Return flow scavenging type hydraulic free piston diesel engine

A diesel engine and scavenging technology, which is applied in the direction of free piston engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of many intermediate transmission links, low mechanical efficiency, and complicated mechanisms, so as to improve passability and mobility, improve Effects of fuel economy and guaranteed thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings.

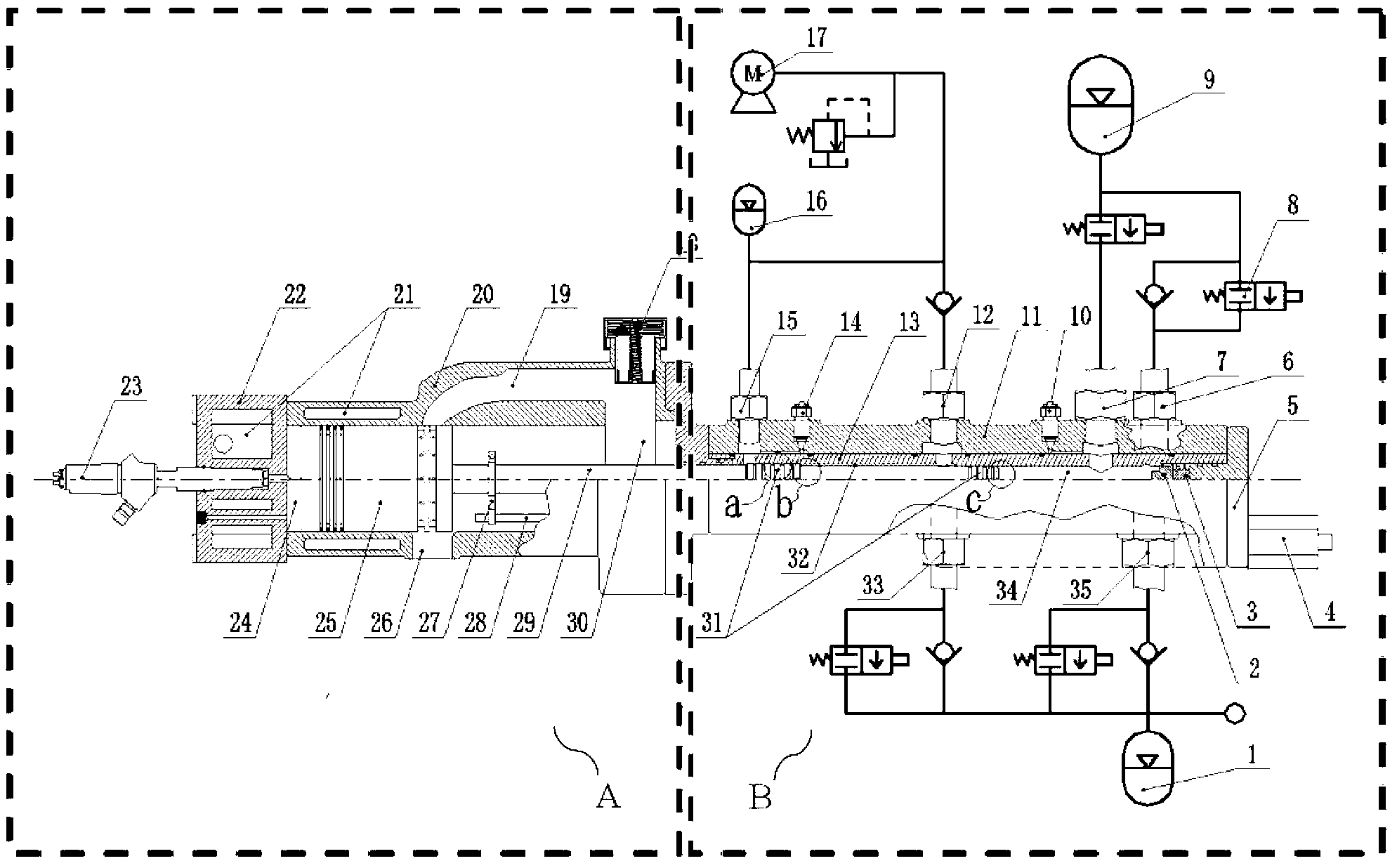

[0058] figure 1 It is the system structural diagram of the piston at the left end (top dead center) position in the present invention. It can be seen from the figure that a return-scavenging hydraulic free-piston diesel engine of the present invention mainly consists of a single-cylinder two-stroke diesel engine A and a hydraulic system B consists of two parts;

[0059] The single-cylinder two-stroke diesel engine A is a single-cylinder diesel engine that does not include a crankshaft and connecting rod, and mainly includes an organic body 20, a cylinder head 22, a piston 25, a fuel injector 23, a connecting rod 29 and an air storage chamber 30; the body 20 and the cylinder The cover 22 is fixedly connected to the coaxial line, the piston 25 is slidably connected inside the body 20, the top surface of the piston 25, the end face of the cylinder head 22 and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com