A large two-stroke diesel engine and a supporting plate structure for connection between an engine main structure and an exhaust gas receiver

A diesel engine and stroke technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as nasty, cracked, and not completely satisfactory solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

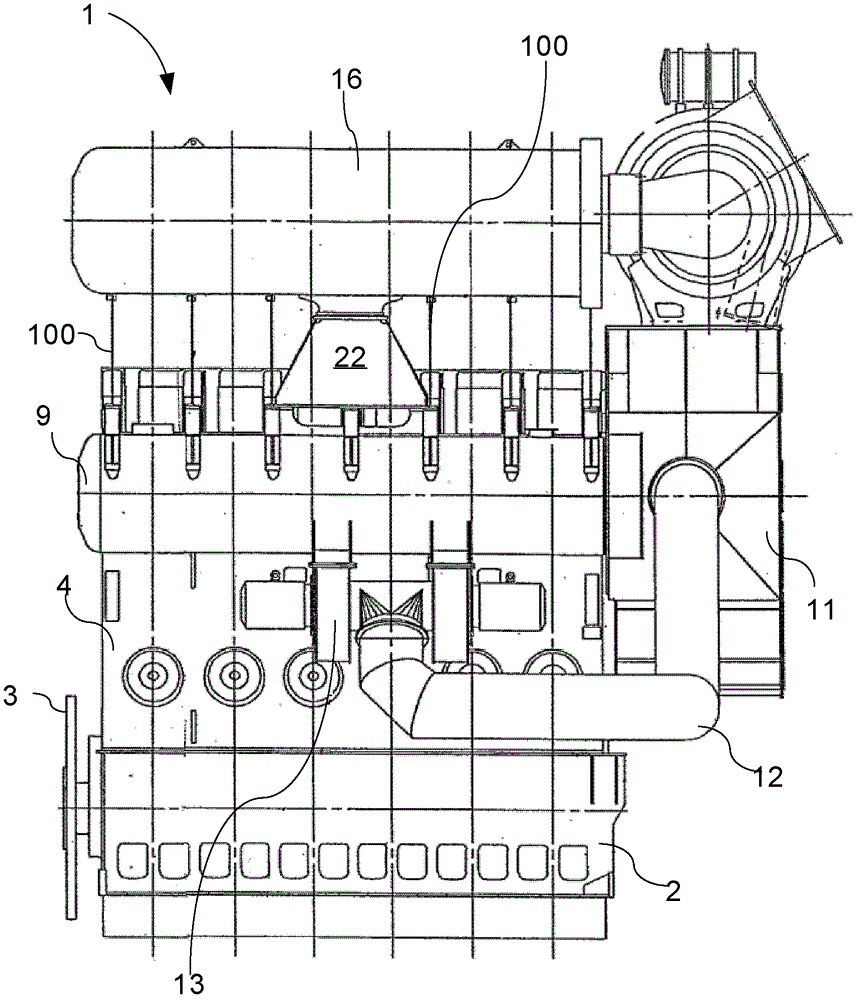

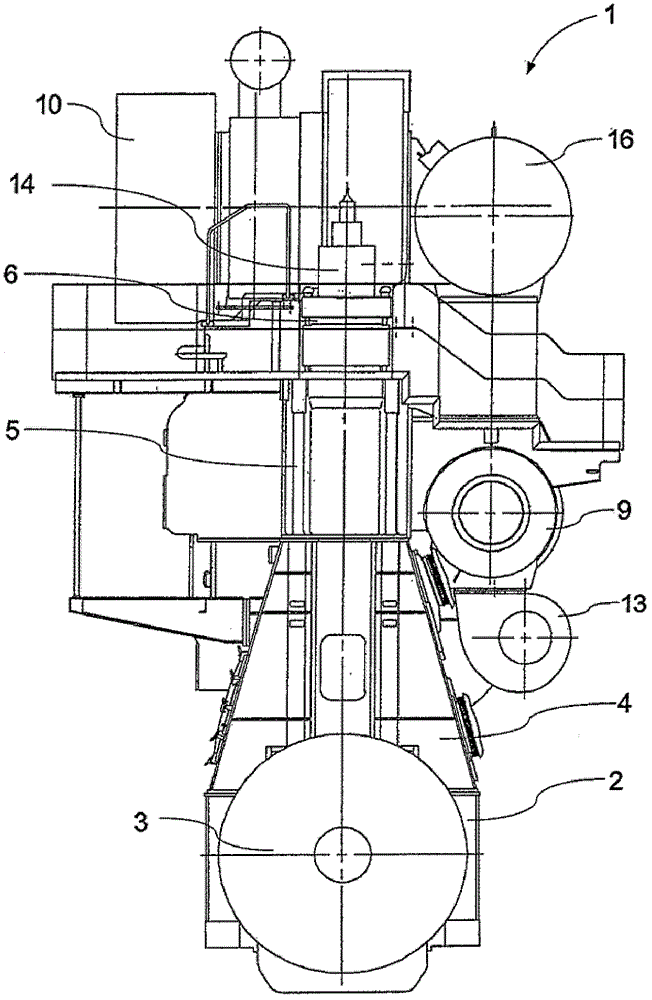

[0018] figure 1 and figure 2 The engine block 1 of a large two-stroke diesel engine is shown in side view and end view, respectively. Said engine is a one-way flow low-speed two-stroke crosshead diesel engine of the crosshead type, which may be a propulsion system in a ship or an engine in a power plant. These engines typically have 3 to 14 cylinders in a row. The engine is built from the base 2 with the main bearings for the crankshaft (only the flywheel 3 attached to the end of the crankshaft is visible). Depending on the production facility, the base 2 can be made in a single piece or can be divided into sections of suitable size.

[0019] An A-frame box 4 of welded design is mounted on the base 2 . On the exhaust side, the frame box 4 is provided with release valves for each cylinder, and on the camshaft side, the frame box 4 is provided with large hinged doors for each cylinder. A crosshead guide surface (not shown) is integrated in the frame box 4 .

[0020] A cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com