of these residual exhaust gases, the exhaust gases remaining in the chamber following the scavenge stroke tend to absorb combustion heat and thereby effectively reduce the peak combustion temperature. This reduction in peak combustion temperature advantageously results in the lower than normal formation of nitrogen oxide (NOx) and, therefore, allows advancement of the injection timing, while still maintaining the NOx emissions coming from the engine lower than those legislatively mandated. Advantageously, the advance in injection timing, which increases NOx emissions, by definition has the effect of also reducing particulate matter emissions. Thus, by increasing the volume of residual exhaust gases within the cylinder, substantial particulate matter emission reductions can be achieved, while at the same time maintaining NOx emissions well below mandated limits. The modified turbocharger component provides an additional charge of oxygen-rich air into the combustion chamber which effectively increases the compression pressure, which, in turn, leads to an earlier start of combustion because of the combustible mixture reaching its auto-ignition temperature at an earlier point in the cycle. This phenomenon leads to more thorough combustion of the fuel and also generally leads to higher exhaust temperatures. Higher exhaust temperatures, in turn, lead to a greater oxidation rate of the soluble organic fraction thus lowering the level of emission from the engine of undesirable particulate matter.

Owner:CLEAN CAM TECH SYST

Integrated waste/heat recycle system

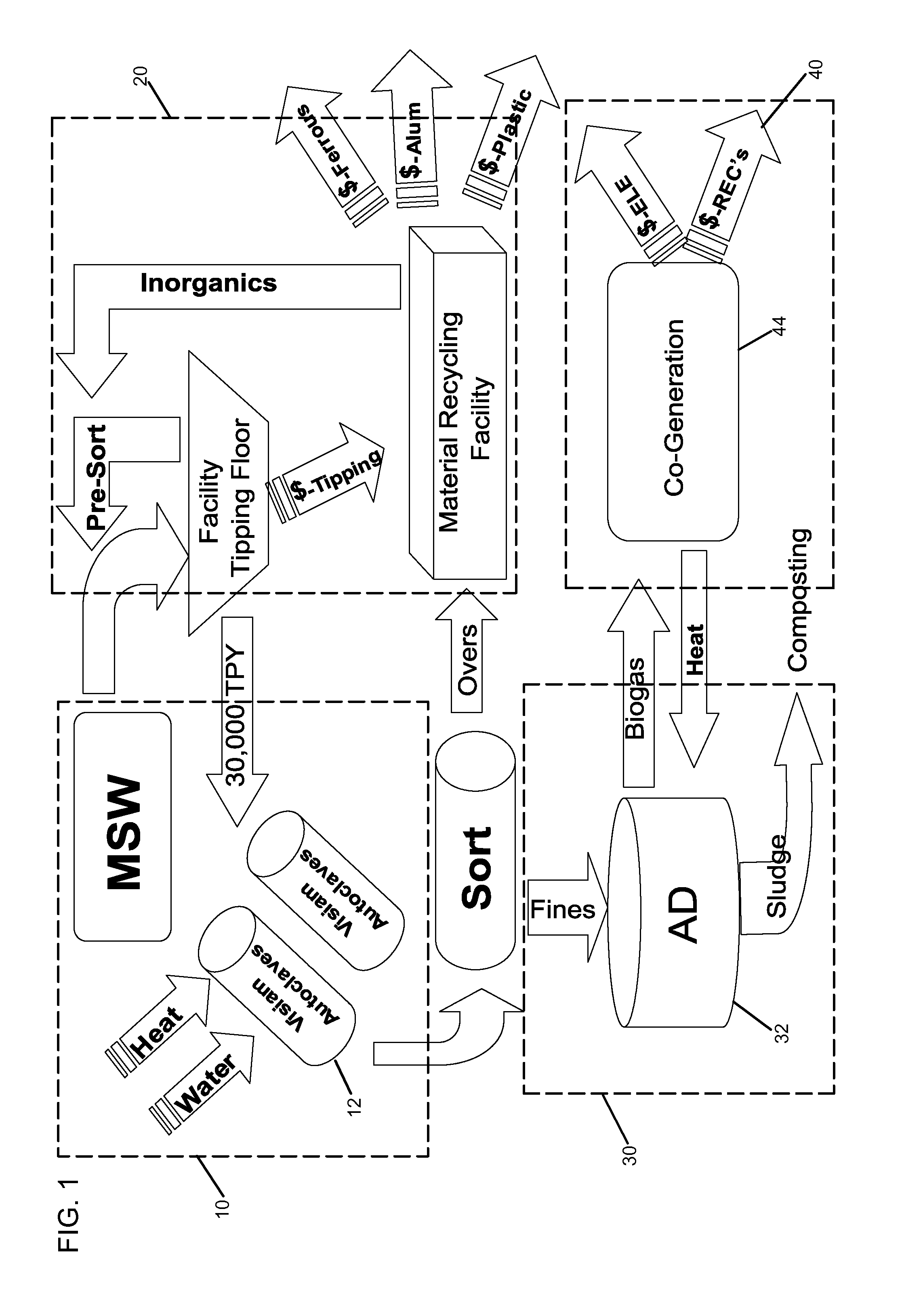

InactiveUS20110008865A1Bioreactor/fermenter combinationsBiological substance pretreatmentsElectricityOrganic fraction

An integrated system and process for the treatment of organic fractions of municipal solid waste is described herein. The system and the process transform solid waste into fuel and energy. The integrated system and process comprise various different processes for pretreatment, sorting / separating, anaerobic digestion and conversion of biomass and gas to various gasseous, liquid and solid fuels and electricity.

Owner:VISIAM

Process for the production of fuel gas from municipal solid waste

InactiveUS20130316428A1Increase productionImprove efficiencyBiological substance pretreatmentsSpecific water treatment objectivesOrganic fractionBiological cell

After separating from solid urban waste an organic fraction containing biological cells, the latter is extruded through a grid having small-bore holes, under a pressure higher than the bursting pressure of the cell membranes, so that most of these are disrupted and a gel of a doughy consistency is produced. The gel is then loaded into a biodigester, where it is readily attacked by bacteria.

Owner:DB TECH BV

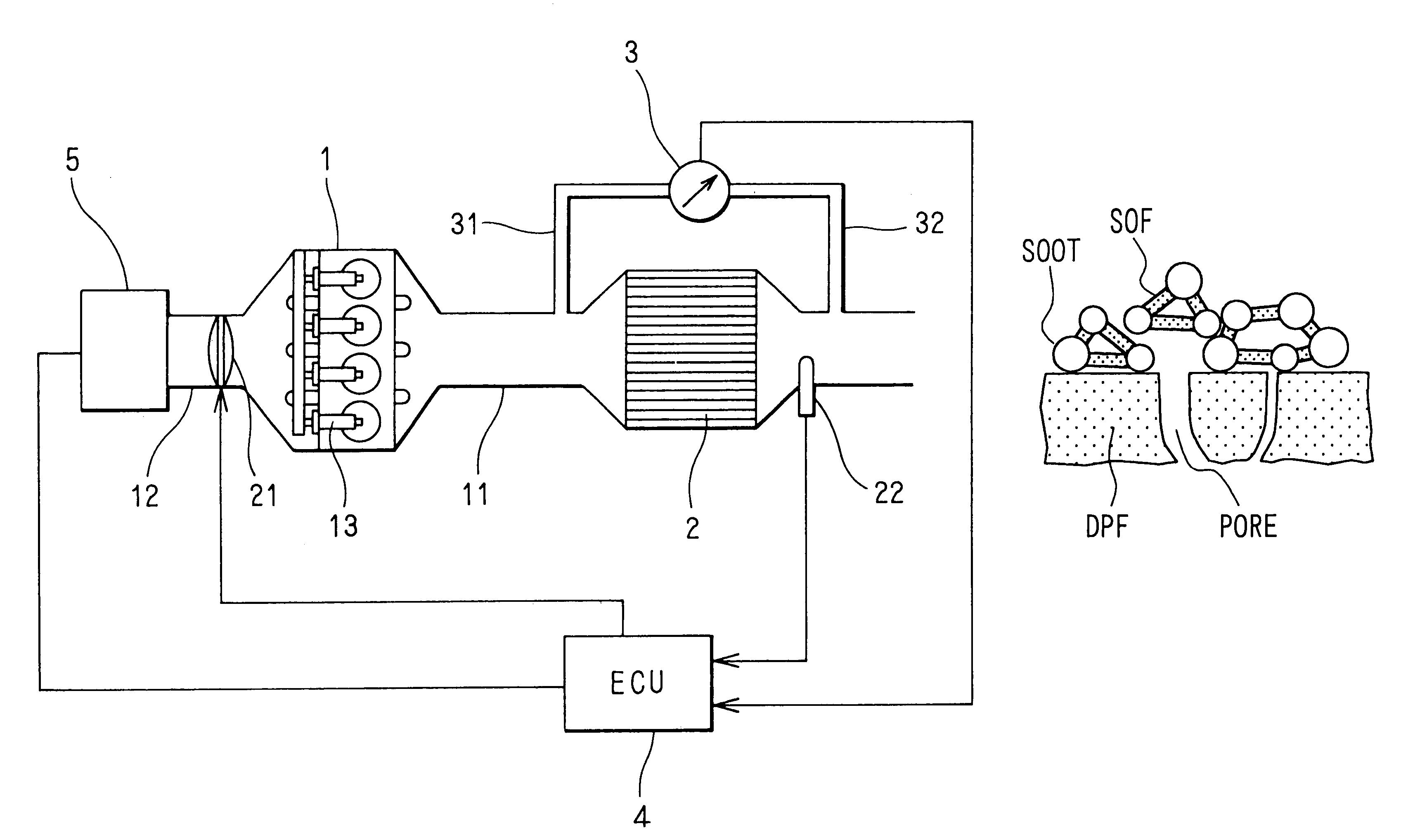

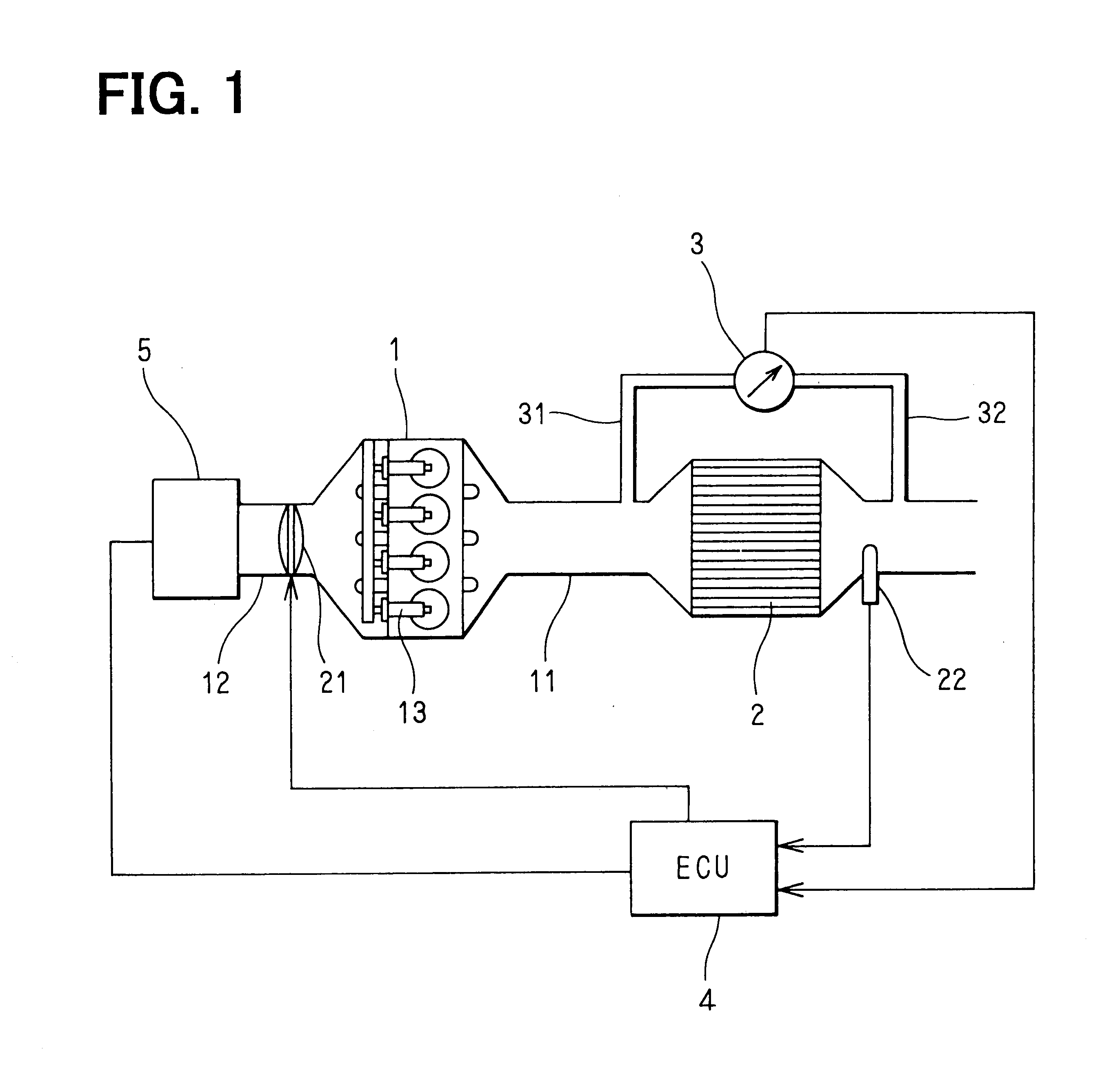

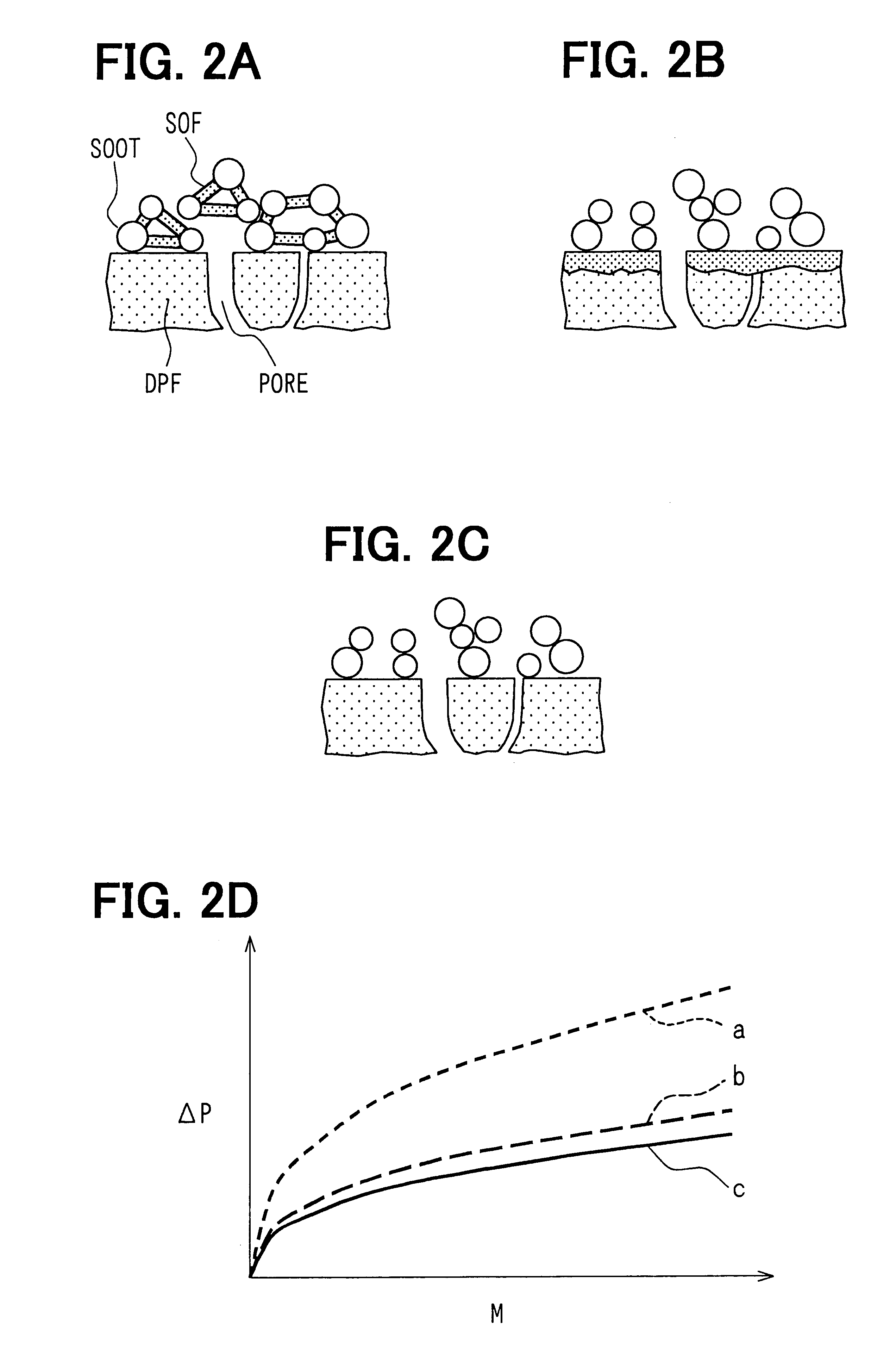

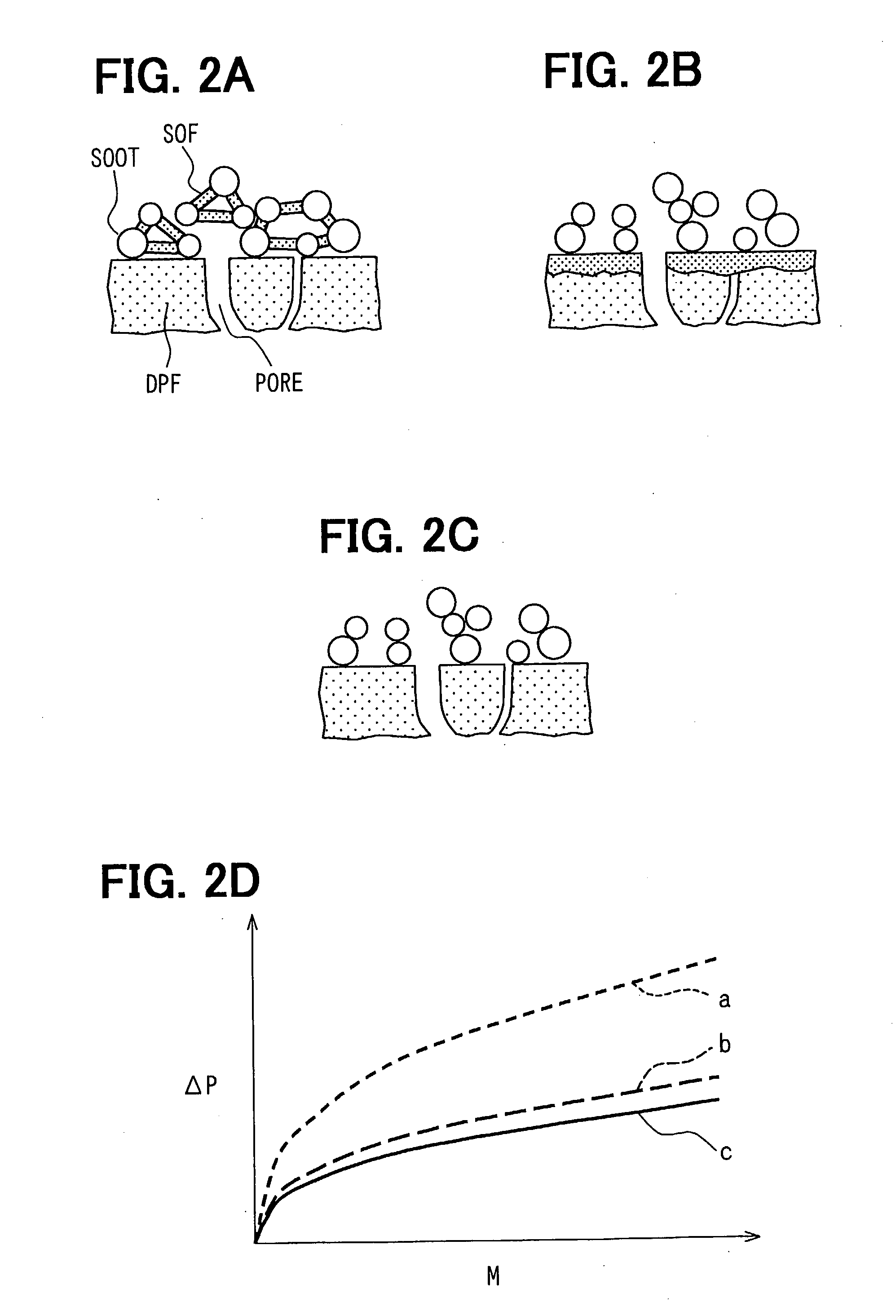

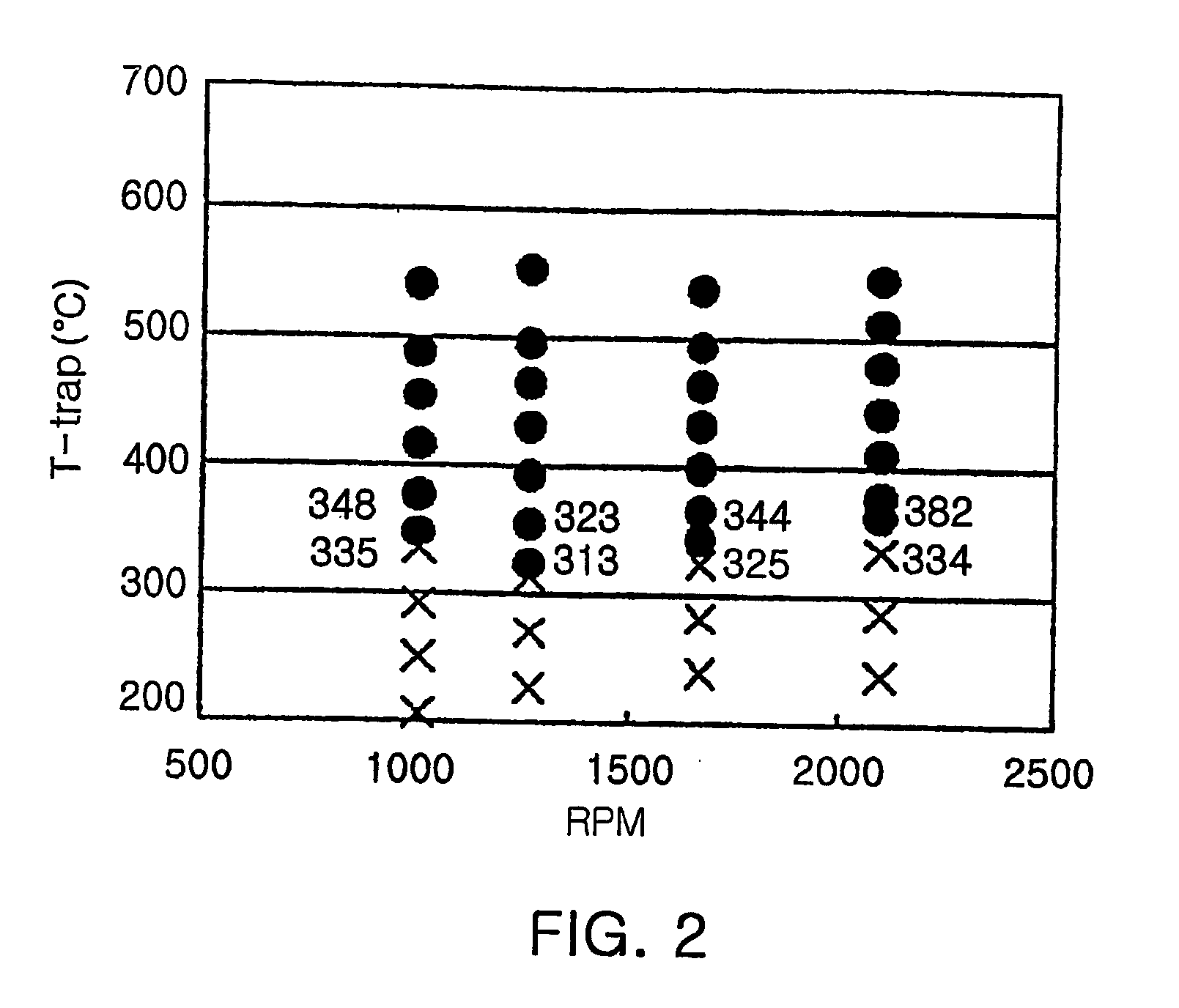

Exhaust gas purification system having particulate filter

An engine control unit of an exhaust gas purification system of an internal combustion engine measures a pressure difference between an upstream and a downstream of a diesel particulate filter (DPF) after heating the DPF at least to a predetermined temperature and maintaining the DPF at the temperature for a while. The DPF is disposed in an exhaust pipe of the engine. A soluble organic fraction included in particulate matters in exhaust gas can be eliminated at the predetermined temperature. The ECU calculates a quantity of the particulate matters trapped by the DPF from the measured pressure difference. Thus, the quantity of the trapped particulate matters is calculated precisely, independently of a composition of the particulate matters or a state of the soluble organic fraction.

Owner:DENSO CORP

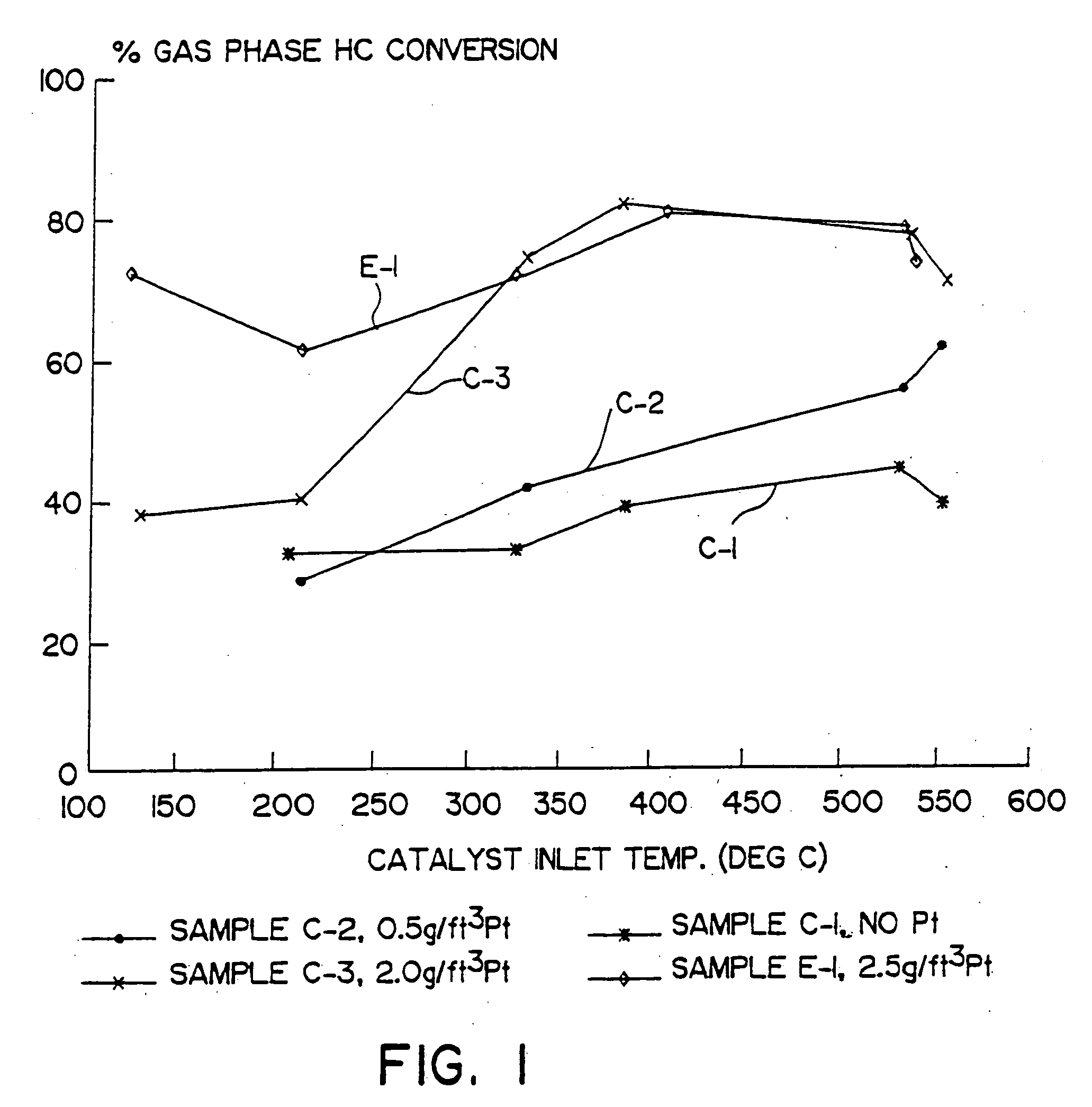

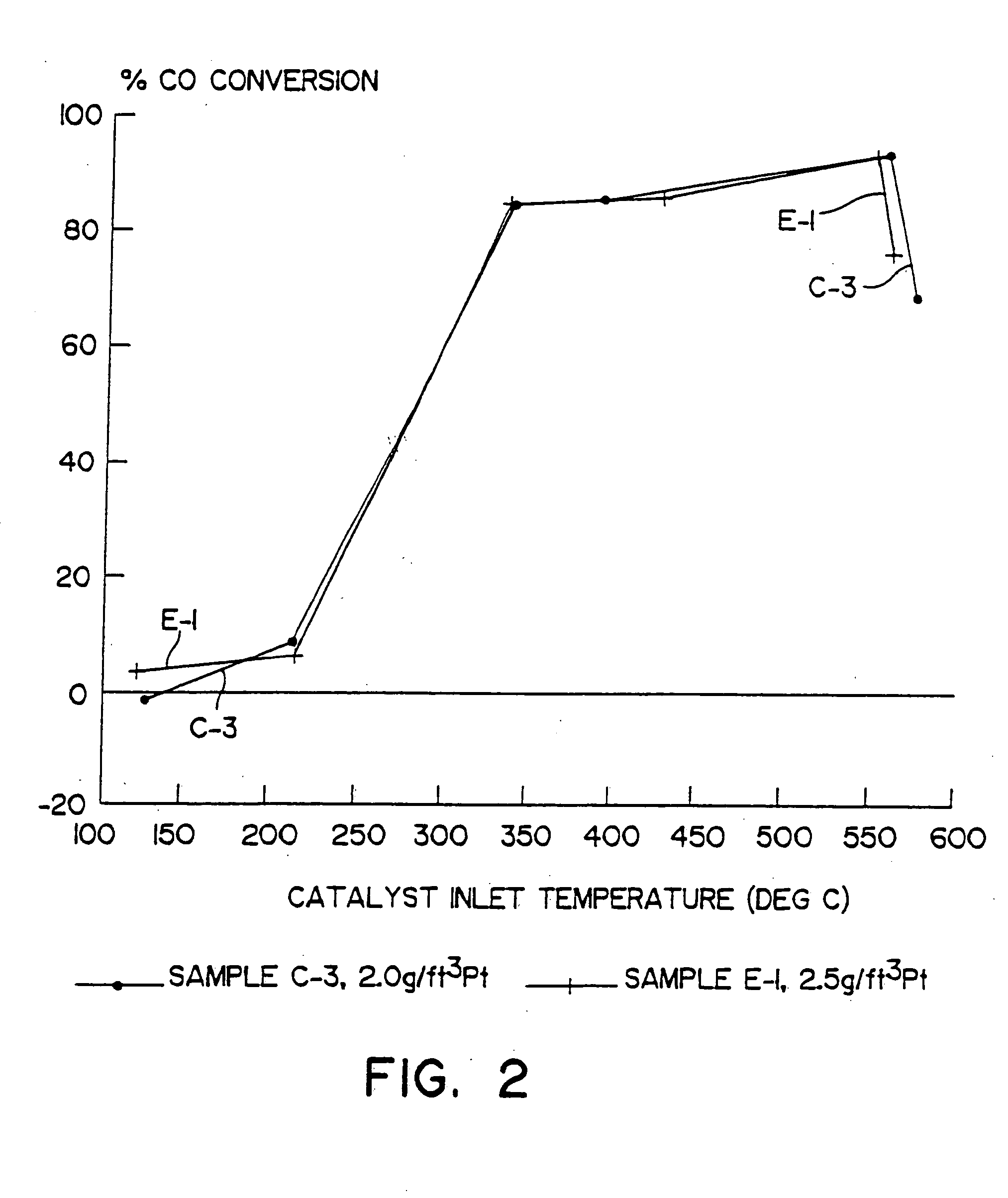

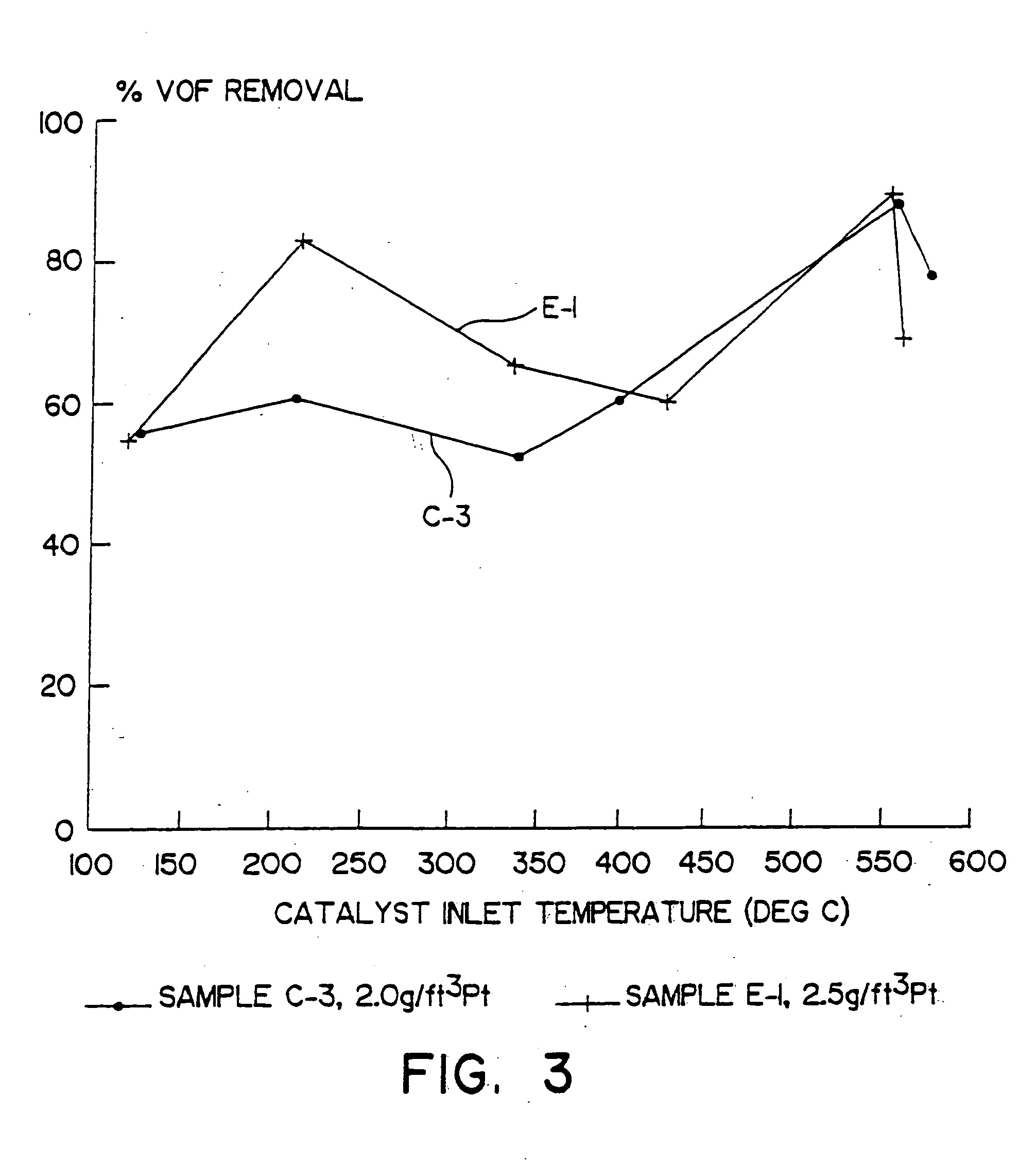

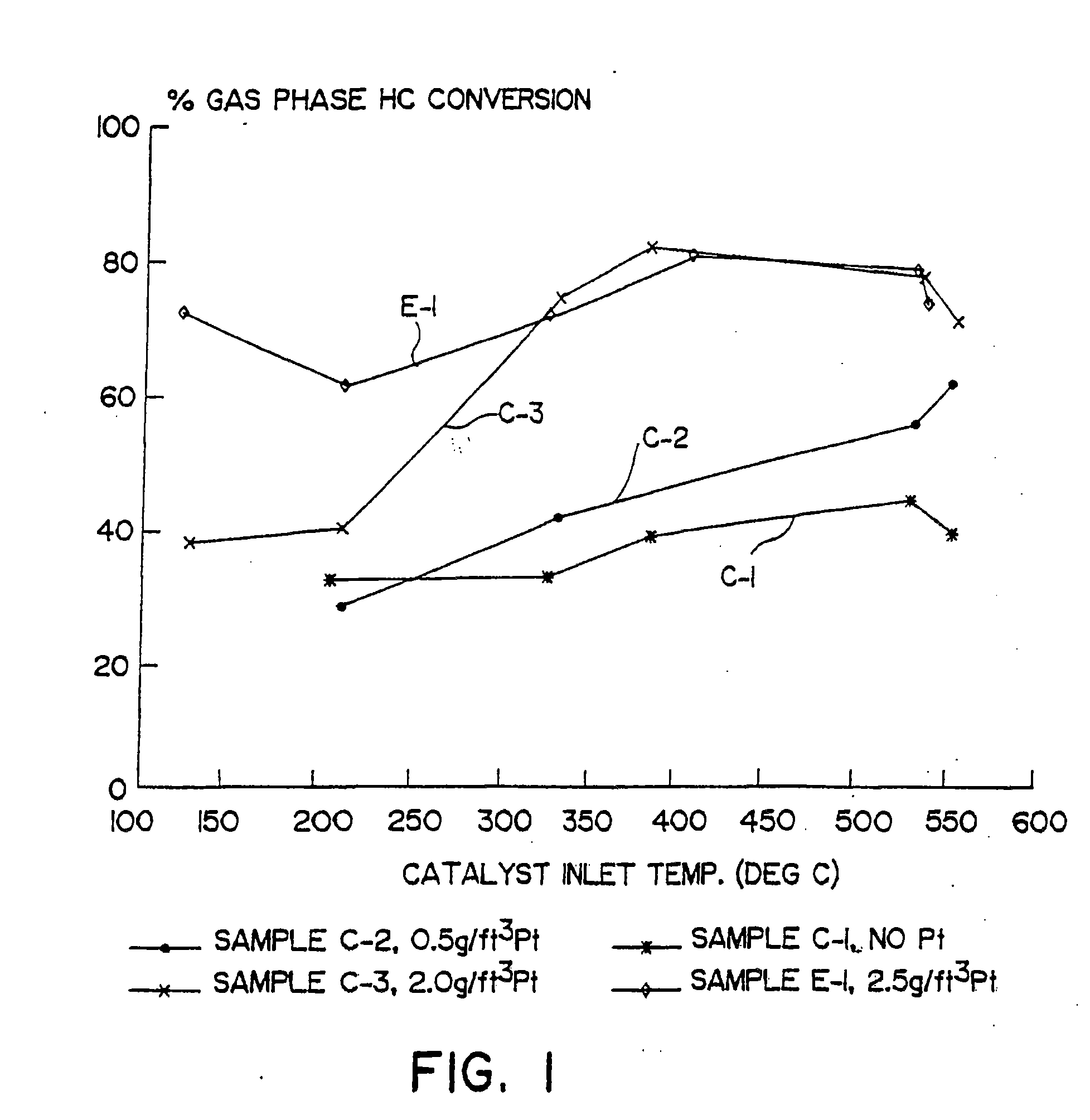

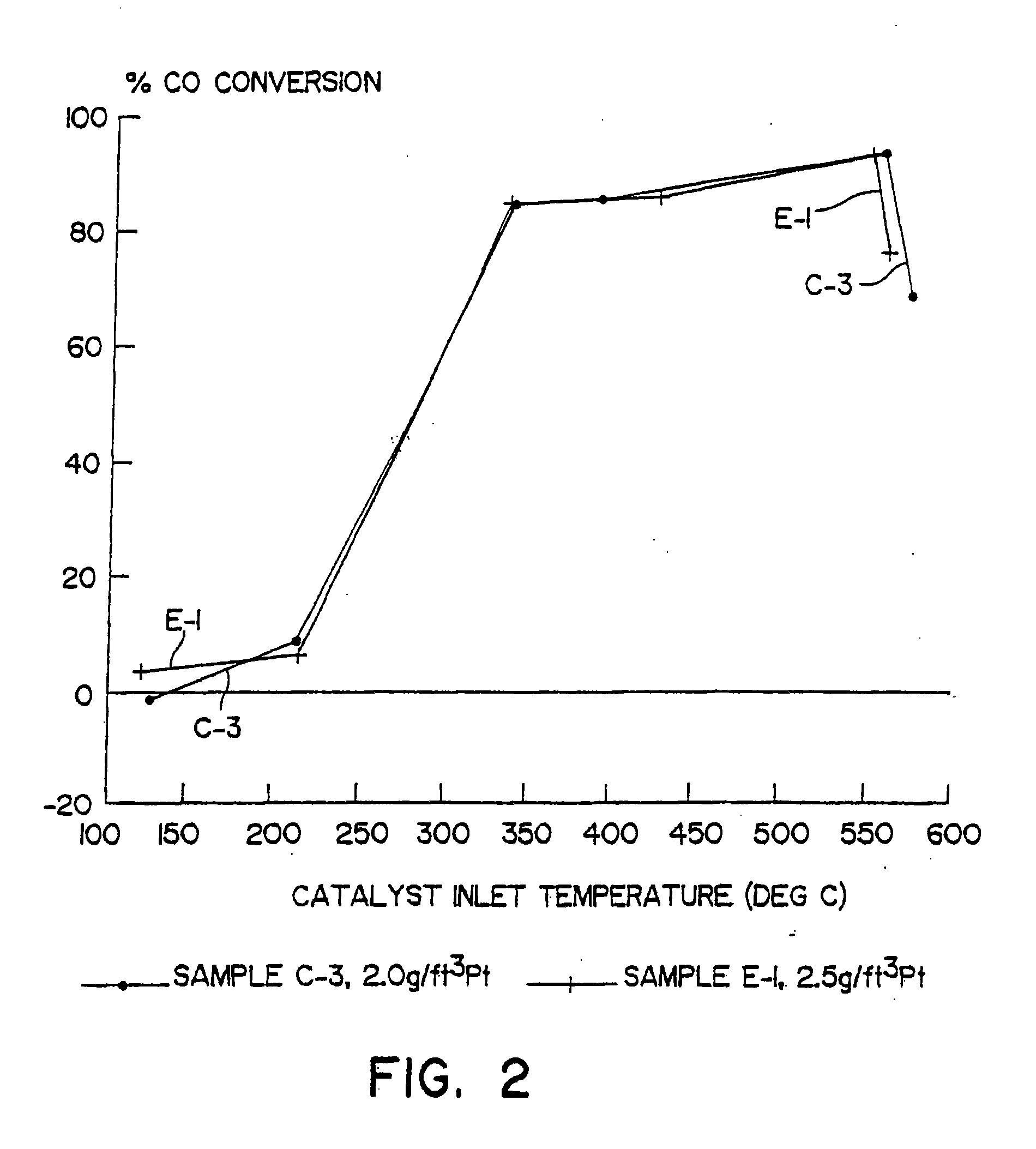

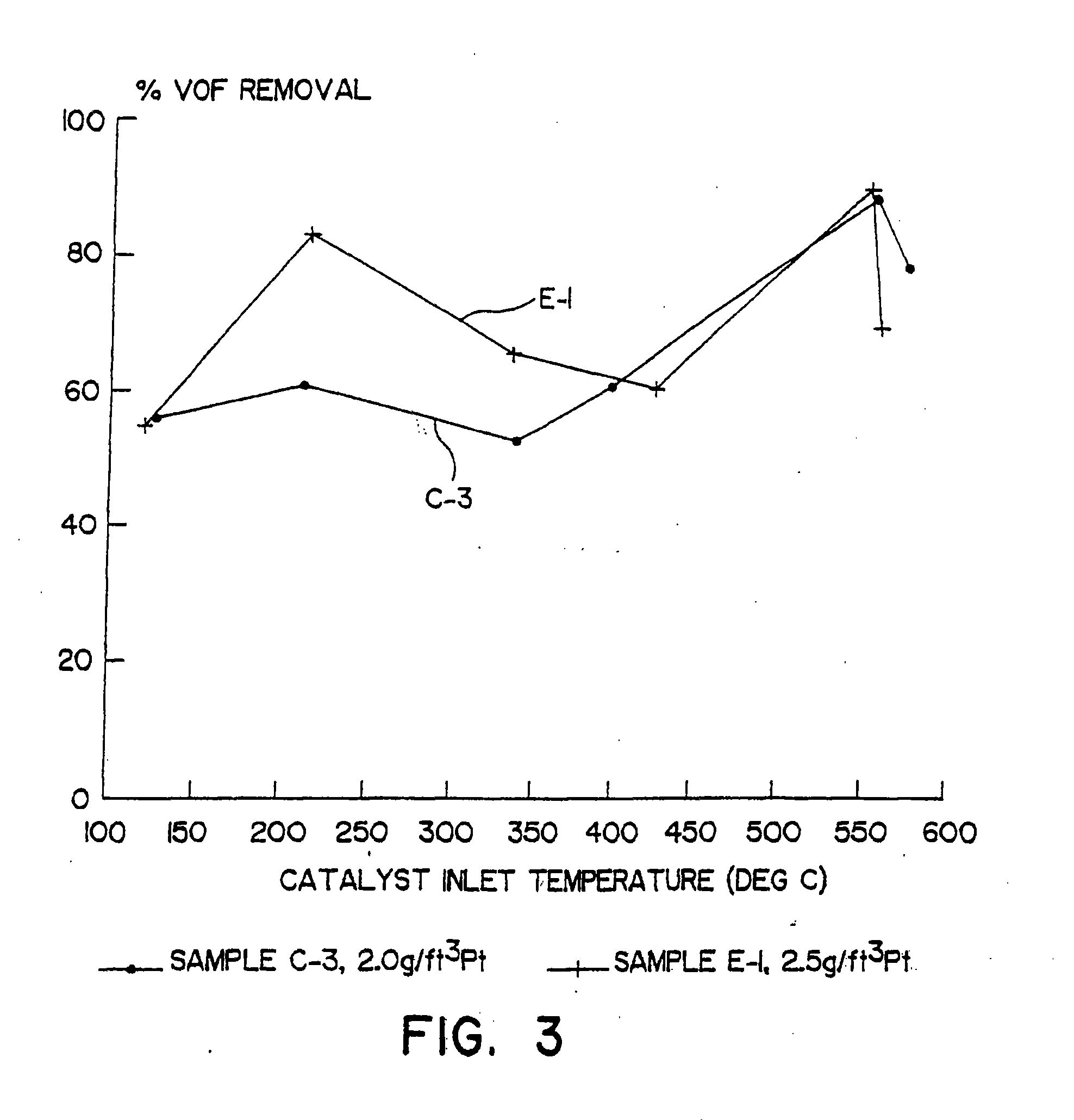

Zeolite-containing oxidation catalyst and method of use

Oxidation catalyst compositions for treating diesel exhaust include ceria and, optionally, alumina, each having a surface area of at least about 10 m2 / g, and a zeolite, e.g., Beta zeolite. Optionally, platinum may be included in the catalytic material, preferably in amounts which are sufficient to promote some gas-phase oxidation of carbon monoxide (“CO”) and hydrocarbons (“HC”) but which are limited to preclude excessive oxidation of SO2 to SO3. Alternatively, palladium in any desired amount may be included in the catalytic material. The zeolite is optionally doped, e.g., ion-exchanged, with one or more of hydrogen, a platinum group metal or other catalytic metals. The catalyst compositions may be used in a method to treat diesel engine exhaust by contacting the hot exhaust with the catalyst composition to promote the oxidation of gas-phase CO and HC and of the volatile organic fraction component of particulates in the exhaust.

Owner:ENGELHARD CORP

Exhaust gas purifier

InactiveUS20060288689A1Good effectIncrease exhaust temperatureElectrical controlInternal combustion piston enginesParticulatesPlasma generator

Provided is an exhaust emission control device which can properly burn off soot and soluble organic fraction attached to and accumulated on electrodes of a plasma generator. The exhaust emission control device with a post-processing device (catalyst regenerative particulate filter 10) for allowing exhaust gas to pass therethrough for gas purification incorporated in an exhaust pipe 9 of an internal combustion engine (diesel engine 1) comprises a plasma generator 11 arranged upstream of the post-processing device for discharging electricity in the exhaust gas 8 to generate plasma, flow-through type oxidation catalyst 12 arranged upstream of the plasma generator 11, fuel adding means (controller 17) arranged upstream of the oxidation catalyst 12 for adding fuel into the exhaust gas 8, temperature increasing means (suction throttling valve 22 or controller 17) for increasing the exhaust temperature to a level enough for oxidation reaction on the oxidation catalyst 12 of the fuel added by said fuel adding means.

Owner:HINO MOTORS LTD

Method for treating wastewater of dilute thiamine

ActiveCN101092265AEfficient removalReduce dosageCalcium/strontium/barium sulfatesAmmonium carbonates/bicarbonatesIon exchangeIon-exchange resin

This invention relates to a method for treating diluted ammonium sulfate wastewater. The method solves the problems of high solid waste and organic nitrile impurity contents, low ammonium sulfate concentration, and difficult ammonium sulfate recovery. The method comprises: (1) removing solid impurities from diluted ammonium sulfate wastewater, adjusting the pH value to 6.5-7.5, performing flash evaporation, stripping or rectification, removing lightweight organic fractions at the overhead, collecting heavy fractions at the bottom, and extracting the rest ammonium sulfate wastewater at 1st-5th theoretical plates from the overhead; (2) sending the rest ammonium sulfate wastewater to ion exchange reaction, and removing NH4+; (3) treating regenerated liquid of the ion exchange resin with Ca(OH)2 aqueous solution to produce CaSO4 and diluted ammonia solution, performing solid-liquid separation, reacting CaSO4 and diluted ammonia solution with CO2 to obtain ammonium carbonate or ammonium hydrogen carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic filter for removing soot particulates from diesel engine exhaust and method of preparing the same

ActiveUS20050239642A1Efficiently oxidizedCombination devicesAuxillary pretreatmentReducing agentMetal salts

Disclosed is a catalytic filter for removing soot particulates from diesel engine exhaust, which is comprised of monolithic oxidation catalyst upstream of the catalytic filter, which effectively oxidize gaseous pollutants and volatile organic fractions, and a catalyzed wall-flow filter downstream serving to low temperature combustion of soot particulates collected on the filter. Also, the preparation method of the catalytic filter is provided, including the colloidal mixture solution of platinum group metal salts and other metal salts with a water-soluble polymer and a reducing agent, which is then impregnated on a catalyst support, followed by calcining at high temperatures. In the present invention, use of the catalytic filter provides effective means of abating diesel exhaust pollutant emissions, that is, particulate matter (PM) and gaseous pollutants (HC, CO, NOx).

Owner:SK ENERGY CO LTD (KR)

Zeolite-Containing Oxidation Catalyst and Method of Use

Owner:YAVUZ BULENT O +4

Process for fractioning vinasse

InactiveUS6022394AIncrease PotassiumPromote crystallizationIon-exchange process apparatusBy-product recoveryOrganic fractionOrganic acid

PCT No. PCT / FI95 / 00329 Sec. 371 Date Mar. 10, 1997 Sec. 102(e) Date Mar. 10, 1997 PCT Filed Jun. 7, 1995 PCT Pub. No. WO96 / 00776 PCT Pub. Date Jan. 11, 1996The invention relates to a process for fractioning vinasse, in which process the pH value of the vinasse is lowered by adding acid, and the formed precipitate is separated in order to obtain an inorganic fraction, whereupon an organic fraction remains. The invention also relates to the products obtained. The inorganic fraction mainly contains potassium salt, and it is useful for example as a fertilizer. The organic fraction mainly contains organic acids, and it is useful for example as an additive in animal feed and in producing silage.

Owner:CULTOR LTD +1

Exhaust emission control device

InactiveUS7331170B2Increase exhaust temperaturePrevent leakageElectrical controlInternal combustion piston enginesParticulatesPlasma generator

Provided is an exhaust emission control device which can properly burn off soot and soluble organic fraction attached to and accumulated on electrodes of a plasma generator. The exhaust emission control device with a post-processing device (catalyst regenerative particulate filter) for allowing exhaust gas to pass therethrough for gas purification incorporated in an exhaust pipe of an internal combustion engine (diesel engine) comprises a plasma generator arranged upstream of the post-processing device for discharging electricity in the exhaust gas to generate plasma, flow-through type oxidation catalyst arranged upstream of the plasma generator, fuel adding means (controller) arranged upstream of the oxidation catalyst for adding fuel into the exhaust gas, temperature increasing means (suction throttling valve or controller) for increasing the exhaust temperature to a level enough for oxidation reaction on the oxidation catalyst of the fuel added by said fuel adding means.

Owner:HINO MOTORS LTD

Method for producing isophorone

InactiveCN102531866AOrganic compound preparationCarbonyl compound preparation by hydrolysisOrganic fractionIsophorone

The invention relates to a method for producing isophorone by catalyzed aldol condensation of acetone as an educt, reprocessing the reaction product, hydrolyzing the product stream, and separating into an organic and an aqueous fraction, obtaining isophorone from the organic fraction, distillatively reprocessing the aqueous fraction, and feeding the vapors from the head of the distillative reprocessing apparatus into the hydrolysis apparatus.

Owner:EVONIK DEGUSSA GMBH

Catalyst for purifying tail gas of diesel automobiles, preparation method and purification device thereof

ActiveCN102489322ANo sheddingImprove uniformityExhaust apparatusDispersed particle separationOrganic fractionCombustion

The invention relates to a catalyst for purifying tail gas of diesel automobiles, a preparation method and a purification device thereof. The catalyst comprises a first carrier taking cordierite honeycomb ceramics as a matrix, and a second carrier taking SiC or a cordierite wall-flow structure as a matrix, a first coating and active components on the first carrier, as well as a second coating and active components on the second carrier. In the invention, coating, roasting and reduction processes are adopted for preparing the coatings composed of composite oxides. The catalyst and the device in the invention employ a technology combining a DOC (diesel oxidation converter) and a CDPF (catalyzed diesel particulate filter). By means of the DOC at a front end, HC, CO as well as the soluble organic fractions (SOF) in PM are removed through oxidation. Meanwhile, NO is converted to NO2 that has stronger reducibility so as to be good for the reaction of NO2 and C, thus reaching the purposes of removing NO and lowering the combustion temperature of C simultaneously. Depending on the self-temperatures of diesel automobiles to realize regeneration of a particulate filter, the purification device in the invention has the characteristics of high purification efficiency and convenient usage, etc.

Owner:CHONGQING MATERIALS RES INST

Method of obtaining a concentrate humic extract from organic and inorganic sources

InactiveUS7510590B2Improve adhesionGood of active ingredient contentExcrement fertilisersLiquid fertilisersOrganic fractionAlkalinity

A process to obtain a humic extract that concentrates features of liquid extracts from mineral and organic sources is provided by first elaborating a humic extract from a first organic source by using an extracting alkaline solution and by utilizing residual alkalinity to partially extract active ingredients from a second mineral source. A product useful to improve cultivation soils and to physiologically activate plants is also provided.

Owner:BIOTECHA ORGANICA S A DE

Method for treating wastewater of dilute thiamine containing acrylonitrile

ActiveCN101092266AImprove recycling qualityQuality improvementWater/sewage treatment by neutralisationWater/sewage treatment by heatingPropionitrileAcrylonitrile

This invention relates to a method for treating diluted ammonium sulfate wastewater containing propionitrile. The method solves the problems of high solid waste and organic nitrile impurity contents, low ammonium sulfate concentration, difficult ammonium sulfate recovery, and low recovered ammonium sulfate quality. The method comprises: (1) removing solid impurities from diluted ammonium sulfate wastewater containing propionitrile, and adjusting the pH value to 6.5-7.5 to obtain material flow 1; (2) sending material flow 1 into a liquid-gas separator, and performing stripping or rectification; (3) removing lightweight organic fractions at the overhead of the liquid-gas separator, collecting polymer fractions at the bottom, extracting the rest wastewater at 1st-5th theoretical plates from the overhead to obtain material flow 2, extracting water free of solids and organic matters from 1st-10th theoretical plates from the bottom to obtain material flow 3, mixing material flow 3 with water added by the quenching system and diluted acid, circulating to the quenching column, and recovering ammonium sulfate from material flow 2.

Owner:CHINA PETROLEUM & CHEM CORP +1

Extraction and quantification of vitamins a and d in fluid samples

The invention discloses monoclonal antibodies for vitamins A (retinol palmitate) and D3 (cholecalciferol); a method for using monoclonal antibodies, and the monoclonal antibodies disclosed herein, in particular, to quantitate these vitamins in fluids such as dairy products, and blood, and also raw or processed agri-food and beverage products. The method involves contacting the sample with a mixture of polar and non-polar organic solvents in combination with inorganic salts to remove fat molecules into an organic fraction, and assaying the organic fraction by immunoassay involving the monoclonal antibodies. The presence of a mixture of non-polar and polar organic solvents increases the separation of vitamins from fat molecules and enables the test samples to be quantified by immunoassay without any further treatment.

Owner:SCIMED TECH

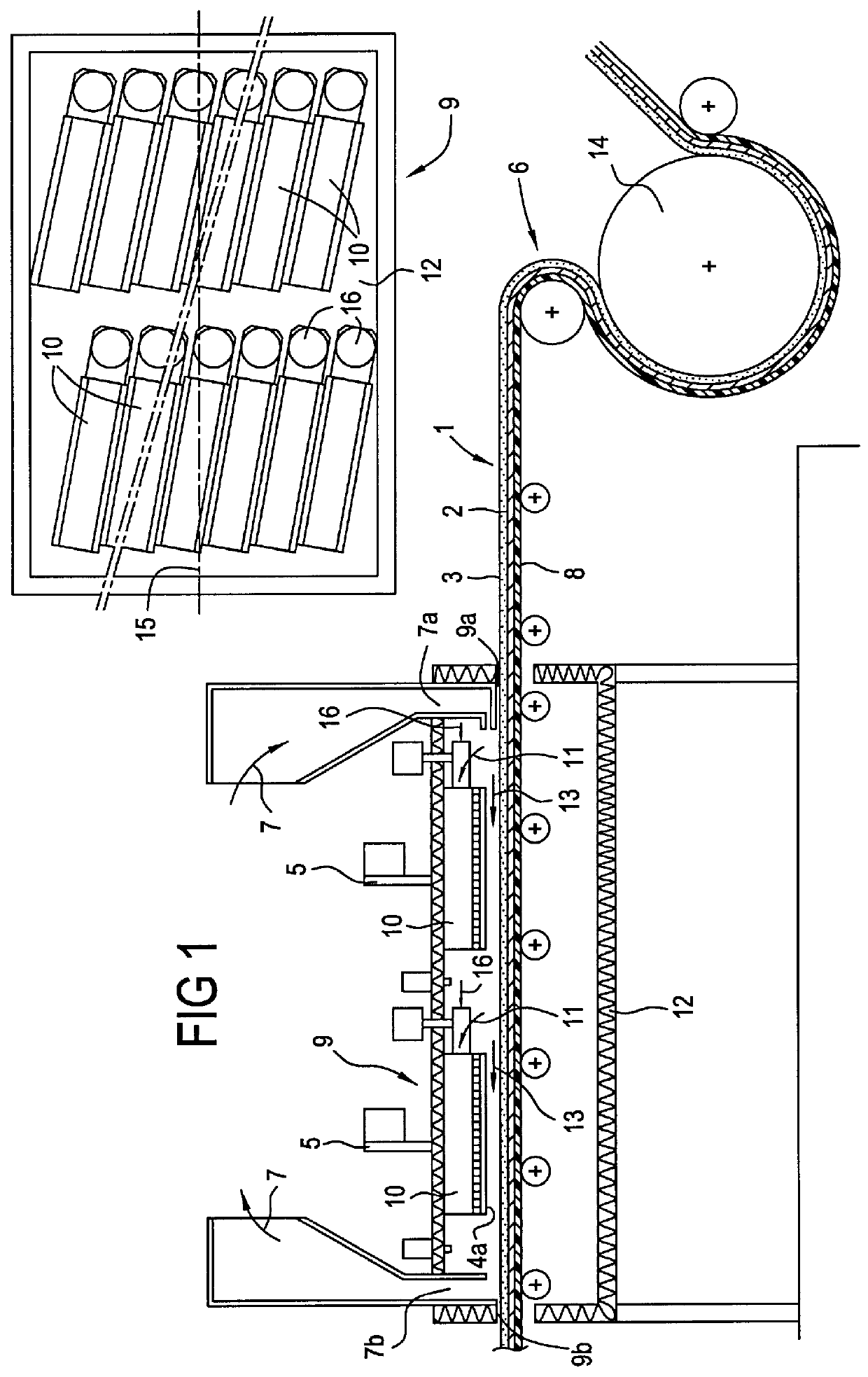

Process and plant for manufacturing a composite plastic structure, for example a floor covering

Process for manufacturing a flat composite plastic structure, for example a floor covering, comprising a textile web and at least one layer of a plastic, for example a polyvinyl chloride, on the reverse side or on the top side, which impregnates the textile web, according to which process: a) the textile web is made available, b) a plastisol is made available, c) the textile web is coated with a layer of plastisol, d) a radiant surface is obtained by combustion of a combustible gas in contact with a porous structure, e) the layer of plastisol is heated, using the radiant surface, in order to remove the volatile organic fraction of the coated layer and to cause the plastisol to gel, wherein the combustion of the combustible gas takes place under flameless, catalytic conditions.

Owner:GERFLOR

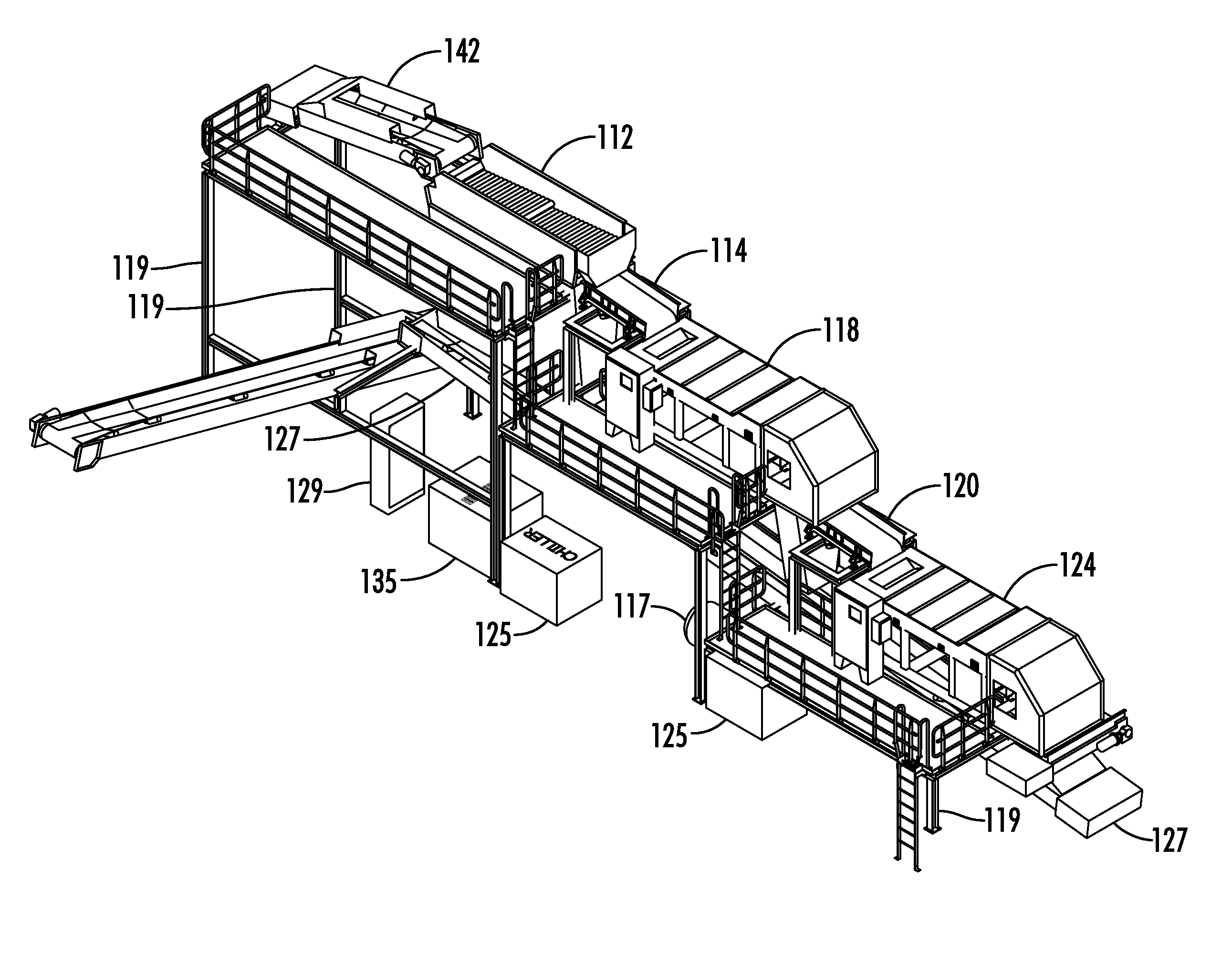

Methods of Processing Waste Material to Render a Compostable Product

InactiveUS20140077007A1Increase productionLess materialSievingGas current separationOrganic fractionInorganic materials

Disclosed herein are methods of processing municipal solid waste in order to isolate a compostable product. The methods and system disclosed allow for municipal solid waste to be separated into an organic fraction and an inorganic fraction. The purity of the organic fraction may be enhanced in certain methods. The overall yield of organic material may be increased by subjecting inorganic material to further separation steps.

Owner:NAT RECOVERY TECH

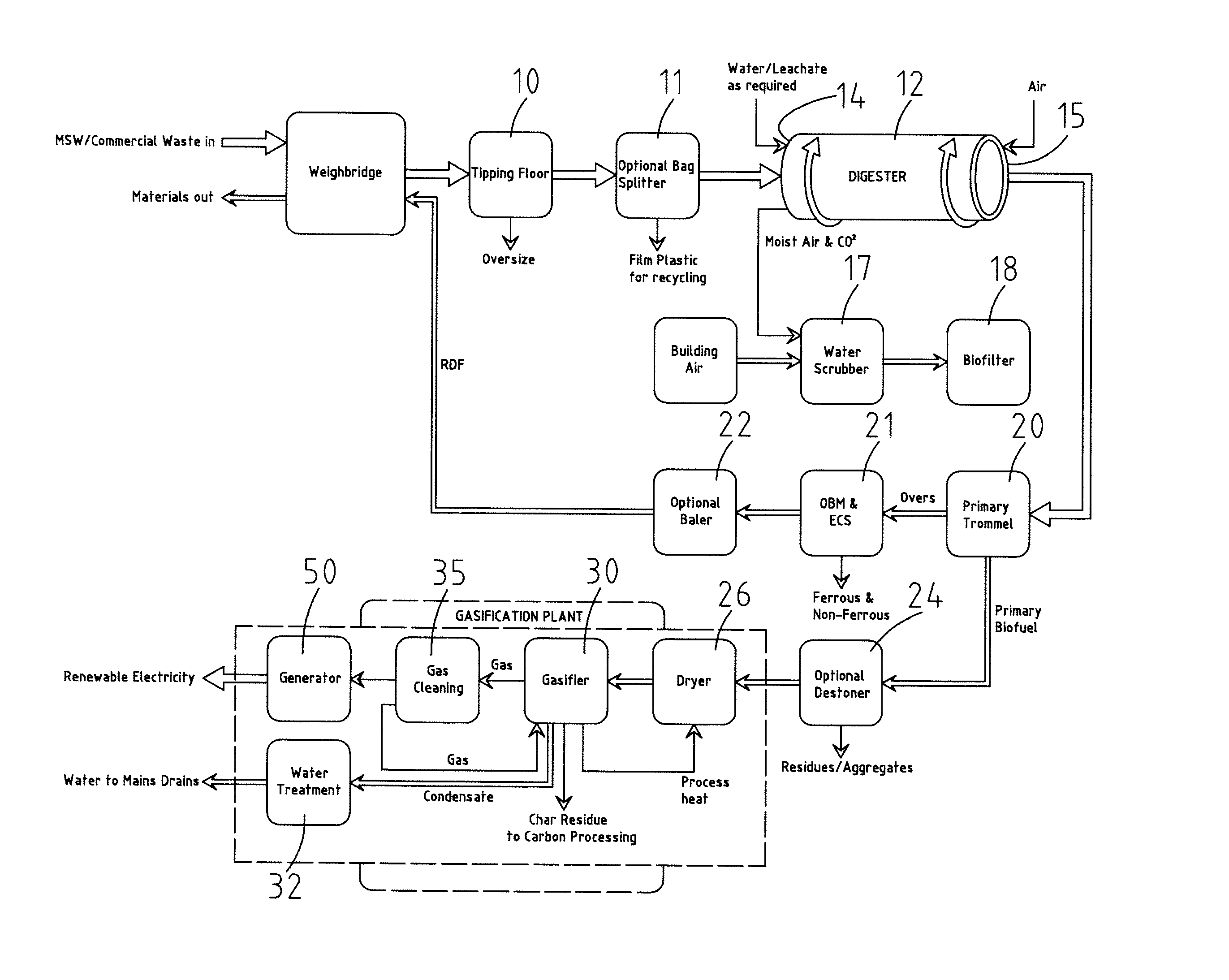

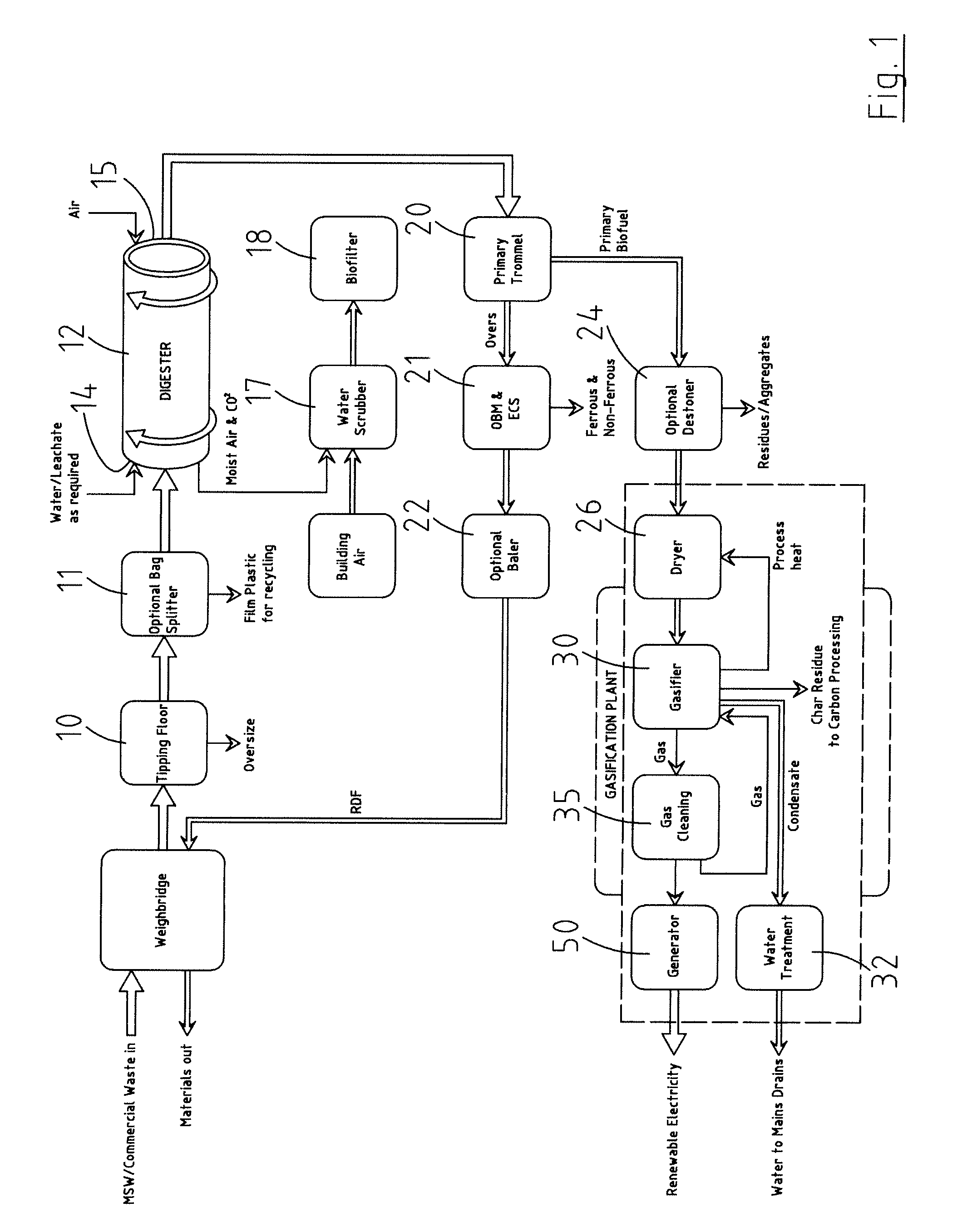

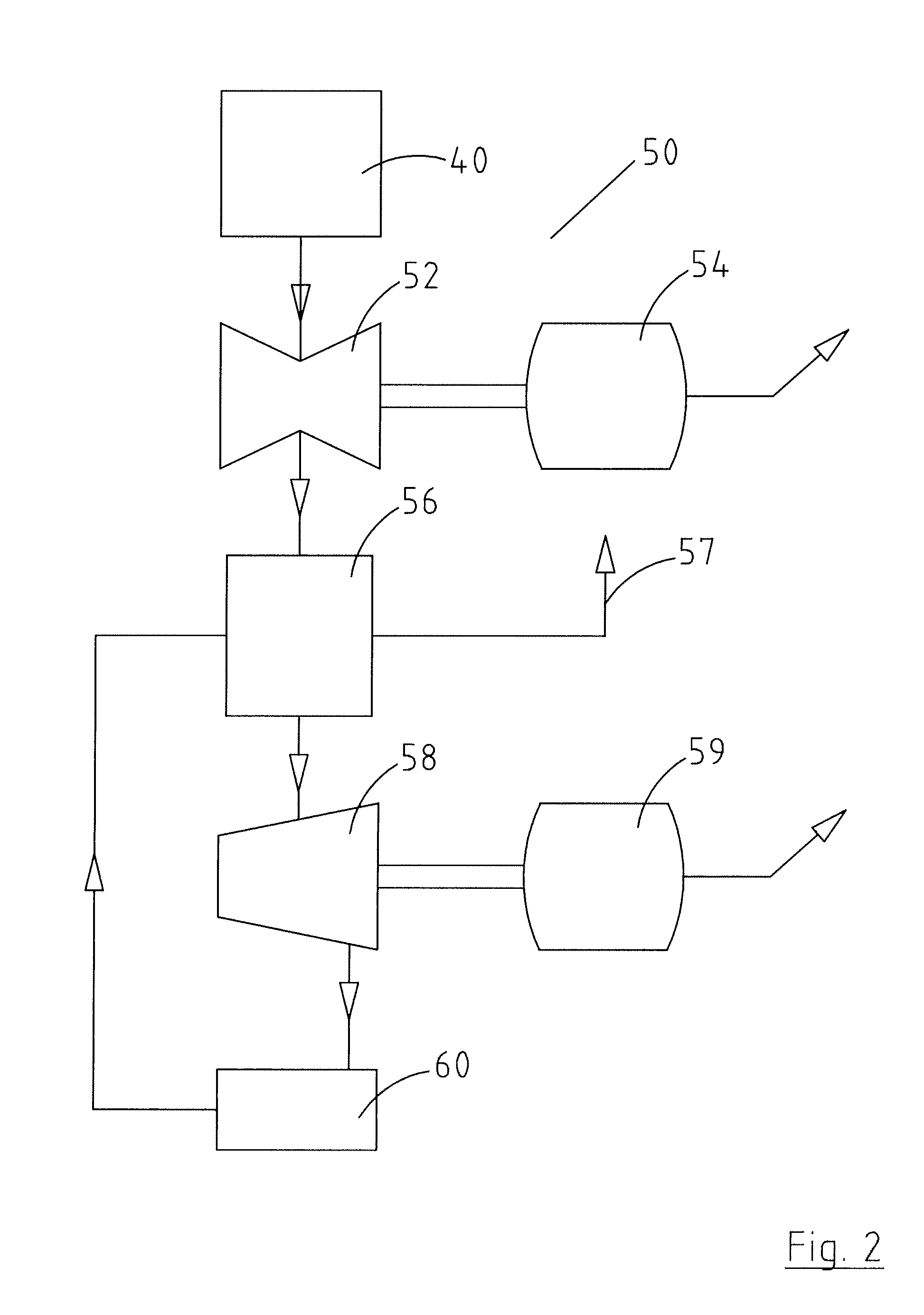

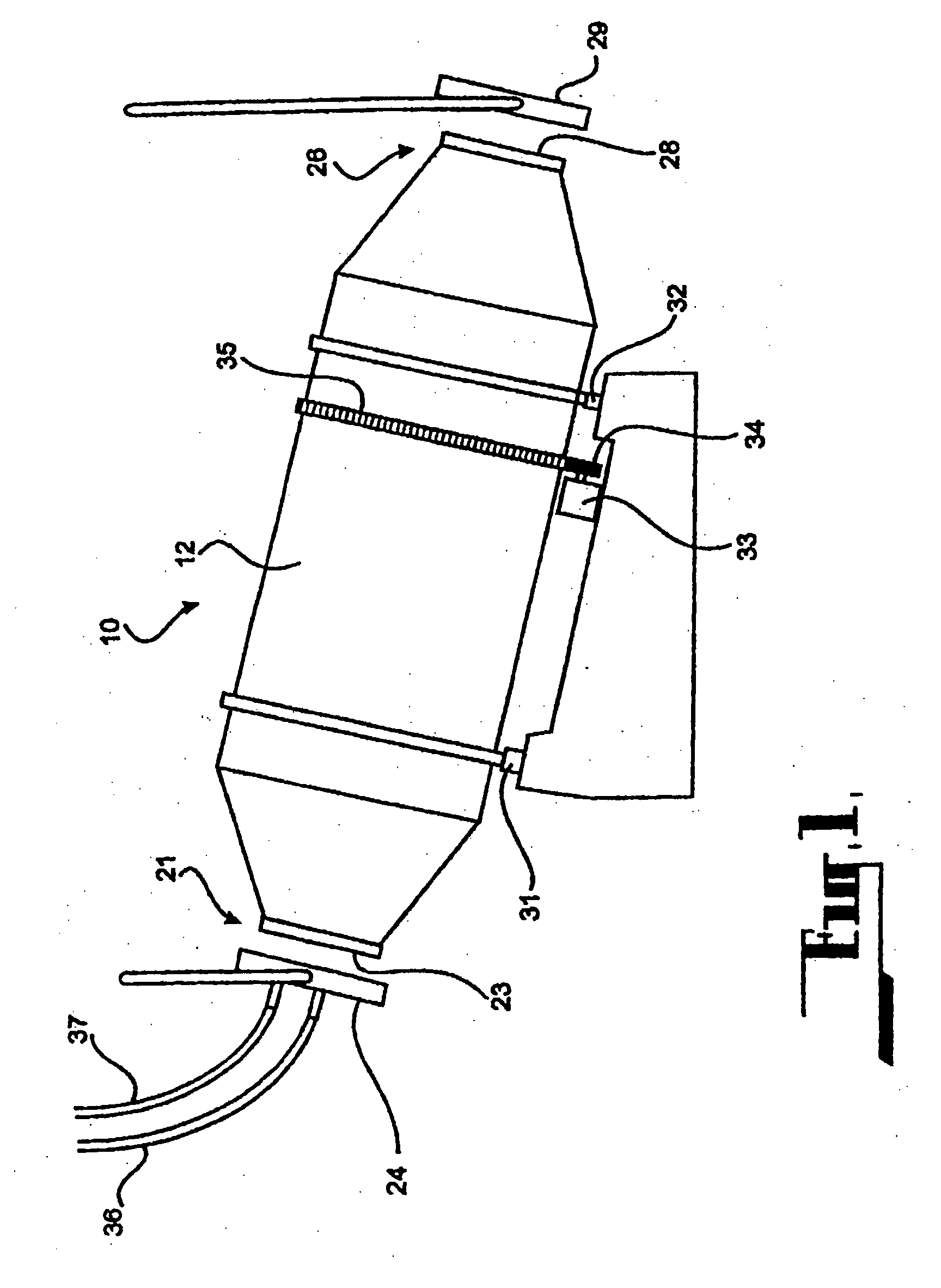

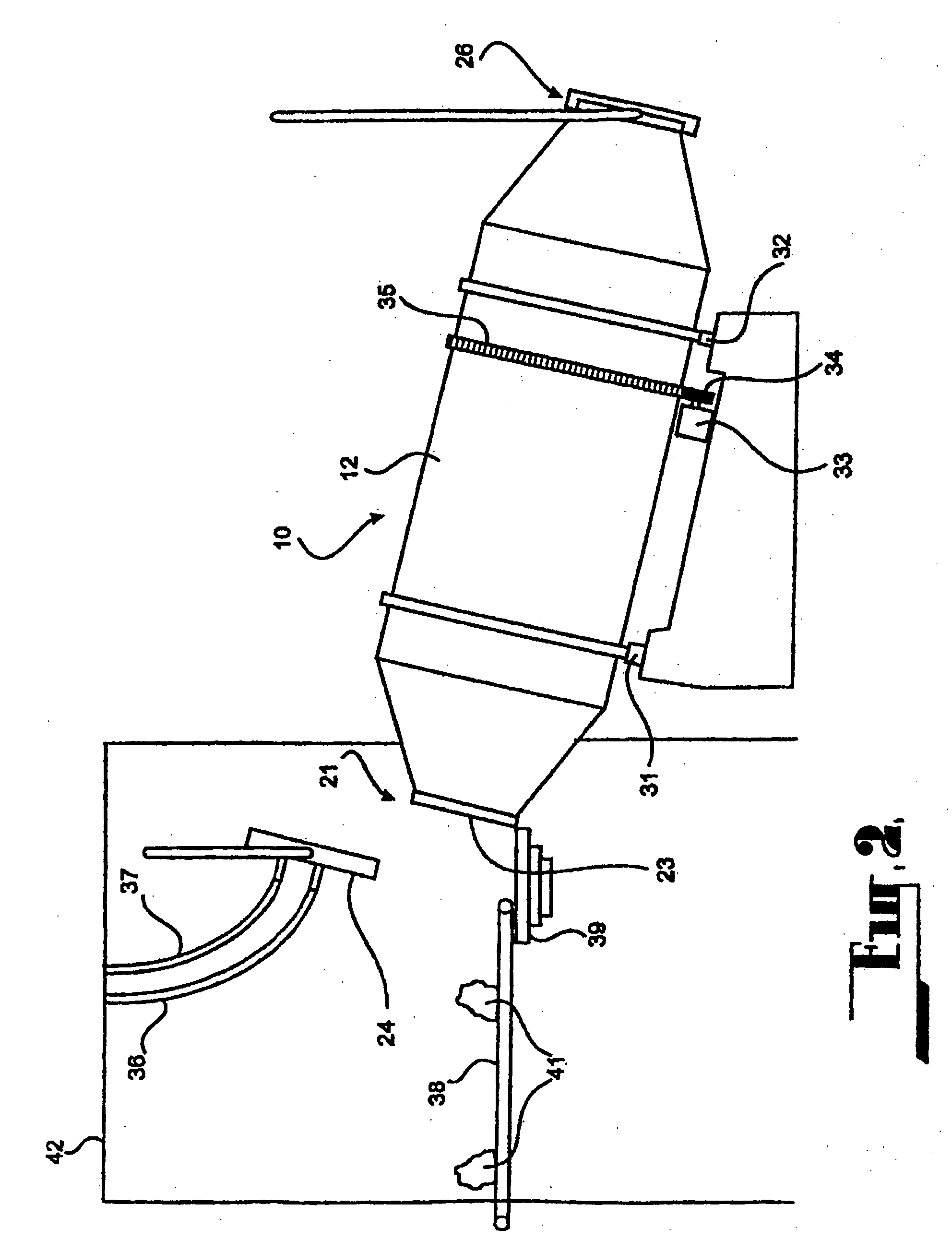

Renewable energy recovery from msw and other wastes

InactiveUS20100071370A1Reduce moisture contentThermal non-catalytic crackingReciprocating combination enginesBiofuelStorage tank

Raw MSW is delivered through an organic digester (12) within which an organic fraction of the MSW is broken down by a combination of aerobic microbial activity and mechanical action and converted into a solid bio fuel material. Treated waste material comprising a mixture of the solid bio fuel material and insert inorganic waste material is discharged from the digester (12). The treated material is delivered through a separator (20) for removal of the inorganic fraction. A substantially homogenous solid bio fuel material is discharged from the separator (20), and passed through a dryer (26) and into a gasifier (30). Within the gasifier (30) the homogenous solid bio fuel material is heated in a depleted oxygen atmosphere to generate a bio fuel gas rich in methane, hydrogen and carbon monoxide. The bio fuel gas is delivered through a cleaner (35) and then collected in a storage tank. Bio fuel gas is fed as required from the storage tank to a power plant (50) for generating electrical energy.

Owner:OKANE PEARSE

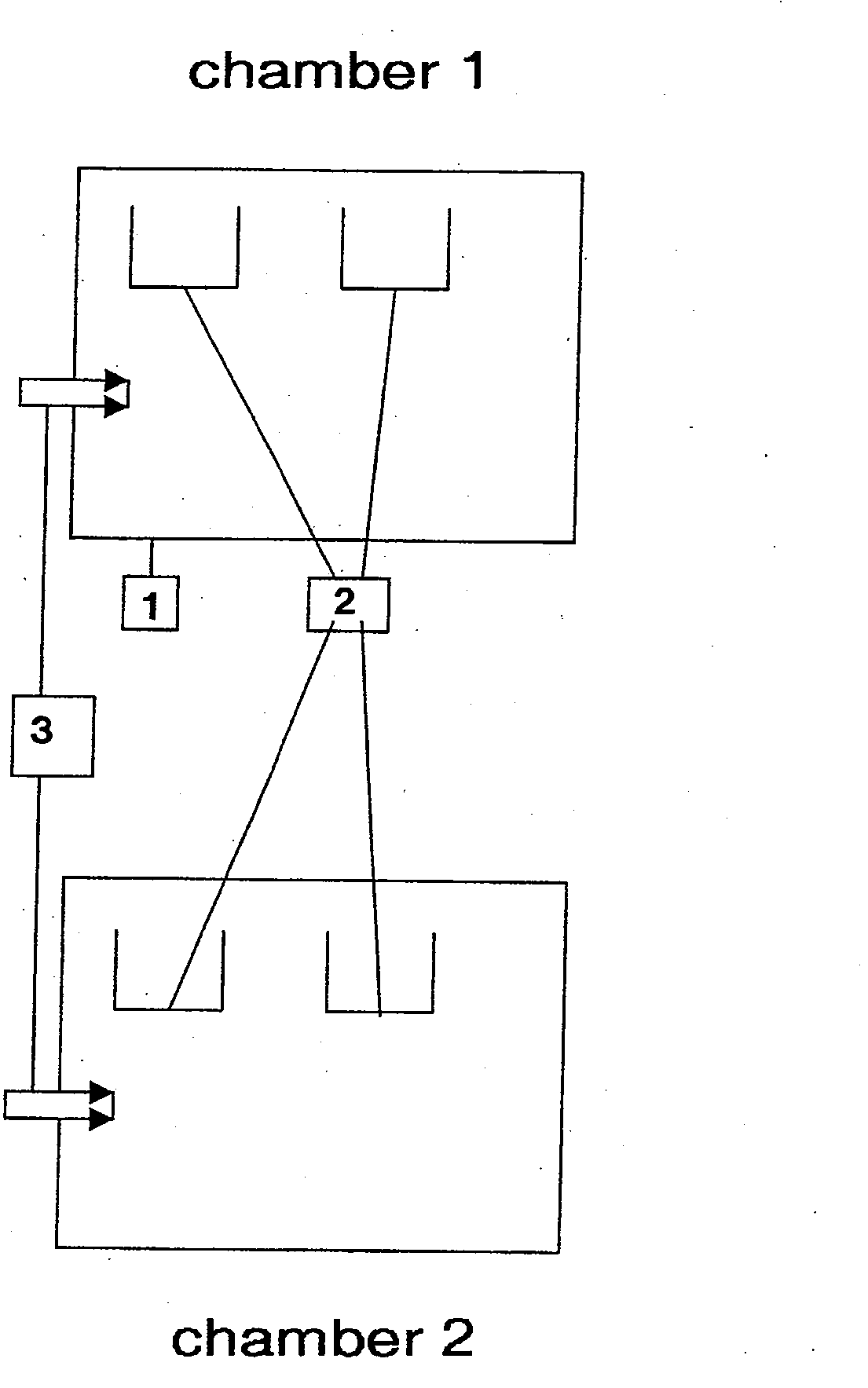

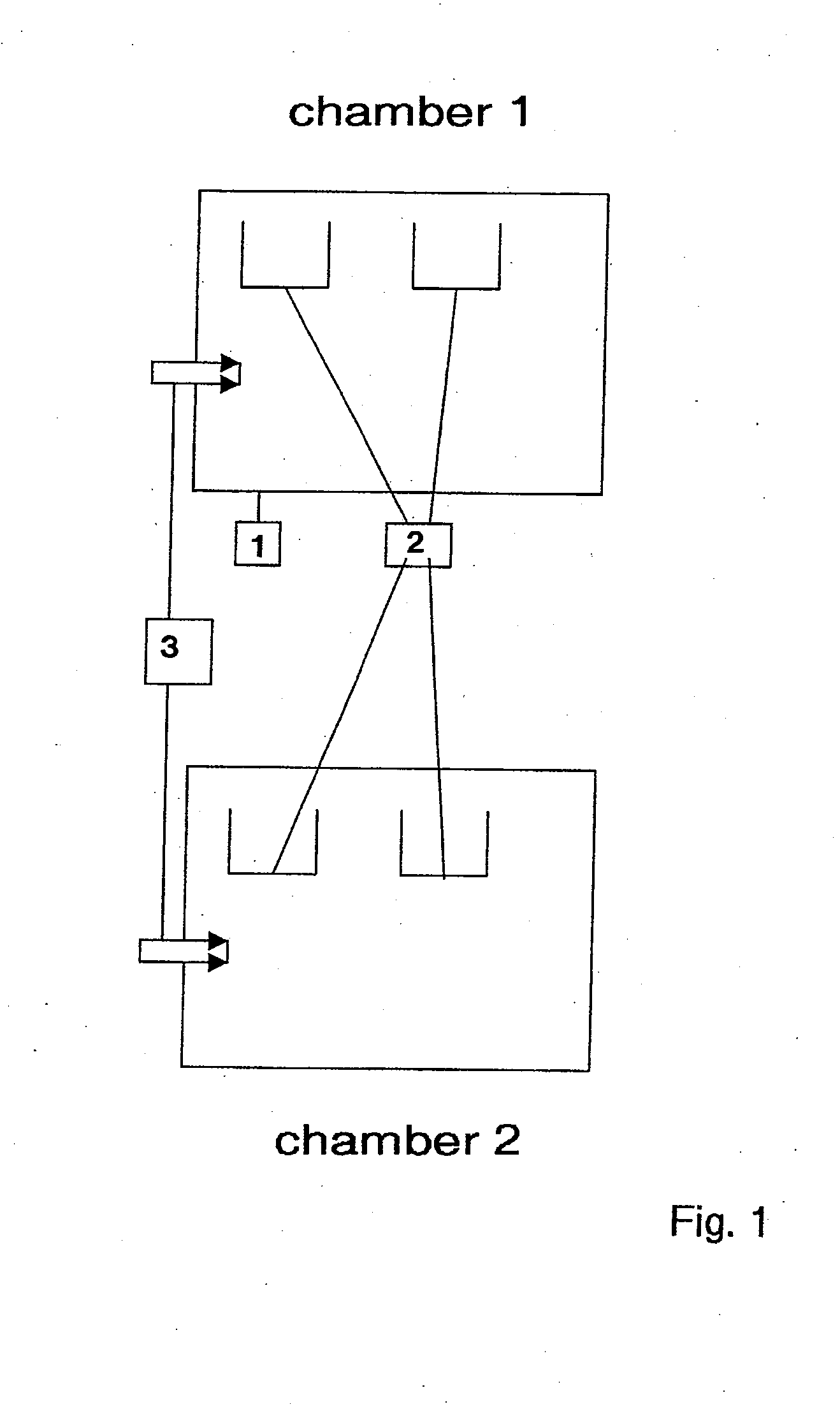

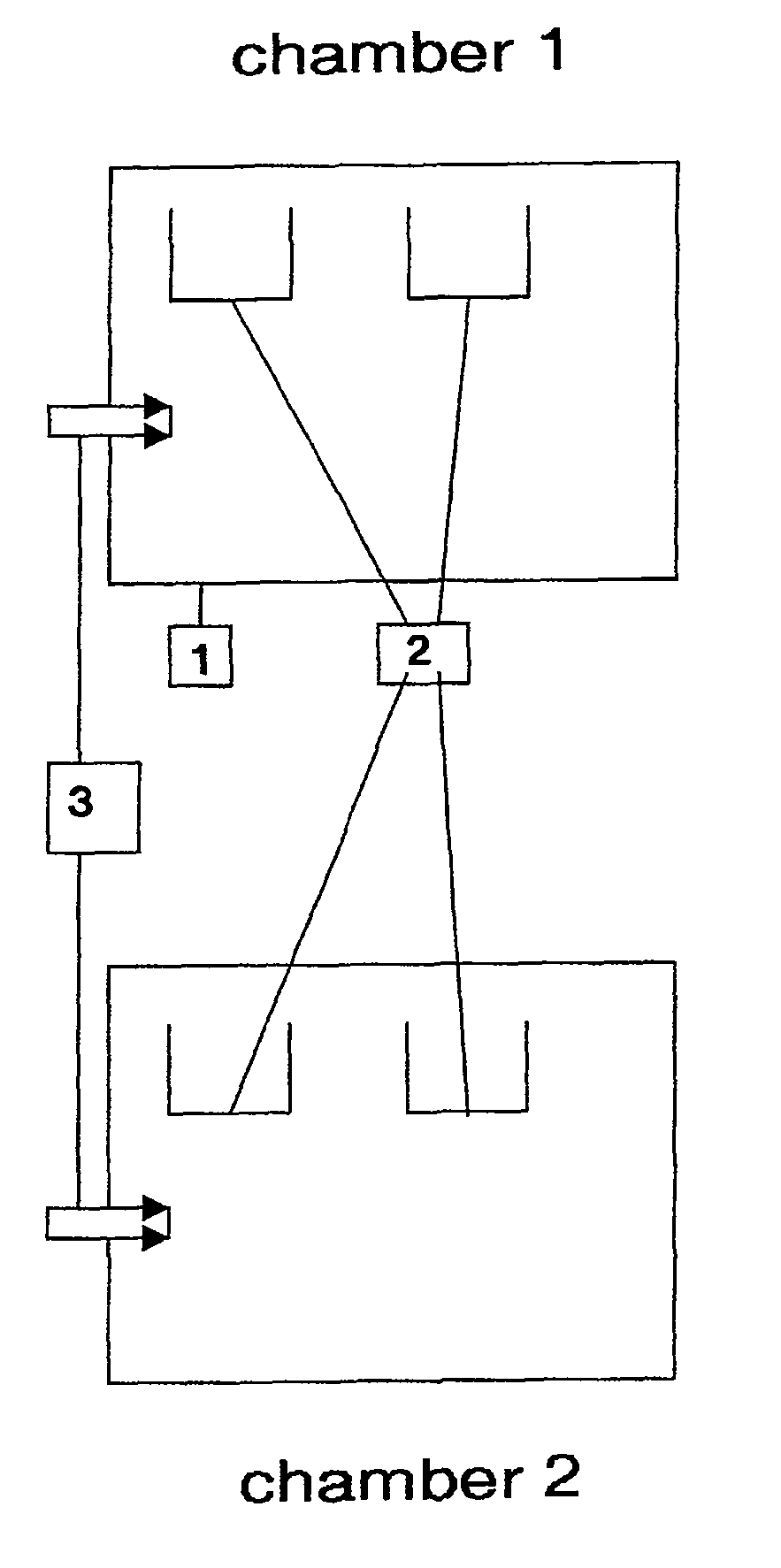

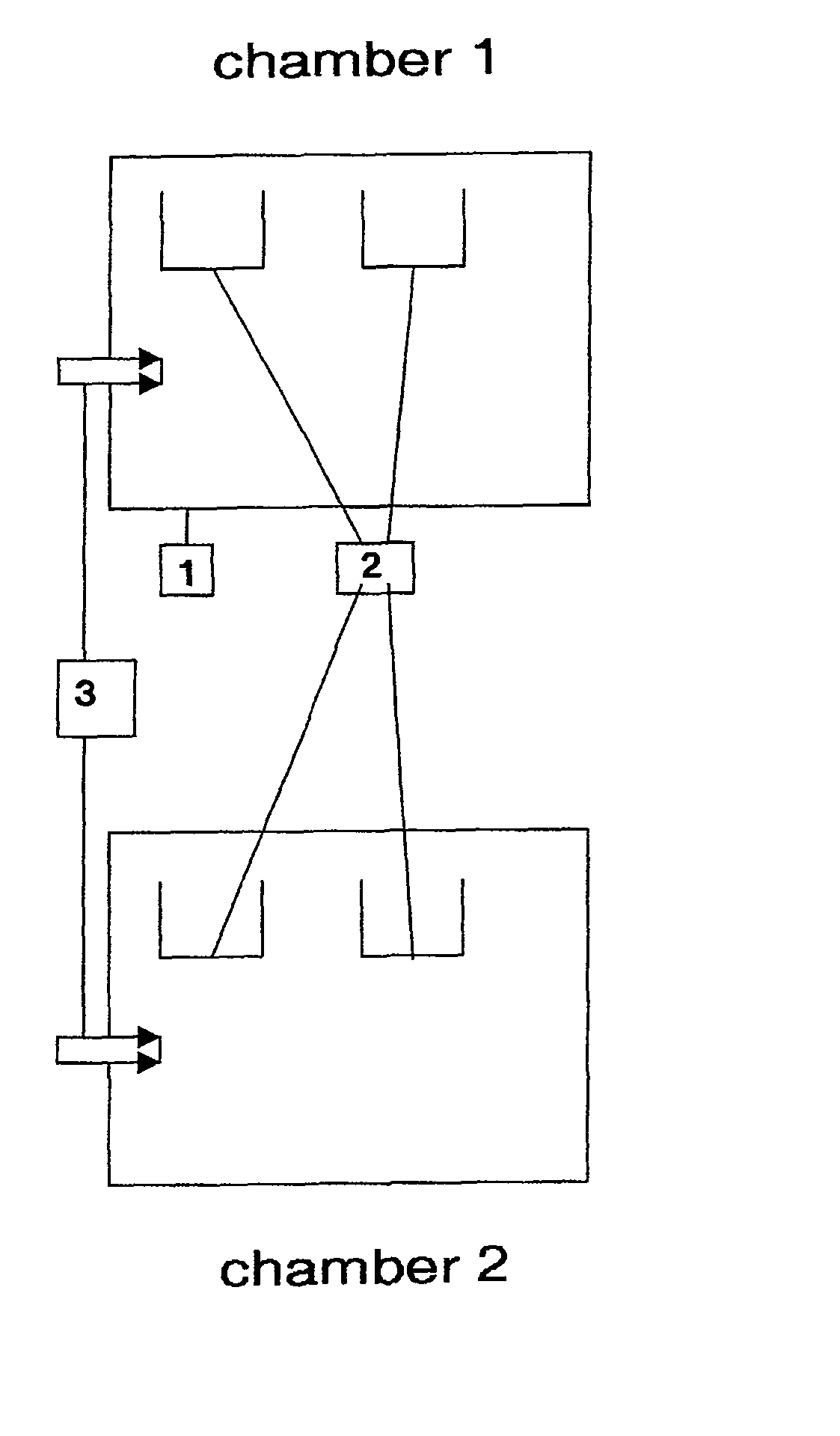

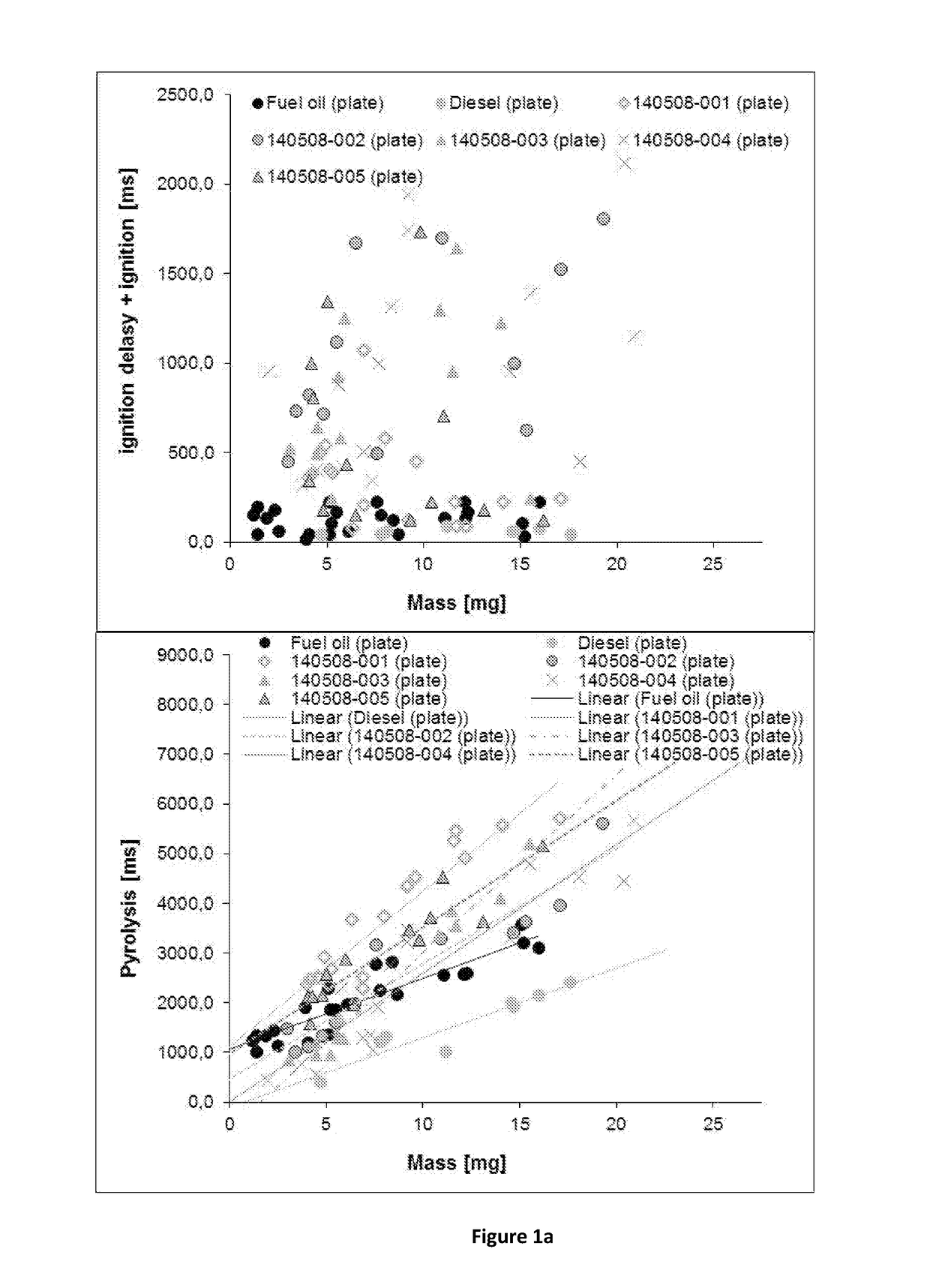

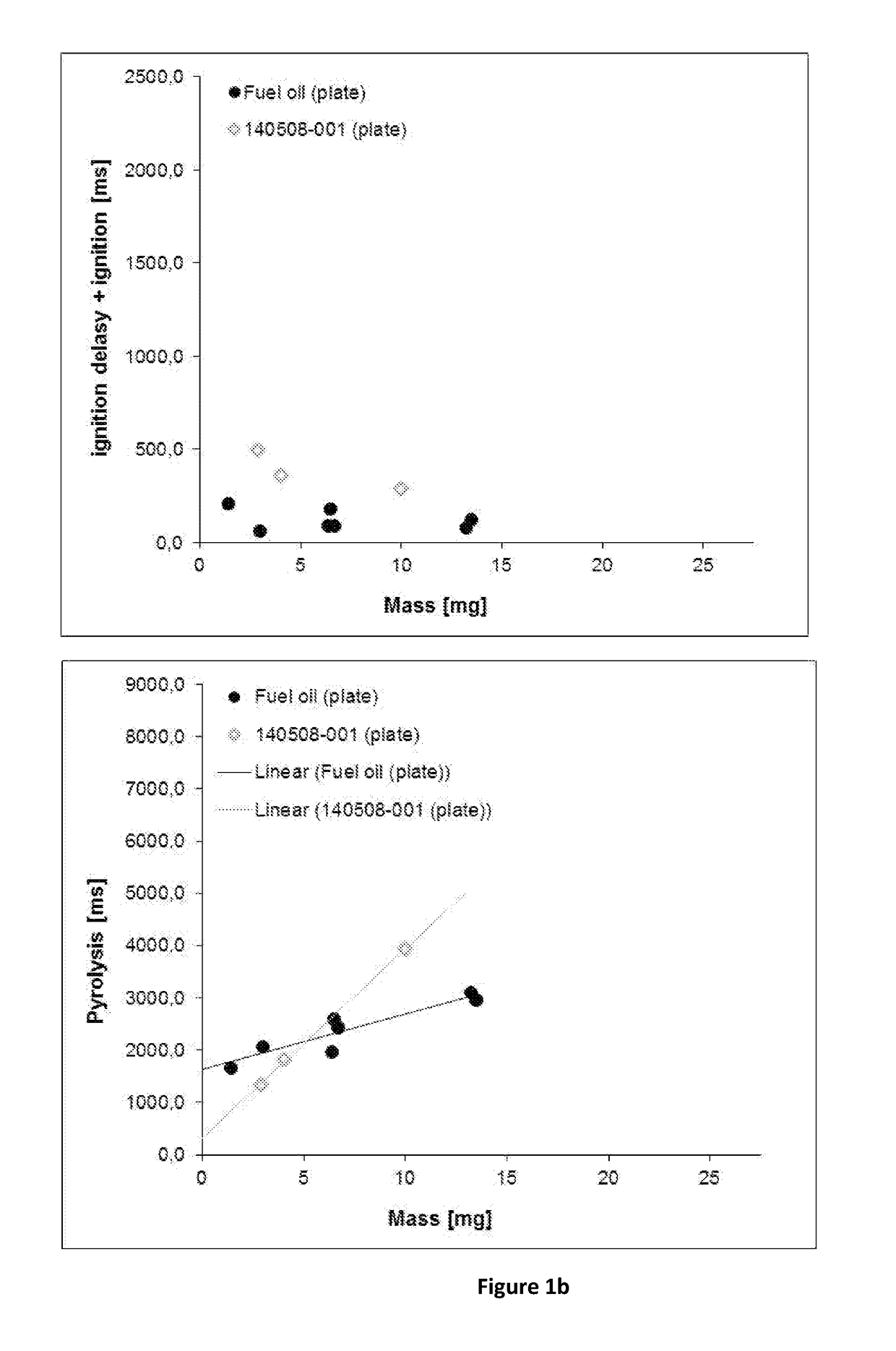

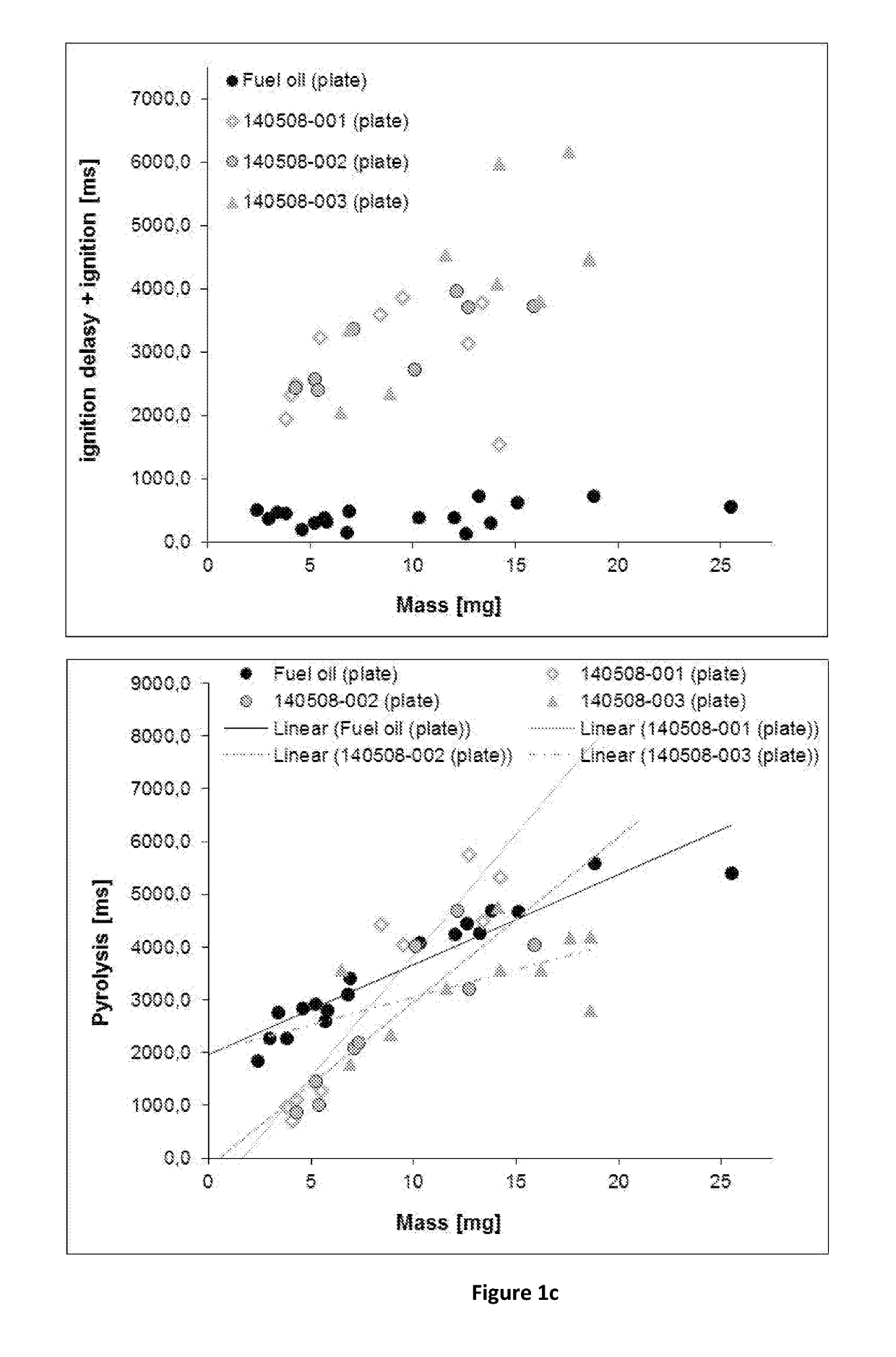

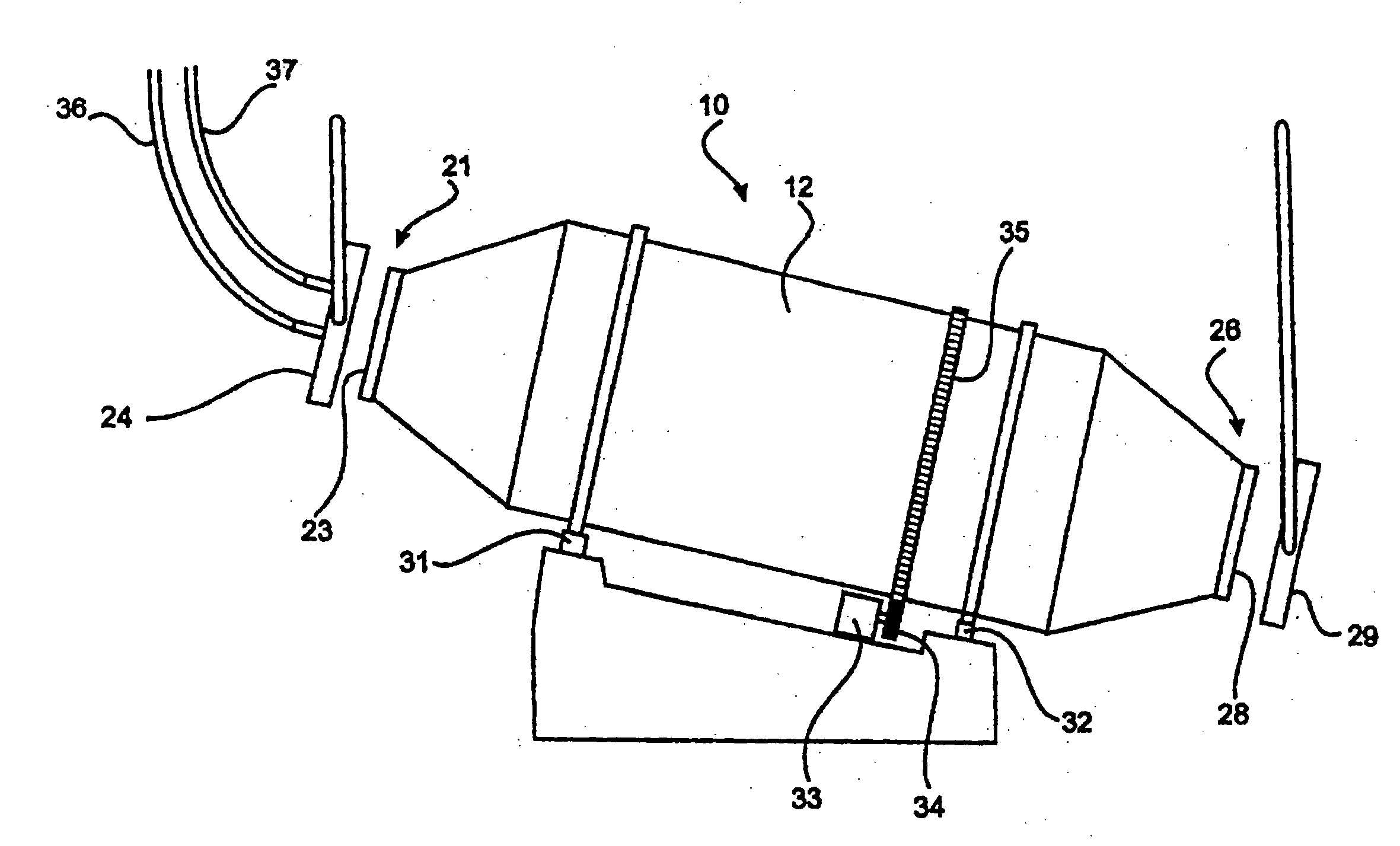

Method and device for burning-off precious metal-containing materials

A recycling furnace and method are provided for processing potentially explosive precious metal-containing materials having organic fractions that combust with great energy, the furnace including a switching facility for alternating operation of a burning-off chamber of the furnace between: (A) pyrolysis or carbonization under protective furnace gas in an atmosphere comprising maximally 6 wt-% oxygen, and (B) oxidative combustion of the organic fractions including carbon. The furnace has indirect heating and a control that determines the end of the pyrolysis or carbonization by a sensor and controls the switching facility to supply air or oxygen to the interior of the furnace. Steps (A) and (B) are carried out sequentially in the furnace chamber, wherein neither the batch is changed, nor the furnace is opened. After the end of step (A) is determined, step (B) proceeds right after the pyrolysis or carbonization by supplying air or oxygen. A dosing of liquid or liquefied substances during the pyrolysis is controlled by at least one parameter of post-combustion. Thermal post-combustion is used for two furnace chambers, one operated for pyrolysis or carbonization and the other operated as a combustion chamber.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Method and device for burning-off precious metal-containing materials

A recycling furnace and method are provided for processing potentially explosive precious metal-containing materials having organic fractions that combust with great energy, the furnace including a switching facility for alternating operation of a burning-off chamber of the furnace between: (A) pyrolysis or carbonization under protective furnace gas in an atmosphere comprising maximally 6 wt-% oxygen, and (B) oxidative combustion of the organic fractions including carbon. The furnace has indirect heating and a control that determines the end of the pyrolysis or carbonization by a sensor and controls the switching facility to supply air or oxygen to the interior of the furnace. Steps (A) and (B) are carried out sequentially in the furnace chamber, wherein neither the batch is changed, nor the furnace is opened. After the end of step (A) is determined, step (B) proceeds right after the pyrolysis or carbonization by supplying air or oxygen. A dosing of liquid or liquefied substances during the pyrolysis is controlled by at least one parameter of post-combustion. Thermal post-combustion is used for two furnace chambers, one operated for pyrolysis or carbonization and the other operated as a combustion chamber.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Fluid composition comprising lignin

InactiveUS20170226330A1Low LIECReduce moisture absorption performanceBiofuelsWaste based fuelCelluloseOrganic fraction

The present invention relates to a fluid composition comprising a solid fraction and a liquid organic fraction, wherein said solid fraction and said liquid fraction are present in a state of being intermixed, wherein said solid fraction comprises a lignin component, wherein said liquid fraction comprises an organic substance. Furthermore, the present invention relates to a process for the manufacture of such fluid compositions, to various uses thereof, and to a process for treatment of a lignocellulosic biomass.

Owner:INBICON AS

Method and Apparatus for Collection and Treatment of Encapsulated Waste

InactiveUS20080206094A1Reduce spacingTransportation and packagingSolid waste disposalOrganic fractionDecomposition

An autoclave reactor for treating municipal solid waste (MSW) including agricultural waste and medical waste wherein the MSW may be encapsulated in plastic bags. The reactor is equipped with a loading internal guiding means for treating the waste in such a manner as to decompose the organic fraction into a pulp which acts as a fluid whereby rigid, material such as metal and glass may be removed by known means. The reactor may also be equipped with: (a) piercing and cutting devices for rupturing the encapsulating material thereby expelling air and releasing the contents, (b) means for collecting vapours and emissions for treatment before they are released into the environment, (c) a vacuum means for removing vapours and drying the resulting products, (d) a sensing means which determines the viscosity of the reactor contents and this information is fed into a computer which determines when the desirable decomposition has been reached.

Owner:HOLLOWAY CLIFFORD C

Extraction and quantification of vitamins A & D in fluid samples

The invention discloses monoclonal antibodies for vitamins A (retinol palmitate) and D3 (cholecalciferol); a method for using monoclonal antibodies, and the monoclonal antibodies disclosed herein, in particular, to quantitate these vitamins in fluids such as dairy products, and blood, and also raw or processed agri-food and beverage products. The method involves contacting the sample with a mixture of polar and non-polar organic solvents in combination with inorganic salts to remove fat molecules into an organic fraction, and assaying the organic fraction by immunoassay involving the monoclonal antibodies. The presence of a mixture of non-polar and polar organic solvents increases the separation of vitamins from fat molecules and enables the test samples to be quantified by immunoassay without any further treatment.

Owner:SCIMED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com