Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

324 results about "Compression pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compression is a process in which air/fuel mixture is confined and pressed into a smaller volume within the area of engine cylinders. This process forces all of the molecules to be "pressed" together under high pressure. In marine gasoline engines, moderate compression is required, 140 to 160 pounds per square inch (PSI).

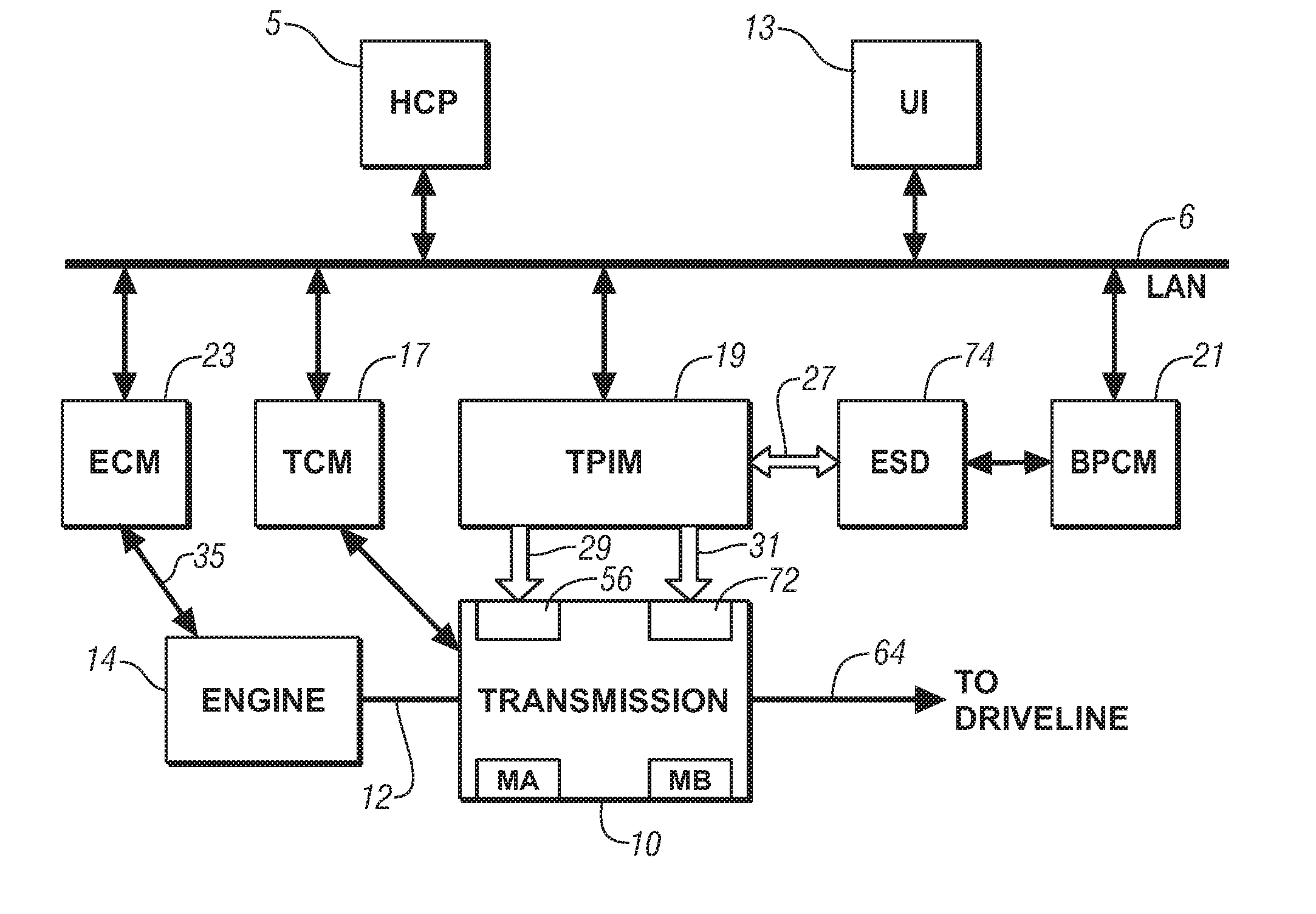

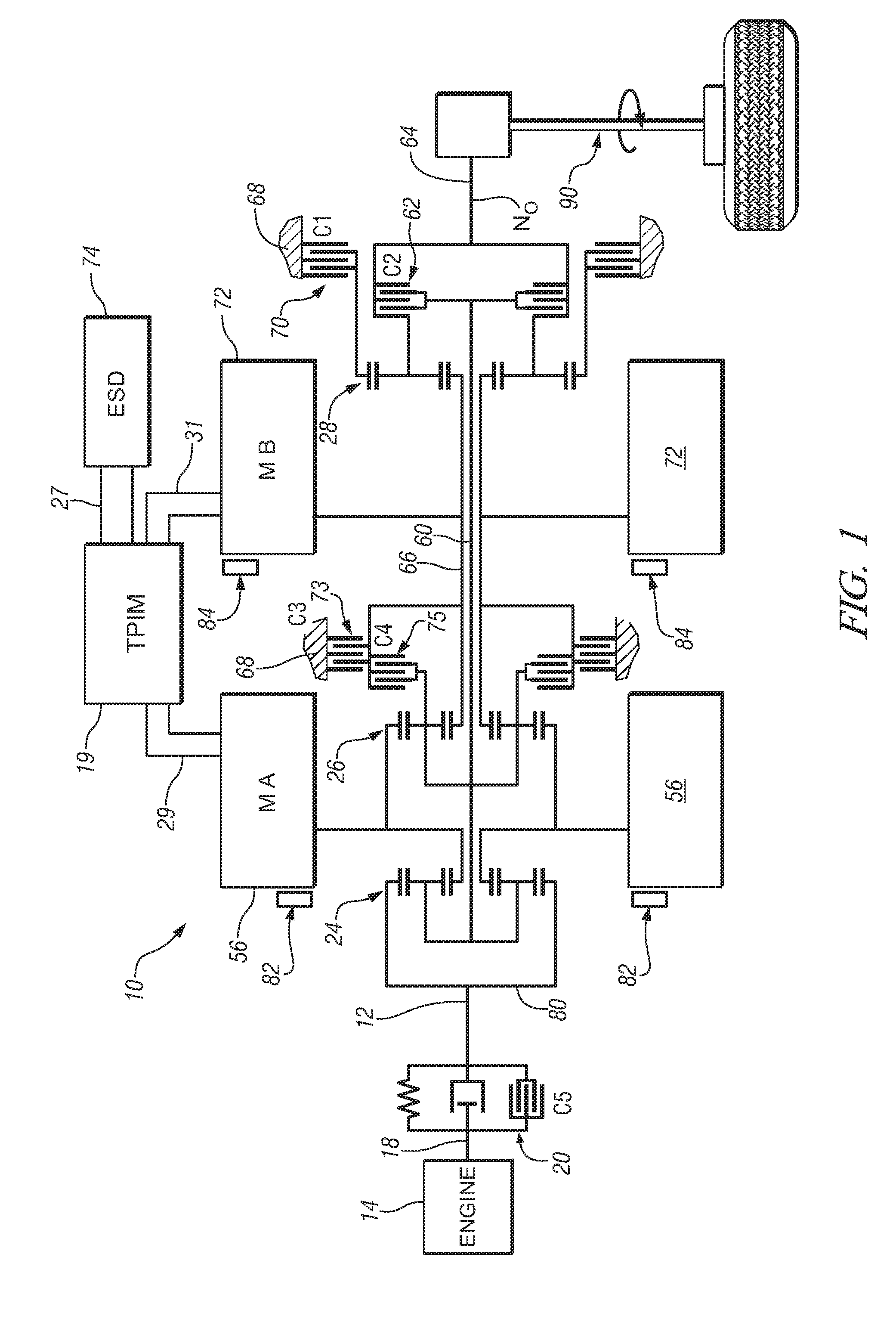

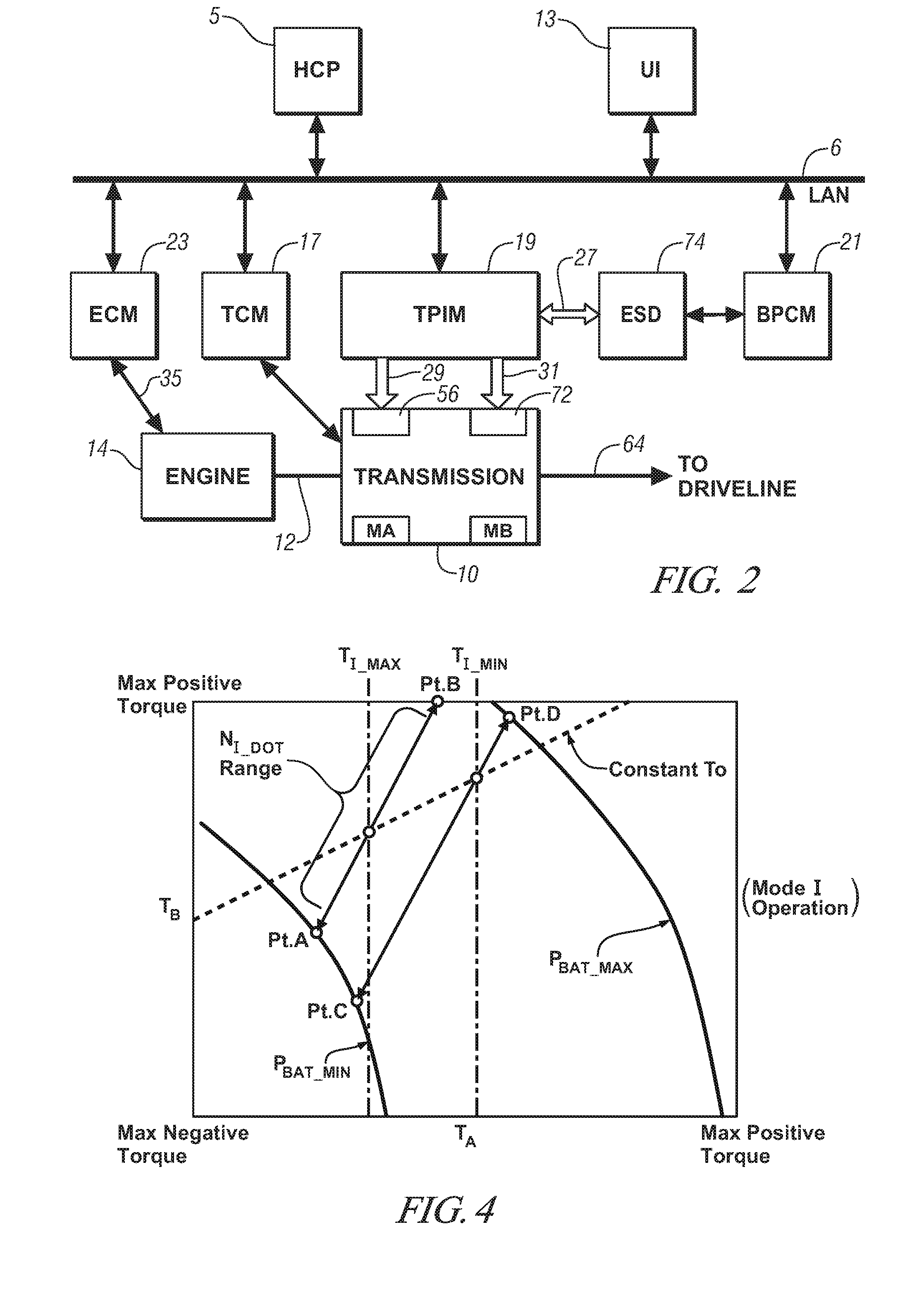

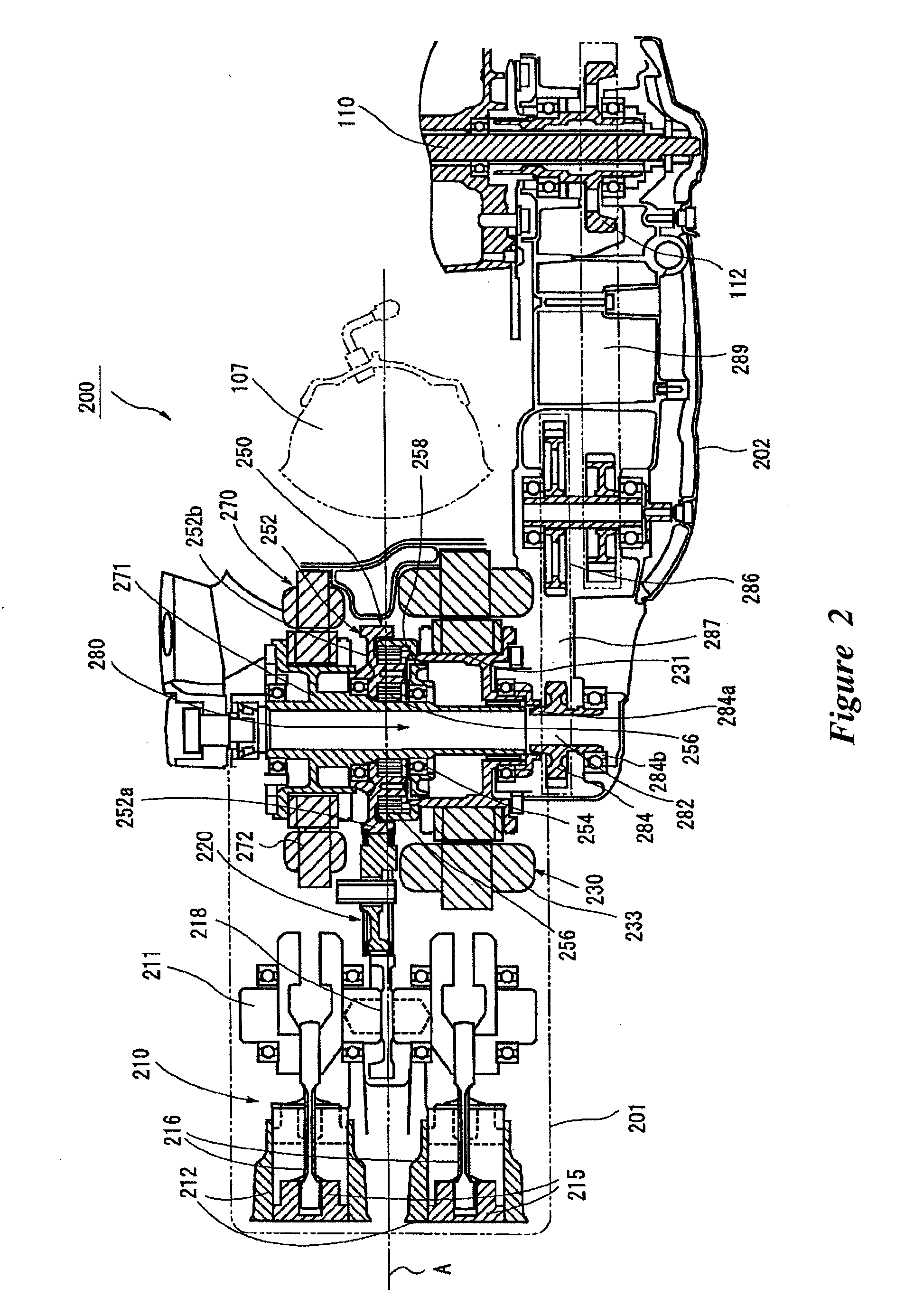

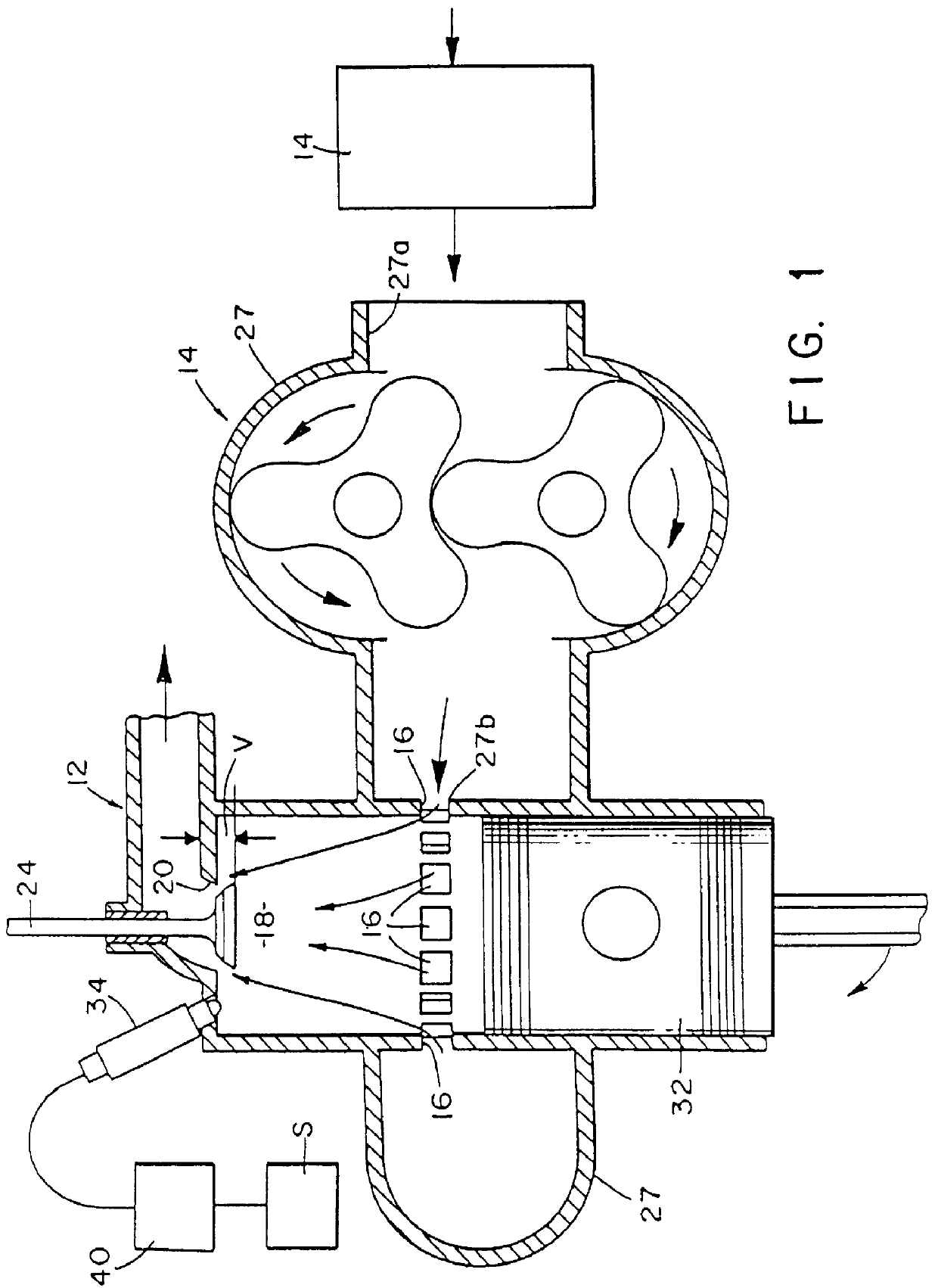

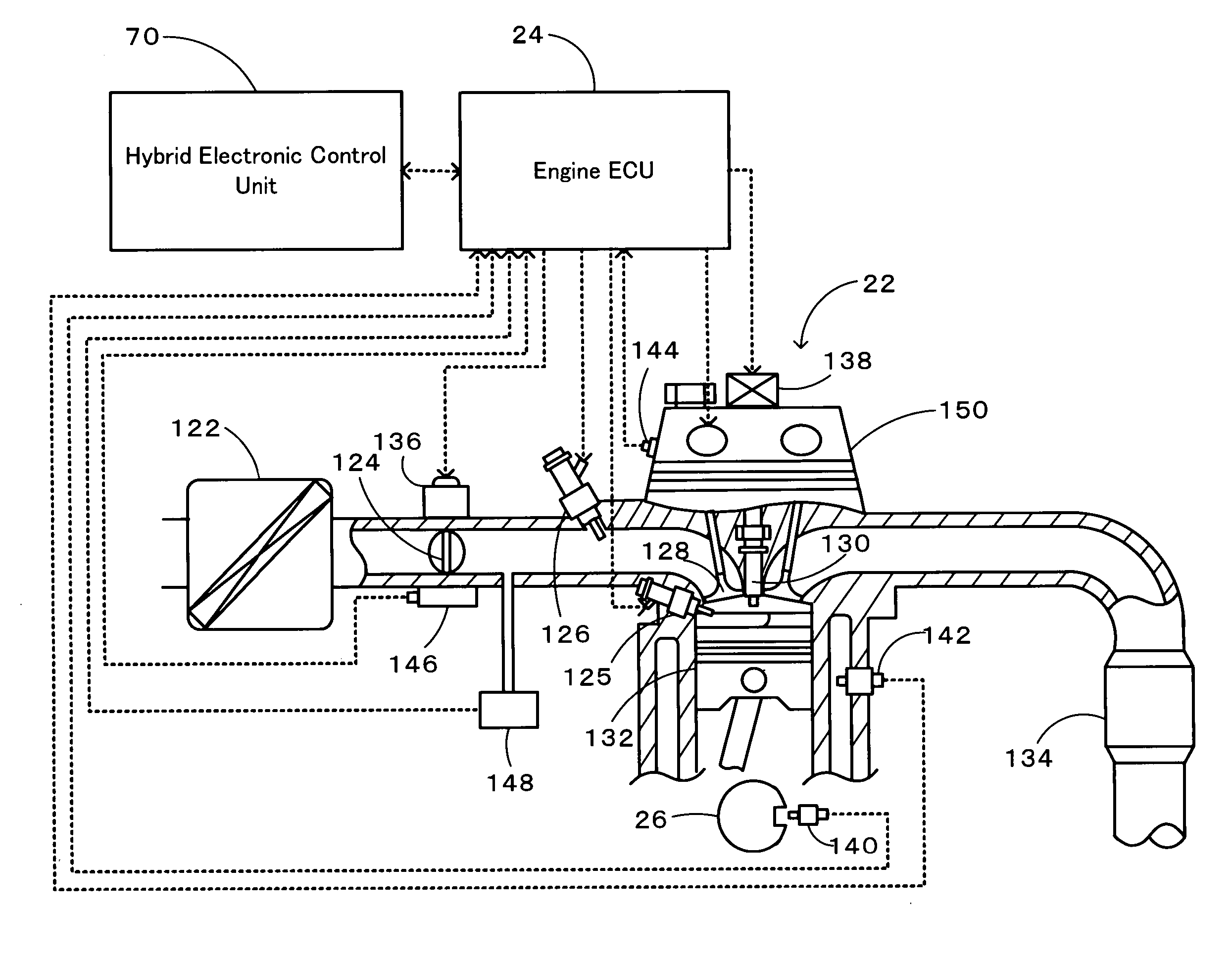

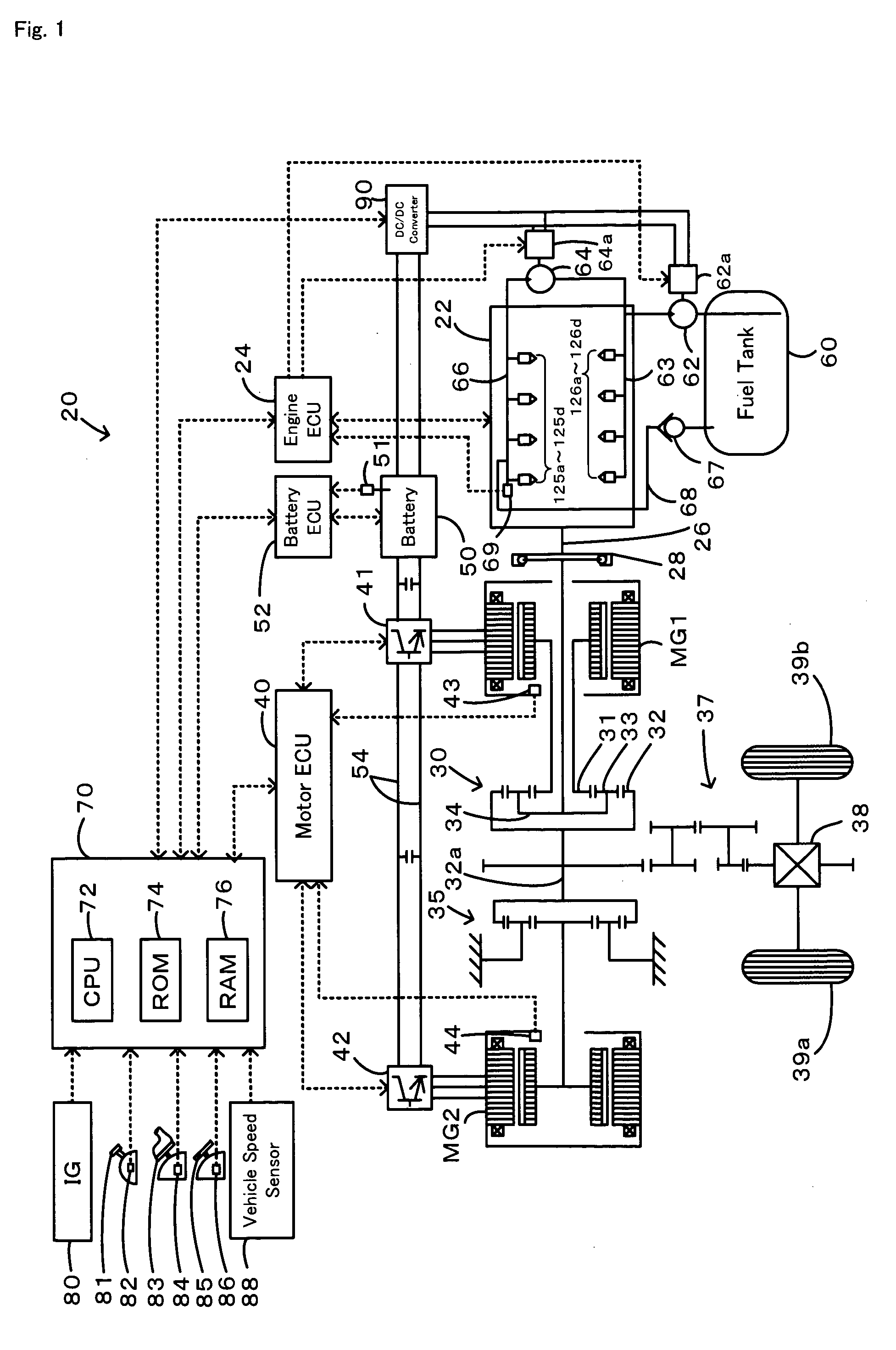

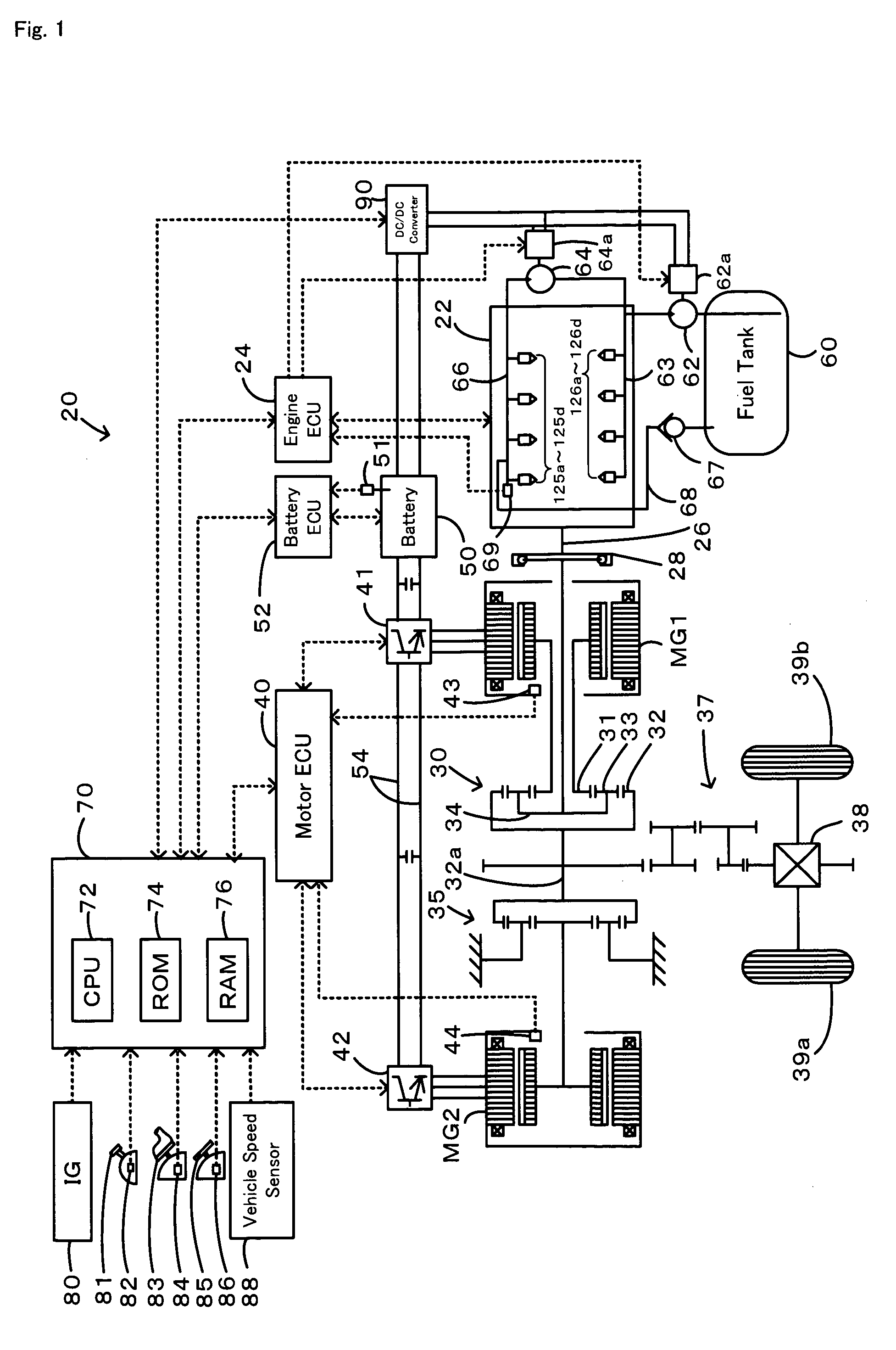

Method and apparatus to control engine restart for a hybrid powertrain system

ActiveUS20080275624A1Accurately determineAccurate pressureInternal combustion piston enginesDigital data processing detailsRotary engineInternal combustion engine

There is provided a control scheme for restarting an internal combustion engine of a hybrid powertrain during ongoing vehicle operation. The method comprises generating a torque output from an electrical machine to rotate the engine, and determining an engine crank torque. The torque output from the electrical machine is selectively controlled based upon the engine crank torque. The engine is fired when rotational speed of the engine exceeds a threshold. An engine torque simulation model accurately determines engine compression pressures in real-time to accommodate changes in engine operating conditions, based upon present engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

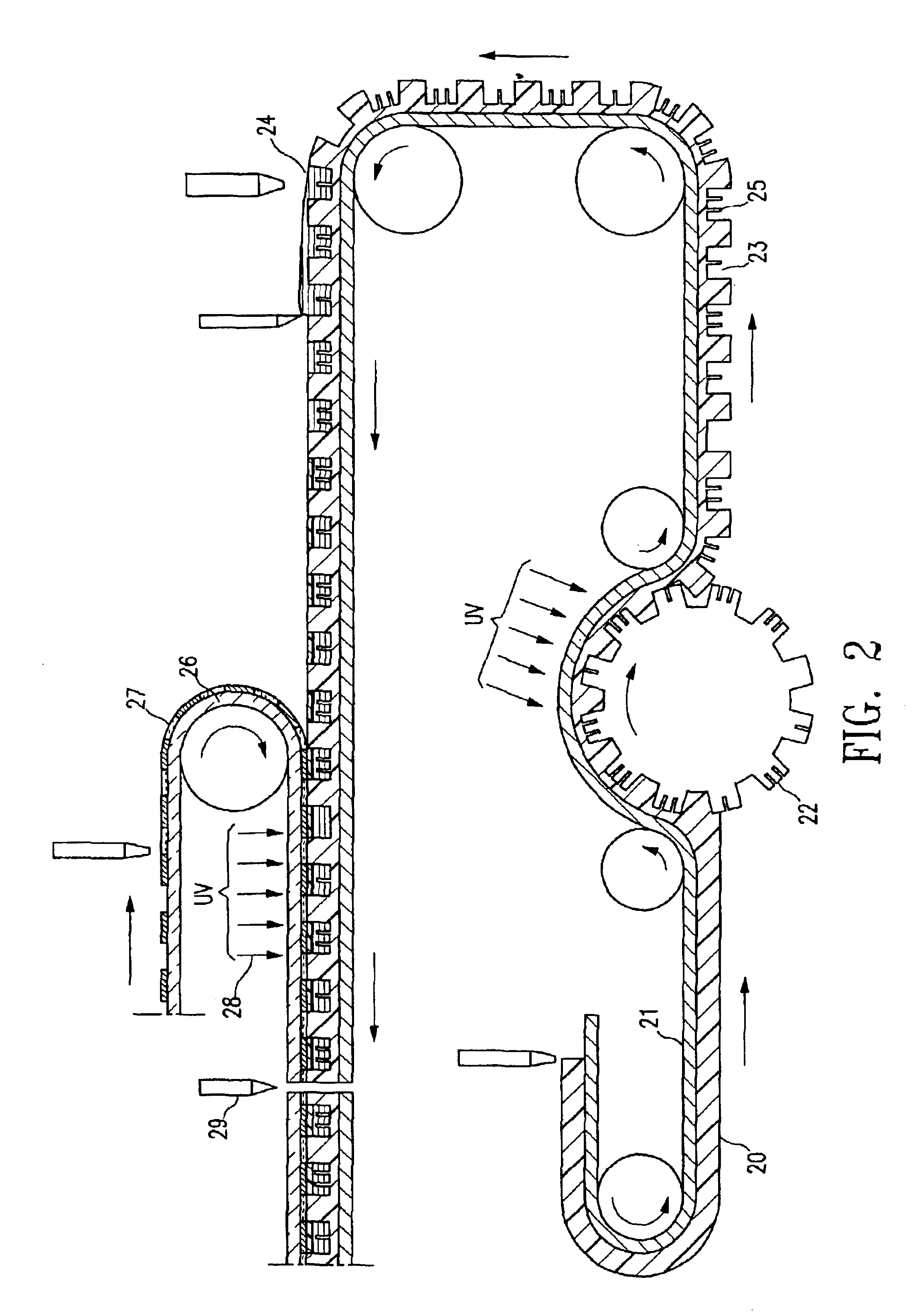

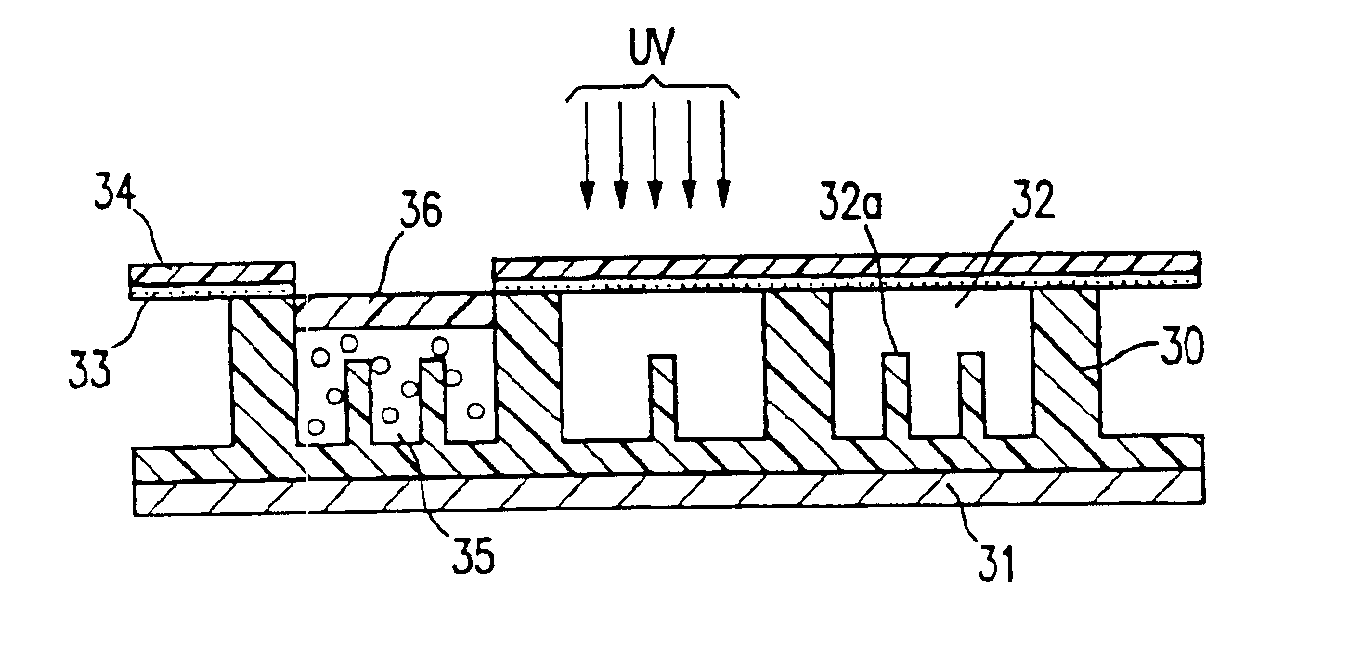

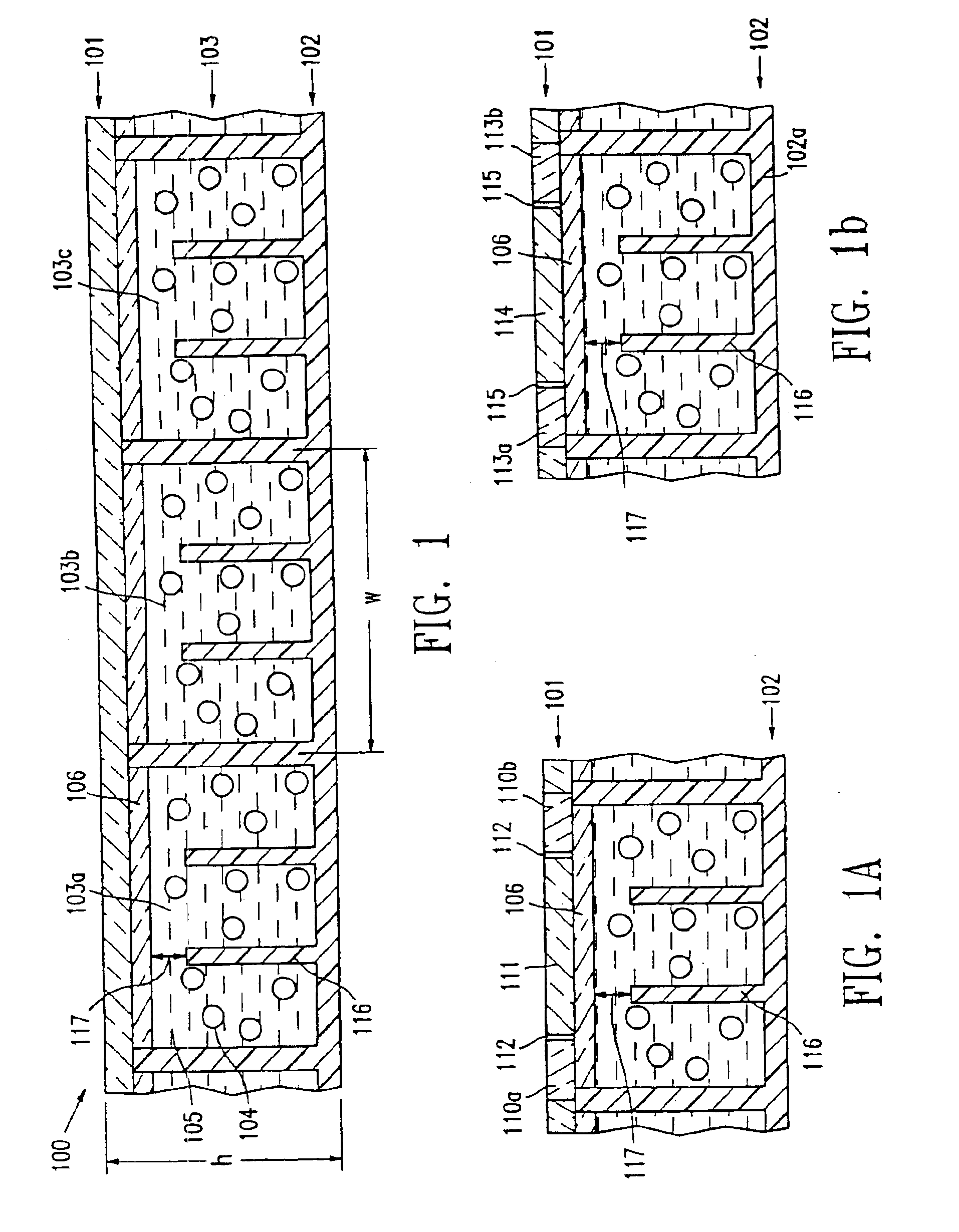

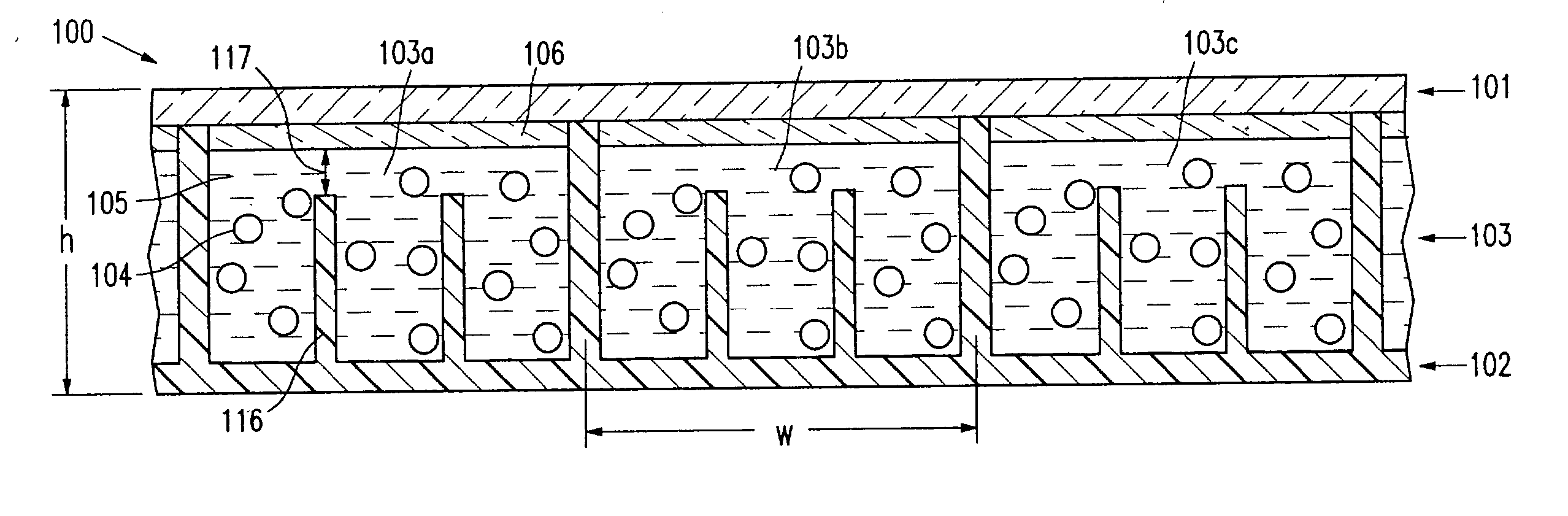

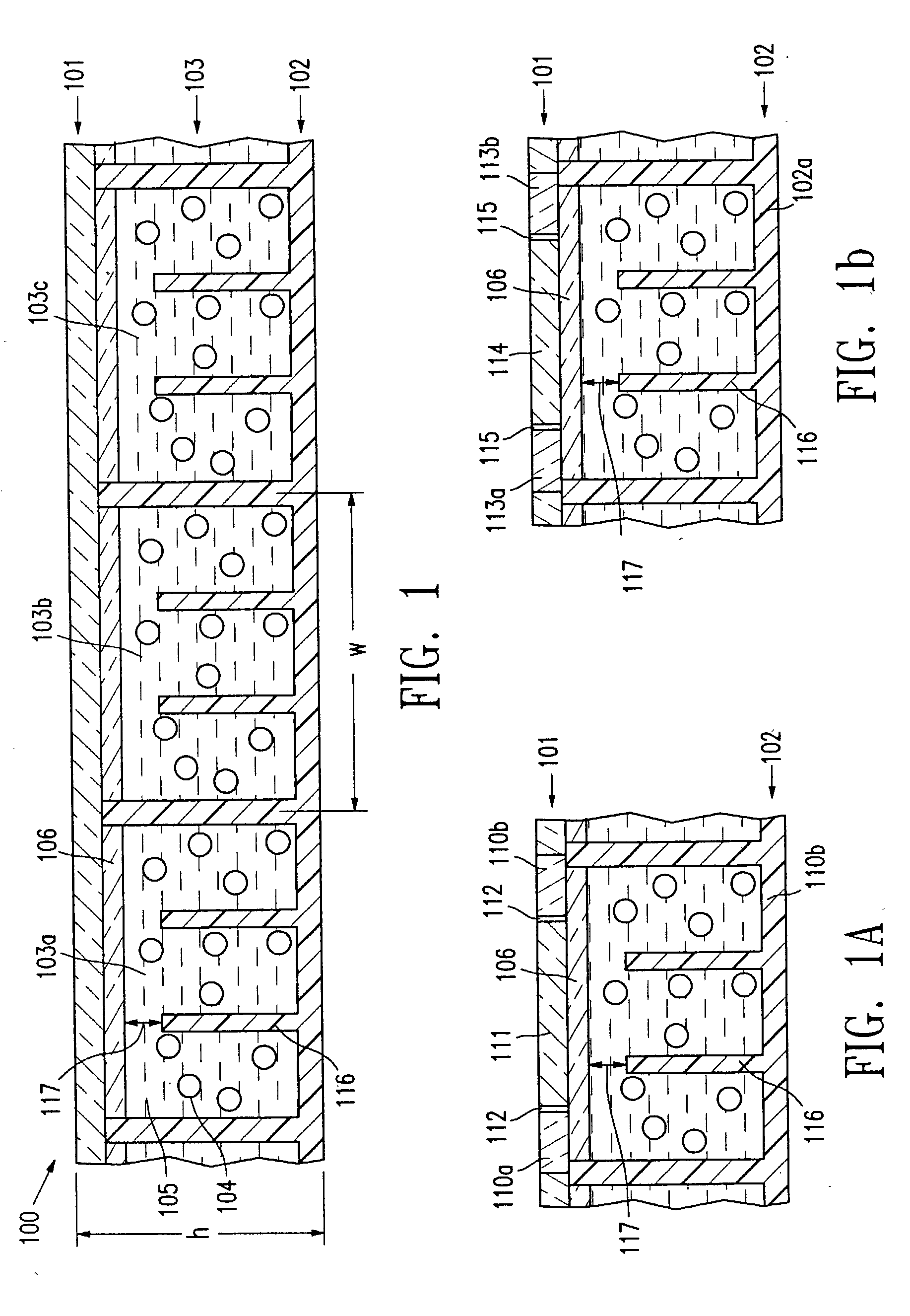

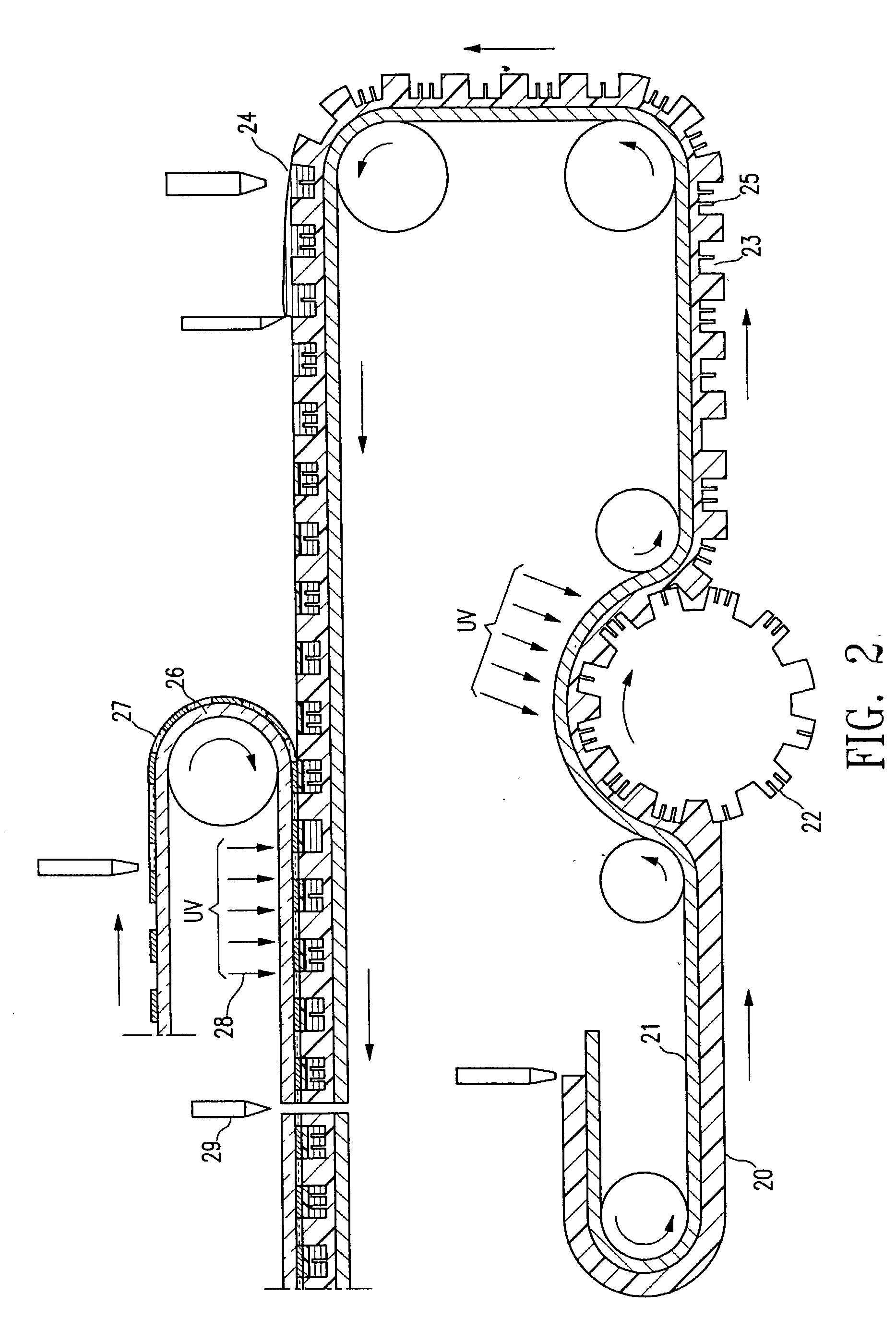

Electrophoretic display with sub relief structure for high contrast ratio and improved shear and/or compression resistance

This invention relates to an electrophoretic display comprising isolated cells of well-defined shape, size and aspect ratio which cells have internal sub relief structures and are filled with charged pigment particles dispersed in a dielectric solvent. The display shows an improved contrast ratio and resistance against shear and compression pressures. The display may have the traditional up / down switching mode, an in-plane switching mode or a dual switching mode.

Owner:E INK CALIFORNIA

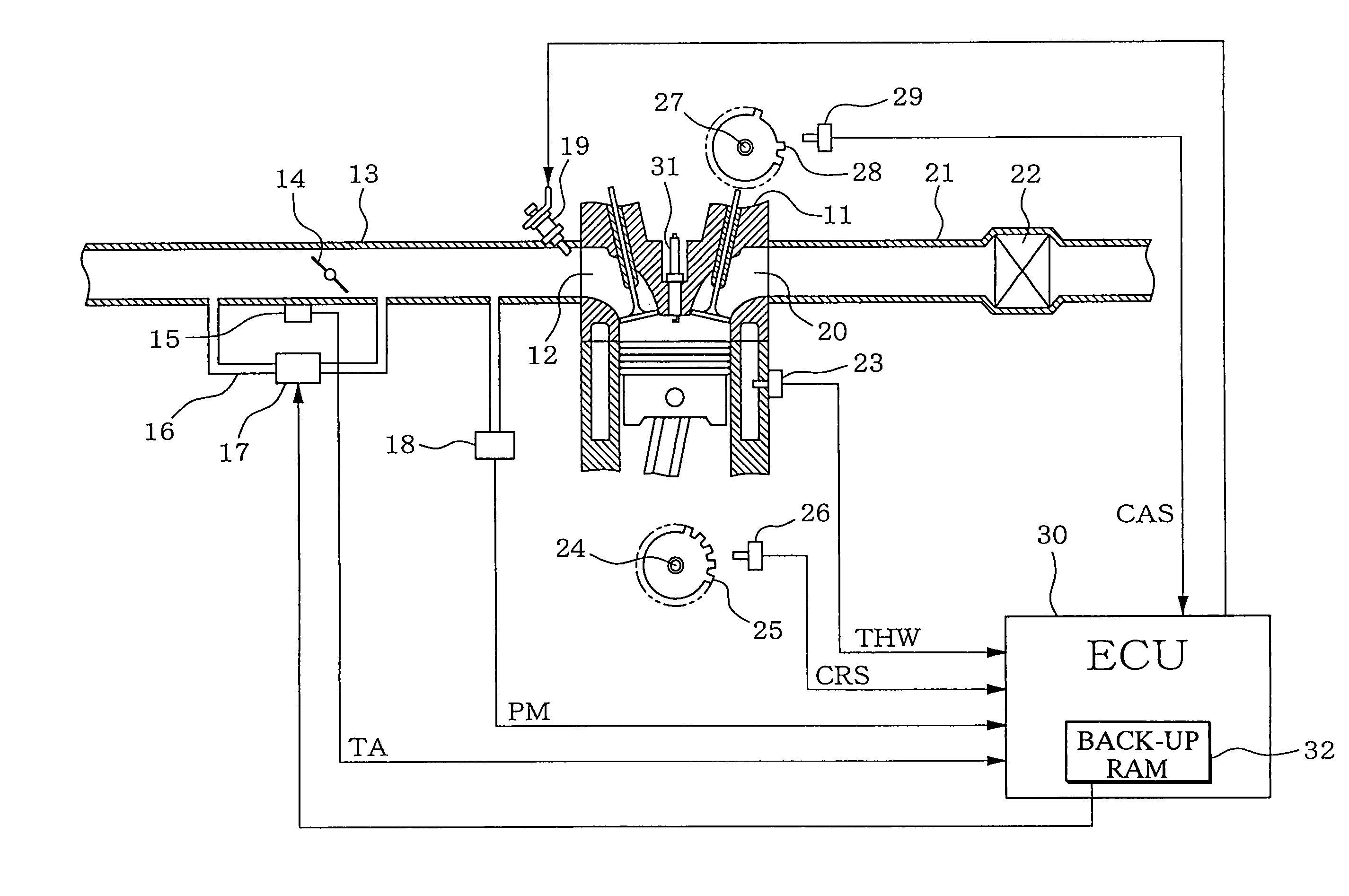

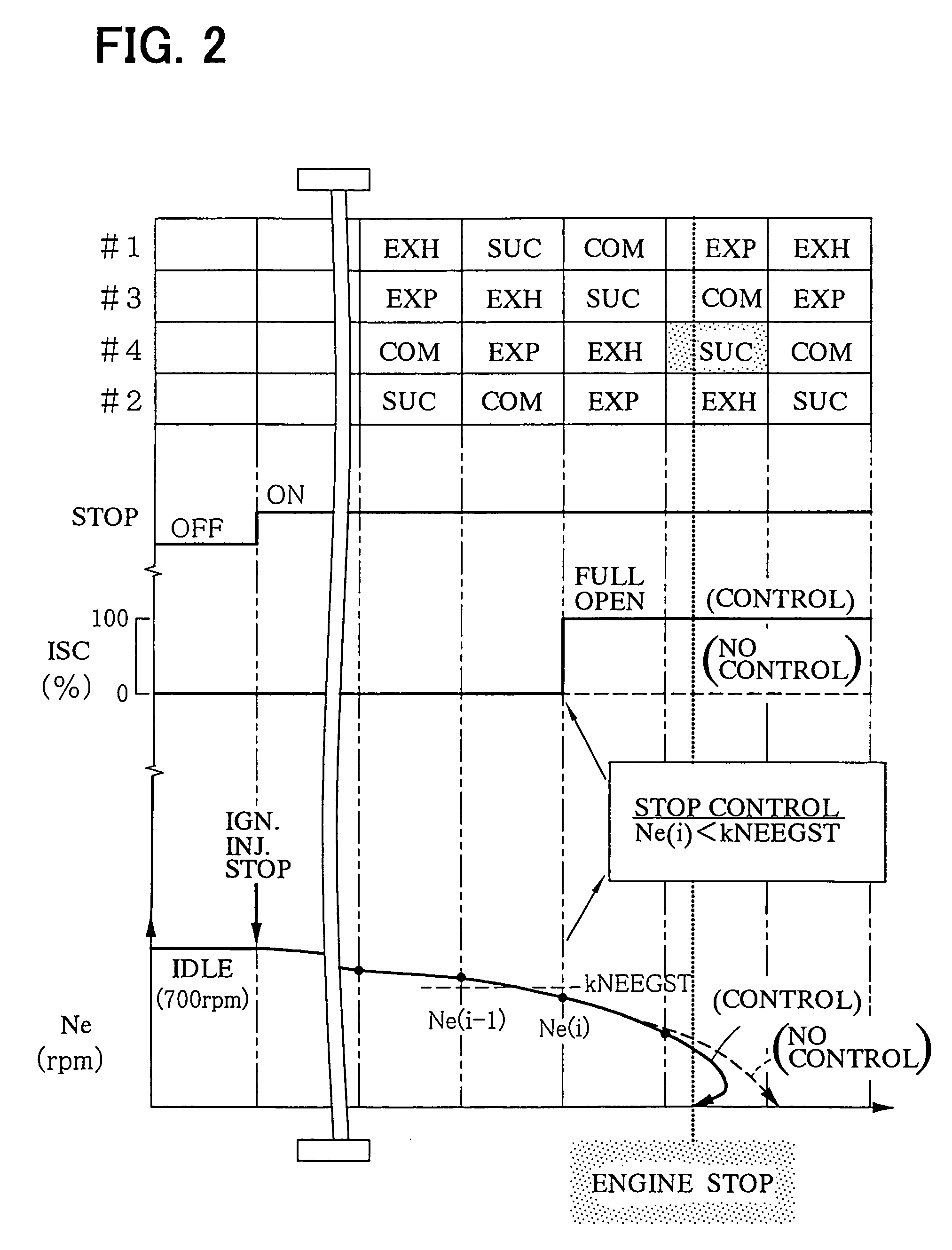

Apparatus for controlling engine rotation stop by estimating kinetic energy and stop position

InactiveUS7027911B2Reduce variationImprove exhaust emissionsAnalogue computers for vehiclesElectrical controlEngineeringSmall range

A control apparatus for an engine increases an intake air quantity just before engine stop to increase a compression pressure in a compression stroke. As the compression pressure is increased, a negative torque in the compression stroke increases and obstructs engine rotation, and brakes the engine rotation. Thus, a range of crank angle, in which torque is below engine friction, that is, in which engine rotation can be stopped, is reduced. As a result, variation in engine rotation stop position is reduced to be within a small range of crank angle. Information of engine rotation stop position is stored, and the stored information of engine rotation stop position is used at the start of an engine to accurately determine an initial injection cylinder and an initial ignition cylinder to start the engine.

Owner:DENSO CORP

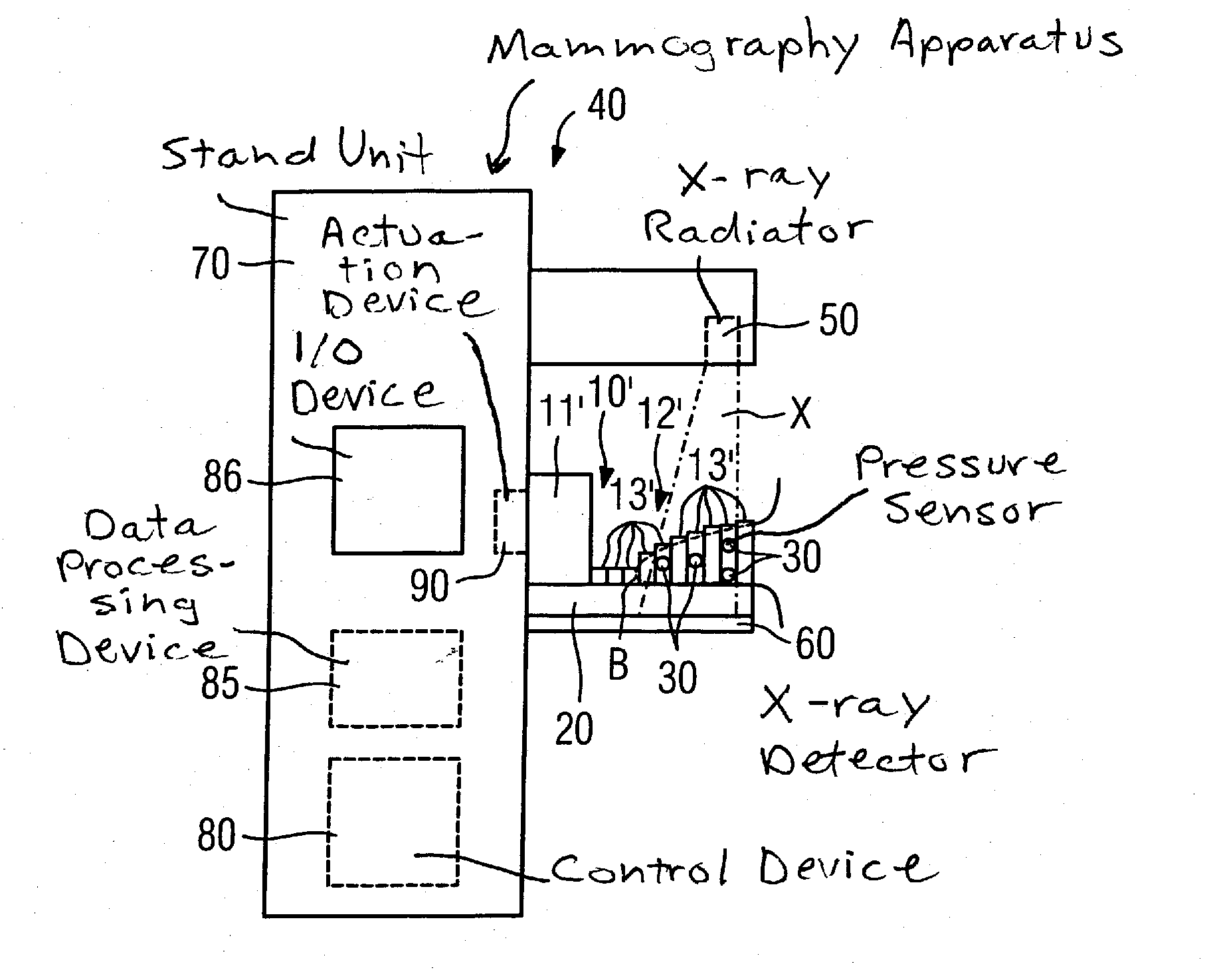

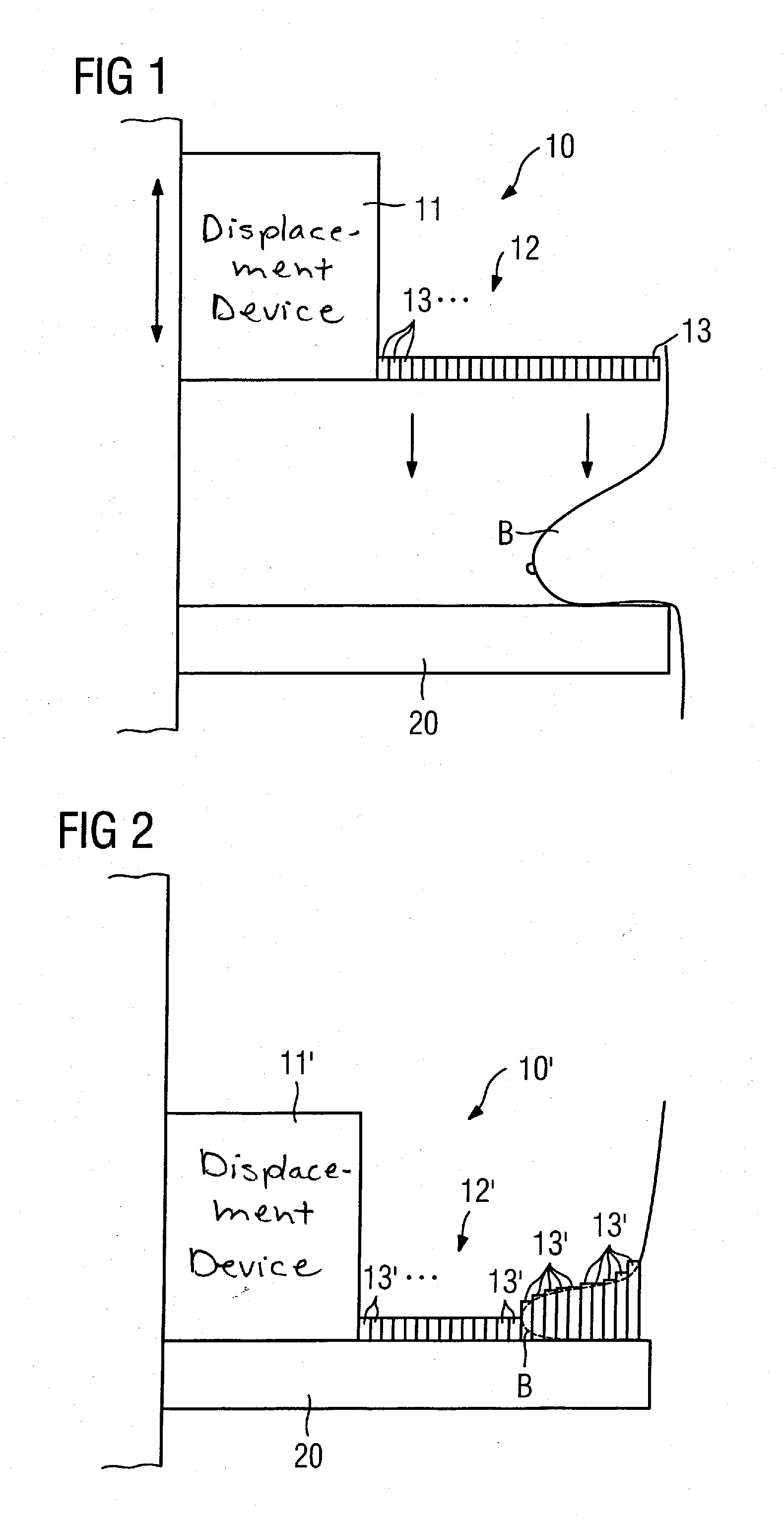

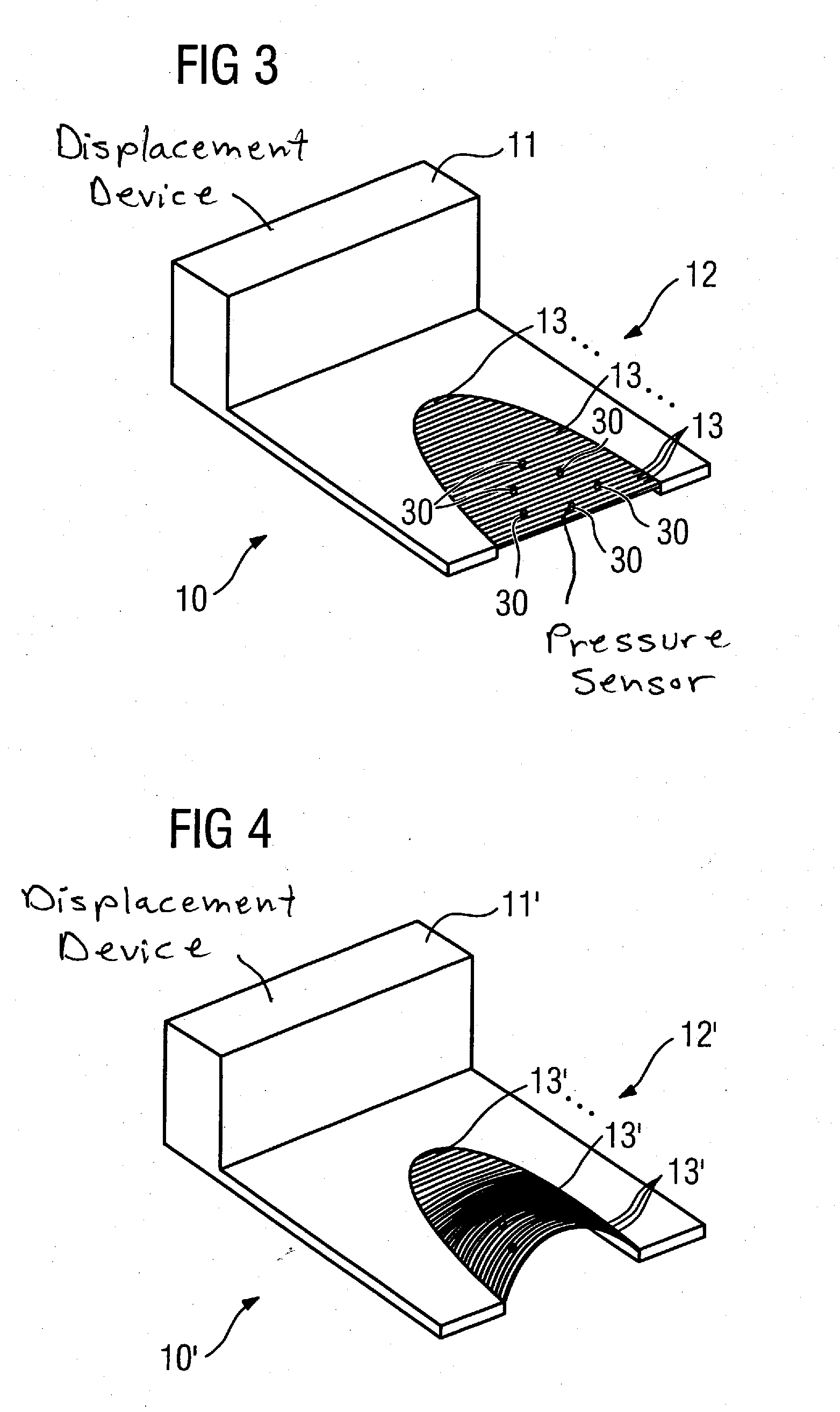

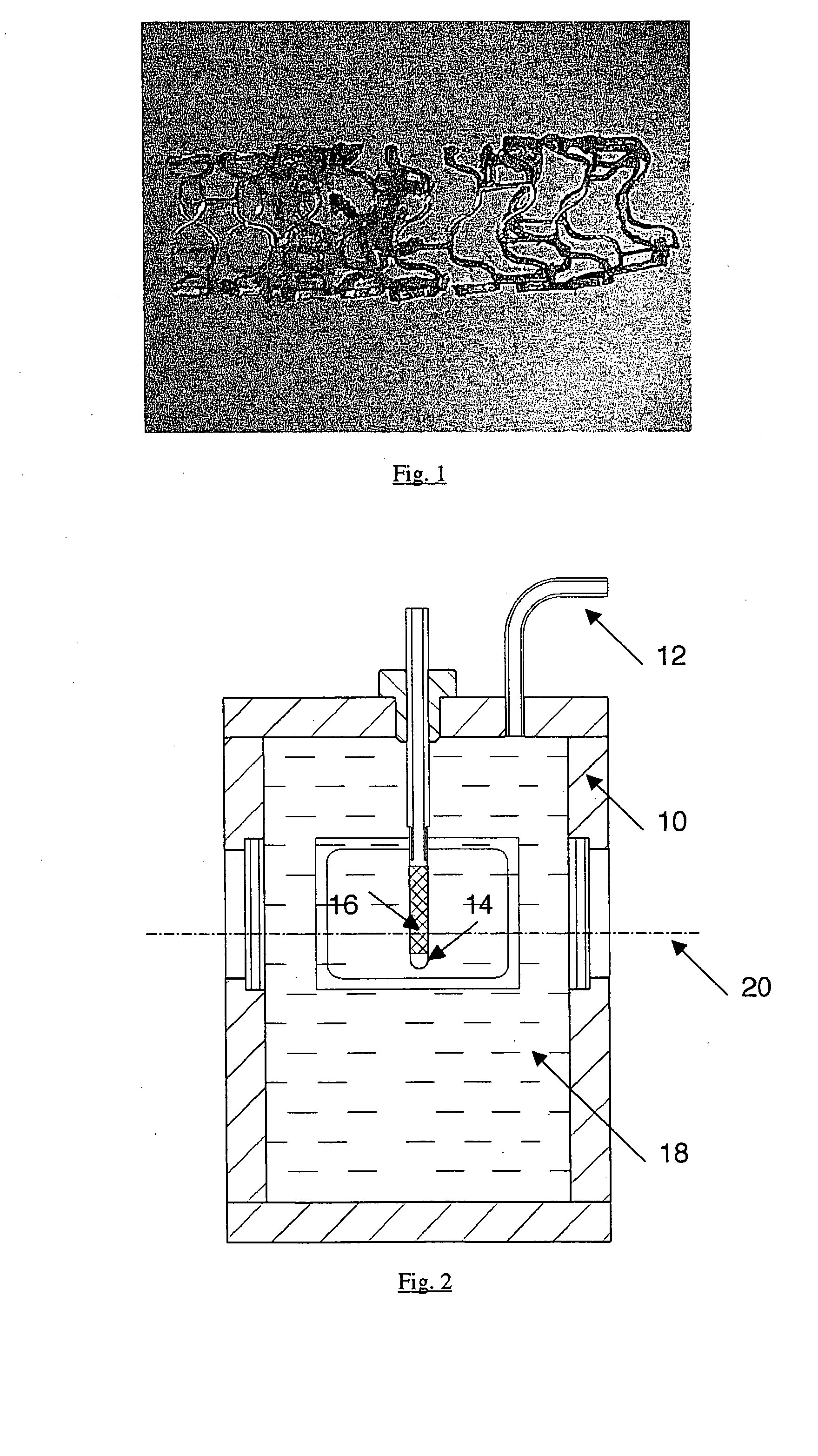

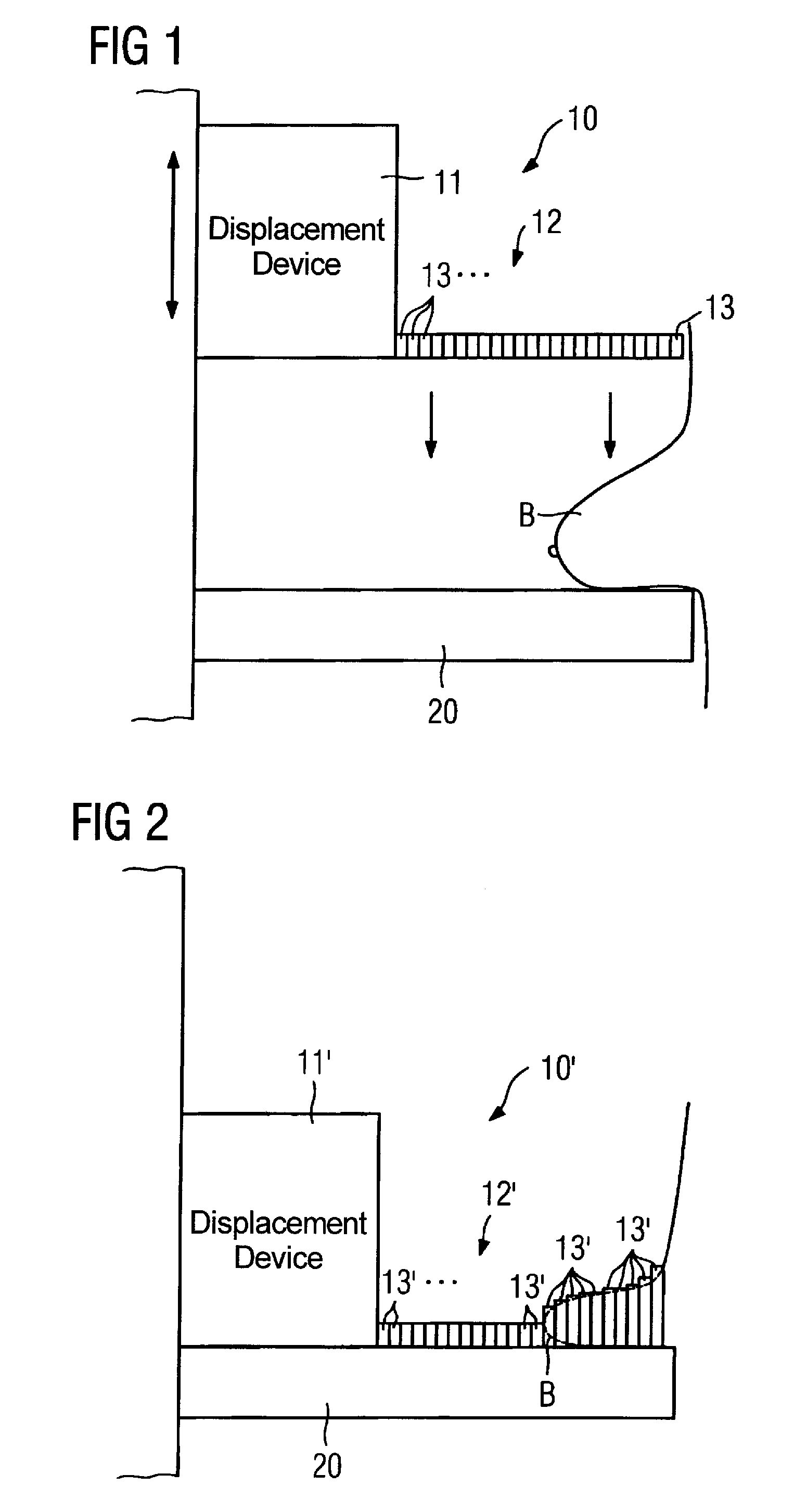

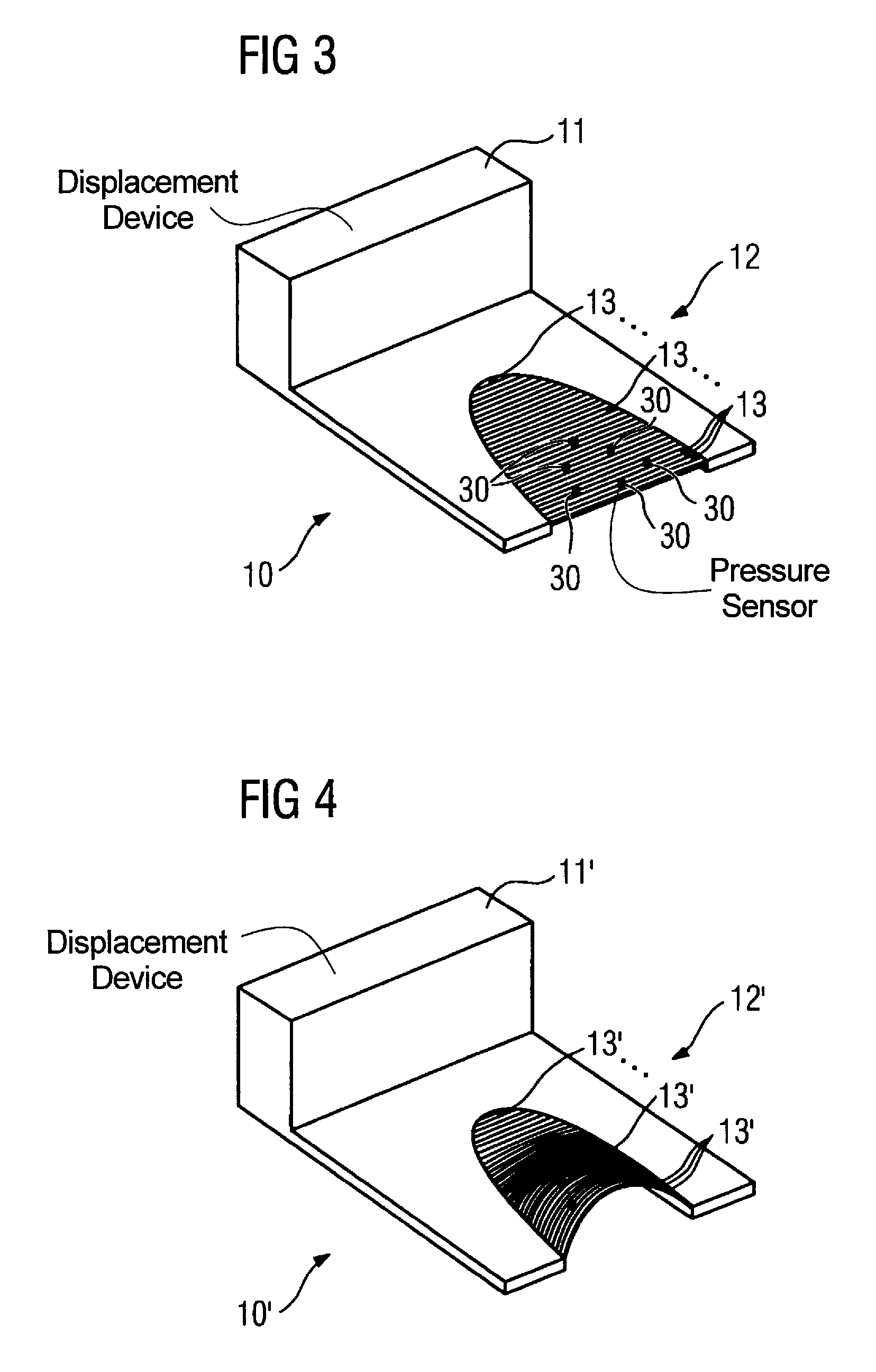

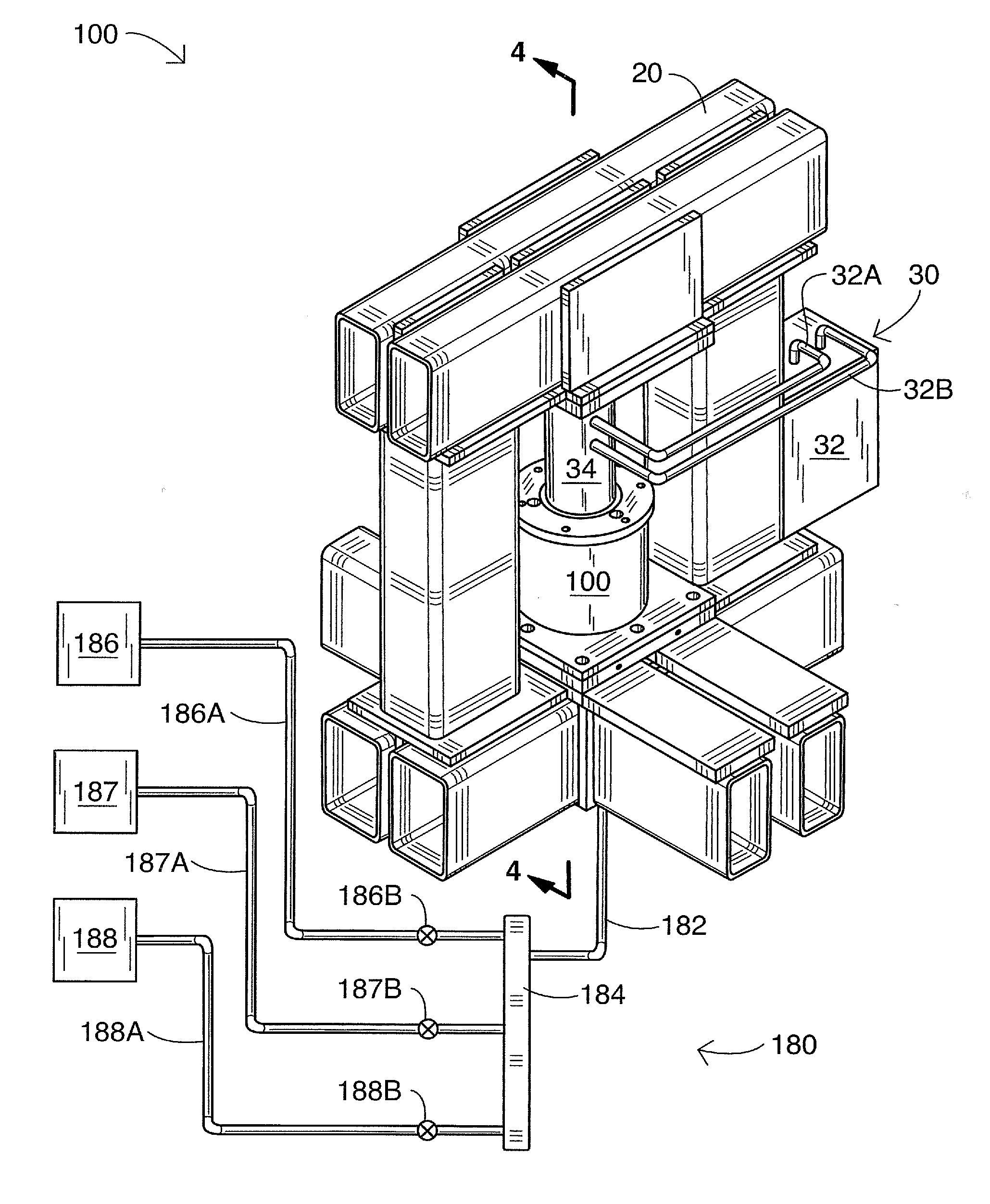

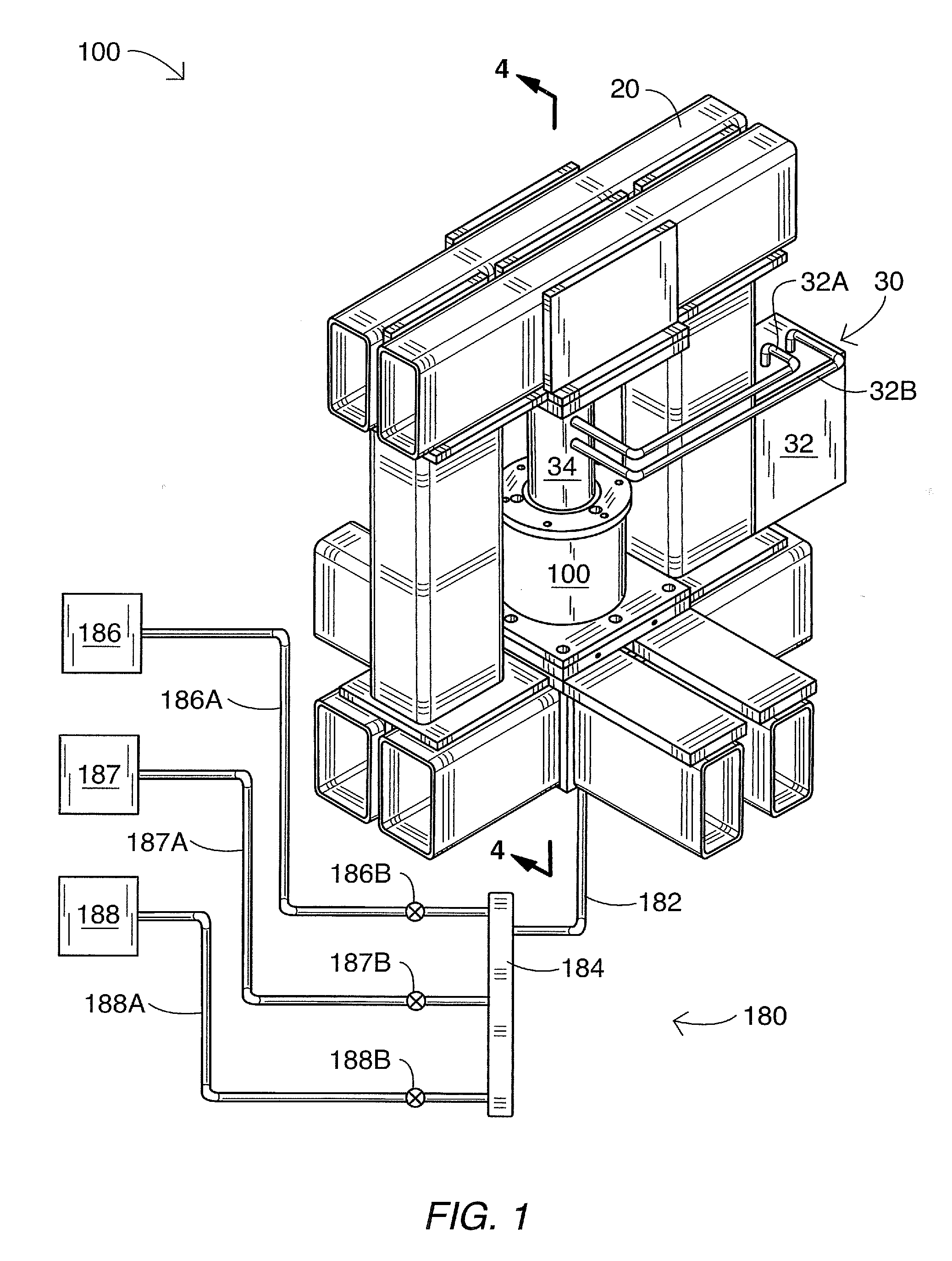

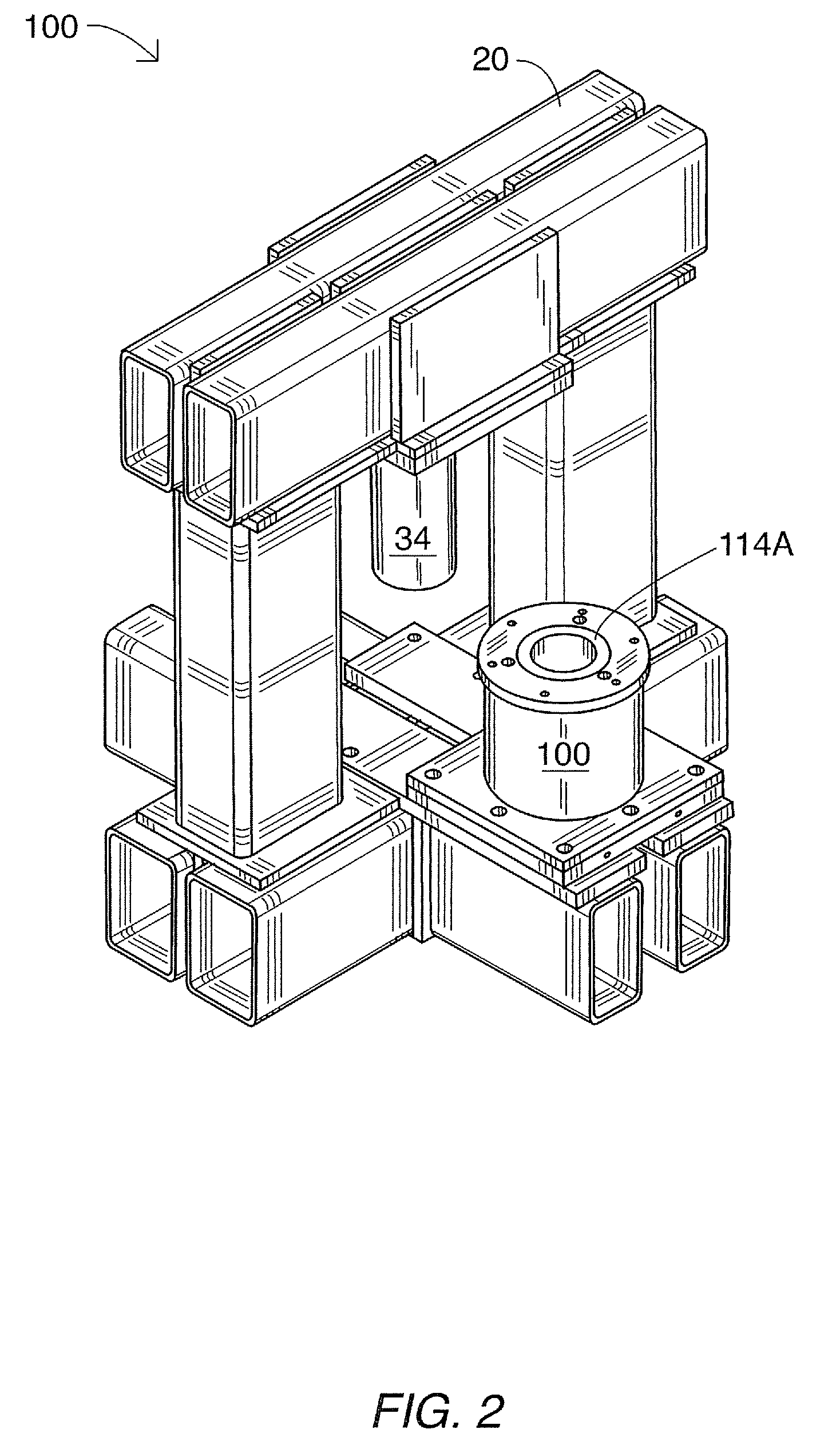

Compression device and method for adjustment of a compression pressure

InactiveUS20080043904A1Sufficient spatial resolutionImprove spatial resolutionOperating chairsPatient positioning for diagnosticsCompression deviceEngineering

A compression device has a compression plate that applies a pressure to a subject on a support plate. The compression plate has a number of elastically-deformable compression plate elements that are substantially transparent for an examination field used with the compression device. In a method for compressing a subject, at least one pressure sensor measures the pressure applied by a compression device to a subject, and wirelessly supplies a signal representing the detected pressure to a control unit, wherein the detected pressure is compared to a stored compression pressure value. The control device adjusts the pressure applied to the subject by the compression device so that the pressure detected by the sensor is equal to the stored compression pressure value.

Owner:SIEMENS HEALTHCARE GMBH

Electrophoretic display with sub relief structure for high contrast ratio and improved shear and/or compression resistance

This invention relates to an electrophoretic display comprising isolated cells of well-defined shape, size and aspect ratio which cells have internal sub relief structures and are filled with charged pigment particles dispersed in a dielectric solvent. The display shows an improved contrast ratio and resistance against shear and compression pressures. The display may have the traditional up / down switching mode, an in-plane switching mode or a dual switching mode.

Owner:E INK CALIFORNIA

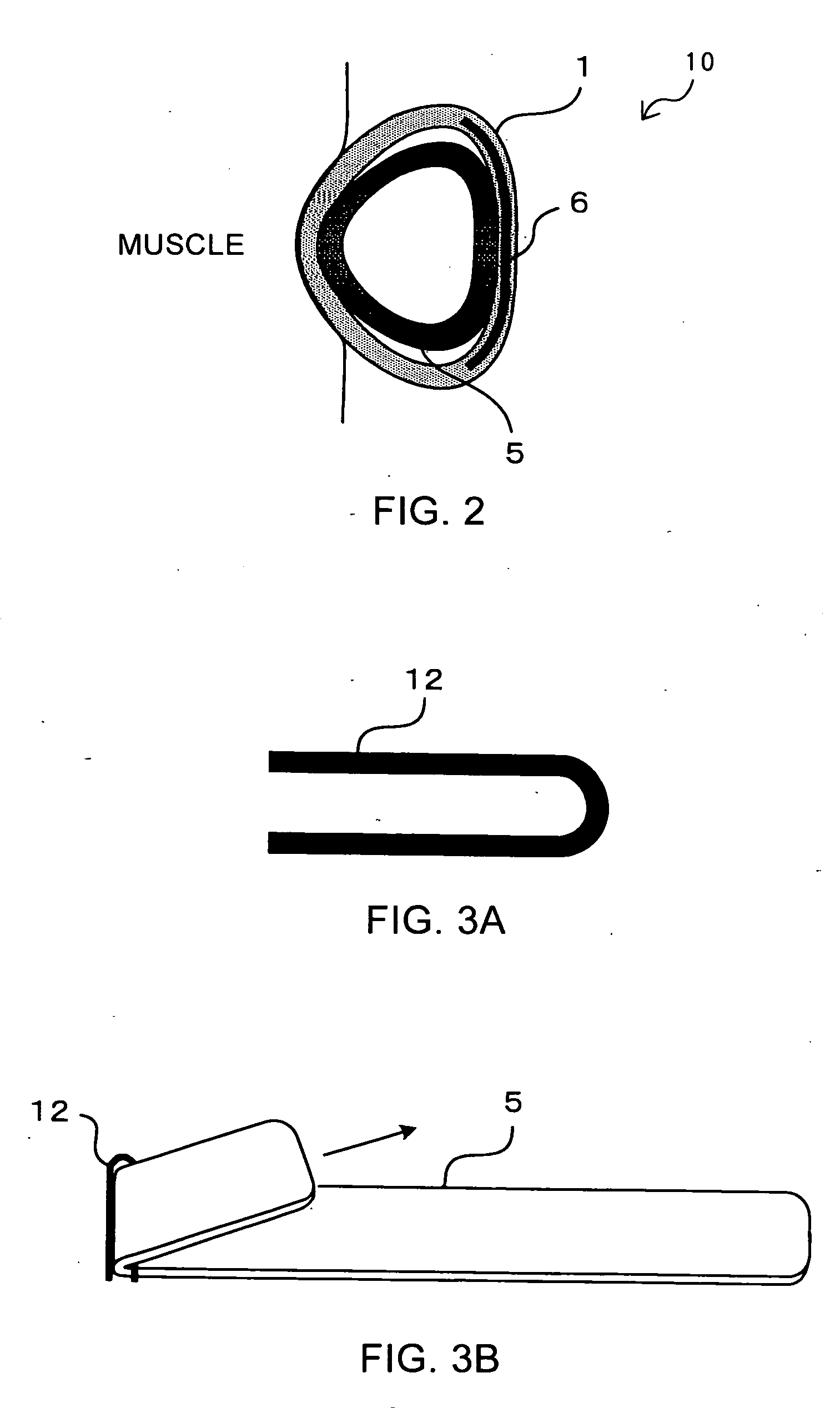

Implant of low radial strength

ActiveUS20060064160A1Easy to adaptEasy to processStentsSurgeryUltimate tensile strengthBiomedical engineering

The invention concerns an endovascular implant comprising a biodegradable material and having a tubular main body which is open at the ends and which is dilatable from an unexpanded condition into an expanded condition. The implant is so designed that when the implant in the expanded condition is subjected to a radially acting compression pressure in the range of between 5 and 30 kPa (0.05-0.3 bar) a cross-sectional area of the implant is reduced to 70% or less of the original cross-sectional area, or an internal volume of the implant is reduced to 70% or less of the original internal volume.

Owner:BIOTRONIK AG

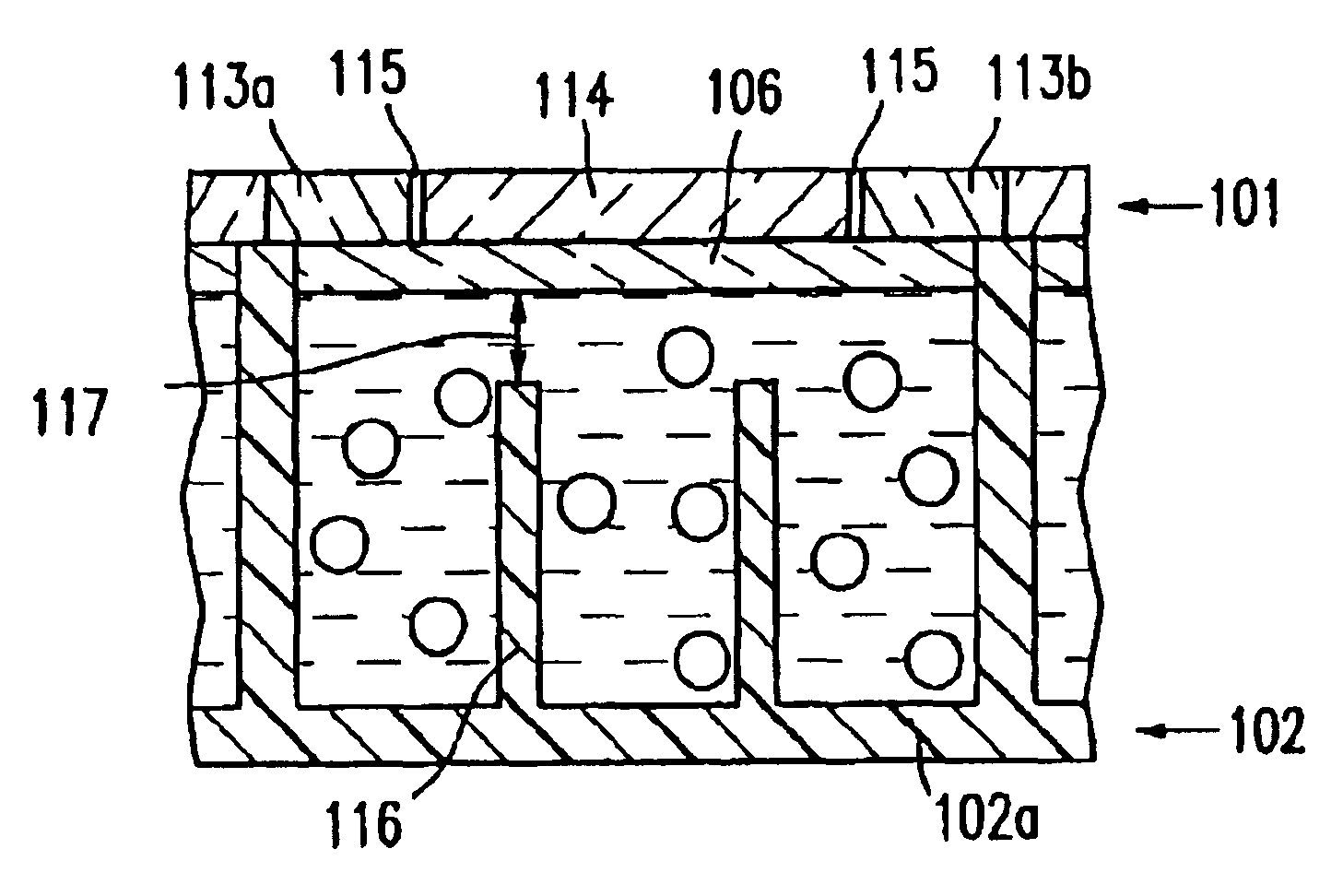

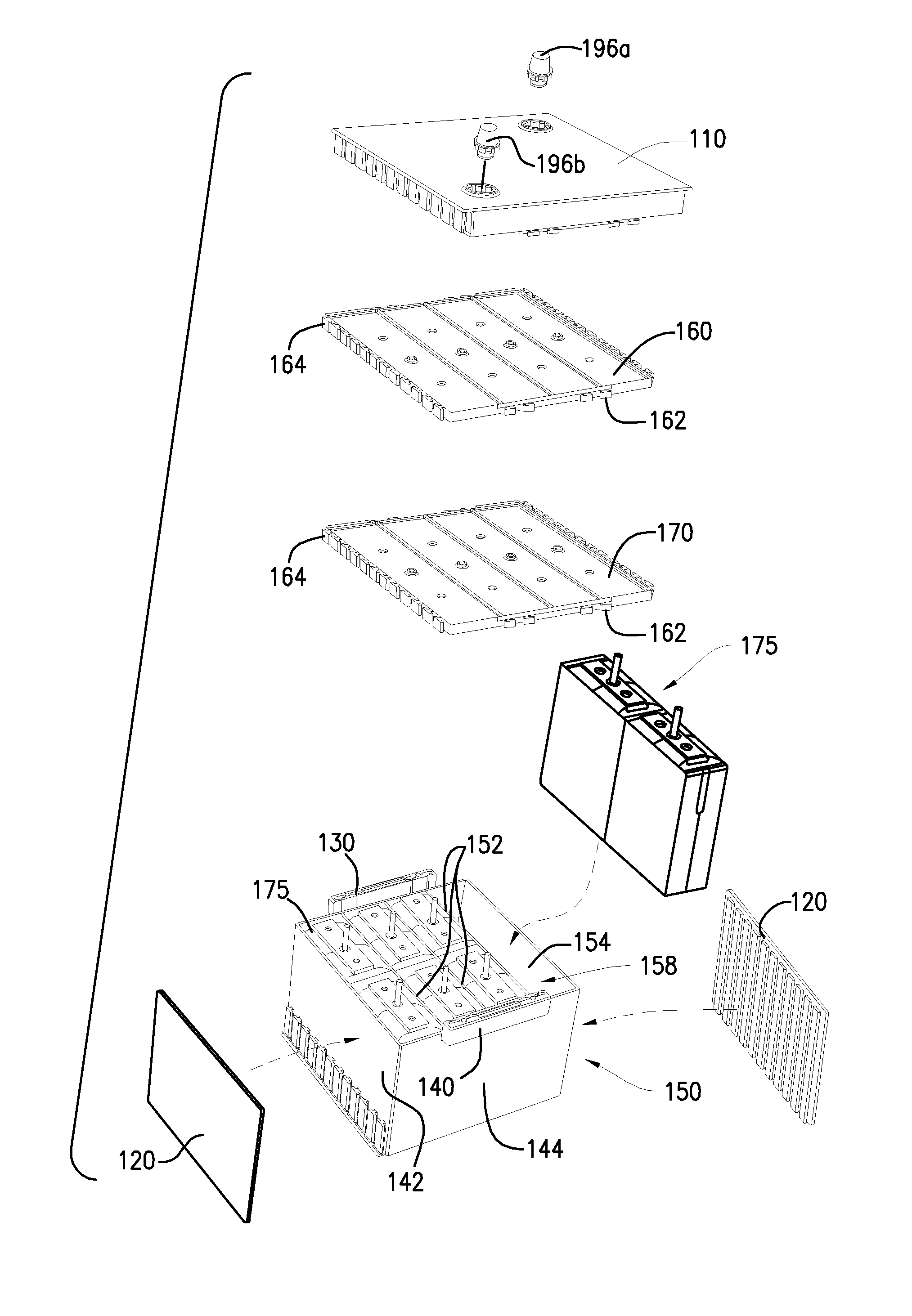

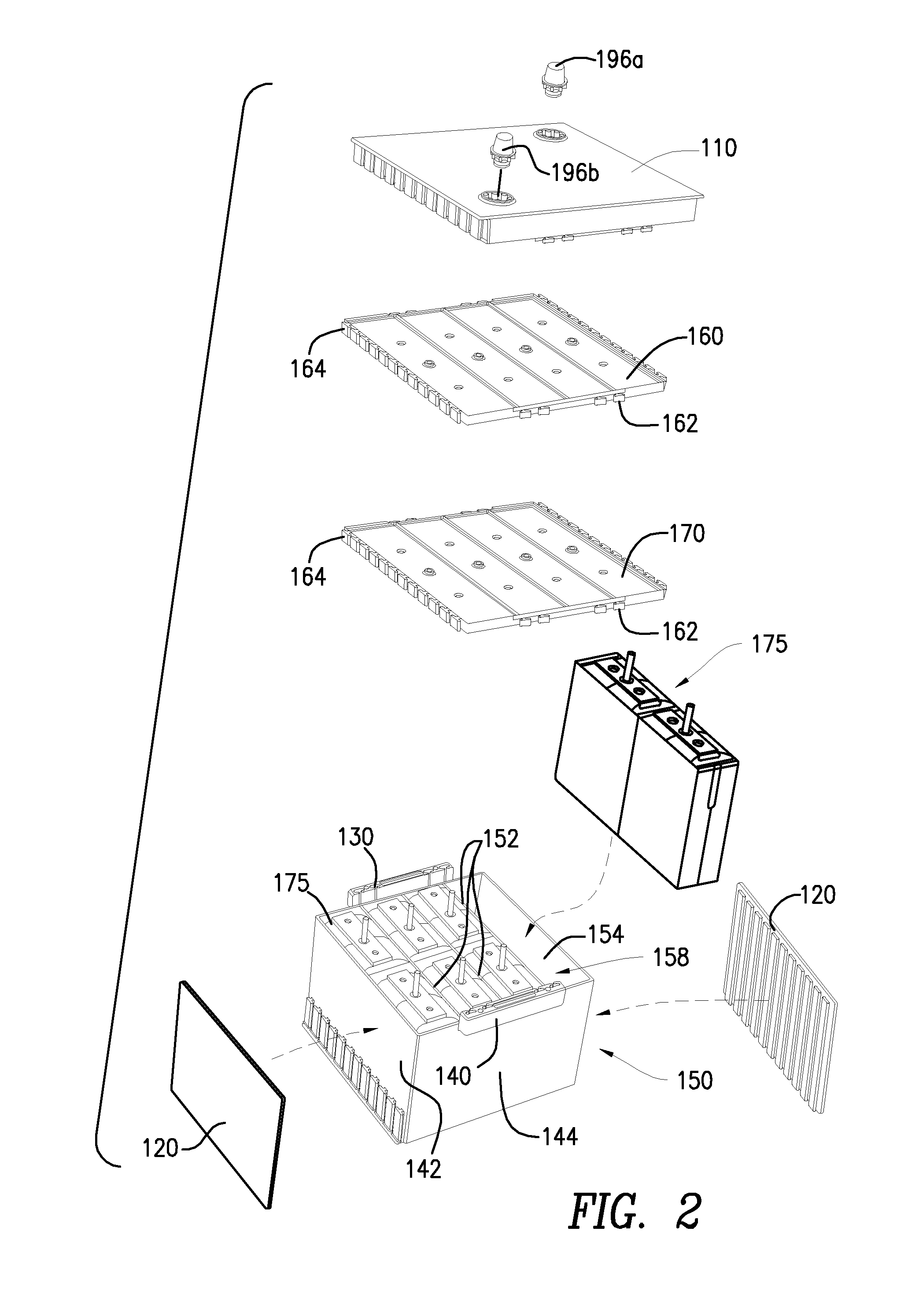

Monoblock lithium ion battery

InactiveUS20100055556A1Primary cell to battery groupingSecondary cellsEngineeringLithium-ion battery

The present invention describes a monoblock for a plurality of lithium ion cells. The monoblock includes a case having a base and a cover dimensioned and configured to the base. The case includes a chamber that includes cell compartments for lithium cells. Each lithium cell is disposed in a leaf spring that applies compression pressure on the cell. The structural integrity of the battery and cells is maintained using internal and external anti-swelling features including a waffle pattern, backing plates, etc. A liquid and gas pressure management system is also incorporated with the case and realized by a vent plenum, check valves, bladders, bags, etc.

Owner:INT BATTERY

Compression device and method for adjustment of a compression pressure

InactiveUS7656993B2Easy to adaptImprove spatial resolutionOperating chairsPatient positioning for diagnosticsCompression deviceEngineering

A compression device has a compression plate that applies a pressure to a subject on a support plate. The compression plate has a number of elastically-deformable compression plate elements that are substantially transparent for an examination field used with the compression device. In a method for compressing a subject, at least one pressure sensor measures the pressure applied by a compression device to a subject, and wirelessly supplies a signal representing the detected pressure to a control unit, wherein the detected pressure is compared to a stored compression pressure value. The control device adjusts the pressure applied to the subject by the compression device so that the pressure detected by the sensor is equal to the stored compression pressure value.

Owner:SIEMENS HEALTHCARE GMBH

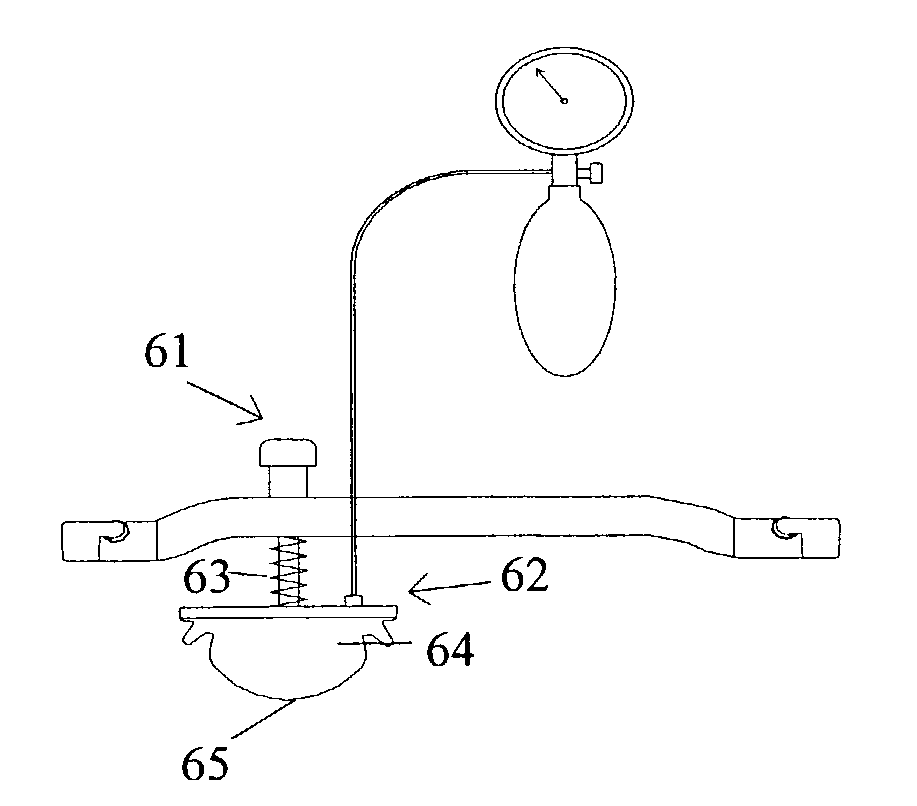

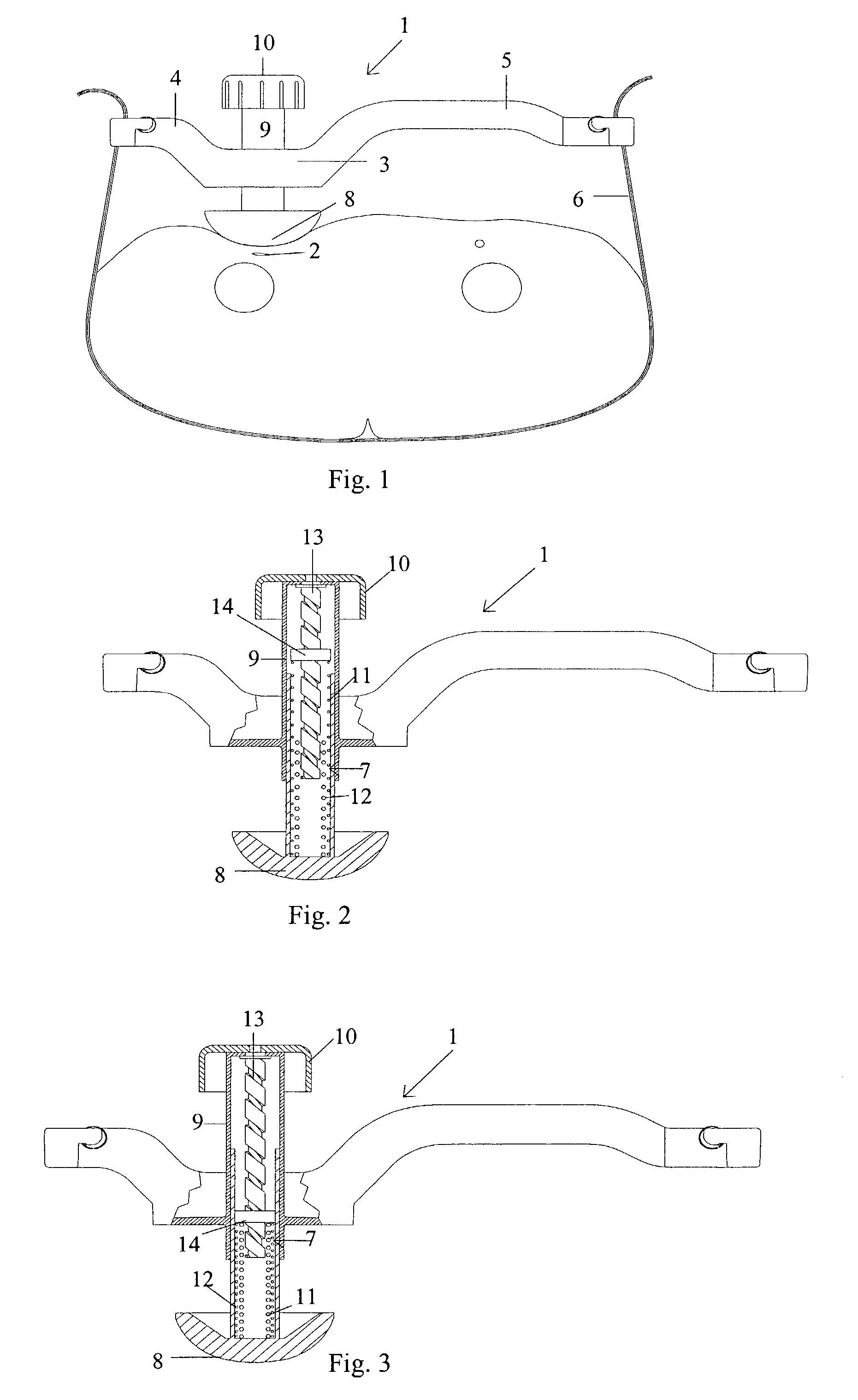

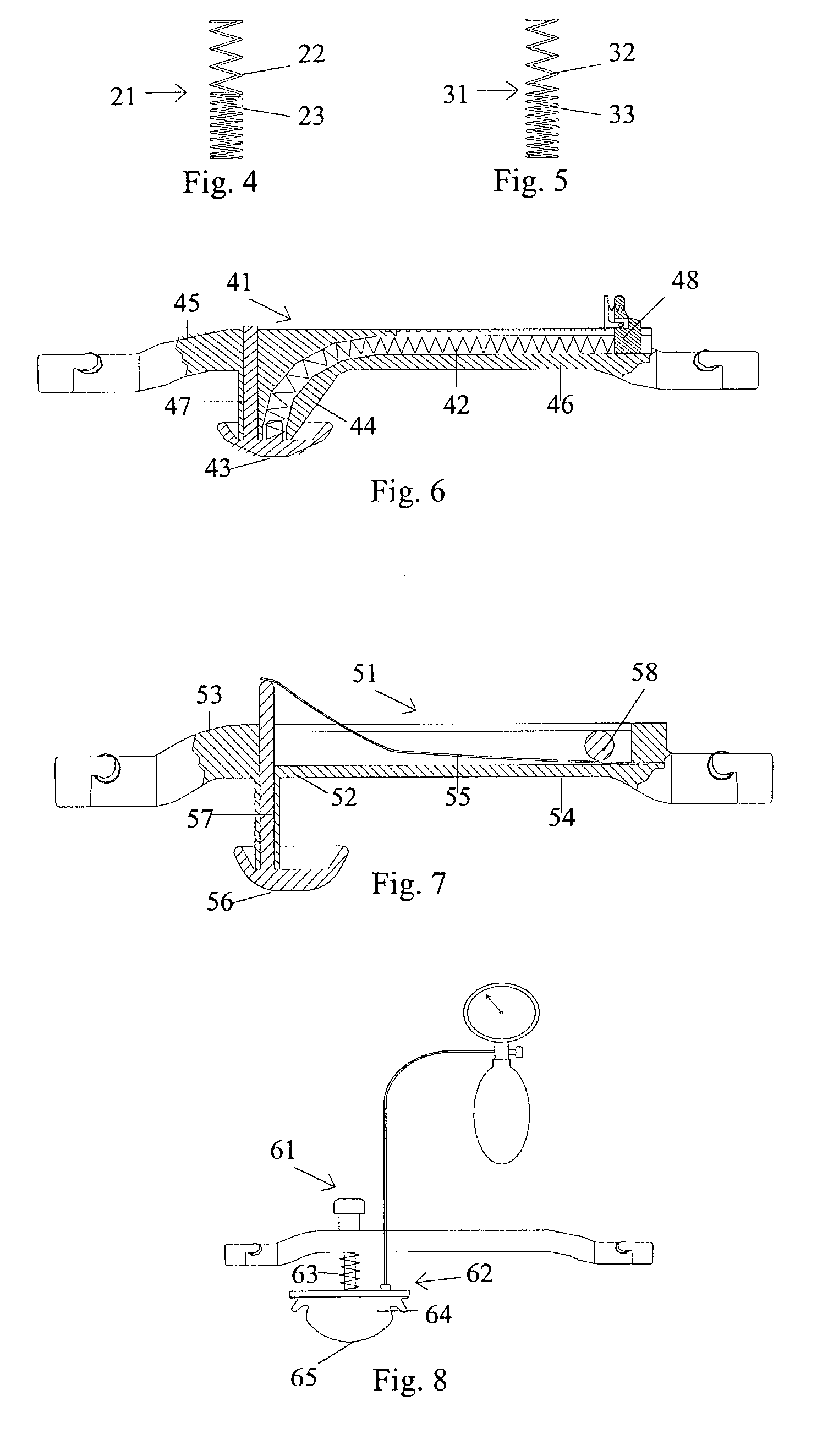

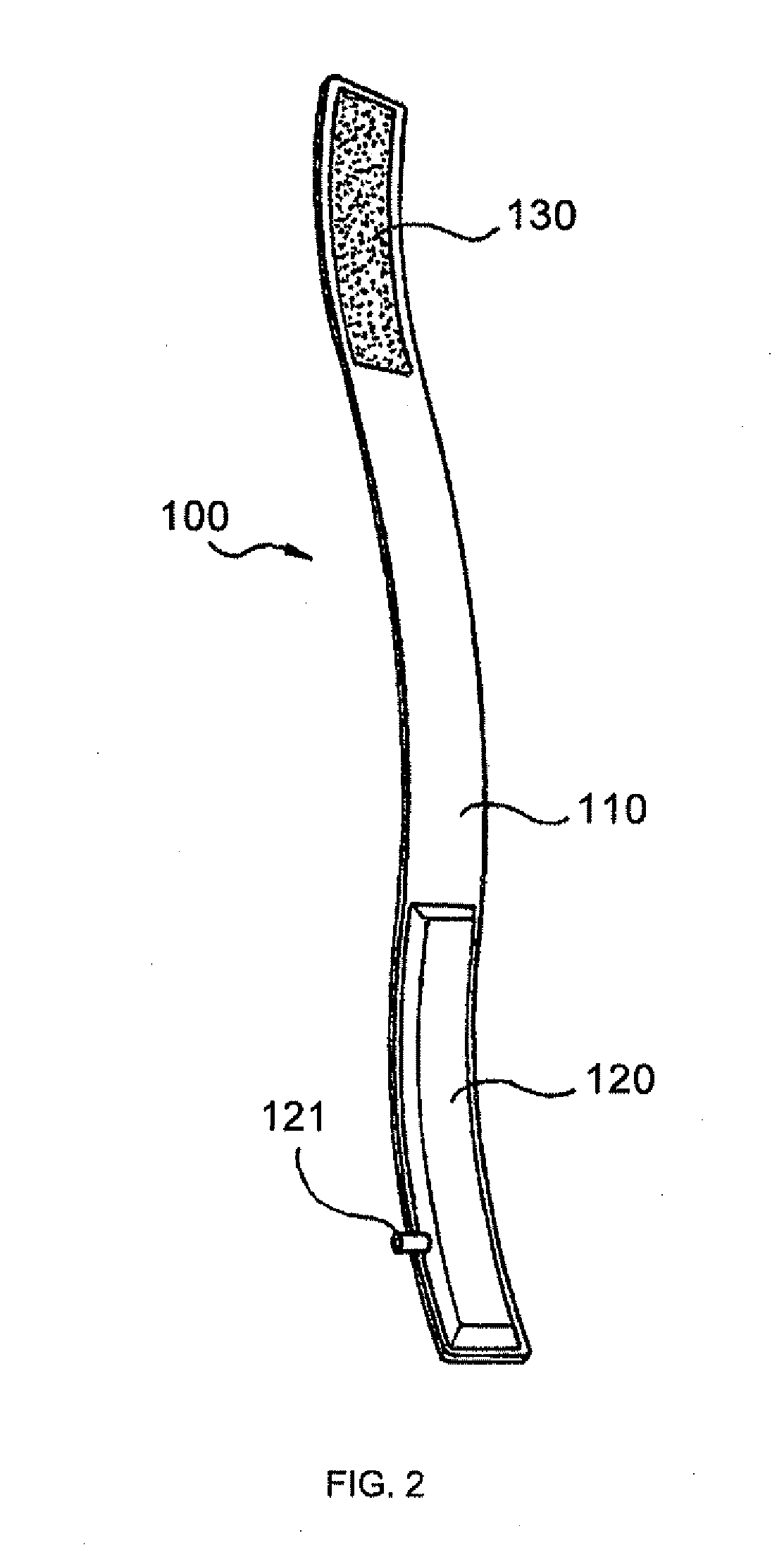

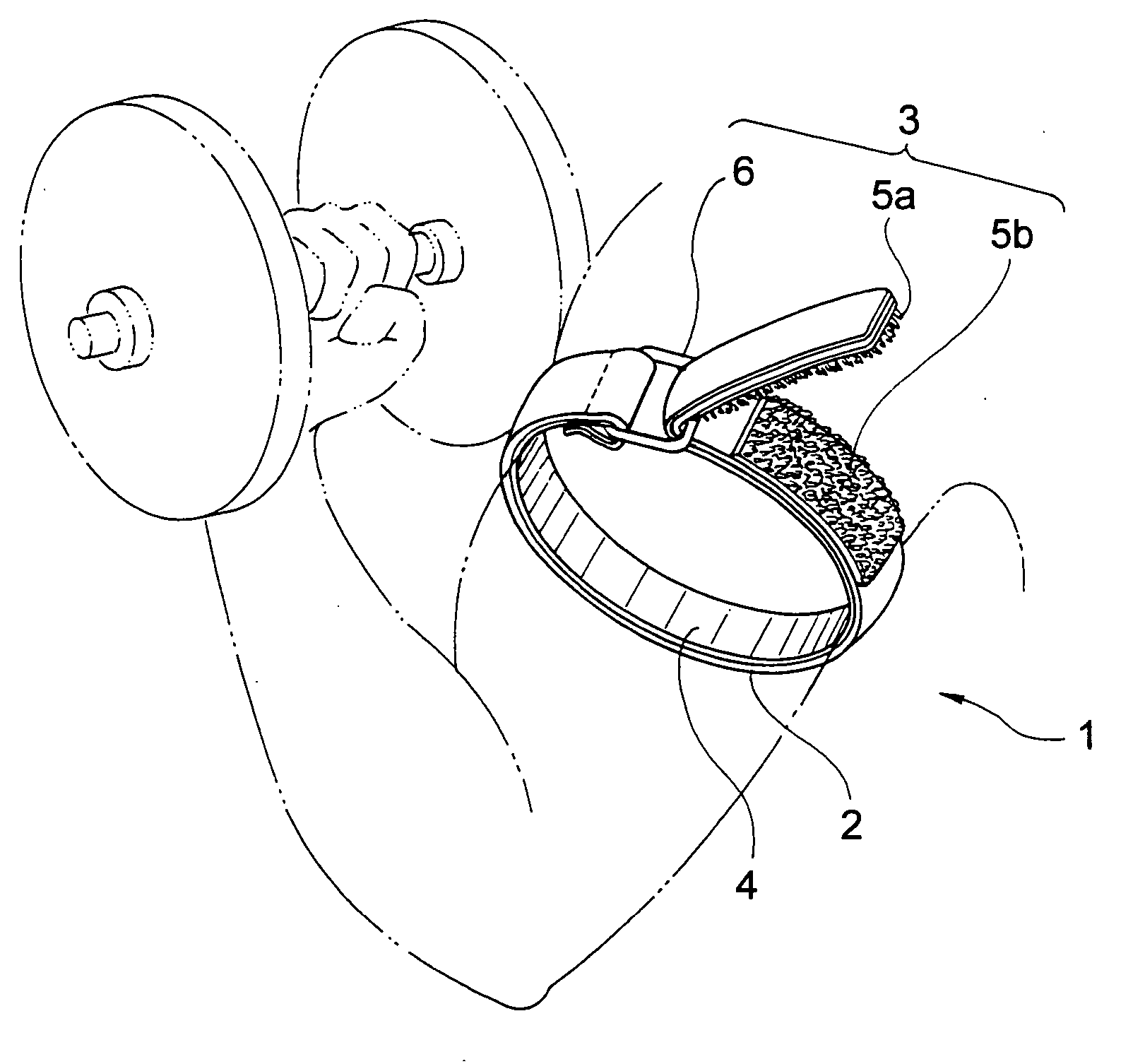

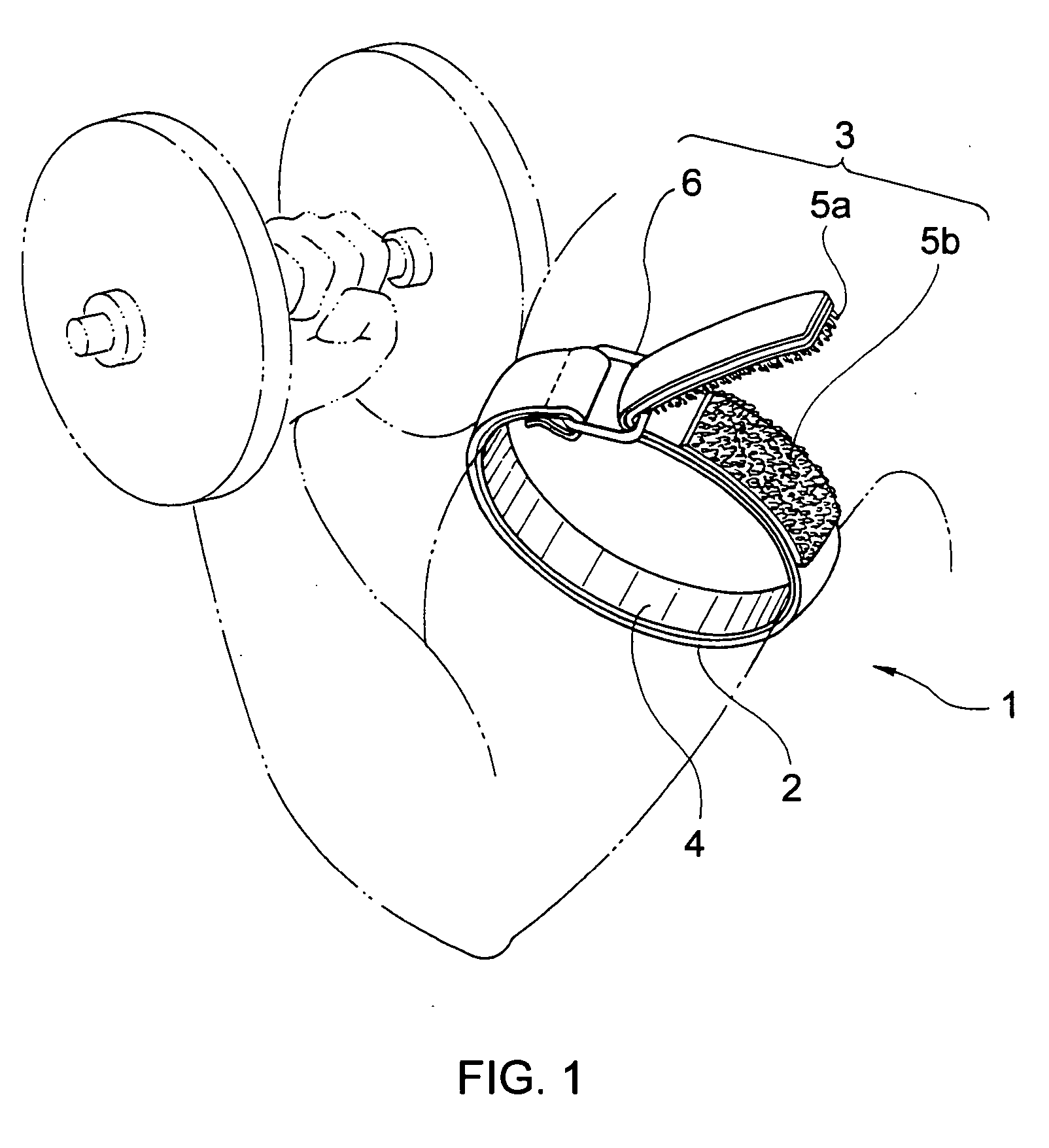

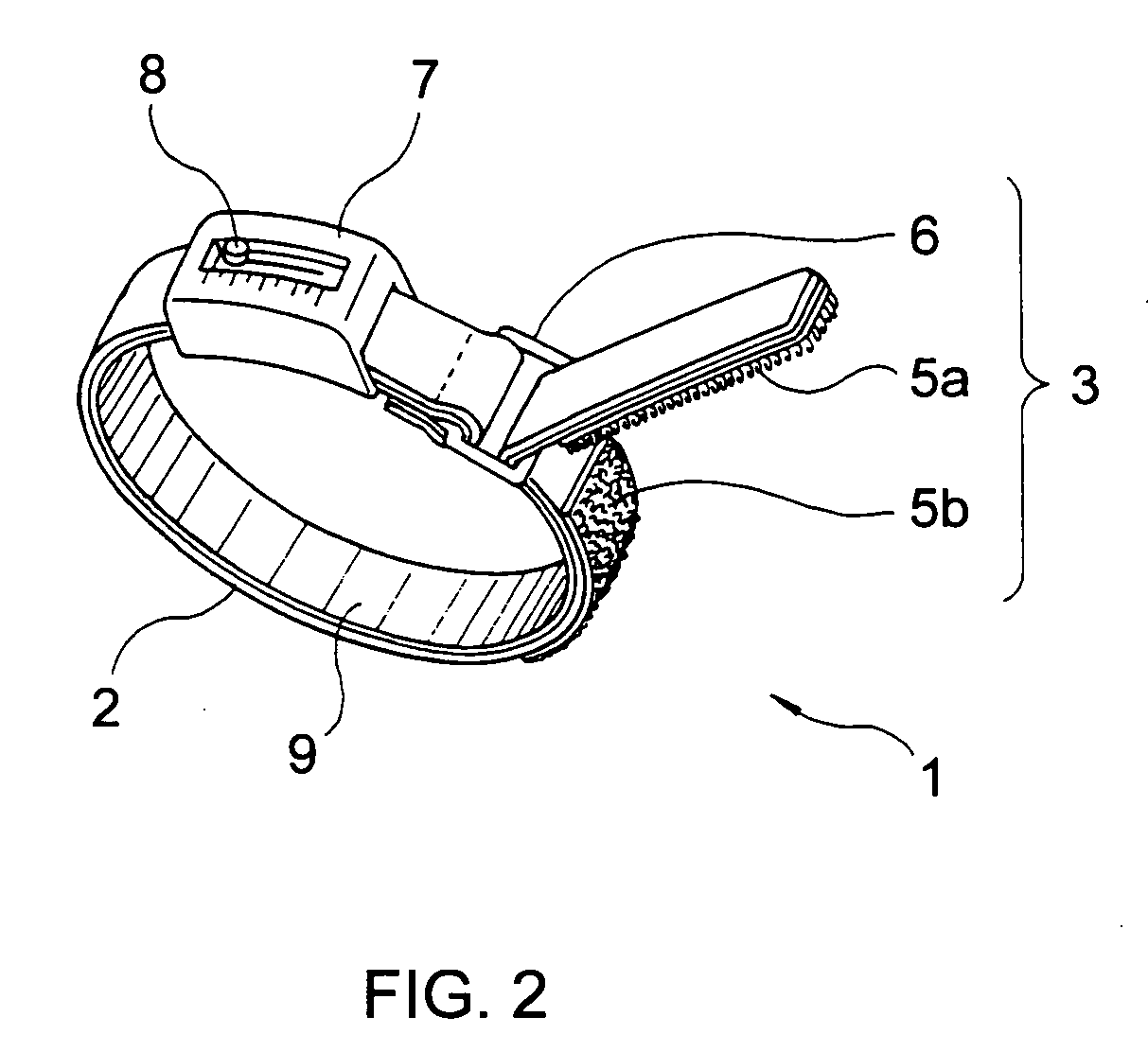

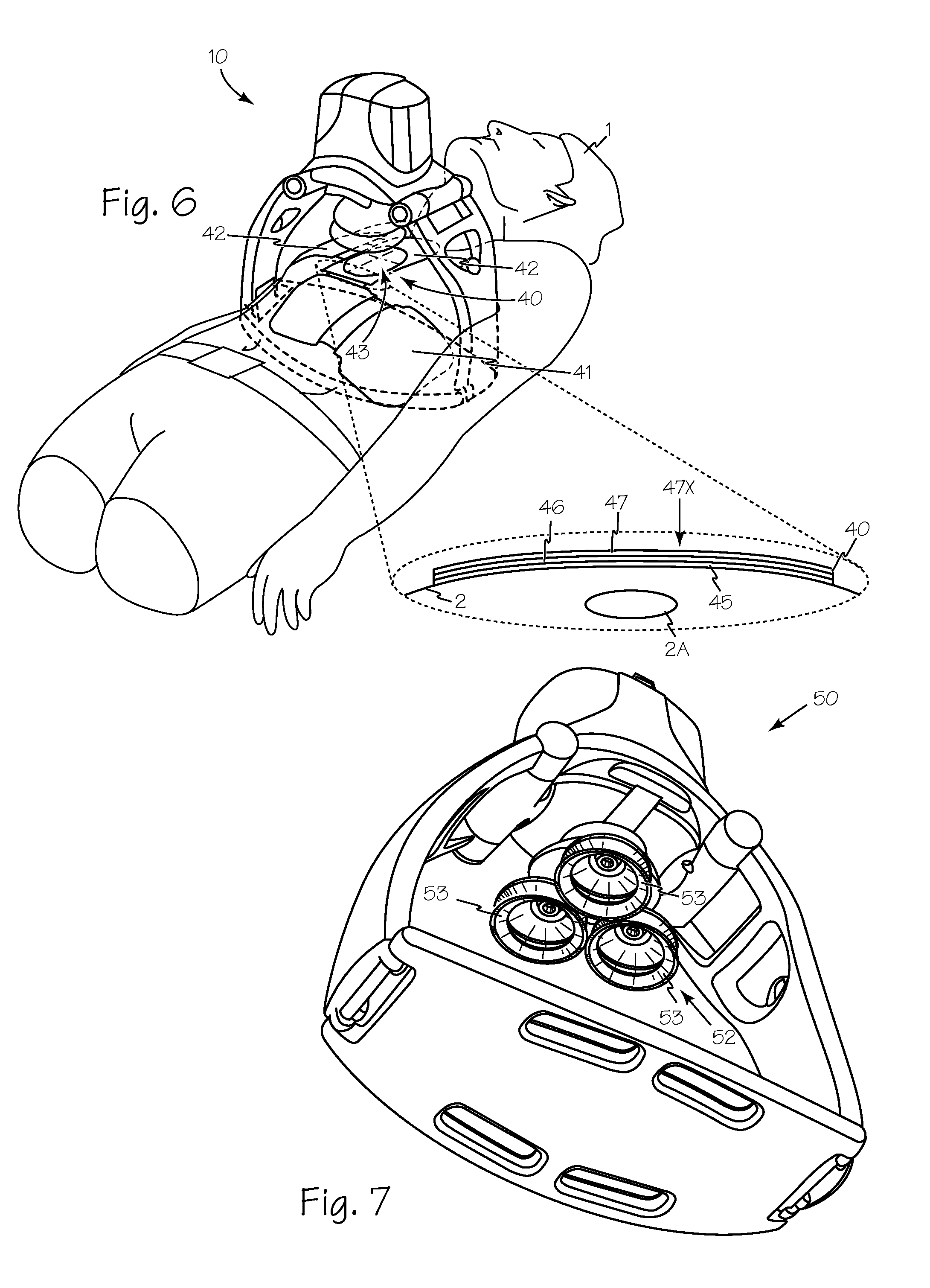

Femoral compression device with progressive pressure device

A femoral compression device (1; 41; 51; 61) for compressing a femoral artery of a patient is provided. The femoral compression device (1; 41; 51; 61) comprises a pressure device (7; 21; 31; 42; 55; 62), a compression member (8; 43; 56; 65) for compressive bearing against a puncture site, a base portion (3; 44; 52) provided with two opposing extensions (4, 5; 45, 46; 53, 54), to the ends of which a belt (6), which is adapted to be arranged around the patient's body, can be fixed. According to the invention, the pressure device (7; 21; 31; 42; 55; 62) is characterized by non-uniform overall action constants, such that when a low compression pressure is applied, the pressure device (7; 21; 31; 42; 55; 62) exhibits a small action constant, and when a high compression pressure is applied, the pressure device (7; 21; 31; 42; 55; 62) exhibits a large action constant.

Owner:ST JUDE MEDICAL COORDINATION CENT

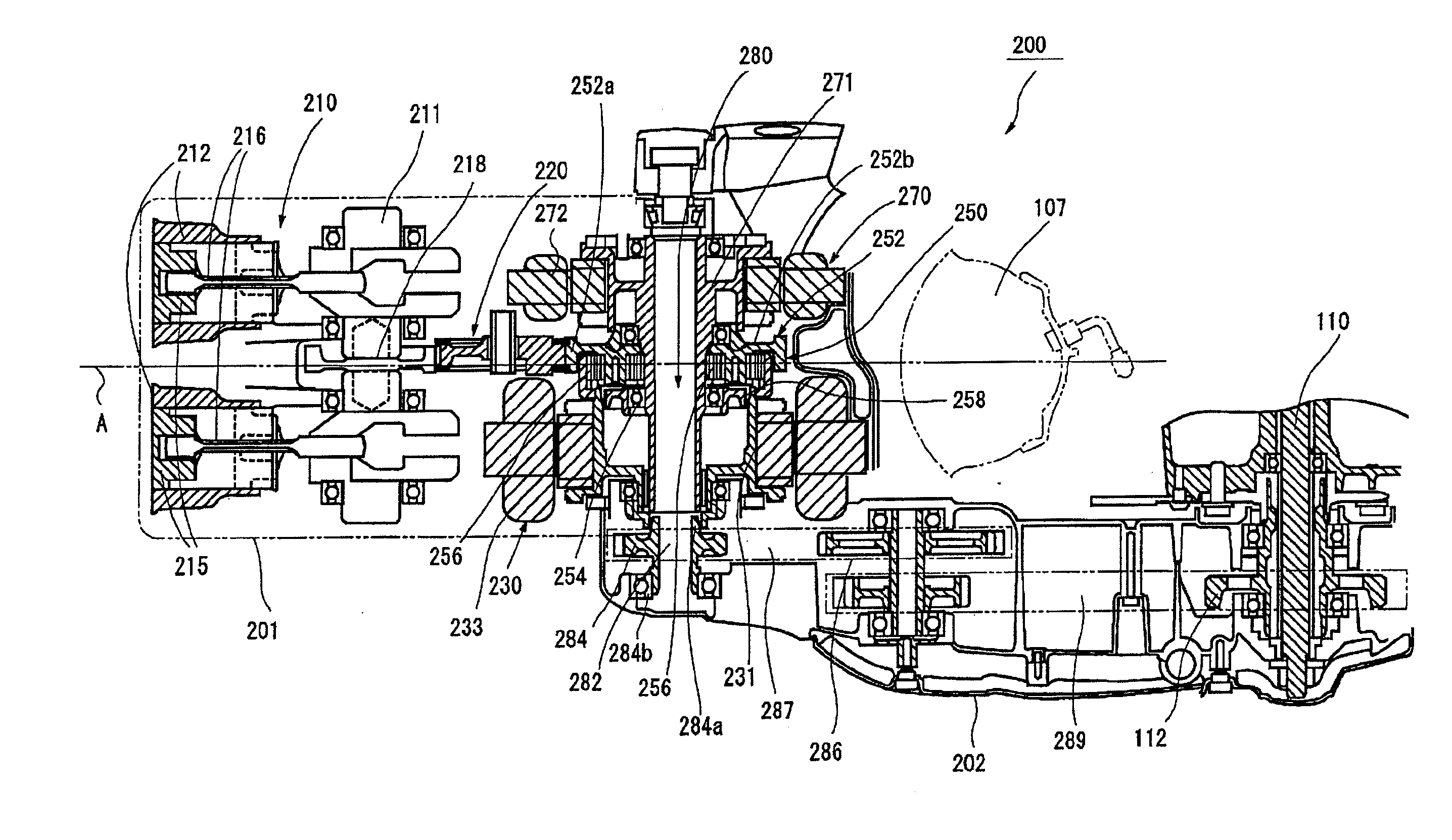

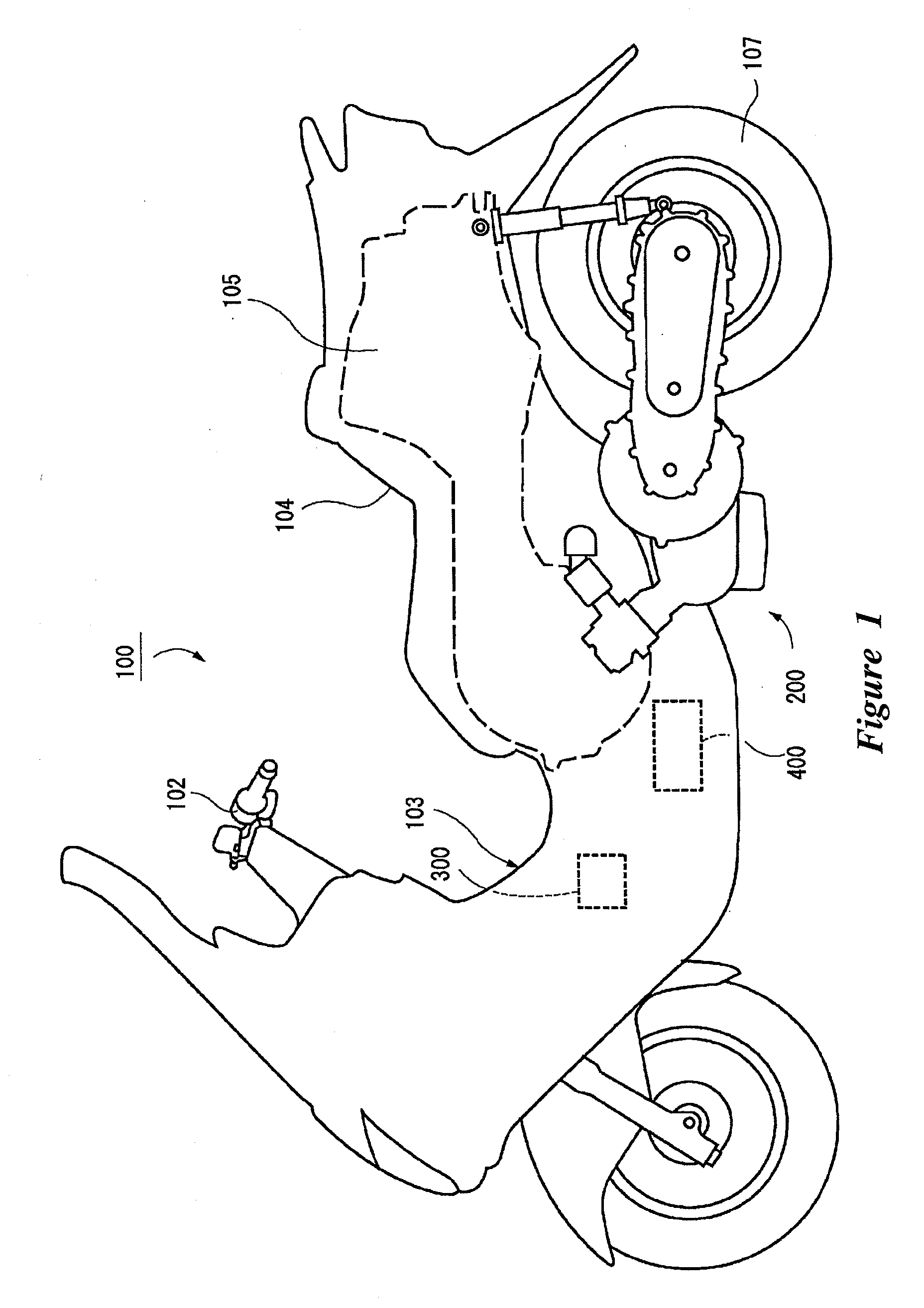

Driving device for a hybrid vehicle, and a hybrid vehicle having the same

InactiveUS20060289214A1Increase and decrease forceEasy to operateHybrid vehiclesValve arrangementsElectricityHybrid vehicle

An engine produces power, which is distributed by a power distribution device to an electric generator and a rear wheel. A motor produces power other than that produced by the engine to drive the rear wheel, and also functions as an electric generator. A control unit drives the electric generator and the motor using electricity from a battery to start up the engine. When starting up the engine, the control unit drives a decompression device provided in the engine to reduce the compression pressure inside a cylinder from the moment when cranking of the engine is started.

Owner:YAMAHA MOTOR CO LTD

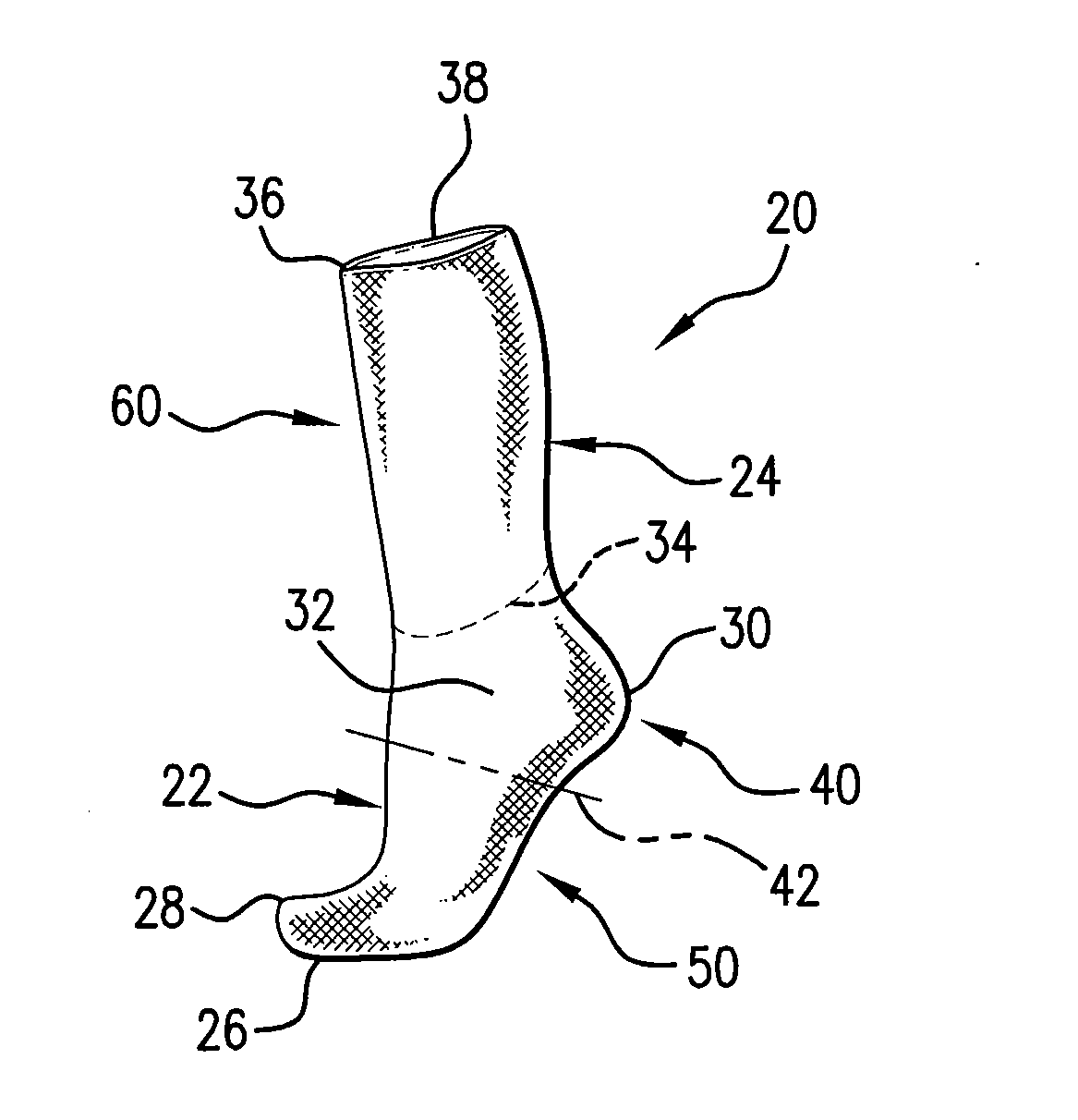

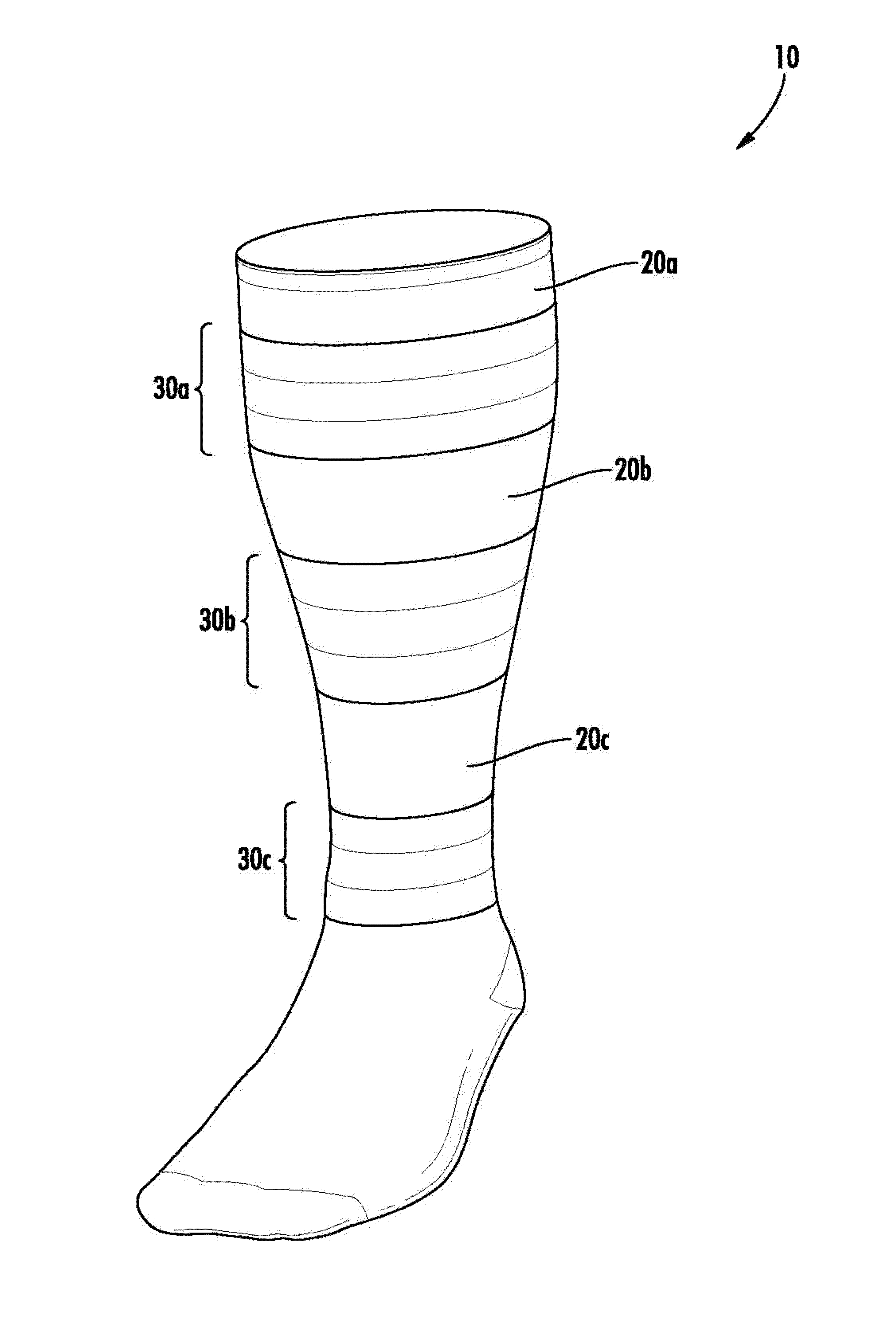

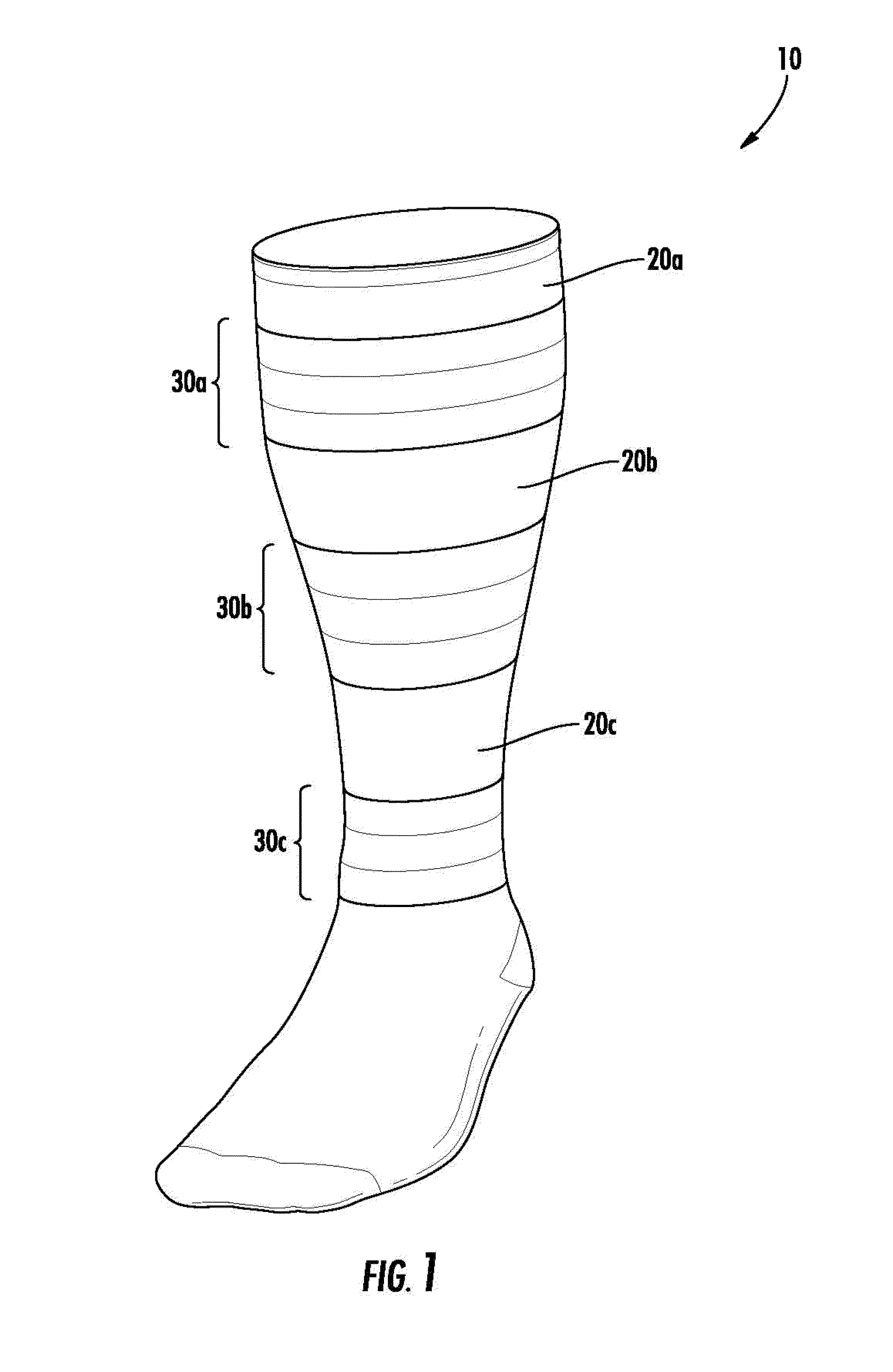

Thermal regulating compression garments

InactiveUS20130047313A1Reduce and eliminate and conditionReduce and eliminate symptomWeft knittingInsolesThermal energyEngineering

A compression garment including a thermal energy regulating fabric. The compression garment has a first region of a first compression pressure. A second region adjacent a first side of the first region includes a first compression gradient increasing in compression pressure in a direction toward the first region. A third region adjacent a second side of the first compression region includes a second compression gradient increasing in compression pressure in a direction toward the first region. The first region includes a consistent compression pressure that is a higher pressure than or the highest pressure of the adjacent increasing pressure gradients.

Owner:MIERS JOHN R

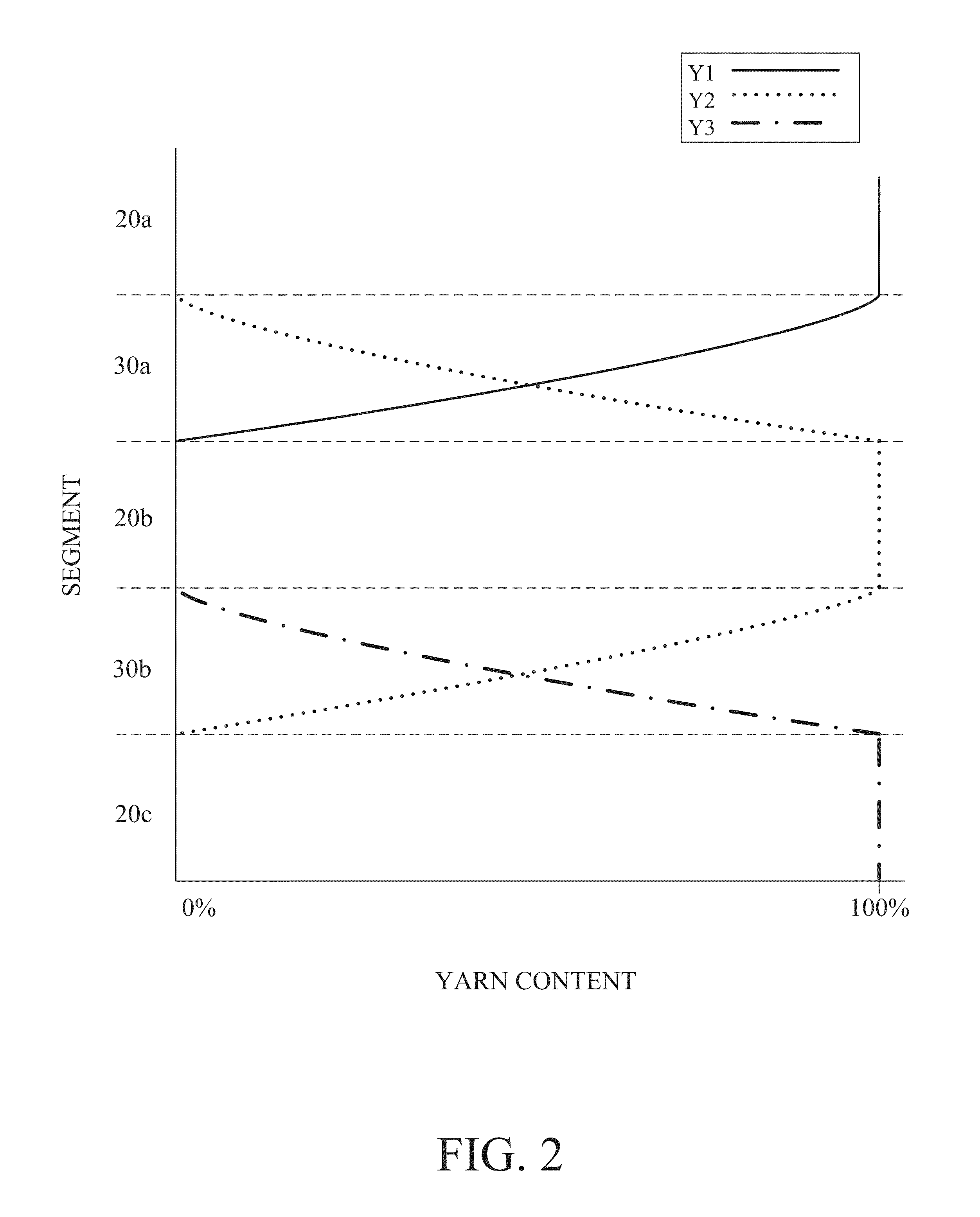

Compression fabrics with tailored comfort

Certain embodiments according to the invention provide compression articles suitable for a wide variety of uses (e.g., compression socks, athletic garments, etc.). In accordance with certain embodiments, the compression article includes at least two uniform compression regions, including a first uniform compression region having a first compression pressure and a second uniform compression region having a second compression pressure, and at least one transitioning compression region, including a first transitioning compression region positioned between the first and second uniform compression regions. The first transitioning compression region comprises a first end adjacent or proximate to the first uniform compression region and a second end adjacent or proximate to the second uniform compression region. The first transitioning compression region comprises a compression pressure gradient extending from the first end to the second end of the first transitioning compression region.

Owner:MYANT CAPITAL PARTNERS

Low emission power plant and method of making same

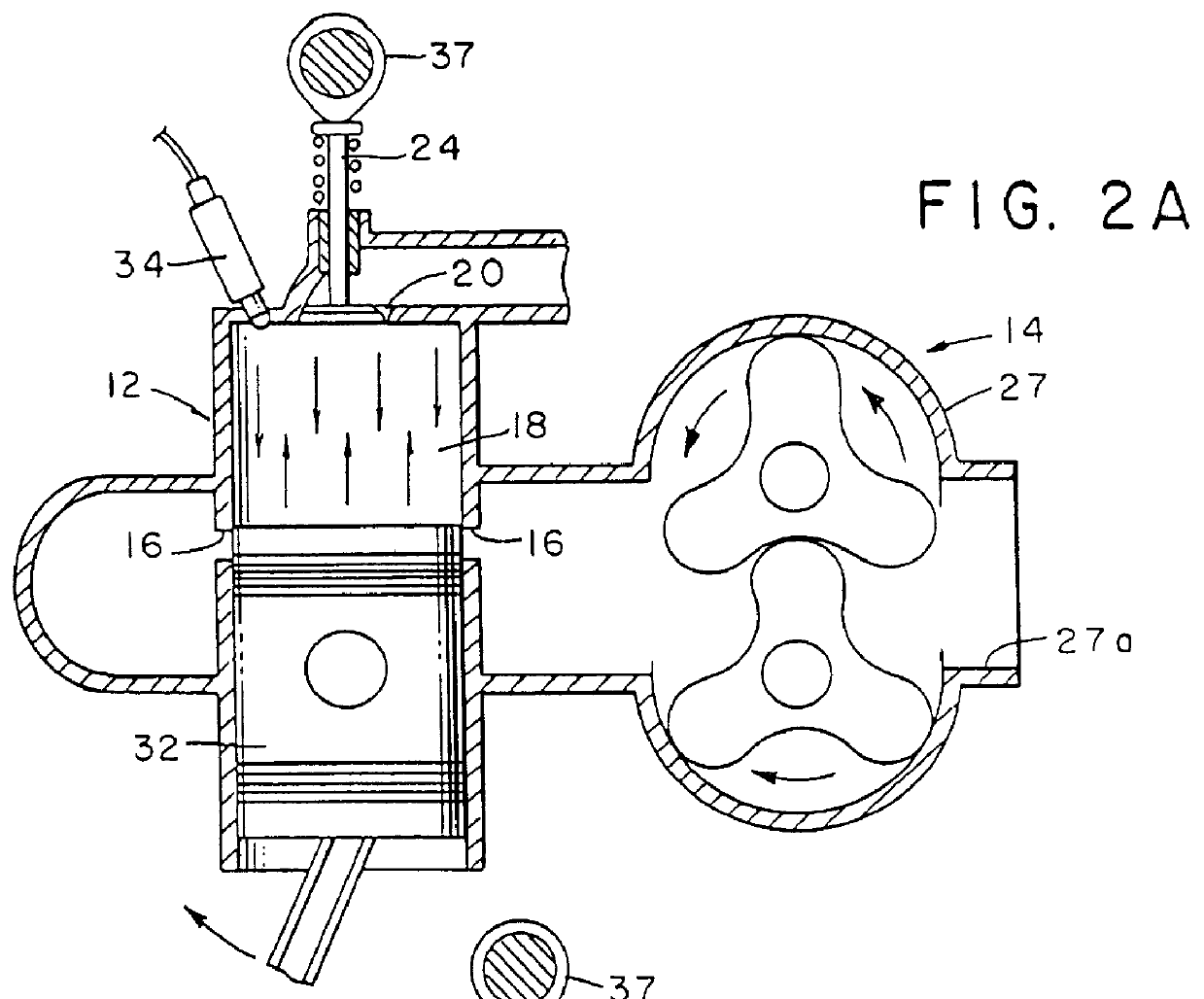

InactiveUS6101989AReduce the amount of solutionLower than normal exhaust valve liftNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesCombustion chamber

A low emission power generating apparatus which comprises a modified two-stroke diesel engine component and a modified turbocharger component which has a relatively low aspect ratio. The diesel engine component is a modification of a conventional two-stroke diesel engine design and includes an exhaust valve cam of unique design that has a cam profile which results in a later than-normal exhaust valve opening and an earlier-than-normal valve closing so that the time during which the exhaust valve remains open is shorter than normal, thereby causing a substantially greater volume of residual gases to remain in the combustion chamber following the scavenge stroke. This increase in the volume of the residual exhaust gases within the chamber leads to an increase in compression temperature and effectively increases the compression ratio and consequently the compression pressure. Because of the heat absorption capacity of these residual exhaust gases, the exhaust gases remaining in the chamber following the scavenge stroke tend to absorb combustion heat and thereby effectively reduce the peak combustion temperature. This reduction in peak combustion temperature advantageously results in the lower than normal formation of nitrogen oxide (NOx) and, therefore, allows advancement of the injection timing, while still maintaining the NOx emissions coming from the engine lower than those legislatively mandated. Advantageously, the advance in injection timing, which increases NOx emissions, by definition has the effect of also reducing particulate matter emissions. Thus, by increasing the volume of residual exhaust gases within the cylinder, substantial particulate matter emission reductions can be achieved, while at the same time maintaining NOx emissions well below mandated limits. The modified turbocharger component provides an additional charge of oxygen-rich air into the combustion chamber which effectively increases the compression pressure, which, in turn, leads to an earlier start of combustion because of the combustible mixture reaching its auto-ignition temperature at an earlier point in the cycle. This phenomenon leads to more thorough combustion of the fuel and also generally leads to higher exhaust temperatures. Higher exhaust temperatures, in turn, lead to a greater oxidation rate of the soluble organic fraction thus lowering the level of emission from the engine of undesirable particulate matter.

Owner:CLEAN CAM TECH SYST

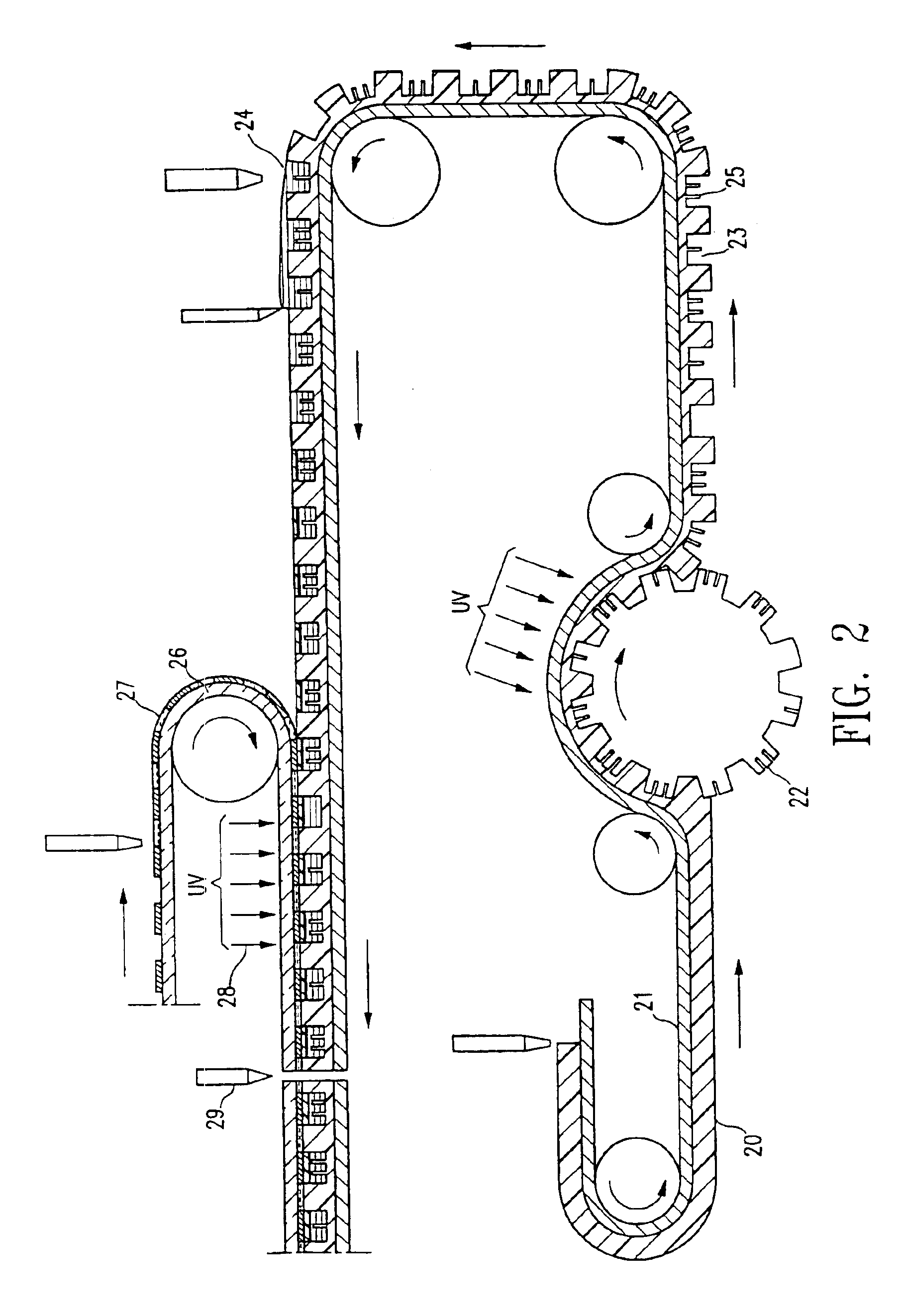

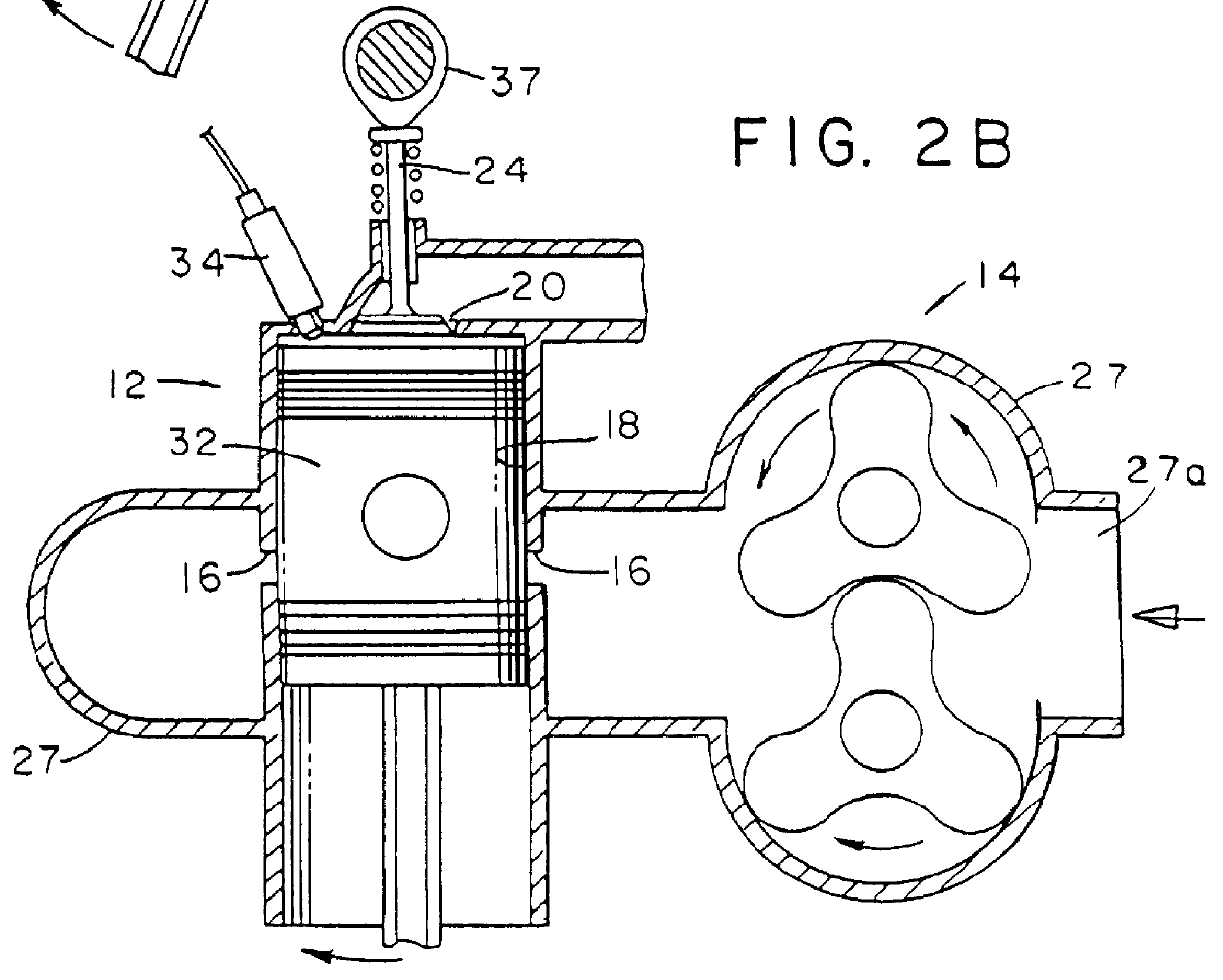

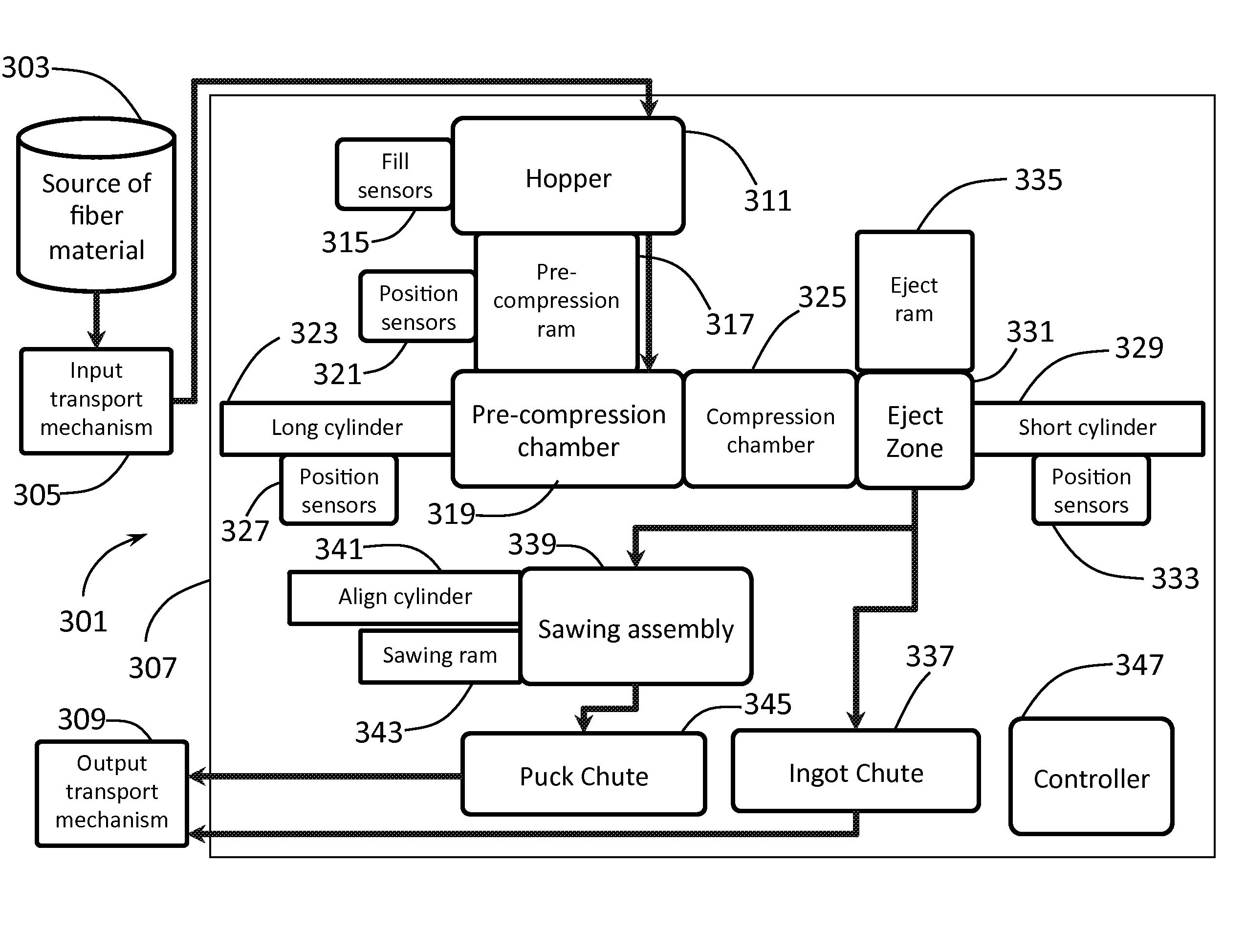

Method and mechanical press system for the generation of densified cylindrical briquettes

InactiveUS8726800B2Promote conversionMinimizes front-end processingBiofuelsSolid fuelsAbutmentBriquette

A method for preparing a pressed article comprises providing a first and a second pressing ram in a compression chamber; supplying biomass particles in the chamber closing the chamber; extending the first pressing ram; displacing the biomass particles with the first pressing ram towards the second pressing ram; detecting abutment of the biomass particles on the second pressing ram; applying pressure to the biomass particles with the first pressing ram and with the second pressing ram detecting a pressure applied to match a predetermined pressure and continuing to extend the first and the second pressing ram until a predetermined time at the matched compression pressure has elapsed; stopping the extension of the second pressing ram when a predetermined extension length is reached; continuing to extend the first pressing ram until a predetermined additional time has elapsed after the stopping; ejecting a pressed article.

Owner:MURRAY DONALD LOUIS +1

Electrophoretic display with sub relief structure for high contrast ratio and improved shear and/or compression resistance

This invention relates to an electrophoretic display comprising isolated cells of well-defined shape, size and aspect ratio which cells have internal sub relief structures and are filled with charged pigment particles dispersed in a dielectric solvent. The display shows an improved contrast ratio and resistance against shear and compression pressures. The display may have the traditional up / down switching mode, an in-plane switching mode or a dual switching mode.

Owner:E INK CALIFORNIA

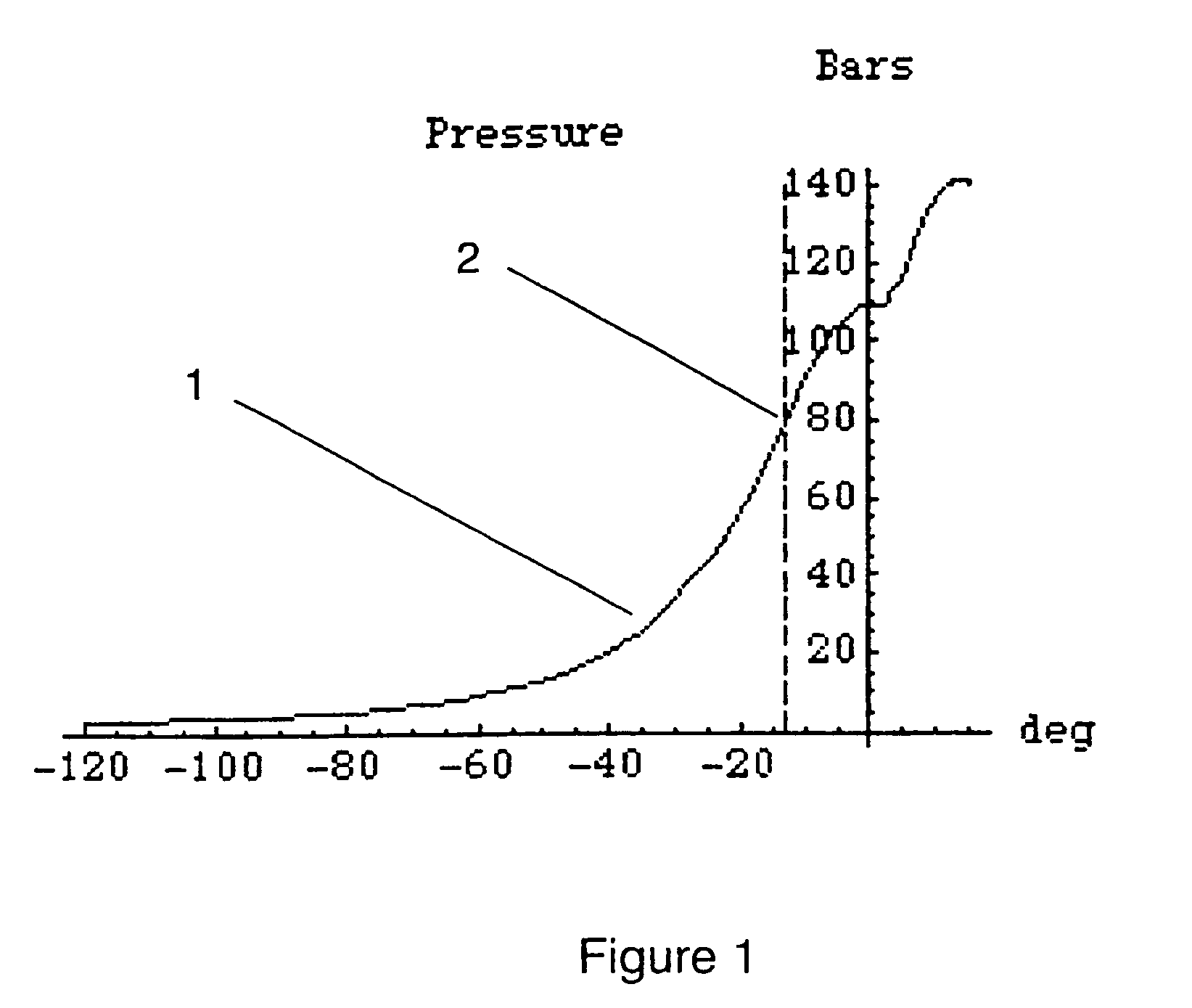

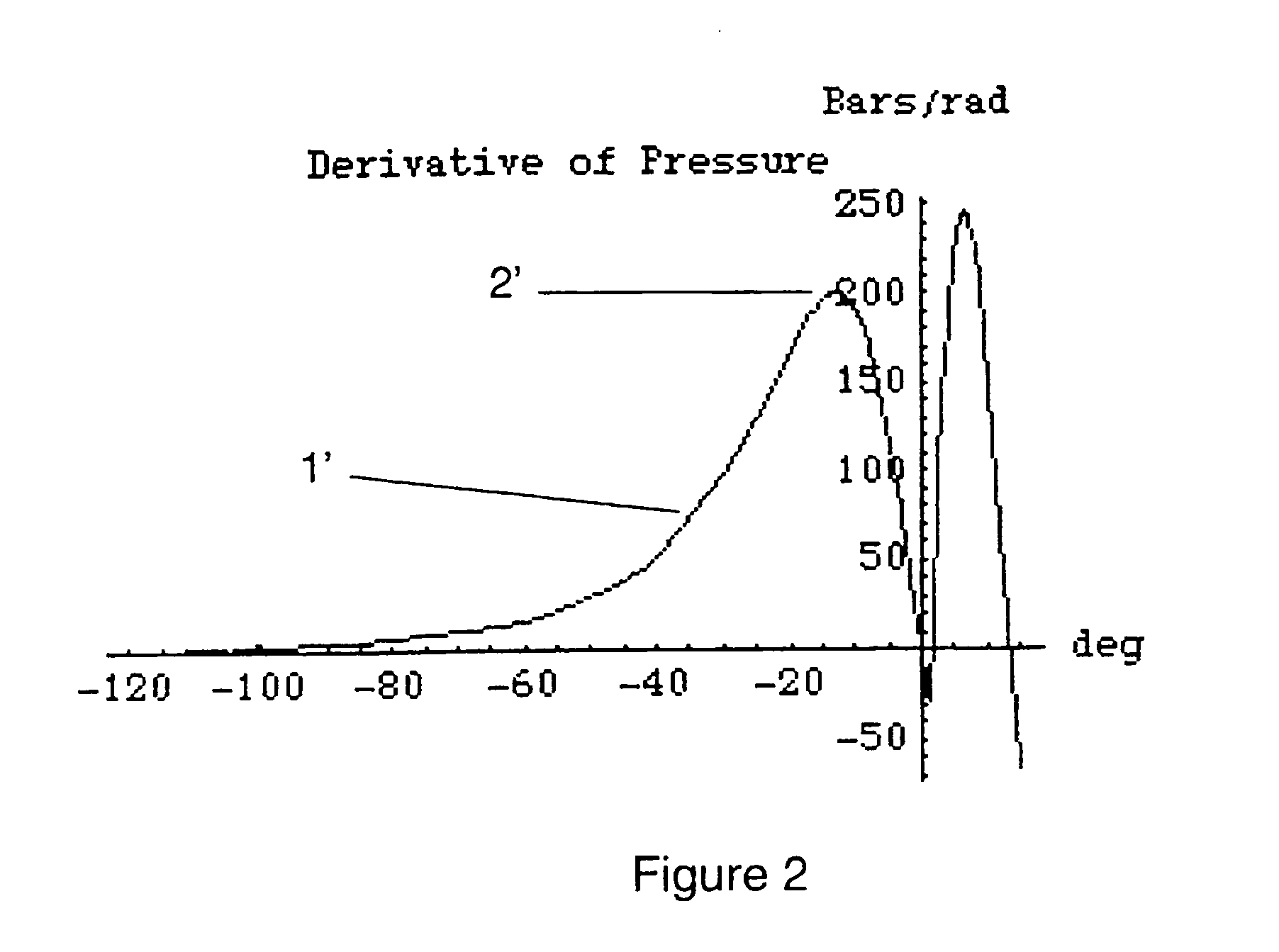

Method to determine tdc in an internal combustion engine

InactiveUS20040236496A1Efficient developmentReduce fuel consumptionInternal-combustion engine testingAnalogue computers for vehiclesFlywheelInternal combustion engine

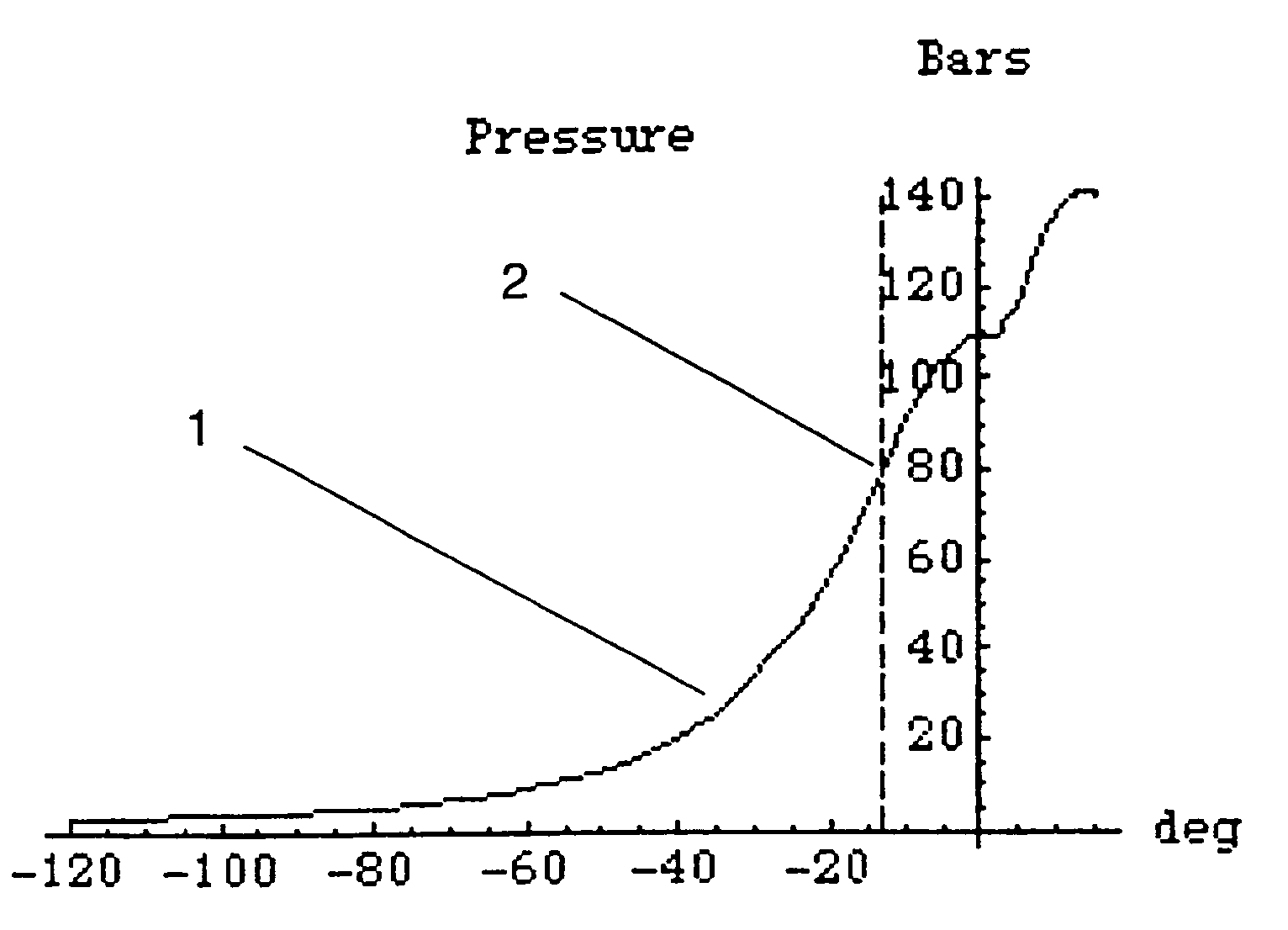

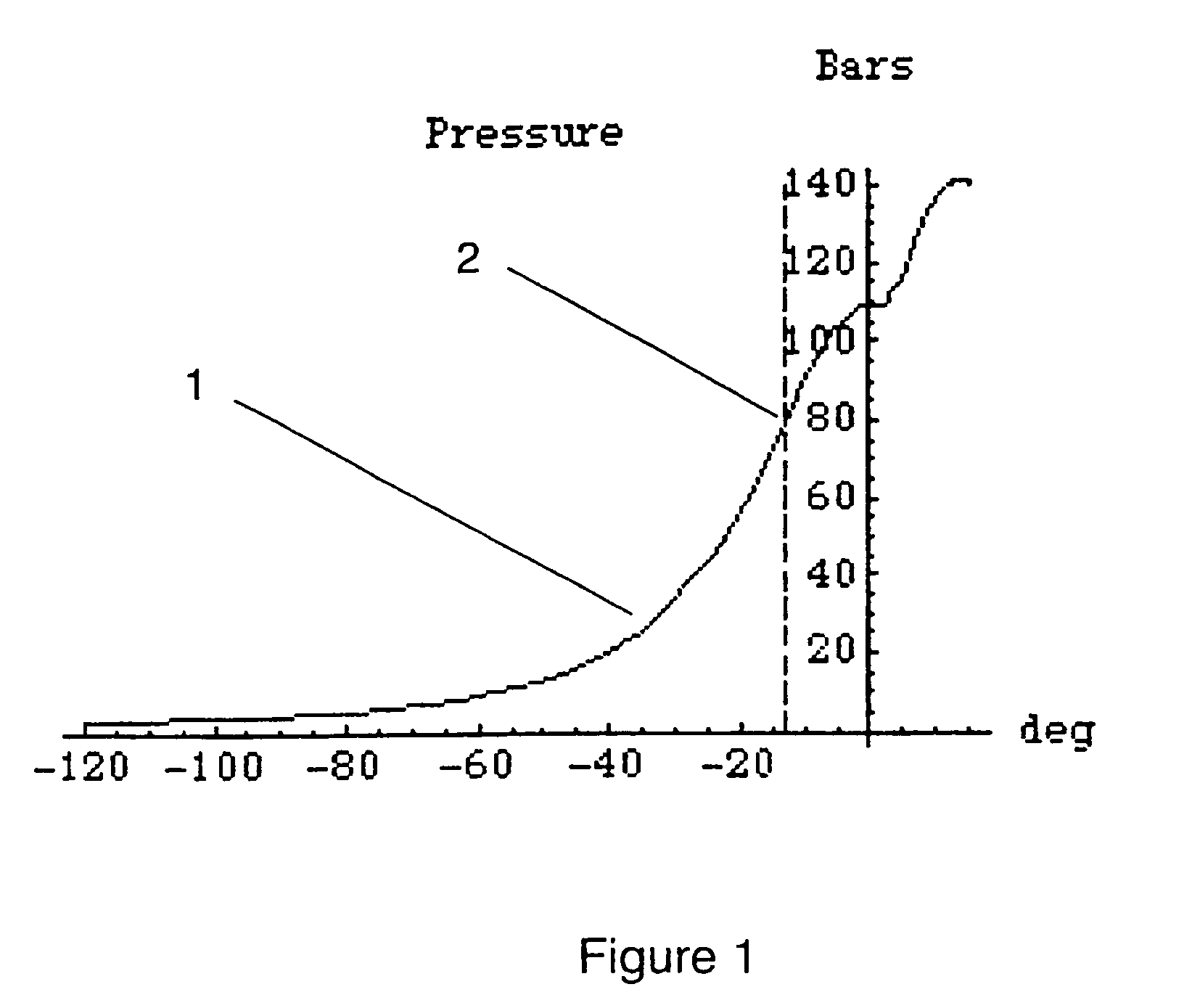

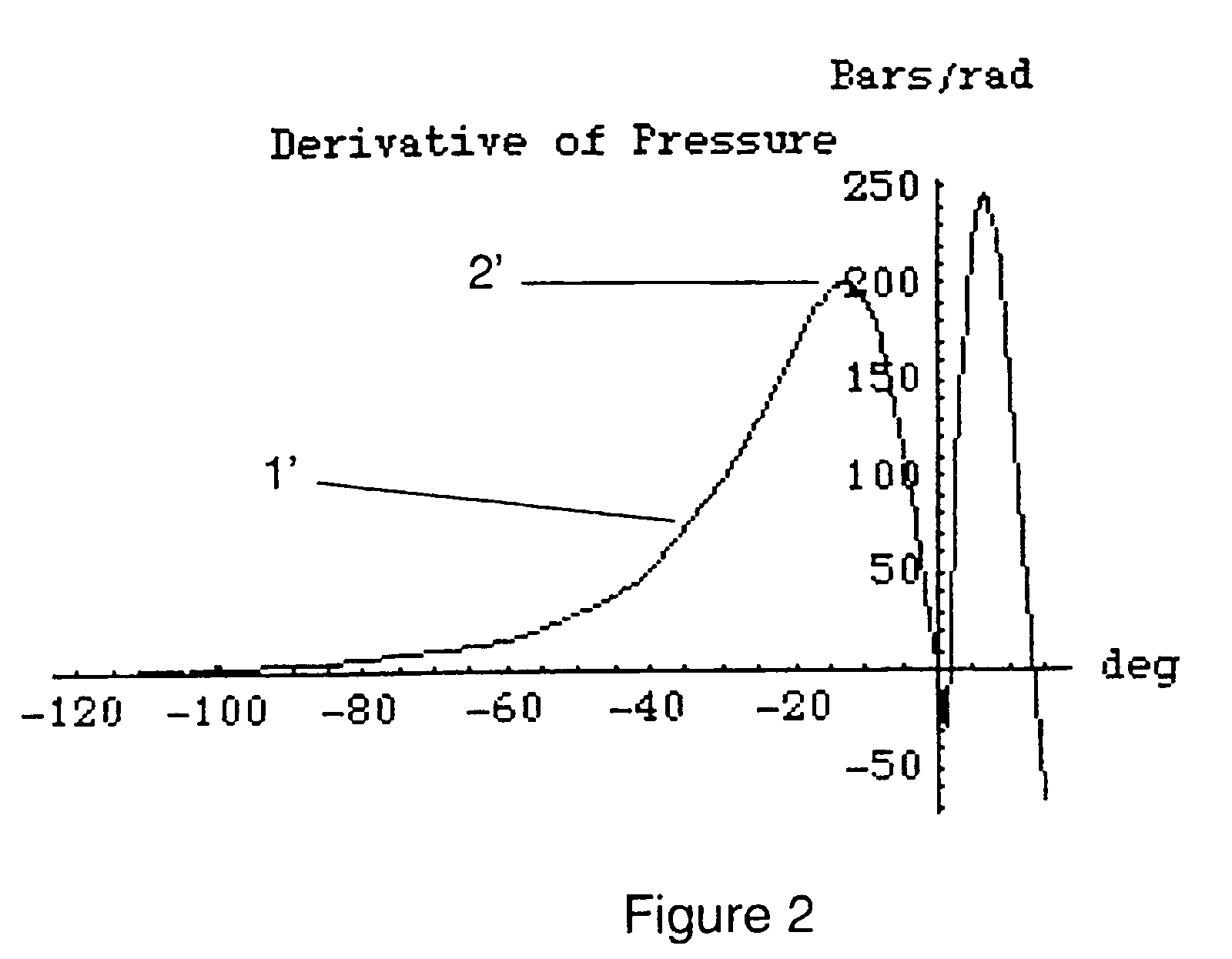

A method and apparatus for accurately determining TTX: in a cylinder of an internal combustion engine. Gas pressure is measured in the cylinder relative to crank angle, giving rise to a curve of gas pressure with crank angle. An offset is found by first computing the angular position of an inflexion point of the compression pressure curve measured as a function of the crank angle, and then computing the offset as the difference between the angular position of a piston in the cylinder and a theoretical value for said angular position of the piston dependent on a known or measured flywheel angle. The value of TDC corrected by the offset is then used to calculate a value of work output such as the indicated Mean Effective Pressure (IMEP) which may be used for diagnostic and / or control purposes.

Owner:ABB (SCHWEIZ) AG

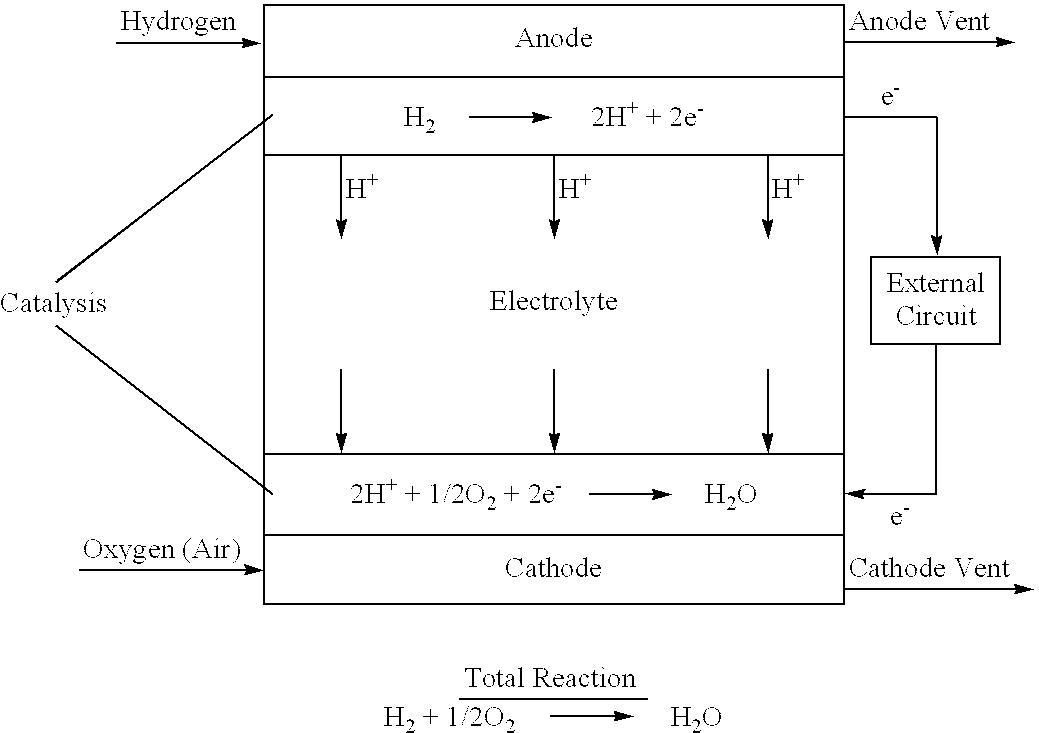

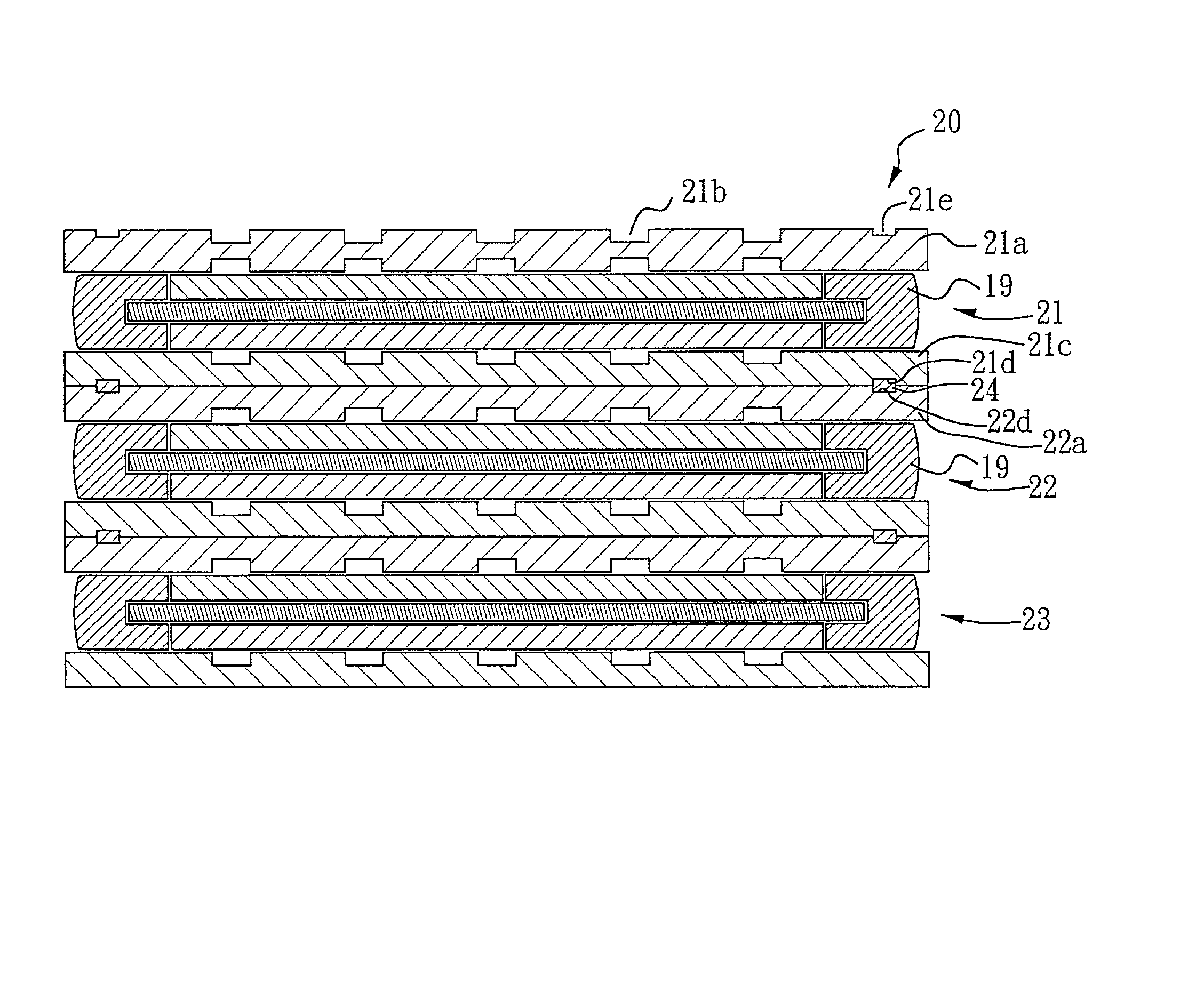

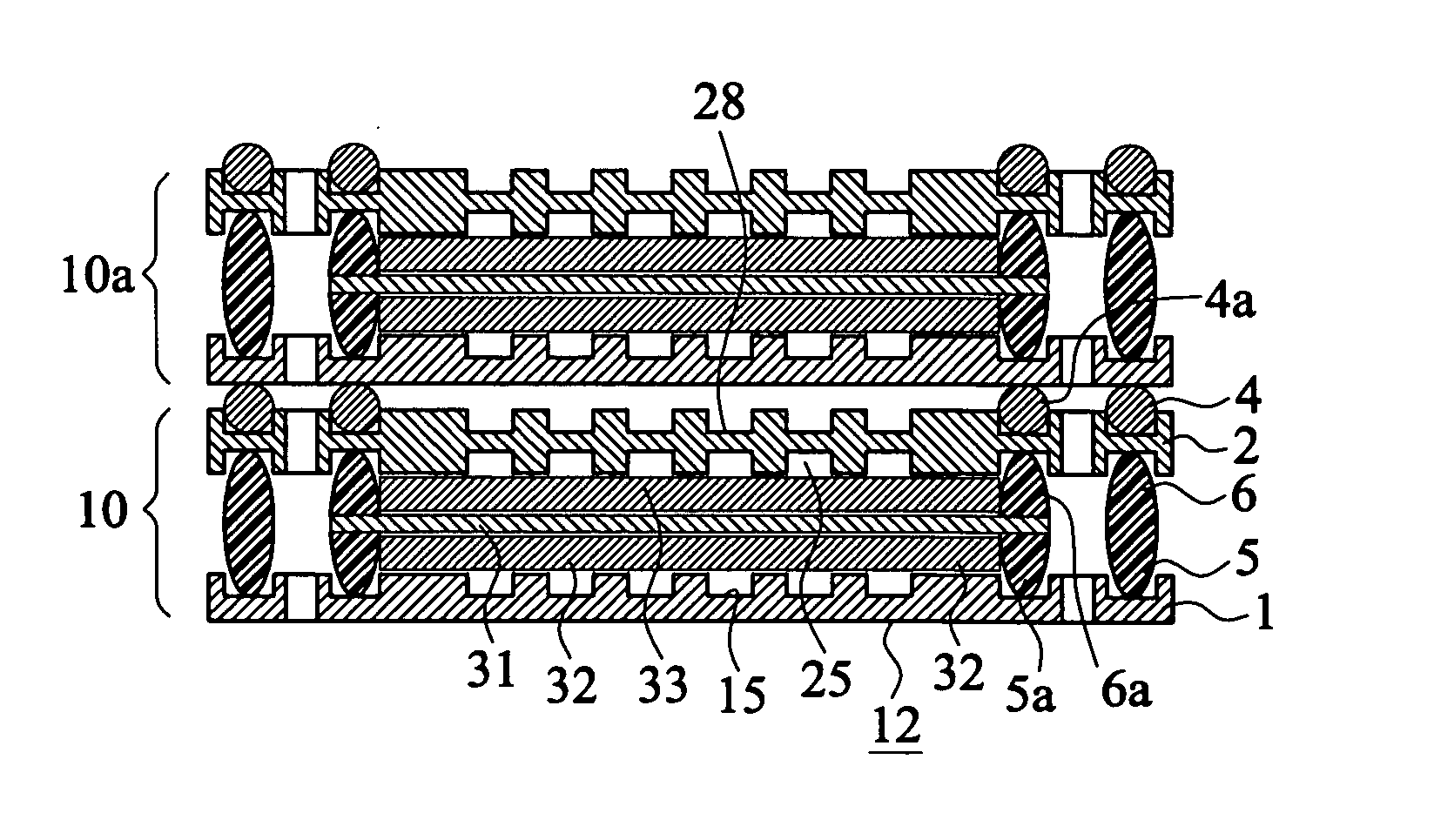

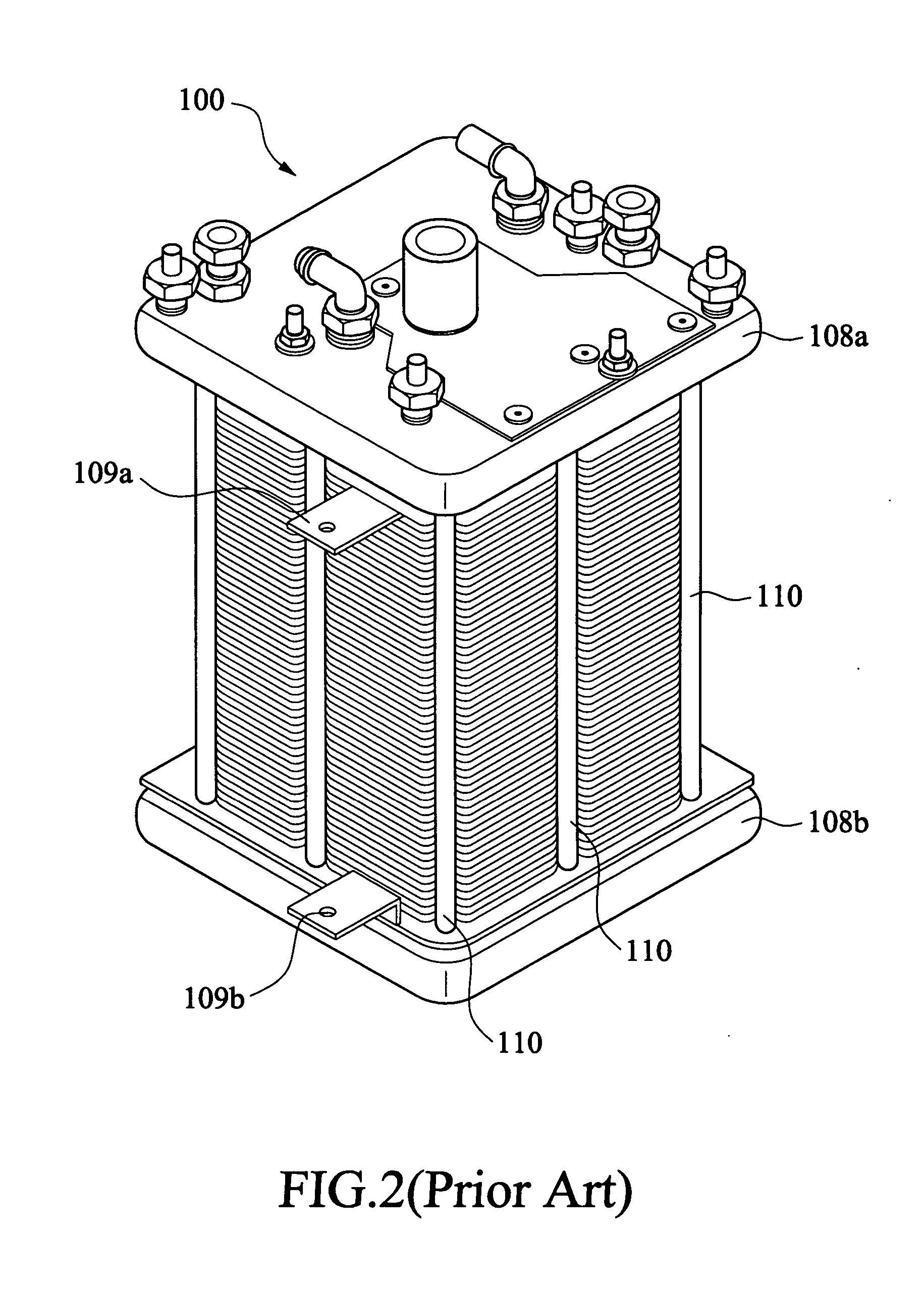

Modulized single cell and assembled cell unit of a proton exchange membrane fuel cell

The present invention relates to a novel structure of a single cell module of a proton exchange membrane fuel cell (PEMFC), comprising an anode bipolar plate, a cathode bipolar plate and a membrane electrode assembly (MEA) sandwiched therebetween. The MEA is substantially disposed on a central portion between the anode and cathode bipolar plates. A desired amount of silicon rubber (RTV), by means of programmed automatic robotic arms, is applied to a circumferential portion between the anode and cathode bipolar plates to seal, cushion and position the anode bipolar plate and cathode bipolar plate under a pre-determined compression pressure after the RTV is cured, thereby forming an integral single cell module. According to the structural concept, a plurality of the single cells can be customized to form a cell unit by superimposing them in sequential order, of which an upper surface of the anode bipolar plate and / or a lower surface of the cathode bipolar plate are / is formed with grooves on their circumferential portions for receiving the RTV so as to provide a sealing, cushioning and positioning contact, and achieve an optimal compression pressure among the layered single cells.

Owner:ASIA PACIFIC FUEL CELL TECH

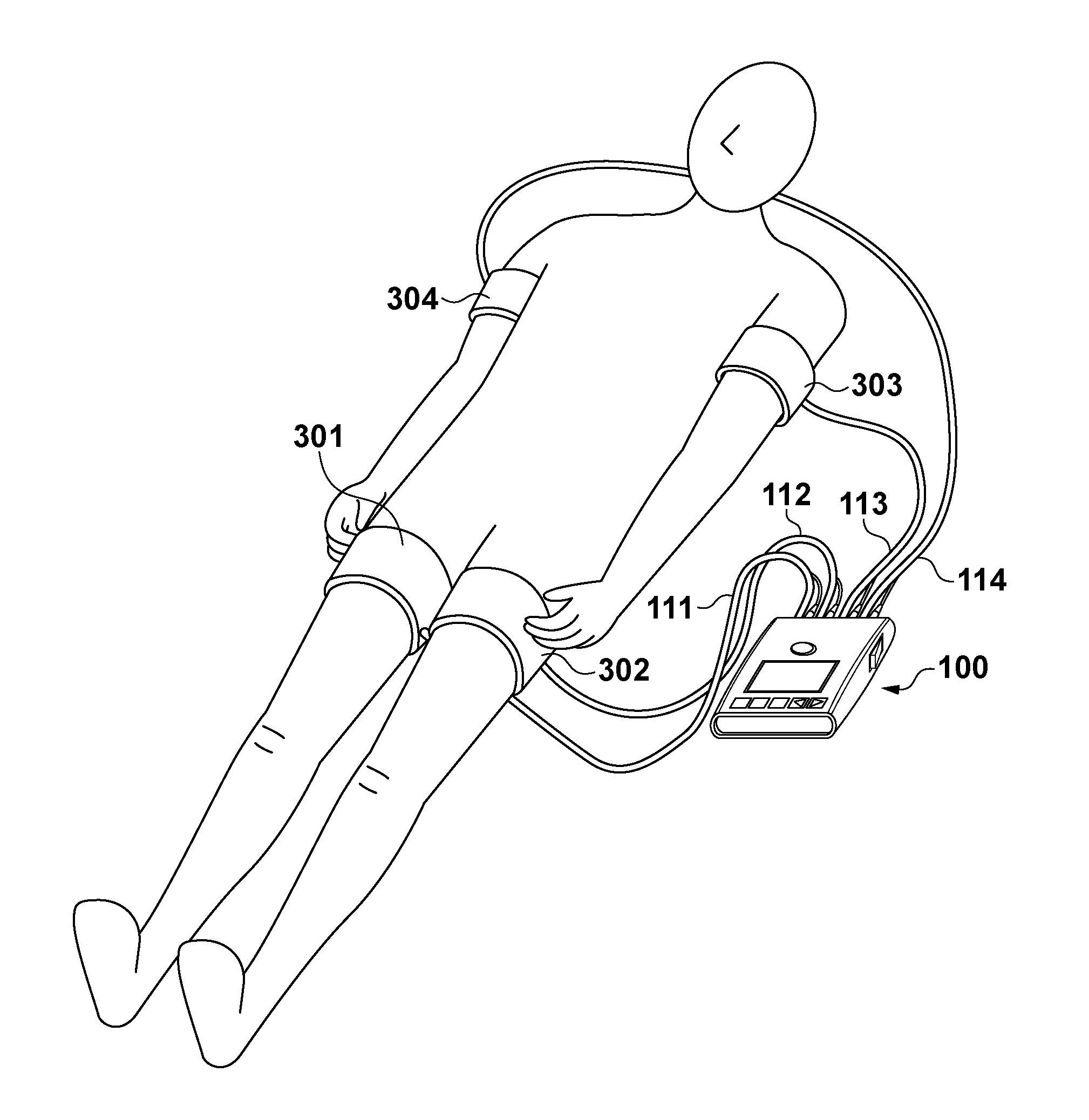

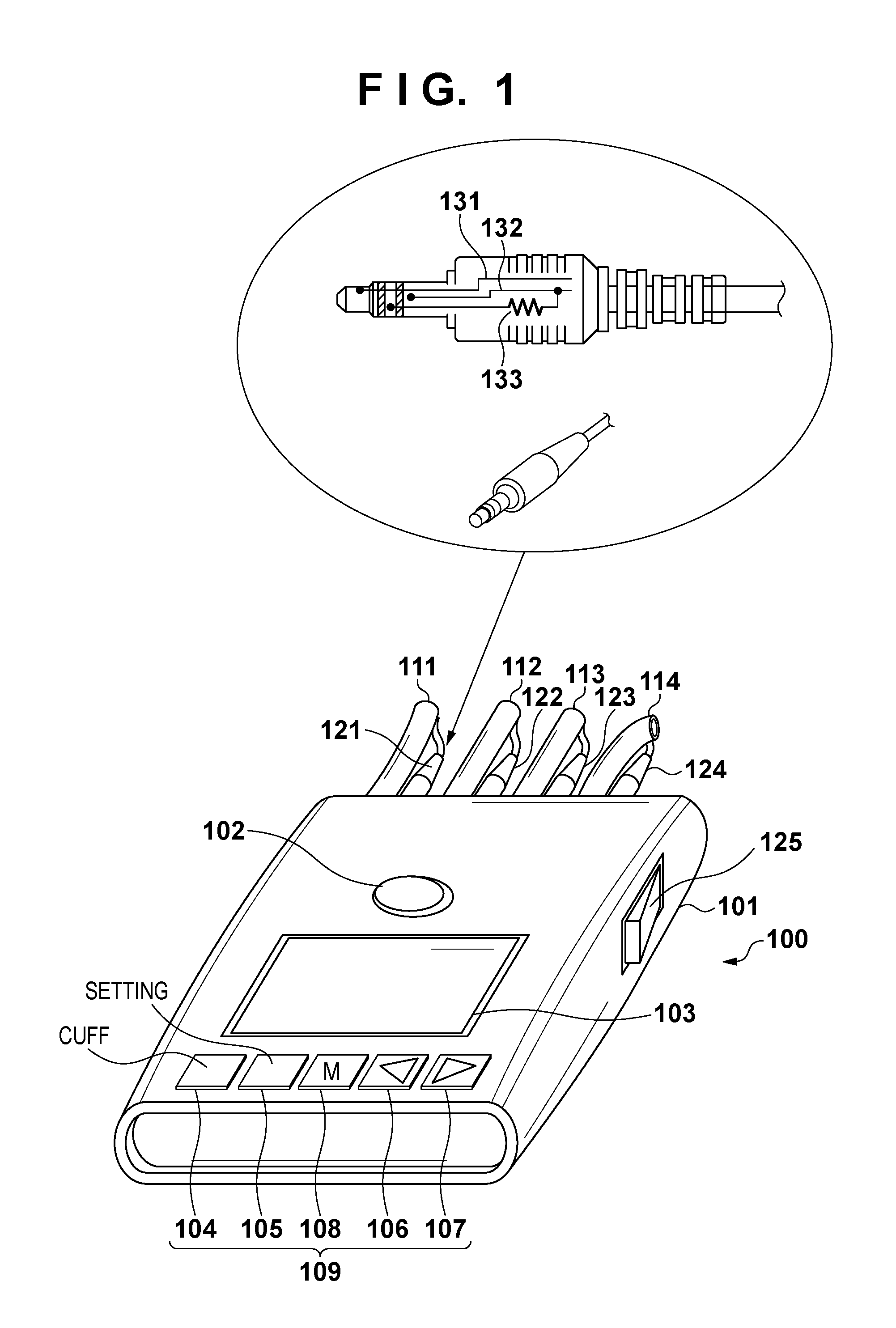

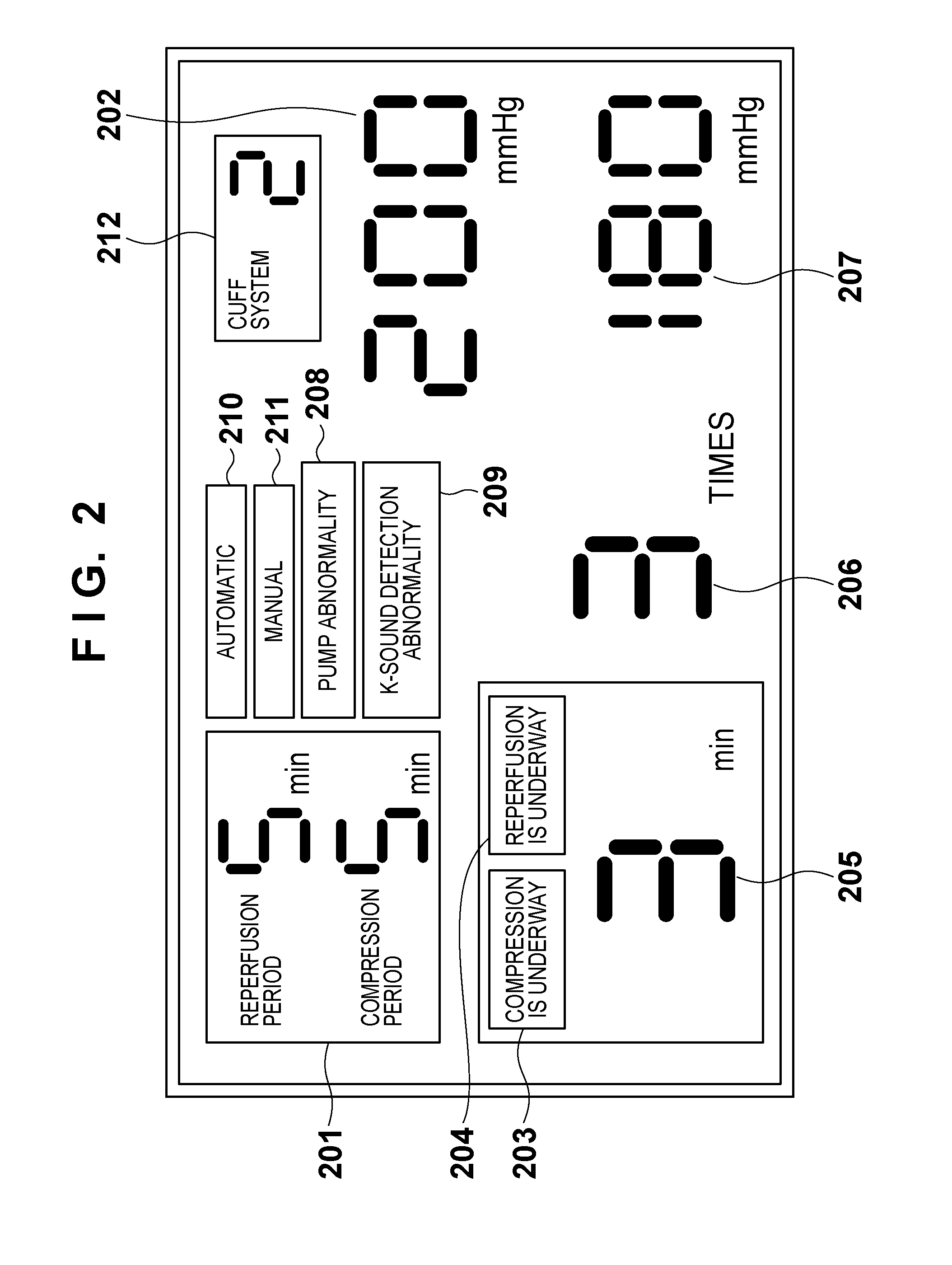

Limb compression device and control method

InactiveUS20140024986A1Eliminate pulsationPneumatic massageEvaluation of blood vesselsBlood pressureCompression device

A limb compression device to which a cuff unit wound around a limb of a patient is connected controls compression and release of the limb by controlling air supply and exhaust of the cuff unit to repeat an compression period and a reperfusion period a predetermined number of times. At the start of the compression period, pressurization using the cuff unit is performed up to a compression pressure value based on a systolic blood pressure of the patient measured by detection of pulsation. During the compression period, the device repeats depressurization of the cuff unit at a low rate until pulsation is detected and pressurization of the cuff unit after the depressurization so as to eliminate pulsation.

Owner:TERUMO KK

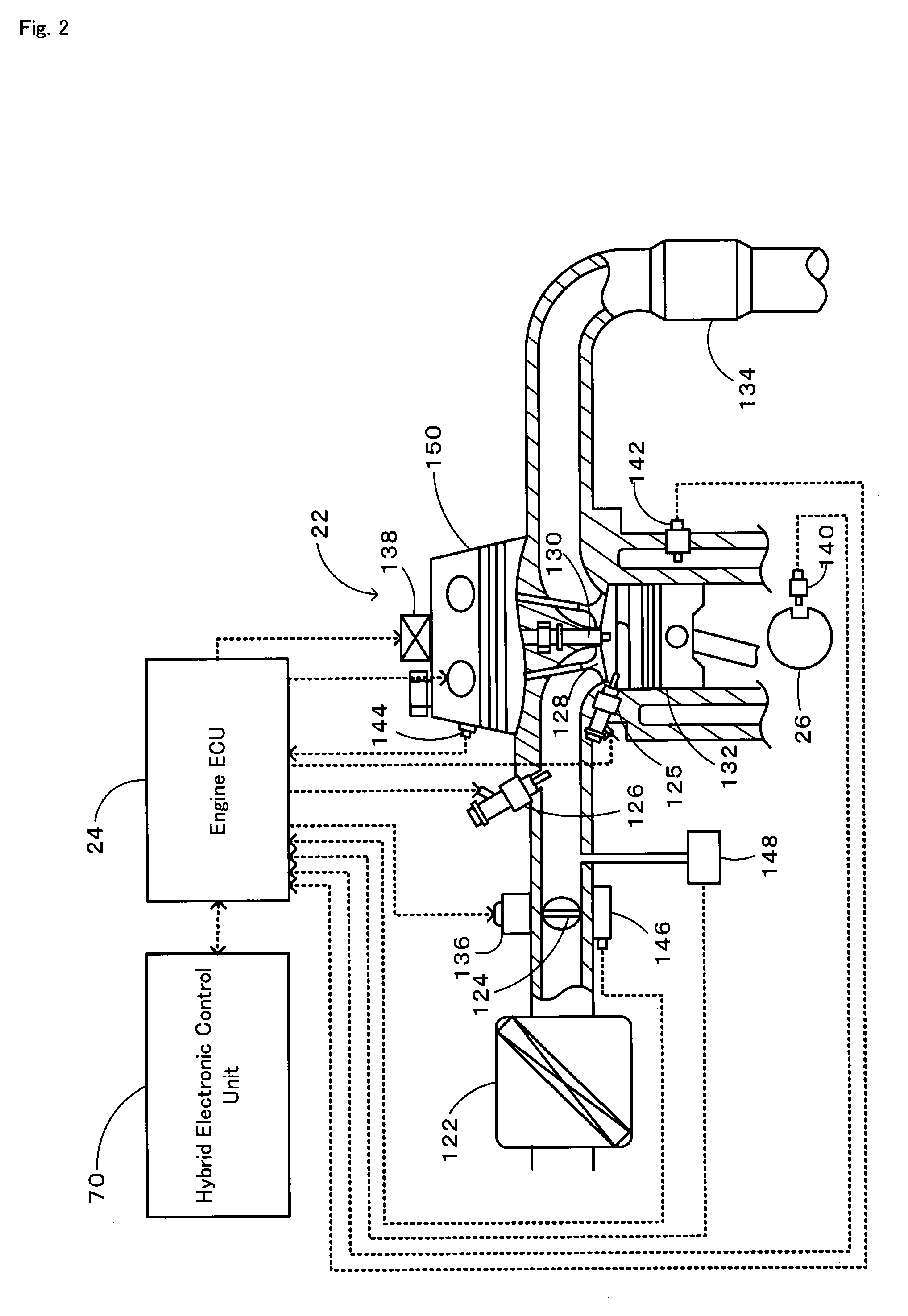

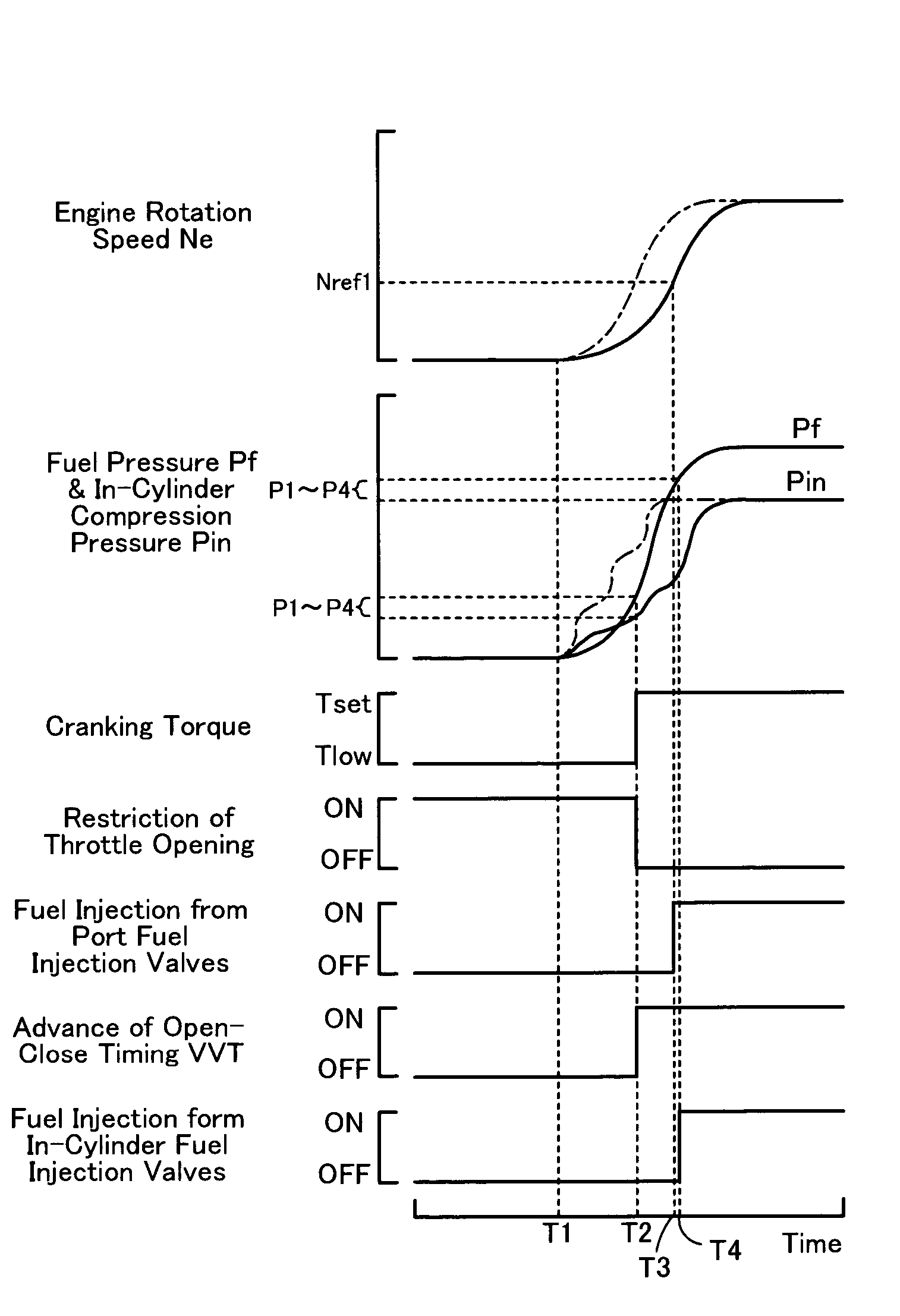

Internal combustion engine system and starting method of internal combustion engine

InactiveUS20060060162A1Increase riseSealing property is deterioratedElectrical controlMachines/enginesEngineeringInternal combustion engine

The start control procedure of the invention lags an open-close timing VVT of an intake valve, restricts a throttle opening TH of a throttle valve, and starts cranking an engine with a lower torque Tlow. When a pressure Pf of a fuel supplied to in-cylinder fuel injection valves reaches or exceeds a preset reference value, which is greater than a sum of an in-cylinder compression pressure Pin and a closed valve position-retaining pressure Pcv of the in-cylinder fuel injection valves, the start control procedure cranks the engine with a standard cranking torque Tset. The start control procedure then starts advance of the open-close timing VVT of the intake valve, cancels the restriction of the throttle opening TH, and starts fuel injection from the in-cylinder fuel injection valves. This arrangement enables the fuel pressure Pf to quickly rise to or above the sum of the in-cylinder compression pressure Pin and the closed valve position-retaining pressure Pcv, and thereby effectively prevents the in-cylinder fuel injection valves from being inadequately opened.

Owner:TOYOTA JIDOSHA KK

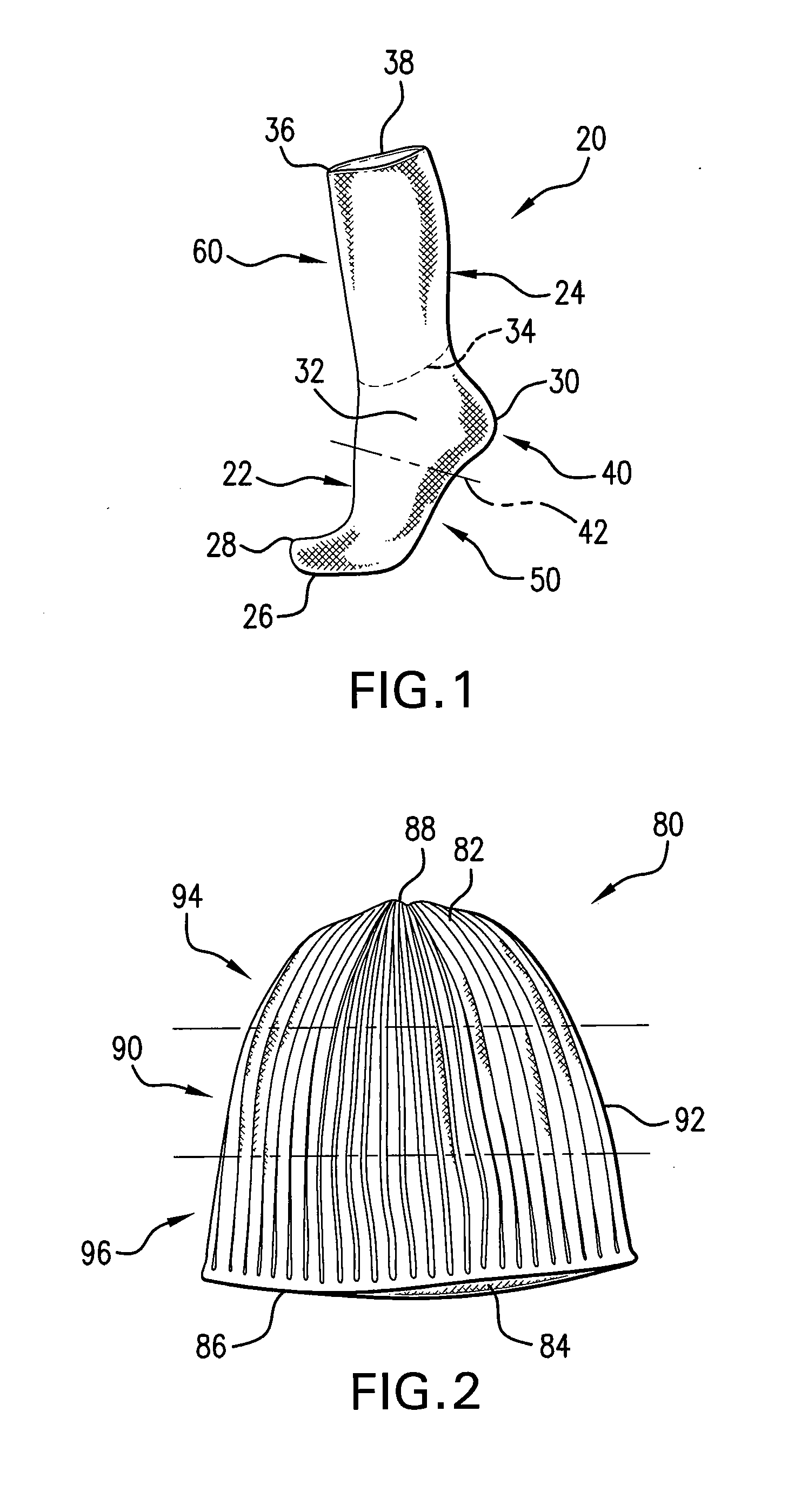

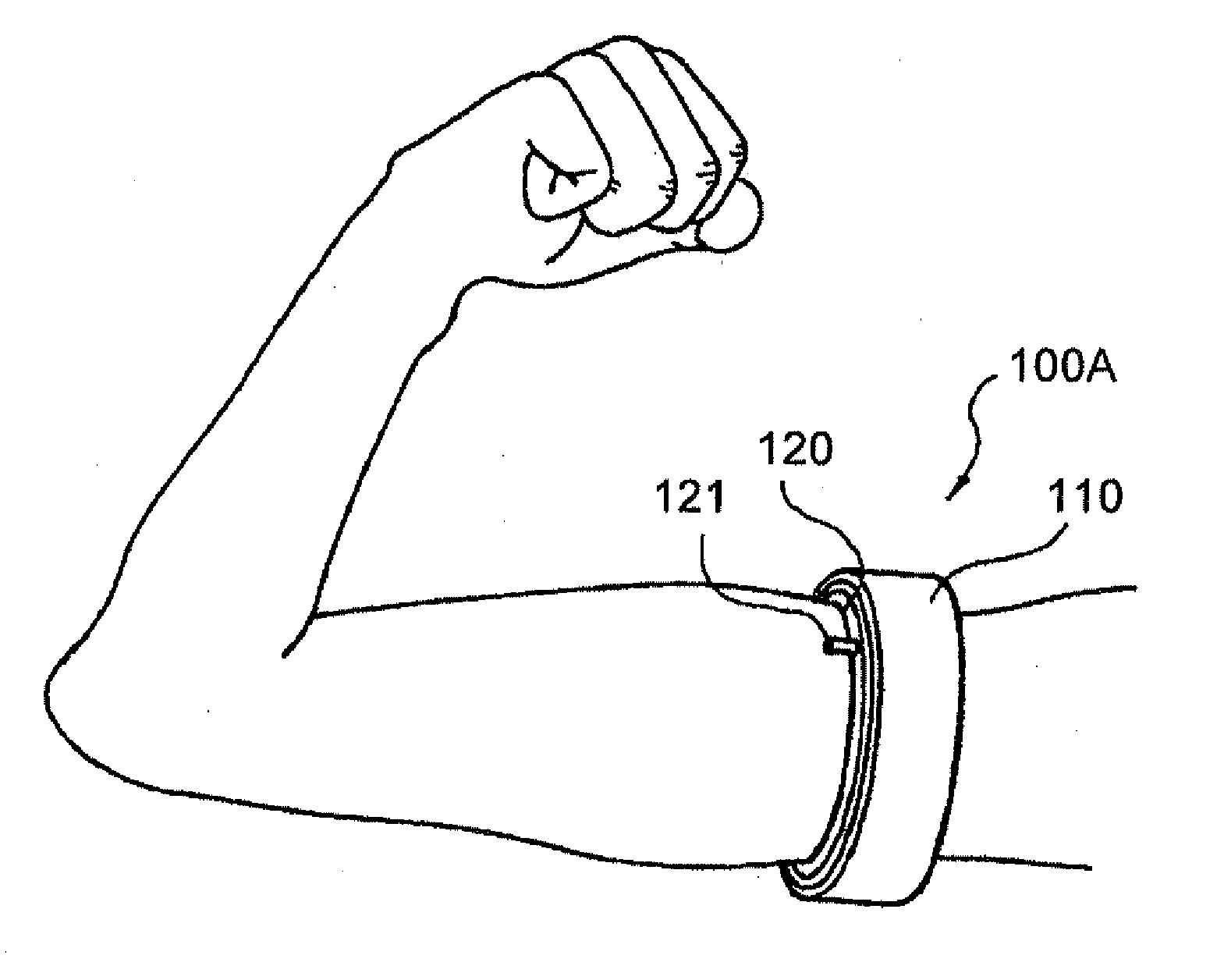

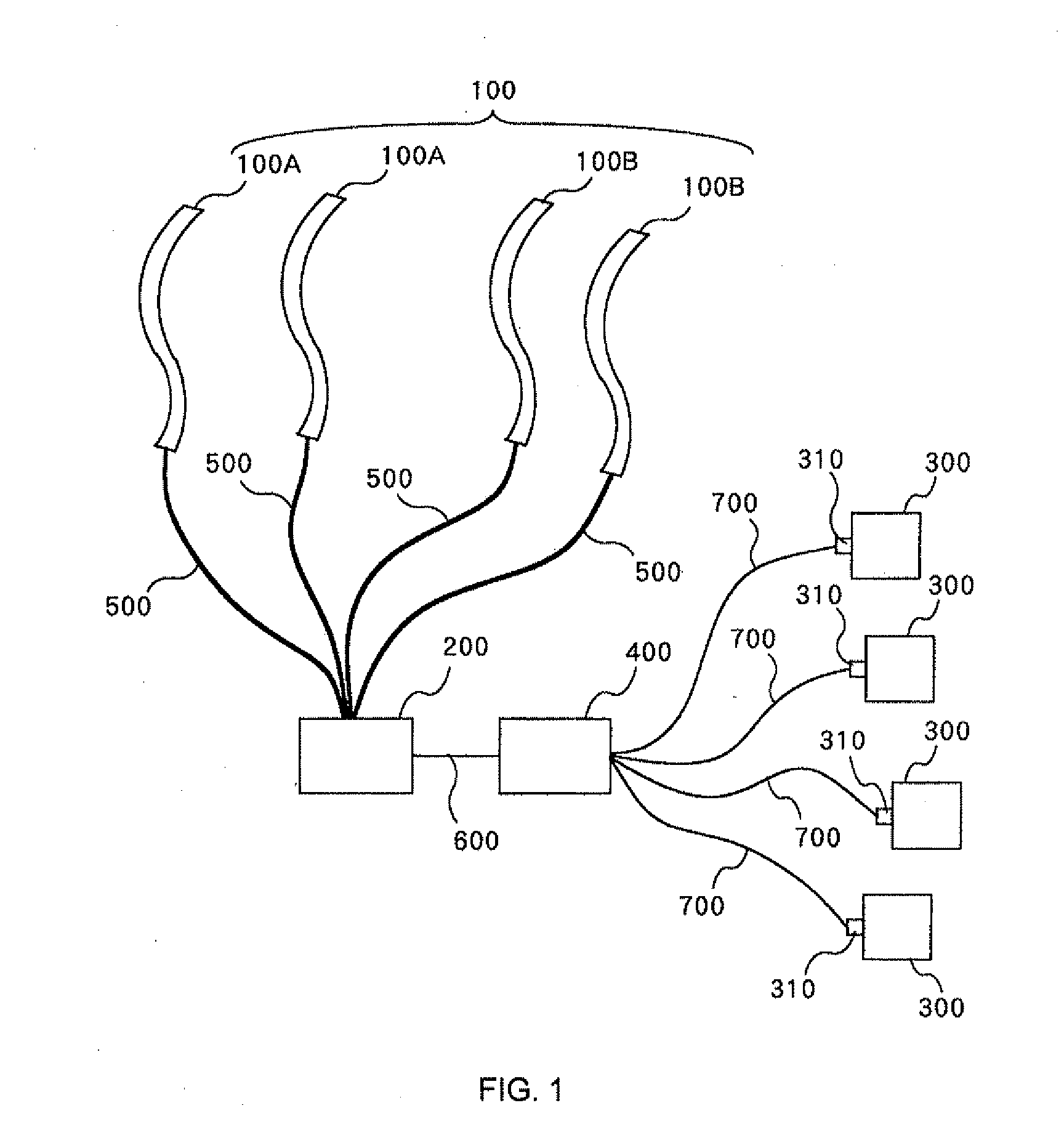

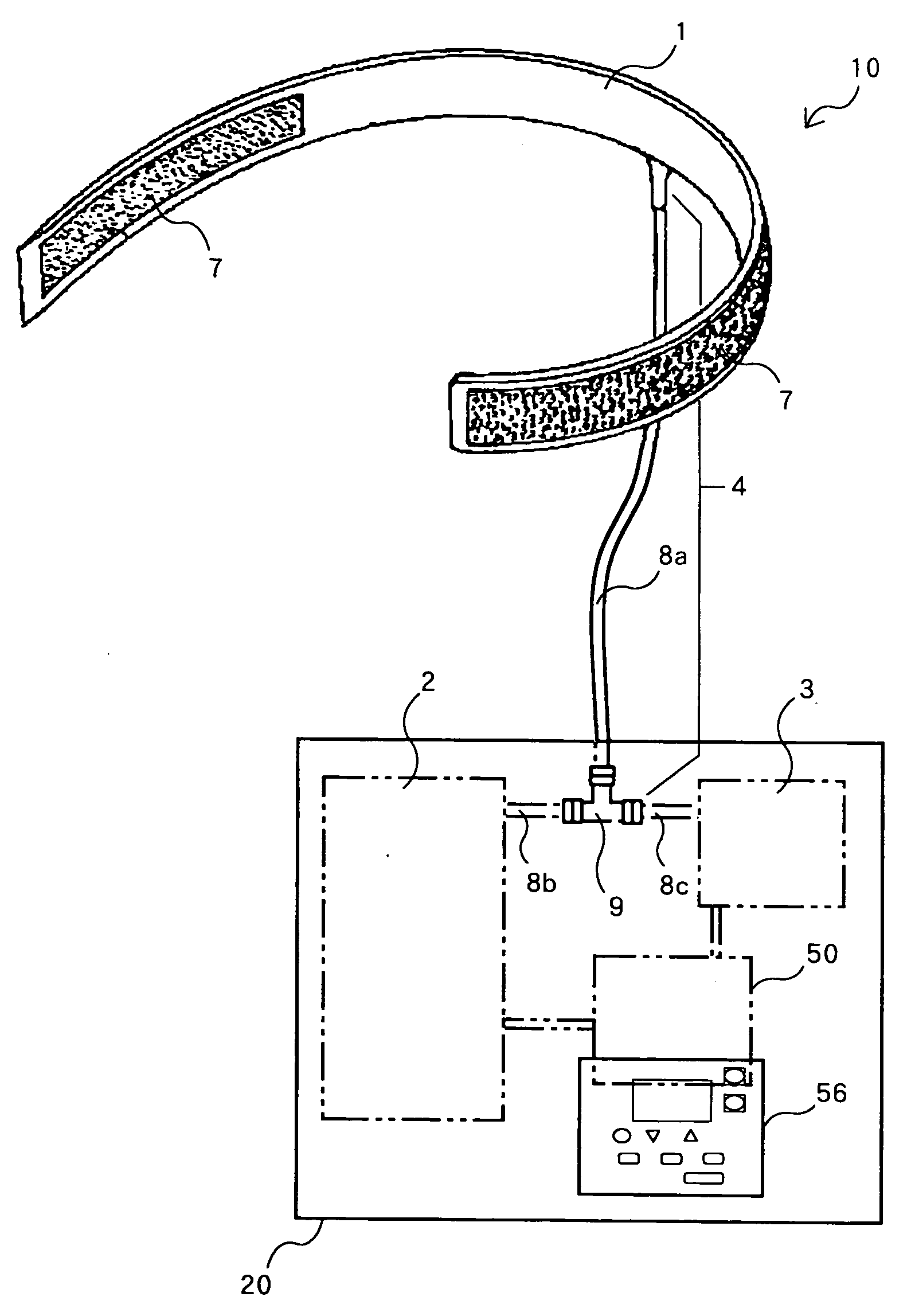

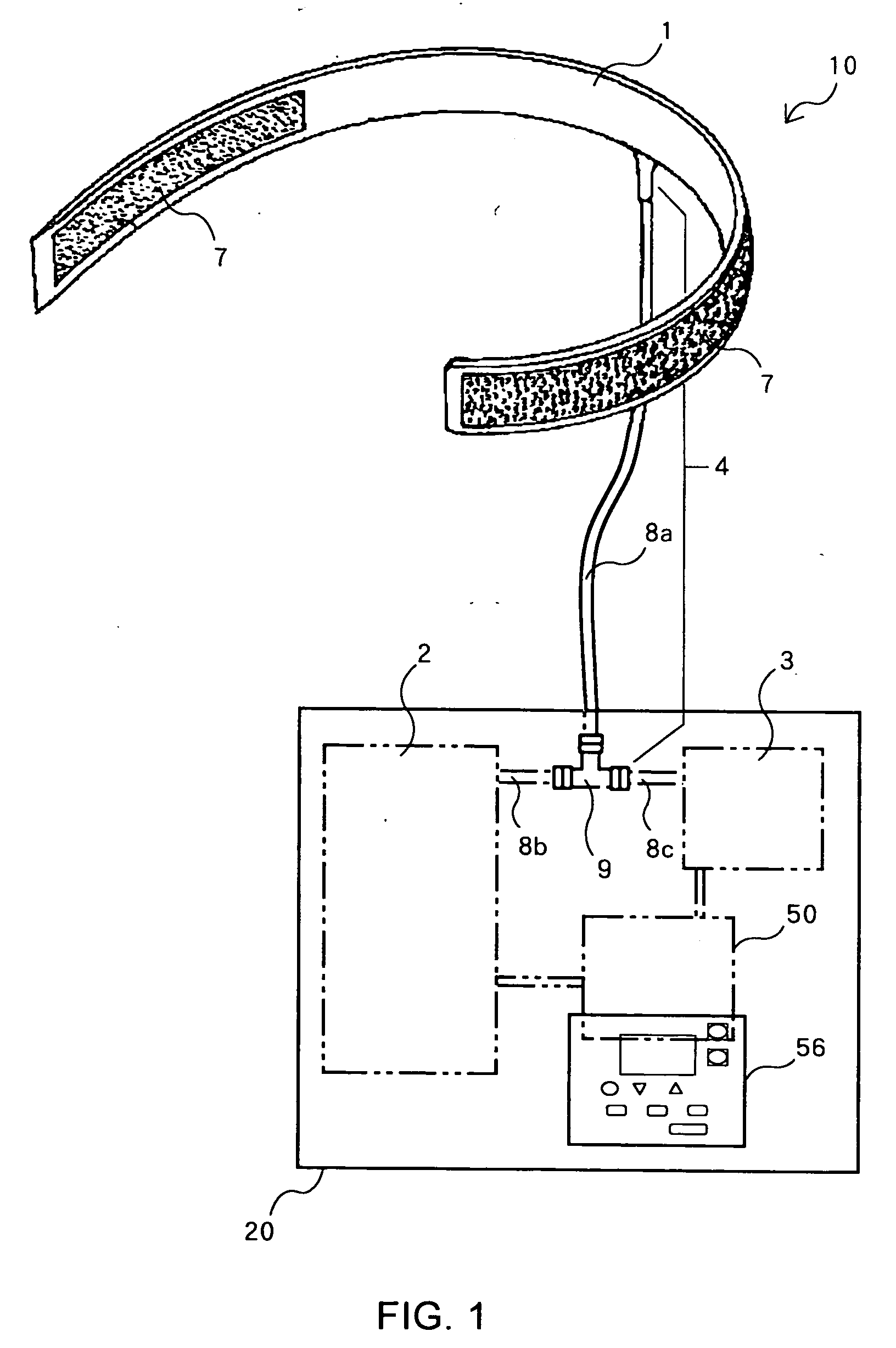

Therapeutic system, therapeutic device, and control method

InactiveUS20110125036A1Reduce pressurePneumatic massageEvaluation of blood vesselsTherapeutic DevicesEngineering

To provide a therapeutic system which is based on the KAATSU training and which is suitable for treating metabolic syndrome.A therapeutic system is comprised of a tight fitting device 100, a body segment 200, a measuring segment 300, and a control segment 400. The tight fitting device 100 is wrapped around a predetermined range on the limb. The tight fitting device 100 has an air-tight gas bag and can change a compression pressure to be applied to the limb by means of introducing and removing air into and from the gas bag. The body segment 200 controls the flow of the air into and from the gas bag. The measuring segment 300 is attached to the limb around which the tight fitting device 100 is wrapped and measures the amplitude of pulse wave. The control segment 400 determines an air pressure within the gas bag at the time point at which the amplitude of the pulse wave reaches its maximum, during preprocessing that is performed prior to the treatment, and uses it as the pressure within the gas bag for the treatment.

Owner:KAATSU JAPAN

Compactor Systems and Methods for Compacting a Mass

A compactor system for compressing a mass including liquid and solids includes: a pressure vessel defining a pressure chamber to hold the mass; a compaction mechanism to compress the mass in the pressure chamber to remove the liquid from the solids; a drain port communicating with the pressure chamber and through which the removed liquid drains out of the pressure chamber; drain piping fluidly connected to the drain port to direct the removed liquid to a collection site; and an influent system configured to inject an influent fluid into the pressure chamber through the drain port.

Owner:CONTAINER PRODS

Method to determine TDC in an internal combustion engine

InactiveUS7117080B2Efficient developmentHigh in technologyInternal-combustion engine testingAnalogue computers for vehiclesInternal combustion engineFlywheel

A method and apparatus for accurately determining TDC in a cylinder of an internal combustion engine. Gas pressure is measured in the cylinder relative to crank angle, giving rise to a curve of gas pressure with crank angle. An offset is found by first computing the angular position of an inflexion point of the compression pressure curve measured as a function of the crank angle, and then computing the offset as the difference between the angular position of a piston in the cylinder and a theoretical value for said angular position of the piston dependent on a known or measured flywheel angle. The value of TDC corrected by the offset is then used to calculate a value of work output such as the Indicated Mean Effective Pressure (IMEP) which may be used for diagnostic and / or control purposes.

Owner:ABB (SCHWEIZ) AG

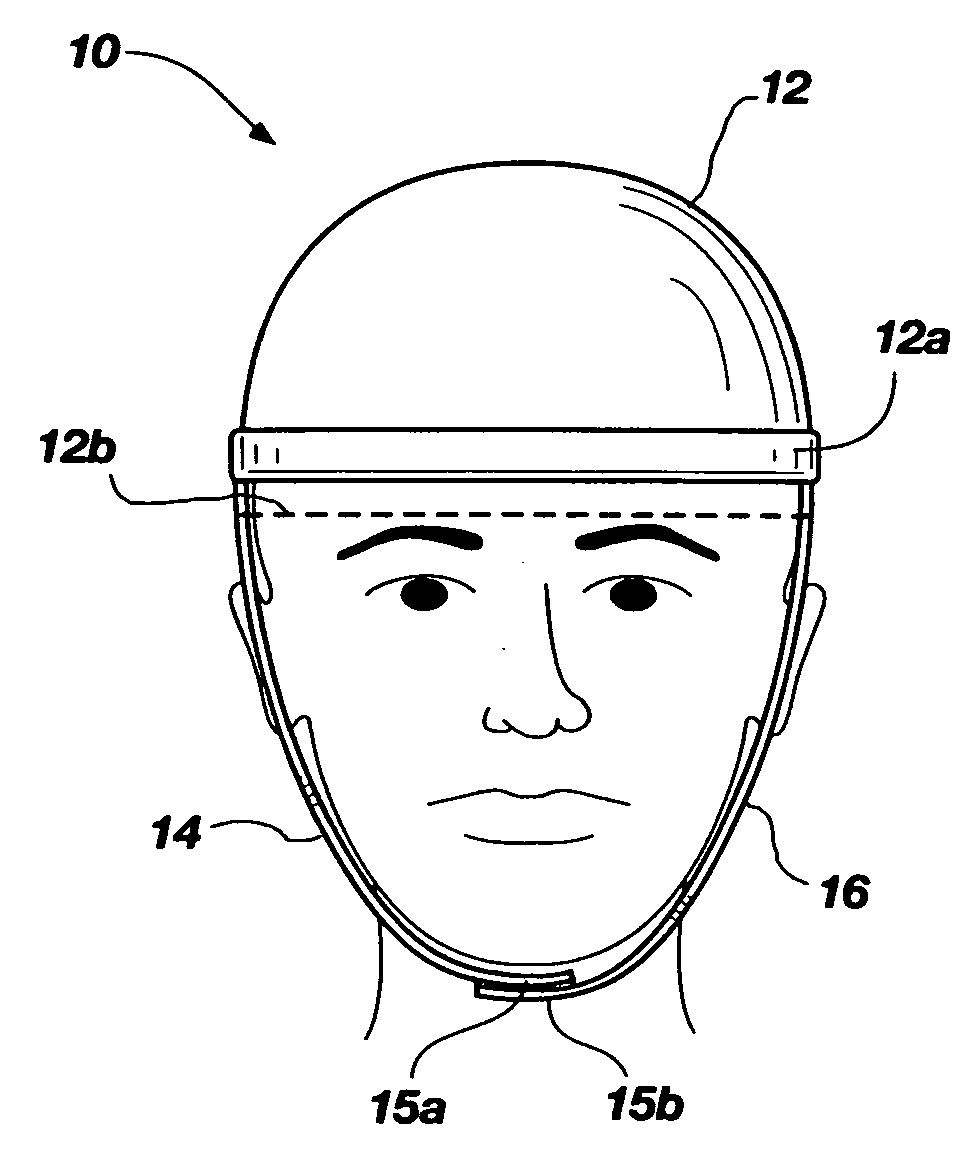

Method for lowering blood glucose levels, method of treating diabetes, and method of prevention of diabetes

InactiveUS20060201522A1Lower blood sugar levelsRestricted blood flowDiagnosticsTourniquetsBlood flowGlucose lowering

To provide a method of lowering blood glucose levels and a method of treating and preventing diabetes. A belt-shaped compression strip 1 is fitted around a tightened area near the proximal end of an arm or a leg of a user and is fastened round the area. In this way, a compression pressure of on the order of 150 mmHg is applied to the tightened area to restrict blood flow through limbs receiving the compression pressure. This condition is held for about 15 minutes. During that time a user may keep rest or may do light exercises, which lowers a blood glucose level of the user. This provides treatment for diabetes for a diabetes patient and provides prevention of diabetes for a person who has a risk of developing diabetes.

Owner:KAATSU JAPAN

Musclar strength increasing system and pressurizing force control device of musclar strength increasing tool

To provide a muscle strength increasing system that is configured to allow more effective muscle development without any extra effort of a wearer. A muscle strength increasing system has a muscle strength increasing device 10 and a compression pressure control unit 20. The muscle strength increasing device 10 includes a tight fitting band 1 having a tube provided therein and a fixing unit 7 for keeping the diameter of a loop formed by the tight fitting band 1. A pressure muscle training method is performed by introducing the air into the tube to apply, with the tight fitting band 1 being wrapped around a predetermined range to be compressed of a limb and fastened with the fixing unit 7, a predetermined compression pressure to the limb around which the tight fitting band 1 is wrapped, thereby restricting the blood flow. The compression pressure control unit 20 controls a built-in pump 2 to automatically control the compression pressure within a range that does not exceed a preset compression pressure.

Owner:SATO SPORTS PLAZA CO LTD

Internal combustion engine system and starting method of internal combustion engine

InactiveUS7281509B2Start fastIncrease riseElectrical controlOutput powerExternal combustion engineInlet valve

The start control procedure of the invention lags an open-close timing VVT of an intake valve, restricts a throttle opening TH of a throttle valve, and starts cranking an engine with a lower torque Tlow. When a pressure Pf of a fuel supplied to in-cylinder fuel injection valves reaches or exceeds a preset reference value, which is greater than a sum of an in-cylinder compression pressure Pin and a closed valve position-retaining pressure Pcv of the in-cylinder fuel injection valves, the start control procedure cranks the engine with a standard cranking torque Tset. The start control procedure then starts advance of the open-close timing VVT of the intake valve, cancels the restriction of the throttle opening TH, and starts fuel injection from the in-cylinder fuel injection valves. This arrangement enables the fuel pressure Pf to quickly rise to or above the sum of the in-cylinder compression pressure Pin and the closed valve position-retaining pressure Pcv, and thereby effectively prevents the in-cylinder fuel injection valves from being inadequately opened.

Owner:TOYOTA JIDOSHA KK

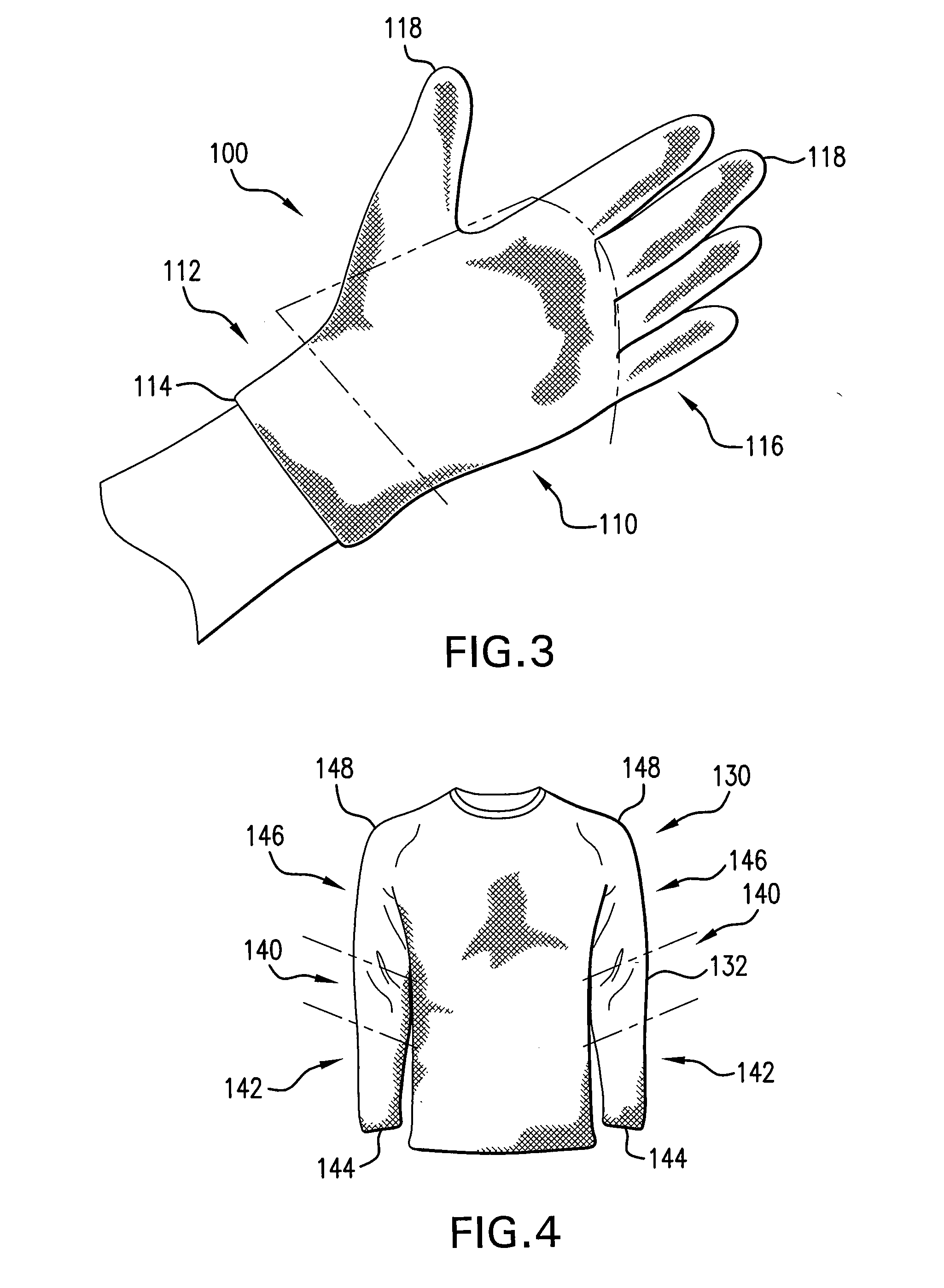

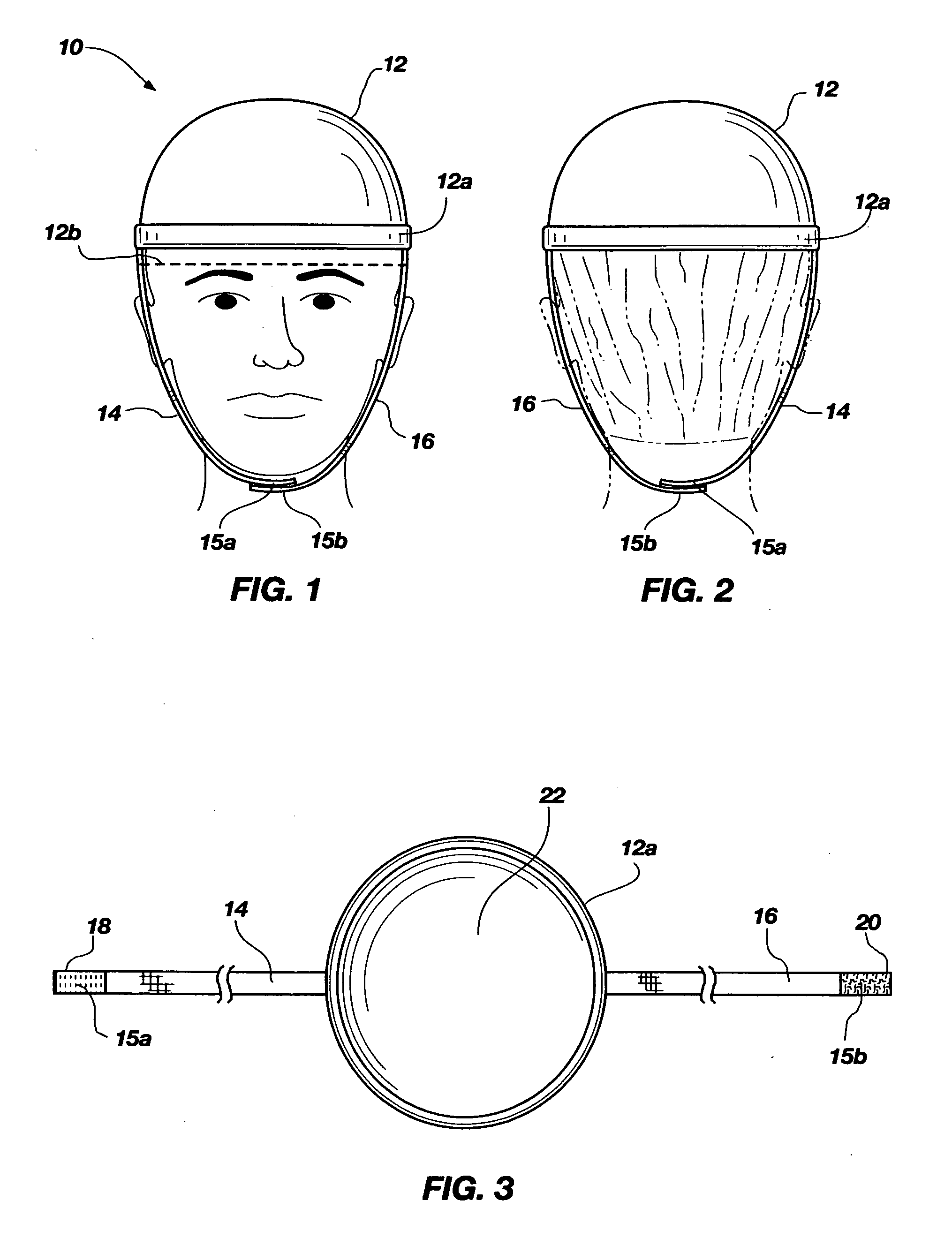

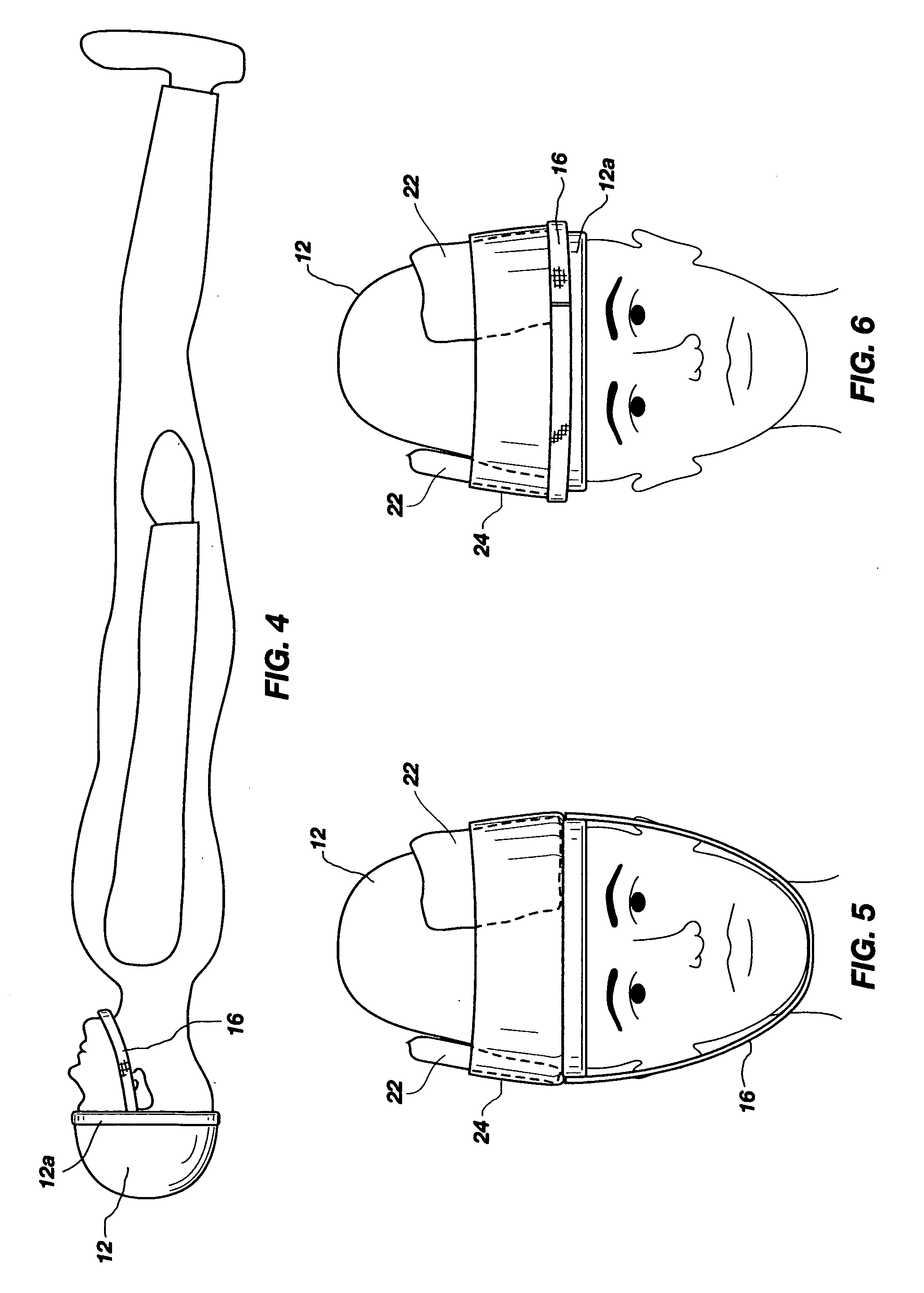

Head trauma cap bandage and method

InactiveUS20090299259A1Fast and easy to applyAbsorb and control bleedingHead bandagesNeck bandagesCervical spine immobilizationEmergency medicine

An emergency head trauma cap bandage and method of use, which, when applied, applies compression pressure to stop bleeding, doesn't compromise cervical spine immobilization, doesn't come apart during treatment and transport, and doesn't require a caregiver to re-wrap the dressing.

Owner:CUMMING MICHELLE +1

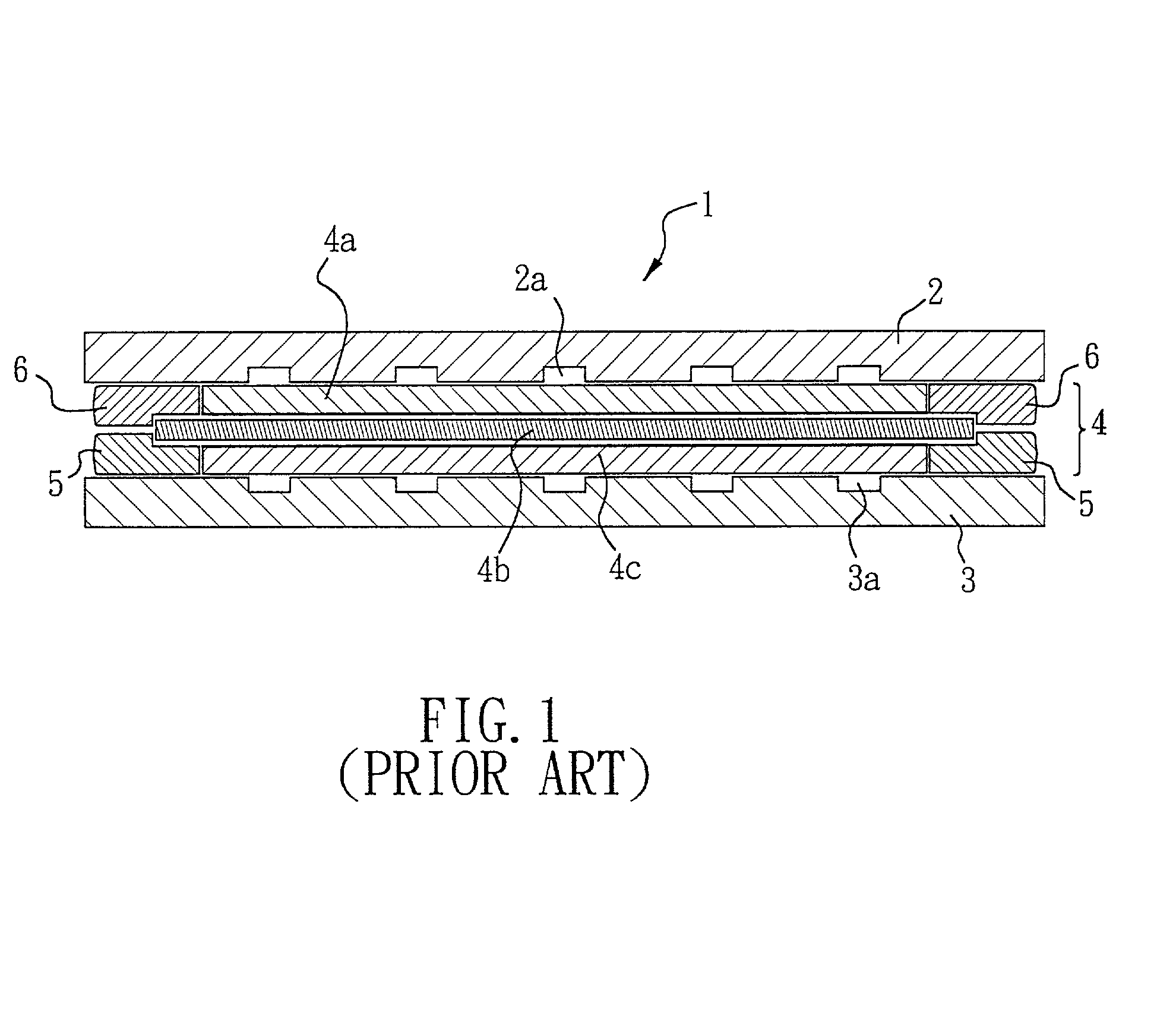

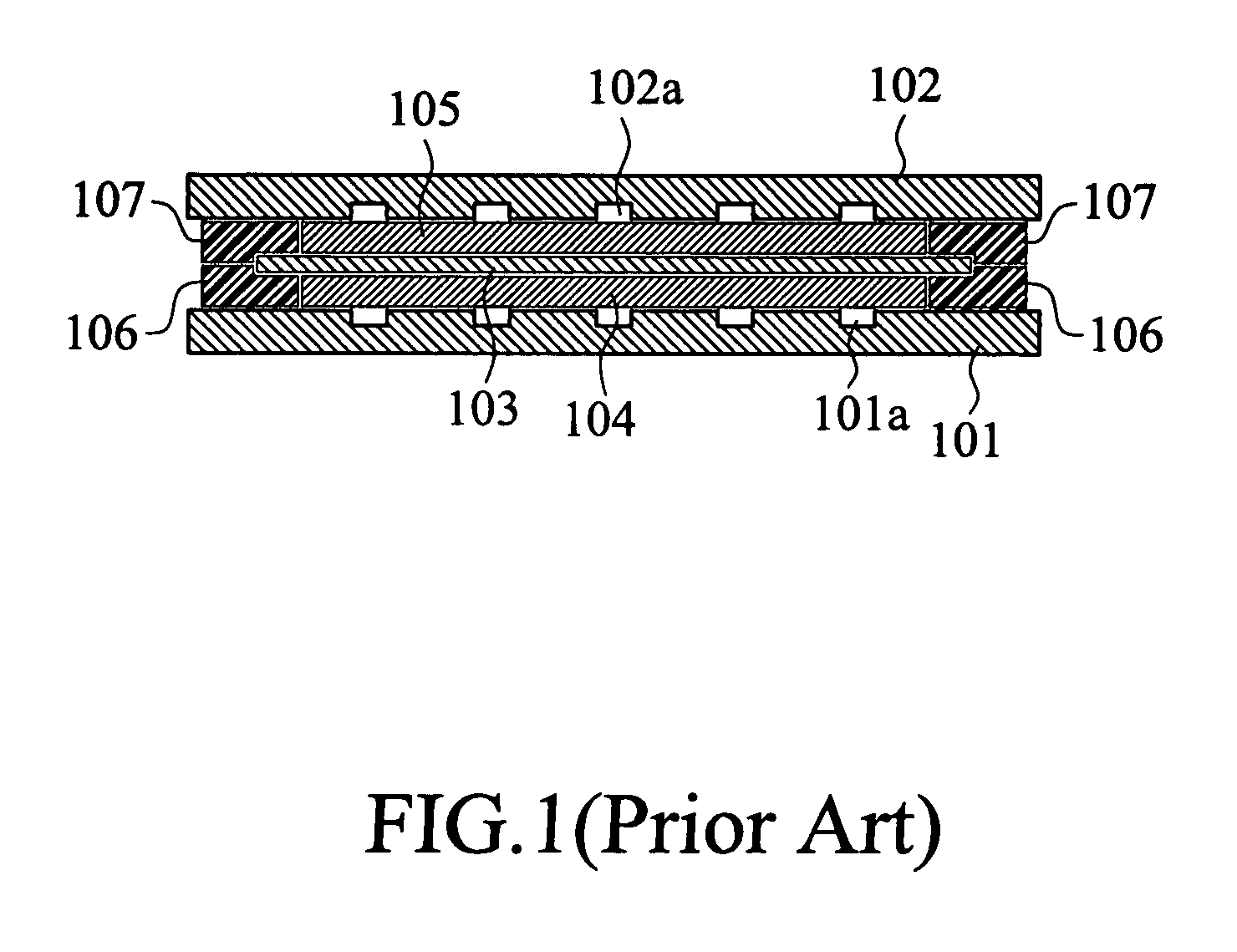

Sealing structure for sealing separator plates of fuel cell modules

ActiveUS20050130016A1Simple manufacturing processImprove fuel qualityFuel cells groupingFuel cell auxillariesEngineeringProton exchange membrane fuel cell

A sealing structure for sealing a proton exchange membrane fuel cell is disclosed. The fuel cell includes a membrane electrode assembly, an anode plate, and a cathode plate. Both of the plates are formed with a peripheral groove and an extended groove at a circumferential portion thereof, and silicon rubber is applied to the peripheral groove and the extended groove. Before the silicon rubber is cured, the anode plate, the membrane electrode assembly and the cathode plate are stacked and compressed with a predetermined compression pressure, such that the silicon rubber at the peripheral groove of the anode plate binds correspondingly to the silicon rubber at the peripheral groove of the cathode plate to form a tight sealing at the circumferential portions between the anode plate and the cathode plate, and the membrane electrode assembly is tightly sandwiched between the silicon rubber at the extended groove of the anode plate and the silicon rubber at the extended groove of the cathode plate to form a tight sealing around the ports between the anode plate and cathode plate.

Owner:ASIA PACIFIC FUEL CELL TECH

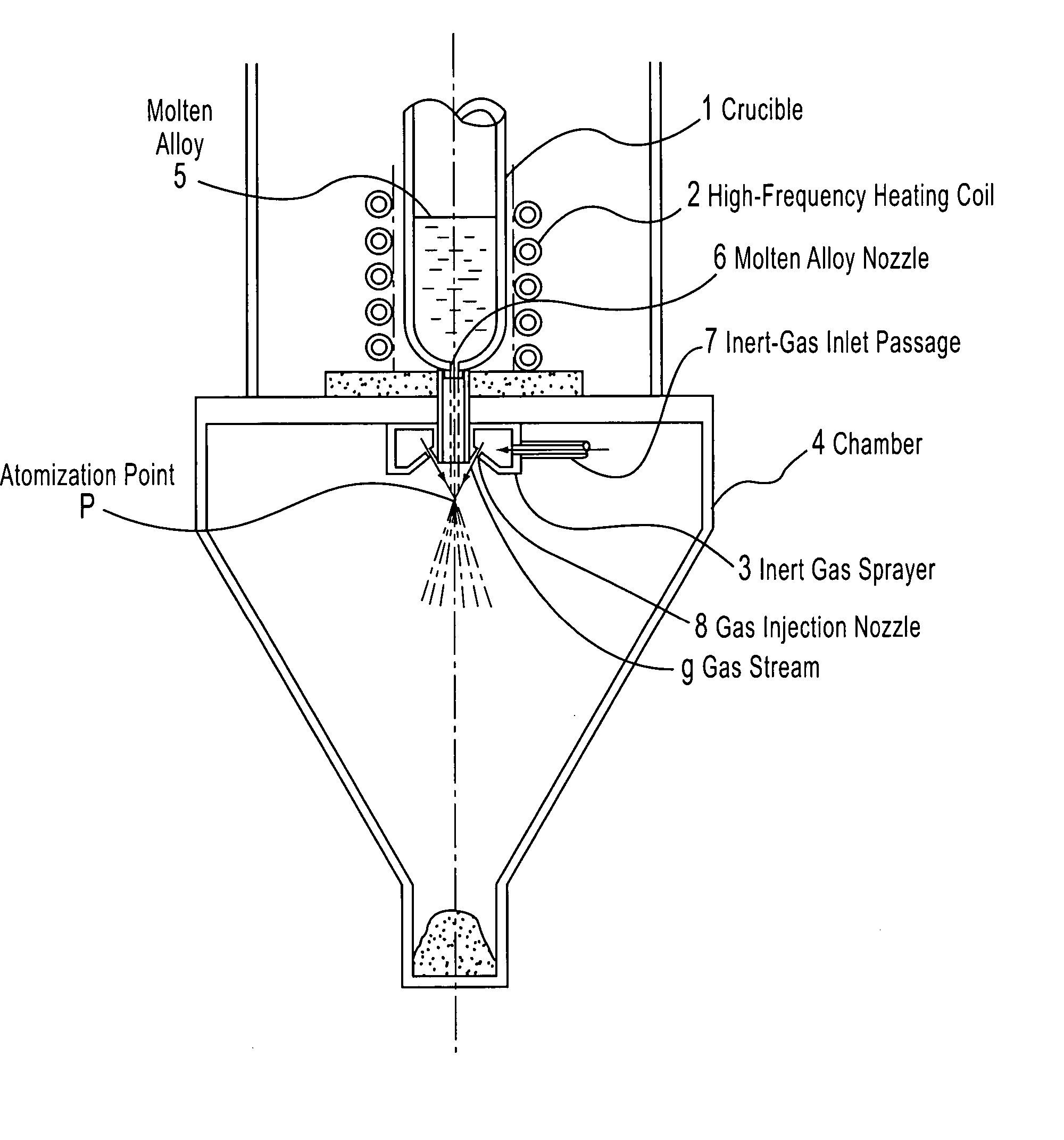

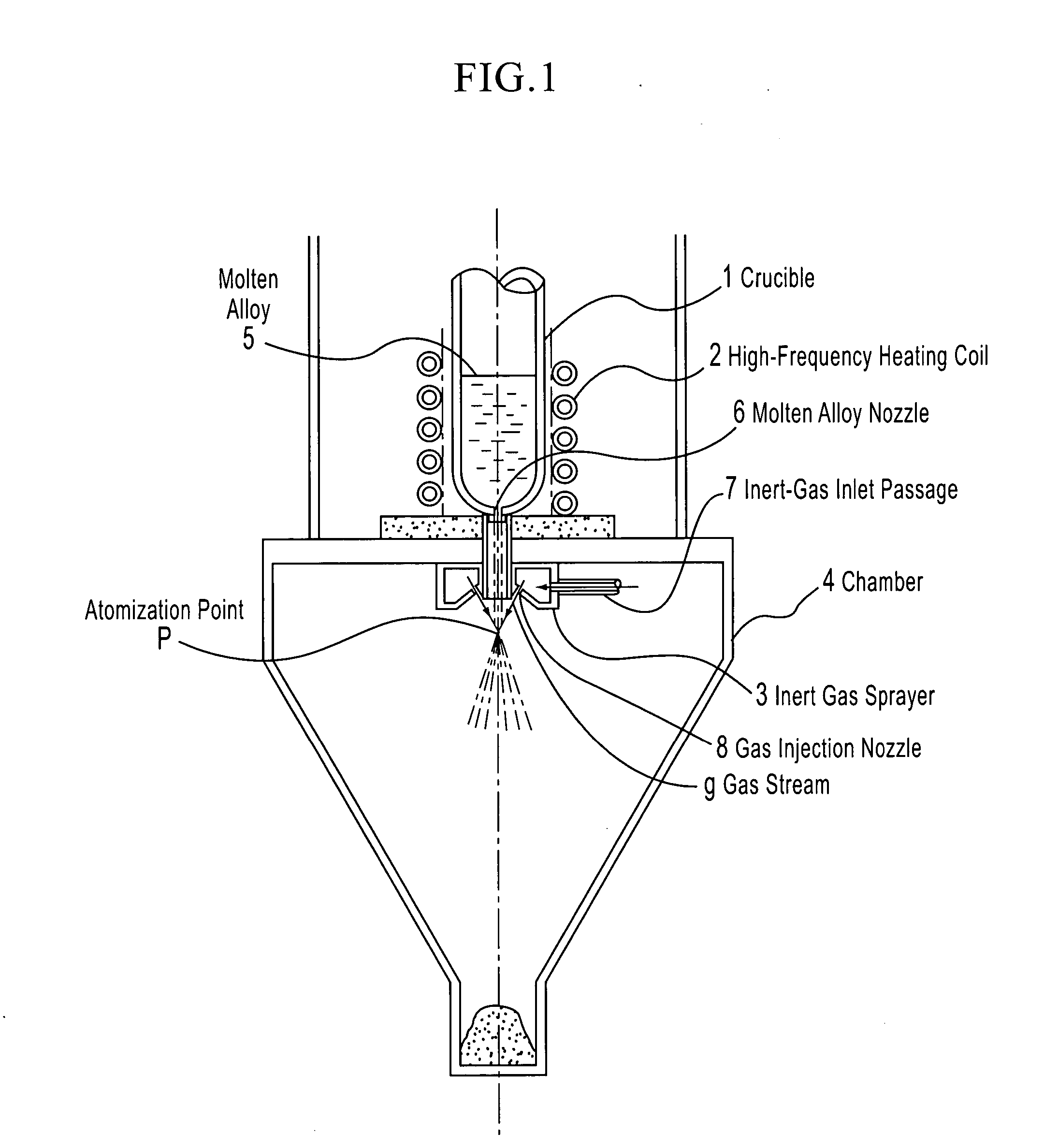

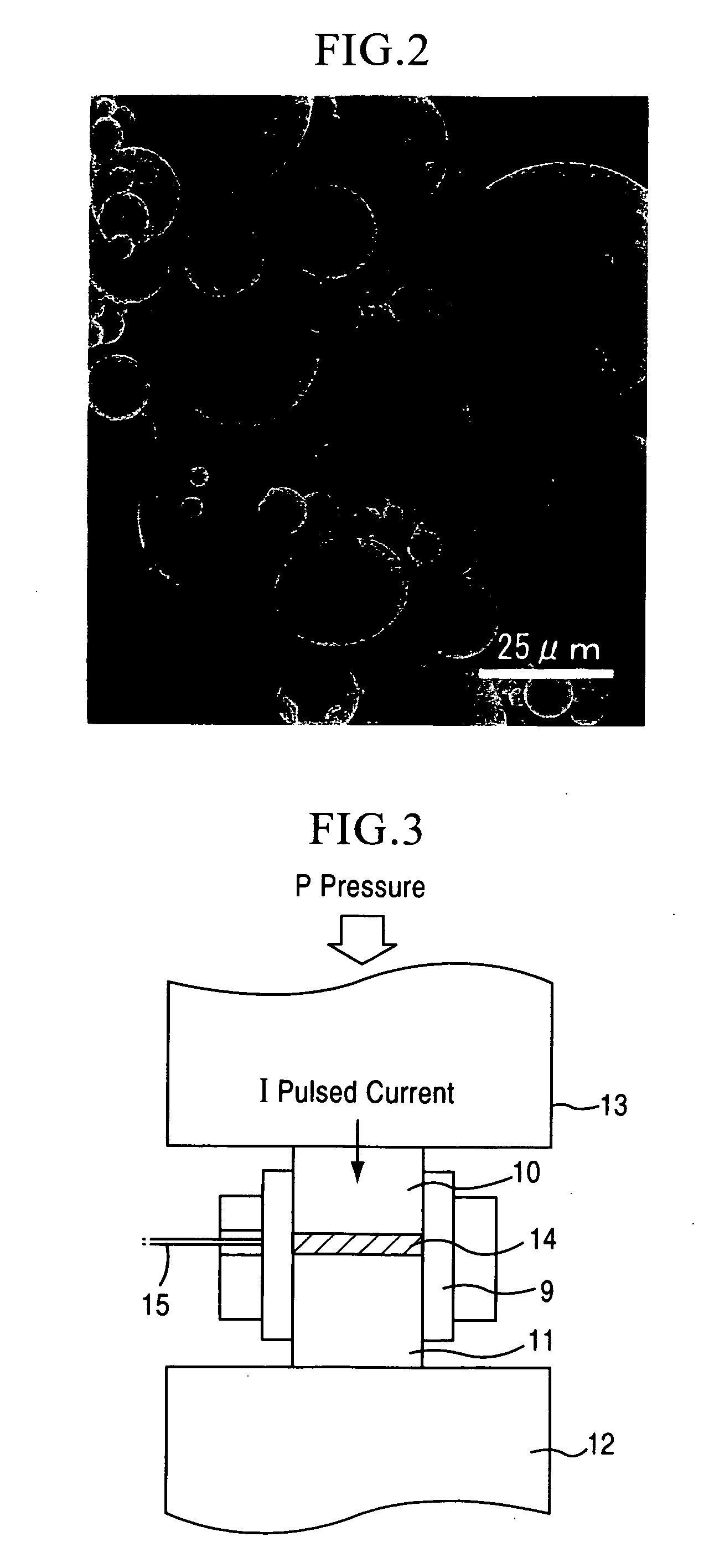

Spherical particles of fe base metallic glass alloy, fe base sintered alloy soft magnetic material in bulk form produced by sintering the same, and method for their production

InactiveUS20060254386A1High amorphous-alloy forming abilityExcellent soft magnetic propertiesTransportation and packagingMetal-working apparatusTransformerSpherical shaped

Disclosed is a Fe—Ga—P—C—B—Si based metallic glass alloy particle prepared by a gas atomizing process, which has an approximately complete spherical shape, a relatively large particle size and a high crystallization temperature (Tx). The plurality of particles may be subjected to a spark plasma sintering process at the crystallization temperature or less under a compression pressure of 200 MPa or more, to provide a bulk Fe-based sintered metal soft magnetic material of metallic glass, which has a high density, a single phase structure of metallic glass in an as-sintered state, excellent soft magnetic characteristics applicable to a core of a magnetic head, a transformer or a motor, and a high specific resistance.

Owner:JAPAN SCI & TECH CORP

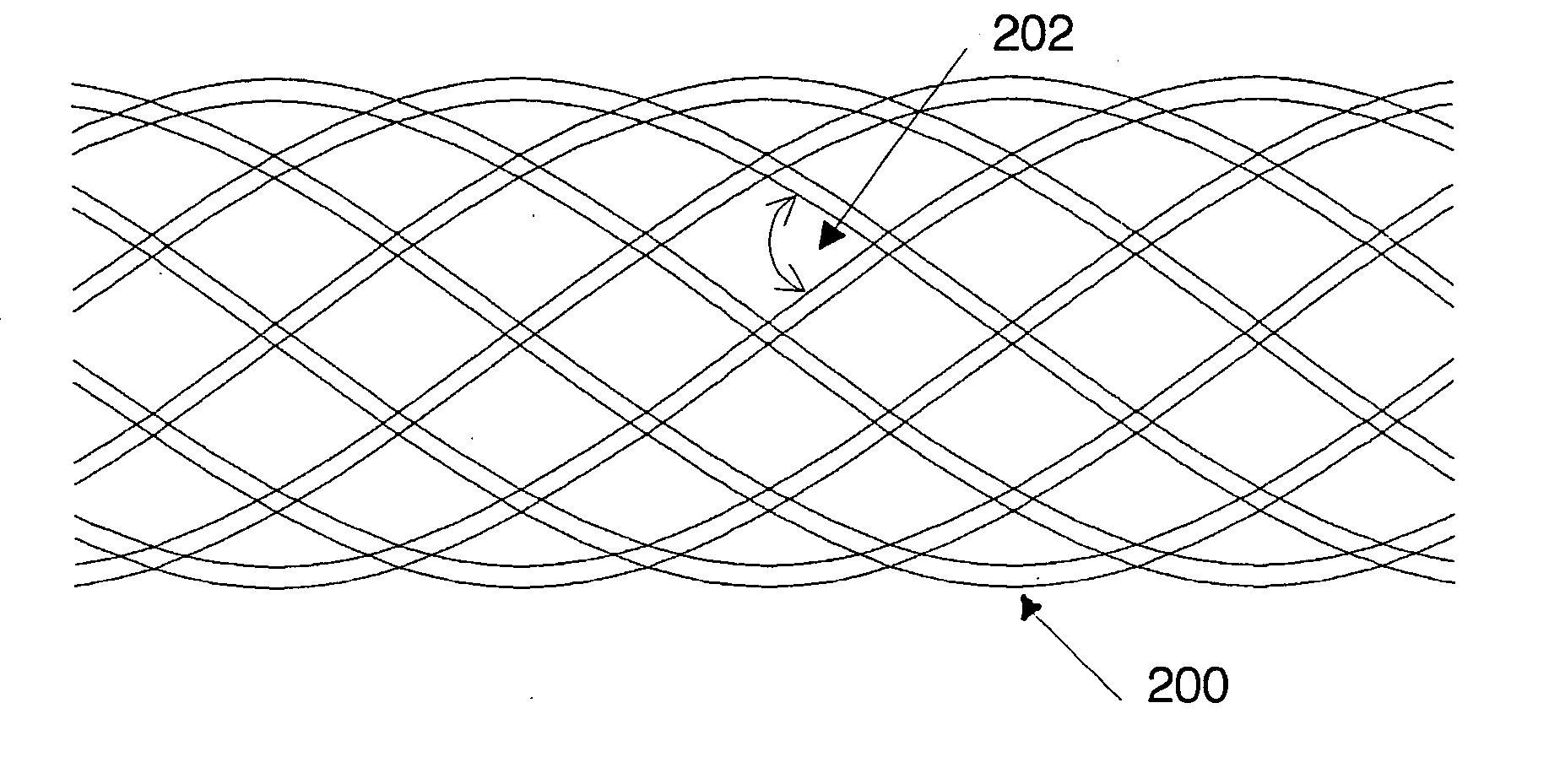

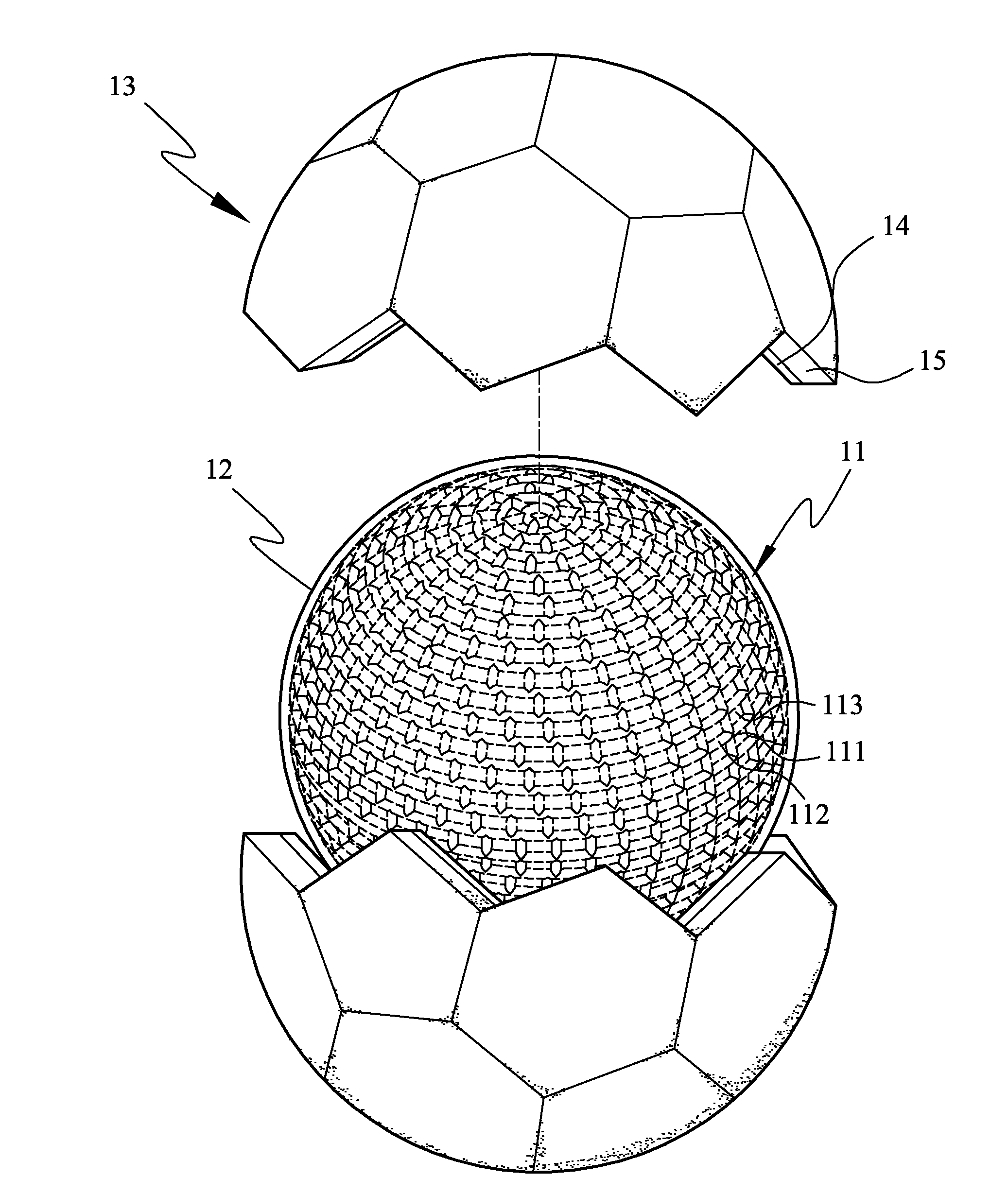

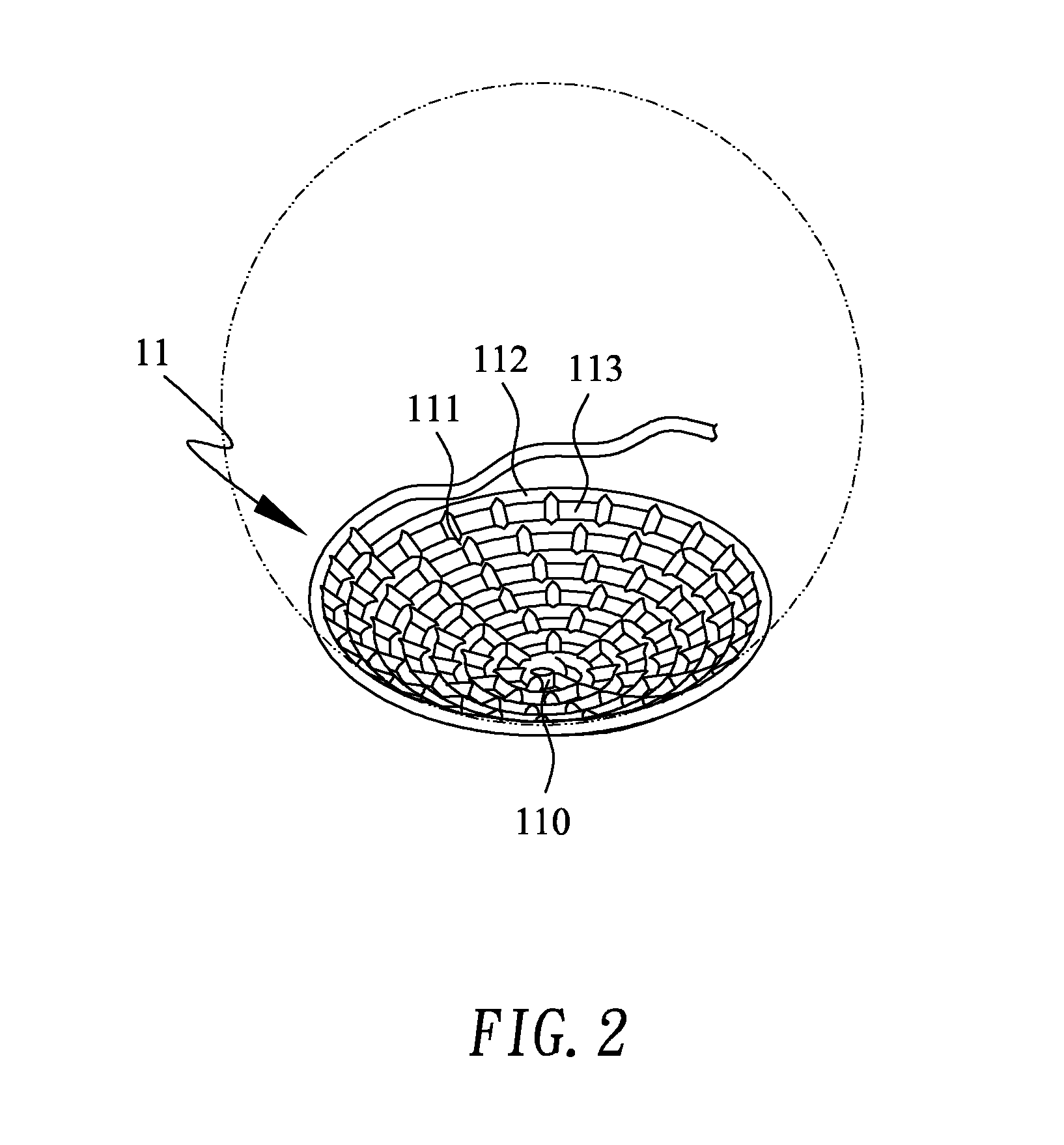

Inner bladder structure for ball

InactiveUS20110177895A1Effectively control expansion degreeEasily subject to deformationWeft knittingHollow inflatable ballsYarnEmulsion

A ball inner bladder structure, particularly suitable for a seamless ball, includes a bladder in the form of a spherical bag, a yarn layer enclosing the bladder, an emulsion layer applied over the yarn layer, and a ball cover layer bonded to the emulsion layer. The yarn layer is an integrally knitted web structure having a 3D spherical shape. Knitted yarns subjected to pressure can displace relative to one another to finely adjust a surface configuration of the web structure for the same to completely bear against the bladder. The emulsion layer fills up voids on the yarn layer to provide a smooth spherical surface. The specifically knitted yarn layer can effectively control an expansion degree of the bladder when the same is inflated. And, expansion or compression pressure applied to the bladder is uniformly distributed over interlocking points of knitted yarns, preventing the bladder from deformation and breaking.

Owner:LONG WAY ENTERPRISE

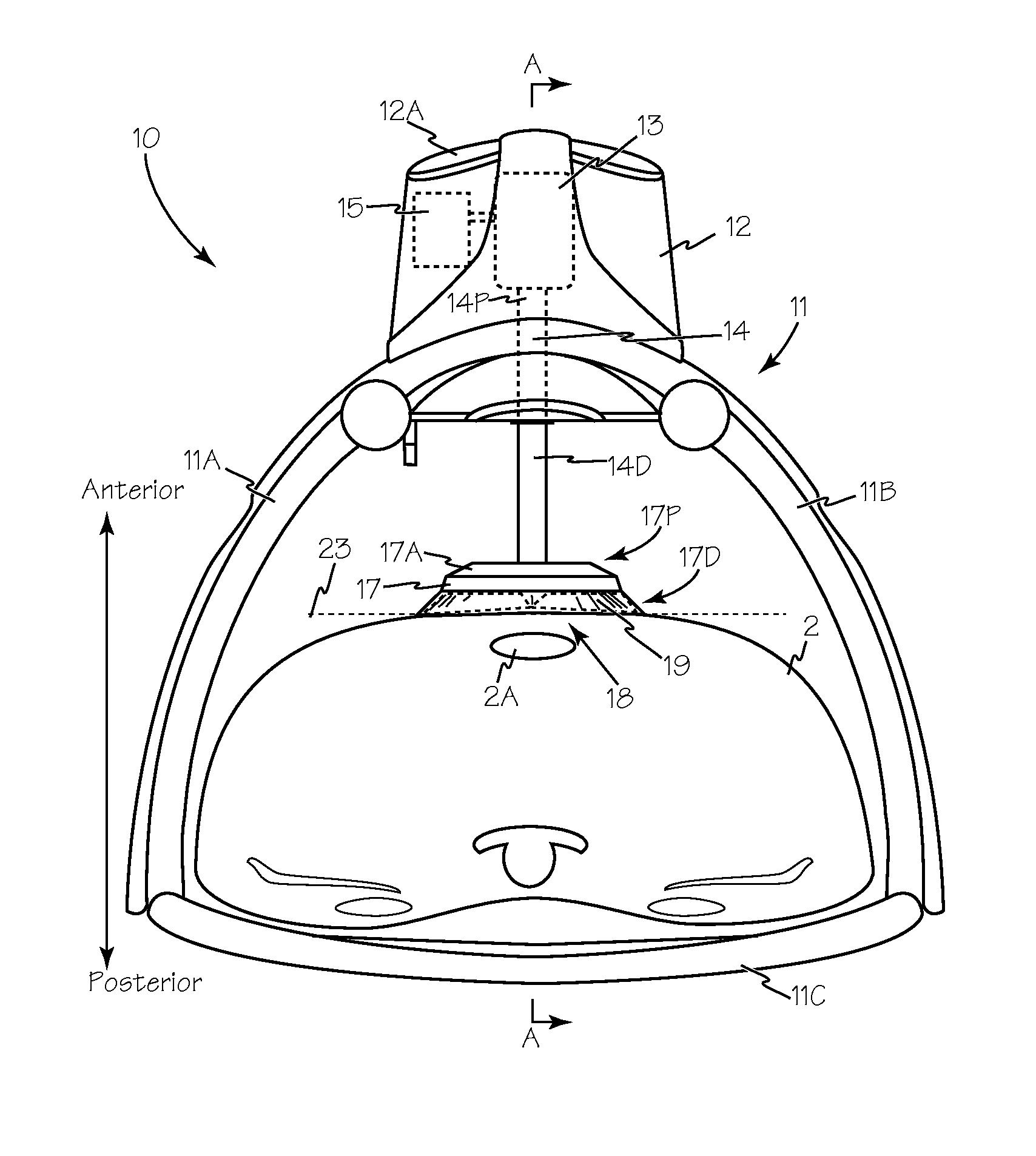

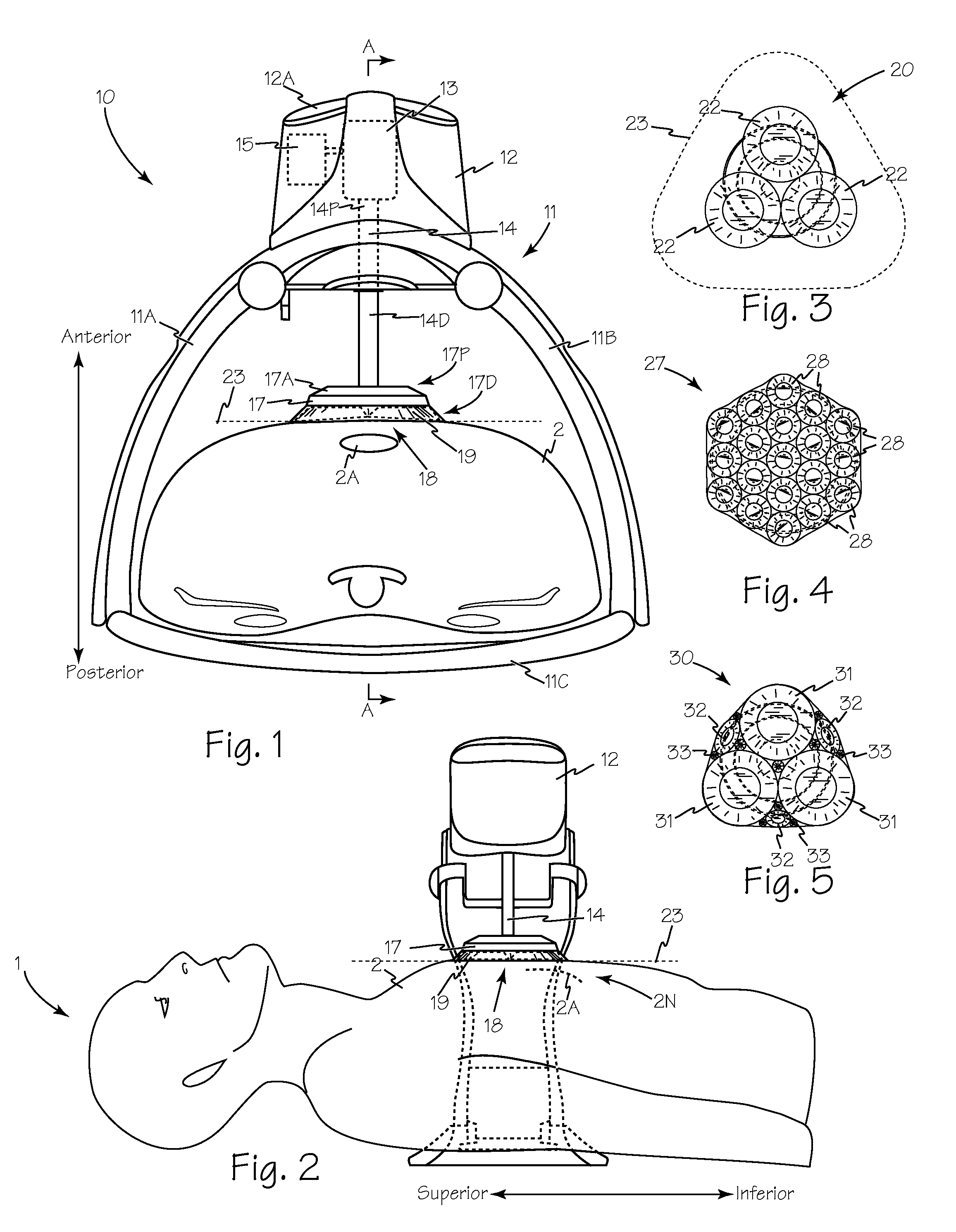

Method and Device for Performing Alternating Chest Compression and Decompression

ActiveUS20140094724A1Easy to attachOptimizes decompression forceElectrotherapyDiagnosticsCompression devicePhysical therapy

A plunger adapter and a detachable compression pad for piston driven chest compression devices optimizes the application of chest compressions to a fixed location on a patient's chest. The detachable compression pad may be removably secured to the patient above the patient's sternum to ensure that the compression pressure from the piston through the piston adapter is applied to a fixed location on the patient's chest. As the plunger and plunger adapter retract from the chest, the compression pad remains fixed to the patient's chest, and as the plunger and plunger adapter extend from the chest compression unit for subsequent compression strokes, the distal end of the plunger adapter reengages the compression pad to apply compression to a fixed location on the patient's chest.

Owner:ZOLL MEDICAL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com